3.1. Electric Generation System Configurations

Four electric generation system configurations will be considered, which are as follows (Note that no solar tracking system has been assumed, which represents the worst-case solar energy harvesting from a cell-site; later in this work, a dual-axis solar tracking system will be incorporated into the system design for comparative purposes):

PV-diesel generator with a battery bank (PV-DG-BB): In this configuration, the PV panels will be supplemented with a DG and a battery bank. The DG will be used to charge the battery, supplement the BS load, or serve as a back-up in the case of a system malfunction, maintenance, or insufficient solar energy.

PV with a battery bank (PV-BB): This configuration is mainly based on using PV panels with a battery bank, while the DG will not be used.

DG with a battery bank (DG-BB): In this configuration, the DG will be used along with a battery bank, and the PV panels will not be utilized.

DG without a battery bank (DG-WBB): This configuration relies solely on the DG to power the base station.

The operation modes of the PV-based electric generation system configurations are as follows [

51]:

- Mode 1:

This mode resembles the normal operation of a PV-based system configuration, in which it feeds the required energy to the BS and stores the excess energy in the battery bank for later use (e.g., at night, or when the output power of the PV panels is insufficient to cover the load).

- Mode 2:

In this mode, the output power of the PV panels is insufficient to cover the load. Specifically, this may happen when the PV panels malfunction, and the battery bank compensates for the shortage in energy. In the case when the battery bank is insufficient to cover the load (i.e., maximum DoD is reached), a backup system (i.e., the diesel generator) is used to supply energy to the BS, as in the PV-DG-BB configuration.

It should be noted that the DG-BB and DG-WBB configurations represent conventional electric generation systems for current DG-powered cellular base stations. In case the DG malfunctions or runs out of fuel, the BB supplies energy to the base station in the DG-BB configuration; however, this is not the case for the DG-WBB configuration, which leads to cellular network coverage outage. Lastly, and for comparative purposes, the designated system configurations will be analyzed in terms of NPC, COE, CO emissions (In this paper, the indirect CO emissions (i.e., emissions resulting from the manufacturing process) are neglected.), and overall area.

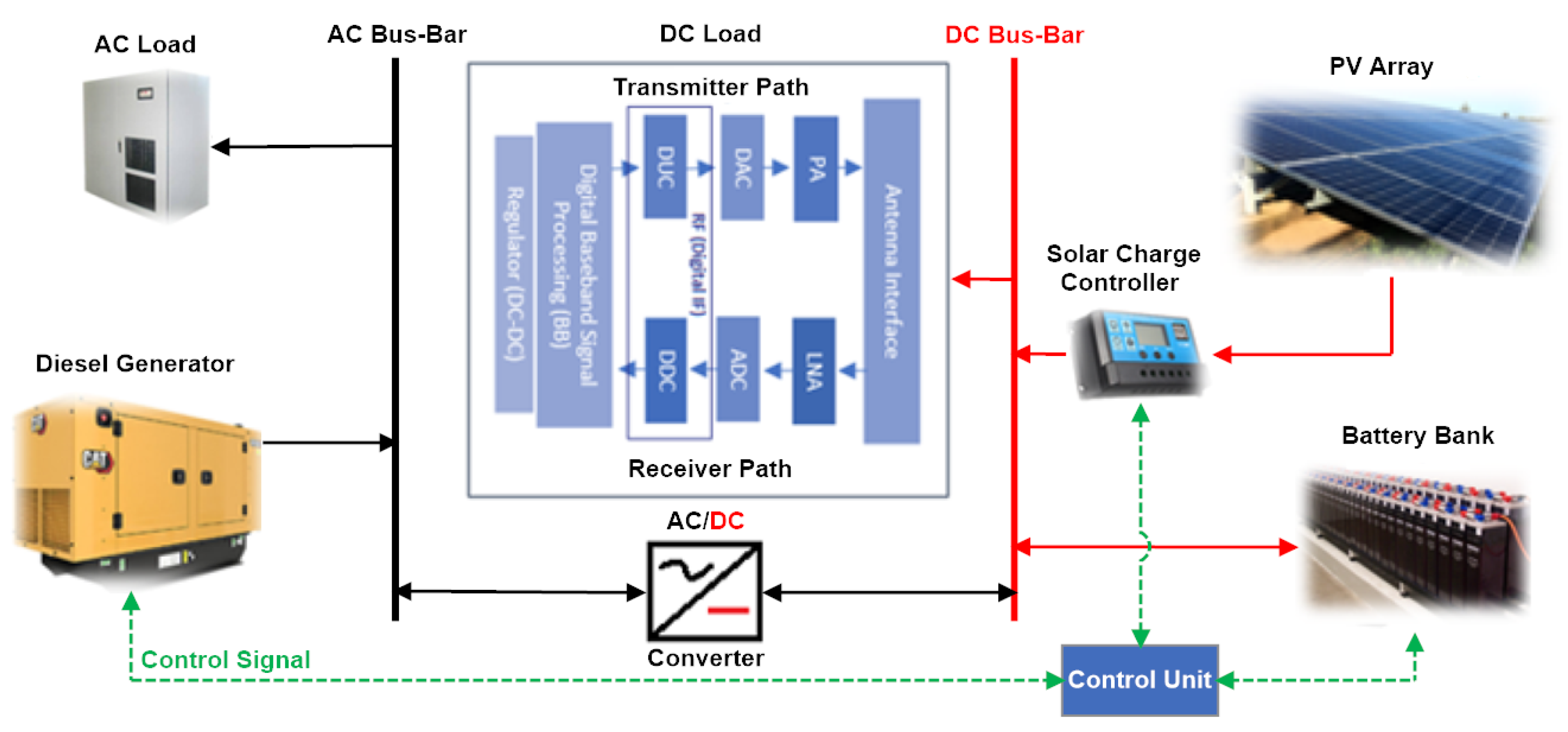

The simulated system design in HOMER is illustrated in

Figure 4.

3.2. Cell-Site and Load Profile

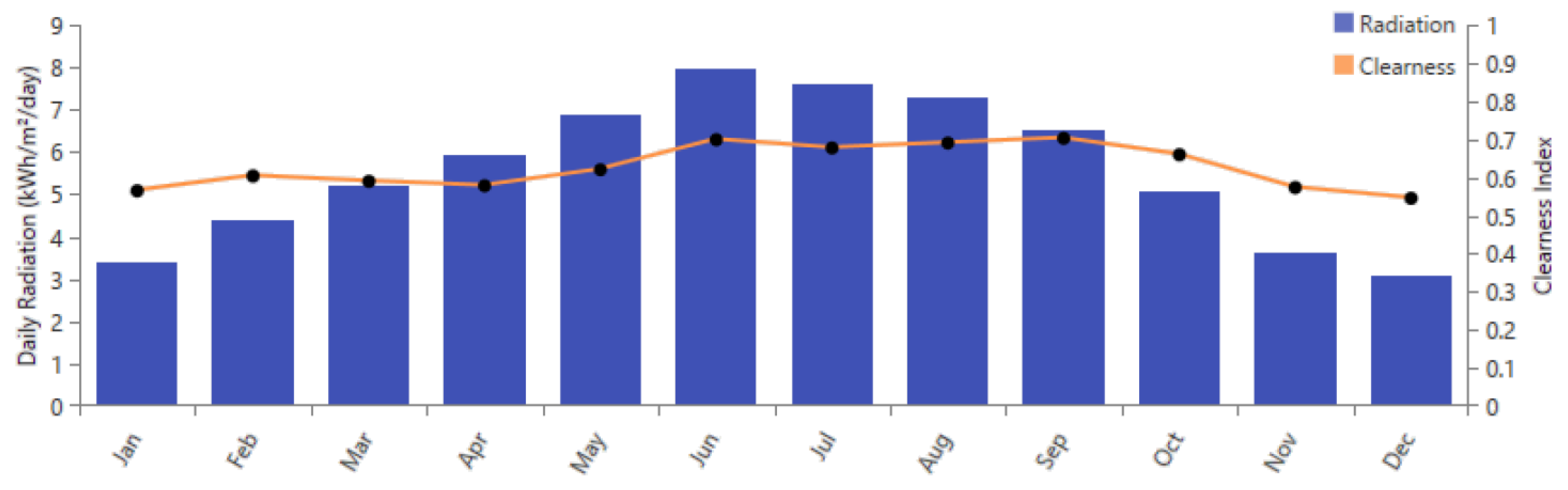

In the simulations, a cell-site at Salmiya (longitude 48.0716° E and latitude 29.3353° N) is considered (Salmiya is located near the capital City of Kuwait, and is densely populated; in densely deployed networks (e.g., city centers and residential areas), the network traffic load can fluctuate very much during the day [

52], and thus, this cell-site can be considered as a worst-case scenario), which is located as shown in

Figure 5 and characterized by an annual average GHI of 5.57 kWh/m

/day (As of NASA prediction of Worldwide Energy Resource (POWER) database [

40]). The BS tower at Salmiya cell-site is operated by Zain, which is a leading mobile telecommunications provider in Kuwait and the Middle East, with over 48.9 million customers to date [

53]. The BS operates both 4G and 5G technologies and is configured as shown in

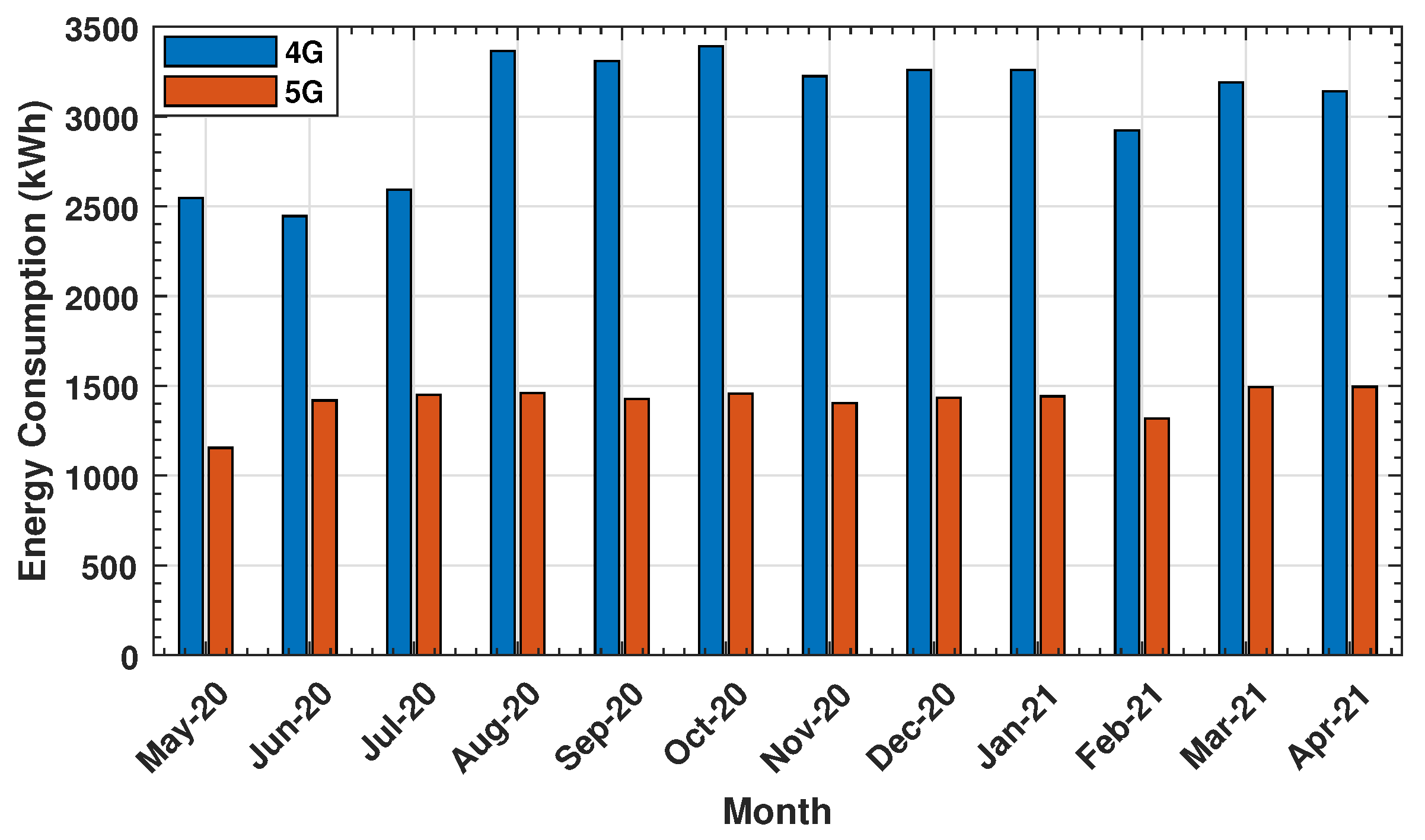

Table 1. The average load profile from May 2020 to April 2021 is shown in

Figure 6. Particularly, the annual average DC load has been determined as 146.95 kWh/day, and the average AC load is 110 kWh/day. The total load averages at 256.95 kWh/day and has a peak power of 31.77 kW (This load profile is considered as a worst-case scenario, which is due to COVID-19. This is particularly in alignment with working from home and lockdown restrictions, which led to a surge in data traffic and network usage).

3.4. Discussion of Results

Table 6 summarizes the optimal sizing, cost factors, fuel consumption, and CO

emissions of the PV-DG-BB and PV-BB system configurations for both PV panels. Firstly, one can see that the PV array capacity of the PV-DG-BB configuration with the 285 W panel is greater than that with the 475 W panel. This is due to the higher number of 285 W PV panels, which is a result of their lower price. A similar observation can be made for the PV-BB configuration. That is, the greater the PV panel peak power is, the fewer the number of panels required to meet the BS load demand. Secondly, one can observe that the LF dispatch strategy is optimal for the PV-DG-BB configuration, while the CC strategy is optimal for the PV-BB. Thirdly, the PV-DG-BB configuration with the 285 W (475 W) panel obtains 95.4% (94.2%) of its energy from the PV panels. This slight decrease in the renewable energy fraction is due to the decreased PV array capacity, while the DG rated power remains fixed at 35 kW. As for the PV-BB configuration, 100% of its energy supply is obtained from the PV panels, as would be expected. More importantly, the PV-BB system configuration requires more PV panels (to produce more power) and batteries than the PV-DG-BB configuration, since it depends solely on the PV panels for energy generation and the back-up battery bank for energy storage. On the other hand, it is evident from

Table 6 that the PV-DG-BB with the 285 W panel yields the lowest NPC and COE and entails the least initial capital; however, it results in 4713 kg/year of CO

emissions. Remarkably, and in comparison to the PV-DG-BB, the PV-BB configuration significantly increases the initial capital and NPC by about 35.7% and 34.71% for the 285 W and 475 W panels, respectively. This is attributed to the increase in the number of PV panels and battery units, which is to compensate for the power that would have been generated by the DG, while still meeting the BS load demand. However, by eliminating the DG, the PV-BB configuration yields zero CO

emissions, which is an important step towards minimizing the global CO

footprint.

From

Table 7, it can be seen that the CC dispatch strategy is optimal for the DG-BB and DG-WBB configurations. Moreover, it is clear that the DG-WBB configuration—despite the lower initial capital—incurs significantly higher NPC and COE than its DG-BB counterpart configuration. This is in addition to the significantly higher annual fuel consumption and CO

emissions, which are attributed to the absence of the battery bank. By comparing

Table 6 and

Table 7, one can see that the cost of the PV-DG-BB and PV-BB configurations—though very high during installation (i.e., initial cost)—have lower NPCs throughout the system lifespan than the DG-BB and DG-WBB configurations, which is in addition to the significantly lower CO

emissions. From an economic aspect, the PV-DG-BB configuration with 285 W panels is the best as it has the lowest NPC and COE among all system configurations. Contrarily, the worst configuration in this site is the DG-WBB as it has the highest NPC and COE. On the other hand, from an environmental-economic aspect, the PV-BB with 285 W panels is the optimal since it achieves zero CO

emissions at the lowest NPC.

Figure 7 summarizes the CO

emissions of the different configurations. Particularly, it is evident that the PV-BB configuration yields zero CO

emissions, while the PV-DG-BB configuration achieves significantly lower CO

emissions than the DG-BB and DG-WBB configurations.

In

Figure 8, the energy production of the PV-DG-BB configuration is illustrated. Particularly,

Figure 8a,b show that the backup DG mainly contributes to serve the BS load in the months of November 2020–April 2021 (i.e., during the winter), which is due to the relatively lower average GHI. Nevertheless, the PV production is significantly higher than that of the DG, which amounts to 95.4% and 94.2% for the PV-DG-BB configuration with the 285 W and 475 W PV panels, respectively, as can be seen in

Table 6. Contrarily,

Figure 9a and

Figure 9b respectively depict the energy production of the PV-BB configuration with the 285 W and 475 W PV panels, where it is evident that 100% of the produced energy comes from the PV arrays. As noted earlier, the lowest energy production occurs in the months of November 2020–April 2021.

Figure 10a illustrates the NPC savings of the PV-DG-BB and PV-BB configurations in comparison to the DG-BB configuration. Specifically, PV-DG-BB configuration with the 285 W (475 W) panel saves about 64.45% (63.1%) in terms of the NPC for the DG-BB configuration. Similarly, the PV-BB configuration with the 285 W (475 W) yields an NPC saving of about 51.75% (50.29%). On the other hand,

Figure 10b depicts the NPC savings of the PV-DG-BB and PV-BB configurations when compared to the DG-WBB configuration. In particular, the PV-DG-BB configuration with the 285 W (475 W) panels yields an NPC saving of 74.94% (74.03%), while the PV-BB configuration saves about 66.04% and 65.01% of the NPC with the 285 W and 475 W PV panels, respectively.

Another important factor worth considering is the days of autonomy of the PV-DG-BB and PV-BB configurations.

Table 8 summarizes the hours/days of autonomy for the PV-DG-BB and PV-BB configurations. It is observed that the PV-DG-BB configuration guarantees 17.5 h (less than a day) of autonomy for both PV panels (This is based on (

8), and is calculated as (20 batteries × 48 V nominal voltage × 244 Ah nominal capacity × DoD 0.8 × 24 h/day) divided by (daily average BS power demand of 256.95 kWh) [

44].), which is due to the fact that the PV-DG-BB configuration is based on 20 battery units for both panels, as can be seen in

Table 6. On the other hand, for the PV-BB configuration with the 285 W PV panel, the total number of required batteries is 40, as given in

Table 6, which implies that the PV-BB configuration with the 285 W PV panel can autonomously supply the BS for 35 h (i.e., 1 day and 11 h). Similarly, for the 475 W PV panel and total number of required batteries of 45, the operation duration that the battery bank can autonomously supply the BS is 39.3 h (i.e., 1 day, 15 h, and 18 min). Generally speaking, the recommended minimum days of autonomy for a sustainable operation of a cellular BS—powered via a standalone electric system—is at least 3 days before reaching the maximum DoD [

19] (Conventionally, 3 days of autonomy are considered rather sufficient for cellular network operators to maintain/repair the PV panels while ensuring continuous network operation [

19]).

A comparative analysis for the cost of ensuring various days of autonomy—as a function of the number of battery units—is shown in

Figure 11. It is clear that increasing the battery bank days of autonomy increases the NPC accordingly, so there is a trade off between the battery bank days of autonomy and the cost of the overall system. However, note that for 3 days of autonomy (i.e., 72 h), the NPC of the PV-DG-BB configuration with the 285 W and 475 W PV panels is USD 212,224 and USD 215,944, respectively. On the other hand, the NPC is about USD 210,499 (USD 214,864) for the PV-BB configuration with the 285 W (475 W) PV panels. Clearly, the NPCs of both configurations for both PV panels and increased days of autonomy are still significantly lower than the NPC of the DG-BB and DG-WBB configurations. Interestingly, although the PV-DG-BB configuration has lower initial capital and NPC, increasing the number of batteries (and hence the days of autonomy) increases the NPC at a rate that is higher than the PV-BB configuration. In other words, for a minimum of 3 days of autonomy, the PV-BB configuration yields lower NPC than the PV-DG-BB configuration. It should be noted that increasing the PV energy generation capacity (i.e., increasing the number of PV panels)—instead of battery storage capacity—can overcome this issue, as it will be more cost effective; however, this is at the expense of more land (as will be demonstrated shortly).

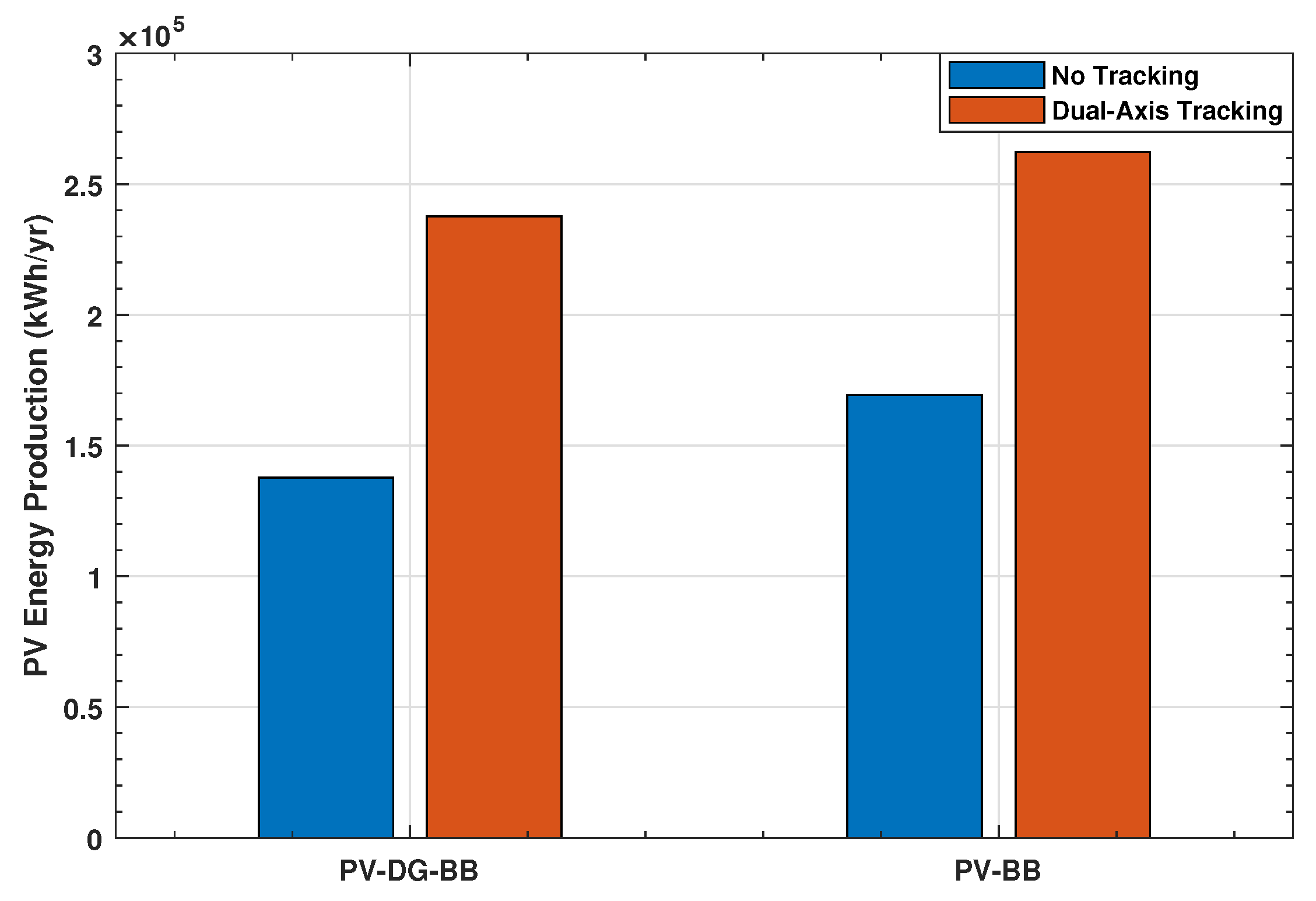

3.6. Utilization of Tracking Systems

Utilizing solar tracking systems could increase the total amount of energy produced by a solar power system [

19]. Thus, and to further reduce the required land, a solar tracking system is applied to study its effect on the PV production and the required area. Particularly, the PV-DG-BB and PV-BB configurations with the 475 W PV panels have been modified to incorporate dual-axis solar trackers. In the dual-axis trackers, the PV panels are rotated around both the horizontal and vertical axes to keep the sun rays always perpendicular to the panel. Although this type is the most expensive among all solar trackers, it maximizes the energy production of the PV panels, which in turn reduces the total area [

69,

70,

71] (Other solar trackers have been simulated but were found to produce less energy and require more land and thus have not been included in the results.). Now,

Table 10 compares the simulation results of both system configurations without tracking and with the dual-axis tracking. In general, it is noticed that the PV array capacity (kW) under both configurations has decreased, while still meeting the BS load demand. For the PV-DG-BB configuration, the DG rated power and number of battery units remained the same, while converter-rated power increased. As for the PV-BB configuration, the number of battery units has increased, which implies higher energy-storing capability so as not to excessively increase the NPC. To see this, the NPC of the PV-DG-BB configuration has decreased slightly, which is due to the decrease in the number of panels; however, the NPC of the PV-BB configuration marginally increased due to the use of additional battery units, despite the decrease in the number of panels. This can be seen from

Table 11, which compares the required land area without and with spacing. As would be expected, utilizing the dual-axis solar tracking decreases the required area, while marginally decreasing (increasing) the NPC for the PV-DG-BB (PV-BB) configuration.

From an energy production perspective,

Figure 12 depicts the impact of utilizing a dual-axis tracking on the PV energy production (kWh/yr) of the PV-DG-BB and PV-BB configurations. It is evident that the dual-axis tracker significantly increases the annual PV energy production for both configurations. That is, with the dual-axis tracking, the produced energy is significant, such that the number of PV panels is reduced while meeting the BS load demand. Additionally, and as noted earlier, the PV-BB configuration with the dual-axis tracker utilizes more battery units to store the energy produced.

3.7. Summary of Findings

The following findings can be stated, which are based on the presented results. Firstly, the PV-DG-BB configuration with the 285 W PV panels achieves the lowest NPC and COE while yielding 95.4% of renewable energy, but at the expense of an average of 4713 kg/yr of CO emissions. The PV-BB configuration with the 285 W panels results in an increase in the NPC by about 35.7%; however, this is with 100% renewable energy and zero CO emissions. Secondly, the DG-WBB incurs significantly higher NPC, COE, annual fuel consumption, and CO emissions than all the other configurations. More importantly, the PV-DG-BB and PV-BB configurations yield significant NPC savings in comparison to the DG-BB and DG-WBB configurations. Thirdly, it has been demonstrated that by ensuring a minimum of 3 days of autonomy, the PV-DG-BB and PV-BB configurations still yield NPCs that are lower than the DG-BB and DG-WBB configurations. Moreover, by increasing the days of autonomy, the PV-BB configuration becomes more cost-effective than the PV-DG-BB configuration.

From an overall system area perspective, the PV-DG-BB configuration requires less area than its PV-BB counterpart by around 40% for the 285 W panel and 44.4% for the 475 W panel. To further reduce the required area of the PV-DG-BB and PV-BB configurations, a dual-axis tracker has been utilized, while considering the 475 W PV panel. Specifically, it has been demonstrated that the dual-axis tracker effectively reduces the required system area, while significantly improving the PV energy production, and thus meeting the required BS load demand.