Improved Image Analysis Method to Evaluate Tracking Property under Successive Flashover Based on Fractal Theory

Abstract

:1. Introduction

2. Experimental Method

2.1. Characteristics of EP Sample

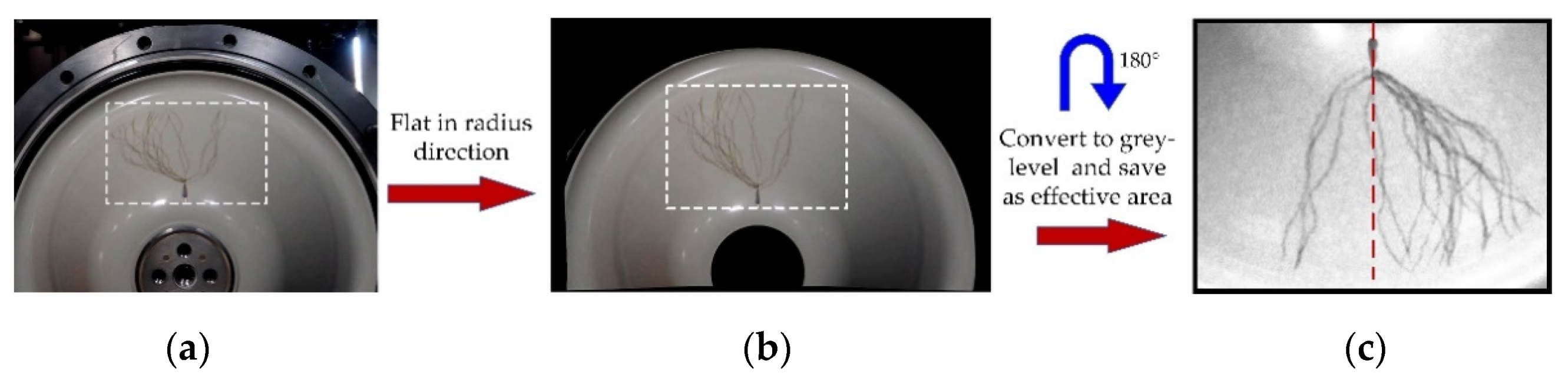

2.2. Surface Flashover Test

3. Improved Differential Box-Counting Method

4. Result and Discussion

4.1. Characteristics of Tracking

4.2. FD Result Based on IDBCM

4.3. Comparation between BCM and IDBCM

5. Conclusions

- (1)

- DC flashover was conducted at SF6/EP interface and obvious brown tracking remained on EP surface as the consequence of successive discharge. Tracking showed obvious main path for particle in the middle region which indicated severe damage due to successive flashover.

- (2)

- Weight factor was applied in covering potential margin with cut-size box during counting procedure to improve DBCM for rectangle image with arbitrary height and width. FD of tracking based on IDBCM showed high value for particle in middle region which can attribute to the fluctuation of color depth in the region of main path.

- (3)

- IDBCM showed advantages compared to BCM in evaluating successive discharge referring to propagation path and corresponding deterioration on the surface since it considered the depth of tracking color. Meanwhile, IDBCM showed universality for the required image quality and could provide additional information to flashover voltage.

- (4)

- This suggested image analysis method proposes a potential approach to reveal flashover characteristics including deterioration property based on fractal analysis of tracking pattern in future research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mazzanti, G.; Stomeo, G.; Mancini, S. State of the Art in Insulation of Gas Insulated Substations: Main Issues, Achievements, and Trends. IEEE Electr. Insul. Mag. 2016, 32, 18–31. [Google Scholar] [CrossRef]

- Koch, H. Gas-Insulated Transmission Lines; John Wiley & Sons: London, UK, 2012; pp. 46–47. [Google Scholar]

- Xing, Y.Q.; Liu, L.; Xu, Y.; Yang, Y.; Li, C.Y. Defects and Failure Types of Solid Insulation in Gas Insulated Switchgear: In situ Study and Case Analysis. High Volt. 2021, 1–7. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, C.J.; Li, C.Y.; Suraci, S.V.; Chen, G.; Riechert, U.; Shahsavarian, T.; Hikita, M.; Tu, Y.P.; Zhang, Z.S.; et al. Gas–Solid Interface Charge Characterisation Techniques for HVDC GIS/GIL Insulators. High Volt. 2020, 5, 95–109. [Google Scholar] [CrossRef]

- Li, X.; Liu, W.D.; Xu, Y.; Chen, W.; Bi, J. Surface Charge Accumulation and Pre-Flashover Characteristics Induced by Metal Particles on The Insulator Surfaces of 1100 kV GILs under AC Voltage. High Volt. 2020, 5, 134–142. [Google Scholar]

- Xie, Q.; Yang, W.; Xiong, L.; He, H.; Cheng, Z.; Shao, T. Characteristics of Microsecond-Pulse Surface Flashover on Epoxy Resin Surfaces in SF6. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2328–2336. [Google Scholar] [CrossRef]

- Que, L.; An, Z.; Yong, M.; Shan, F.; Zhang, Y. High Resistance of Surface Fluorinated Epoxy Insulators to Surface Discharge in SF6 Gas. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 245–252. [Google Scholar] [CrossRef]

- Li, C.; Hu, J.; Lin, C.; Zhang, B.; Zhang, G.; He, J. Surface Charge Migration and DC Surface Flashover of Surface-Modified Epoxy-Based Insulators. J. Phys. D 2017, 50, 065301. [Google Scholar] [CrossRef]

- Que, L.; An, Z.; Yong, M.; Xie, D.; Zheng, F.; Zhang, Y. Improved DC Flashover Performance of Epoxy Insulators in SF6 Gas by Direct Fluorination. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1153–1161. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, W.; Yu, J.; Qi, S.; Hui, H. Insulation Condition Monitoring of Epoxy Spacers in GIS Using A Decomposed Gas CS2. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2152–2157. [Google Scholar] [CrossRef]

- Prasad, D.S.; Reddy, B.S. Digital Image Processing Techniques for Estimating Power Released from The Corona Discharges. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 75–82. [Google Scholar] [CrossRef]

- Chaou, A.; Mekhaldi, A.; Teguar, M. Elaboration of Novel Image Processing Algorithm for Arcing Discharges Recognition on HV Polluted Insulator Model. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 990–999. [Google Scholar] [CrossRef]

- Koppisetty, K.; Serkan, M.; Kirkici, H. Image Analysis: A Tool for Optical-Emission Characterization of Partial-Vacuum Breakdown. IEEE Trans. Plasma Sci. 2009, 37, 153–158. [Google Scholar] [CrossRef]

- Niemeyer, L.; Pietronero, L.; Wiesmann, H.J. Fractal Dimension of Dielectric Breakdown. Phys. Rev. Lett. 1984, 52, 1033–1036. [Google Scholar] [CrossRef]

- Amarasinghe, D.; Sonnadara, U.; Berg, M.; Cooray, V. Fractal Dimension of Long Electrical Discharges. J. Electrost. 2015, 73, 33–37. [Google Scholar] [CrossRef]

- Dirnberger, A.; Kovaleski, S.D.; Norgard, P.; Thagard, S.M.; Franclemont, J. In-Liquid Streamer Characterization and Fractal Analysis. IEEE Trans. Plasma Sci. 2018, 46, 2550–2557. [Google Scholar] [CrossRef]

- Xie, Q.; Liang, S.; Fu, K.; Liu, L.; Huang, H.; Lv, F. Distribution of Polymer Surface Charge under DC Voltage and Its Influence on Surface Flashover Characteristics. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2157–2168. [Google Scholar] [CrossRef]

- Beroual, A.; Dang, V.H. Fractal Analysis of Lightning Impulse Surface Discharges Propagating over Pressboard Immersed in Mineral and Vegetable Oils. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1402–1408. [Google Scholar] [CrossRef]

- Du, B.X.; Xue, J.S.; Zhang, M.M. Effect of Pulse Duration on Electrical Tree and Breakdown Process of Epoxy Resin in LN2. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 359–366. [Google Scholar] [CrossRef]

- Kebbabi, L.; Beroual, A. Fractal Analysis of Creeping Discharge Patterns Propagating at Solid/Liquid Interfaces: Influence of The Nature and Geometry of Solid Insulators. J. Phys. D 2006, 39, 177–183. [Google Scholar] [CrossRef]

- Ai, T.; Zhang, R.; Zhou, H.W.; Pei, J.L. Box-Counting Methods to Directly Estimate the Fractal Dimension of a Rock Surface. Appl. Surf. Sci. 2014, 314, 610–621. [Google Scholar] [CrossRef]

- Li, J.; Du, Q.; Sun, C. An Improved Box-Counting Method for Image Fractal Dimension Estimation. Pattern Recogn. 2009, 42, 2460–2469. [Google Scholar] [CrossRef]

- Yu, L.; Chen, L.; Wang, H.; Jiang, L.; Song, Y. An Improved Differential Box-Counting Method to Estimate Fractal Dimensions of Gray-Level Images. J. Visual Commun. Image Represent. 2014, 25, 1102–1111. [Google Scholar]

- Bo, Q.; Cheng, R.L.; Zhen, H.; Bi, B.G.; Dang, G.X.; Shao, Y.L.; Deng, C. Surface Discharge Initiated by Immobilized Metallic Particles Attached to Gas Insulated Substation Insulators: Process and Features. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 792–800. [Google Scholar]

- Min, L.; Peng, F. A Box-Counting Method with Adaptable Box Height for Measuring the Fractal Feature of Images. Radioengineering 2013, 22, 208–213. [Google Scholar]

- Zhou, H.W.; Xie, H. Direct Estimation of The Fractal Dimensions of A Fracture Surface of Rock. Surf. Rev. Lett. 2003, 10, 751–762. [Google Scholar] [CrossRef]

- Jing, J.; Feng, P.; Wei, S.; Zhao, H.; Liu, Y. Investigation on The Surface Morphology of Si3N4 Ceramics by A New Fractal Dimension Calculation Method. Appl. Surf. Sci. 2016, 387, 812–821. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Cao, C.; Lin, X. Improved Image Analysis Method to Evaluate Tracking Property under Successive Flashover Based on Fractal Theory. Energies 2021, 14, 8253. https://doi.org/10.3390/en14248253

Li X, Cao C, Lin X. Improved Image Analysis Method to Evaluate Tracking Property under Successive Flashover Based on Fractal Theory. Energies. 2021; 14(24):8253. https://doi.org/10.3390/en14248253

Chicago/Turabian StyleLi, Xiaolong, Chen Cao, and Xin Lin. 2021. "Improved Image Analysis Method to Evaluate Tracking Property under Successive Flashover Based on Fractal Theory" Energies 14, no. 24: 8253. https://doi.org/10.3390/en14248253

APA StyleLi, X., Cao, C., & Lin, X. (2021). Improved Image Analysis Method to Evaluate Tracking Property under Successive Flashover Based on Fractal Theory. Energies, 14(24), 8253. https://doi.org/10.3390/en14248253