Simplified Thermal Performance Evaluation of a PCM-Filled Triple-Glazed Window under Arctic Climate Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Model Description

2.1.1. Physical Model

2.1.2. Mathematical Model

- One-dimensional and transient heat transfers perpendicular to the glass surface;

- Convection within the PCM layer is negligible due its small thickness;

- The thermo-physical properties of the glass are isotropic;

- Of the thermo-physical properties of the PCM, conduction and density are temperature independent, while specific heat is temperature dependent;

- The radiative heat exchange between the glass surfaces facing the PCM layer is neglected;

- Volume expansion during the phase change, and the scattering effects of the paraffin, are ignored.

2.2. Numerical Methods and Validation

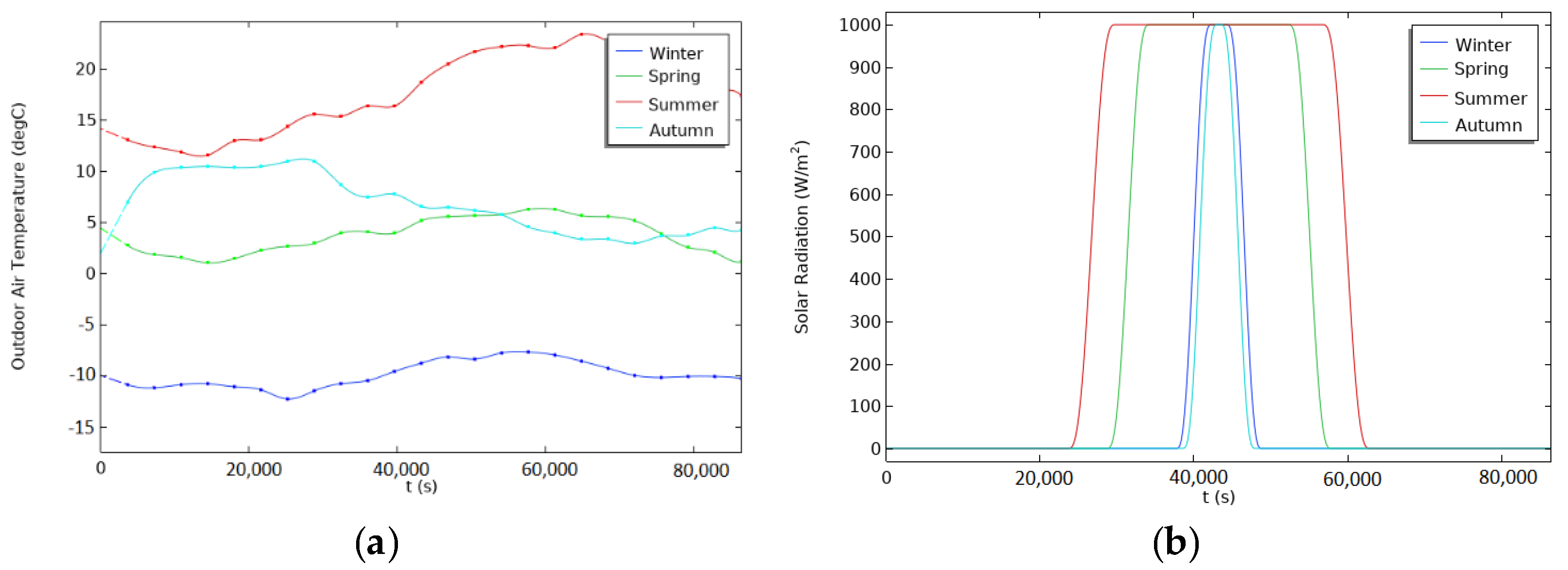

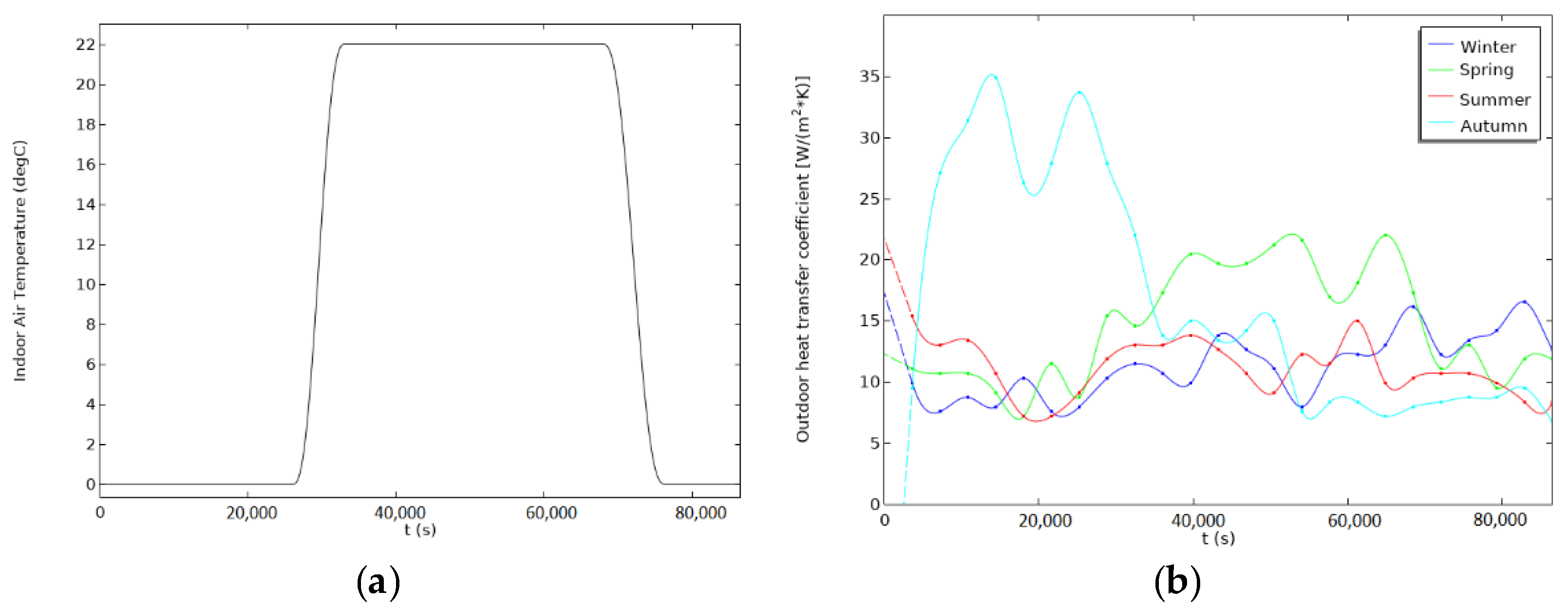

2.3. Environmental Conditions

2.4. Simulation Parameters

3. Results and Discussion

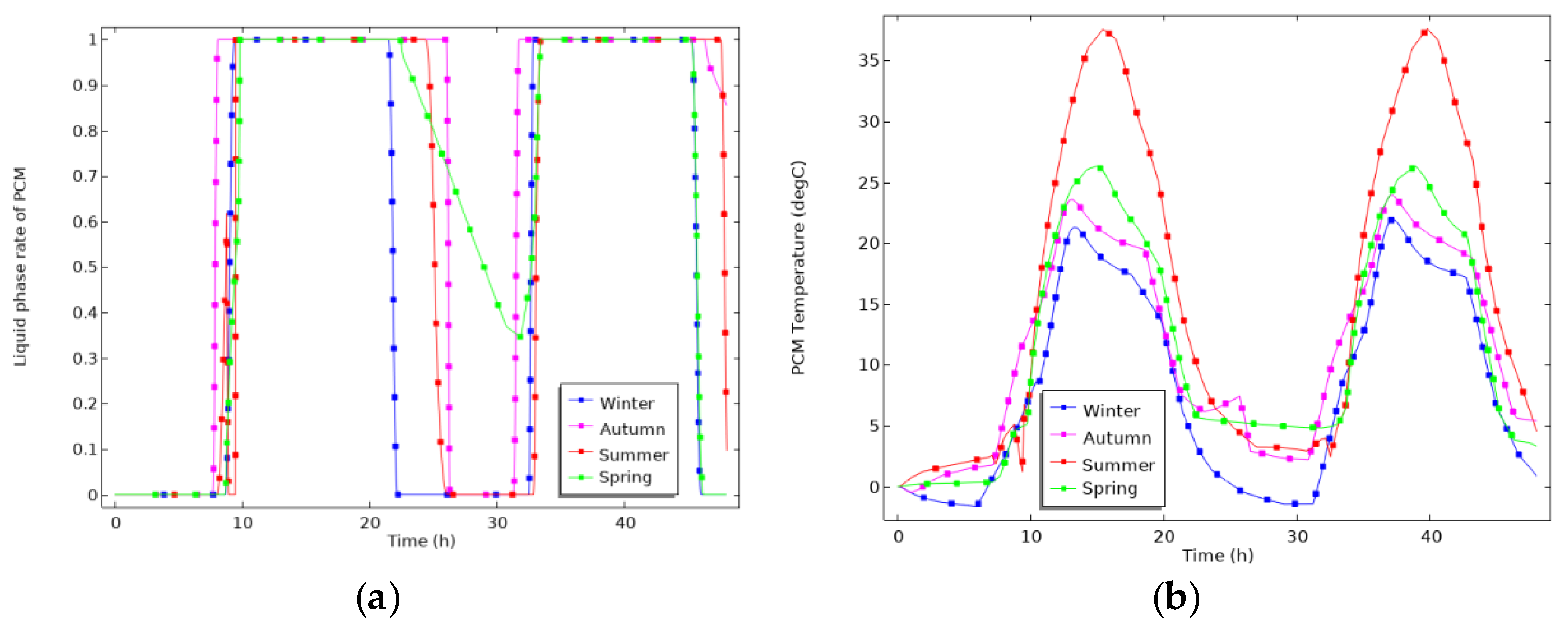

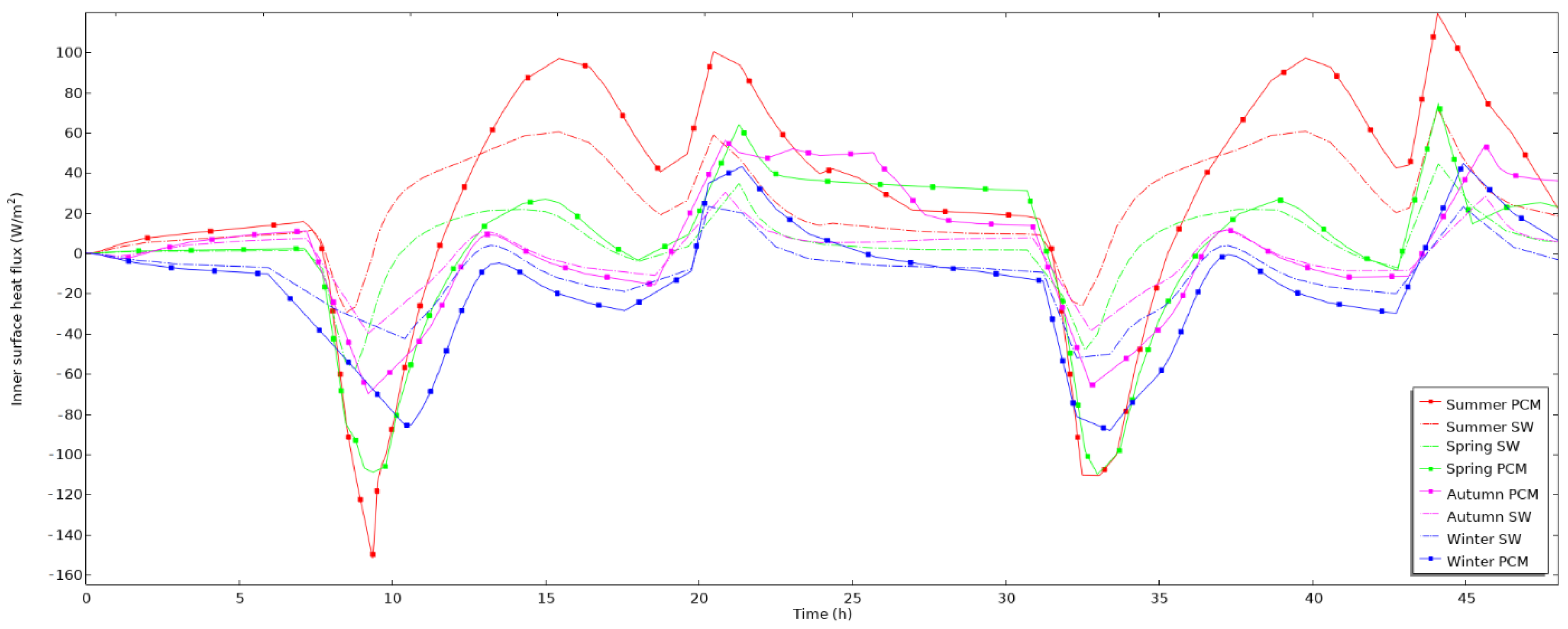

3.1. Calculated Parameters

- Inner surface temperature;

- Liquid phase rate of the PCM;

- Heat flux through the inner surface.

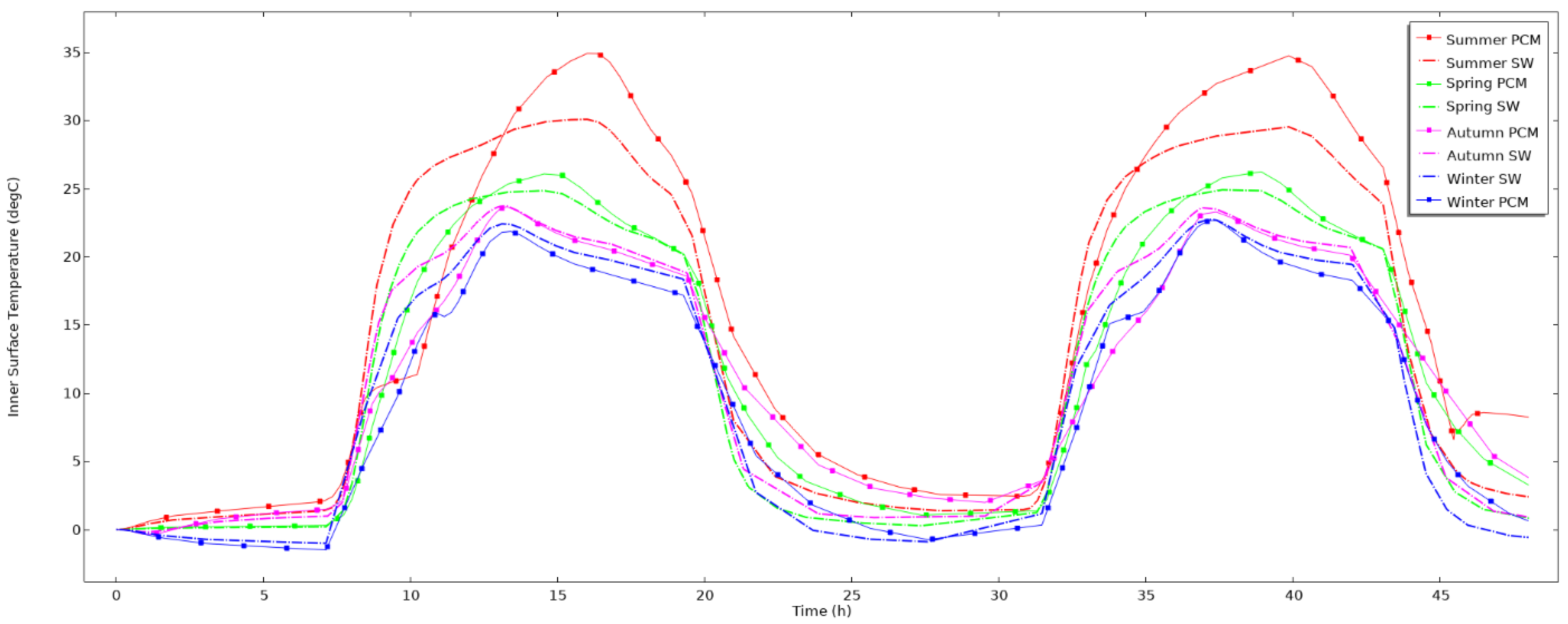

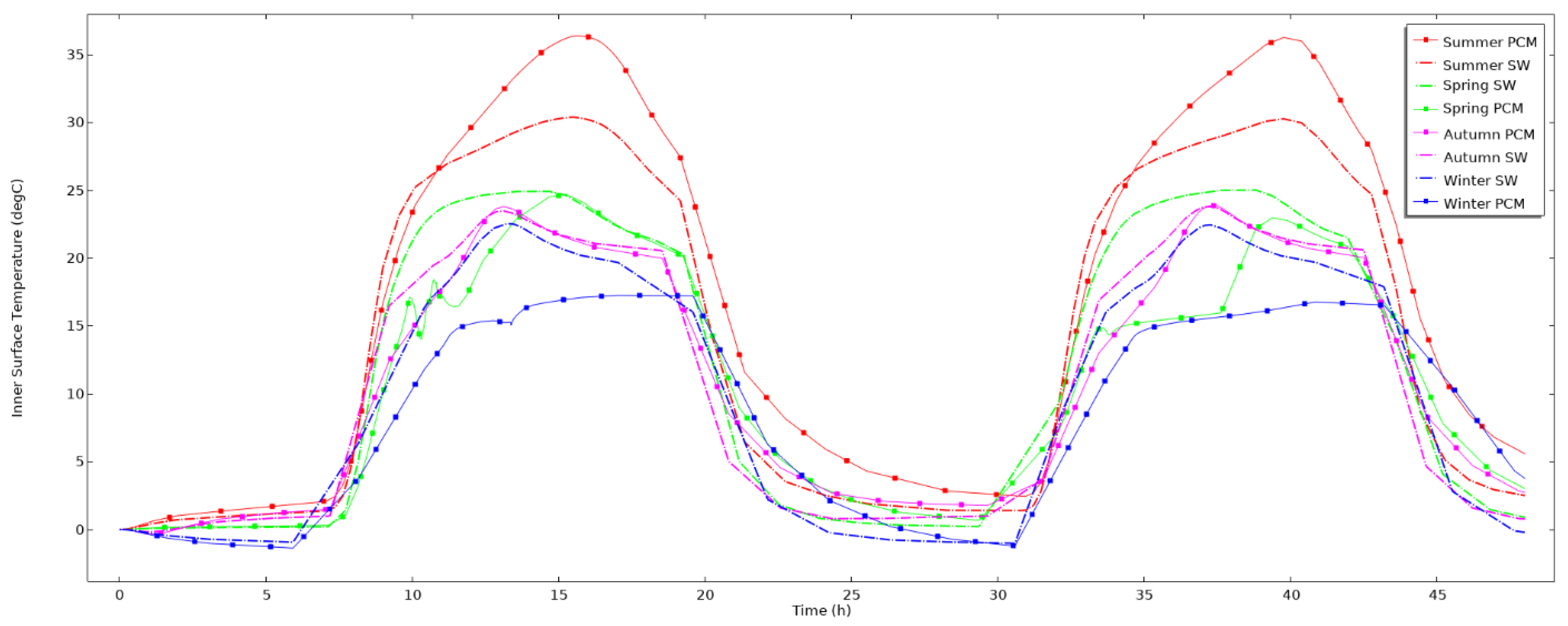

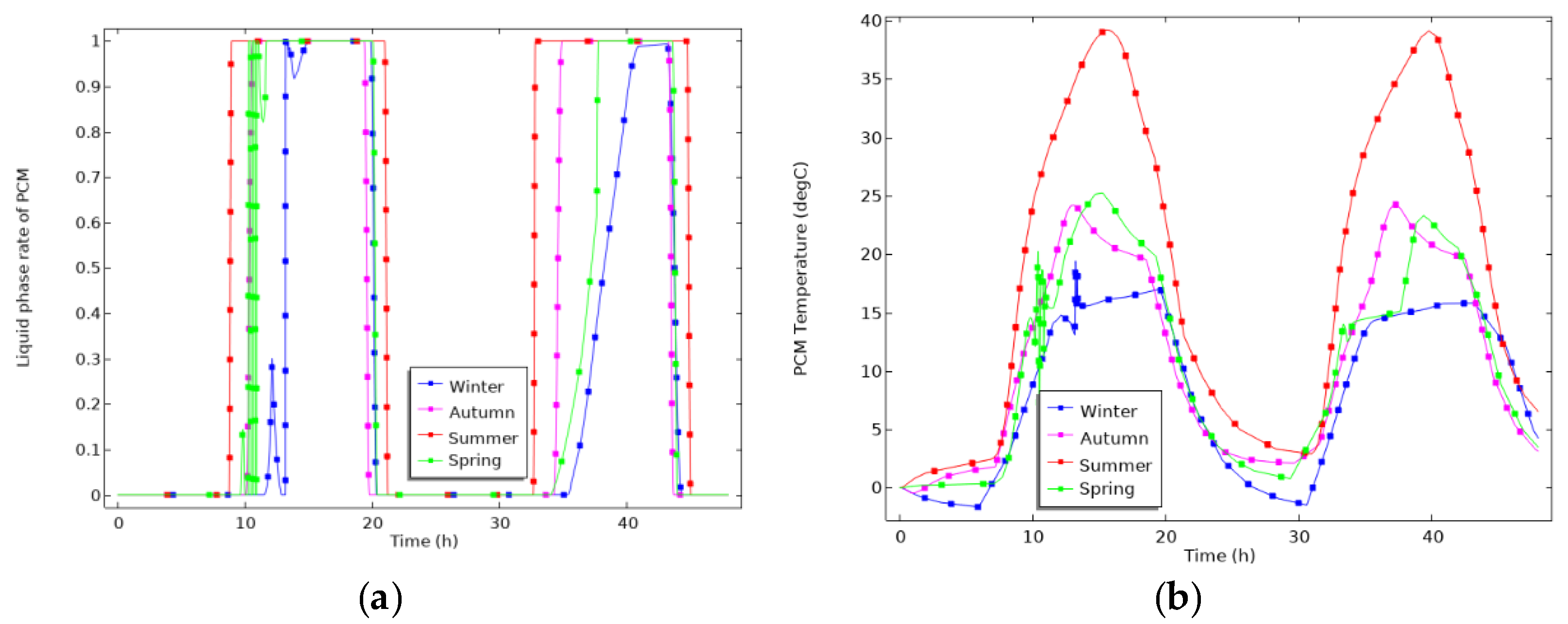

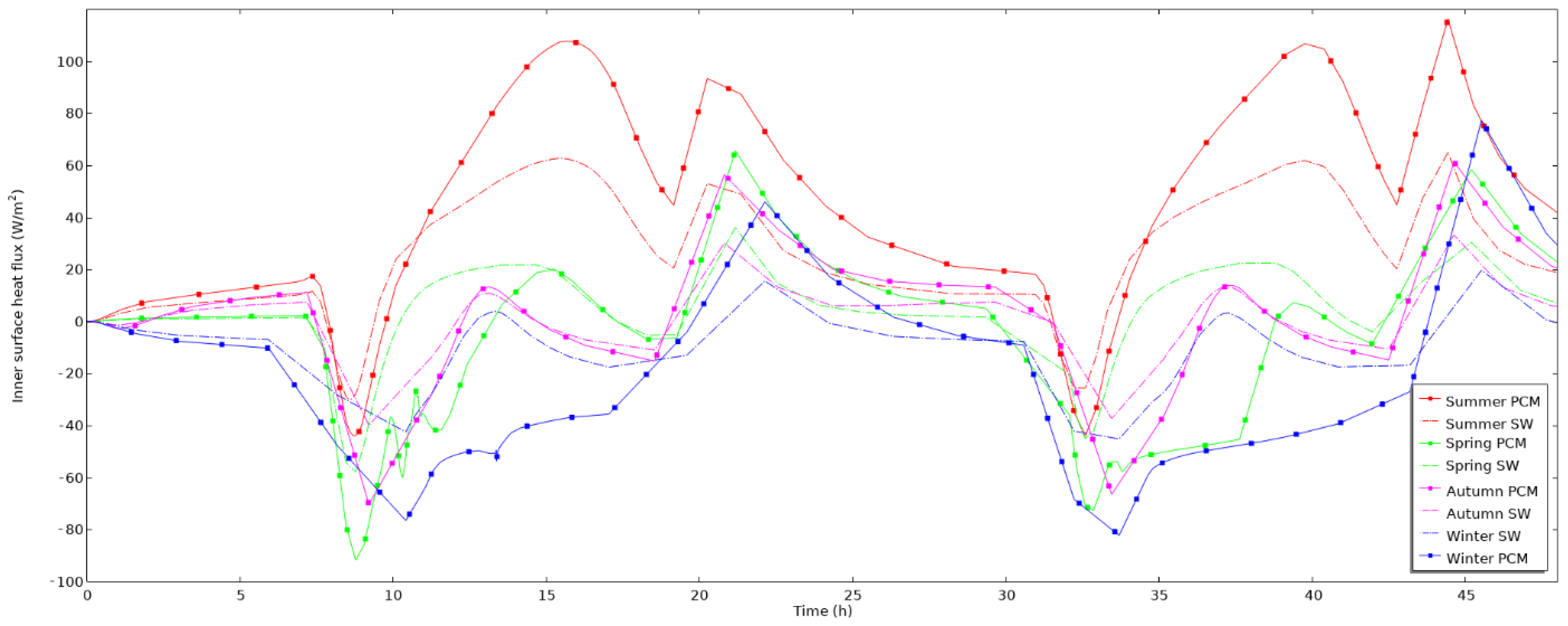

3.2. Paraffin 5

3.3. Paraffin 10

3.4. Paraffin 15

4. Conclusions

- During summer, the PCM-filled window had better thermal performance—measured as inner surface temperature and thermal insulation—compared to a standard window. This was because summer is characterized by higher outdoor temperatures and more availability of solar resource than other seasons.

- During spring and autumn, paraffin 10 performed better than paraffin 5 and paraffin 15, resulting in higher average and maximum inner surface temperature. Indeed, with paraffin 10 the PCM layer stayed in a liquid phase for longer time compared to other cases, hence leading to better performance.

- During winter season, no benefit was observed for a PCM-filled window. The energy efficiency of the PCM-filled cavity was either worse than, or at best similar to, the efficiency of a standard window. This was because of the extremely low outdoor temperatures and the lack of solar radiation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Global Alliance for Buildings and Construction; International Energy Agency (IEA). 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Building and Construction Sector; Global Alliance for Buildings and Construction: Paris, France, 2020. [Google Scholar]

- Arctic Monotoring and Assessment Programme (AMAP). Impact of Short-Lived Climate Forcers on Arctic Climate, Air Quality and Human Health; Arctic Monotoring and Assessment Programme (AMAP): Oslo, Norway, 2021. [Google Scholar]

- Arctic Monotoring and Assessment Programme (AMAP). Arctic Climate Change Update 2021: Key Trends and Impact; Arctic Monotoring and Assessment Programme (AMAP): Oslo, Norway, 2021. [Google Scholar]

- Durakovic, B. Introduction. In Pcm-Based Building Envelope Systems: Innovative Energy Solutions for Passive Design; Edited by Springer International Publishing AG.; Springer International Publishing AG: Cham, Switzerland, 2020; pp. 1–16. [Google Scholar]

- Zhang, S.; Hu, W. Energy Efficiency Optimization of Pcm and Aerogel-Filled Multiple Glazing Windows. Energy J. 2021, 222, 119916. [Google Scholar] [CrossRef]

- Durakovic, B. Pcm-Based Glazing Systems and Components. In Pcm-Based Building Envelope Systems: Innovative Energy Solutions for Passive Design; Edited by Springer International Publishing AG.; Springer International Publishing AG: Cham, Switzerland, 2020; pp. 89–120. [Google Scholar]

- Bianco, L.; Vigna, I. Energy Assessment of a Novel Dynamic Pcms Based Solar Shading: Results from an Experimental Campaign. Energy Build. 2017, 150, 608–624. [Google Scholar] [CrossRef]

- Vigna, I.; Bianco, L. Phase Change Materials in Transparent Building Envelopes: A Strengths, Weakness, Opportunities and Threats (Swot) Analysis. Energies 2018, 11, 111. [Google Scholar] [CrossRef] [Green Version]

- Goia, F.; Perino, M. A Numerical Model to Evaluate the Thermal Behaviour of Pcm Glazing System Configurations. Energy Build. 2012, 54, 141–153. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M. Improving Thermal Comfort Conditions by Means of Pcm Glazing Systems. Energy Build. 2013, 60, 442–452. [Google Scholar] [CrossRef]

- Li, S.; Zhong, K. Comparative Study on the Dynamic Heat Transfer Characteristics of Pcm-Filled Glass Window and Hollow Glass Window. Energy Build. 2014, 85, 483–492. [Google Scholar] [CrossRef]

- Bianco, L.; Cascone, Y. Responsive Glazing Systems: Characterisation Methods and Winter Performance. Energy Build. 2017, 155, 372–387. [Google Scholar] [CrossRef] [Green Version]

- Goia, F.; Perino, M. Experimental Analysis of the Energy Performance of a Full-Scale Pcm Glazing Prototype. Sol. Energy 2014, 100, 217–233. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, G. Thermal Performance of Non-Ventilated Multilayer Glazing Facades Filled with Phase Change Material. Sol. Energy 2019, 177, 464–470. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y. Numerical Investigation of Thermal and Optical Performance of Window Units Filled with Nanoparticle Enhanced Pcm. Int. J. Heat Mass Transf. 2018, 125, 1321–1332. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y. Energy Investigation of Glazed Windows Containing Nano-Pcm in Different Seasons. Energy Convers. Manag. 2018, 172, 119–128. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C. Thermal Performance Evaluation of Glass Window Combining Silica Aerogels and Phase Change Materials for Cold Climate of China. Appl. Therm. Eng. 2020, 165, 114547. [Google Scholar] [CrossRef]

- Serreze, M.C.; Barry, R.G. Physical Characteristics and Basic Climatic Features. In The Arctic Climate System, 2nd ed.; Edited by Cambridge University Press; Cambridge University Press: Cambridge, UK, 2014; pp. 23–64. [Google Scholar]

- Beausoleil-Morrison, I. The Adaptive Simulation of Convective Heat Transfer at Internal Building Surfaces. Build. Environ. 2002, 37, 791–806. [Google Scholar] [CrossRef]

- Yr. Available online: https://www.yr.no/en/forecast/daily-table/5-84701/Norway/Nordland/Narvik/Narvik (accessed on 1 September 2021).

- National Solar Radiation Database. Available online: https://nsrdb.nrel.gov/ (accessed on 1 September 2021).

| Property | Glass | Air | Paraffin 5/10/15 |

|---|---|---|---|

| k [W/(m∙K)] | 1 | 0.024 | 0.2 |

| ρ [kg/m3] | 2700 | 1.276 | 885 |

| cp [J/(kg∙K)] | 840 | 1006 | - |

| cp,s [J/(kg∙K)] | - | - | 2320 |

| cp,l [J/(kg∙K)] | - | - | 2240 |

| LH [J/kg] | - | - | 185,000 |

| Tm [K] | - | - | 279.15/283.15/288.15 |

| dT [K] | - | - | 2 |

| Season | Parameter | Paraffin 5 | Paraffin 10 | Paraffin 15 | Standard Window |

|---|---|---|---|---|---|

| Winter | Maximum inner surface temperature [°C] | 21.9 | 22.7 | 17.2 | 24.7 |

| Average inner surface temperature [°C] | 8.6 | 9.2 | 8.6 | 10.7 | |

| Maximum inner surface heat flux [W/m2] | 44.8 | 58.7 | 77.2 | 65.6 | |

| Average inner surface heat flux [W/m2] | −16 | −13.4 | −18.9 | −2.7 | |

| Spring | Maximum inner surface temperature [°C] | 25.6 | 26.2 | 22.5 | 24.9 |

| Average inner surface temperature [°C] | 11.3 | 11.9 | 9.3 | 11.3 | |

| Maximum inner surface heat flux [W/m2] | 74.6 | 80.9 | 23.3 | 44.7 | |

| Average inner surface heat flux [W/m2] | 4.1 | 8.4 | −10 | 4.8 | |

| Summer | Maximum inner surface temperature [°C] | 34.9 | 34.9 | 36.3 | 30.1 |

| Average inner surface temperature [°C] | 14.8 | 15.8 | 16.7 | 14.2 | |

| Maximum inner surface heat flux [W/m2] | 119.4 | 110.7 | 116.1 | 72.3 | |

| Average inner surface heat flux [W/m2] | 30.2 | 37.4 | 46.4 | 26.2 | |

| Autumn | Maximum inner surface temperature [°C] | 23.5 | 23.7 | 24.7 | 24.9 |

| Average inner surface temperature [°C] | 11.3 | 11.6 | 10.7 | 11.3 | |

| Maximum inner surface heat flux [W/m2] | 56.3 | 79.1 | 65.6 | 44.7 | |

| Average inner surface heat flux [W/m2] | 2.9 | 2.6 | −2.7 | 4.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravasio, L.; Calay, R.K.; Riise, R. Simplified Thermal Performance Evaluation of a PCM-Filled Triple-Glazed Window under Arctic Climate Conditions. Energies 2021, 14, 8068. https://doi.org/10.3390/en14238068

Ravasio L, Calay RK, Riise R. Simplified Thermal Performance Evaluation of a PCM-Filled Triple-Glazed Window under Arctic Climate Conditions. Energies. 2021; 14(23):8068. https://doi.org/10.3390/en14238068

Chicago/Turabian StyleRavasio, Lucrezia, Rajnish Kaur Calay, and Raymond Riise. 2021. "Simplified Thermal Performance Evaluation of a PCM-Filled Triple-Glazed Window under Arctic Climate Conditions" Energies 14, no. 23: 8068. https://doi.org/10.3390/en14238068

APA StyleRavasio, L., Calay, R. K., & Riise, R. (2021). Simplified Thermal Performance Evaluation of a PCM-Filled Triple-Glazed Window under Arctic Climate Conditions. Energies, 14(23), 8068. https://doi.org/10.3390/en14238068