Optimization of Integrated Gasification Combined-Cycle Power Plant for Polygeneration of Power and Chemicals

Abstract

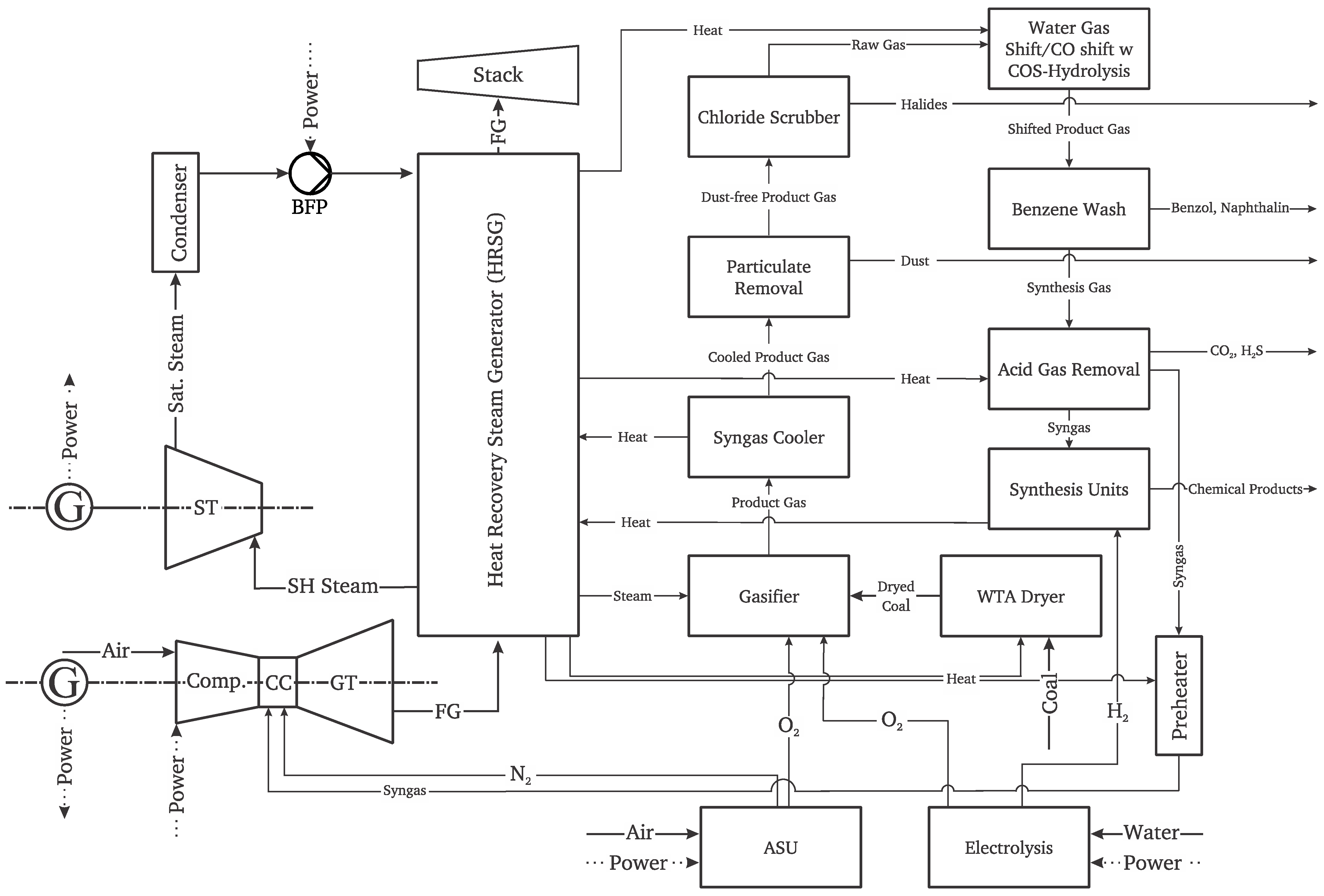

:1. Introduction

- To validate the model calculations against measurement data obtained from a real natural gas-fired combined cycle power plant (NGCC).

- To modify the model for the use of syngas by the gas turbine instead of natural gas.

- To integrate steam extractions for the heat integration of the syngas generation process into the model.

- To optimize the suggested modifications regarding to the output of the steam turbine.

- To perform an energy analysis to achieve the optimal result from the proposed optimizations.

- To conduct a sensitivity analysis to evaluate the impact of varying the mass flow rate of steam extraction on the output of the IGCC.

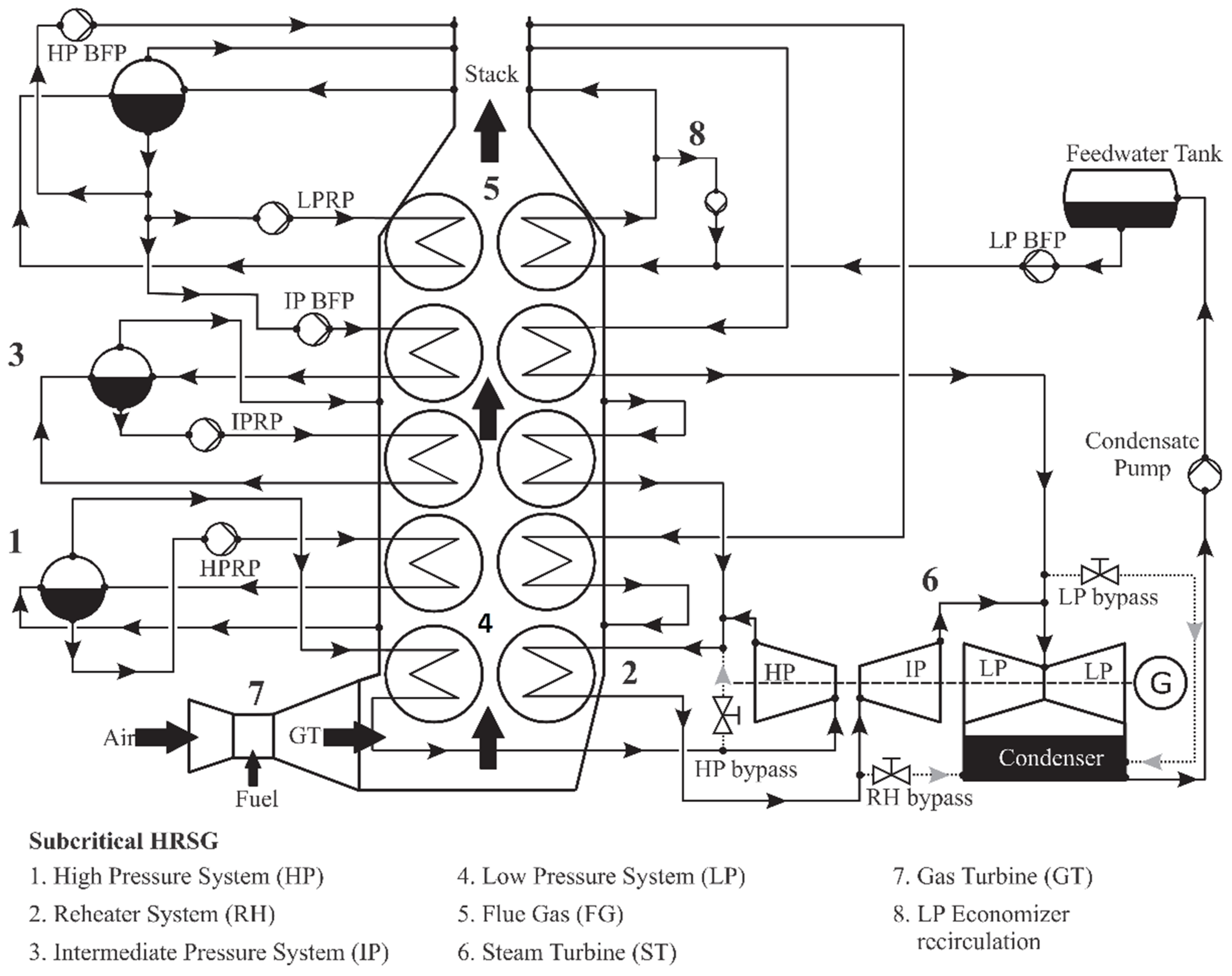

2. Reference Combined-Cycle Power Plant

3. Process Simulation Software

3.1. Heat Exchanger

3.2. Pump

3.3. Steam Turbine

3.4. Throttle

4. Description of Process Flow Simulation Model

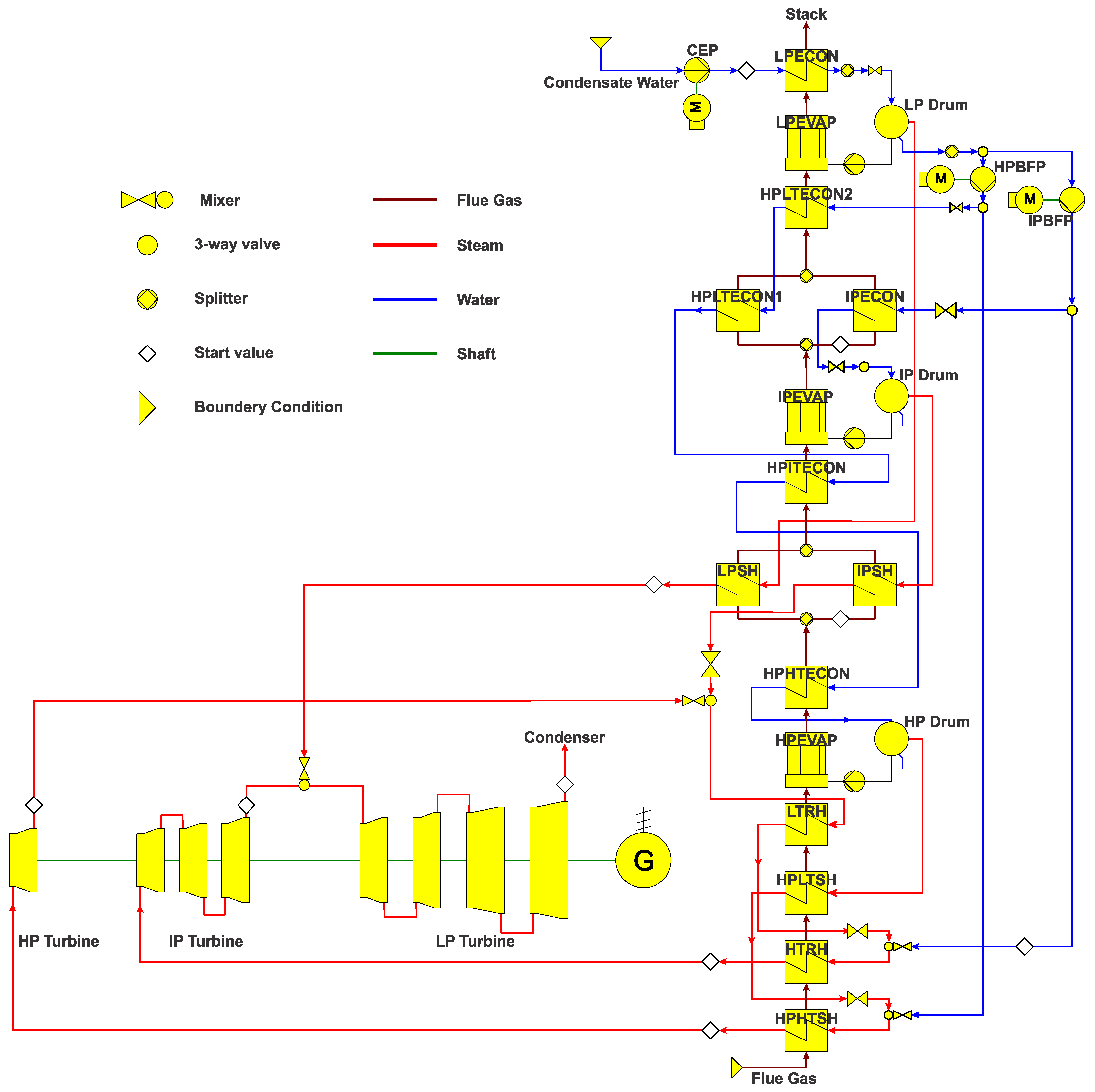

4.1. HRSG Simulation Model

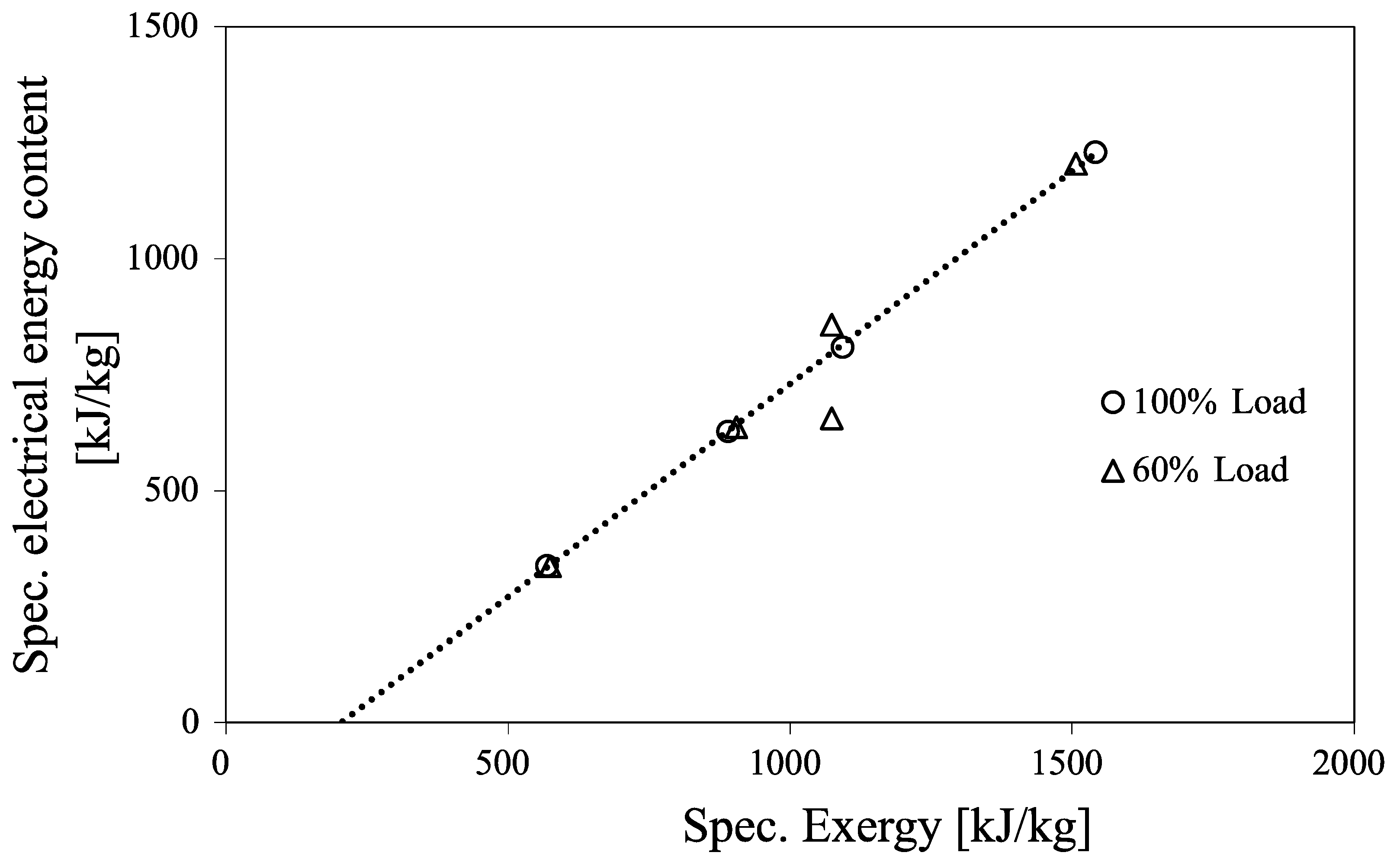

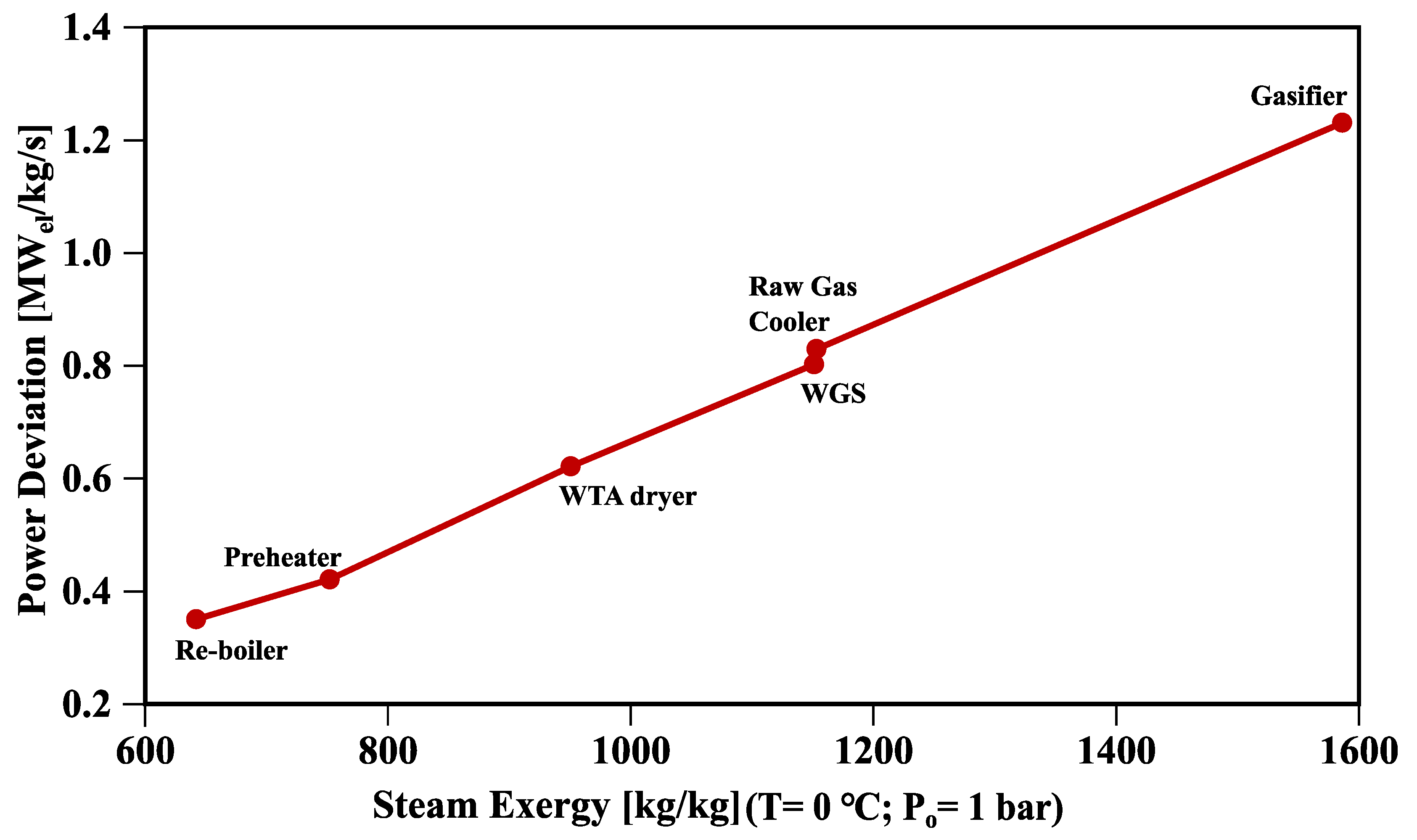

4.2. Heat Integration

5. Validation and Modification

5.1. Validation

5.2. Modification for Synthesis Gas Turbine

6. Results and Evaluation

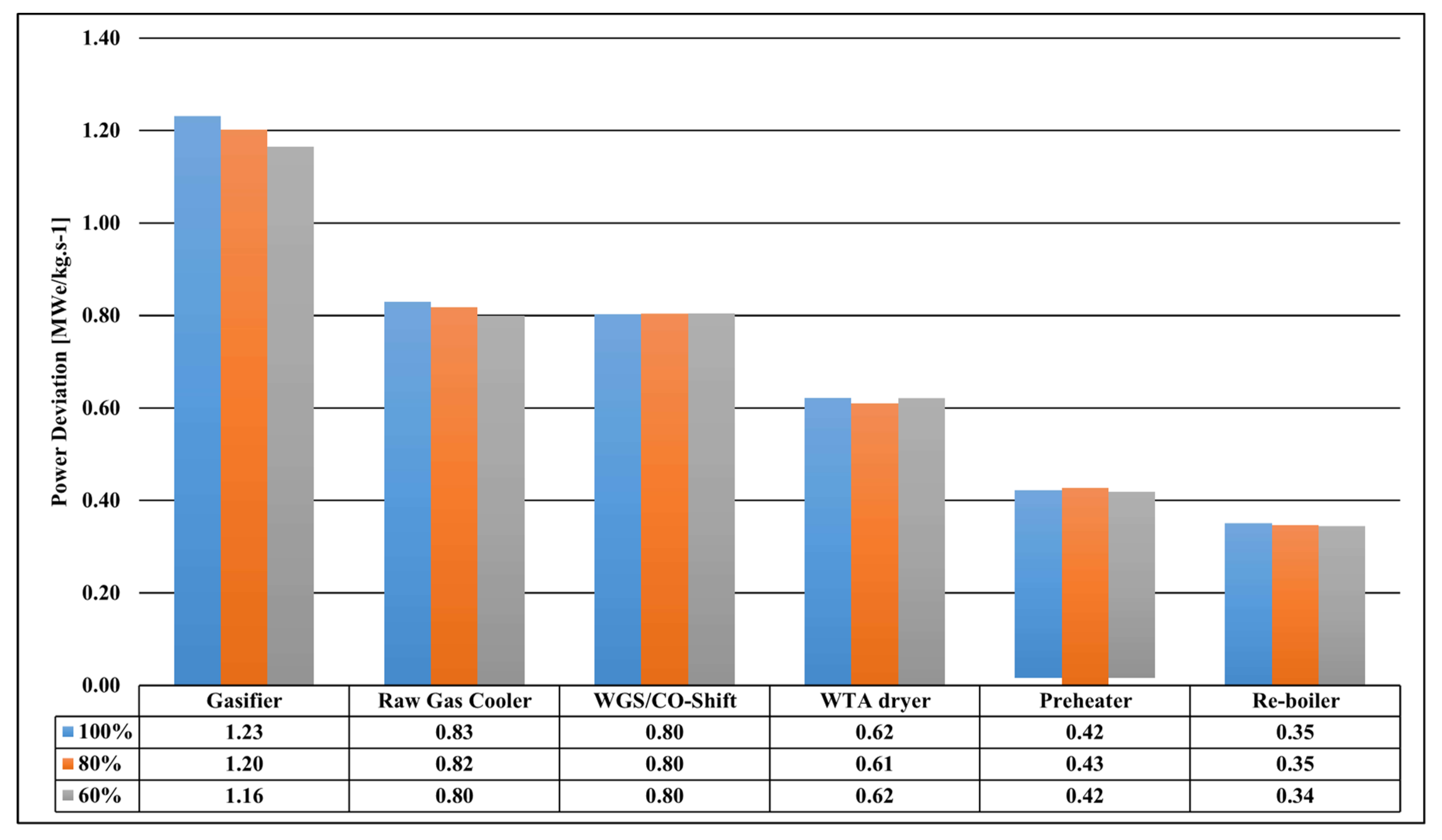

6.1. Integration of the Predefined Extractions

6.2. Optimization of Predefined Extractions

6.2.1. Optimization of WTA Dryer Extraction

6.2.2. Optimization of Gas Preheating and Acid Gas Removal Extractions

6.2.3. Optimization of Gasifier and WGS Extractions

6.2.4. Modification of the Intermediate Pressure System

6.2.5. Variation of the Gasifier and WGS Extractions

6.2.6. Optimizing the Heat Input of the Raw Gas Cooler

6.2.7. Optimized Model

6.3. Assessment of the Optimizations

7. Conclusions

- The numerical model created in EBSILON Professional can quantitatively represent the real plant in the different load cases. Especially for the values of pressure and temperature, relative errors below 1% were found. For the mass flow, there were somewhat higher deviations from the measured data. For this reason, the performance of the steam turbine of the model was compared to the performance of the steam turbine under the conditions of the measurements. This resulted in relative errors below 5% in all load cases. Thus, the model was considered valid.

- The model was successfully modified to use synthesis gas, and predefined extractions were integrated. The output of the steam turbine of the model was 71.3 MWel at 100% load, 54.6 MWel at 80% load, and 39.6 MWel at 60% load. These values were selected as reference values for the optimization.

- The optimization allowed the output of the steam turbine to be significantly increased in all three load cases. In the 100% load case, there was a relative increase in output of the steam turbine of 34.2% with an output value of 95.7 MWel. The output increase at 80% load was 35.9% (74.2 MWel) and at 60% load 45.9% (57.8 MWel).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AGR | Acid Gas Removal |

| CCPP | Combined Cycle Power Plant |

| ECON | Economizer |

| EVAP | Evaporator |

| FG | Flue Gas |

| FW | Feedwater |

| G | Generator |

| GT | Gas Turbine |

| GUI | Graphical user interface |

| HP | High Pressure |

| HRSG | Heat Recovery Steam Generator |

| HT | High Temperature |

| IGCC | Integrated Gasification Combined Cycle |

| IP | Intermediate Pressure |

| LP | Low Pressure |

| RH | Reheater |

| SH | Superheater |

| ST | Steam Turbine |

| TTD | Terminal Temperature Difference |

| WGS | Water Gas Shift |

| WTA | Fluidized-Bed Drying Process |

References

- Arto, I.; Capellán-Pérez, I.; Lago, R.; Bueno, G.; Bermejo, R. The energy requirements of a developed world. Energy Sustain. Dev. 2016, 33, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Klare, M.T. Rising Powers, Shrinking Planet: The New Geopolitics of Energy; Henry Holt and Co.: New York, NY, USA, 2009. [Google Scholar]

- Lambert, J.G.; Hall, C.A.S.; Balogh, S.; Gupta, A.; Arnold, M. Energy, EROI and quality of life. Energy Policy 2014, 64, 153–167. [Google Scholar] [CrossRef] [Green Version]

- Di Muzio, T. Energy, Capital as Power and World Order. In The Palgrave Handbook of Critical International Political Economy; Palgrave Macmillan: London, UK, 2016; pp. 267–287. [Google Scholar] [CrossRef] [Green Version]

- IEA. Global Energy Review 2020; IEA: Paris, France, 2020. [Google Scholar]

- IEA. CO2 Emissions from Fuel Combustion: Overview; IEA: Paris, France, 2020. [Google Scholar]

- Dröge, S. The Paris Agreement 2015, Turning Point for the International Climate Regime; Stiftung Wissenschaft und Politik -SWP- Deutsches Institut für Internationale Politik und Sicherheit: Berlin, Germany, 2016; Volume 4. [Google Scholar]

- Lund, H. Large-scale integration of wind power into different energy systems. Energy 2005, 30, 2402–2412. [Google Scholar] [CrossRef]

- Alshahrani, A.; Omer, S.; Su, Y.; Mohamed, E.; Alotaibi, S. The Technical Challenges Facing the Integration of Small-Scale and Large-scale PV Systems into the Grid: A Critical Review. Electronics 2019, 8, 1443. [Google Scholar] [CrossRef] [Green Version]

- Verzijlbergh, R.A.; De Vries, L.J.; Dijkema, G.P.J.; Herder, P.M. Institutional challenges caused by the integration of renewable energy sources in the European electricity sector. Renew. Sustain. Energy Rev. 2017, 75, 660–667. [Google Scholar] [CrossRef] [Green Version]

- Parraga, J.; Khalilpour, K.R.; Vassallo, A. Polyfeed and polyproduct integrated gasification systems. In Polygeneration with Polystorage: For Chemical and Energy Hubs; Elsevier: Amsterdam, The Netherlands, 2018; pp. 175–212. [Google Scholar] [CrossRef]

- Shi, B.; Wen, F.; Wu, W. Performance evaluation of air-blown IGCC polygeneration plants using chemical looping hydrogen generation and methanol synthesis loop. Energy 2020, 200, 117564. [Google Scholar] [CrossRef]

- Cocco, D.; Serra, F.; Tola, V. Assessment of energy and economic benefits arising from syngas storage in IGCC power plants. Energy 2013, 58, 635–643. [Google Scholar] [CrossRef]

- Liu, G.; Larson, E.D.; Williams, R.H.; Kreutz, T.G.; Guo, X. Making Fischer-Tropsch Fuels and Electricity from Coal and Biomass: Performance and Cost Analysis. Energy Fuels 2011, 25, 415–437. [Google Scholar] [CrossRef]

- Liu, P.; Gerogiorgis, D.I.; Pistikopoulos, E.N. Modeling and optimization of polygeneration energy systems. Catal. Today 2007, 127, 347–359. [Google Scholar] [CrossRef]

- Hoang, T.-D.; Pawluskiewicz, D.K.; Kazimierz Pawluskiewicz, D. The efficiency analysis of different combined cycle power plants based on the impact of selected parameters Optimization of Rotor bearing systems View project Optimal geometrics of an air cooled heat sink View project The efficiency analysis of different combined cycle power plants based on the impact of selected parameters. Artic. Int. J. Smart Grid Clean Energy 2016. [Google Scholar] [CrossRef]

- Descamps, C.; Bouallou, C.; Kanniche, M. Efficiency of an Integrated Gasification Combined Cycle (IGCC) power plant including CO2 removal. Energy 2008, 33, 874–881. [Google Scholar] [CrossRef]

- Gräbner, M.; Morstein, O.; von Rappold, D.; Günster, W.; Beysel, G.; Meyer, B. Constructability study on a German reference IGCC power plant with and without CO2-capture for hard coal and lignite. Energy Convers. Manag. 2010, 51, 2179–2187. [Google Scholar] [CrossRef]

- Higman, C.; van der Burgt, M. Gasification; Elsevier Inc.: Amsterdam, The Netherlands, 2008. [Google Scholar] [CrossRef]

- Wang, T.; Stiegel, G. Integrated Gasification Combined Cycle (IGCC) Technologies; Elsevier Inc.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Gonzalez-Salazar, M.A.; Kirsten, T.; Prchlik, L. Review of the operational flexibility and emissions of gas- and coal-fired power plants in a future with growing renewables. Renew. Sustain. Energy Rev. 2018, 82, 1497–1513. [Google Scholar] [CrossRef]

- Heinze, C.; May, J.; Peters, J.; Ströhle, J.; Epple, B. Techno-economic assessment of polygeneration based on fluidized bed gasification. Fuel 2019, 250, 285–291. [Google Scholar] [CrossRef]

- Segurado, R.; Pereira, S.; Correia, D.; Costa, M. Techno-economic analysis of a trigeneration system based on biomass gasification. Renew. Sustain. Energy Rev. 2019, 103, 501–514. [Google Scholar] [CrossRef]

- Shi, B.; Xu, W.; Wu, E.; Wu, W.; Kuo, P.C. Novel design of integrated gasification combined cycle (IGCC) power plants with CO2 capture. J. Clean. Prod. 2018, 195, 176–186. [Google Scholar] [CrossRef]

- Giuffrida, A.; Romano, M.C.; Lozza, G. Efficiency enhancement in IGCC power plants with air-blown gasification and hot gas clean-up. Energy 2013, 53, 221–229. [Google Scholar] [CrossRef]

- Cormos, C.C. Evaluation of energy integration aspects for IGCC-based hydrogen and electricity co-production with carbon capture and storage. Int. J. Hydrogen Energy 2010, 35, 7485–7497. [Google Scholar] [CrossRef]

- Gaspar, J.; Cormos, A.M. Dynamic modeling and absorption capacity assessment of CO2 capture process. Int. J. Greenh. Gas Control. 2012, 8, 45–55. [Google Scholar] [CrossRef]

- Lee, J.C.; Lee, H.H.; Joo, Y.J.; Lee, C.H.; Oh, M. Process simulation and thermodynamic analysis of an IGCC (integrated gasification combined cycle) plant with an entrained coal gasifier. Energy 2014, 64, 58–68. [Google Scholar] [CrossRef]

- Lee, C.; Lee, S.J.; Yun, Y. Effect of air separation unit integration on integrated gasification combined cycle performance and NOx emission characteristics. Korean J. Chem. Eng. 2007, 24, 368–373. [Google Scholar] [CrossRef]

- Gharaie, M.; Jobson, M.; Panjeshahi, M.H.; Zhang, N.; Smith, R. Techno-economic optimization of IGCC integrated with utility system for CO2 emissions reduction—Simultaneous heat and power generation from IGCC. Chem. Eng. Res. Des. 2015, 94, 428–439. [Google Scholar] [CrossRef]

- Frey, H.C.; Zhu, Y. Improved System Integration for Integrated Gasification Combined Cycle (IGCC) Systems. Environ. Sci. Technol. 2006, 40, 1693–1699. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhang, R.; Liu, H.; Gao, H.; Liang, Z. Evaluating CO2 desorption performance in CO2-loaded aqueous tri-solvent blend amines with and without solid acid catalysts. Appl. Energy 2018, 218, 417–429. [Google Scholar] [CrossRef]

- Mondol, J.D.; McIlveen-Wright, D.; Rezvani, S.; Huang, Y.; Hewitt, N. Techno-economic evaluation of advanced IGCC lignite coal fuelled power plants with CO2 capture. Fuel 2009, 88, 2495–2506. [Google Scholar] [CrossRef]

- Majoumerd, M.M.; Raas, H.; Jana, K.; De, S.; Assadi, M. Coal Quality Effects on the Performance of an IGCC Power Plant with CO2 Capture in India. Energy Procedia 2017, 114, 6478–6489. [Google Scholar] [CrossRef]

- Li, Z.; Liang, X.; Xue, Y. Techno-economic comparison of IGCC systems employing bituminous and lignite. Zhongguo Dianji Gongcheng Xuebao. Chin. Soc. Electr. Eng. 2012, 32, 39–47. [Google Scholar]

- Bonalumi, D.; Ciavatta, A.; Giuffrida, A. Thermodynamic Assessment of Cooled and Chilled Ammonia-based CO2 Capture in Air-Blown IGCC Plants. Energy Procedia 2016, 86, 272–281. [Google Scholar] [CrossRef] [Green Version]

- Sheikh, H.M.; Ullah, A.; Hong, K.; Zaman, M. Thermo-economic analysis of integrated gasification combined cycle (IGCC) power plant with carbon capture. Chem. Eng. Process.-Process. Intensif. 2018, 128, 53–62. [Google Scholar] [CrossRef]

- Sofia, D.; Coca Llano, P.; Giuliano, A.; Iborra Hernández, M.; García Peña, F.; Barletta, D. Co-gasification of coal–petcoke and biomass in the Puertollano IGCC power plant. Chem. Eng. Res. Des. 2014, 92, 1428–1440. [Google Scholar] [CrossRef]

- Thallam Thattai, A.; Oldenbroek, V.; Schoenmakers, L.; Woudstra, T.; Aravind, P.V. Experimental model validation and thermodynamic assessment on high percentage (up to 70%) biomass co-gasification at the 253 MWe integrated gasification combined cycle power plant in Buggenum, The Netherlands. Appl. Energy 2016, 168, 381–393. [Google Scholar] [CrossRef] [Green Version]

- Cormos, C.C. Integrated assessment of IGCC power generation technology with carbon capture and storage (CCS). Energy 2012, 42, 434–445. [Google Scholar] [CrossRef]

- Cau, G.; Tola, V.; Deiana, P. Comparative performance assessment of USC and IGCC power plants integrated with CO2 capture systems. Fuel 2014, 116, 820–833. [Google Scholar] [CrossRef]

- Bany Ata, A.; Alobaid, F.; Heinze, C.; Almoslh, A.; Sanfeliu, A.; Epple, B. Comparison and validation of three process simulation programs during warm start-up procedure of a combined cycle power plant. Energy Convers. Manag. 2020, 207, 112547. [Google Scholar] [CrossRef]

- Alobaid, F.; Postler, R.; Ströhle, J.; Epple, B.; Kim, H.G. Modeling and investigation start-up procedures of a combined cycle power plant. Appl. Energy 2008, 85, 1173–1189. [Google Scholar] [CrossRef]

- Alobaid, F.; Karner, K.; Belz, J.; Epple, B.; Kim, H.G. Numerical and experimental study of a heat recovery steam generator during start-up procedure. Energy 2014, 64, 1057–1070. [Google Scholar] [CrossRef]

- GmbH SES. STEAG EBSILON n.d. Available online: https://www.ebsilon.com/en/ (accessed on 17 February 2021).

- GmbH SES. EBSILON® Professional The Planning Tool for the Power Plant Process; STEAG Energy Services GmbH: Zwingenberg, Germany, 2021. [Google Scholar]

- Wolfersdorf, C.; Meyer, B. The current status and future prospects for IGCC systems. In Integrated Gasification Combined Cycle (IGCC) Technologies; Woodhead Publishing: Sawston, UK, 2017; pp. 847–889. [Google Scholar] [CrossRef]

- Gadde, S.; Wu, J.; Gulati, A.; McQuiggan, G.; Koestlin, B.; Prade, B. Syngas capable combustion systems development for advanced gas turbines. In Proceedings of the ASME Turbo Expo, Barcelona, Spain, 6–11 May 2006; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2006; Volume 4, pp. 547–554. [Google Scholar] [CrossRef] [Green Version]

- Daniel Brdar, R.; Jones, R.M. GE Power Systems GE IGCC Technology and Experience with Advanced Gas Turbines; GE Power Systems: Schenectady, NY, USA, 2000. [Google Scholar]

| HRSG Outlet Steam Parameters | |||

|---|---|---|---|

| Pressure (bar) | Temperature (°C) | Mass Flowrate (kg/s) | |

| HP | 97.7 | 567 | 78.2 |

| RH/IP | 21.4 | 567 | 83.2 |

| LP | 4.1 | 293 | 9.8 |

| Condenser | 0.052 | 35 | 93 |

| Flue gas parameters | |||

| Mass flowrate (kg/s) | 587 | ||

| Temperature (°C) | Inlet | 628 | |

| Outlet | 81 | ||

| Power generation units | |||

| Gas turbine power (MWel) | 220 | ||

| Steam turbine power (MWel) | 140 | ||

| Extraction | Presser (bar) | Temperature (°C) |

|---|---|---|

| Steam extraction | ||

| WTA drying | 4.2 | Sat. Steam |

| HTW gasifier | 35 | 560 |

| Water-gas shift | 35 | Sat. Steam |

| Heat consumers | ||

| Acid gas removal (reboiler) | Sat. Steam | 90 |

| Preheating gas turbine | 180 | |

| Heat suppliers | ||

| Raw gas cooler | Sat. Steam | <260 |

| Methanol synthesis | Sat. Steam | <260 |

| Load | 100% | 80% | 60% | |

|---|---|---|---|---|

| Mass flow rate (kg/s) | Operational Data | 78.20 | 66.90 | 58.30 |

| Simulation Results | 77.63 | 65.81 | 57.34 | |

| Relative Error | −0.73% | −1.63% | −1.65% | |

| Temperature (°C) | Operational Data | 567.00 | 566.80 | 566.90 |

| Simulation Results | 567.00 | 567.00 | 567.00 | |

| Relative Error | 0.00% | 0.04% | 0.02% | |

| Pressure (bar) | Operational Data | 97.70 | 88.00 | 76.20 |

| Simulation Results | 97.70 | 88.00 | 76.20 | |

| Relative Error | 0% | 0% | 0% | |

| Load | 100% | 80% | 60% | |

|---|---|---|---|---|

| Mass flow rate (kg/s) | Operational Data | 83.2 | 74.7 | 64.9 |

| Simulation Results | 83.53 | 74.86 | 63.31 | |

| Relative Error | 0.40% | 0.21% | −2.45% | |

| Temperature (°C) | Operational Data | 567 | 567 | 566.9 |

| Simulation Results | 567 | 567 | 567 | |

| Relative Error | 0.00% | 0.00% | 0.02% | |

| Pressure (bar) | Operational Data | 21.4 | 20.6 | 17.7 |

| Simulation Results | 21.4 | 20.6 | 17.7 | |

| Relative Error | 0% | 0% | 0% | |

| Load | 100% | 80% | 60% | |

|---|---|---|---|---|

| Mass flow rate (kg/s) | Operational Data | 9.8 | 7.7 | 6.4 |

| Simulation Results | 9.93 | 8.31 | 6.757 | |

| Relative Error | 1.33% | 7.92% | 5.58% | |

| Temperature (°C) | Operational Data | 293 | 289.9 | 281 |

| Simulation Results | 292.52 | 289.91 | 282 | |

| Relative Error | −0.16% | 0.00% | 0.36% | |

| Pressure (bar) | Operational Data | 4.1 | 3.9 | 3.3 |

| Simulation Results | 4.1 | 3.9 | 3.3 | |

| Relative Error | 0% | 0% | 0% | |

| Load | Operational Data | Simulation Results | Relative Error |

|---|---|---|---|

| 100% | 131.82 | 133.83 | 1.52% |

| 80% | 114.41 | 113.26 | −1.01% |

| 60% | 96.08 | 93.86 | −2.31% |

| Load | With Synthetic GT | With Natural Gas GT | Deviation |

|---|---|---|---|

| 100% | 128.27 | 133.83 | −4.15% |

| 80% | 109.62 | 113.26 | −3.21% |

| 60% | 94.57 | 93.86 | +0.76 |

| Extractions | Temperature (°C) | Pressure (bar) | Mass Flow Rate (kg/s) |

|---|---|---|---|

| WTA dryer | 145.44 | 4.2 | 56.46 |

| Gasifier | 560 | 96 | 5.02 |

| WGS/CO shift | 242.58 | 35 | 21.55 |

| Extractions | Power (MWth) | Minimum Temperature (°C) |

|---|---|---|

| CO2 HP Reboiler | 9.66 | 26.75 |

| CO2 LP Reboiler | 4.35 | 21.35 |

| H2S Reboiler | 21.48 | 65.01 |

| Gas preheater | 48.73 | 160 |

| Load | ST Power (MWel) |

|---|---|

| 100% | 71.3 |

| 80% | 54.6 |

| 60% | 39.6 |

| Load | Reference Output | Modified Model Output | Improvement |

|---|---|---|---|

| 100% | 71.31 | 78.46 | +10.0% |

| 80% | 54.64 | 61.71 | +12.9% |

| 60% | 39.67 | 46.74 | +17.8% |

| Load | Reference Output | Modified Pressure Model Output | Improvement (%) |

|---|---|---|---|

| 100% | 128.27 | 125.95 | −1.04% |

| 80% | 109.62 | 98.79 | −5.62% |

| 60% | 94.57 | 83.09 | −9.85% |

| Load | Reference Output | Modified Model Output | Improvement |

|---|---|---|---|

| 100% | 71.3 | 95.7 | +34.2% |

| 80% | 54.6 | 74.2 | +35.9% |

| 60% | 39.6 | 57.8 | +45.9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bany Ata, A.; Seufert, P.M.; Heinze, C.; Alobaid, F.; Epple, B. Optimization of Integrated Gasification Combined-Cycle Power Plant for Polygeneration of Power and Chemicals. Energies 2021, 14, 7285. https://doi.org/10.3390/en14217285

Bany Ata A, Seufert PM, Heinze C, Alobaid F, Epple B. Optimization of Integrated Gasification Combined-Cycle Power Plant for Polygeneration of Power and Chemicals. Energies. 2021; 14(21):7285. https://doi.org/10.3390/en14217285

Chicago/Turabian StyleBany Ata, Ammar, Peter Maximilian Seufert, Christian Heinze, Falah Alobaid, and Bernd Epple. 2021. "Optimization of Integrated Gasification Combined-Cycle Power Plant for Polygeneration of Power and Chemicals" Energies 14, no. 21: 7285. https://doi.org/10.3390/en14217285

APA StyleBany Ata, A., Seufert, P. M., Heinze, C., Alobaid, F., & Epple, B. (2021). Optimization of Integrated Gasification Combined-Cycle Power Plant for Polygeneration of Power and Chemicals. Energies, 14(21), 7285. https://doi.org/10.3390/en14217285