Updates on Evaporation and Condensation Methods for the Performance Improvement of Solar Stills

Abstract

:1. Introduction

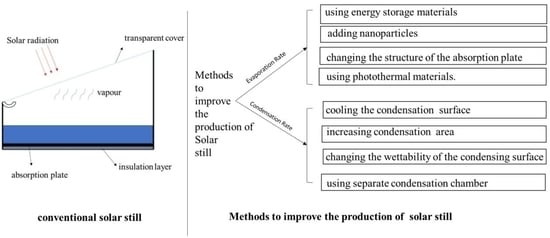

2. Solar Still

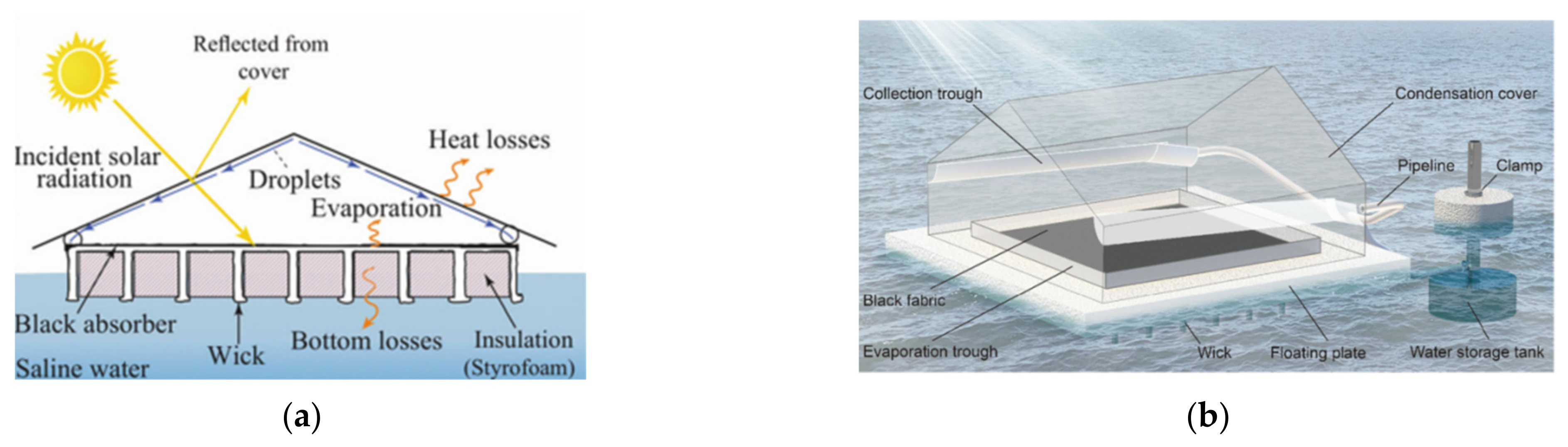

2.1. Passive Solar Still

2.2. Active Solar Still

2.3. Factors Influencing the Performance of Solar Stills

2.3.1. Controllable Factors

2.3.2. Uncontrollable Factors

3. Methods to Increase the Productivity of Solar Stills

3.1. Improvement of Evaporation Efficiency

3.1.1. Using Energy Storage Materials

| Energy Storage Materials | Type of Solar Still | Productivity | Productivity Increase | Ref. |

|---|---|---|---|---|

| Charcoal | DSDB solar still | 4.5 L/m2/d | 125% | [46] |

| Rectangular solar still | 1.46 L/m2/d | 15% | [47] | |

| Sand | SSSB solar still | 3 L/m2/d | 75% | [48] |

| SSSB solar still | 5.06 L/m2/d | 34.57% | [49] | |

| Black granite gravel | Double basin (DB) solar still with Vacuum collector tube | 8 L/m2/d | 65% | [50] |

| SSSB solar still | 3.9 kg/m2/d | 18% | [51] | |

| Paraffin wax PCM | SSSB solar still | 3.572 L/m2/d | 9.5% | [52] |

| SSSB solar still of V-shaped absorption plate | 3.761 L/m2/d | 12% | [53] | |

| SSSB solar still coupled with solar air collector | 9.36 L/m2/d | 108% | [54] | |

| SSSB solar still | 2.47 L/m2/d | 0.48% | [43] | |

| Sponge | SSSB solar still | — | 273% | [55] |

3.1.2. Adding Nanoparticles

3.1.3. Changing the Structure of the Absorption Plate

| Type of Fin | Type of Solar Still | Productivity | Productivity Increase | Ref. | |

|---|---|---|---|---|---|

| Fins with 4 cm height and 1 mm thickness | SSSB solar still | /d | Productivity increased with the increase of fin height, a decrease of fin thickness, and a number of fins. | [70] | |

| Aluminum fin | SSSB solar still | /d | 11.36% | [71] | |

| Pin fins | SSSB solar still | 14.53% | [72] | ||

| Porous fin | SSSB solar still | /d | In February | 56% | [73] |

| In May | 23% | ||||

| Rectangular fins | SSSB solar still | /d | 45.5% | [74] | |

| Fins made of different materials | SSSB solar still | /d | The material of fin has little effect on the productivity. | [75] | |

| Pin fin | SSSB solar still | /d | 23% | [76] | |

3.1.4. Using Photothermal Materials

3.2. Improvement of Condensation Efficiency

3.2.1. Cooling the Condensing Surface

3.2.2. Increasing the Condensation Area

3.2.3. Changing the Wettability of the Condensing Surface

3.2.4. Using the Separate Condenser

4. Economic Analysis of Solar Still

5. Challenges and Perspectives

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| SSSB | single-slope single-basin |

| DSDB | double slope double basin |

| SMDP | stepped multiple basin pyramid |

| CPC-TSS | compound parabolic collector tubular solar still |

| CPC-CTSS | compound parabolic concentrator concentric tubular solar still |

| PCM | phase change material |

| DB | double basin (DB) |

| DS | double slope |

| PCF | polypyrrole shells onto cellulose fiber |

| FAC | forced convection air cooling |

| CSS | conventional solar still |

| PV | Photovoltaic |

| IASS | inverted absorber solar still |

| ETC | (evacuated tube collectors) |

| HP | heat pipe |

| EC | external condenser |

References

- Han, D.; Currell, M.J.; Cao, G. Deep challenges for China’s war on water pollution. Environ. Pollut. 2016, 218, 1222–1233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ge, L.; Xie, G.; Zhang, C.; Li, S.; Qi, Y.; Cao, S.; He, T. An Evaluation of China’s Water Footprint. Water Resour. Manag. 2011, 25, 2633–2647. [Google Scholar] [CrossRef] [Green Version]

- Ma, T.; Sun, S.; Fu, G.; Hall, J.W.; Ni, Y.; He, L.; Yi, J.; Zhao, N.; Du, Y.; Pei, T.; et al. Pollution exacerbates China’s water scarcity and its regional inequality. Nat. Commun. 2020, 11, 650. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, Z.; Peng, D.; Wang, H. Seawater desalination in China: An overview. J. Water Reuse Desalination 2019, 9, 115–132. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Chen, S.; Wang, H.; Chen, X. Calculation of Carbon Footprints for Water Diversion and Desalination Projects. Energy Procedia 2015, 75, 2483–2494. [Google Scholar] [CrossRef] [Green Version]

- Mollahosseini, A.; Abdelrasoul, A.; Sheibany, S.; Amini, M.; Salestan, S.K. Renewable energy-driven desalination opportunities—A case study. J. Environ. Manag. 2019, 239, 187–197. [Google Scholar] [CrossRef]

- Asadi, R.Z.; Suja, F.; Ruslan, M.H.; Jalil, N.A.A. The application of a solar still in domestic and industrial wastewater treatment. Sol. Energy 2013, 93, 63–71. [Google Scholar] [CrossRef]

- Tiwari, G.; Singh, H.; Tripathi, R. Present status of solar distillation. Sol. Energy 2003, 75, 367–373. [Google Scholar] [CrossRef]

- Kabeel, A.; Harby, K.; Abdelgaied, M.; Eisa, A. A comprehensive review of tubular solar still designs, performance, and economic analysis. J. Clean. Prod. 2020, 246, 119030. [Google Scholar] [CrossRef]

- Jobrane, M.; Kopmeier, A.; Kahn, A.; Cauchie, H.-M.; Kharroubi, A.; Penny, C. Internal and external improvements of wick type solar stills in different configurations for drinking water production—A review. Groundw. Sustain. Dev. 2021, 12, 100519. [Google Scholar] [CrossRef]

- Sharshir, S.; Ellakany, Y.M.; Algazzar, A.; Elsheikh, A.; Elkadeem, M.; Edreis, E.M.; Waly, A.S.; Sathyamurthy, R.; Panchal, H.; Elashry, M.S. A mini review of techniques used to improve the tubular solar still performance for solar water desalination. Process. Saf. Environ. Prot. 2019, 124, 204–212. [Google Scholar] [CrossRef]

- Arunkumar, T.; Raj, K.; Winfred Rufuss, D.D.; Denkenberger, D.; Tingting, G.; Xuan, L.; Velraj, R. A review of efficient high productivity solar stills. Renew. Sustain. Energy Rev. 2019, 101, 197–220. [Google Scholar] [CrossRef]

- Kumar, H.A.; Venkateswaran, H.; Kabeel, A.E.; Chamkha, A.; Athikesavan, M.M.; Sathyamurthy, R.; Kasi, K. Recent advancements, technologies, and developments in inclined solar still—A comprehensive review. Environ. Sci. Pollut. Res. 2021, 28, 35346–35375. [Google Scholar] [CrossRef] [PubMed]

- Delyannis, E. Historic background of desalination and renewable energies. Sol. Energy 2003, 75, 357–366. [Google Scholar] [CrossRef]

- Agrawal, A.; Rana, R.S.; Srivastava, P.K. Heat transfer coefficients and productivity of a single slope single basin solar still in Indian climatic condition: Experimental and theoretical comparison. Resour. Technol. 2017, 3, 466–482. [Google Scholar] [CrossRef]

- Sathyamurthy, R.; Kennady, H.J.; Nagarajan, P.; Ahsan, A. Factors affecting the performance of triangular pyramid solar still. Desalination 2014, 344, 383–390. [Google Scholar] [CrossRef]

- Arunkumar, T.; Jayaprakash, R.; Denkenberger, D.; Ahsan, A.; Okundamiya, M.; Kumar, S.; Tanaka, H.; Aybar, H. An experimental study on a hemispherical solar still. Desalination 2012, 286, 342–348. [Google Scholar] [CrossRef]

- Rajaseenivasan, T.; Murugavel, K.K. Theoretical and experimental investigation on double basin double slope solar still. Desalination 2013, 319, 25–32. [Google Scholar] [CrossRef]

- Gad, H.; El-Din, S.S.; Hussien, A.; Ramzy, K. Thermal analysis of a conical solar still performance: An experimental study. Sol. Energy 2015, 122, 900–909. [Google Scholar] [CrossRef]

- Abujazar, M.S.S.; Fatihah, S.; Lotfy, E.; Kabeel, A.; Sharil, S. Performance evaluation of inclined copper-stepped solar still in a wet tropical climate. Desalination 2018, 425, 94–103. [Google Scholar] [CrossRef]

- Karima, A.; Islam, K.M.S. Drinking water desalination using low-cost Tubular Solar Still. Appl. Water Sci. 2020, 10, 4. [Google Scholar] [CrossRef] [Green Version]

- Prakash, A.; Jayaprakash, R. Performance evaluation of stepped multiple basin pyramid solar still. Mater. Today Proc. 2021, 45, 1950–1956. [Google Scholar] [CrossRef]

- Ni, G.; Zandavi, S.H.; Javid, S.M.; Boriskina, S.V.; Cooper, T.A.; Chen, G. A salt-rejecting floating solar still for low-cost desalination. Energy Environ. Sci. 2018, 11, 1510–1519. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, P.; Xie, G.; Wei, Y.; Lyu, Y.; Zhang, Y.; Yan, T.; Zhang, T. A floating solar still inspired by continuous root water intake. Desalination 2021, 512, 115133. [Google Scholar] [CrossRef]

- Omara, Z.M.; Eltawil, M.A. Hybrid of solar dish concentrator, new boiler and simple solar collector for brackish water desalina-tion. Desalination 2013, 326, 62–68. [Google Scholar] [CrossRef]

- Arunkumar, T.; Velraj, R.; Denkenberger, D.; Sathyamurthy, R.; Kumar, K.V.; Ahsan, A. Productivity enhancements of compound parabolic concentrator tubular solar stills. Renew. Energy 2016, 88, 391–400. [Google Scholar] [CrossRef]

- Pounraj, P.; Winston, P.; Kabeel, A.; Kumar, B.P.; Manokar, M.; Sathyamurthy, R.; Christabel, S.C. Experimental investigation on Peltier based hybrid PV/T active solar still for enhancing the overall performance. Energy Convers. Manag. 2018, 168, 371–381. [Google Scholar] [CrossRef]

- Manokar, A.M.; Winston, D.P.; Kabeel, A.E.; Sathyamurthy, R. Sustainable fresh water and power production by integrating PV panel in inclined solar still. J. Clean. Prod. 2018, 172, 2711–2719. [Google Scholar] [CrossRef]

- Manokar, A.M.; Winston, D.P.; Kabeel, A.E.; El-Agouz, S.A.; Sathyamurthy, R.; Arunkumar, T.; Madhu, B.; Ahsan, A. Inte-grated PV/T solar still- A mini-review. Desalination 2018, 435, 259–267. [Google Scholar] [CrossRef]

- Abdullah, A. Improving the performance of stepped solar still. Desalination 2013, 319, 60–65. [Google Scholar] [CrossRef]

- Omara, Z.; Kabeel, A.; Younes, M. Enhancing the stepped solar still performance using internal and external reflectors. Energy Convers. Manag. 2014, 78, 876–881. [Google Scholar] [CrossRef]

- Subramanian, R.S.; Kumaresan, G.; Ajith, R.; Sabarivasan, U.; Gowthamaan, K.; Anudeep, S. Performance analysis of modified solar still integrated with flat plate collector. Mater. Today Proc. 2021, 45, 1382–1387. [Google Scholar] [CrossRef]

- Panchal, H.; Hishan, S.S.; Rahim, R.; Sadasivuni, K.K. Solar still with evacuated tubes and calcium stones to enhance the yield: An experimental investigation. Process. Saf. Environ. Prot. 2020, 142, 150–155. [Google Scholar] [CrossRef]

- Beik, A.J.G.; Assari, M.R.; Tabrizi, H.B. Passive and active performance of a multi-side-stepped square pyramid so-lar still; experimental and modeling. J. Energy Storage 2020, 32, 101832. [Google Scholar] [CrossRef]

- Elbar, A.R.A.; Hassan, H. Experimental investigation on the impact of thermal energy storage on the solar still performance coupled with PV module via new integration. Sol. Energy 2019, 184, 584–593. [Google Scholar] [CrossRef]

- Tiwari, G.; Sumegha, C.; Yadav, Y. Effect of water depth on the transient performance of a double basin solar still. Energy Convers. Manag. 1991, 32, 293–301. [Google Scholar] [CrossRef]

- Manokar, A.M.; Taamneh, Y.; Winston, D.P.; Vijayabalan, P.; Balaji, D.; Sathyamurthy, R.; Sundar, S.P.; Mageshbabu, D. Effect of water depth and insulation on the productivity of an acrylic pyramid solar still—An experimental study. Groundw. Sustain. Dev. 2020, 10, 100319. [Google Scholar] [CrossRef]

- Kumar, S.; Tiwari, G.; Singh, H. Annual performance of an active solar distillation system. Desalination 2000, 127, 79–88. [Google Scholar] [CrossRef]

- Khalifa, A.J. On the effect of cover tilt angle of the simple solar still on its productivity in different seasons and latitudes. Energy Convers. Manag. 2011, 52, 431–436. [Google Scholar] [CrossRef]

- Rahbar, N.; Esfahani, J.A. Experimental study of a novel portable solar still by utilizing the heatpipe and thermoelectric module. Desalination 2012, 284, 55–61. [Google Scholar] [CrossRef]

- Al-Hinai, H.; Al-Nassri, M.; Jubran, B. Effect of climatic, design and operational parameters on the yield of a simple solar still. Energy Convers. Manag. 2002, 43, 1639–1650. [Google Scholar] [CrossRef]

- Zurigat, Y.H.; Abu-Arabi, M.K. Modelling and performance analysis of a regenerative solar desalination unit. Appl. Therm. Eng. 2004, 24, 1061–1072. [Google Scholar] [CrossRef]

- Mousa, H.; Naser, J.; Gujarathi, A.M.; Al-Sawafi, S. Experimental study and analysis of solar still desalination using phase change materials. J. Energy Storage 2019, 26, 100959. [Google Scholar] [CrossRef]

- Radhwan, A.M. Transient performance of a stepped solar still with built-in latent heat thermal energy storage. Desalination 2004, 171, 61–76. [Google Scholar] [CrossRef]

- Samuel, D.H.; Nagarajan, P.K.; Sathyamurthy, R.; El-Agouz, S.A.; Kannan, E. Improving the yield of fresh water in conven-tional solar still using low cost energy storage material. Energy Convers. Manag. 2016, 112, 125–134. [Google Scholar] [CrossRef]

- Rajamanickam, M.; Velmurugan, P.; Ragupathy, A.; Sivaraman, E. Use of thermal energy storage materials for enhancement in distillate output of double slope solar still. Mater. Today Proc. 2021, 34, 416–419. [Google Scholar] [CrossRef]

- Naim, M.M.; El Kawi, M.A.A. Non-conventional solar stills Part Non-conventional solar stills with charcoal particles as absorber medium. Desalination 2003, 153, 55–64. [Google Scholar] [CrossRef]

- Tabrizi, F.F.; Sharak, A.Z. Experimental study of an integrated basin solar still with a sandy heat reservoir. Desalination 2010, 253, 195–199. [Google Scholar] [CrossRef]

- Attia, M.E.H.; Kabeel, A.E.; Abdelgaied, M.; Driss, Z. Productivity enhancement of traditional solar still by using sandbags of El Oued, Algeria. Heat Transf. 2021, 50, 768–783. [Google Scholar] [CrossRef]

- Panchal, H. Enhancement of distillate output of double basin solar still with vacuum tubes. J. King Saud Univ.-Eng. Sci. 2015, 27, 170–175. [Google Scholar] [CrossRef] [Green Version]

- Sakthivel, M.; Shanmugasundaram, S. Effect of energy storage medium (black granite gravel) on the performance of a solar still. Int. J. Energy Res. 2008, 32, 68–82. [Google Scholar] [CrossRef]

- Yousef, M.S.; Hassan, H. Energetic and exergetic performance assessment of the inclusion of phase change materials (PCM) in a solar distillation system. Energy Convers. Manag. 2019, 179, 349–361. [Google Scholar] [CrossRef]

- Kabeel, A.; Abdelgaied, M.; Mahgoub, M. The performance of a modified solar still using hot air injection and PCM. Desalination 2016, 379, 102–107. [Google Scholar] [CrossRef]

- Shehata, A.I.; Kabeel, A.; Dawood, M.M.K.; Elharidi, A.M.; Abd_Elsalam, A.; Ramzy, K.; Mehanna, A. Enhancement of the productivity for single solar still with ultrasonic humidifier combined with evacuated solar collector: An experimental study. Energy Convers. Manag. 2020, 208, 112592. [Google Scholar] [CrossRef]

- Abu-Hijleh, B.A.K.; Rababa, H.H.M. Experimental study of a solar still with sponge cubes in basin. Energy Convers. Manag. 2003, 44, 1411–1418. [Google Scholar] [CrossRef]

- Modi, K.V.; Shukla, D.; Ankoliya, D.B. A Comparative Performance Study of Double Basin Single Slope Solar Still With and Without Using Nanoparticles. J. Sol. Energy Eng. 2018, 141, 031008. [Google Scholar] [CrossRef]

- Yu, W.; France, D.M.; Routbort, J.L.; Choi, S.U.S. Review and Comparison of Nanofluid Ther-mal Conductivity and Heat Transfer Enhancements. Heat Transfer. Eng. 2008, 29, 432–460. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Aghakhani, S.; Afrand, M.; Mahmoudi, B.; Mahian, O.; Wongwises, S. An updated review on applica-tion of nanofluids in heat exchangers for saving energy. Energy Convers. Manag. 2019, 198, 111886. [Google Scholar] [CrossRef]

- Gupta, B.; Shankar, P.; Sharma, R.; Baredar, P. Performance Enhancement Using Nano Particles in Modified Passive Solar Still. Procedia Technol. 2016, 25, 1209–1216. [Google Scholar] [CrossRef] [Green Version]

- Sahota, L.; Tiwari, G. Effect of Al2O3 nanoparticles on the performance of passive double slope solar still. Sol. Energy 2016, 130, 260–272. [Google Scholar] [CrossRef]

- Elango, T.; Kannan, A.; Murugavel, K.K. Performance study on single basin single slope solar still with different water nanofluids. Desalination 2015, 360, 45–51. [Google Scholar] [CrossRef]

- Modi, K.V.; Jani, H.K.; Gamit, I.D. Impact of orientation and water depth on productivity of single-basin dual-slope solar still with Al2O3 and CuO nanoparticles. J. Therm. Anal. Calorim. 2021, 143, 899–913. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, A.; Baredar, P.V. Experimental Investigation on Modified Solar Still Using Nanoparticles and Water Sprinkler Attachment. Front. Mater. 2017, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- El-Gazar, E.; Zahra, W.; Hassan, H.; Rabia, S.I. Fractional modeling for enhancing the thermal performance of conventional solar still using hybrid nanofluid: Energy and exergy analysis. Desalination 2021, 503, 114847. [Google Scholar] [CrossRef]

- Hansen, R.S.; Murugavel, K.K. Enhancement of integrated solar still using different new absorber configurations: An experimental approach. Desalination 2017, 422, 59–67. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Aboul-Enein, S.; El-Bialy, E. Single basin solar still with baffle suspended absorber. Energy Convers. Manag. 2000, 41, 661–675. [Google Scholar] [CrossRef]

- Nafey, A.; Abdelkader, M.; Abdelmotalip, A.; Mabrouk, A. Enhancement of solar still productivity using floating perforated black plate. Energy Convers. Manag. 2002, 43, 937–946. [Google Scholar] [CrossRef]

- Panchal, H.; Nurdiyanto, H.; Sadasivuni, K.K.; Hishan, S.S.; Essa, F.A.; Khalid, M.; Dharaskar, S.; Shanmugan, S. Experimental inves-tigation on the yield of solar still using manganese oxide nanoparticles coated absorber. Case Stud. Therm. Eng. 2021, 25, 100905. [Google Scholar] [CrossRef]

- Bataineh, K.M.; Abbas, M.A. Performance analysis of solar still integrated with internal reflectors and fins. Sol. Energy 2020, 205, 22–36. [Google Scholar] [CrossRef]

- El-Sebaii, A.; Ramadan, M.; Aboul-Enein, S.; El-Naggar, M. Effect of fin configuration parameters on single basin solar still performance. Desalination 2015, 365, 15–24. [Google Scholar] [CrossRef]

- Manokar, A.M.; Winston, D.P. Comparative study of finned acrylic solar still and galvanised iron solar still. Mater. Today Proc. 2017, 4, 8323–8327. [Google Scholar] [CrossRef]

- Rabhi, K.; Nciri, R.; Nasri, F.; Ali, C.; Ben Bacha, H. Experimental performance analysis of a modified single-basin single-slope solar still with pin fins absorber and condenser. Desalination 2017, 416, 86–93. [Google Scholar] [CrossRef]

- Srivastava, P.K.; Agrawal, S. Winter and summer performance of single sloped basin type solar still integrated with extended porous fins. Desalination 2013, 319, 73–78. [Google Scholar] [CrossRef]

- Appadurai, M.; Velmurugan, V. Performance analysis of fin type solar still integrated with fin type mini solar pond. Sustain. Energy Technol. Assess. 2015, 9, 30–36. [Google Scholar] [CrossRef]

- El-Sebaii, A.; El-Naggar, M. Year round performance and cost analysis of a finned single basin solar still. Appl. Therm. Eng. 2017, 110, 787–794. [Google Scholar] [CrossRef]

- Alaian, W.; Elnegiry, E.; Hamed, A.M. Experimental investigation on the performance of solar still augmented with pin-finned wick. Desalination 2016, 379, 10–15. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, D.; Xiang, H.; Ren, S.; Zhu, Z.; Liu, D.; Xu, H.; Cui, F.; Wang, W. Easily scaled-up photo-thermal membrane with struc-ture-dependent auto-cleaning feature for high-efficient solar desalination. J. Membr. Sci. 2019, 586, 222–230. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, J.; Liu, D.; Xu, H.; Cui, F.; Wang, W. Origami system for efficient solar driven distillation in emergency water supply. Chem. Eng. J. 2019, 356, 869–876. [Google Scholar] [CrossRef]

- Wu, D.; Qu, D.; Jiang, W.; Chen, G.; An, L.; Zhuang, C.; Sun, Z. Self-floating nanostructured Ni–NiOx/Ni foam for solar thermal water evaporation. J. Mater. Chem. A 2019, 7, 8485–8490. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.; Chang, C.; Fu, B.; Tao, P.; Song, C.; Shang, W.; Deng, T. Solar-driven interfacial desalination for simultaneous fresh-water and salt generation. Desalination 2020, 484, 114423. [Google Scholar] [CrossRef]

- Wu, X.; Robson, M.E.; Phelps, J.L.; Tan, J.S.; Shao, B.; Owens, G.; Xu, H. A flexible photothermal cotton-CuS nanocage-agarose aerogel towards portable solar steam generation. Nano Energy 2019, 56, 708–715. [Google Scholar] [CrossRef]

- Feng, X.; Zhao, J.; Sun, D.; Shanmugam, L.; Kim, J.; Yang, J. Novel onion-like graphene aerogel beads for efficient solar vapor gen-eration under non-concentrated illumination. J. Mater. Chem. A 2019, 7, 4400–4407. [Google Scholar] [CrossRef]

- Weng, D.; Xu, F.; Li, X.; Li, Y.; Sun, J. Bioinspired photothermal conversion coatings with self-healing superhydrophobicity for effi-cient solar steam generation. J. Mater. Chem. A 2018, 6, 24441–24451. [Google Scholar] [CrossRef]

- Zhang, P.; Liao, Q.; Zhang, T.; Cheng, H.; Huang, Y.; Yang, C.; Li, C.; Jiang, L.; Qu, L. High throughput of clean water excluding ions, organic media, and bacteria from defect-abundant graphene aerogel under sunlight. Nano Energy 2018, 46, 415–422. [Google Scholar] [CrossRef]

- Yi, L.; Ci, S.; Luo, S.; Shao, P.; Hou, Y.; Wen, Z. Scalable and low-cost synthesis of black amorphous Al-Ti-O nanostructure for high-efficient photothermal desalination. Nano Energy 2017, 41, 600–608. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, Q.; Liang, X.; Xu, J.; Chang, C.; Song, C.; Shang, W.; Wu, J.; Tao, P.; Deng, T. Paper-based membranes on silicone floaters for efficient and fast solar-driven interfacial evaporation under one sun. J. Mater. Chem. A 2017, 5, 16359–16368. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, H.; Yin, Z.; Zhao, J.; Yin, X.; Li, N.; Yin, D.; Li, Y.; Lei, B.; Du, Y.; et al. A general salt-resistant hydrophilic hydrophobic nanoporous double layer design for efficient and stable solar water evaporation distillation. Mater. Horiz. 2018, 5, 1143–1150. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Huang, Q.; Liang, X.; Zhou, X.; Fu, H.; Wu, Q.; Zhang, J.; Xie, W. A high-absorption and self-driven salt-resistant black gold nanoparticle-deposited sponge for highly efficient, salt-free, and long-term durable solar desalination. J. Mater. Chem. A 2019, 7, 2581–2588. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, H.; Xiao, X.; Wang, H.; Yan, L.; Shi, Z.; Chen, Y.; Xu, W.; Wang, X. A new self-desalting solar evaporation system based on a vertically oriented porous polyacrylonitrile foam. J. Mater. Chem. A 2019, 7, 14620–14628. [Google Scholar] [CrossRef]

- Fang, Q.; Li, T.; Chen, Z.; Lin, H.; Wang, P.; Liu, F. Full Biomass-Derived Solar Stills for Robust and Stable Evaporation To Collect Clean Water from Various Water-Bearing Media. ACS Appl. Mater. Interfaces 2019, 11, 10672–10679. [Google Scholar] [CrossRef]

- Wu, L.; Dong, Z.; Cai, Z.; Ganapathy, T.; Fang, N.X.; Li, C.; Yu, C.; Zhang, Y.; Song, Y. Highly efficient three-dimensional solar evapo-rator for high salinity desalination by localized crystallization. Nat. Commun. 2020, 11, 521. [Google Scholar] [CrossRef] [Green Version]

- Lei, W.; Khan, S.; Chen, L.; Suzuki, N.; Terashima, C.; Liu, K.; Fujishima, A.; Liu, M. Hierarchical structures hydrogel evaporator and superhydrophilic water collect device for efficient solar steam evaporation. Nano Res. 2021, 14, 1135–1140. [Google Scholar] [CrossRef]

- Yu, F.; Chen, Z.; Guo, Z.; Irshad, M.S.; Wang, X. Molybdenum Carbide/Carbon-Based Chitosan Hydrogel as an Effective Solar Wa-ter Evaporation Accelerator. ACS Sustain. Chem. Eng. 2020, 8, 7139–7149. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Bapeshwararao, V. Transient performance of a single basin solar still with water flowing over the glass cover. Desalination 1984, 49, 231–241. [Google Scholar] [CrossRef]

- Lawrence, S.; Gupta, S.; Tiwari, G. Effect of heat capacity on the performance of solar still with water flow over the glass cover. Energy Convers. Manag. 1990, 30, 277–285. [Google Scholar] [CrossRef]

- Tiwari, G.; Sinha, S. Parametric studies of active regenerative solar still. Energy Convers. Manag. 1993, 34, 209–218. [Google Scholar] [CrossRef]

- Abu-Hijleh, B.A.K. Enhanced solar still performance using water film cooling of the glass cover. Desalination 1996, 107, 235–244. [Google Scholar] [CrossRef]

- Ahmed, H.M.; Alfaylakawi, K.A. Productivity Enhancement of Conventional Solar Stills Using Water Sprinklers and Cooling Fan. J. Adv. Sci. Eng. Res. 2012, 2, 168–177. [Google Scholar]

- Somwanshi, A.; Tiwari, A. Performance enhancement of a single basin solar still with flow of water from an air cooler on the cover. Desalination 2014, 352, 92–102. [Google Scholar] [CrossRef]

- Gupta, B.; Sharma, R.; Shankar, P.; Baredar, P. Performance enhancement of modified solar still using water sprinkler: An exper-imental approach. Perspect. Sci. 2016, 8, 191–194. [Google Scholar] [CrossRef] [Green Version]

- Suneesh, P.U.; Jayaprakash, R.; Arunkumar, T.; Denkenberger, D. Effect of air flow on “V” type solar still with cotton gauze cool-ing. Desalination 2014, 337, 1–5. [Google Scholar] [CrossRef]

- Arunkumar, T.; Jayaprakash, R.; Ahsan, A.; Denkenberger, D.; Okundamiya, M. Effect of water and air flow on concentric tubular solar water desalting system. Appl. Energy 2013, 103, 109–115. [Google Scholar] [CrossRef]

- El-Samadony, Y.; Kabeel, A. Theoretical estimation of the optimum glass cover water film cooling parameters combinations of a stepped solar still. Energy 2014, 68, 744–750. [Google Scholar] [CrossRef]

- Srithar, K.; Rajaseenivasan, T.; Karthik, N.; Periyannan, M.; Gowtham, M. Stand alone triple basin solar desalination system with cover cooling and parabolic dish concentrator. Renew. Energy 2016, 90, 157–165. [Google Scholar] [CrossRef]

- Morad, M.M.; El-Maghawry, H.A.M.; Wasfy, K.I. Improving the double slope solar still performance by using flat-plate solar col-lector and cooling glass cover. Desalination 2015, 373, 1–9. [Google Scholar] [CrossRef]

- Kabeel, A.; Sharshir, S.; Abdelaziz, G.; Halim, M.; Swidan, A. Improving performance of tubular solar still by controlling the water depth and cover cooling. J. Clean. Prod. 2019, 233, 848–856. [Google Scholar] [CrossRef]

- Bhardwaj, R.; Kortenaar, M.T.; Mudde, R. Maximized production of water by increasing area of condensation surface for solar distillation. Appl. Energy 2015, 154, 480–490. [Google Scholar] [CrossRef]

- Bhardwaj, R.; Kortenaar, M.T.; Mudde, R. Inflatable plastic solar still with passive condenser for single family use. Desalination 2016, 398, 151–156. [Google Scholar] [CrossRef] [Green Version]

- Bhardwaj, R.; Kortenaar, M.T.; Mudde, R. Influence of condensation surface on solar distillation. Desalination 2013, 326, 37–45. [Google Scholar] [CrossRef]

- Zanganeh, P.; Goharrizi, A.S.; Ayatollahi, S.; Feilizadeh, M. Productivity enhancement of solar stills by nano-coating of condensing surface. Desalination 2019, 454, 1–9. [Google Scholar] [CrossRef]

- Zanganeh, P.; Goharrizi, A.S.; Ayatollahi, S.; Feilizadeh, M. Nano-coated condensation surfaces enhanced the productivity of the single-slope solar still by changing the condensation mechanism. J. Clean. Prod. 2020, 265, 121758. [Google Scholar] [CrossRef]

- Khanmohammadi, S.; Khanjani, S. Experimental study to improve the performance of solar still desalination by hydrophobic condensation surface using cold plasma technology. Sustain. Energy Technol. Assess. 2021, 45, 101129. [Google Scholar] [CrossRef]

- Fath, H.E.; Elsherbiny, S.M. Effect of adding a passive condenser on solar still performance. Energy Convers. Manag. 1993, 34, 63–72. [Google Scholar] [CrossRef]

- Nijegorodov, N.; Jain, P.K.; Carlsson, S. Thermal-electrical, high efficiency solar stills. Renew. Energy 1994, 4, 123–127. [Google Scholar] [CrossRef]

- El-Bahi, A.; Inan, D. Analysis of a parallel double glass solar still with separate condenser. Renew. Energy 1999, 17, 509–521. [Google Scholar] [CrossRef]

- Sathyamurthy, R.; El-Agouz, S.A.; Dharmaraj, V. Experimental analysis of a portable solar still with evaporation and condensa-tion chambers. Desalination 2015, 367, 180–185. [Google Scholar] [CrossRef]

- El-Samadony, Y.A.F.; Abdullah, A.S.; Omara, Z.M. Experimental Study of Stepped Solar Still Integrated with Reflectors and Ex-ternal Condenser. Exp. Heat Transfer. 2014, 28, 392–404. [Google Scholar] [CrossRef]

- Omara, Z.; Kabeel, A.; Essa, F. Effect of using nanofluids and providing vacuum on the yield of corrugated wick solar still. Energy Convers. Manag. 2015, 103, 965–972. [Google Scholar] [CrossRef]

- Mohaisen, H.S.; Esfahani, J.A.; Ayani, M.B. Effect of condensing cavity on the performance of a passive solar desalination system: An experimental study. Environ. Sci. Pollut. Res. 2021, 28, 5080–5091. [Google Scholar] [CrossRef]

- Kumar, R.A.; Esakkimuthu, G.; Murugavel, K.K. Performance enhancement of a single basin single slope solar still using agitation effect and external condenser. Desalination 2016, 399, 198–202. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, D.; Devnani, G.L.; Sinha, S.; Singh, D. Potable water production via desalination technique using solar still inte-grated with partial cooling coil condenser. Sustain. Energy Technol. Assess. 2021, 43, 100927. [Google Scholar]

- Kabeel, A.; Hamed, A.; El-Agouz, S. Cost analysis of different solar still configurations. Energy 2010, 35, 2901–2908. [Google Scholar] [CrossRef]

- Ranjan, K.; Kaushik, S. Energy, exergy and thermo-economic analysis of solar distillation systems: A review. Renew. Sustain. Energy Rev. 2013, 27, 709–723. [Google Scholar] [CrossRef]

- Kianifar, A.; Heris, S.Z.; Mahian, O. Exergy and economic analysis of a pyramid-shaped solar water purification system: Active and passive cases. Energy 2012, 38, 31–36. [Google Scholar] [CrossRef]

- Bait, O. Exergy, environ–economic and economic analyses of a tubular solar water heater assisted solar still. J. Clean. Prod. 2019, 212, 630–646. [Google Scholar] [CrossRef]

- Sanserwal, M.; Singh, A.K.; Singh, P. Impact of materials and economic analysis of single slope single basin passive solar still: A review. Mater. Today Proc. 2020, 21, 1643–1652. [Google Scholar] [CrossRef]

- Shalaby, S.; El-Bialy, E.; El-Sebaii, A. An experimental investigation of a v-corrugated absorber single-basin solar still using PCM. Desalination 2016, 398, 247–255. [Google Scholar] [CrossRef]

- Arunkumar, T.; Kabeel, A.; Raj, K.; Denkenberger, D.; Sathyamurthy, R.; Ragupathy, P.; Velraj, R. Productivity enhancement of solar still by using porous absorber with bubble-wrap insulation. J. Clean. Prod. 2018, 195, 1149–1161. [Google Scholar] [CrossRef]

- Tuly, S.; Rahman, M.; Sarker, M.; Beg, R. Combined influence of fin, phase change material, wick, and external condenser on the thermal performance of a double slope solar still. J. Clean. Prod. 2021, 287, 125458. [Google Scholar] [CrossRef]

- Amarloo, A.; Shafii, M. Enhanced solar still condensation by using a radiative cooling system and phase change material. Desalination 2019, 467, 43–50. [Google Scholar] [CrossRef]

- Dev, R.; Abdul-Wahab, S.A.; Tiwari, G.N. Performance study of the inverted absorber solar still with water depth and total dis-solved solid. Appl. Energy 2011, 88, 252–264. [Google Scholar] [CrossRef]

- Faegh, M.; Shafii, M.B. Experimental investigation of a solar still equipped with an external heat storage system using phase change materials and heat pipes. Desalination 2017, 409, 128–135. [Google Scholar] [CrossRef] [Green Version]

- Kateshia, J.; Lakhera, V.J. Analysis of solar still integrated with phase change material and pin fins as absorbing material. J. Energy Storage 2021, 35, 102292. [Google Scholar] [CrossRef]

- El-Said, E.M.; Elshamy, S.M.; Kabeel, A. Performance enhancement of a tubular solar still by utilizing wire mesh packing under harmonic motion. Desalination 2020, 474, 114165. [Google Scholar] [CrossRef]

- Maliani, O.; Bekkaoui, A.; Baali, E.; Guissi, K.; El Fellah, Y.; Errais, R. Investigation on novel design of solar still coupled with two axis solar tracking system. Appl. Therm. Eng. 2020, 172, 115144. [Google Scholar] [CrossRef]

- Hassan, H.; Ahmed, M.S.; Fathy, M.; Yousef, M.S. Impact of salty water medium and condenser on the performance of single act-ing solar still incorporated with parabolic trough collector. Desalination 2020, 480, 114324. [Google Scholar] [CrossRef]

- Khalilmoghadam, P.; Rajabi-Ghahnavieh, A.; Shafii, M.B. A novel energy storage system for latent heat recovery in solar still us-ing phase change material and pulsating heat pipe. Renew Energy 2021, 163, 2115–2127. [Google Scholar] [CrossRef]

- Shoeibi, S.; Rahbar, N.; Esfahlani, A.A.; Kargarsharifabad, H. Energy matrices, exergoeconomic and enviroeconomic analysis of air-cooled and water-cooled solar still: Experimental investigation and numerical simulation. Renew. Energy 2021, 171, 227–244. [Google Scholar] [CrossRef]

- Vasu, A.; Hagos, F.Y.; Noor, M.; Mamat, R.; Azmi, W.; Abdullah, A.A.; Ibrahim, T. Corrosion effect of phase change materials in solar thermal energy storage application. Renew. Sustain. Energy Rev. 2017, 76, 19–33. [Google Scholar] [CrossRef] [Green Version]

- Rashidi, S.; Karimi, N.; Mahian, O.; Esfahani, J.A. A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J. Therm. Anal. Calorim. 2019, 135, 1145–1159. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Lai, Y.; Zhao, B.; Bradley, R.; Wu, W. Photothermal materials for efficient solar powered steam generation. Front. Chem. Sci. Eng. 2019, 13, 636–653. [Google Scholar] [CrossRef] [Green Version]

| Type of Solar Still | Productivity | The Advantage Compared with Single Basin Single Slope Solar Still | Ref. |

|---|---|---|---|

| SSSB solar still | 3.2 kg/m2/d | _ | [15] |

| pyramid solar still | 3.51 L/m2/d | Eliminates the shading impact of the sidewall, increases condensing area. | [16] |

| solar still with a hemispheric top | 4.23 kg/m2/d | Eliminates the shading impact of the sidewall, increases condensing area. | [17] |

| DSDB solar still | 4.75 L/m2/d | The upper basin absorbs more radiation, and storage heat, the latent heat of the lower basin is absorbed by the upper basin and evaporates water. | [18] |

| conical solar still | 3.38 L/m2/d | Eliminates the shading impact of the sidewall. | [19] |

| stepped solar still | 4.353 L/m2/d | Reduce convection and the distance from the cover to water, minimize shadows, and the water layer is thinner. | [20] |

| tubular solar still | 3.83 L/m2/d | Eliminates the shading impact of the sidewall. | [21] |

| SMBP solar still | 3.52 L/d | Reduce the thermal capacity in the solar still, increase condensing area. | [22] |

| Type of Passive Solar Still | Productivity | Type of Active Solar Still | Productivity | Productivity Increase | Ref. |

|---|---|---|---|---|---|

| SSSB solar still | 3.4 L/m2/d | Stepped solar still with solar air heater | 6.3 L/m2/d | 112% | [30] |

| SSSB solar still | 3.6 L/m2/d | Stepped solar still with internal and external reflector | 8.1 L/m2/d | 125% | [31] |

| SSSB solar still | 1.66 L/d | Pyramid solar still with flat plate collector | 3.1 L/d | 60% | [32] |

| SSSB solar still | 2.488 L/d | SSSB solar still with evacuated tubes | 5.09 L/d | 104.68% | [33] |

| Multi-side-stepped square pyramid (MSSSP) solar still | 13.44 L/m2/d | MSSSP solar still with a small salt-gradient solar pond | 15.18 L/m2/d. | 13% | [34] |

| SSSB solar still | 2.4 L/m2/d | SSSB solar still with PV | 2.62 L/m2/d | 10% | [35] |

| Nanoparticles | Type of Solar Still | The Productivity before Adding Nanoparticles | The Productivity after Adding Nanoparticles | Productivity/Productivity Increase | Reference | ||

|---|---|---|---|---|---|---|---|

| CuO | SSSB solar still | at the depth of 5 cm | 2.814 L/m2/d | 3.445 L/m2/d | 22.4% | [59] | |

| at the depth of 10 cm | 2.351 L/m2/d | 3.058 L/m2/d | 30% | ||||

| Al2O3 | Double slope (DS) solar still | 1.2225 L/m2/d | 0.04% | 2.665 L/d | 8.99% | [60] | |

| 0.08% | 2.691 L/d | 10.06% | |||||

| 0.12% | 2.744 L/d | 12.23% | |||||

| Al2O3 | SSSB solar still | 0.655 L/m2/d | 0.935 L/m2/d | 29.95% | [61] | ||

| ZnO | 0.75 L/m2/d | 12.67% | |||||

| TiO2 | 0.805 L/m2/d | 18.63% | |||||

| Al2O3 | DSSB solar still | 0.989 L/m2/d | 1.252 L/m2/d | 26.60% | [62] | ||

| CuO | 1.014 L/m2/d | 1.585 L/m2/d | 56.31% | ||||

| Cu2O | SSSB solar still | 2.9 L/m2/d | 4 L/m2/d | 54.54% | [63] | ||

| Al2O3-CuO | SSSB solar still | summer | 4.392 L/m2/d | 5.5239 L/m2/d | 27.2% | [64] | |

| winter | 2.553 L/m2/d | 3.1079 L/m2/d | 21.7% | ||||

| Photothermal Materials | Type of Solar Still | the Evaporation Rate of Water | Productivity | Salt Accumulation | Ref. |

|---|---|---|---|---|---|

| Cotton-CuS Aerogel | SSSB solar still | 1.03 kg/m2/h | — | No salt scale was observed. | [81] |

| hybrid aerogel | SSSB solar still | 0.90 kg/m2/h | 2 L/m2/d | Virtually free of salt particles. | [82] |

| beeswax, MCNTs, and PDMS | Pyramid solar still | 1.30 kg/m2/h | — | No salt crystallization on the surface. | [83] |

| Small-size GO sheets | SSSB solar still | 1.73 kg/m2/h. | 9.52 kg/d | — | [84] |

| Al-Ti-O composite membrane | SSSB solar still | 1.24 kg/m2/h | 4 L/m2/d | — | [85] |

| Paper-based rGO composite membrane | SSSB solar still | 1.778 kg/m2/h | — | Salts can be redissolved. | [86] |

| Cu2SnSe3 double-layer membrane | SSSB solar still | 1.657 kg/m2/h | — | Salt cannot crystalize on the surface. | [87] |

| Black gold sponge | SSSBsolar still | 1.24 kg/m2/h | 7.4–8.0 kg/m2/d | No salt crystallization on the surface. | [88] |

| RGO/cotton fabric | DSSB solar still | 1.47 kg/m2/h | 4 L/m2/d | Salts redissolved quickly in channels. | [89] |

| Carbonized rice straw composited with bacterial cellulose | SSSB solar still | 1.2 kg/m2/h | 4.6–7.9 kg/m2/d | Salt crystallizes at the edge. | [90] |

| 3D evaporator with CNT | SSSB solar still | 2.63 kg/m2/h | 1.72 kg/m2/h | Salts can be easily removed and collected. | [91] |

| Graphene PVA hydrogel | SSSB solar still | 2.19 kg/m2/h | 13.68 kg/m2/d | Salt resistance. | [92] |

| Molybdenum Carbide / Carbon-Based Chitosan Hydrogel | self-designed solar still | 1.77 kg/m2/h | 12 L/m2/d | — | [93] |

| Methods | Advantages | Disadvantage |

|---|---|---|

| Using energy storage materials | store an amount of heat and release it at night or low solar irradiation | salt and rust in saline water would accumulate on sponges, which would reduce capillarity some phase change materials may affect the water quality |

| Adding nanoparticles | enhance the absorption of light at certain wavelengths by absorbing, scattering, and reflecting | poor dispersion stability and easy agglomeration increased thermal resistance serious heat loss might be toxic |

| Changing the structure of the absorption plate | increases the heat transfer area | the increased shadow leads to the loss of a part of the solar radiation |

| Using photothermal materials | high solar energy absorption conversion efficiency low thermal conductivity | some materials price is high salt accumulation on materials surface |

| Type of Solar Still | Method of Cooling Cover | Productivity without Cooling the Condensing Surface | Productivity with Cooling the Condensing Surface | Productivity Increase | Ref. | |

|---|---|---|---|---|---|---|

| SSSB solar still | air cooling cover | 2.805 L/m2/d | 3.24 L/m2/d | 15.5% | [98] | |

| Water cooling cover | 3.23 L/m2/d | 4.259 L/m2/d | 31.8% | |||

| Water cooling cover | 1.48 L/m2/d | 2.19 L/m2/d | 47.6% | [99] | ||

| Water cooling cover | 2.94 L/d | 3.541 L/d | 20% | [100] | ||

| “V”type solar still | Water cooling cover | 3.3 L/m2/d | 4.3 L/m2/d | 30.3% | [101] | |

| Water and air cooling cover | 4.6 L/m2/d | 39.4% | ||||

| Tubular solar still | Air cooling cover | 2.05 L/d | 3.05 L/d | 49% | [102] | |

| Water cooling cover | 5 L/d | 64% | ||||

| Stepped solar still | Water cooling cover | 4 kg/m2/d | 5.58 kg/m2/d | 39.5% | [103] | |

| Triple basin solar still | Water cooling cover | 5 kg/m2/d | 8.58 kg/m2/d | 30% | [104] | |

| DBSB solar still | Water cooling cover | passive solar still | 1.15 L/m2/d. | 1.33 L/m2/d | 15.7% | [105] |

| active solar still | 1.35 L/m2/d | 1.63 L/m2/d | 20.7% | |||

| Tubular solar still | Water cooling cover | 4.5 L/m2/d | 5.85 L/m2/d | 31.4% | [106] | |

| Methods | Advantages | Disadvantage |

|---|---|---|

| Cooling the condensing surface | increases the temperature difference between the water and the condensation surface | reduce the absorption of solar radiation offset some of the effects of wind speed |

| Increasing the condensation area | increasing the surface area for condensation | solar still takes up more space and becomes more complicated |

| Changing the wettability of the condensing surface | the higher heat transfer achieved through drop-wise condensation droplets move faster | reduce the absorption of solar radiation |

| Using the separate condenser | the temperature of the glass cover is greatly reduced glass and basin water temperatures of solar still integrated with the external condenser are less than that of conventional solar still | solar still takes up more space and becomes more complicated electricity consumption by a pump in forced circulation mode |

| Type of Passive Solar Still | L (L/Year) | CPL (USD/L) | Reference |

|---|---|---|---|

| SSSB | 876 | 0.0435 | [35] |

| SSSB + PV | 956.3 | 0.052 | |

| SSSB + PV + FAC (forced convection air cooling) | 1047.55 | 0.0493 | |

| CSS + PV as a reflector | 952.65 | 0.0418 | |

| DSSB | 766.5 | 0.0135 | [129] |

| DSSB + fin | 839.5 | 0.0133 | |

| DSSB + fin + PCM + EC + wick | 1250.55 | 0.0177 | |

| Solar still with air-condenser | 780.7 | 0.0384 | [130] |

| Solar still with PCM-condenser+ air-condenser | 1023.8 | 0.042 | |

| IASS (inverted absorber solar still) | 1569.135 | 0.0148 | [131] |

| ETC (evacuated tube collectors) | 1288.158 | 0.021245 | [132] |

| ETC + PCM + HP(heat pipe) | 1361.158 | 0.026645 | |

| ETC + EC (external condenser) | 2005.675 | 0.013777 | |

| ETC + PCM + HP + EC | 2392.575 | 0.01527 | |

| SSSB | 760 | 0.0222 | [133] |

| SSSB + PCM | 980 | 0.019 | |

| SSSB + PCM + fin | 1100 | 0.0176 | |

| TCSS | 1186.25 | 0.0348–0.0393 | [134] |

| TCSS + wire mesh | 1533 | 0.0309–0.0347 | |

| SSSB + PTC | 1050 | 0.038 | [135] |

| SSSB + PTC | 2182 | 0.021754 | [136] |

| SSSB + sand | 1330 | 0.021054 | |

| SSSB + PTC + sand | 2469.7 | 0.01937 | |

| SSSB+ Wire mesh | 1348.2 | 0.022554 | |

| SSSB + PTC + Wire mesh | 2523.3 | 0.019913 | |

| SSSB + plated finned heat sink condenser | 1263.5 | 0.023186 | |

| SSSB + plated finned heat sink condenser + PTC | 2419.4 | 0.020308 | |

| SSSB + plated finned heat sink condenser + sand | 1462.3 | 0.020288 | |

| SSSB + plated finned heat sink condenser + PTC + sand | 2725.4 | 0.018164 | |

| SSSB + plated finned heat sink condenser + wire mesh | 1348.2 | 0.022554 | |

| SSSB + plated finned heat sink condenser + PTC + wire mesh | 2523.3 | 0.019913 | |

| SSSB | 1168 | 0.0065 | [137] |

| SSSB + built-in condenser | 1569.5 | 0.0056 | |

| SSSB + built-in condenser + double-layered walls | 1799.45 | 0.0101 | |

| SSSB + PCM + pulsating heat pipe+ built-in condenser | 2299.5 | 0.0093 | |

| SSSB + air-cooled | 212.8 | 0.234 | [138] |

| SSSB + water-cooled | 385.5 | 0.277 | |

| SSSB+ modified water-cooled | 468.4 | 0.201 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, H.; Dai, M.; Song, H.; Hou, X.; Riaz, F.; Li, S.; Yang, K.; Ali, I.; Peng, C.; Sultan, M. Updates on Evaporation and Condensation Methods for the Performance Improvement of Solar Stills. Energies 2021, 14, 7050. https://doi.org/10.3390/en14217050

Fu H, Dai M, Song H, Hou X, Riaz F, Li S, Yang K, Ali I, Peng C, Sultan M. Updates on Evaporation and Condensation Methods for the Performance Improvement of Solar Stills. Energies. 2021; 14(21):7050. https://doi.org/10.3390/en14217050

Chicago/Turabian StyleFu, He, Min Dai, Hanwen Song, Xiaoting Hou, Fahid Riaz, Shuai Li, Ke Yang, Imran Ali, Changsheng Peng, and Muhammad Sultan. 2021. "Updates on Evaporation and Condensation Methods for the Performance Improvement of Solar Stills" Energies 14, no. 21: 7050. https://doi.org/10.3390/en14217050

APA StyleFu, H., Dai, M., Song, H., Hou, X., Riaz, F., Li, S., Yang, K., Ali, I., Peng, C., & Sultan, M. (2021). Updates on Evaporation and Condensation Methods for the Performance Improvement of Solar Stills. Energies, 14(21), 7050. https://doi.org/10.3390/en14217050