Optimal Configuration of the Integrated Charging Station for PV and Hydrogen Storage

Abstract

:1. Introduction

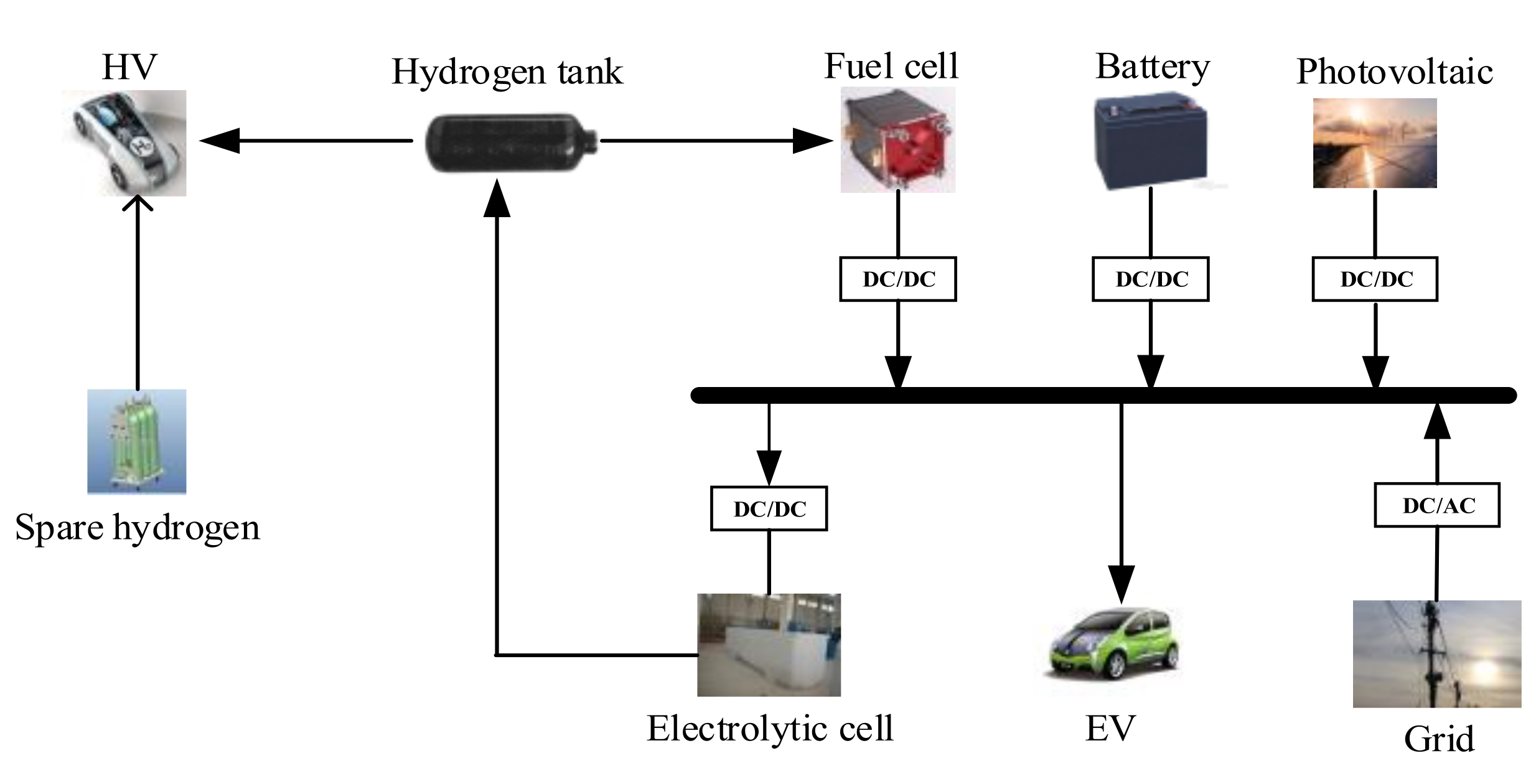

2. Structure and Component Mathematical Model of Integrated Charging Station

2.1. Structure of Integrated Charging Station

2.2. Component Mathematical Model

3. Optimized Configuration Model

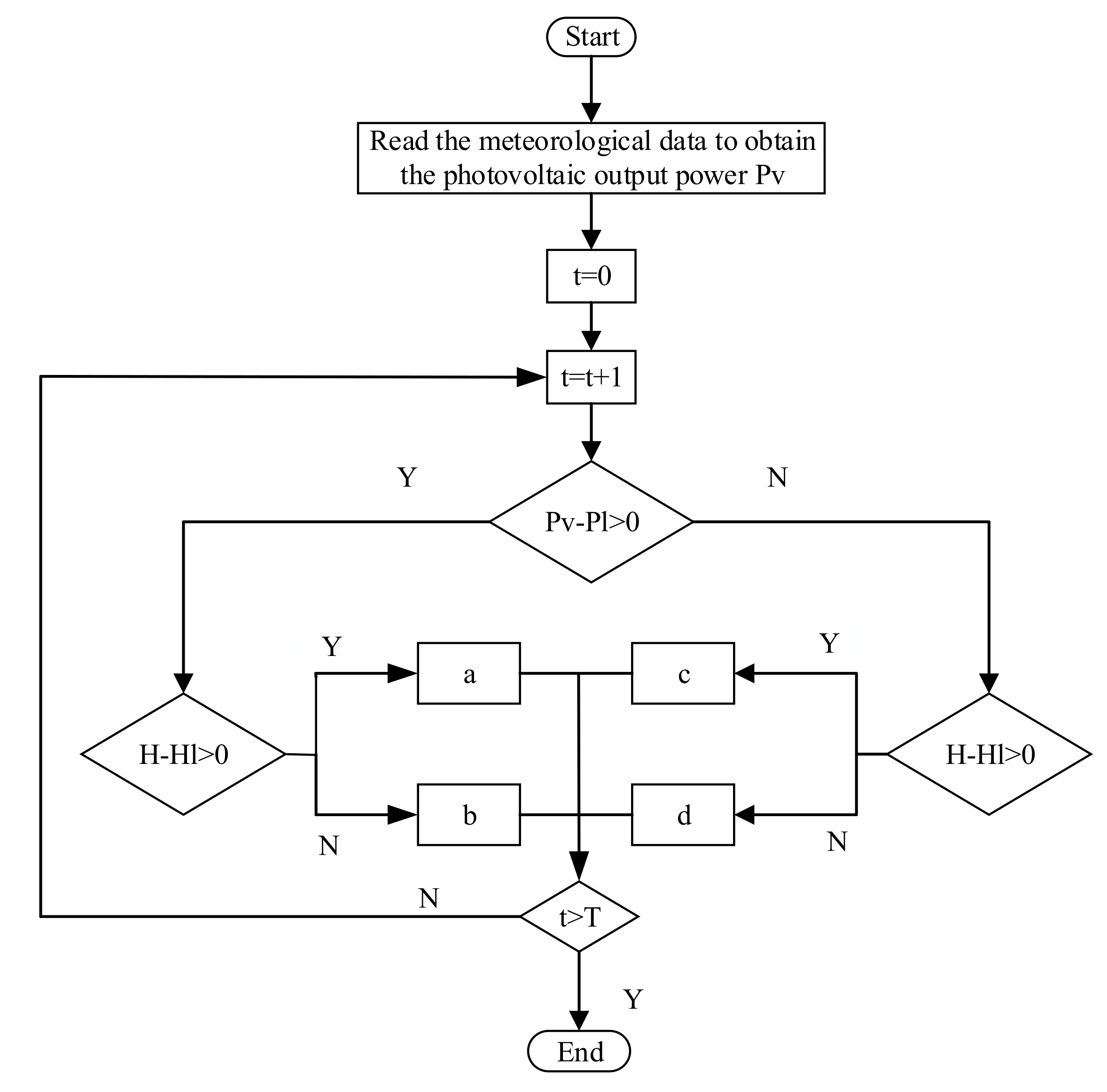

3.1. Energy Flow Strategy

- a:

- If the requirements of EV and HV are met., the remaining power of photovoltaic power generation will charge the battery in turn, the electrolytic cell will store hydrogen, and finally, the remaining power will be connected to the grid.

- b:

- If the requirements of EV are met, the requirements of HV are not met. The remaining power of photovoltaic power generation is first used for electrolytic hydrogen storage in the electrolytic cell. When used for battery charging, HV is still in shortage and is supplemented with purchased standby hydrogen.

- c:

- If the requirements of HV are met, the requirements of EV are not met. The primary discharge of battery and fuel cells provides the demand for EV, finally supplemented by the power grid.

- d:

- There is a shortage in EV and HV demand. The EV demand is discharged by the battery first, and the power grid will supplement the power shortage. HV needs to purchase a standby hydrogen supplement.

3.2. Optimization Model

4. Optimization Model Solution

4.1. Optimize Process

4.2. Fuzzy Comprehensive Evaluation

5. Example Analysis

5.1. Scene and Parameters

5.2. Capacity Optimization Configuration Results

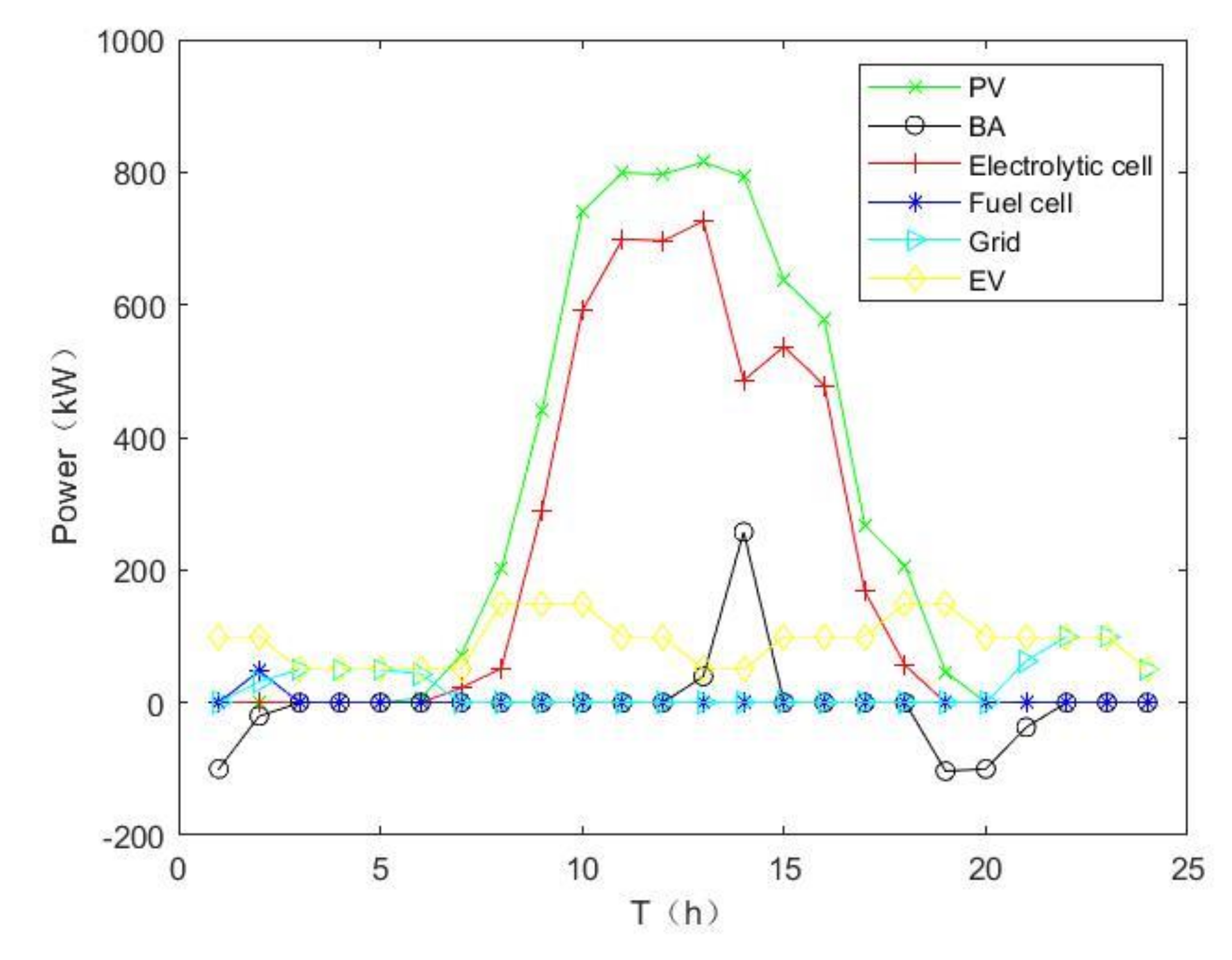

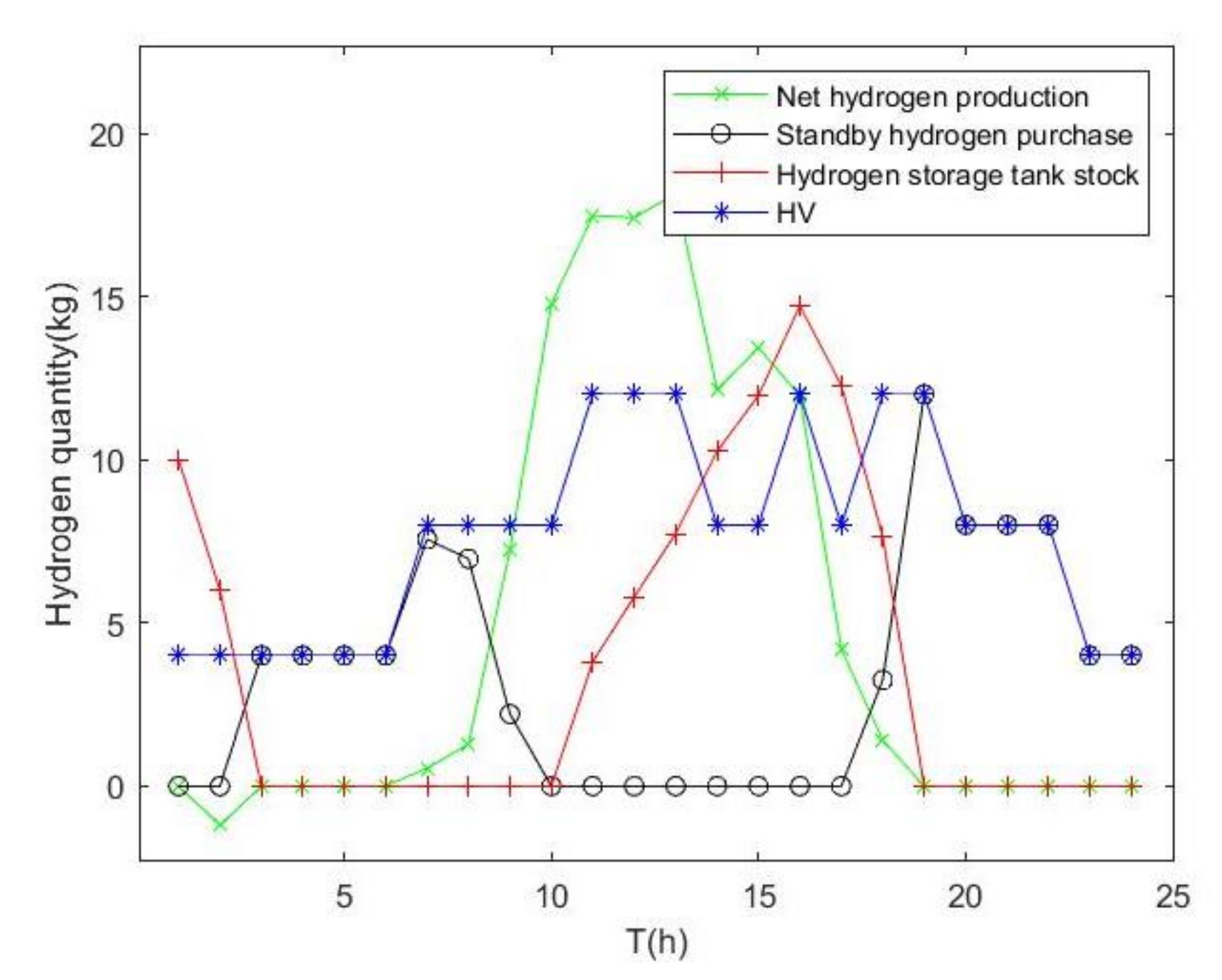

5.3. Operation Analysis of Integrated Charging Station

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CRF | Capital recovery factor |

| Investment cost | |

| Maintenance cost | |

| Running cost | |

| Sale of electricity revenue | |

| EV | Electric vehicle |

| Unit price of photovoltaic | |

| Unit price of battery | |

| Unit price of electrolytic cell | |

| Unit price of fuel cell | |

| Unit price of hydrogen tank | |

| Unit price of electricity | |

| Unit price of hydrogen | |

| Unit price of selling electricity | |

| Capacity of battery | |

| Operating cost | |

| Purchase electricity proportional to demand | |

| Purchase hydrogen proportional to demand | |

| Function value of the m non-inferior solution of the n objective function | |

| Sunlight intensity | |

| Rated sunlight intensity | |

| Hydrogen content of the hydrogen storage tank | |

| HV | Hydrogen vehicle |

| Electrolytic cell manufacturing hydrogen | |

| Fuel battery consumption hydrogen gas | |

| Hydrogen vehicle demand | |

| Consumption of spare hydrogen | |

| HHV | Ratio conversion of hydrogen and electricity |

| Maintenance factor | |

| PV | Photovoltaic |

| Photovoltaic power generation | |

| Photovoltaic rated power | |

| Battery charge and discharge power | |

| Electrolytic cell consumption power | |

| Fuel cell power supply | |

| Electric vehicle demand | |

| Grid power | |

| Grid power supply | |

| Power on grid | |

| Annual interest rate | |

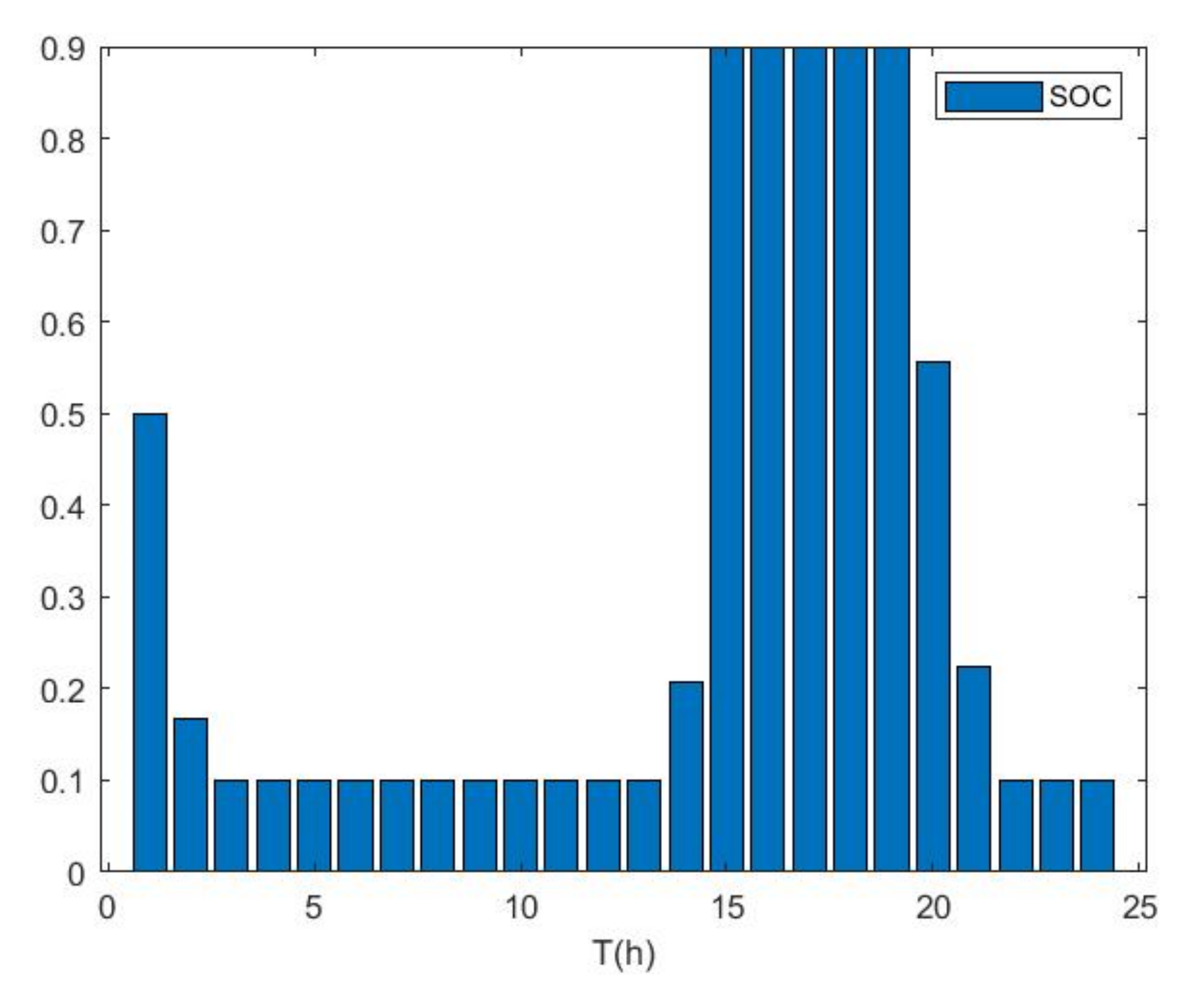

| SOC | State of charge |

| Temperature | |

| Rated temperature | |

| Active life | |

| Efficiency of battery | |

| Efficiency of electrolytic cell | |

| Efficiency of fuel cell | |

| Membership of the m non-inferior solution of the n objective function |

References

- Zeng, M.; Wang, Y.; Zhang, S.; Liu, Y. 12 key issues in the energy planning of the 14th five-year plan and the realization of the “30.60” double carbon goal. China Power Enterp. Manag. 2021, 1, 41–43. [Google Scholar]

- Li, W. Analysis of energy status and some important strategic countermeasures. Chem. Enterp. Manag. 2021, 10, 13–14. [Google Scholar]

- Pan, Q.; Hao, L. The impact of the new round of oil crisis on China’s National Defense Supply and countermeasures. Def. Ind. Convers. China 2020, 6, 39–40. [Google Scholar]

- Fang, G.; Wang, Q. Exploration on the path of energy low-carbon transformation under the guidance of double carbon goal. Coal Econ. Res. 2021, 41, 4–12. [Google Scholar]

- Hosseini, S.E.; Wahid, M.A. Hydrogen production from renewable and sustainable energy resources: Promising green energy carrier for clean development. Renew Sustain. Energy Rev. 2016, 57, 850–866. [Google Scholar] [CrossRef]

- Jahangiri, M.; Soulouknga, M.H.; Bardei, F.K.; Shamsabadi, A.A.; Akinlabi, E.T.; Sichilalu, S.M.; Mostafaeipour, A. Techno-econo-environmental optimal operation of grid-wind-solar electricity generation with hydrogen storage system for domestic scale, case study in Chad. Int. J. Hydrog. Energy 2019, 44, 28613–28628. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Ker, P.J.; Begum, R.A.; Agelidis, V.G.; Blaabjerg, F. Power electronics contribution to renewable energy conversion addressing emission reduction: Applications, issues, and recommendations. Appl. Energy 2019, 251, 113404. [Google Scholar] [CrossRef]

- Su, S.; Jiang, X.; Wang, W.; Jiang, J.; Geng, J. Microgrid energy optimization management considering electric vehicles and photovoltaic energy storage. Autom. Electr. Power Syst. 2015, 39, 164–171. [Google Scholar]

- Lu, X.; Liu, L.; Chen, Z.; Zhang, J.; Xiao, X. Multi objective optimal scheduling method for electric vehicle photovoltaic charging station. Trans. China Electrotechical Soc. 2014, 29, 46–56. [Google Scholar]

- Liu, S.; Zhang, H. Development status and Enlightenment of foreign electric vehicle industry. China Natl. Cond. Strength 2020, 10, 63–66. [Google Scholar]

- Chen, Z.; Xiao, X.; Lu, X.; Liu, N.; Zhang, J. Multi objective capacity optimization allocation method for electric vehicle charging station with photovoltaic power generation system. Trans. China Electrotechical Soc. 2013, 28, 238–248. [Google Scholar]

- Zhang, Y.; Liu, N.; Zhang, J.; Li, Y. Optimal capacity allocation of wind solar complementary system with electric vehicle charging station. Power Syst. Prot. Control 2013, 41, 126–134. [Google Scholar]

- Lu, J.; Yang, Y.; Wang, Y.; He, T. Energy storage configuration of electric vehicle photovoltaic charging station based on Copula theory. Acta Energ. Sol. Sin. 2016, 37, 780–786. [Google Scholar]

- Sun, Y.; Liu, J.; Liu, H.; Zhang, K.; Chu, Z.; Liu, J. Capacity configuration of centralized charging station considering recycling of rechargeable battery pack. Electr. Meas. Instrum. 2016, 53, 80–86. [Google Scholar]

- Li, W.; Tong, Y.; Zhang, W. Energy storage capacity allocation method of electric vehicle charging station considering battery service life. Adv. Technol. Electr. Eng. Energy 2019, 39, 55–63. [Google Scholar]

- Li, J.; Shi, Y.; Zhang, L.; Yang, X.; Wang, L.; Chen, X. Energy storage capacity optimization strategy of optical storage and charging station considering orderly charging of electric vehicles. Power Syst. Prot. Control 2021, 49, 94–102. [Google Scholar]

- Li, Q.; Zhao, S.; Pu, Y.; Chen, W.; Yu, J. Capacity allocation optimization of hybrid energy storage microgrid considering electric hydrogen coupling. Trans. China Electrotechical Soc. 2021, 36, 486–495. [Google Scholar]

- Liu, N. Research on Multi-Objective Optimization Algorithm and Application Based on Evolutionary Algorithm. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2010. [Google Scholar]

- Zhang, T.; Wang, C.; Wang, L.; Zhang, D.; Zhang, J. Double level optimal dispatching model of power selling companies considering the participation of virtual power plants. Power Syst. Technol. 2019, 43, 952–961. [Google Scholar]

- Tong, S.J.; Same, A.; Kootstra, M.A.; Park, J.W. Off-grid photovoltaic vehicle charge using second life lithium batteries: An experimental and numerical investigation. Appl. Energy 2013, 104, 740–750. [Google Scholar] [CrossRef]

- Liu, G.; Yu, H.; Kang, K.; Zhang, J. Capacity allocation of optical storage and charging station considering demand response and carbon emission. Proc. CSU-EPSA 2021, 33, 106–112. [Google Scholar]

- Xiong, Y.; Si, Y.; Zheng, T.; Chen, L.; Mei, S. Optimal allocation of hydrogen energy storage in integrated energy system of Industrial Park Based on master-slave game. Trans. China Electrotechical Soc. 2021, 36, 507–516. [Google Scholar]

| Component | Power Price (yuan/kW) | Service Life (year) |

|---|---|---|

| Photovoltaic | 7000 | 20 |

| Battery | 1200 | 5 |

| Electrolytic cell | 14,000 | 10 |

| Fuel cell | 14,000 | 10 |

| Hydrogen tank | 3380 | 10 |

| Optimization Objective | Optimization Result |

|---|---|

| Photovoltaic (kW) | 100 |

| Battery (kW) | 362 |

| Electrolytic cell (kW) | 734 |

| Fuel cell (kW) | 136 |

| Hydrogen tank (kg) | 64 |

| Annualized cost (yuan) | 3,620,953.085 |

| The proportion of power purchase (%) | 0.305 |

| The proportion of standby hydrogen purchase (%) | 0.481 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Dong, X.; Zhai, Y. Optimal Configuration of the Integrated Charging Station for PV and Hydrogen Storage. Energies 2021, 14, 7087. https://doi.org/10.3390/en14217087

Wang M, Dong X, Zhai Y. Optimal Configuration of the Integrated Charging Station for PV and Hydrogen Storage. Energies. 2021; 14(21):7087. https://doi.org/10.3390/en14217087

Chicago/Turabian StyleWang, Min, Xiaobin Dong, and Youchun Zhai. 2021. "Optimal Configuration of the Integrated Charging Station for PV and Hydrogen Storage" Energies 14, no. 21: 7087. https://doi.org/10.3390/en14217087

APA StyleWang, M., Dong, X., & Zhai, Y. (2021). Optimal Configuration of the Integrated Charging Station for PV and Hydrogen Storage. Energies, 14(21), 7087. https://doi.org/10.3390/en14217087