Refrigerated Transport: State of the Art, Technical Issues, Innovations and Challenges for Sustainability

Abstract

1. Introduction

- Production/Packaging;

- Storage;

- Transport (also present among other phases);

- Sale;

- Preservation (consumer).

- Heterogeneity of air and food temperatures inside the refrigerated compartment, due to the type of the air delivery systems and the load patterns used;

- Increase in air and, consequently, food temperatures due to warm air infiltration that occurs during door openings in loading/unloading operations;

- Insufficient refrigeration capacity.

- Transmission load, depending on the shape, size, color of the refrigerated vehicle, the stratigraphy of the insulated walls and the characteristics of the route taken;

- Infiltration load, due to the doors opening/closing cycles during loading and unloading operations;

- Respiration heat load, due to the transformation of sugar and oxygen into CO2 e H2O that takes place in fresh products such as fruits and vegetables.

- a review by Selvnes et al. [17] on publications concerning the use of PCMs in refrigerated transport until 2021;

- a review by James et al. [18] on publications concerning models for estimating the temperature field inside refrigerated compartments until 2006;

- a review by Awad et al. [19] on publications concerning the solution of the Vehicle Routing Problem applied to refrigerated transport until 2020.

2. Standard for Refrigerated Transport

- Tests for three temperature levels between −25 °C and +12 °C obtained by using the on board thermostat. One of the three temperature levels is at the minimum prescribed for the class of the vehicle;

- A test for the evaluation of the maximum cooling capacity, obtained by excluding the intervention of the thermostat.

- Air temperatures: at least four thermometers are uniformly distributed at the inlet of the evaporator. The same for the outlet of the evaporator and the inlet of the condenser;

- Electrical energy and fuel consumption;

- Speed of rotation of the compressors. “If the compressor is driven by the vehicle engine, the test shall be carried out at both the minimum speed and at the nominal speed of rotation of the compressor as specified by the manufacturer” [16]. If the compressor is driven by the vehicle motion, i.e., if the compressor supply system, other than the vehicle’s engine, allows it to operate at a fixed optimal speed, “the test shall be carried out at the nominal speed of rotation of the compressor as specified by the manufacturer” [16];

- Pressure level at the condenser, the evaporator and the compressor inlet.

Testing Methods

3. Refrigeration Systems Currently in Use

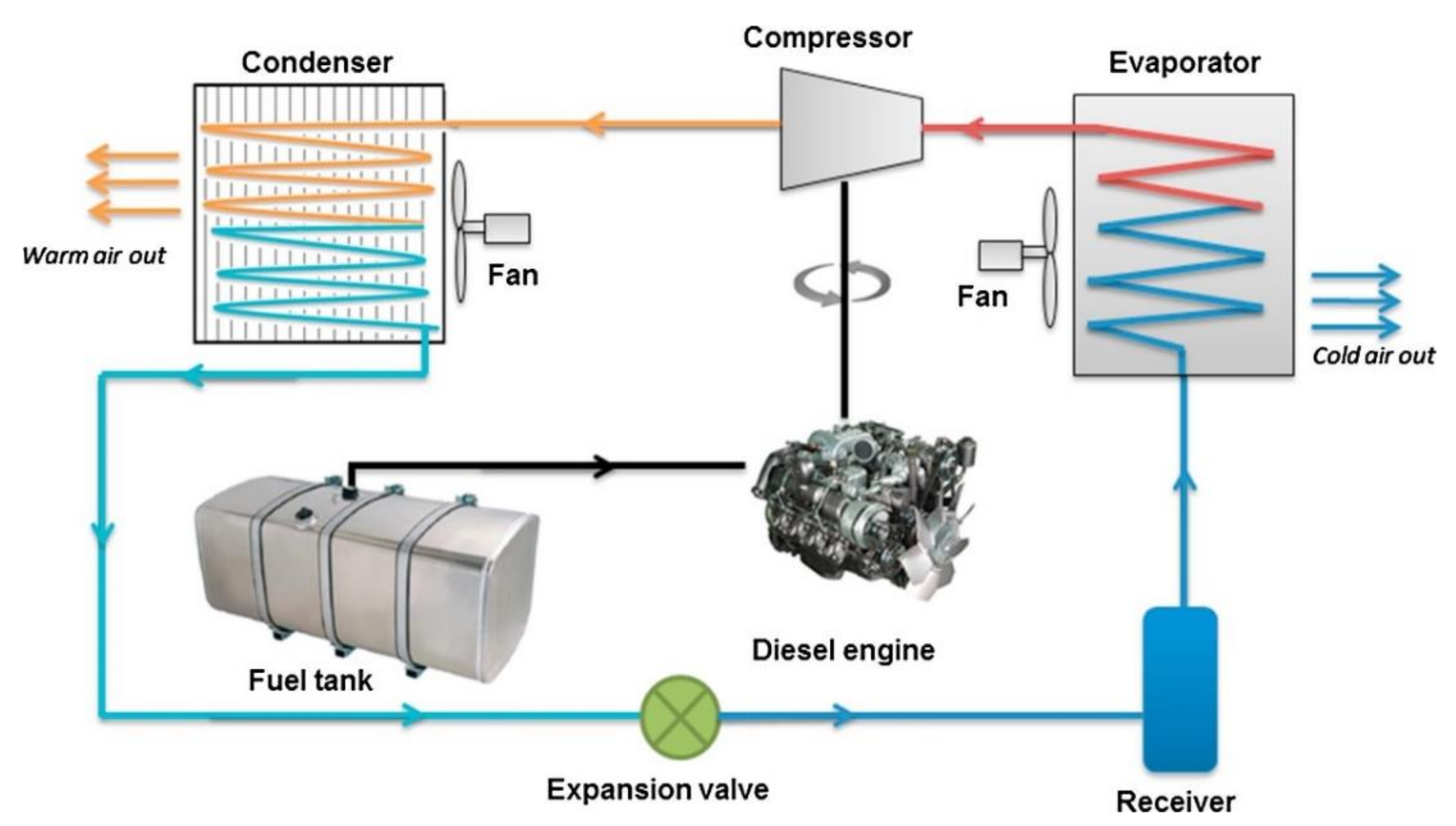

3.1. Vapour Compression Refrigeration Systems

- Evaporator: allows for the evaporation of the refrigerant by absorbing thermal energy from the environment to be cooled (cooling effect);

- Compressor: compresses the refrigerant from the minimum pressure of the cycle (evaporator) to the maximum pressure (condenser) by absorbing mechanical energy from an external source;

- Condenser: allows for the condensation of the refrigerant by rejecting thermal energy to the external environment;

- Expansion device: allows for the pressure drop from the condenser level to the evaporator level.

- Direct belt drive: the vehicle engine directly drives the compressor through a belt [12];

- Auxiliary Diesel Unit: the compressor is powered by an auxiliary diesel engine;

- Auxiliary alternator unit: a dedicated large alternator driven by the main traction engine through a belt is used to power the compressor. An alternative arrangement is to use a diesel generator system;

- Vehicle alternator unit: the vehicle engine crankshaft drives a single alternator that charges the vehicle battery, which feeds a small refrigeration system (usually with 12 V dc supply).

- Increase in condenser and evaporator exchange surface;

- Use of a two-stage compressor;

- Performance evaluation using alternative refrigerants;

- Reduction of the energy absorbed by the fans of the heat exchangers.

3.2. Phase Change Materials (PCM)

- Organic: Paraffin or non-paraffin;

- Inorganic: Salt hydrates or metals;

- Eutectic solutions: combinations of two or more materials.

- Latent heat of fusion: represents the thermal energy that the PCM is able to absorb during the phase transition, per unit volume. It is therefore preferable to choose a material with high latent heat of fusion (lower volumes with the same thermal load);

- Melting temperature: identifies the field of application of the material;

- Thermal conductivity.

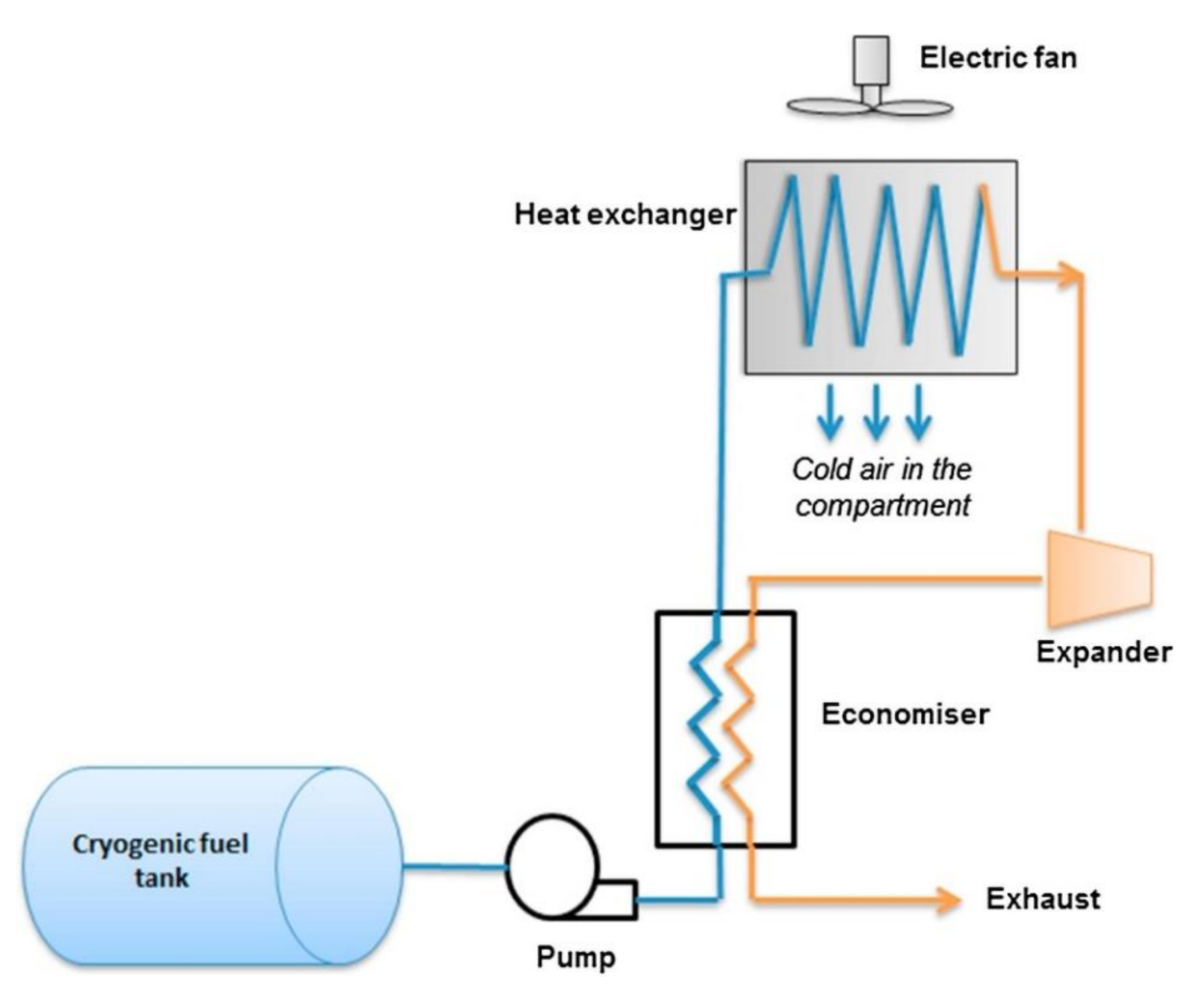

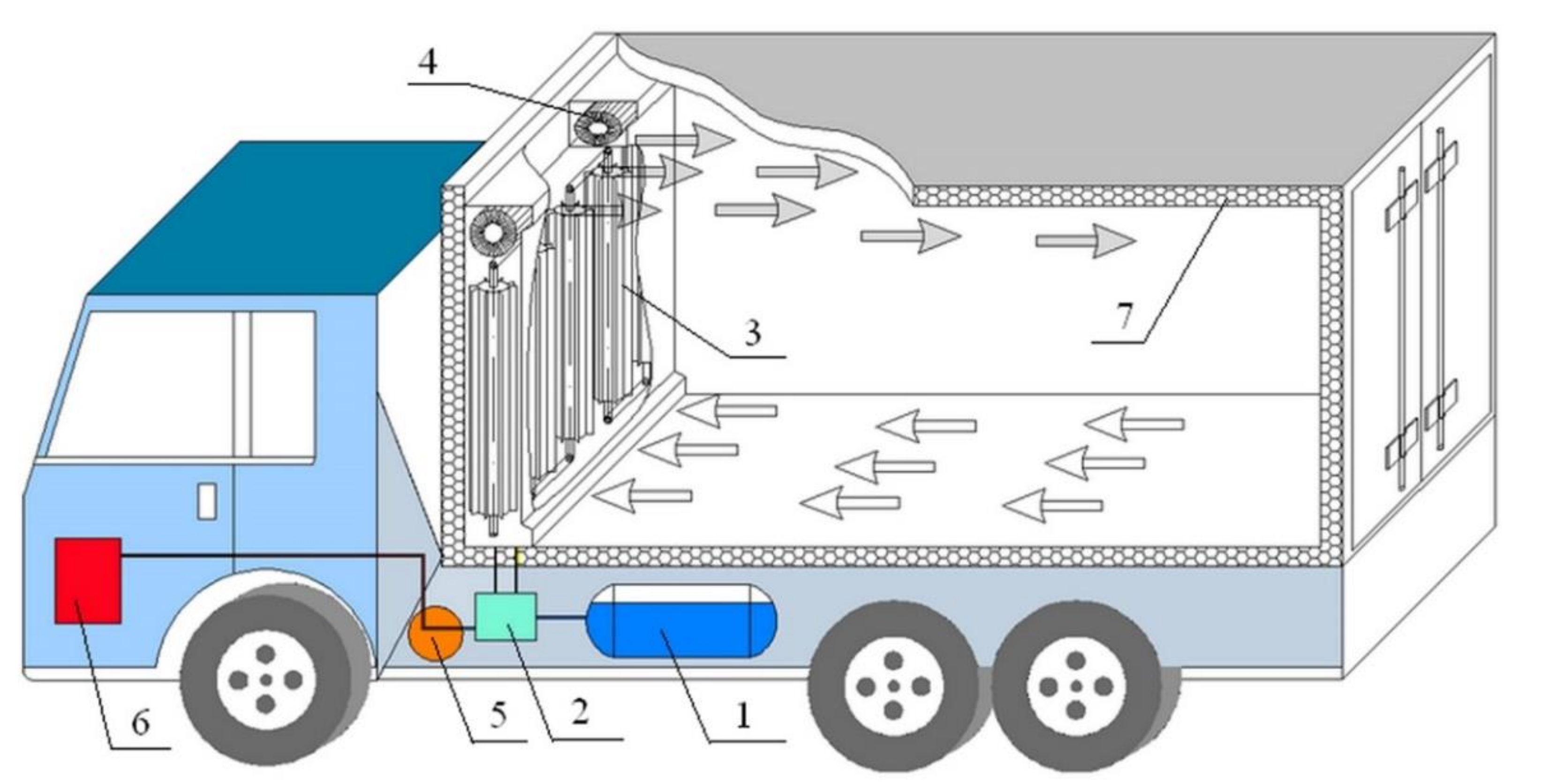

3.3. Cryogenic Systems

- Direct: the cryogenic fluid is injected directly into the refrigerated compartment where it evaporates absorbing thermal energy, and then released into the external environment during the door openings. The scheme of a generic direct cryogenic system is represented in Figure 9.

- 2.

- Indirect: the cryogenic gas is expanded in a heat exchanger, in which it absorbs thermal energy from the recirculated indoor air. The gas is then dispersed into the atmosphere. The scheme of a generic indirect cryogenic system is shown in Figure 10.

- 3.

- Hybrids: a direct or indirect cryogenic system is added to a VCR system. The cryogenic system allows it to obtain a surplus of cooling capacity, useful especially in the pull-down phases [46].

4. Possible Alternative Technologies

4.1. Sorption Systems

4.1.1. Vapour Absorption Refrigeration Systems

- Optimization of the heat exchanger for heat exchange with exhaust gases, in order to increase the thermal energy absorbed, reduce the corrosive effect that the gases have on the heat exchanger material and limit the negative impact on the efficiency of the internal combustion engine;

- Addition of an alternative fuel system that feeds the refrigeration unit when the vehicle is stationary;

- Installation of the system on vehicles (limited on-board space).

- improve the effectiveness of the solution heat exchanger;

- reduce the absorber rejection temperature;

- increase the difference between the concentrations of the strong and the weak solutions.

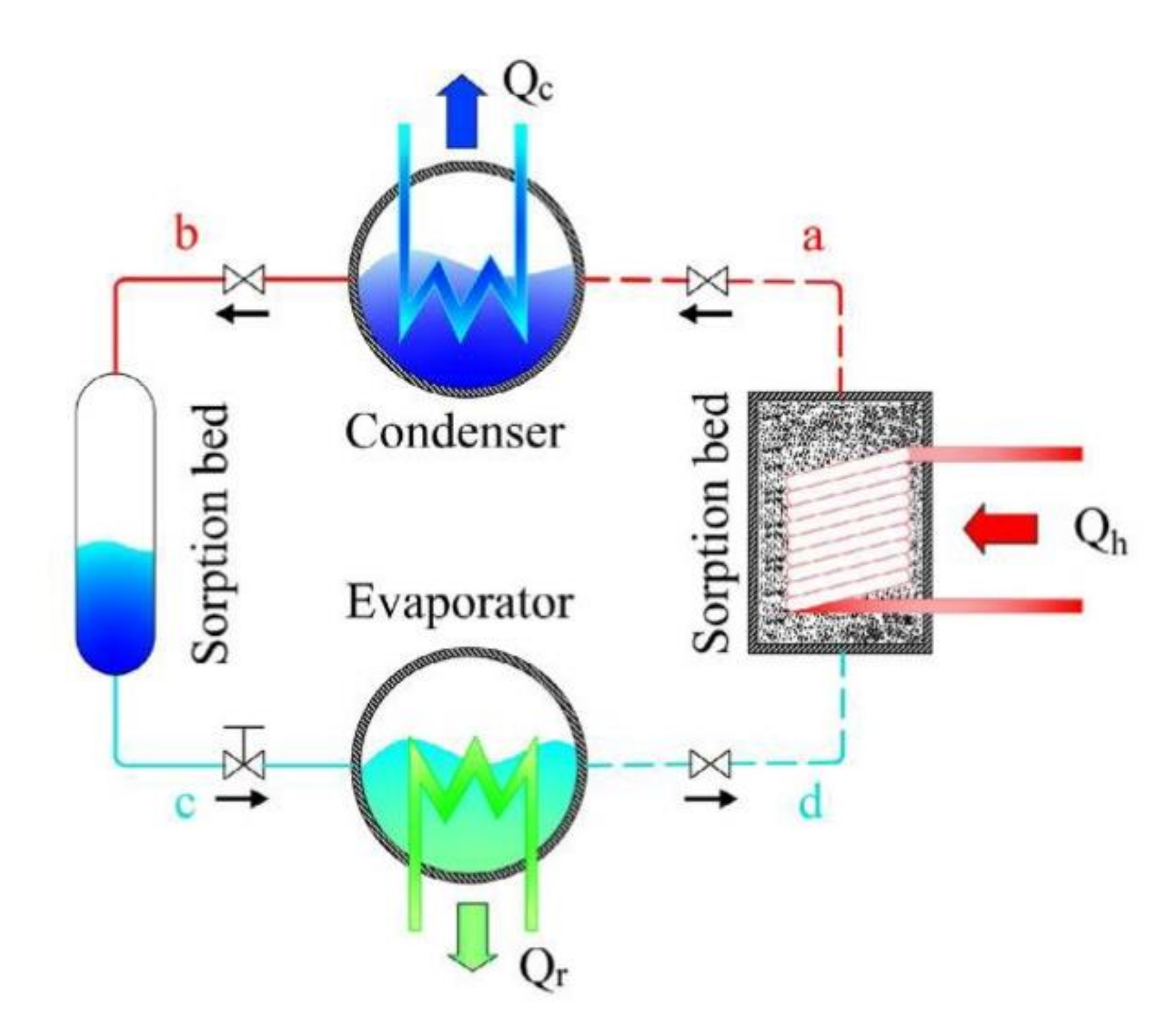

4.1.2. Solid Sorption Refrigeration Systems

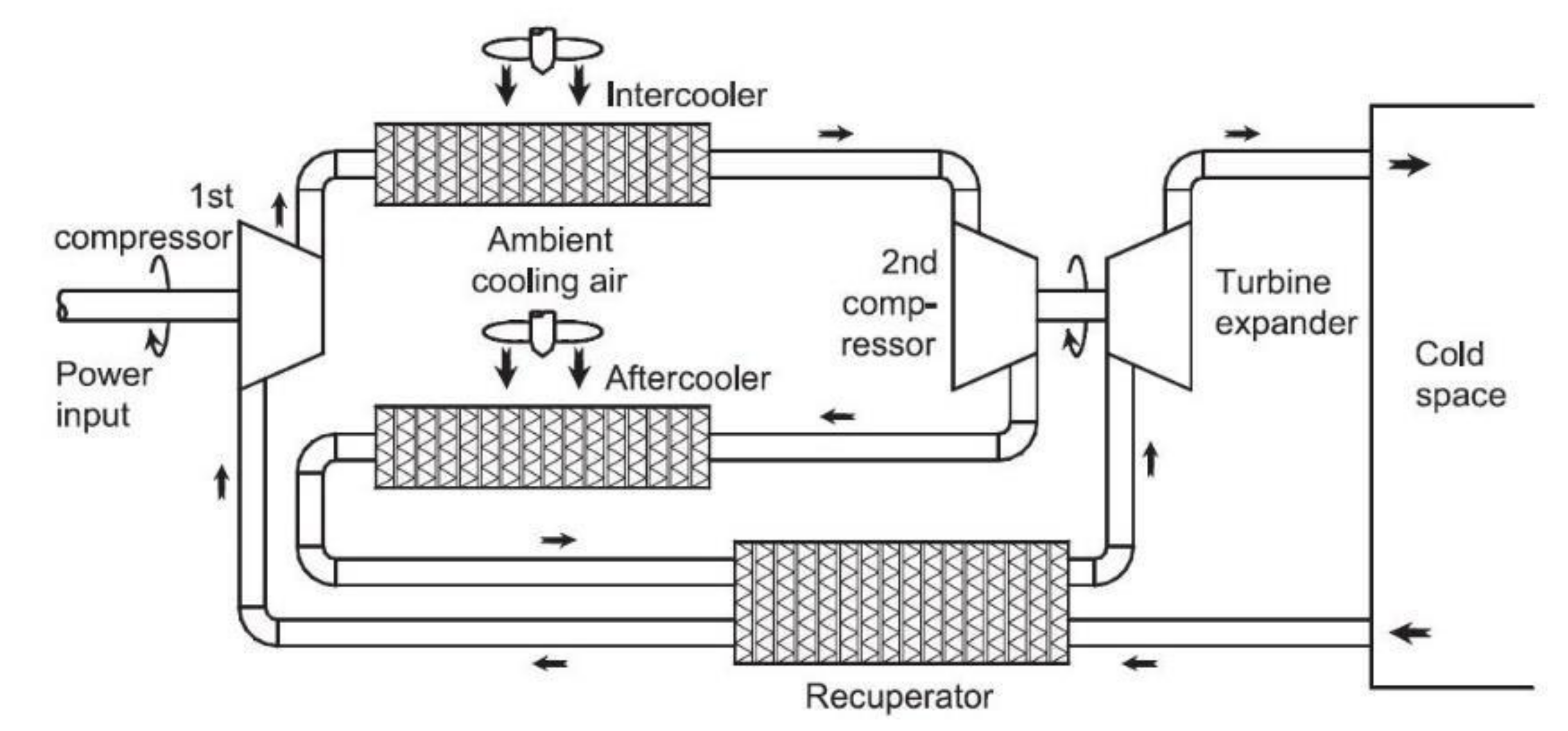

4.2. Air Cycles

4.3. Low GWP Refrigerants

- 28.2% higher average refrigeration capacity;

- Comparable measured power consumption;

- 28.6% higher measured COP.

- Traditional cycle with low pressure liquid receiver, expansion by back-pressure valve and presence of the internal heat exchanger: the refrigerant leaves the liquid/vapor receiver in saturated vapor conditions. Before being compressed, it is brought into superheated vapor conditions by the internal heat exchanger. After the compression phase, the fluid is sent to the gas cooler/condenser and then undergoes further cooling inside the internal heat exchanger. This is followed by the expansion by means of a back-pressure valve and evaporation phases before returning to the liquid/vapour receiver;

- Cycle with low pressure liquid receiver, expansion by fixed geometry ejector in parallel to the back-pressure valve and absence of the internal heat exchanger (the refrigerant in the compressor suction line is in saturated vapor condition): at the outlet of the gas cooler/condenser there is a fixed geometry ejector, to which a parallel by-pass back-pressure valve is added in order to control the refrigerant flow rate processed by the ejector. The flow rates from the ejector and valve are mixed and sent to the liquid/vapor receiver. The liquid refrigerant is then expanded to evaporation pressure by means of a manual throttling valve and sent to the evaporator. The vapour refrigerant, eventually superheated, is sent to the suction nozzle of the ejector.

- Cycle with low pressure liquid receiver, expansion by fixed geometry ejector in parallel to the back-pressure valve, absence of the internal heat exchanger and presence of an auxiliary evaporator between the expansion devices and the liquid receiver: the refrigeration cycle is very similar to that adopted in configuration (b), with the addition of an auxiliary evaporator between the outlet of the ejector/back-pressure valve and the liquid/vapour receiver. The cooling capacity in this configuration is divided between the main evaporator and the auxiliary evaporator.

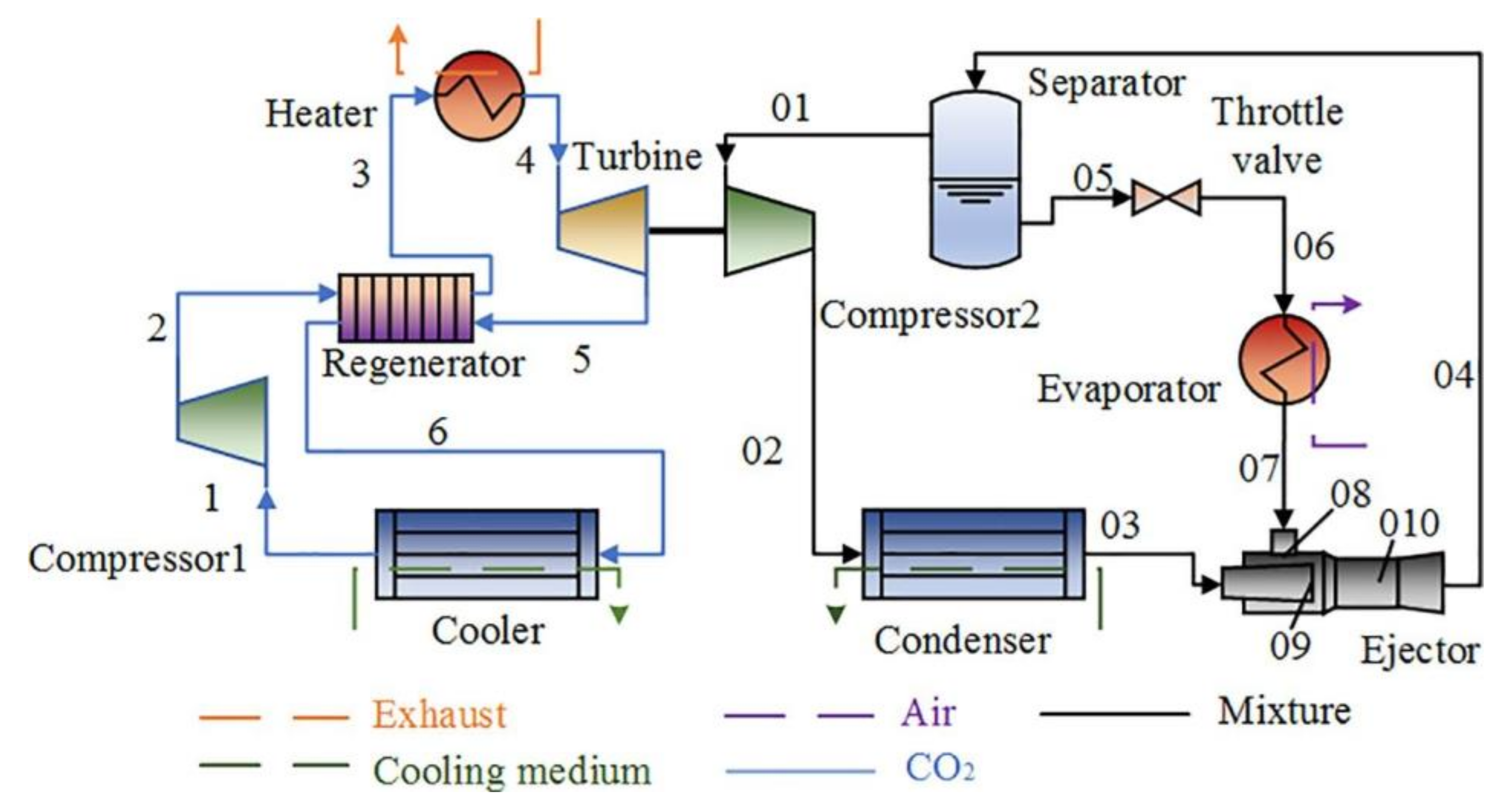

- Mode R: the system produced only cooling energy. The generator was disconnected from the turbine, which only powered the compressors;

- Mode P: the system produced only electrical energy. The refrigeration cycle was excluded by means of the three-way valve, so the MM-CRPC became a classic Brayton cycle for the production of electrical energy;

- Mode RP: the system produced electrical and cooling energy in a combined manner. When the heat load was low the turbine was able to power both the compressors and the generator.

- maximum temperature of the RSCBC (Tmax) = 220 °C;

- maximum pressure of the RSCBC (Pmax) = 15 Mpa;

- minimum temperature of the RSCBC (Tmin) = 32 °C;

- minimum pressure of the RSCBC (Pmin) = 7.6 MPa;

- condensing temperature (Tcond) = 30 °C

- evaporating temperature (Teva) = 10 °C

- pressure drop in the suction nozzle (ΔP) = 0.015 MPa.

5. System Optimization

5.1. Transmission Thermal Load Reduction

5.2. Infiltration Heat Load Reduction

- Buoyancy driven flow: unsteady flow due to the difference in density between indoor and outdoor air;

- Boundary layer flow: natural air convection on the cold vertical walls of the refrigerated compartment. This flow is established when the internal temperature approaches the external one. Therefore, an almost stationary heat exchange condition is reached until the door is closed. In this case it is possible to use the classic formulations for natural convection on a vertical wall.

5.3. Temperature Distribution Inside a Refrigerated Compartment

5.4. Vehicle Routing Problem (VRP)

- Distance traveled by vehicles;

- Fuel consumption, which can be calculated considering:

- Driving and idling;

- Vehicle’s motion and refrigeration systems operation;

- Vehicle acceleration, weight and the slope of the road.

- Truck maintenance and annual check-up costs;

- Transportation mode (e.g., truck, train, airplane or ship);

- Toll payments and parking costs;

- Drivers’ wages based on working time.

- Maintaining the temperature inside the compartments;

- Temperature inside and outside the vehicle;

- Vehicle’s door openings frequency and duration;

- Humidity, vibration, lightning intensity inside the compartments, sensory index (e.g., odor and color of products);

- Non-delivery due to a poor quality of products, causing waste disposal or rerouted shipment costs;

- Excessive duration of the delivery mission;

- Packaging method;

- Multiple or single compartment delivery.

- Energy or fuel consumption, which can be converted into emissions by using car-bon emission coefficients;

- Number of vehicles and their capacity;

- Direct emissions due to refrigerant leakage.

6. Conclusions

- The use of electrical energy storage allows a strong reduction in consumption and emissions due to the operation of a VCR system, especially if coupled to a photovoltaic system. However, PV systems, even if coupled with a battery pack, could not be sufficient to overcome the cooling demand, so a backup system (internal combustion engine) is still needed;

- The stability problems between the PCMs and the containers, as well as the limiting operating conditions imposed (operating temperature, duration of the refrigeration effect, no optimization of the shape of the containers) do not allow a widespread use of this type of systems, although the potential for reducing energy consumption and emissions are far from negligible;

- Cryogenic systems represent a valid alternative to traditional VCR systems and allow one to obtain lower pull-down phases duration. However, the high energy consumption linked to the liquefaction processes of cryogenic gases does not allow for an effective reduction in emissions related to refrigeration. Consequently, these systems’ use is still limited;

- Air-based and CO2-based refrigeration systems respond to the demand for cleaner refrigerants than current HFCs, allowing a reduction in direct emissions related to refrigeration. The use of air systems is however limited by the lack of standard components for application in refrigerated transport. In recent years the use of R290 (propane) in VCR systems have been considered. To date, there are still few studies about it’s performance in the refrigerated transport sector;

- Absorption/adsorption systems allow the recovery of residual thermal energy contained in vehicle exhaust gases, but their operation is compromised at low engine loads (exhaust gas temperature below 200 °C). This problem can be solved with several methods, but they greatly increase the complexity of the system. In general, These systems are still studied as protypes. An optimization of the design of the components in terms of downsizing is indispensable in order to include these systems within the physical envelope of a refrigerated vehicle;

- the use of a PV/battery system to power the VCR unit;

- the addition of PCM to reduce the thermal load and/or increasing the OFF time of the compressor;

- the use of a natural refrigerant (such as R290).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Modelling of Food Transport Systems

| Authors | Application | |

|---|---|---|

| Models of the environment in refrigerated transport units | Comini et al., 1995 | A finite element model was used to calculate the solid’s temperature distribution and the fluid’s bulk temperature variations. Standard egineering procedures were used to estimate average fluid velocities and the convective heat transfer coefficient. |

| Lindqvist, 1998 | An integral-differential-algebraic solver was used to simulate the air distribution under different conditions, considering the effect of pallet loading in refeer holds. The model did not consider heat transfer from walls, packaging, ceiling and floor. | |

| Zertal-Menia et al., 2002; Moureh et al., 2002 | CFD was used to optimize the air distribution, in order to decrease the temperature variation in the compartments of refrigerated vehicles. | |

| Moureh and Flick, 2003 | CFD was used to optimize the air distribution, in order to decrease the temperature variation in the compartments of refrigerated vehicles. In addition, it was used to model a wall jet airflow within a long and empty slot-ventilated enclosure. The standard k-ε model and a renormalization group (RNG) one, were tested, contrasted and compared. Only the RSM model allowed to detect the presence and the localization of separated flow. In addition it was able to predict primary and secondary recirculation airflow patterns. | |

| Moureh and Flick, 2004 | CFD was used to optimize the air distribution in refrigerated vehicles and to consider the effect of air ducts on temperature difference throughout the cargo. | |

| Tso et al., 2002 | The effect of door openings on air temperature in the compartment of a refrigerated truck (unprotected doors, presence of plastic curtain strips, presence of air curtains) was modeled by using a commercial CFD program. | |

| Models of heat and mass transfer in foods and packages during transport | Rushbrook, 1974; Rushbrook, 1976 | The heat flow into cartons of chilled meat in a standard VCR container was simulated by using a simple 1-D model. Various types of control systems and measurement positions were considered. The model allowed to evaluate the effects on return air, delivery air and meat surface temperature. |

| Meffert, 1976; Meffert, 1983; Meffert, 1993 (a); Meffert, 1993 (b); Meffert, 1998; | A simple model for a steady state condition was developed to evaluate the temperature drop across the air cooler in a refrigerated container. This method can be applied in refrigerated containers and vehicles, storage rooms and retail cabinets. | |

| Moureh and Derens, 2000 | A CFD model was used to evaluate temperature rises in pallet load of frozen food during distribution. | |

| Stubbs et al., 2004 | A numerical model was used to evaluate the time food products could be mantained below 5 or 8 °C if contained in an expanded polystyrene box with a gel coolant. | |

| Models of refrigeration performance during transport | Jolly et al., 2000 | The steady state performance of a refrigerated container system was modelled, considering compressor, evaporator, condenser and thermostatic expansion valve submodels. Coupling this model to appropriate mass and energy transfer relations allowed to obtain ±10% agreement with respect to experimental data. |

| Combined models | Frith, 2003–2004 | A software model called “Censor”, based on a three-dimensional finite element analysis, was developed to estimate products’ temperatures during normal and abnormal operations of refrigerated containers. |

| Parry-Jones and James, 1994; James, 1997; Gigiel, 1997; Gigiel, 1998 | A model (CoolVan program) was used to predict the temperature of food products during multi-drop deliveries. The model was validated by using measured data from a real delivery mission, with an accuracy better than 1 °C when considering mean temperature. | |

| Modelling of microbial growth during transport | Baranyi et al., 2001; McMeekin et al., 1993; van Impe et al., 1992 | Only the growth of microorganisms in food during transportation was considered. |

| Almonacid-Merino and Torres, 1993 | A simple combined heat transfer (finite difference method) and microbial growth model was developed to evaluate the effect of temperature abuse during distribution. | |

| Gill and Philips, 1993 | Microbial growth models were integrated with recorded temperature data. | |

| Taoukis, 2001 | Use of Time Temperature Indicators (TTI) in transport applications and modelling was described. | |

| Estrada-Flores and Tanner, 2005 | The growth of pseudomonads and Escherichia coli has been predicted by coupling recorded temperature histories with mathematical models, considering multi-temperature small vans. | |

| James and Evans, 1992 | Recorded temperature histories were coupled with mathematical microbial growth prediction models. | |

| Other transport factors that have been modelled | Golob and Regan, 2001 | The perception of road congestion and low average speed problems were considered |

| Chatzidakis and Chatzidakis, 2005 | A transient finite difference model was applied to isothermal tanks, widely used for the transport of perishable liquid foodstuffs. | |

| Milano and Corsi, 1982 | Finite difference methods were used to evaluate the overall heat transfer coefficient of a refrigerated vehicle assuming a steady state condition. | |

| Zhang et al., 1994 | Other methods, more complex than the one proposed by Milano and Corsi (1982), were used to evaluate the overall heat transfer coefficient of a refrigerated vehicle without neglecting the unsteady temperature distribution in the insulating material. |

References

- She, X.; Cong, L.; Nie, B.; Leng, G.; Peng, H.; Chen, Y.; Zhang, X.; Wen, T.; Yang, H.; Luo, Y. Energy-Efficient and -Economic Technologies for Air Conditioning with Vapor Compression Refrigeration: A Comprehensive Review. Appl. Energy 2018, 232, 157–186. [Google Scholar] [CrossRef]

- Koronaki, I.P.; Cowan, D.; Maidment, G.; Beerman, K.; Schreurs, M.; Kaar, K.; Chaer, I.; Gontarz, G.; Christodoulaki, R.I.; Cazauran, X. Refrigerant Emissions and Leakage Prevention across Europe—Results from the RealSkillsEurope Project. Energy 2012, 45, 71–80. [Google Scholar] [CrossRef]

- Tassou, S.A.; Grace, I.N. Fault Diagnosis and Refrigerant Leak Detection in Vapour Compression Refrigeration Systems. Int. J. Refrig. 2005, 28, 680–688. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. The European Parliament and the Council of the European Union Regulation (EU) No 517/2014 of the European Parliament and the Council of 16 April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006; The European Parliament and the Council of the European Union: Brussels, Belgium, 2014. [Google Scholar]

- Heredia-Aricapa, Y.; Belman-Flores, J.M.; Mota-Babiloni, A.; Serrano-Arellano, J.; García-Pabón, J.J. Overview of Low GWP Mixtures for the Replacement of HFC Refrigerants: R134a, R404A and R410A. Int. J. Refrig. 2020, 111, 113–123. [Google Scholar] [CrossRef]

- Nair, V. HFO Refrigerants: A Review of Present Status and Future Prospects. Int. J. Refrig. 2021, 122, 156–170. [Google Scholar] [CrossRef]

- Llopis, R.; Calleja-Anta, D.; Maiorino, A.; Nebot-Andrés, L.; Sánchez, D.; Cabello, R. TEWI Analysis of a Stand-Alone Refrigeration System Using Low-GWP Fluids with Leakage Ratio Consideration. Int. J. Refrig. 2020, 118, 279–289. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Barbosa, J.R.; Makhnatch, P.; Lozano, J.A. Assessment of the Utilization of Equivalent Warming Impact Metrics in Refrigeration, Air Conditioning and Heat Pump Systems. Renew. Sustain. Energy Rev. 2020, 129, 109929. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture—Trends and Challenges; FAO: Rome, Italy, 2017. [Google Scholar]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time–Temperature Management Along the Food Cold Chain: A Review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Oury, A.; Namy, P.; Youbi-Idrissi, M. Aero-Thermal Simulation of a Refrigerated Truck under Open and Closed Door Cycles. In Proceedings of the 2015 COMSOL Conference, Grenoble, France, 14–16 October 2015. [Google Scholar]

- Tassou, S.; De-Lille, G.; Ge, Y. Food transport refrigeration—Approaches to reduce energy consumption and environmental impacts of road transport. Appl. Therm. Eng. 2009, 29, 1467–1477. [Google Scholar] [CrossRef]

- Yang, Z.; Tate, J.E.; Morganti, E.; Shepherd, S.P. Real-World CO2 and NOX Emissions from Refrigerated Vans. Sci. Total Environ. 2021, 763. [Google Scholar] [CrossRef]

- Ahmed, M.; Meade, O.; Medina, M.A. Reducing Heat Transfer across the Insulated Walls of Refrigerated Truck Trailers by the Application of Phase Change Materials. Energy Convers. Manag. 2010, 51, 383–392. [Google Scholar] [CrossRef]

- Adekomaya, O.; Jamiru, T.; Sadiku, R.; Huan, Z. Sustaining the Shelf Life of Fresh Food in Cold Chain—A Burden on the Environment. Alex. Eng. J. 2016, 55, 1359–1365. [Google Scholar] [CrossRef]

- United Nations. The Agreement on the International Carriage of Perishable Foodstuffs and on the Special Equipment to Be Used for Such Carriage; United Nations: New York, NY, USA, 1970. [Google Scholar]

- Selvnes, H.; Allouche, Y.; Manescu, R.I.; Hafner, A. Review on Cold Thermal Energy Storage Applied to Refrigeration Systems Using Phase Change Materials. Therm. Sci. Eng. Prog. 2021, 22, 100807. [Google Scholar] [CrossRef]

- James, S.J.; James, C.; Evans, J.A. Modelling of Food Transportation Systems—A Review. Int. J. Refrig. 2006, 29, 947–957. [Google Scholar] [CrossRef]

- Awad, M.; Ndiaye, M.; Osman, A. Vehicle Routing in Cold Food Supply Chain Logistics: A Literature Review. Int. J. Logist. Manag. 2020, 32, 592–617. [Google Scholar] [CrossRef]

- Chatzidakis, S.K.; Chatzidakis, K.S. Refrigerated Transport and Environment. Int. J. Energy Res. 2004, 28, 887–897. [Google Scholar] [CrossRef]

- Estrada-Flores, S.; Eddy, A. Thermal Performance Indicators for Refrigerated Road Vehicles. Int. J. Refrig. 2006, 29, 889–898. [Google Scholar] [CrossRef]

- Lawton, R.; Rhodes, C.; Mynott, T. Considerations for Emissions Test Methodology for Diesel-Engine Driven Transport Refrigeration Systems. In Proceedings of the 6th IIR International Conference on Sustainability and the Cold Chain, Nantes, France, 26–28 August 2020; pp. 394–401. [Google Scholar]

- Chindamo, D.; Gadola, M. What Is the Most Representative Standard Driving Cycle to Estimate Diesel Emissions of a Light Commercial Vehicle? IFAC Pap. 2018, 51, 73–78. [Google Scholar] [CrossRef]

- Lawton, R.; Mynott, T.; Marshall, N.; Wagner, F. Emission Testing of a Transport Refrigeration Unit. In Proceedings of the 25th IIR International Congress of Refrigeration, Montreal, QC, Canada, 24–30 August 2019; pp. 3729–3736. [Google Scholar]

- Fabris, F.; Artuso, P.; Rossetti, A.; Minetto, S.; Marinetti, S. Impact of the Refrigeration System on the Fuel Consumption and on the Emissions of a Small Refrigerated Truck. In Proceedings of the 6th IIR International Conference on Sustainability and the Cold Chain, Nantes, France, 26–28 August 2020. [Google Scholar]

- Rai, A.; Tassou, S.A. Environmental Impacts of Vapour Compression and Cryogenic Transport Refrigeration Technologies for Temperature Controlled Food Distribution. Energy Convers. Manag. 2017, 150, 914–923. [Google Scholar] [CrossRef]

- Li, B.; Otten, R.; Chandan, V.; Mohs, W.F.; Berge, J.; Alleyne, A.G. Optimal On-off Control of Refrigerated Transport Systems. Control. Eng. Pract. 2010, 18, 1406–1417. [Google Scholar] [CrossRef]

- Huang, Y.; Khajepour, A.; Khazraee, M.; Bahrami, M. A Comparative Study of the Energy-Saving Controllers for Automotive Air-Conditioning/Refrigeration Systems. J. Dyn. Syst. Meas. Control. Trans. ASME 2017, 139, 014504-9. [Google Scholar] [CrossRef]

- Hua, K. Study on a Novel Variable Capacity Technology and Control Strategy for Refrigerated Shipping Container Unit. IOP Conf. Ser. Earth Environ. Sci. 2018, 186, 12050. [Google Scholar] [CrossRef]

- Mohagheghi Fard, S.; Khajepour, A. An Optimal Power Management System for a Regenerative Auxiliary Power System for Delivery Refrigerator Trucks. Appl. Energy 2016, 169, 748–756. [Google Scholar] [CrossRef]

- Bagheri, F.; Fayazbakhsh, M.A.; Bahrami, M. Évaluation Des Performances en Temps Réel et de La Réduction Potentielle Des GES Dans Les Remorques Frigorifiques. Int. J. Refrig. 2017, 73, 24–38. [Google Scholar] [CrossRef]

- Bahaj, A. World’s first solar powered transport refrigeration system. Renew. Energy 1998, 15, 572–576. [Google Scholar] [CrossRef]

- Bahaj, A.S. Photovoltaic power for refrigeration of transported perishable goods. In Proceedings of the Conference Record of the Twenty-Eighth IEEE Photovoltaic Specialists Conference-2000 (Cat. No. 00CH37036), Anchorage, AK, USA, 15–22 September 2000; Volume 2000, pp. 1563–1566. [Google Scholar] [CrossRef]

- Bahaj, A.S.; James, P.A.B. Economics of solar powered refrigeration transport applications. In Proceedings of the Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference 2002, New Orleans, LA, USA, 19–24 May 2002; pp. 1561–1564. [Google Scholar]

- Bergeron, D. Solar Powered Refrigeration for Transport Application—A Feasibility Study; Sandia Report; Sandia National Laboratories: Livermore, CA, USA, 2001. [Google Scholar]

- Elliston, B.; Dennis, M. Feasibility of Solar-Assisted Refrigerated Transport in Australia. In Proceedings of the 47th Conference of the Australia and New Zealand Solar Energy Society (Solar 2009), Australian and New Zealand Solar Energy Society (ANZSES), Townsville, Australia, 29 September–2 October 2009. [Google Scholar]

- Rossetti, A.; Artuso, P.; Minetto, S.; Marinetti, S.; Zennaro, D. Innovative Layout for Electric Powered Refrigeration for Insulated Trucks: The Integration of Photovoltaic Generator. In Proceedings of the 25th IIR International Congress of Refrigeration, Montreal, QC, Canada, 24–30 August 2019; pp. 3704–3711. [Google Scholar]

- Meneghetti, A.; Dal Magro, F.; Romagnoli, A. Renewable Energy Penetration in Food Delivery: Coupling Photovoltaics with Transport Refrigerated Units. Energy 2021, 232, 120994. [Google Scholar] [CrossRef]

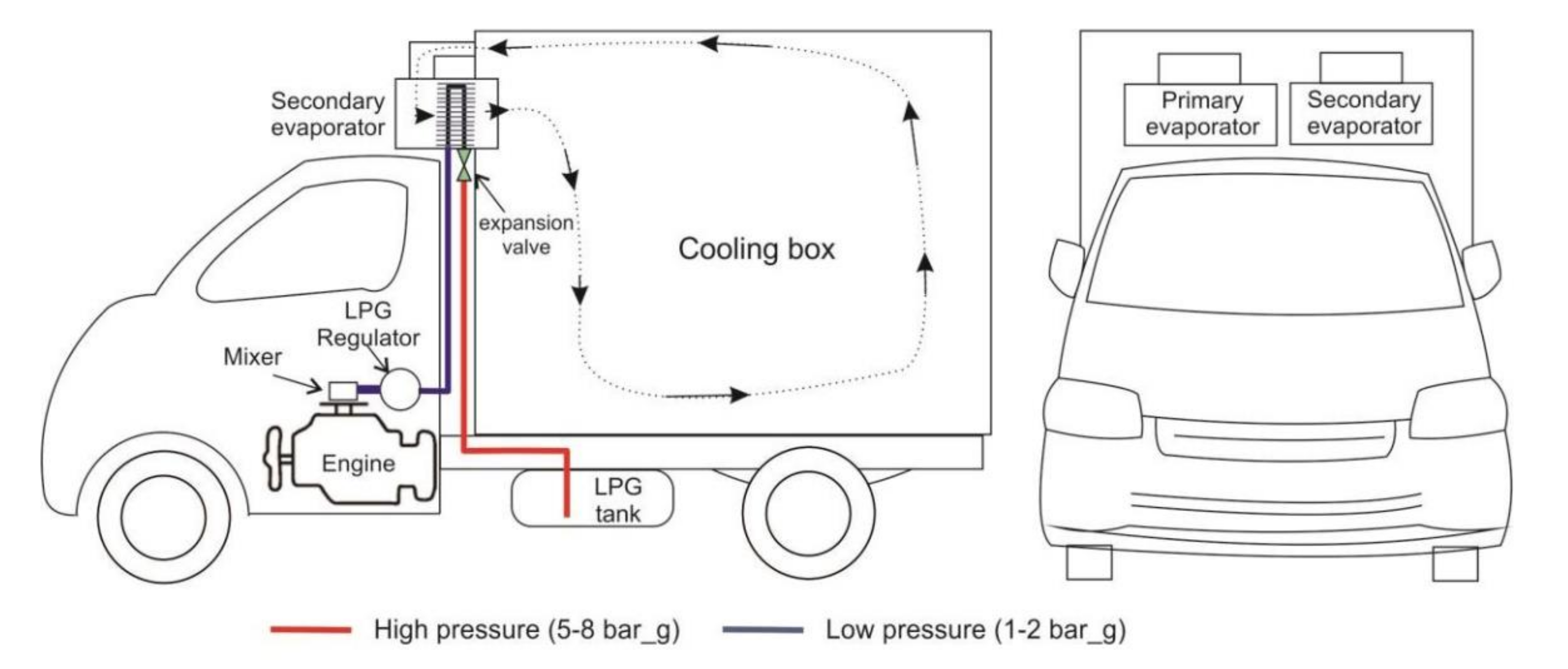

- Setiyo, M.; Waluyo, B.; Purnomo, B.C.; Karmiadji, D.W.; Setiawan, I.C. Potential of 1/2 Cycle Refrigeration System for Food Transport Application. IOP Conf. Ser. Mater. Sci. Eng. 2018, 403, 12093. [Google Scholar] [CrossRef]

- Setiyo, M.; Soeparman, S.; Wahyudi, S.; Hamidi, N. A simulation for predicting potential cooling effect on LPG-fuelled vehicles. In Proceedings of the 4th International Conference and Exhibition on Sustainable Energy and Advanced Materials 2015 (ICE-SEAM 2015), Solo, Indonesia, 11 November 2016; Volume 1717, p. 30002. [Google Scholar]

- Garde, R.; Jiménez, F.; Larriba, T.; García, G.; Aguado, M.; Martínez, M. Development of a Fuel Cell-Based System for Refrigerated Transport. Energy Procedia 2012, 29, 201–207. [Google Scholar] [CrossRef][Green Version]

- Ndanduleni, C.; Huan, Z. Review on Phase Change Materials for Sub-Zero Temperature Application in Transport Refrigeration. Suid- Afrik. Tydskr. Vir Nat. En Tegnol. 2019, 38, 1–10. [Google Scholar]

- Radebe, T.B.; Huan, Z.; Baloyi, J. A Simulation Study of Natural Convection Airflow Pattern for a Phase Change Material Chamber. SSRN Electron. J. 2019. [Google Scholar] [CrossRef]

- Shafiei, S.E.; Alleyne, A. Model Predictive Control of Hybrid Thermal Energy Systems in Transport Refrigeration. Appl. Therm. Eng. 2015, 82, 264–280. [Google Scholar] [CrossRef]

- Mousazade, A.; Rafee, R.; Valipour, M.S. Thermal Performance of Cold Panels with Phase Change Materials in a Refrigerated Truck. Int. J. Refrig. 2020, 120, 119–126. [Google Scholar] [CrossRef]

- Pedolsky, H.; La Bau, R. Reintroduction of Cryogenic Refrigeration for Cold Transport Reintroduction of Cryogenic Refrigeration for Cold Transport. In Proceedings of the 13th International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 12–15 July 2015. [Google Scholar]

- Tassou, S.A.; Hadawey, A.; Ge, Y.T.; Lagroy De Groutte, B. Carbon Dioxide Cryogenic Transport Refrigeration Systems; The Centre for Energy and Built Environment Research, Brunel University: Uxbridge, Middlesex, UK, 2009. [Google Scholar]

- Tan, H.; Li, Y.; Tuo, H. Theoretical and Experimental Study on a Self-Refrigerating System for LNG-Fueled Refrigerated Vehicles. J. Nat. Gas Sci. Eng. 2014, 20, 192–199. [Google Scholar] [CrossRef]

- Wang, F.; Li, M.; Zhang, Y.; Liu, X.; Xie, D.; Zhang, Q.; Yang, H. Study on Roof-Mounted Radiant Cooling System for LNG-Fueled Refrigerated Vehicles. Int. J. Low-Carbon Technol. 2021, 16, 268–274. [Google Scholar] [CrossRef]

- Tan, H.; Li, Y.; Tuo, H.; Zhou, M.; Tian, B. Experimental Study on Liquid/Solid Phase Change for Cold Energy Storage of Liquefied Natural Gas (LNG) Refrigerated Vehicle. Energy 2010, 35, 1927–1935. [Google Scholar] [CrossRef]

- Gao, P.; Wang, L.W.; Zhu, F.Q. Vapor-Compression Refrigeration System Coupled with a Thermochemical Resorption Energy Storage Unit for a Refrigerated Truck. Applied Energy. 2021, 290, 116756. [Google Scholar] [CrossRef]

- Koehler, J.; Tegethoff, W.J.; Westphalen, D.; Sonnekalb, M. Absorption Refrigeration System for Mobile Applications Utilizing Exhaust Qases. Heat Mass Transf. Waerme Stoffuebertragung 1997, 32, 333–340. [Google Scholar] [CrossRef]

- Horuz, I. An Alternative Road Transport Refrigeration. Turk. J. Eng. Environ. Sci. 1998, 22, 211–222. [Google Scholar]

- Horuz, I. Vapor Absorption Refrigeration in Road Transport Vehicles. J. Energy Eng. 1999, 125, 48–58. [Google Scholar] [CrossRef]

- Venkataraman, V.; Pacek, A.W.; Steinberger-Wilckens, R. Coupling of a Solid Oxide Fuel Cell Auxiliary Power Unit with a Vapour Absorption Refrigeration System for Refrigerated Truck Application. Fuel Cells 2016, 16, 273–293. [Google Scholar] [CrossRef]

- Venkataraman, V.; El-Kharouf, A.; Pandya, B.; Amakiri, E.; Steinberger-Wilckens, R. Coupling of Engine Exhaust and Fuel Cell Exhaust with Vapour Absorption Refrigeration/Air Conditioning Systems for Transport Applications: A Review. Therm. Sci. Eng. Prog. 2020, 18. [Google Scholar] [CrossRef]

- Pandya, B.; El-Kharouf, A.; Venkataraman, V.; Steinberger-Wilckens, R. Comparative Study of Solid Oxide Fuel Cell Coupled Absorption Refrigeration System for Green and Sustainable Refrigerated Transportation. Appl. Therm. Eng. 2020, 179. [Google Scholar] [CrossRef]

- Bibwe, B.; Kannaujia, P.; Mahawar, M.; Aradwad, P. Refrigerated transport systems for fruits and vegetables handling and its future prospect, AGRICULTURE & FOOD: E-Newsletter. 2019, pp. 278–284. Available online: http://www.agrifoodmagazine.co.in/wp-content/uploads/2019/04/May-2019.pdf (accessed on 27 September 2021).

- Gao, P.; Wang, L.W.; Wang, R.Z.; Zhang, X.F.; Li, D.P.; Liang, Z.W.; Cai, A.F. Experimental Investigation of a MnCl2/CaCl2-NH3 Two-Stage Solid Sorption Freezing System for a Refrigerated Truck. Energy 2016, 103, 16–26. [Google Scholar] [CrossRef]

- Gao, J.; Wang, L.W.; Gao, P.; An, G.L.; Wang, Z.X.; Xu, S.Z.; Wang, R.Z. Performance Investigation of a Freezing System with Novel Multi-Salt Sorbent for Refrigerated Truck. Int. J. Refrig. 2019, 98, 129–138. [Google Scholar] [CrossRef]

- Gao, P.; Wang, L.W.; Zhu, F.Q. A Novel Hybrid Solid Sorption-Compression Refrigeration Technology for Refrigerated Transportation and Storage. Int. J. Refrig. 2021, 122, 1–10. [Google Scholar] [CrossRef]

- Sharafian, A.; Bahrami, M. Assessment of Adsorber Bed Designs in Waste-Heat Driven Adsorption Cooling Systems for Vehicle Air Conditioning and Refrigeration. Renew. Sustain. Energy Rev. 2014, 30, 440–451. [Google Scholar] [CrossRef]

- Spence, S.W.T.; Doran, W.J.; Artt, D.W. Design, Construction and Testing of an Air-Cycle Refrigeration System for Road Transport. Int. J. Refrig. 2004, 27, 503–510. [Google Scholar] [CrossRef]

- Spence, S.W.T.; John Doran, W.; Artt, D.W.; McCullough, G. Performance Analysis of a Feasible Air-Cycle Refrigeration System for Road Transport. Int. J. Refrig. 2005, 28, 381–388. [Google Scholar] [CrossRef]

- Colbourne, D.; Solomon, P.; Wilson, R.; de Swardt, L.; Nosbers, R.; Schuster, M. Development of R290 Transport Refrigeration System; Institute of Refrigeration: Carshalton, UK, 2017. [Google Scholar]

- Ramaube, M.; Huan, Z. Testing and Performance Evaluation of a R404A Transport Refrigeration System Retrofitted With R290. In Proceedings of the AIUE 17th Industrial and Commercial Use of Energy (ICUE) Conference, Cape Town, South Africa, 26 November 2019. [Google Scholar]

- Barta, R.B.; Groll, E.A.; Ziviani, D. Review of Stationary and Transport CO2 Refrigeration and Air Conditioning Technologies. Appl. Thermal Eng. 2021, 185, 116422. [Google Scholar] [CrossRef]

- Fabris, F.; Artuso, P.; Marinetti, S.; Minetto, S.; Rossetti, A. Dynamic Modelling of a CO2 Transport Refrigeration Unit with Multiple Configurations. Appl. Thermal Eng. 2021, 189, 116749. [Google Scholar] [CrossRef]

- Kim, M.H.; Pettersen, J.; Bullard, C.W. Fundamental Process and System Design Issues in CO2 Vapor Compression Systems. Prog. Energy Combust. Sci. 2004, 30, 119–174. [Google Scholar] [CrossRef]

- NaturaLINE. Carrier Transicold NaturaLINE®—The World’s First Natural Refrigerant Unit for Container Refrigeration; NaturaLINE: Beijing, China, 2020. [Google Scholar]

- Lawrence, N.; Elbel, S.; Hrnjak, P. Design and Investigation of a Transcritical R744 Refrigerated Container for Military Applications. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 9–12 July 2018. [Google Scholar]

- Artuso, P.; Marinetti, S.; Minetto, S.; del Col, D.; Rossetti, A. Modelling the Performance of a New Cooling Unit for Refrigerated Transport Using Carbon Dioxide as the Refrigerant. Int. J. Refrig. 2020, 115, 158–171. [Google Scholar] [CrossRef]

- Shi, L.; Tian, H.; Shu, G. Multi-Mode Analysis of a CO2-Based Combined Refrigeration and Power Cycle for Engine Waste Heat Recovery. Appl. Energy 2020, 264, 114670. [Google Scholar] [CrossRef]

- Pan, M.; Bian, X.; Zhu, Y.; Liang, Y.; Lu, F.; Xiao, G. Thermodynamic Analysis of a Combined Supercritical CO2 and Ejector Expansion Refrigeration Cycle for Engine Waste Heat Recovery. Energy Convers. Manag. 2020, 224, 113373. [Google Scholar] [CrossRef]

- Glouannec, P.; Michel, B.; Delamarre, G.; Grohens, Y. Experimental and Numerical Study of Heat Transfer across Insulation Wall of a Refrigerated Integral Panel Van. Appl. Therm. Eng. 2014, 73, 196–204. [Google Scholar] [CrossRef]

- Jovanović, B.; Maljković, M.; Stamenković, D.; Popović, V. Fuel Savings by Using Better-Quality Insulation in Refrigerated Vans. Industrija 2021, 49, 81–91. [Google Scholar] [CrossRef]

- Artuso, P.; Rossetti, A.; Minetto, S.; Marinetti, S.; Moro, L.; Col, D. del Dynamic Modeling and Thermal Performance Analysis of a Refrigerated Truck Body during Operation. Int. J. Refrig. 2019, 99, 288–299. [Google Scholar] [CrossRef]

- Michel, B.; Glouannec, P.; Fuentes, A.; Chauvelon, P. Experimental and Numerical Study of Insulation Walls Containing a Composite Layer of PU-PCM and Dedicated to Refrigerated Vehicle. Appl. Therm. Eng. 2017, 116, 382–391. [Google Scholar] [CrossRef]

- Tinti, A.; Tarzia, A.; Passaro, A.; Angiuli, R. Thermographic Analysis of Polyurethane Foams Integrated with Phase Change Materials Designed for Dynamic Thermal Insulation in Refrigerated Transport. Appl. Therm. Eng. 2014, 70, 201–210. [Google Scholar] [CrossRef]

- Copertaro, B.; Principi, P.; Fioretti, R. Thermal Performance Analysis of PCM in Refrigerated Container Envelopes in the Italian Context—Numerical Modeling and Validation. Appl. Therm. Eng. 2016, 102, 873–881. [Google Scholar] [CrossRef]

- Principi, P.; Fioretti, R.; Copertaro, B. Energy Saving Opportunities in the Refrigerated Transport Sector through Phase Change Materials (PCMs) Application. J. Phys. Conf. Ser. 2017, 923, 12043. [Google Scholar] [CrossRef]

- Lawton, A.R.; Marshall, R.E. Developments in Refrigerated Transport Insulation since the Phase out of CFC and HCFC Refrigerants. In Proceedings of the 22nd IIR International Congress of Refrigeration, Beijing, China, 21–26 August 2007. [Google Scholar]

- Uwa, C.A.; Jamiru, T.; Sadiku, E.R.; Huan, Z.; Mpofu, K. Polypropylene/Nanoclay Composite: A Solution to Refrigerated Vehicles. Procedia Manuf. 2019, 35, 174–180. [Google Scholar] [CrossRef]

- Azzouz, A.; Gossé, J.; Duminil, M. Détermination Expérimentale des Pertes de Froid Occasionnées Par l’ouverture d’une Porte de Chambre Froide Industrielle. Int. J. Refrig. 1993, 16, 57–66. [Google Scholar] [CrossRef]

- Lafaye De Micheaux, T.; Ducoulombier, M.; Moureh, J.; Sartre, V.; Bonjour, J. Experimental and Numerical Investigation of the Infiltration Heat Load during the Opening of a Refrigerated Truck Body. Int. J. Refrig. 2015, 54, 170–189. [Google Scholar] [CrossRef]

- Gonçalves, J.C.; Costa, J.J.; Lopes, A.M.G. Analysis of the Air Infiltration through the Doorway of a Refrigerated Room Using Different Approaches. Appl. Therm. Eng. 2019, 159. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. ASHRAE Handbook: Refrigeration; ASHRAE: Peachtree Corners, GA, USA, 2018; ISBN 9781-939200983. [Google Scholar]

- Foster, A.M.; Swain, M.J.; Barrett, R.; D’Agaro, P.; Ketteringham, L.P.; James, S.J. Three-Dimensional Effects of an Air Curtain Used to Restrict Cold Room Infiltration. Appl. Math. Model. 2007, 31, 1109–1123. [Google Scholar] [CrossRef]

- Rai, A.; Sun, J.; Tassou, S.A. Numerical Investigation of the Protective Mechanisms of Air Curtain in a Refrigerated Truck during Door Openings. Energy Procedia 2019, 161, 216–223. [Google Scholar] [CrossRef]

- Tso, C.; Yu, S.; Poh, H.; Jolly, P. Experimental study on the heat and mass transfer characteristics in a refrigerated truck. Int. J. Refrig. 2002, 25, 340–350. [Google Scholar] [CrossRef]

- Foster, A.M.; Swain, M.J.; Barrett, R.; D’Agaro, P.; James, S.J. Effectiveness and Optimum Jet Velocity for a Plane Jet Air Curtain Used to Restrict Cold Room Infiltration. Int. J. Refrig. 2006, 29, 692–699. [Google Scholar] [CrossRef]

- Rai, A.; Sun, J.; Tassou, S.A. Numerical Investigation into the Influence of Air Curtain Discharge Angles in Refrigerated Trucks. Energy Procedia 2019, 161, 207–215. [Google Scholar] [CrossRef]

- Rai, A.; Sun, J.; Tassou, S.A. Three-Dimensional Investigation on the Positioning of Air Curtain on Its Effectiveness in Refrigerated Vehicles Used for Food Distribution. Energy Procedia 2019, 161, 224–231. [Google Scholar] [CrossRef]

- Li, B.; Guo, J.; Xia, J.; Wei, X.; Shen, H.; Cao, Y.; Lu, H.; Lü, E. Temperature Distribution in Insulated Temperature-Controlled Container by Numerical Simulation. Energies 2020, 13. [Google Scholar] [CrossRef]

- Moureh, J.; Menia, N.; Flick, D. Numerical and Experimental Study of Airflow in a Typical Refrigerated Truck Configuration Loaded with Pallets. Comput. Electron. Agric. 2002, 34, 25–42. [Google Scholar] [CrossRef]

- Han, J.-W.; Zhu, W.-Y.; Ji, Z.-T. Comparison of Veracity and Application of Different CFD Turbulence Models for Refrigerated Transport. Artif. Intell. Agric. 2019, 3, 11–17. [Google Scholar] [CrossRef]

- Kayansayan, N.; Alptekin, E.; Ezan, M.A. Analyse Thermique Du Débit d’air à l’intérieur d’un Conteneur Réfrigéré. Int. J. Refrig. 2017, 84, 76–91. [Google Scholar] [CrossRef]

- Jara, P.B.T.; Rivera, J.J.A.; Merino, C.E.B.; Silva, E.V.; Farfán, G.A. Thermal Behavior of a Refrigerated Vehicle: Process Simulation. Int. J. Refrig. 2019, 100, 124–130. [Google Scholar] [CrossRef]

- Jiang, T.; Xu, N.; Luo, B.; Deng, L.; Wang, S.; Gao, Q.; Zhang, Y. Analysis of an Internal Structure for Refrigerated Container: Improving Distribution of Cooling Capacity. Int. J. Refrig. 2020, 113, 228–238. [Google Scholar] [CrossRef]

- Meneghetti, A.; Da Rold, G.; Cortella, G. Sustainable refrigerated food transport: Searching energy efficient routes. IFAC—PapersOnLine 2018, 51, 618–623. [Google Scholar] [CrossRef]

- Li, L.; Yang, Y.; Qin, G. Optimization of Integrated Inventory Routing Problem for Cold Chain Logistics Considering Carbon Footprint and Carbon Regulations. Sustainability 2019, 11, 4628. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y.; Wen, H. Optimization of Vehicle Routing Problem with Time Windows for Cold Chain Logistics Based on Carbon Tax. Sustainability 2017, 9, 694. [Google Scholar] [CrossRef]

| Vehicle | A | B1 | B2 |

|---|---|---|---|

| Engine Power (kW) | 90 | 120 | 120 |

| Vehicle mass (kg) | 2150 | 3450 | 3450 |

| Vehicle loading (kg) | 375 | 0 | 4050 |

| Road type | Urban, suburban, motorway | Suburban | Suburban |

| Duration (s) | 14,019 | 2930 | 2930 |

| Distance (km) | 140 | 27 | 27 |

| Average speed (km/h) | 35.92 | 32.65 | 32.65 |

| Maximum acceleration (m/s2) | 2.67 | 2.67 | 2.67 |

| Authors | Brief Description | Main Results |

|---|---|---|

| Fard and Kajepour, 2016 | An anti-idling system was proposed by adding an engine driven auxiliary electric generator and a rechargeable battery. The use of a regenerative breaking system was also considered. | Fuel consumption reduction both in city drive (−11.9%) and in highway drive (−6.6%). |

| Bagheri et al., 2017 | A mathematical model to simulate the performance of the on-board VCR systems in trailers was developed [31]. | The yearly-averaged simulated and measured COP of the trailers were found to be, respectively, 0.58 and 0.62. Fuel consumption reduction (−3105kg/year) and CO2 emissions reduction (−8320 kg/year) were found by replacing the engine-driven VCR systems by battery-powered VCR systems. |

| Bahaj, 1998, 2000, 2002 | The world’s first solar powered transport refrigeration system was developed by installing a photovoltaic system on the roof of a trailer and adding a charge regulator, a lead-acid battery and an inverter in order to power a VCR system. | The effect of a week’s operation was a reduction in battery charge by 20% (full capacity of 28 kWh). A payback time of ~15 years was found. |

| Bergheron, 2001 | A feasibility study was conducted to evaluate if a PV system was able to power a VCR system. Battery storage and PCM storage were considered. | Feasibility was proven. The choice between battery storage and PCM storage should be carefully considered as it has significant impacts on the design of the refrigeration system [35]. The use of PCM offers the best long-term benefit [35], but presents more development effort. |

| Elliston and Dennis, 2009 | A feasibility study was conducted to evaluate if a PV system was able to power a VCR system in Australia. Battery storage was considered. | Fuel consumption reduction (−85%) in order to refrigerate the trailer down to −18 °C. |

| Rossetti et al., 2019 | A prototype of PV powered VCR unit, consisting of PV modules, charge controller and battery pack, was developed for a small refrigerated truck application. Numerical simulations of delivery missions in Athens were carried out in order to evaluate the feasibility of such a system. | Results show that the energy produced by the PV system was always higher than the one required by the VCR unit (at least 25% higher), so feasibility was demonstrated. |

| Meneghetti et al., 2021 | An optimization model to size a PV system (PV panels on the vehicle rooftop, power conversion system-PCS and a Li-ion battery bank) for a typical semitrailer used for frozen food transportation was developed. | The optimization model was used to size a PV system used to power a VCR unit instead of a diesel engine. With such a system, a reduction in emissions up to 89% in the reference case (North-Eastern Italy) considered and a pay back period of about six years was estimated. The percentage of coverage of the refrigeration needs moves from 58% (reference case, North-Eastern Italy deliveries) to about 80%, leading to a pay back period of 4.75 years with 37.2 kgCO2eq emissions saving per trip. |

| Setiyo et al., 2018 | Use of LPG evaporation to refrigerate the transportation box as a secondary refrigeration system in LPG fuelled vehicles was analyzed. | This system provides a cooling effect of more than 0.8 kW (about 25% of a medium-size cooler box requirement in terms of refrigeration capacity) [39] at LPG flow rate of 2.4 g/s (stationary condition of 3000 rpm). The driving mode strongly affects the potential cooling effect that can be harvested. |

| Garde et al., 2012 | Fuel cells powered VCR system was considered. A tool to size fuel cells system was developed. | Feasibility was proven. The Tool results show that the hydrogen requirements for a heavy refrigerated truck is about 0.3 kg/100 km [41], which means that using a 7.5 kg hydrogen tank, the autonomy would be as high as 2200 km. An onsite optimized electrolysis system to produce hydrogen could reduce hydrogen costs to the equivalent of 6 EUR/kg [41]. This could lead to a 21 tons reduction in CO2 emissions [41]. A payback time of ~4 years was found. |

| Authors | Brief Description | Main Results |

|---|---|---|

| Shafiei and Alleyne, 2015 | A hybrid vapour compression system that included a Thermal Energy Storage was proposed. The VCR system was able to refrigerate the transportation box and recharge the PCM when the vehicle’s speed exceeded a threshold value. | Energy consumption reduced by 17% with respect to traditional systems. |

| Mousazade et al., 2020 | A PCM refrigerating unit was proposed. The internal or external VCR system was only used to recharge PCM plates when needed. | Different PCMs’ melting time was evaluated. |

| Authors | Brief Description | Main Results |

|---|---|---|

| Rai and Tassou, 2017 | A diesel driven VCR system was compared to LCO2 and LN2 cryogenic systems. Two types of vehicle (18 t and 38 t) and two types of products (precooled and frozen) were considered. | Considering the same cooling demand, results show that the emissions related to the production of the diesel fuel and refrigerant in the case of the VCR system are up to 66% lower than those related to the production of LCO2 and LN2 (a larger quantity of cryogenic fluids needs to be produced to overcome the same cooling demand). Total emissions (production and operation) from VCR and cryogenic systems, instead, result to be similar, as diesel combustion and refrigerant leakage during operation cause a considerable increase in the diesel engine driven VCR system emissions. |

| Tan et al., 2010 | A new refrigeration system in which the evaporation of LNG allowed to recharge a PCM, in particular water/ice was proposed. The heat transfer tubes were internally cooled by LNG, while water solidified outside. Both smooth and internally finned tube heat exchangers were considered. | When considering a smooth tube heat exchanger, the thermal resistance due to the ice layer accounts for a small part (less than 10%) of the total value. The greatest contribution is given by the weak convective heat exchange related to LNG. An internally finned tube (LNG side) heat exchanger greatly improves the convective heat exchange related to the LNG flow. Results show that the thermal resistance related to the ice layer accounts for 70–77% of the total value. With reference to the ice formation dynamics, none of the conducted tests provide a direct comparison between the two types of heat exchangers. |

| Tan et al., 2014 | Feasibility analysis of a self-refrigerated vehicle, obtained by recovering the cold energy of LNG fuel evaporation (indirect cryogenic system). | The experiment results show that the refrigerating temperature of the compartment could be kept lower than −20 °C when the LNG flow rate exceeds 5.607 kg/h. This value can be achieved when the power output of the engine for the LNG-fuelled refrigerated vehicle is more than 75 kW, which is one third of its maximum output power [48]. The internal temperature of the compartment drops from 28 °C to −20 °C in about 2.5 h when the LNG flow rate is 5.709 kg/h. |

| Wang et al., 2020 | A roof-mounted radiant cooling system was designed for use on LNG-fuelled refrigerated vehicles. The relationship between cooling capacity and LNG flow rate was studied. | The cooling capacity of the system increases by 0.28 kW with each 1 kg/h increase in the LNG flow rate when considering a coolant flow rate of 70 kg/h. When considering a LNG flow rate of 8.8 kg/h, as the coolant flow rate increases by 1 kg/h, the cooling capaciy of the system increases by 0.03 kW. |

| Type of Truck | External Length (m) | External Width (m) | External Height (m) |

|---|---|---|---|

| Large (40 t) | 13.6 | 2.6 | 2.4 |

| Medium (12 t) | 9.4 | 2.5 | 2.5 |

| Small (0.7 t) | 2.48 | 1.88 | 1.57 |

| Authors | Brief Description | Main Results |

|---|---|---|

| Koehler et al., 1997 | Analysis of the recoverable energy from the exhaust gases to power a VAR system used for the application in a refrigerated truck. An absorption refrigeration system prototype was designed, built and tested. | The unoptimized prototype has a COP of about 0.27. Results show that it can be improved by more than 25% by optimizing the heat exchangers design and the insulation of the generator. The cooling capacity of the prototype is able to satisfy the cooling needs of a typical 40 t truck trailer [52]. |

| Horuz, 1998–1999 | Analysis of the recoverable energy in the exhaust gases from the vehicle’s engine to power a VAR system. | The use of VAR systems in refrigerated transport field was proven. The use of eutectic plates as backup systems was suggested by the author. Introducing a VAR system into the exhaust system reduces engine efficiency by 2%. |

| Venkataraman et al., 2016, 2020 | A model to simulate a VAR system powered by a solid oxide fuel cell for a truck application was developed. | The COP of the considered scenario (internal temperature of −20 °C) is around 0.42 for a single stage NH3–H2O system. The maximum COP that can possibly be achieved is 0.7, after implementation of improvement strategies. |

| Pandya et al., 2020 | A thermo-economic study for two different solid oxide fuel cell system configurations was conducted. Series and parallel configurations were compared to optimize the fuel cell sub-system layout. | The parallel configuration of heat exchangers required 45–65% less cell active surface to satisfy the refrigeration needs. In addition, “an enhanced thermodynamic performance by 4–10%, a 5–30% lower amount of CO2 emissions, and 2–7% lower cost of cogeneration under various operating conditions” [57] were shown by parallel configuration, referring to a refrigeration load of 6 kW (large truck). |

| Refrigerating Temperature (°C) | Required Refrigerated Capacity (W) |

|---|---|

| 0 | 971.2 |

| −5 | 1133.1 |

| −10 | 1295 |

| −15 | 1456.8 |

| −18 | 1554 |

| Authors | Brief Description | Main Results |

|---|---|---|

| Gao et al., 2016 | A dual-stage MnCl2/CaCl2–NH3 adsorption refrigeration system using engine exhaust gases was built and tested. Refrigerating capacity of the system was evaluated. | Low temperature exhaust gases (210 °C) are sufficient to transport cooled goods (0 °C or −5 °C refrigerating temperature), showing a COP of 0.14. Lower refrigerating temperatures need higher exhaust gas temperature (higher than 270 °C). |

| Gao et al., 2019 | A freezing system with CaCl2/MnCl2 multi-salt sorbent was proposed for refrigerated trucks. | At the heating temperature of 200 °C, most of the ammonia can desorb from the sorbent [60]. The proposed system can produce cooling power for the refrigerated truck at low heating temperature and high cooling temperature. The COP of the system ranges from ~0.27 to ~0.43 when the refrigeration is between −15 °C and 5 °C. |

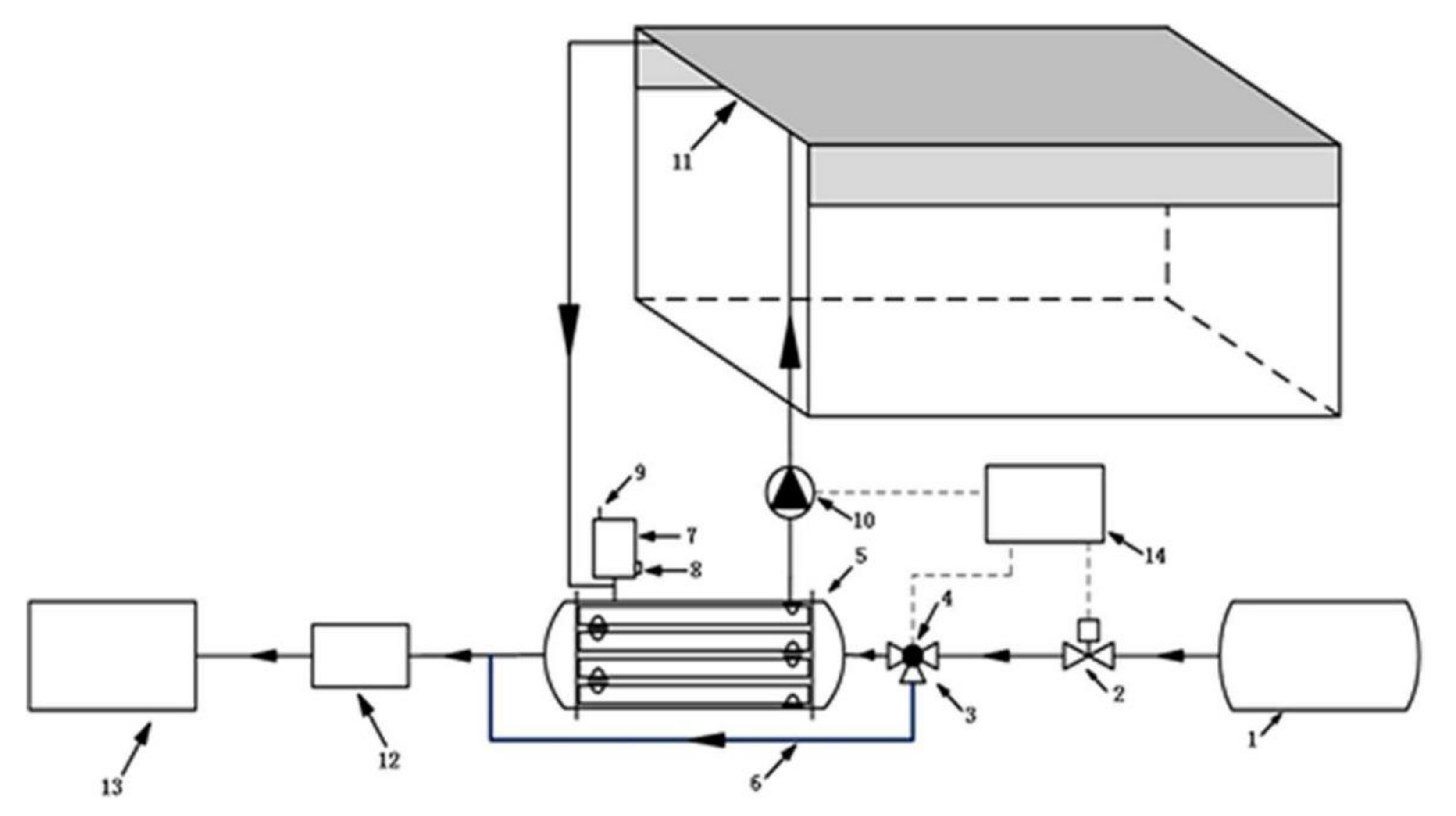

| Gao et al., 2021 | A system involving a mechanical compressor and two adsorption beds (MnCl2/CaCl2-NH3), which acted as thermochemical energy storage, was proposed. | The thermochemical energy storage is able to recover exhaust gas waste heat to store cold energy. During the discharging process, at an evaporator outlet temperature of −15 °C, the refrigerating capacity is 2.2 kW. At an ambient temperature and a refrigerating temperature respectively of 30 °C and −20 °C, the energy efficiency of the proposed system is 1.4, which is twice the value of a conventional system [51]. |

| Gao et al., 2021 | A compressor was added between the sorption bed and the condenser to control desorption pressure, allowing sorbent to regenerate at a lower heat source temperature. | At a condensing temperature and an evaporating temperature respectively of 50 °C and −25 °C, the COP of the hybrid system is up to 5. |

| Sharafian and Bahrami, 2014 | An in-depth assessment of available adsorber bed design for waste-heat driven adsorption refrigeration system was presented with a focus on vehicle air conditioning and refrigeration applications. | Finned tube adsorber beds have better performance among the existing adsorber beds. Prominent finned tube adsorber bed designs were selected for vehicle air conditioning and refrigeration applications. In order to increase heat and mass transfer rates inside the adsorber beds, the authors proposed an increase in the thermal conductivity of adsorbent materials, as well as an optimization of fin spacing and height in finned tube adsorber beds [62]. |

| Authors | Brief Description | Main Results |

|---|---|---|

| Spence et al., 2004–2005 | An air cycle-based system was designed and fitted within the physical envelope of an existing VCR trailer unit. The performance of such system was analysed and compared with the VCR original system. | At −20 °C, The full load capacity of the air-cycle system was 7.8 kW, 8% greater than the equivalent VCR unit, but its fuel consumption was excessively high. “At part load operation the disparity in fuel consumption dropped from approximately 200% to around 80%” [63]. The components used in the aircycle demonstrator were not optimized, so considerable potential exists for efficiency improvements. The power requirement of the optimized air-cycle unit was 7% greater than the equivalent VCR unit at full-load operation. However, at part-load operation the air-cycle unit was estimated to absorb 35% less power than the VCR unit. The COP of the optimized system is 0.53 for a refrigerating temperature of −20 °C. |

| RSCBC/EERC | Tmax | 320 °C |

| Pmax | 25 MPa | |

| Tmin | 40 °C | |

| Pmin | 7.5 MPa | |

| Tcond | 30 °C | |

| Teva | 0 °C | |

| ΔP | 45 kPa | |

| VARS Li-H2O | Generating temperature | 80 °C |

| Absorbing temperature | 30 °C | |

| Condensing temperature | 30 °C | |

| Evaporating Temperature | 0 °C | |

| Solution concentration at the outlet of the absorber | 55% |

| Parameters | RSCBC/EERC | VARS |

|---|---|---|

| Net power output (kW) | 20.84 | / |

| Refrigerating Capacity (kW) | 225.5 | 89.0245 |

| Energy recovered (kW) | 86.74 | 117.61 |

| COP | 2.053 | 0.7569 |

| Authors | Brief Description | Main Results |

|---|---|---|

| Lawrence et al., 2018 | The design and performance of a transcritical CO2 multi-temperature refrigerated container system were analyzed. The use of a microchannel gas cooler and the addition of an internal heat exchanger and an ejector to the cycle was considered. | It has been seen that, compared to a traditional transcritical system, the internal heat exchanger, the microchannel exchanger for the gas cooler and the ejector allow a maximum increase in COP respectively of 35.3%, 5.6% and 27.3%. The obtained COP is up to 0.96 at very high ambient temperature (57 °C). |

| Artuso et al., 2020 | The thermal performance of a CO2 VCR system for refrigerated transport applications was analyzed. Three different configurations were investigated: the standard back-pressure with low pressure receiver lay-out and two arrangements integrating a two-phase ejector. In particular, in order to extend the ejector operating range, the use of an auxiliary evaporator was considered [72]. | At hot climate conditions (ambient temperature and internal space temperature respectively of 42 °C and −5 °C), the ejector cycle configuration is convenient and has a maximum COP increase equal to 15.9%, if compared to the traditional configuration. The operating range of the ejector can be extended to lower ambient temperatures by using an auxiliary evaporator. This configuration allow a maximum COP improvement of 21.0%, if compared to the traditional configuration, at ambient temperature and internal space temperature respectively of 25 °C and 5 °C [72]. |

| Fabris et al., 2021 | The dynamic simulation of a CO2 system designed for a medium-size refrigerated truck. The system involved a two-phase ejector to improve its performances. In order to extend the ejector operating range, an auxiliary evaporator was considered. A safety system was also implemented in order to limit the increase in temperature and pressure (low pressure side) due to long periods of inactivity. This system worked by turning on the compressor and by-passing the evaporator [68]. | Results show that the system has an average COP of 1.60. For the delivery mission considered, an overall Duty Cycle of 10% is obtained. The 96.6% of the total cooling energy provided by the system is given by exploiting both the main and the auxiliary evaporator. However, results show that exploiting both evaporators can become counterproductive when the systems operate during the hottest hours of the day [68]. |

| Shi et al., 2020 | A system able to produce cooling and electrical power simultaneously was proposed. Such system consisted of a CO2 Brayton cycle for electrical power production, and a transcritical CO2 ejector cycle for refrigeration. The system was able to operate in three different modes: R (Refrigeration), P (Power generation) and RP (Refrigeration and power generation). | The feasibility of the multi-mode operation was demonstrated. The proposed energy solution (engine + MM-CRPC) could replace the original energy solution (engine + VCR system) by recovering the waste heat of exhaust gas. Under the refrigeration ondition, the system allow to obtain a 2.9% fuel saving and 4.8% power increase at the same time. Under freezing condition, a 3.4% fuel saving and 1.6% power increase simultaneously can be achieved. The fuel economy is correspondingly improved by 7.4% and 4.9%. When the MM-CRPC operates in full refrigeration mode, the maximum refrigeration capacity of the proposed system is up to four times and twice the values of the original refrigerator respectively under the refrigeration and freezing conditions. When the system operates in full power mode (no refrigeration demand), a 8.3% extra power relative to the engine power can be produced [73]. |

| Pan et al., 2020 | A combined power and refrigeration system, consisting of a regenerative supercritical CO2 Brayton cycle and an ejector expansion refrigeration cycle, was proposed. The Brayton cycle generated power by recovering the waste heat of the engine [74]. | The refrigerating capacity and COP of the system are respectively up to 225.5 kW and 2.05, if considering the R32/CO2 (0.9/0.1 ratio) mixture. The total energy consumption, including the additional weight and power consumed by the second compressor contributions, accounts for 14.4% of the engine power output to realize refrigeration. The total energy consumed by the VCR system is about 18% of the engine power output, which is higher than that of the RSCBC/EERC related to the same refrigerating capacity (225.5 kW) [74] |

| Material | Melting Temperature (°C) | Latent Heat (kJ/kg) | Type of Product |

|---|---|---|---|

| E-65 | −65 | 240 | Inorganic |

| SP-50 | −50 to −48 | 200 | Inorganic |

| E-50 | −50 | 175 | Inorganic |

| PureTemp-37 | −37 | 175 | Bio-based organic |

| E-37 | −37 | 225 | Inorganic |

| E-34 | −34 | 200 | Inorganic |

| ATS-40 | −33 | 300 | Inorganic |

| E-32 | −32 | 225 | Inorganic |

| va-Q-accu-32G | −32 | 243 | n.a. |

| PCM-30 | −30 | 150–160 | Organic |

| HS30N | −30 | 224 | Inorganic |

| E-29 | −29 | 250 | Inorganic |

| SP-30 | −29 to −28 | 250 | Inorganic |

| SP-28 | −29 to −28 | 260 | Inorganic |

| HS26N | −26 | 274 | Inorganic |

| E-26 | −26 | 265 | Inorganic |

| SP-24 | −25 to −23 | 285 | Inorganic |

| HS23N | −23 | 262 | Inorganic |

| E-22 | −22 | 305 | Inorganic |

| CrodaTherm-22 | −23 | 217 | n.a. |

| va-Q-accu-21G | −21 | 234 | n.a. |

| ClimSel C-21 | −21 | 285 | Inorganic |

| PureTemp-21 | −21 | 239 | Bio-based organic |

| E-21 | −21 | 285 | Inorganic |

| ATS-21 | −21 | 320 | Inorganic |

| SP-21 | −21 to −19 | 285 | Inorganic |

| E-19 | −19 | 300 | Inorganic |

| HS18N | −18 | 242 | Inorganic |

| ClimSel C-18 | −18 | 288 | Inorganic |

| SP-17 | −18 to −17 | 300 | Inorganic |

| E-15 | −15 | 320 | Inorganic |

| HS15N | −15 | 308 | Inorganic |

| PureTemp-15 | −15 | 301 | Bio-based organic |

| ATS-12 | −12 | 360 | Inorganic |

| E-11 | −12 | 310 | Inorganic |

| SP-11 | −12 to −11 | 240 | Inorganic |

| SP-11 UK | −12 to −10 | 330 | Inorganic |

| PCM-10 | −10 | 175–185 | Organic |

| MPCM-10 | −10 | 170–180 | Organic |

| MPCM-10D | −10 | 170–180 | Organic |

| HS10N | −10 | 290 | Inorganic |

| RT-9 HC | −9 | 250 | Organic |

| HS7N | −7 | 296 | Inorganic |

| SP-7 | −7 to −5 | 290 | Inorganic |

| ATS-6 | −6 | 360 | Inorganic |

| E-6 | −6 | 300 | Inorganic |

| RT-4 | −4 | 180 | Organic |

| E-3 | −4 | 330 | Inorganic |

| HS3N | −3 | 346 | Inorganic |

| ATS-3 | −3 | 330 | Inorganic |

| PureTemp-2 | −2 | 277 | Bio-based organic |

| E-2 | −2 | 325 | Inorganic |

| RT0 | 0 | 175 | Organic |

| E0 | 0 | 395 | Inorganic |

| va-Q-accu + 00G | 0 | 330 | n.a. |

| HS01 | 1 | 350 | Inorganic |

| A2 | 2 | 230 | Organic |

| ATP 2 | 2 | 215 | Organic |

| RT2 HC | 2 | 200 | Organic |

| SP5 gel | 2 to 7 | 155 | Inorganic |

| va-Q-accu + 05G | 2 to 8 | 240 | n.a. |

| OM03 | 3 | 229 | Organic |

| FS03 | 3 | 161 | Organic (fatty acid) |

| RT3 HC | 3 | 190 | Organic |

| A3 | 3 | 230 | Organic |

| RT4 | 4 | 175 | Organic |

| PureTemp 4 | 5 | 187 | Organic |

| A4 | 4 | 235 | Organic |

| RT5 | 5 | 180 | Organic |

| RT5 HC | 5 | 250 | Organic |

| OM05P | 5 | 216 | Organic |

| A5 | 5 | 170 | Organic |

| CrodaTherm 5 | 5 | 191 | Bio-based organic |

| SP7 gel | 5 to 8 | 155 | Inorganic |

| ATP 6 | 6 | 275 | Organic |

| A6 | 6 | 185 | Organic |

| A6.5 | 6.5 | 190 | Organic |

| CrodaTherm 6.5 | 6.8 | 184 | Organic plant-based |

| Gaia OM PCM7 | 7 | 180 | Organic |

| ClimSel C7 | 8 | 123 | Inorganic |

| A7 | 7 | 190 | Organic |

| PureTemp 8 | 8 | 178 | Organic |

| OM08 | 8 | 175 | Organic |

| RT8 | 8 | 175 | Organic |

| RT8 HC | 8 | 190 | Organic |

| S8 | 8 | 130 | Inorganic |

| A8 | 8 | 180 | Organic |

| A9 | 9 | 190 | Organic |

| CrodaTherm 9.5 | 9.7 | 186 | Bio-based organic |

| RT10 | 10 | 160 | Organic |

| RT10 HC | 10 | 200 | Organic |

| A10 | 10 | 210 | Organic |

| S10 | 10 | 170 | Inorganic |

| SP9 gel | 10 to 11 | 155 | Inorganic |

| Category | Property |

|---|---|

| Thermal | Suitable phase change temperature; High latent heat capacity; Good heat transfer characteristics |

| Physical | Favorable phase equilibrium; High density; Small volume change; Low vapour pressure |

| Kinetic | No supercooling; Sufficient crystallisation rate |

| Chemical | Long term stability; Compatibility of PCM with other materials; No toxicity; No flammability concerns |

| Economic and environmental | Abundant; Available; Cost-effective; Good recyclability |

| Application | Theoretical (T) Experimental (E) | PCM (Tmelting (°C)) | Main Results | Reference |

|---|---|---|---|---|

| Wall for refrigerated vehicle | E | RT5 (5) | Peak shift (2 to 2.5 h); Peak heat transfer reduction (29.1%); Average heat transfer reduction (16.3%) | Ahmed et al., 2010 |

| Wall for refrigerated vehicle | T/E | Energain PCM panel (21) | Average heat transfer reduction daytime (25%) | Glouannec et al., 2014 |

| Wall of 20 ft ISO container | T/E | RT35HC (35) | Peak shift (3 h); Peak heat transfer reduction (20%); Average heat transfer reduction (about 4.5%) | Copertaro et al., 2016 |

| Wall for refrigerated vehicle | T/E | RT35HC (35) | Peak shift (3.5 to 4.5 h); Peak heat transfer reduction (5.5 to 8.5%) | Fioretti et al., 2016 |

| Wall for refrigerated vehicle | T/E | Composite PU/PCM C18 Inertek (18) | Average heat transfer reduction (0.3 to 4.1%) | Michel et al., 2017 |

| Storage container for cold/hot food | T/E | RT-2 (2); PT-15 (−15); PT-63 (63) | Increase in storage time (320% to 400%) | Oró et al., 2013 |

| Storage container for ice cream | T/E | E-21 (−21) | Decrease in product temperature when stored in room temperature (10 K) | Oró et al., 2013 |

| Storage container for ice cream | E | E-21 (−21) | Decrease in product surface temperature during heat load test (17 K) | Leducq et al., 2015 |

| Packaging for chilled food | T/E | RT5 (5) | Increase in thermal buffering capacity; Increased shelf life of ham (6.7%) | Hoang et al., 2015 |

| Packaging for blood bags | E | Mixture of n-alkanes (4.8) | Correct storage temperature for 6 h (8 times increase) | Mondieig et al., 2003 |

| PCM-HEX system for refrigerated transport | T/E | Inorganic salt-water solution (−26.8) | Reduction in annual cost (51 to 86.4%); Storage space kept at −18 °C for 10 h | Liu et al., 2012; Liu et al., 2014 |

| Insulating Material | |

|---|---|

| Polyurethane (PU) | 0.022–0.028 |

| Reflective Multi-Foil | 0.035 |

| Aerogel | 0.0217 |

| Vacuum insulation Panel | 0.002–0.004 |

| Polypropilene + nanoclay | 0.123–0.293 |

| Model | Equation |

|---|---|

| Brown-Solvason (1963) | |

| Tamm (1966) | |

| Fritzsche-Lilienblum (1968) | |

| Gosney-Olama (1975) | |

| Pham-Oliver (1983) | |

| Jones et al. (1983) | |

| Wilson-Kiel (1990) | |

| Authors | Application |

|---|---|

| Kayansayan et al., 2017 | Numerical analysis of heat transfer inside a refrigerated container. The effects of “the container shape factor, the inlet air slot width, and the Reynolds number of supplied cold air on the temperature distribution” [97] were analyzed. |

| Jara et al., 2019 | A numerical analysis of the temperature distribution inside a refrigerated vehicle in transient conditions, without load, was carried out [98]. |

| Radebe et al., 2019 | A 3D model, including the turbulence RSM, was used to measure the temperature distribution and the velocity of natural convection airflow inside a refrigerated vehicle equipped with eutectic plates at a temperature of −18 °C. Three different configurations were considered [43]. |

| Jiang et al., 2020 | The effect of the presence of fruit stacks on the distribution of cooling capacity inside the compartment was analyzed. In addition, the positive effect of adding baffles that can improve the cold air flow through the products was evaluated. The fruit stacks were simplified to be porous medium [99]. |

| Li et al., 2020 | The temperature distribution in a container was evaluated. Four velocities and four locations of the fan were considered and the performance obtained were compared to explore the influence of different operating parameters on temperature distribution [94]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maiorino, A.; Petruzziello, F.; Aprea, C. Refrigerated Transport: State of the Art, Technical Issues, Innovations and Challenges for Sustainability. Energies 2021, 14, 7237. https://doi.org/10.3390/en14217237

Maiorino A, Petruzziello F, Aprea C. Refrigerated Transport: State of the Art, Technical Issues, Innovations and Challenges for Sustainability. Energies. 2021; 14(21):7237. https://doi.org/10.3390/en14217237

Chicago/Turabian StyleMaiorino, Angelo, Fabio Petruzziello, and Ciro Aprea. 2021. "Refrigerated Transport: State of the Art, Technical Issues, Innovations and Challenges for Sustainability" Energies 14, no. 21: 7237. https://doi.org/10.3390/en14217237

APA StyleMaiorino, A., Petruzziello, F., & Aprea, C. (2021). Refrigerated Transport: State of the Art, Technical Issues, Innovations and Challenges for Sustainability. Energies, 14(21), 7237. https://doi.org/10.3390/en14217237