Performance Assessment of Using Thermoelectric Generators for Waste Heat Recovery from Vapor Compression Refrigeration Systems

Abstract

:1. Introduction

2. Methodology

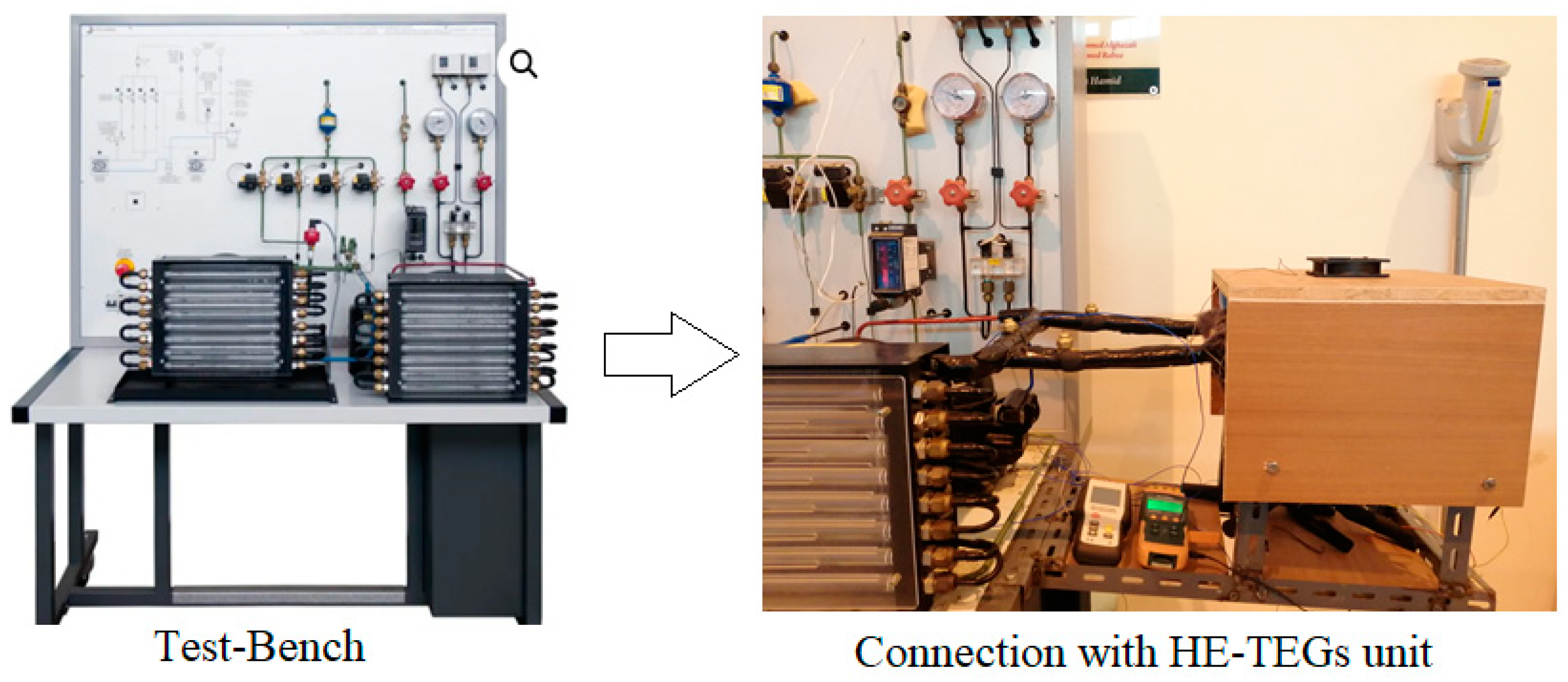

3. Design and Manufacturing of Heat Exchanger TEGs Unit (HE-TEGs)

4. System Integration and Experimental Set-up

5. Evaluation of Performance Parameters

6. Results and Discussion

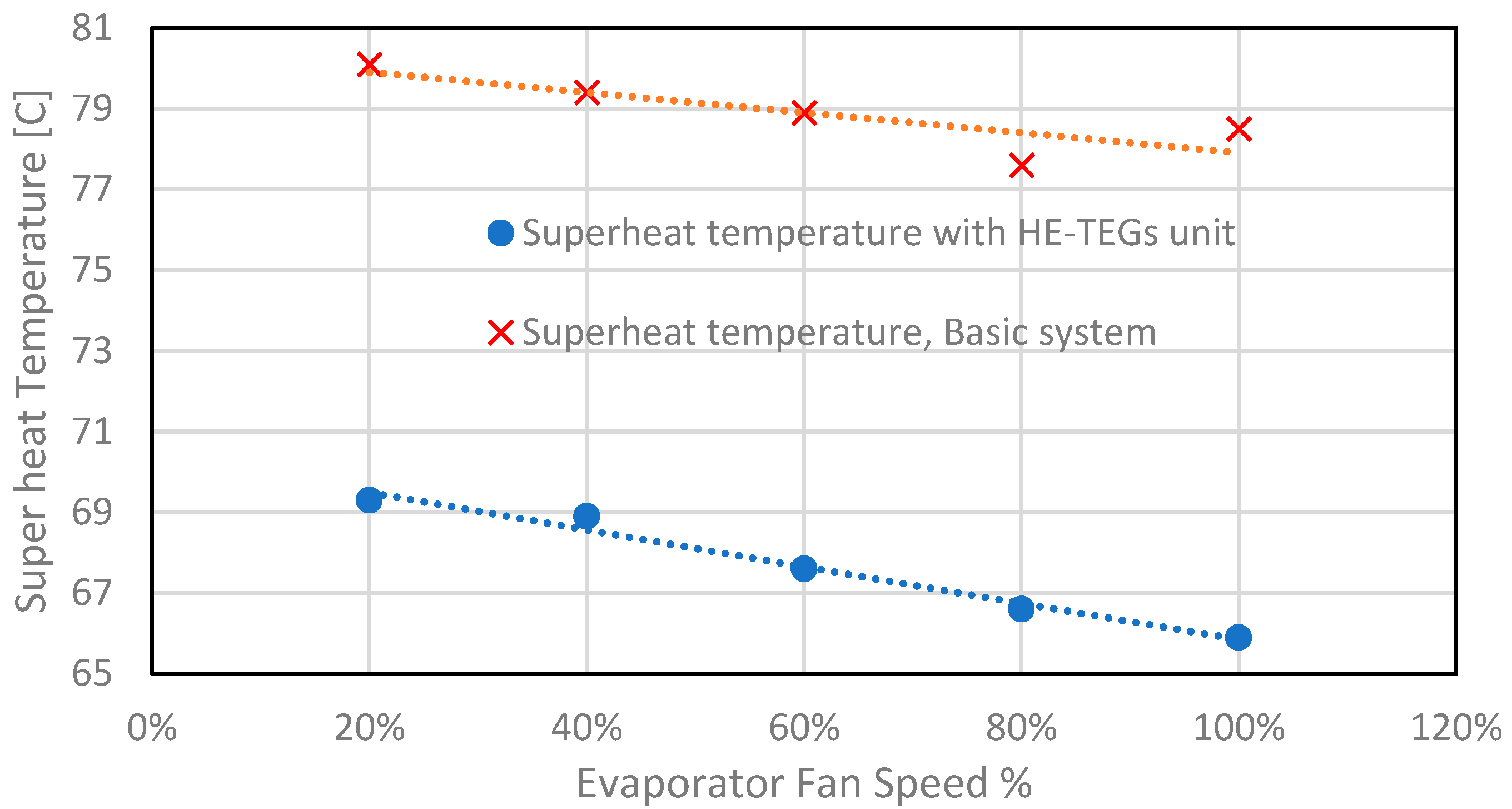

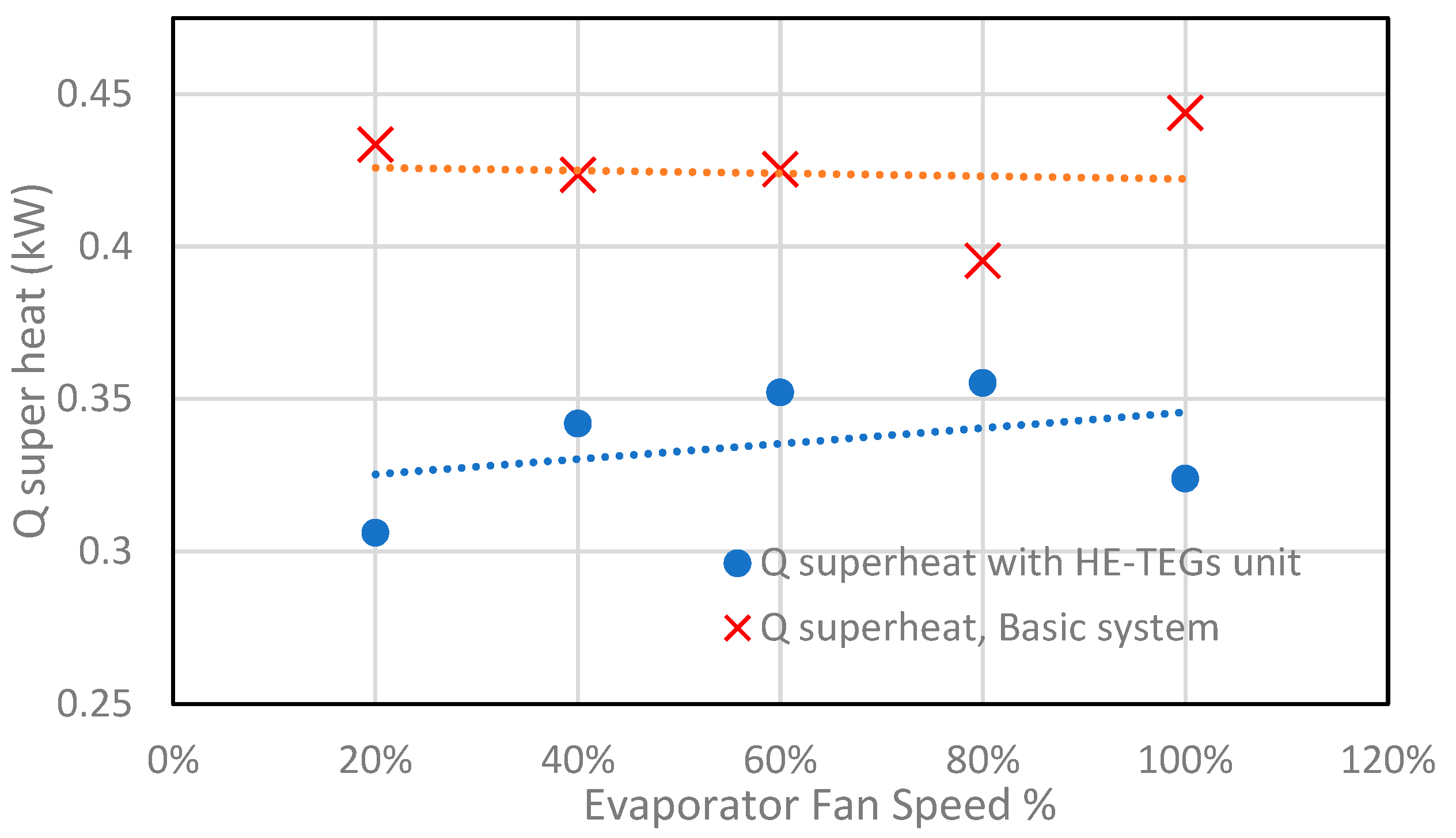

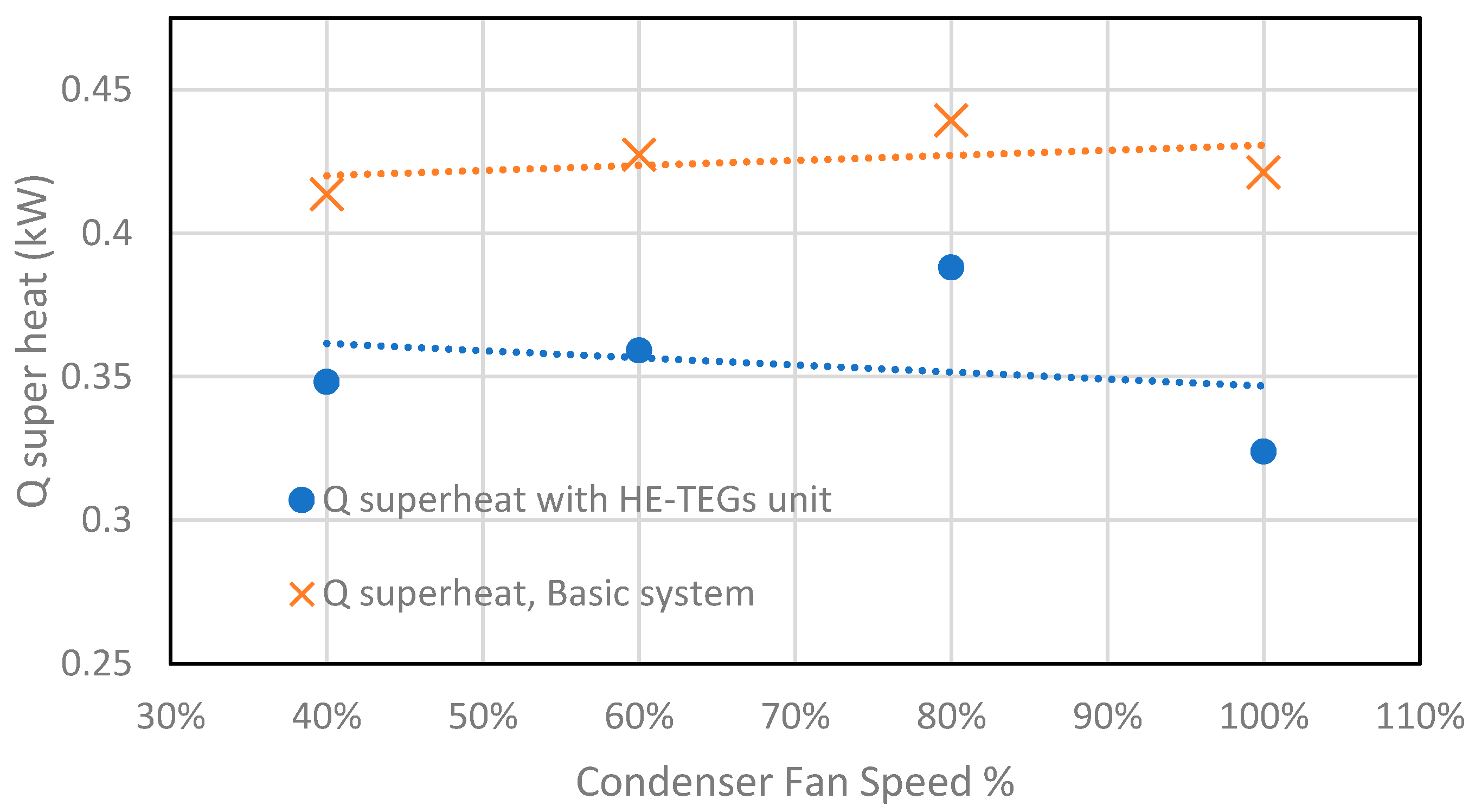

6.1. Superheat Temperature and Waste Heat Recovery

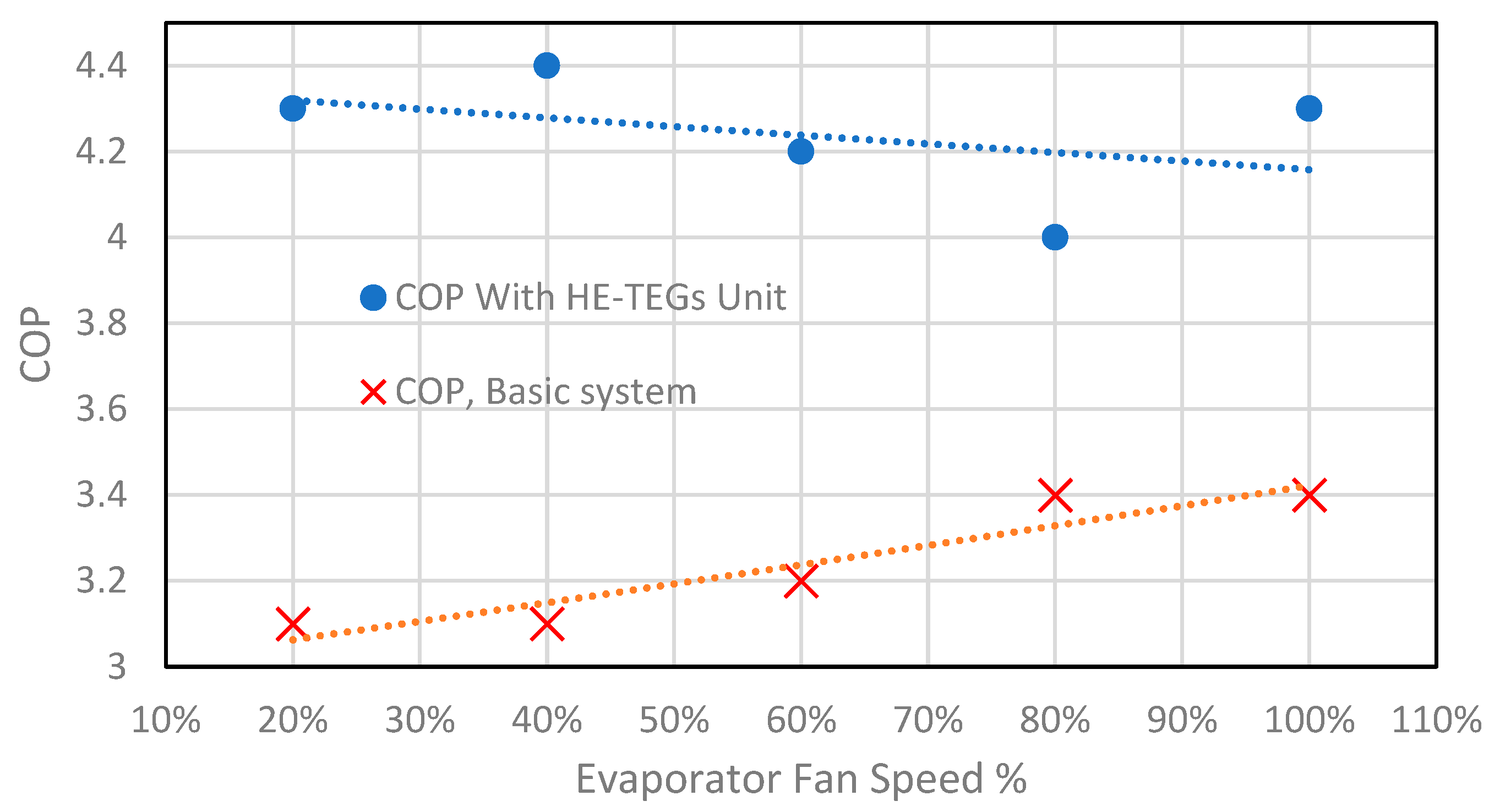

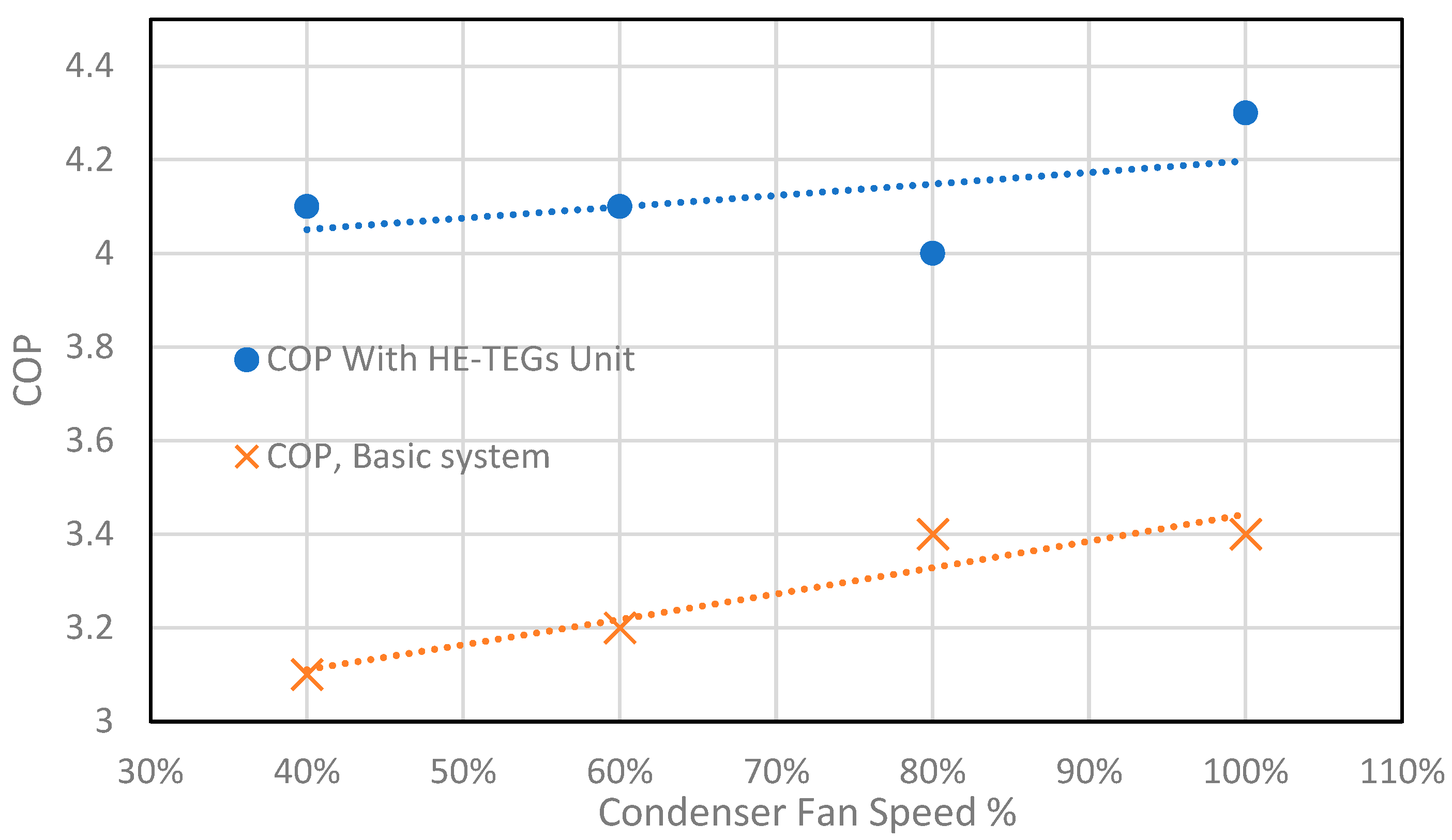

6.2. Overall Coefficient of Performance of Refrigeration System

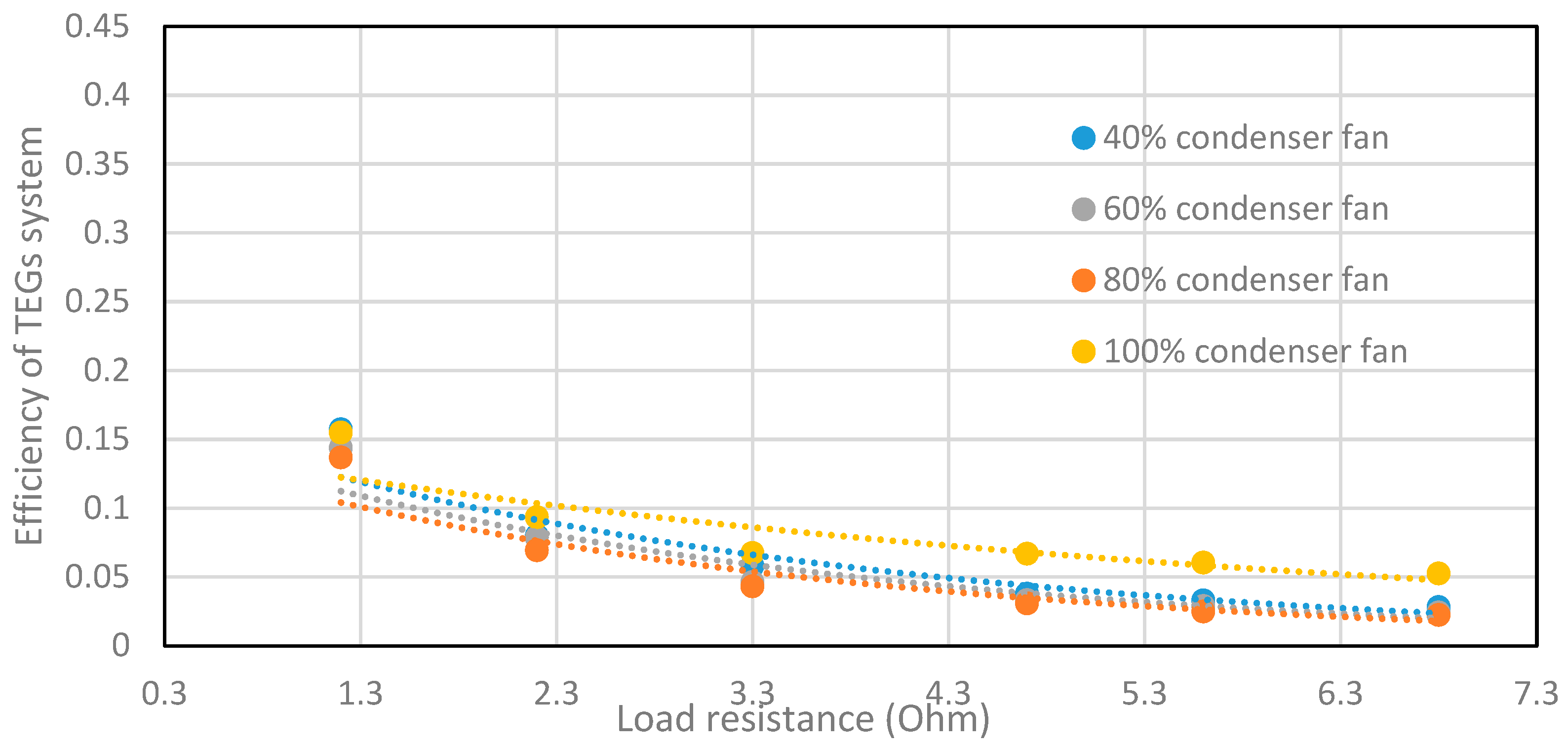

6.3. Analysis of TEGs Performance

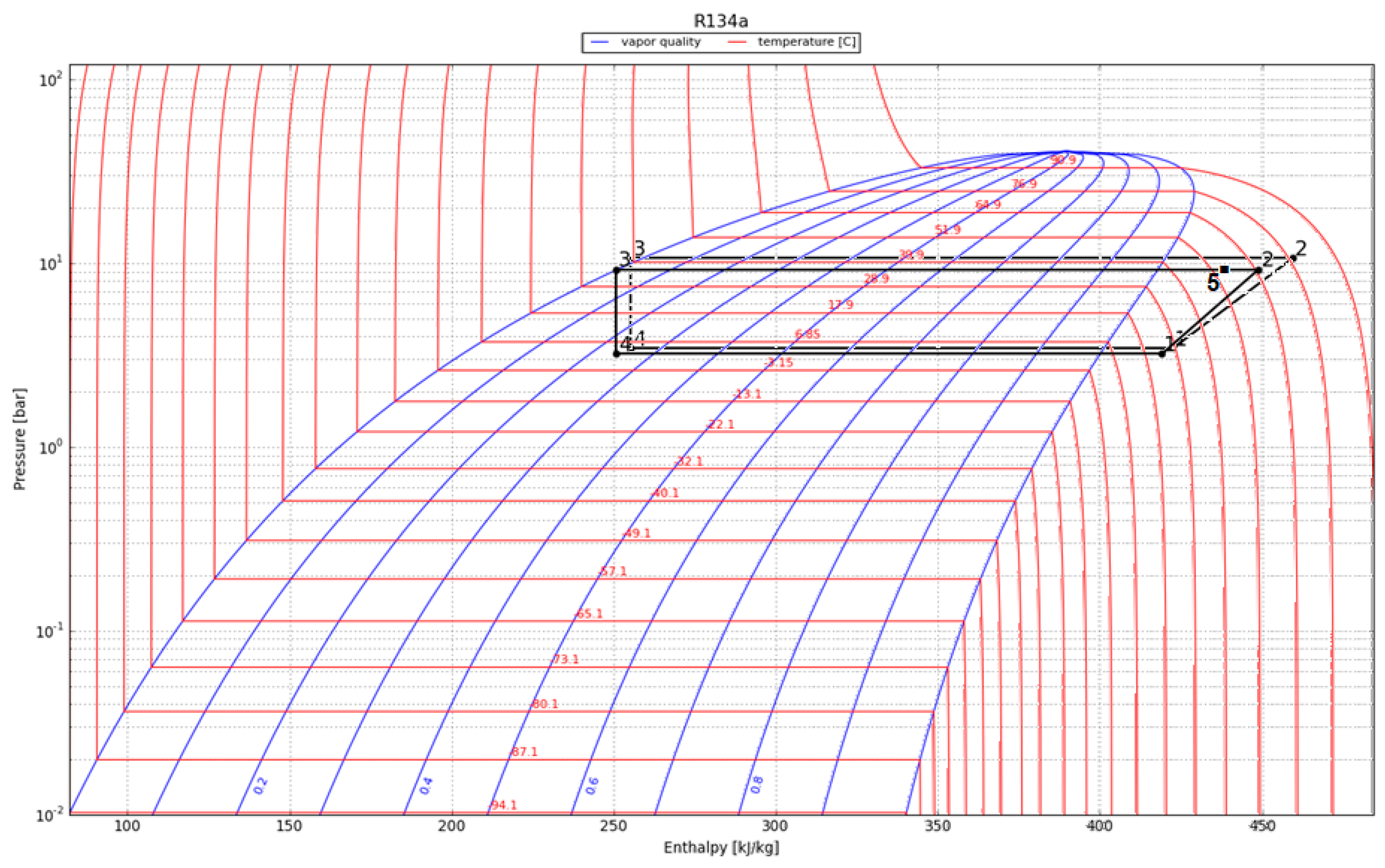

6.4. Analysis of Refrigeration Cycle

6.5. Exergy Analsyis Sustainbility Indicator

6.6. Economic Analysis

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The Future of Cooling: Opportunities for Energy Efficient Air Conditioning, International Energy Agency. Technology Report. Available online: https://www.iea.org/reports/the-future-of-cooling (accessed on 2 December 2021).

- Hughes, B.R.; Chaudhry, H.N.; Ghani, S.A. A review of sustainable cooling technologies in buildings. Renew. Sustain. Energy Rev. 2011, 15, 3112–3120. [Google Scholar] [CrossRef]

- She, X.; Cong, L.; Nie, B.; Leng, G.; Peng, H.; Chen, Y.; Zhang, X.; Weng, T.; Yang, H.; Luo, Y. Energy-efficient and -economic technologies for air conditioning with vapor compression refrigeration: A comprehensive review. Appl. Energy 2018, 232, 157–186. [Google Scholar] [CrossRef]

- Gu, Z.; Liu, H.; Li, Y. Thermal energy recovery of air conditioning system––Heat recovery system calculation and phase change materials development. Appl. Therm. Eng. 2004, 24, 2511–2526. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, S.; Yu, M.; Lin, Y. Experimental research on condensing heat recovery using phase change material. Appl. Therm. Eng. 2011, 31, 3736–3740. [Google Scholar] [CrossRef]

- Xia, M.; Yuan, Y.; Zhao, X.; Cao, X.; Tang, Z. Cold storage condensation heat recovery system with a novel composite phase change material. Appl. Energy 2016, 175, 259–268. [Google Scholar] [CrossRef]

- Byrne, P.; Fournaison, L.; Delahaye, A.; Oumeziane, Y.A.; Serres, L.; Loulergue, P.; Szymczyk, A.; Mugnier, D.; Malaval, J.; Bourdais, R.; et al. A review on the coupling of cooling, desalination and solar photovoltaic systems. Renew. Sustain. Energy Rev. 2015, 47, 703–717. [Google Scholar] [CrossRef]

- Slesarenko, V.V. Heat pumps as a source of heat energy for desalination of seawater. Desalination 2001, 139, 405–410. [Google Scholar] [CrossRef]

- Byrne, P.; Miriel, J.; Serres, L.; Ghoubali, R. Etude Simulée D’un Système De Dessalement D’eau De Mer Et De Production De Froid Par Thermofrigopompe Couplée À Des Panneaux Solaires. 2ème Colloque International Francophone En Energétique Et Mécanique; CIFEM: Ouagadougou, Burkina Faso, 2012. [Google Scholar]

- Byrne, P.; Ait Oumeziane, Y.; Serres, L.; Miriel, J. Etude Simulée D’un Système De Distillation Membranaire Pour Le Dessalement D’eau De Mer Couplé À Une Thermofrigopompe, 3ème Colloque International Francophone En Energétique Et Mécanique; CIFEM: Moroni, Comores, 2014. [Google Scholar]

- Byrne, P.; Ait Oumeziane, Y.; Serres, L.; Miriel, J. Study of a heat pump for simultaneous cooling and desalination. In Proceedings of the IMAT Conference, Kuala Lumpur, Malaysia, 26–27 November 2014. [Google Scholar]

- Aguilar, F.J.; Quiles, P.V.; Aledo, S. Operation and energy efficiency of a hybrid air conditioner simultaneously connected to the grid and to photovoltaic panels. Energy Procedia 2014, 48, 768–777. [Google Scholar] [CrossRef] [Green Version]

- Rady, M.; Albatati, F.; Hegab, A.; Abuhabaya, A.; Attar, A. Design and analysis of waste heat recovery from residential air conditioning units for cooling and pure water production. Int. J. Low-Carbon Technol. 2021, 16, 1018–1032. [Google Scholar] [CrossRef]

- Pourkiaei, S.M.; Ahmadi, M.H.; Sadeghzadeh, M.; Moosavi, S.; Pourfayaz, F.; Chen, L.; Yazdi, M.A.P.; Kumar, R. Thermoelectric cooler and thermoelectric generator devices: A review of present and potential applications, modeling and materials. Energy 2019, 186, 115849. [Google Scholar] [CrossRef]

- Ramadan, M.; Ali, S.; Bazzi, H.; Khaled, M. New hybrid system combining TEG, condenser hot air and exhaust airflow of all-air HVAC systems. Case Stud. Therm. Eng. 2017, 10, 154–160. [Google Scholar] [CrossRef]

- Damanhuri, A.A.M.; Abdullah, M.I.H.C.; Lubis, A.M.H.S.; Zakaria, M.Z.; Hussin, M.S.F.; Kasno, M.A. Development Of TEG Peltier Device For Heat Harvesting From 1.5 HP Split Unit Air Conditioning System. Int. J. Appl. Eng. Res. 2018, 13, 2390–2394. [Google Scholar]

- Navarro-Peris, E.; Corberan, J.M.; Ancik, Z. Evaluation of the potential recovery of compressor heat losses to enhance the efficiency of refrigeration systems by means of thermoelectric generation. Appl. Therm. Eng. 2015, 89, 755–762. [Google Scholar] [CrossRef]

- Sánchez, D.; Aranguren, P.; Casi, A.; Llopis, R.; Cabello, R.; Astrain, D. Experimental enhancement of a CO2 transcritical refrigerating plant including thermoelectric subcooling. Int. J. Refrig. 2020, 120, 178–187. [Google Scholar] [CrossRef]

- Radermacher, R.; Yang, B.; Hwang, Y. Integrating alternative and conventional cooling technologies. ASHRAE 2007, 49, 28–35. [Google Scholar]

- Wantha, C. Experimental investigation of the influence of thermoelectric subcooler on the performance of R134a refrigeration systems. Appl. Therm. Eng. 2020, 180, 115829. [Google Scholar] [CrossRef]

- TE Technology, Inc. Specification Sheet. Available online: https://tetech.com/wp-content/uploads/2019/03/HP-127-1.4-1.15-71.pdf (accessed on 5 September 2021).

- Holman, J. Experimental Methods for Engineers, 8th ed.; McGraw-Hill Series in Mechanical Engineering; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Grisolia, G.; Fino, D.; Lucia, U. Thermodynamic optimization of the biofuel production based on mutualism. Energy Rep. 2020, 6, 1561–1571. [Google Scholar] [CrossRef]

- Arora, A.; Arora, B.B.; Pathak, B.D.; Sachdev, H.L. Exergy analysis of a vapor compression refrigeration system with R-22, R-407C and R-410A. Int. J. Exergy. 2007, 4, 441–454. [Google Scholar] [CrossRef]

- Cengel, Y.; Boles, M. Thermodynamics: An Engineering Approach, 8th ed.; McGraw-Hill: New York, NY, USA, 2015. [Google Scholar]

- Saudi Electricity Company, Customers Tariff Rates. Available online: https://www.se.com.sa/ar-sa/Customers/Pages/TariffRates.aspx (accessed on 30 October 2021).

| Instrument | Uncertainty |

|---|---|

| Type T thermocouple | ±0.3 (°C) |

| Pressure gauges | ±0.01 (bar) |

| Flow meter | ±0.001 (L/min) |

| Digital Watt meter | ±1 (W) |

| TEG voltage (V) | ±5 (µV) |

| TEG current (I) | ±0.01 (mA) |

| TEG Load resistance (Ω) | ±0.001 (Ω) |

| Experiment | Evaporator Fan Speed (%) | Condenser Fan Speed (%) | Discharge Pressure (bar) | Suction Pressure (bar) | Ambient Temperature (℃) |

|---|---|---|---|---|---|

| Basic refrigeration system without HE-TEGs unit, base case | 100% | 100% | 10.64 | 3.46 | 27 |

| 80% | 100% | 10.75 | 3.55 | ||

| 60% | 100% | 10.71 | 3.52 | ||

| 40% | 100% | 10.70 | 3.45 | ||

| 20% | 100% | 10.40 | 3.21 | ||

| 100% | 80% | 10.78 | 3.48 | ||

| 100% | 60% | 10.98 | 3.53 | ||

| 100% | 40% | 12.05 | 3.68 | ||

| Refrigeration system with integration of HE-TEGs unit | 100% | 100% | 9.24 | 3.20 | 27 |

| 80% | 100% | 8.90 | 2.79 | ||

| 60% | 100% | 8.96 | 2.84 | ||

| 40% | 100% | 9.10 | 2.92 | ||

| 20% | 100% | 9.23 | 2.96 | ||

| 100% | 80% | 9.24 | 2.98 | ||

| 100% | 60% | 9.38 | 3.04 | ||

| 100% | 40% | 10.55 | 3.12 |

| Component | Compressor | Condenser | Expansion Valve | Evaporator | HE-TEGs Unit | Total Exergy Destruction | Sustainability Indicator |

|---|---|---|---|---|---|---|---|

| Basic system exergy destruction (kW) | 0.096 | 0.248 | 0.032 | 0.249 | - | 0.625 | 0.350 |

| System with HE-TEGs unit exergy destruction (kW) | 0.062 | 0.155 | 0.031 | 0.281 | 0.012 | 0.542 | 0.308 |

| Condenser Fan Speed % | COP with HE-TEGs Unit | COP Basic System | Power Consumption of Basic System (W) | Savings % | Annual Savings (kW·hr) | Annual Savings $ | Pay-Back Period (Year) |

|---|---|---|---|---|---|---|---|

| 100 | 4.3 | 3.4 | 401 | 26.4 | 581.15 | 27.89 | 2.86 |

| 80 | 4 | 3.4 | 405 | 17.6 | 391.30 | 18.78 | 4.25 |

| 60 | 4.1 | 3.2 | 409 | 28.1 | 629.79 | 30.23 | 2.64 |

| 40 | 4.1 | 3.1 | 435 | 32.2 | 768.26 | 36.87 | 2.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Attar, A.; Rady, M.; Abuhabaya, A.; Albatati, F.; Hegab, A.; Almatrafi, E. Performance Assessment of Using Thermoelectric Generators for Waste Heat Recovery from Vapor Compression Refrigeration Systems. Energies 2021, 14, 8192. https://doi.org/10.3390/en14238192

Attar A, Rady M, Abuhabaya A, Albatati F, Hegab A, Almatrafi E. Performance Assessment of Using Thermoelectric Generators for Waste Heat Recovery from Vapor Compression Refrigeration Systems. Energies. 2021; 14(23):8192. https://doi.org/10.3390/en14238192

Chicago/Turabian StyleAttar, Alaa, Mohamed Rady, Abdullah Abuhabaya, Faisal Albatati, Abdelkarim Hegab, and Eydhah Almatrafi. 2021. "Performance Assessment of Using Thermoelectric Generators for Waste Heat Recovery from Vapor Compression Refrigeration Systems" Energies 14, no. 23: 8192. https://doi.org/10.3390/en14238192

APA StyleAttar, A., Rady, M., Abuhabaya, A., Albatati, F., Hegab, A., & Almatrafi, E. (2021). Performance Assessment of Using Thermoelectric Generators for Waste Heat Recovery from Vapor Compression Refrigeration Systems. Energies, 14(23), 8192. https://doi.org/10.3390/en14238192