Non-Destructive Diagnostic Methods for Fire-Side Corrosion Risk Assessment of Industrial Scale Boilers, Burning Low Quality Solid Biofuels—A Mini Review

Abstract

:1. Introduction

- water wall (evaporator) corrosion

- corrosion of the superheaters

2. The Problem of the Fire-Side Corrosion

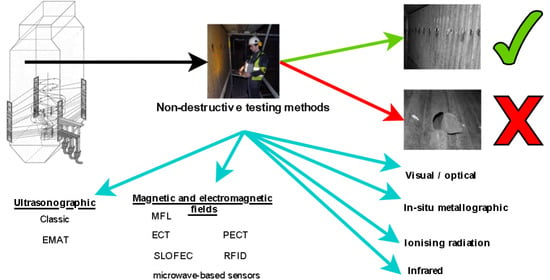

3. Non-Destructive Testing Methods for Fire-Side Corrosion Testing

3.1. Ultrasonographic Methods

- the classic one, which uses the transmitter head generating vibrations;

- the EMAT Method, in which the mechanical vibrations are evoked in the material studied.

3.2. Methods Employing the Magnetic and Electromagnetic Fields

3.3. Methods Employing Ionizing Radiation

3.4. Infrared Radiation-Based Methods

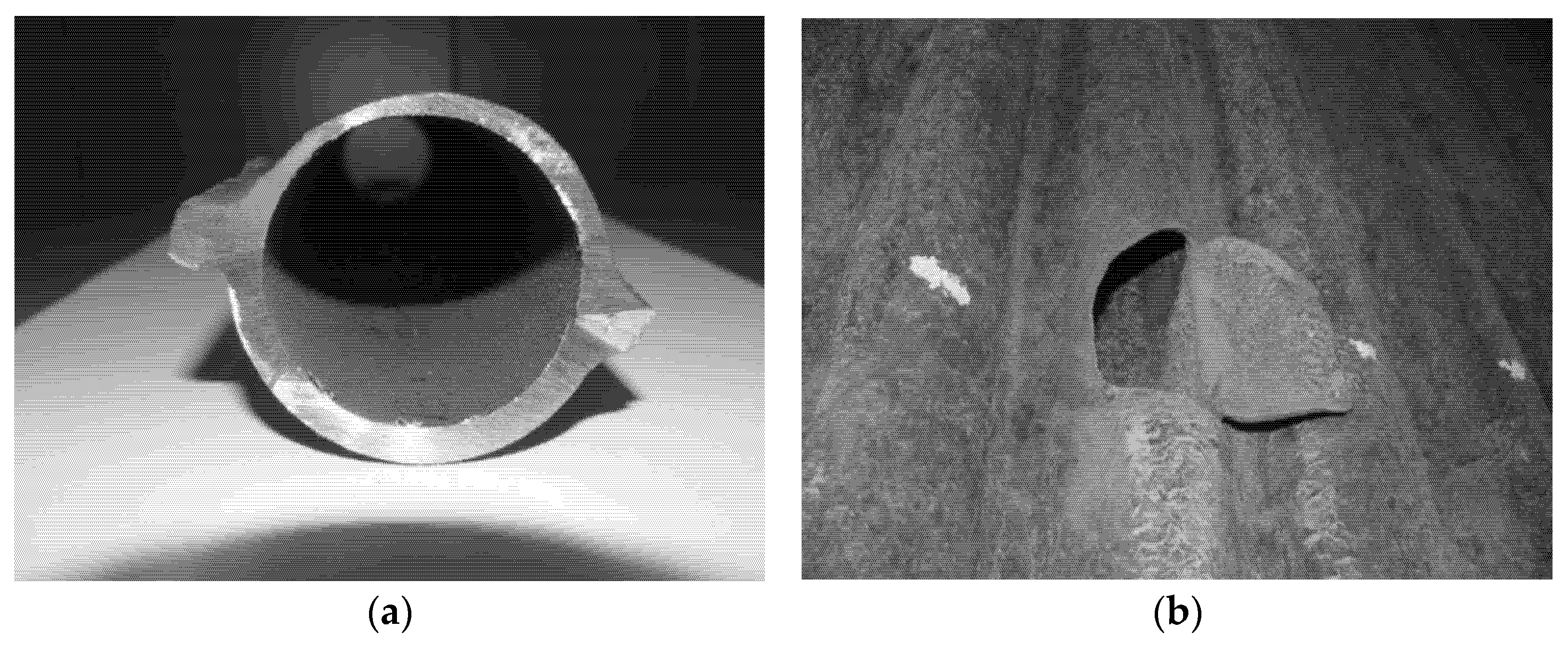

3.5. Other Methods

4. Available Automatic Systems with Visual Data Processing

5. Conclusions

- a physical phenomenon used for collecting measurement data;

- processing the collected data by means of computer techniques.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pronobis, M. Evaluation of the influence of biomass co-combustion on boiler furnace slagging by means of fusibility correlations. Biomass Bioenergy 2005, 28, 375–383. [Google Scholar] [CrossRef]

- Pronobis, M. Modernizacja Kotłów Energetycznych; WNT: Warszawa, Poland, 2009; ISBN 9788379261352. [Google Scholar]

- Hein, K.R.G. Operational Problems, Trace Emissions and By-Product Management for Industrial Biomass Co-Combustion; CORDIS: Brussels, Belgium, 2000. [Google Scholar]

- Harb, J.; Smith, E. Fireside corrosion in pc-fired boilers. Prog. Energy Combust. Sci. 1990, 16, 169–190. [Google Scholar] [CrossRef]

- Li, G.; Li, S.; Huang, Q.; Yao, Q. Fine particulate formation and ash deposition during pulverized coal combustion of high-sodium lignite in a down-fired furnace. Fuel 2015, 143, 430–437. [Google Scholar] [CrossRef]

- Zheng, S.; Zeng, X.; Qi, C.; Zhou, H. Mathematical modeling and experimental validation of ash deposition in a pulverized-coal boiler. Appl. Eng. 2017, 110, 720–729. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Z.; Wei, B.; Zhang, L.; Tan, H.; Yang, T.; Mikulčić, H.; Duić, N. The ash deposition mechanism in boilers burning Zhundong coal with high contents of sodium and calcium: A study from ash evaporating to condensing. Appl. Eng. 2015, 80, 150–159. [Google Scholar] [CrossRef] [Green Version]

- Gao, Q.; Li, S.; Yang, M.; Biswas, P.; Yao, Q. Measurement and numerical simulation of ultrafine particle size distribution in the early stage of high-sodium lignite combustion. Proc. Combust. Inst. 2017, 36, 2083–2090. [Google Scholar] [CrossRef]

- Golański, G.; Lachowicz, M.M. Failure cause analysis for the suspension element of boiler superheater. Eng. Fail. Anal. 2019, 105, 490–495. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Niedźwiecki, Ł.; Ostrycharczyk, M.; Czerep, M.; Plutecki, Z. Potential and methods for increasing the flexibility and efficiency of the lignite fired power unit, using integrated lignite drying. Energy 2019, 181, 1142–1151. [Google Scholar] [CrossRef]

- Duarte, C.A.; Espejo, E.; Martinez, J.C. Failure analysis of the wall tubes of a water-tube boiler. Eng. Fail. Anal. 2017, 79, 704–713. [Google Scholar] [CrossRef]

- Sims, R. The Brilliance of Bioenergy: In Business and Practice; Earthscan Publications Ltd.: London, UK, 2002; ISBN 978-1902916286. [Google Scholar]

- Sher, F.; Iqbal, S.Z.; Liu, H.; Imran, M.; Snape, C.E. Thermal and kinetic analysis of diverse biomass fuels under different reaction environment: A way forward to renewable energy sources. Energy Convers. Manag. 2020, 203, 112266. [Google Scholar] [CrossRef]

- Tzelepi, V.; Zeneli, M.; Kourkoumpas, D.S.; Karampinis, E.; Gypakis, A.; Nikolopoulos, N.; Grammelis, P. Biomass availability in europe as an alternative fuel for full conversion of lignite power plants: A critical review. Energies 2020, 13, 3390. [Google Scholar] [CrossRef]

- Jewiarz, M.; Wróbel, M.; Mudryk, K.; Szufa, S. Impact of the drying temperature and grinding technique on biomass grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Romanowska-Duda, Z.; Piotrowski, K.; Wolska, B.; Debowski, M.; Zielinski, M.; Dziugan, P.; Szufa, S. Stimulating Effect of Ash from Sorghum on the Growth of Lemnaceae—A New Source of Energy Biomass; Springer International Publishing: 2020; pp. 341–349, ISBN 9783030138882. Available online: https://link.springer.com/chapter/10.1007/978-3-030-13888-2_34 (accessed on 1 September 2021).

- Szufa, S.; Wielgosiński, G.; Piersa, P.; Czerwińska, J.; Dzikuć, M.; Adrian, Ł.; Lewandowska, W.; Marczak, M. Torrefaction of Straw from Oats and Maize for Use as a Fuel and Additive to Organic Fertilizers—TGA Analysis, Kinetics as Products for Agricultural Purposes. Energies 2020, 13, 2064. [Google Scholar] [CrossRef] [Green Version]

- Luo, H.; Lu, Z.; Jensen, P.A.; Glarborg, P.; Lin, W.; Dam-Johansen, K.; Wu, H. Experimental and modelling study on the influence of wood type, density, water content, and temperature on wood devolatilization. Fuel 2020, 260, 116410. [Google Scholar] [CrossRef]

- Tran, K.Q.; Werle, S.; Trinh, T.T.; Magdziarz, A.; Sobek, S.; Pogrzeba, M. Fuel characterization and thermal degradation kinetics of biomass from phytoremediation plants. Biomass Bioenergy 2020, 134, 105469. [Google Scholar] [CrossRef]

- Polesek-Karczewska, S.; Turzyński, T.; Kardaś, D.; Heda, Ł. Front velocity in the combustion of blends of poultry litter with straw. Fuel Process. Technol. 2018, 176, 307–315. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash deposition in biomass combustion or co-firing for power/heat generation. Energies 2012, 5, 5171–5189. [Google Scholar] [CrossRef]

- Magdziarz, A.; Gajek, M.; Nowak-Woźny, D.; Wilk, M. Mineral phase transformation of biomass ashes—Experimental and thermochemical calculations. Renew. Energy 2018, 128, 446–459. [Google Scholar] [CrossRef]

- Zuwała, J.; Lasek, J. Co-combustion of low-rank coals with biomass. In Low-Rank Coals for Power Generation, Fuel and Chemical Production; Woodhead Publishing: Sawston, UK, 2017; pp. 125–158. ISBN 9780081008959. [Google Scholar]

- Mlonka-Mędrala, A.; Magdziarz, A.; Gajek, M.; Nowińska, K.; Nowak, W. Alkali metals association in biomass and their impact on ash melting behaviour. Fuel 2020, 261, 116421. [Google Scholar] [CrossRef]

- Mlonka-Mędrala, A.; Magdziarz, A.; Dziok, T.; Sieradzka, M.; Nowak, W. Laboratory studies on the influence of biomass particle size on pyrolysis and combustion using TG GC/MS. Fuel 2019, 252, 635–645. [Google Scholar] [CrossRef]

- Phongphiphat, A.; Ryu, C.; Yang, Y.B.; Finney, K.N.; Leyland, A.; Sharifi, V.N.; Swithenbank, J. Investigation into high-temperature corrosion in a large-scale municipal waste-to-energy plant. Corros. Sci. 2010, 52, 3861–3874. [Google Scholar] [CrossRef] [Green Version]

- Viklund, P.; Hjörnhede, A.; Henderson, P.; Stålenheim, A.; Pettersson, R. Corrosion of superheater materials in a waste-to-energy plant. Fuel Process. Technol. 2013, 105, 106–112. [Google Scholar] [CrossRef]

- Wan, W.; Engvall, K.; Yang, W. Model investigation of condensation behaviors of alkalis during syngas treatment of pressurized biomass gasification. Chem. Eng. Process.-Process. Intensif. 2018, 129, 28–36. [Google Scholar] [CrossRef]

- Mlonka-Mędrala, A.; Gołombek, K.; Buk, P.; Cieślik, E.; Nowak, W. The influence of KCl on biomass ash melting behaviour and high-temperature corrosion of low-alloy steel. Energy 2019, 188, 116062. [Google Scholar] [CrossRef]

- Sandhi, K.K.; Szpunar, J. Analysis of Corrosion of Hastelloy-N, Alloy X750, SS316 and SS304 in Molten Salt High-Temperature Environment. Energies 2021, 14, 543. [Google Scholar] [CrossRef]

- Kofstad, P. High Temperature Corrosion; Elsevier Applied Science: London, UK; New York, NY, USA, 1988; ISBN 1-85166-154-9. [Google Scholar]

- Von Bohnstein, M.; Yildiz, C.; Frigge, L.; Ströhle, J.; Epple, B. Simulation study of the formation of corrosive gases in coal combustion in an entrained flow reactor. Energies 2020, 13, 4523. [Google Scholar] [CrossRef]

- Tesfaye, F.; Lindberg, D.; Moroz, M.; Hupa, L. Investigation of the K-Mg-Ca Sulfate System as Part of Monitoring Problematic Phase Formations in Renewable-Energy Power Plants. Energies 2020, 13, 5366. [Google Scholar] [CrossRef]

- Sweden Linnæus University (Project Leader); Estonia Tallinn University of Technology; Greece CERTH; Italy IVALSA-Ireland Tipperary Energy Agency. The Bioenergy System Planners Handbook-BISYPLAN. Available online: http://bisyplan.bioenarea.eu/html-files-en/ (accessed on 24 July 2016).

- Basu, P. Combustion and Gasification in Fluidized Beds; CRC Press: Boca Raton, FL, USA, 2006; ISBN 9780849333965. [Google Scholar]

- Kulokas, M.; Praspaliauskas, M.; Pedišius, N. Investigation of Buckwheat Hulls as Additives in the Production of Solid Biomass Fuel from Straw. Energies 2021, 14, 265. [Google Scholar] [CrossRef]

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2008; ISBN 978-1-84407-249-1. [Google Scholar]

- Keipi, T.; Tolvanen, H.; Kokko, L.; Raiko, R. The effect of torrefaction on the chlorine content and heating value of eight woody biomass samples. Biomass Bioenergy 2014, 66, 232–239. [Google Scholar] [CrossRef]

- Reza, M.T.; Yan, W.; Uddin, M.H.; Lynam, J.G.; Hoekman, S.K.; Coronella, C.J.; Vásquez, V.R. Reaction kinetics of hydrothermal carbonization of loblolly pine. Bioresour. Technol. 2013, 139, 161–169. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers. Manag. 2015, 105, 746–755. [Google Scholar] [CrossRef]

- Śliz, M.; Wilk, M. A comprehensive investigation of hydrothermal carbonization: Energy potential of hydrochar derived from Virginia mallow. Renew. Energy 2020, 156, 942–950. [Google Scholar] [CrossRef]

- Wilk, M.; Magdziarz, A.; Kalemba-Rec, I.; Szymańska-Chargot, M. Upgrading of green waste into carbon-rich solid biofuel by hydrothermal carbonization: The effect of process parameters on hydrochar derived from acacia. Energy 2020, 202, 117717. [Google Scholar] [CrossRef]

- Smith, A.M.; Ekpo, U.; Ross, A.B. The influence of pH on the combustion properties of bio-coal following hydrothermal treatment of swine manure. Energies 2020, 13, 331. [Google Scholar] [CrossRef] [Green Version]

- Aragón-Briceño, C.I.; Grasham, O.; Ross, A.B.; Dupont, V.; Camargo-Valero, M.A. Hydrothermal carbonization of sewage digestate at wastewater treatment works: Influence of solid loading on characteristics of hydrochar, process water and plant energetics. Renew. Energy 2020, 157, 959–973. [Google Scholar] [CrossRef]

- Aragón-Briceño, C.I.; Ross, A.B.; Camargo-Valero, M.A. Mass and energy integration study of hydrothermal carbonization with anaerobic digestion of sewage sludge. Renew. Energy 2021, 167, 473–483. [Google Scholar] [CrossRef]

- Surup, G.R.; Leahy, J.J.; Timko, M.T.; Trubetskaya, A. Hydrothermal carbonization of olive wastes to produce renewable, binder-free pellets for use as metallurgical reducing agents. Renew. Energy 2020, 155, 347–357. [Google Scholar] [CrossRef]

- Ameen, M.; Zamri, N.M.; May, S.T.; Azizan, M.T.; Aqsha, A.; Sabzoi, N.; Sher, F. Effect of acid catalysts on hydrothermal carbonization of Malaysian oil palm residues (leaves, fronds, and shells) for hydrochar production. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Atallah, E.; Zeaiter, J.; Ahmad, M.N.; Leahy, J.J.; Kwapinski, W. Hydrothermal carbonization of spent mushroom compost waste compared against torrefaction and pyrolysis. Fuel Process. Technol. 2021, 216, 106795. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Yang, X.; Guo, S.; Zhan, H.; Zhang, Y.; Fang, Y. Influence of coal ash on potassium retention and ash melting characteristics during gasification of corn stalk coke. Bioresour. Technol. 2018, 270, 416–421. [Google Scholar] [CrossRef]

- Elled, A.L.; Davidsson, K.O.; Åmand, L.E. Sewage sludge as a deposit inhibitor when co-fired with high potassium fuels. Biomass Bioenergy 2010, 34, 1546–1554. [Google Scholar] [CrossRef] [Green Version]

- Aho, M.; Yrjas, P.; Taipale, R.; Hupa, M.; Silvennoinen, J. Reduction of superheater corrosion by co-firing risky biomass with sewage sludge. Fuel 2010, 89, 2376–2386. [Google Scholar] [CrossRef]

- Kassman, H.; Pettersson, J.; Steenari, B.M.; Åmand, L.E. Two strategies to reduce gaseous KCl and chlorine in deposits during biomass combustion—Injection of ammonium sulphate and co-combustion with peat. Fuel Process. Technol. 2013, 105, 170–180. [Google Scholar] [CrossRef]

- Niu, Y.; Tan, H.; Hui, S. Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog. Energy Combust. Sci. 2016, 52, 1–61. [Google Scholar] [CrossRef]

- Wang, L.; Skreiberg, Ø.; Becidan, M.; Li, H. Investigation of rye straw ash sintering characteristics and the effect of additives. Appl. Energy 2016, 162, 1195–1204. [Google Scholar] [CrossRef]

- Antunes, R.A.; de Oliveira, M.C.L. Corrosion in biomass combustion: A materials selection analysis and its interaction with corrosion mechanisms and mitigation strategies. Corros. Sci. 2013, 76, 6–26. [Google Scholar] [CrossRef]

- Naganuma, H.; Ikeda, N.; Ito, T.; Satake, H.; Matsuura, M.; Ueki, Y.; Yoshiie, R.; Naruse, I. Control of ash deposition in solid fuel fired boiler. Fuel Process. Technol. 2013, 105, 77–81. [Google Scholar] [CrossRef]

- Pophali, A.; Emami, B.; Bussmann, M.; Tran, H. Studies on sootblower jet dynamics and ash deposit removal in industrial boilers. Fuel Process. Technol. 2013, 105, 69–76. [Google Scholar] [CrossRef]

- Kruczek, H. Effect of staged combustion in PC boilers on rate of fire-side corrosion. In Proceedings of the 7th European Conference on Industrial Furnaces and Boilers, Porto, Portugal, 18–21 April 2006. [Google Scholar]

- Hardy, T.; Kakietek, S.; Janda, T. A tool for on-line control of high-temperature corrosion hazard in steam boilers. Arch. Combust. 2017, 37, 107–118. [Google Scholar]

- Pronobis, M.; Litka, R. Rate of corrosion of waterwalls in supercritical pulverised fuel boilers. Chem. Process. Eng.-Inz. Chem. I Proces. 2012, 33, 263–277. [Google Scholar] [CrossRef] [Green Version]

- Wejkowski, R.; Kalisz, S.; Hardy, T.; Sarapata, B.; Kubiczek, H.; Janda, T. The control of high temperature corrosion phenomenon in boundary layer using different measurement methods. In Modern Energy Technologies, Systems and Units; Taler, J., Ed.; Publishing House of Kraków University of Technology: Krakow, Poland, 2013; pp. 289–300. [Google Scholar]

- Modlinski, N.J. Computational modelling of a tangentially fired boiler with deposit formation phenomena. Chem. Process. Eng.-Inz. Chem. I Proces. 2014, 35, 361–368. [Google Scholar] [CrossRef] [Green Version]

- Weber, R.; Mancini, M.; Schaffel-Mancini, N.; Kupka, T. On predicting the ash behaviour using Computational Fluid Dynamics. Fuel Process. Technol. 2013, 105, 113–128. [Google Scholar] [CrossRef]

- Davis, K.A.; Linjewile, T.M.; Valentine, J.; Swensen, D.; Shino, D.; Letcavits, J.J.; Sheidler, R.; Cox, W.M.; Carr, R.N.; Harding, N.S. A multi-point corrosion monitoring system applied in a 1300 MW coal-fired boiler. Anti-Corros. Methods Mater. 2004, 51, 321–330. [Google Scholar] [CrossRef]

- Hardy, T.; Modlinski, N. Development of Prognostic Tool for High-temperature Corrosion Risk Assessment in Pulverised Coal Boilers Based on the Waterwalls Boundary Layer Monitoring System and CFD Simulations. Energy Procedia 2017, 105, 1833–1838. [Google Scholar] [CrossRef]

- Modlinski, N.; Hardy, T. Development of high-temperature corrosion risk monitoring system in pulverized coal boilers based on reducing conditions identification and CFD simulations. Appl. Energy 2017, 204, 1124–1137. [Google Scholar] [CrossRef]

- Gruber, T.; Schulze, K.; Scharler, R.; Obernberger, I. Investigation of the corrosion behaviour of 13CrMo4-5 for biomass fired boilers with coupled online corrosion and deposit probe measurements. Fuel 2015, 144, 15–24. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, Y.; Jin, B.; Zhang, Y.; Zhou, C.; Sher, F. Effect of Slot Wall Jet on Combustion Process in a 660 MW Opposed Wall Fired Pulverized Coal Boiler. Int. J. Chem. React. Eng. 2019, 17, 1–13. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Burleigh, D.D. Review of pulsed thermal NDT: Physical principles, theory and data processing. NDT E Int. 2015, 73, 28–52. [Google Scholar] [CrossRef]

- Vakhguelt, A.; Kapayeva, S.D.; Bergander, M.J. Combination Non-Destructive Test (NDT) Method for Early Damage Detection and Condition Assessment of Boiler Tubes. Procedia Eng. 2017, 188, 125–132. [Google Scholar] [CrossRef]

- Ho, M.; El-Borgi, S.; Patil, D.; Song, G. Inspection and monitoring systems subsea pipelines: A review paper. Struct. Health Monit. 2020, 19, 606–645. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and application of magnetic flux leakage pipeline detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef]

- Lu, X.; Liu, G.; Luan, S. The development of the boiler water wall tube inspection. In Proceedings of the 2008 3rd International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008; pp. 2415–2420. [Google Scholar] [CrossRef]

- Hariyadi, A.; Kis Agustin, H.C.; Wijayanti, I.D. Metallography Investigation of Dry Corrosion Boiler Tube. Appl. Mech. Mater. 2016, 836, 72–77. [Google Scholar] [CrossRef]

- Meribout, M.; Mekid, S.; Kharoua, N.; Khezzar, L. Online monitoring of structural materials integrity in process industry for I4.0: A focus on material loss through erosion and corrosion sensing. Meas. J. Int. Meas. Confed. 2021, 176, 109110. [Google Scholar] [CrossRef]

- Vakhguelt, A.; Jo, R.S.; Bergander, M.J. Electromagnetic acoustic boiler tubes inspection with robotic device. Vibroeng. Procedia 2017, 15, 115–118. [Google Scholar] [CrossRef] [Green Version]

- Bergander, M.J. EMAT thickness measurement for tubes in coal-fired boilers. Appl. Energy 2003, 74, 439–444. [Google Scholar] [CrossRef]

- Kogia, M.; Gan, T.-H.; Balachandran, W.; Livadas, M.; Kappatos, V.; Szabo, I.; Mohimi, A.; Round, A. High Temperature Shear Horizontal Electromagnetic Acoustic Transducer for Guided Wave Inspection. Sensors 2016, 16, 582. [Google Scholar] [CrossRef] [Green Version]

- Klepacki, F. Ocena stanu rur kotłowych, których grubość ścianek uległa zmniejszeniu wskutek erozji lub korozji. Energetyka 2005, 886–888. Available online: https://www.pronovum.pl/static/upload/store/Ocena_stanu_rur_kotlowych_ktorych_gruboisc_scianek_ulega_zmniejszeniu_wskutek_erozji_lub_korozji.pdf (accessed on 30 September 2021).

- Innospection SLOFEC TM—Fast Corrosion Screening Technique. Available online: http://www.ndttechnologies.com/Brochures/TankScanning/SLOFECTechnique.pdf (accessed on 1 September 2021).

- Cheng, W. Pulsed eddy current testing of carbon steel pipes’ wall-thinning through insulation and cladding. J. Nondestruct. Eval. 2012, 31, 215–224. [Google Scholar] [CrossRef]

- Fernandez, N.M.; Charlton, P.C.; Granville, R.K. Pulsed Eddy Current CUI Simulation with Coupled Electric Circuit Analysis using Quickfield FEA. e-J. Nondestruct. Test. 2019. Available online: https://www.ndt.net/article/ndtnet/papers/Pulsed-Eddy-Current-CUI-Simulation-with-Coupled-Electric-Circuit-Analysis-using-Quickfield-FEA.pdf (accessed on 30 September 2021).

- Cheng, W.; Komura, I. Pulsed Eddy Current Testing of Carbon Steel Pipes’ Wall-thinning. In Proceedings of the 9th International Conference on NDE in Relation to Structural Integrity for Nuclear and Pressurized Components, Seattle, DC, USA, 22–24 May 2012; pp. 336–342. [Google Scholar]

- Katagiri, T.; Chen, G.; Yusa, N.; Hashizume, H. Demonstration of detection of the multiple pipe wall thinning defects using microwaves. Meas. J. Int. Meas. Confed. 2021, 175, 109074. [Google Scholar] [CrossRef]

- Boateng, A.; Danso, K.A.; Dagadu, C.P.K. Non-Destructive Evaluation Of Corrosion On Insulated Pipe Using Double Wall Radiographic Technique. Chem. Mater. Res. 2013, 3, 73–83. [Google Scholar]

- Boateng, A.; Danso, K.A.; Dagadu, C.P.K. Non-Destructive Evaluation Of Corrosion On Insulated Pipe Using Tangential Radiographic Technique. Int. J. Sci. Technol. Res. 2013, 2, 7–13. [Google Scholar]

- Edalati, K.; Rastkhah, N.; Kermani, A.; Seiedi, M.; Movafeghi, A. The use of radiography for thickness measurement and corrosion monitoring in pipes. Int. J. Press. Vessel. Pip. 2006, 83, 736–741. [Google Scholar] [CrossRef]

- MISTRAS Automated Thickness Measurement Using Line Scanning Thermography (LST)TM. Available online: http://www.mistrasgroup.com/services/company/publications/Line_Scanning_Thermography.pdf (accessed on 1 July 2018).

- Al-mayouf, A.M.; Al-shalwi, M.N. Galvanic sensor for detecting corrosion during acid cleaning of magnetite in steam boilers. Metals 2021, 11, 343. [Google Scholar] [CrossRef]

- Badodkar, D.N.; Singh, N.K.; Dalal, N.S.; Singh, M. EMAT Integrated with Vertical Climbing Robot for Boiler Tube Inspection. In Proceedings of the National Seminar & Exhibition on Non-Destructive Evaluation, Tiruchirappalli, India, 10–12 December 2009; pp. 32–36. [Google Scholar]

- Vajpayee, A.; Russell, D. Automated Condition Assessment of Boiler Water Wall Tubes Using Remote Field Technology. A Revolution Over Traditional and Existing Techniques. In Proceedings of the 10th International Conference of the Slovenian Society for Non-Destructive Testing 2009, Application of Contemporary Non-Destructive Testing in Engineering, Ljubljana, Slovenia, 1–3 September 2009; pp. 523–530. [Google Scholar]

- Caprari, G.; Breitenmoser, A.; Fischer, W.; Hürzeler, C.; Tâche, F.; Siegwart, R.; Schoeneich, P.; Rochat, F.; Mondada, F.; Moser, R. Highly compact robots for inspection of power plants. In Proceedings of the 1st International Conference on Applied Robotics for the Power Industry (CARPI), Montreal, QC, Canada, 5–7 October 2010. [Google Scholar] [CrossRef] [Green Version]

- Rafajłowicz, E.; Wietrzych, J.; Rafajłowicz, W. A computer vision system for evaluation of high temperature corrosion damages in steam boilers. In Intelligent Systems in Technical and Medical Diagnostics. Advances in Intelligent Systems and Computing; Korbicz, J., Kowal, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 230. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hardy, T.; Arora, A.; Pawlak-Kruczek, H.; Rafajłowicz, W.; Wietrzych, J.; Niedźwiecki, Ł.; Vishwajeet; Mościcki, K. Non-Destructive Diagnostic Methods for Fire-Side Corrosion Risk Assessment of Industrial Scale Boilers, Burning Low Quality Solid Biofuels—A Mini Review. Energies 2021, 14, 7132. https://doi.org/10.3390/en14217132

Hardy T, Arora A, Pawlak-Kruczek H, Rafajłowicz W, Wietrzych J, Niedźwiecki Ł, Vishwajeet, Mościcki K. Non-Destructive Diagnostic Methods for Fire-Side Corrosion Risk Assessment of Industrial Scale Boilers, Burning Low Quality Solid Biofuels—A Mini Review. Energies. 2021; 14(21):7132. https://doi.org/10.3390/en14217132

Chicago/Turabian StyleHardy, Tomasz, Amit Arora, Halina Pawlak-Kruczek, Wojciech Rafajłowicz, Jerzy Wietrzych, Łukasz Niedźwiecki, Vishwajeet, and Krzysztof Mościcki. 2021. "Non-Destructive Diagnostic Methods for Fire-Side Corrosion Risk Assessment of Industrial Scale Boilers, Burning Low Quality Solid Biofuels—A Mini Review" Energies 14, no. 21: 7132. https://doi.org/10.3390/en14217132

APA StyleHardy, T., Arora, A., Pawlak-Kruczek, H., Rafajłowicz, W., Wietrzych, J., Niedźwiecki, Ł., Vishwajeet, & Mościcki, K. (2021). Non-Destructive Diagnostic Methods for Fire-Side Corrosion Risk Assessment of Industrial Scale Boilers, Burning Low Quality Solid Biofuels—A Mini Review. Energies, 14(21), 7132. https://doi.org/10.3390/en14217132