Unlocking the UK Continental Shelf Electrification Potential for Offshore Oil and Gas Installations: A Power Grid Architecture Perspective

Abstract

:1. Introduction

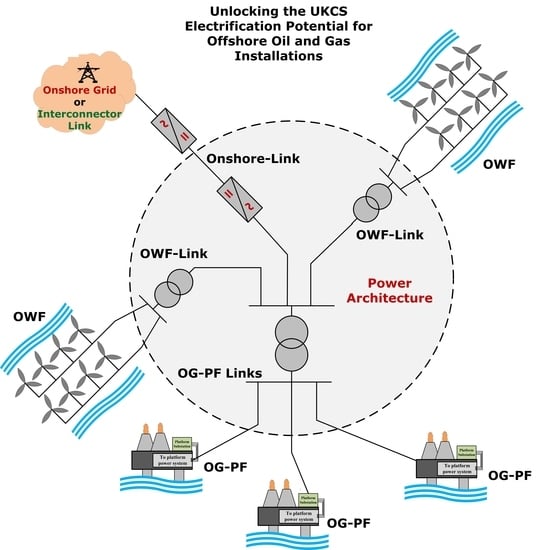

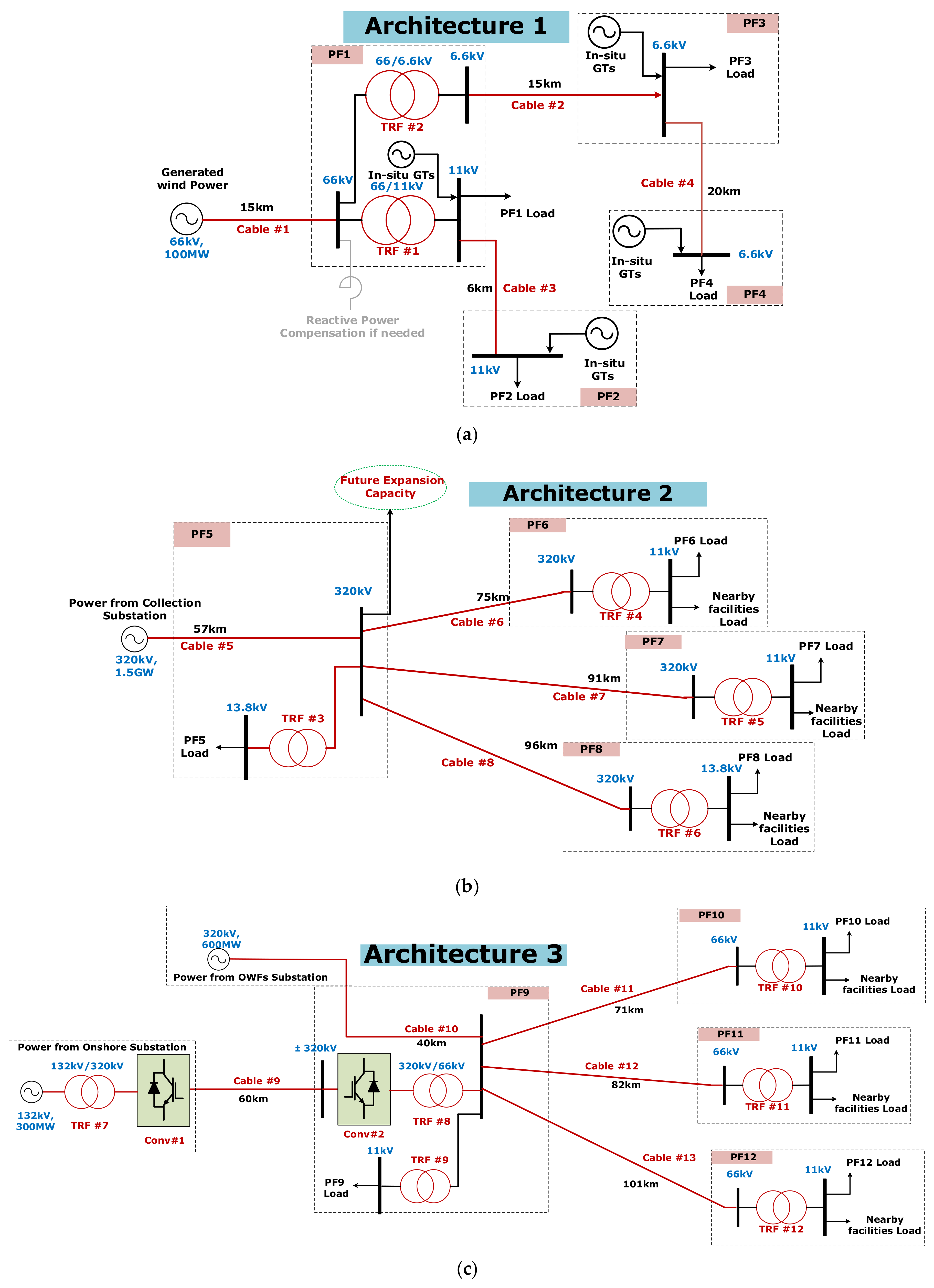

- Architecture 1: Utilise the installation of a local floating wind-farm feeding a network of isolated OG PFs.

- Architecture 2: Create a power hub fed from large-scale wind farms; therefore, access to clean energy is made possible.

- Architecture 3: Create a network of offshore wind power, onshore grid power and OG PFs. The power direction and amount are fully controlled and flexible.

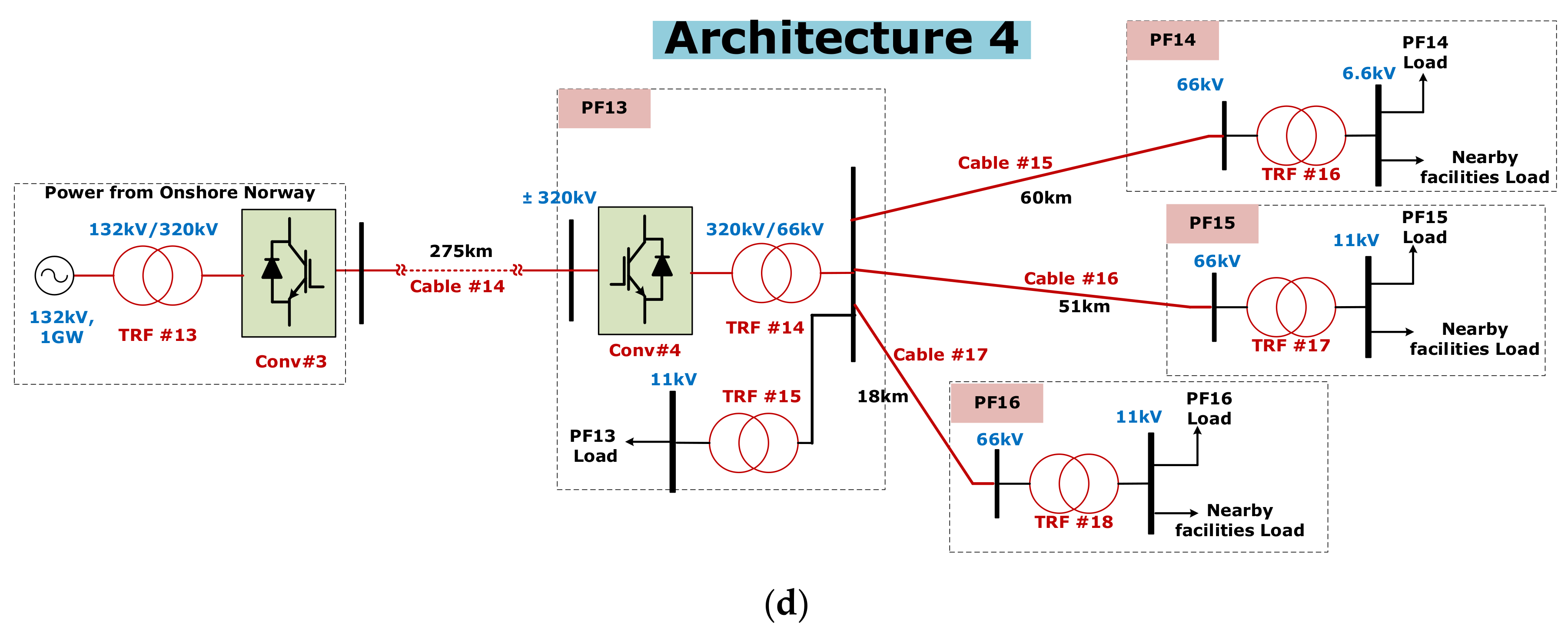

- Architecture 4: Providing the possibility of connecting remote OG PFs to other nearby countries’ grids—Norway, for example.

2. Offshore OG-PF Electrical Demand

2.1. Typical Offshore OG-PF Load Types

2.2. Estimating the OG PF’s Load Demand

3. The UK Offshore Wind

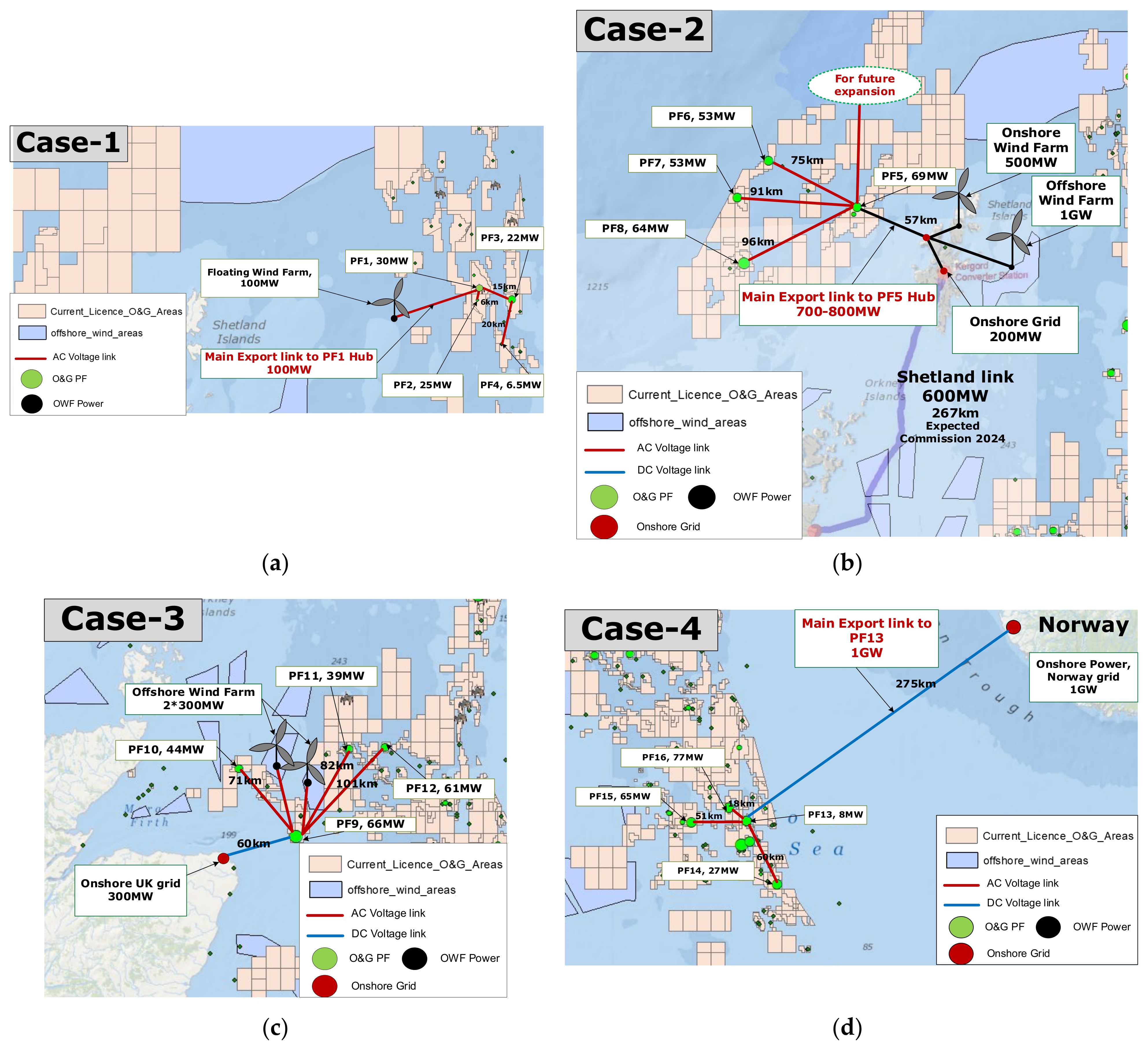

4. The Hypothetical Case Studies

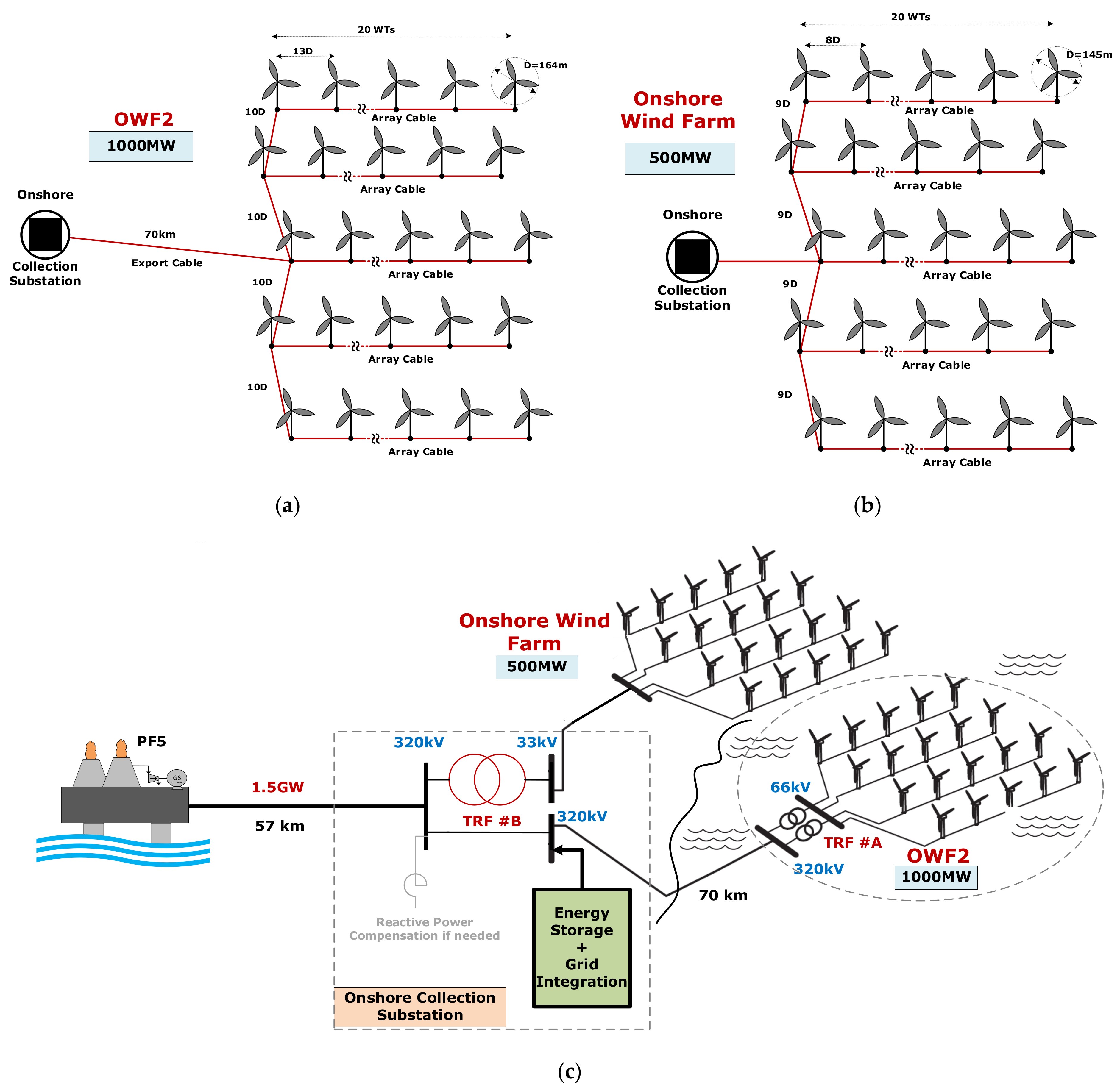

5. Wind Farms’ Layout and Power Densities

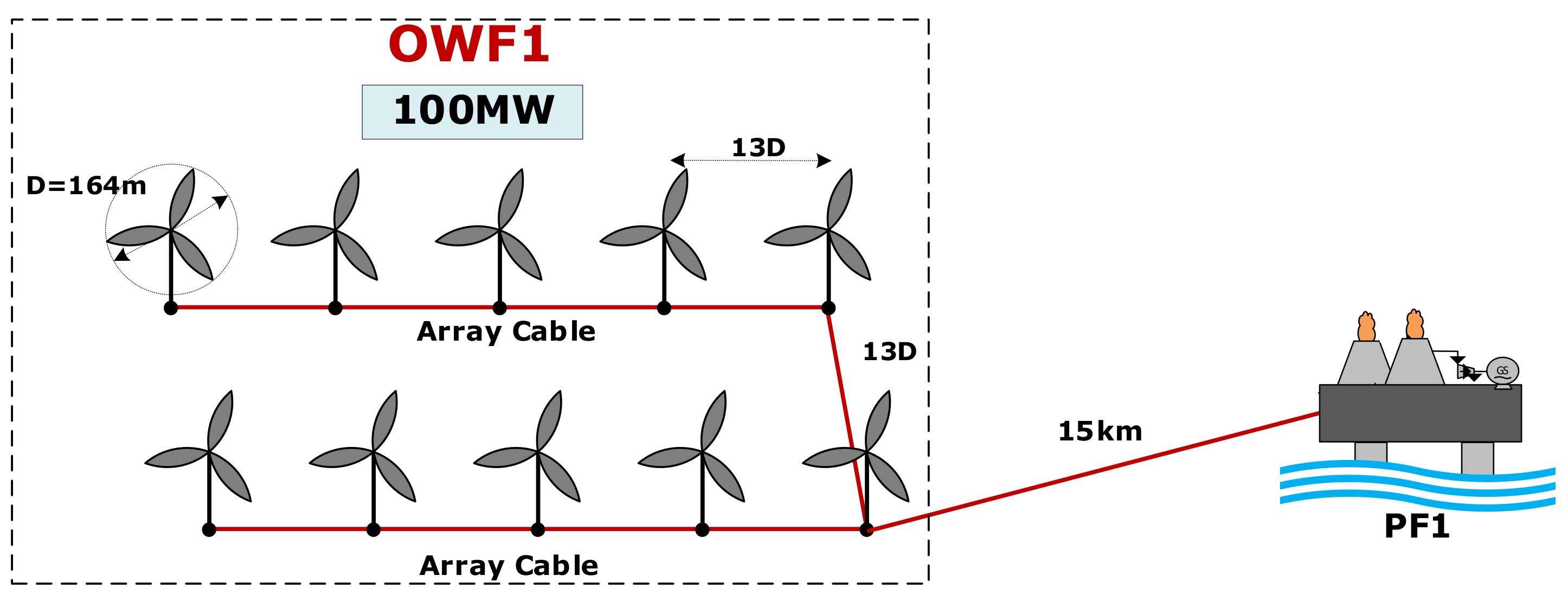

5.1. Offshore Wind Farms

5.2. Onshore Wind Farm

6. Proposed Power Architectures for UKCS Offshore OG PFs’ Electrification

- In all the proposed architectures, one of the platforms is selected (based on the available space on it and the closeness to other platforms) to be a power hub. Hence, hub and designed architectures are adopted.

- All the power generated from the wind farms is transmitted to the prospective power hub in AC. The power distribution from the main power hub to the nearby OG PFs is AC; therefore, minimal on-board modifications and components are required (in comparison with HVDC or low-frequency AC transmission).

- As a result, in the proposed architectures, all the cables are AC 3-phase cables, except Cable#9 and Cable#14 are DC cables.

- The power factor (pf) is 0.9 and balanced three-phase AC systems.

- The AC cables are of XLPE 3-core type, hence no more than 320 kV transmission voltage is used. The conductor type is Aluminum (although its conductivity is lower than copper but it is generally cheaper).

- For Case-3, the HVDC link is adopted to connect PF9 with the onshore grid. Thus, facilitating bi-directional power is made easier and controllable. Whenever there is a surplus power generated from the OWFs, the power flow can be reversed and fed to the grid. On the other hand, the HVDC link in Case-4 is the viable option to transmit bulk power at a long distance.

- In both Case-3 and Case-4, the HVDC adopted technology is voltage source converter based; hence, minimum filtering and reactive power are needed with black-start and power-reversal capabilities [36].

- All the proposed architectures require the minimum possible components, thus reducing the required on-platform space and footprint. Nevertheless, if the platform has limited space and/or the isolation requirement exceeds the available space, attaching a bridge link PF to the existing OG PF is possible.

- Although subsea transformers are now available and possible for deep water (>3000 m), they are not considered in the main theme of the architecture. This is because their cost is five times the top-side transformer; hence, they may increase the cost significantly. Nevertheless, they may be considered as a design option if preferred by the operators or when there is not enough space on the platform and it is not possible to attach a bridge-linked PF to it.

7. CapEx for the Proposed Power Architectures

- The wind farm (onshore/offshore).

- The cables (AC/DC).

- The transformers.

- The VSC–HVDC converters.

7.1. Offshore Wind Farms

7.2. Onshore Wind Farms

7.3. Cables Cost

7.4. Transformers Cost

7.5. VSC–HVDC Cost

8. Discussion

9. Conclusions and Future Directions

- Energy storage: With OWF capacities reaching 60% in the North Sea, it is still extremely important to provide some sort of energy storage [42]. A promising solution that can be integrated with OWFs is green hydrogen-energy storage, which not only will be green but also will provide supply security for OG operations.

- Electric component footprint: Due to the limited space on the top side of the OG PFs, two alternative approaches can be adopted to overcome the limited space: either create the power hubs by using subsea technology, which is gaining potential and maturity, or utilise nearby gravity-based decommissioned platforms as a power hub.

- Regulations: It needs to be clear who will control and own the operation of these assets and OWFs. Therefore, government legislations need to organize and protect all parties for smoother operation. Therefore, a clear pathway for standardization is inevitable for the net-zero race.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Cables and Transformers Ratings

| Cable | Power Rating (MW) | Rated Phase Voltage (kV) | Rated Current (A) | Number of Circuits per Phase | Maximum Current per Circuit (A) | Cross-Sectional Area (mm2) |

|---|---|---|---|---|---|---|

| Cable#1 | 100 | 972 | 2 | 540 | 500 | |

| Cable#2 | 20 | 1950 | 4 | 540 | 500 | |

| Cable#3 | 10 | 585 | 1 | 660 | 800 | |

| Cable#4 | 6.5 | 630 | 1 | 660 | 800 |

| Transformer | Power Rating (MVA) | Voltage Rating (kV) | Number Winding | Estimated Weight (t) | Dimensions (m) | Location | ||

|---|---|---|---|---|---|---|---|---|

| TRF#1 | 55 | 2 | 100 | 7 | 2.9 | 5.5 | PF1 | |

| TRF#2 | 55 | 2 | 100 | 7 | 2.9 | 5.5 | PF1 | |

| Cable | Power Rating (MW) | Rated Phase Voltage (kV) | Rated Current (A) | Number of Circuits per Phase | Maximum Current per Circuit (A) | Cross-Sectional Area (mm2) |

|---|---|---|---|---|---|---|

| Cable#5 | 1500 | 3007 | 5 | 720 | 1000 | |

| Cable#6 | 75 | 150 | 1 | 430 | 300 | |

| Cable#7 | 75 | 150 | 1 | 430 | 300 | |

| Cable#8 | 85 | 3900 | 5 | 720 | 1000 |

| Transformer | Power Rating (MVA) | Voltage Rating (kV) | Number of Units | Power Rating (MVA) per Unit | Estimated Weight per Unit (t) | Dimensions per Unit (m) | Location | ||

|---|---|---|---|---|---|---|---|---|---|

| TRF#3 | 95 | 320/11 | 1 | 100 | 144 | 7.8 | 3.3 | 5.8 | PF5 |

| TRF#4 | 78 | 320/11 | 1 | 80 | 110 | 7.4 | 3.1 | 5.8 | PF6 |

| TRF#5 | 78 | 320/11 | 1 | 80 | 110 | 7.4 | 3.1 | 5.8 | PF7 |

| TRF#6 | 85 | 320/13.8 | 2 | 80 | 110 | 7.4 | 3.1 | 5.8 | PF8 |

| Cable | Power Rating (MW) | Rated Phase Voltage (kV) | Rated Current (A) | Number of Circuits per Phase | Maximum Current per Circuit (A) | Cross-Sectional Area (mm2) |

|---|---|---|---|---|---|---|

| Cable#10 | 600 | 1200 | 2 | 660 | 800 | |

| Cable#11 | 44 | 428 | 1 | 485 | 400 | |

| Cable#12 | 39 | 379 | 1 | 430 | 300 | |

| Cable#13 | 61 | 590 | 1 | 660 | 800 |

| Cable | Power Rating (MW) | Rated DC Voltage (kV) | Rated Current (A) | Maximum Current per Circuit (A) | Cross-Sectional Area (mm2) |

|---|---|---|---|---|---|

| Cable#9 | 300 | 469 | 523 | 150 |

| Transformer | Power Rating (MVA) | Voltage Rating (kV) | Number of Units | Power Rating (MVA) per Unit | Estimated Weight per Unit (t) | Dimensions per Unit (m) | Location | ||

|---|---|---|---|---|---|---|---|---|---|

| TRF#7 | 310 | 132/320 | 1 | 310 | 326 | 13.1 | 7.3 | 7.7 | Onshore SS |

| TRF#8 | 930 | 320/66 | 3 | 310 | 185 | 13.1 | 7.3 | 7.8 | PF9 |

| TRF#9 | 100 | 66/11 | 1 | 100 | 144 | 7.8 | 3.4 | 6.1 | PF9 |

| TRF#10 | 40 | 66/11 | 1 | 40 | 76 | 6.9 | 2.9 | 5.4 | PF10 |

| TRF#11 | 50 | 66/11 | 1 | 50 | 87 | 7 | 2.9 | 5.5 | PF11 |

| TRF#12 | 80 | 66/11 | 1 | 80 | 118 | 7.4 | 3.1 | 5.8 | PF12 |

| VSC-HVDC | Power Rating (MW) | Rated DC Voltage (kV) | Converter Model | Power Capability (MW) | Number of Units | Transmission Distance |

|---|---|---|---|---|---|---|

| Conv#1 | 300 | M7 | 405 | 1 | Onshore | |

| Conv#2 | 300 | M7 | 405 | 1 | 57 km |

| Cable | Power Rating (MW) | Rated Phase Voltage (kV) | Rated Current (A) | Number of Circuits per Phase | Maximum Current per Circuit (A) | Cross-Sectional Area (mm2) |

|---|---|---|---|---|---|---|

| Cable#15 | 30 | 290 | 1 | 335 | 185 | |

| Cable#16 | 75 | 730 | 2 | 430 | 300 | |

| Cable#17 | 90 | 875 | 2 | 540 | 500 |

| Cable | Power Rating (MW) | Rated DC Voltage (kV) | Rated Current (A) | Maximum Current per Circuit (A) | Cross-Sectional Area (mm2) |

|---|---|---|---|---|---|

| Cable#1 | 1000 | 1562.5 | 1644 | 1000 |

| Transformer | Power Rating (MVA) | Voltage Rating (kV) | Number of Units | Power Rating (MVA) per Unit | Estimated Weight per Unit (t) | Dimensions per Unit (m) | Location | ||

|---|---|---|---|---|---|---|---|---|---|

| TRF#13 | 1000 | 132/320 | 3 | 350 | 326 | 13.1 | 7.3 | 7.7 | Onshore |

| TRF#14 | 1000 | 320/66 | 3 | 350 | 326 | 13.1 | 7.3 | 7.7 | PF13 |

| TRF#15 | 12.5 | 66/11 | 1 | 12.5 | 56 | 6.7 | 2.7 | 4.8 | PF13 |

| TRF#16 | 31.5 | 66/6.6 | 1 | 31.5 | 68 | 6.8 | 2.8 | 5.4 | PF14 |

| TRF#17 | 80 | 66/11 | 1 | 80 | 118 | 7.4 | 3.1 | 5.8 | PF15 |

| TRF#18 | 100 | 66/11 | 1 | 100 | 144 | 7.8 | 3.3 | 6.1 | PF16 |

| VSC-HVDC | Power Rating (MW) | Rated DC Voltage (kV) | Converter Model | Power Capability (MW) | Number of Units | Transmission Distance |

|---|---|---|---|---|---|---|

| Conv#1 | 1000 | M9 | 1220 | 1 | Onshore | |

| Conv#2 | 1000 | M9 | 1220 | 1 | 275 km |

References

- United Nations. Take Action for the Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 15 July 2021).

- Vella, H. Ten Steps to net zero: As the goal to reach net zero in the UK rapidly approaches, we examine Boris Johnson’s 10-point plan for a green industrial revolution. Eng. Technol. Mag. 2021, 16, 20–25. [Google Scholar] [CrossRef]

- Climate Change Committee. Progress in Preparing for Climate Change. Available online: https://www.theccc.org.uk/publication/progress-in-preparing-for-climate-change-2019-progress-report-to-parliament/ (accessed on 1 June 2021).

- OGUK’s Environment Report. Available online: https://oilandgasuk.co.uk/wp-content/uploads/2019/08/Environment-Report-2019-AUG20.pdf (accessed on 1 July 2020).

- OGUK’s Economic Report. Available online: https://oilandgasuk.co.uk/wp-content/uploads/2019/09/Economic-Report-2019-OGUK.pdf (accessed on 1 July 2020).

- UK’s 2019 Energy Transition Outlook. Available online: https://oilandgasuk.co.uk/wp-content/uploads/2019/03/OGUK-Energy-Transition-Outlook-2018.pdf (accessed on 1 July 2020).

- Troll, A. Available online: https://new.abb.com/systems/hvdc/references/troll-a (accessed on 10 July 2020).

- Valhall. Available online: https://new.abb.com/systems/hvdc/references/valhall (accessed on 10 July 2020).

- Sverdrup, J. Available online: https://new.abb.com/systems/hvdc/references/johan-sverdrup (accessed on 10 July 2020).

- Thibaut, E.; Leforgeais, B. Martin Linge electric power from shore. In Proceedings of the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, United Arab Emirates, 11–14 November 2012. [Google Scholar]

- ABB Commissions Cable Link to Deliver Clean Power to Goliat Offshore Oil Field. Available online: http://www.abb.com/cawp/seitp202/7293e63bf1fd8881c1257f0d00292ff8.aspx (accessed on 20 July 2020).

- Gjøa Receives Power from Shore. Available online: http://www.abb.co.uk/cawp/seitp202/b6dcda123bb5d28bc125778500352b28.aspx (accessed on 20 July 2020).

- Shi, G.; Peng, S.; Cai, X.; Chen, Z.; He, W. Grid integration of offshore wind farms and offshore oil/gas platforms. In Proceedings of the 7th International Power Electronics and Motion Control Conference, Harbin, China, 2–5 June 2012; pp. 1301–1305. [Google Scholar]

- Hadiya, M. Case Study of Offshore Wind Farm Integration to Offshore Oil and Gas Platforms as an Isolated System-System Topologies, Steady State and Dynamic Aspects. Master’s Thesis, Institute for Norwegian University of Science and Technology, Gjøvik, Norway, 2011. [Google Scholar]

- He, W.; Uhlen, K.; Hadiya, M.; Chen, Z.; Shi, G.; del Rio, E. Case study of integrating an offshore wind farm with offshore oil and gas platforms and with an onshore electrical grid. J. Renew. Energy 2013, 2013, 607165. [Google Scholar] [CrossRef] [Green Version]

- Svendsen, H.G.; Hadiya, M.; Øyslebø, E.V.; Uhlen, K. Integration of offshore wind farm with multiple oil and gas platforms. In Proceedings of the 2011 IEEE Trondheim PowerTech, Trondheim, Norway, 19–23 June 2011; pp. 1–3. [Google Scholar]

- Tiong, Y.K.; Zahari, M.A.; Wong, S.F.; Dol, S.S. The Feasibility of Wind and Solar Energy Application for Oil and Gas Offshore Platform; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; Volume 78, p. 012042. [Google Scholar]

- Gusatu, L.F.; Yamu, C.; Zuidema, C.; Faaij, A. A Spatial Analysis of the Potentials for Offshore Wind Farm Locations in the North Sea Region: Challenges and Opportunities. ISPRS Int. J. Geo Inf. 2020, 9, 96. [Google Scholar] [CrossRef] [Green Version]

- Fard, R.N.; Tedeschi, E. Integration of distributed energy resources into offshore and subsea grids. CPSS Trans. Power Electron. Appl. 2018, 3, 36–45. [Google Scholar] [CrossRef]

- He, W.; Jacobsen, G.; Anderson, T.; Olsen, F.; Hanson, T.D.; Korpås, M.; Toftevaag, T.; Eek, J.; Uhlen, K.; Johansson, E. The Potential of Integrating Wind Power with Offshore Oil and Gas Platforms. Wind Eng. 2010, 34, 125–137. [Google Scholar] [CrossRef]

- Årdal, A.R.; Sharifabadi, K.; Bergvoll, Ø.; Berge, V. Challenges with integration and operation of offshore oil & gas platforms connected to an offshore wind power plant. In Proceedings of the 2014 Petroleum and Chemical Industry Conference Europe, Amsterdam, The Netherlands, 3–5 June 2014; pp. 1–9. [Google Scholar]

- UK Parliament. Fossil Fuelled Power Stations: Carbon Emissions and Nitrogen Oxides. Available online: https://questions-statements.parliament.uk/written-questions/detail/2015-11-26/17799 (accessed on 31 August 2020).

- The Department for Business Energy & Industrial Strategy (BEIS). 2019 Government Greenhouse Gas Conversion Factors for Company Reporting. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/829336/2019_Green-house-gas-reporting-methodology.pdf (accessed on 31 August 2020).

- Ulsund, R. Offshore Power Transmission: Submarine High Voltage Transmission Alternatives. Master’s Thesis, Institutt for Elkraftteknikk, Trondheim, Norway, 2009. [Google Scholar]

- Sorknæs, P.; Lund, H.; Skov, I.R.; Djørup, S.; Skytte, K.; Morthorst, P.E.; Fausto, F. Smart Energy Markets—Future electricity, gas and heating markets. Renew. Sustain. Energy Rev. 2020, 119, 109655. [Google Scholar] [CrossRef]

- Kota, S.; Bayne, S.B.; Nimmagadda, S. Offshore wind energy: A comparative analysis of UK, USA and India. Renew. Sustain. Energy Rev. 2015, 41, 685–694. [Google Scholar] [CrossRef]

- Johnston, B.; Foley, A.; Doran, J.; Littler, T. Levelised cost of energy, A challenge for offshore wind. Renew. Energy 2020, 160, 876–885. [Google Scholar] [CrossRef]

- Korpås, M.; Warland, L.; He, W.; Tande, J.O.G. A Case-Study on Offshore Wind Power Supply to Oil and Gas Rigs. Energy Proc. 2012, 24, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Borrmann, R.; Rehfeldt, K.; Wallasch, A.-K.; Lüers, S. Capacity Densities of European Offshore Wind Farms. Available online: https://www.windguard.com/publications-wind-energy-statistics.html?file=files/cto_layout/img/unternehmen/veroeffentlichungen/2018/Capacity%20Density%20of%20European%20Offshore%20Windfarmslr.pdf (accessed on 10 January 2020).

- V164-10.0MW Wind Turbine. Available online: https://www.vestas.com/en/products/offshore%20platforms/v164_10_0_mw#!grid_0_content_0_Container (accessed on 10 January 2020).

- Parker, M.A.; Anaya-Lara, O. Cost and losses associated with offshore wind farm collection networks which centralise the turbine power electronic converters. IET Renew. Power Gener. 2013, 7, 390–400. [Google Scholar] [CrossRef] [Green Version]

- Enevoldsen, P.; Permien, F.-H.; Bakhtaoui, I.; Krauland, A.-K.V.; Jacobson, M.Z.; Xydis, G.; Sovacool, B.K.; Valentine, S.V.; Luecht, D.; Oxley, G. How much wind power potential does europe have? Examining european wind power potential with an enhanced socio-technical atlas. Energy Policy 2019, 132, 1092–1100. [Google Scholar] [CrossRef]

- Viking Energy. Harnessing Shetland’s Natural Resources. Available online: https://www.vikingenergy.co.uk/the-project (accessed on 1 February 2020).

- Onshore Wind Turbine (SG 5.0-145) Manufactured by Siemens Gamesa. Available online: https://www.siemensgamesa.com/en-int/products-and-services/onshore/wind-turbine-sg-5-0-145 (accessed on 1 February 2020).

- XLPE Submarine Cable Systems, ABB. Available online: https://new.abb.com/docs/default-source/ewea-doc/xlpe-submarine-cable-systems-2gm5007.pdf (accessed on 15 March 2020).

- HVDC Light-It’s Time to Connect. Available online: https://vdocument.in/hvdc-light-its-time-to-connect-abb-s-time-to-connect-1-introducing-hvdc.html (accessed on 15 March 2020).

- Siemens Power Engineering Guide, Transformers, 4th ed. Available online: http://www.tekhar.com/Programma/Siemens/Commutacia/High_voltage/pdf_pict/5_transformers.pdf (accessed on 20 March 2020).

- Crown Estate and the Offshore Renewable Energy Catapult. Guide to an Offshore Wind Farm. Available online: https://www.thecrownestate.co.uk/media/2861/guide-to-offshore-wind-farm-2019.pdf (accessed on 10 February 2020).

- National Renewable Energy Laboratory (NREL). 2019 Cost of Wind Energy Review. Available online: https://www.nrel.gov/docs/fy18osti/72167.pdf (accessed on 10 February 2020).

- Electricity Ten Year Statement 2015, Appendix E. Available online: https://www.nationalgrideso.com/document/47036/download (accessed on 1 March 2020).

- Elgenedy, M.A.; Ahmed, K.H.; Aboushady, A.A.; Abdelsalam, I. DC–DC converter concept allowing line commutated converters and voltage source converters based HVDC systems connectivity. IET Power Electron. 2020, 13, 3294–3304. [Google Scholar] [CrossRef]

- Elgenedy, M.A.; Massoud, A.M.; Ahmed, S. Energy in smart grid: Strategies and technologies for efficiency enhancement. In Proceedings of the 2015 First Workshop on Smart Grid and Renewable Energy (SGRE), Doha, Qatar, 22–23 March 2015; pp. 1–6. [Google Scholar]

| Project | Power (MW) | HVDC Transmission Voltage (kV) | Submarine Cable Length (km) | Manufacturer |

|---|---|---|---|---|

| Troll-A | 188 | 120 | 70 | ABB |

| Valhall | 78 | 150 | 292 | ABB |

| Johan Sverdrup | 100 | 160 | 200 | ABB |

| Project | Power (MW) | HVAC Transmission Voltage (kV) | Submarine Cable Length (km) | Manufacturer |

|---|---|---|---|---|

| Martin Linge | 55 | 300 | 161 | Siemens |

| Gjøa | 40 | 90 | 98.5 | ABB |

| Goliat | 75 | 132 | 105.5 | ABB |

| Case-1 |

|

| Case-2 |

|

| Case-3 |

|

| Case-4 |

|

| OG PF Name | Load Demand (MW) | Voltage/Frequency | OG PF Name | Load Demand (MW) | Voltage/Frequency |

|---|---|---|---|---|---|

| PF1 | 30 | 11 kV/60 Hz | PF9 | 66 | 11 kV/60 Hz |

| PF2 | 25 | 11 kV/60 Hz | PF10 | 44 | 11 kV/60 Hz |

| PF3 | 22 | 6.6 kV/60 Hz | PF11 | 39 | 11 kV/60 Hz |

| PF4 | 6.5 | 6.6 kV/60 Hz | PF12 | 61 | 11 kV/60 Hz |

| PF5 | 69 | 13.8 kV/60 Hz | PF13 | 8 | 11 kV/60 Hz |

| PF6 | 53 | 11 kV/60 Hz | PF14 | 27 | 11 kV/60 Hz |

| PF7 | 53 | 11 kV/60 Hz | PF15 | 65 | 11 kV/60 Hz |

| PF8 | 64 | 13.8 kV/60 Hz | PF16 | 77 | 11 kV/60 Hz |

| Wind Farm | Water Depth | Average Wind Speed | Area Required | Total Power Capacity | Number of WTs |

|---|---|---|---|---|---|

| OWF1 | ≈140 m | ≈9–10 m/s | ≈20 km2 | 100 MW | 10 |

| OWF2 | ≈100 m | ≈9–10 m/s | ≈388 km2 | 1000 MW | 100 |

| OWF3 | 60–100 m | ≈9–10 m/s | ≈105 km2 | 300 MW | 30 |

| OWF4 | 60–100 m | ≈9–10 m/s | ≈102 km2 | 300 MW | 30 |

| Wind Speed | ≈7–8 m/s |

| Area Required | ≈110 km2 |

| Individual WT Rating | 5 MW (SG 5.0-145) |

| Number of WTs | 100 |

| Total Power Capacity | 500 MW |

| Wind Farm | Costs in £M | in £M | ||

|---|---|---|---|---|

| WTs | Balance of Plant | Installation and Commissioning | ||

| OWF1 | 100 | 400 | 65 | 565 |

| OWF2 | 1000 | 4000 | 650 | 5650 |

| OWF3 | 300 | 1200 | 195 | 1695 |

| OWF4 | 300 | 1200 | 195 | 1695 |

| Onshore Wind Farm | Costs in £M | in £M | ||

|---|---|---|---|---|

| Wind Turbine | Balance of System | Installation and Commissioning | ||

| 500 MW | 500 | 750 | 250 | 1500 |

| AC Cables | ||

| Voltage Rating at 300 MW 1 | <150 kV | 320 kV |

| Cable cost | 0.5 £M/km | 0.8 £M/km |

| Trenching and laying cost | 0.33 £M/km | |

| DC Cables | ||

| Power Rating at 320 kV | 300 MW | 1000 MW |

| Cable cost | 0.423 £M/km | 0.565 £M/km |

| Trenching and laying cost | 0.3 £M/km | |

| Architecture | Cables ID | Costs in £M | in £M | |

|---|---|---|---|---|

| Cable | Trenching and Laying | |||

| Architecture 1 | #1 to #4 | 28 | 18.5 | 46.5 |

| Architecture 2 | #5 to #8 | 437.6 | 180.5 | 618.1 |

| Architecture 3 | #10 to #13 | 191 | 110.22 | 301.22 |

| Architecture 4 | #15 to #17 | 99 | 65.34 | 164.34 |

| Architecture | Cables ID | Costs in £M | in £M | |

|---|---|---|---|---|

| Cable | Trenching and Laying | |||

| Architecture 3 | #9 | 13.8 | 18 | 31.8 |

| Architecture 4 | #14 | 155.37 | 82.5 | 237.87 |

| Architecture | Transformer ID | Cost in £M |

|---|---|---|

| Architecture 1 | #1 and #2 | 1.32 |

| Architecture 2 | #3 to #6 | 4.53 |

| Architecture 3 | #7 to #12 | 13.31 |

| Architecture 4 | #13 to #18 | 17.6 |

| Architecture | Converter ID | Cost in £M | in £M |

|---|---|---|---|

| Architecture 3 | Conv#1 | 88 | 176 |

| Conv#2 | 88 | ||

| Architecture 4 | Conv#3 | 140 | 280 |

| Conv#4 | 140 |

| Architecture | Total Cost (£M) | Power Capacity (MW) |

|---|---|---|

| Architecture 1 | 612.8 | 100 |

| Architecture 2 | 7772.63 | 1500 |

| Architecture 3 | 3912.33 | 600 |

| Architecture 4 | 699.81 | 1000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elgenedy, M.; Ahmed, K.; Burt, G.; Rogerson, G.; Jones, G. Unlocking the UK Continental Shelf Electrification Potential for Offshore Oil and Gas Installations: A Power Grid Architecture Perspective. Energies 2021, 14, 7096. https://doi.org/10.3390/en14217096

Elgenedy M, Ahmed K, Burt G, Rogerson G, Jones G. Unlocking the UK Continental Shelf Electrification Potential for Offshore Oil and Gas Installations: A Power Grid Architecture Perspective. Energies. 2021; 14(21):7096. https://doi.org/10.3390/en14217096

Chicago/Turabian StyleElgenedy, Mohamed, Khaled Ahmed, Graeme Burt, Graeme Rogerson, and Greg Jones. 2021. "Unlocking the UK Continental Shelf Electrification Potential for Offshore Oil and Gas Installations: A Power Grid Architecture Perspective" Energies 14, no. 21: 7096. https://doi.org/10.3390/en14217096