Numerical Investigation on Propagation Behaviors of a Three-Dimensional Fracture Network Coupled with Microseismicity in Fractured Shale Reservoirs

Abstract

:1. Introduction

2. Discrete Lattice Method

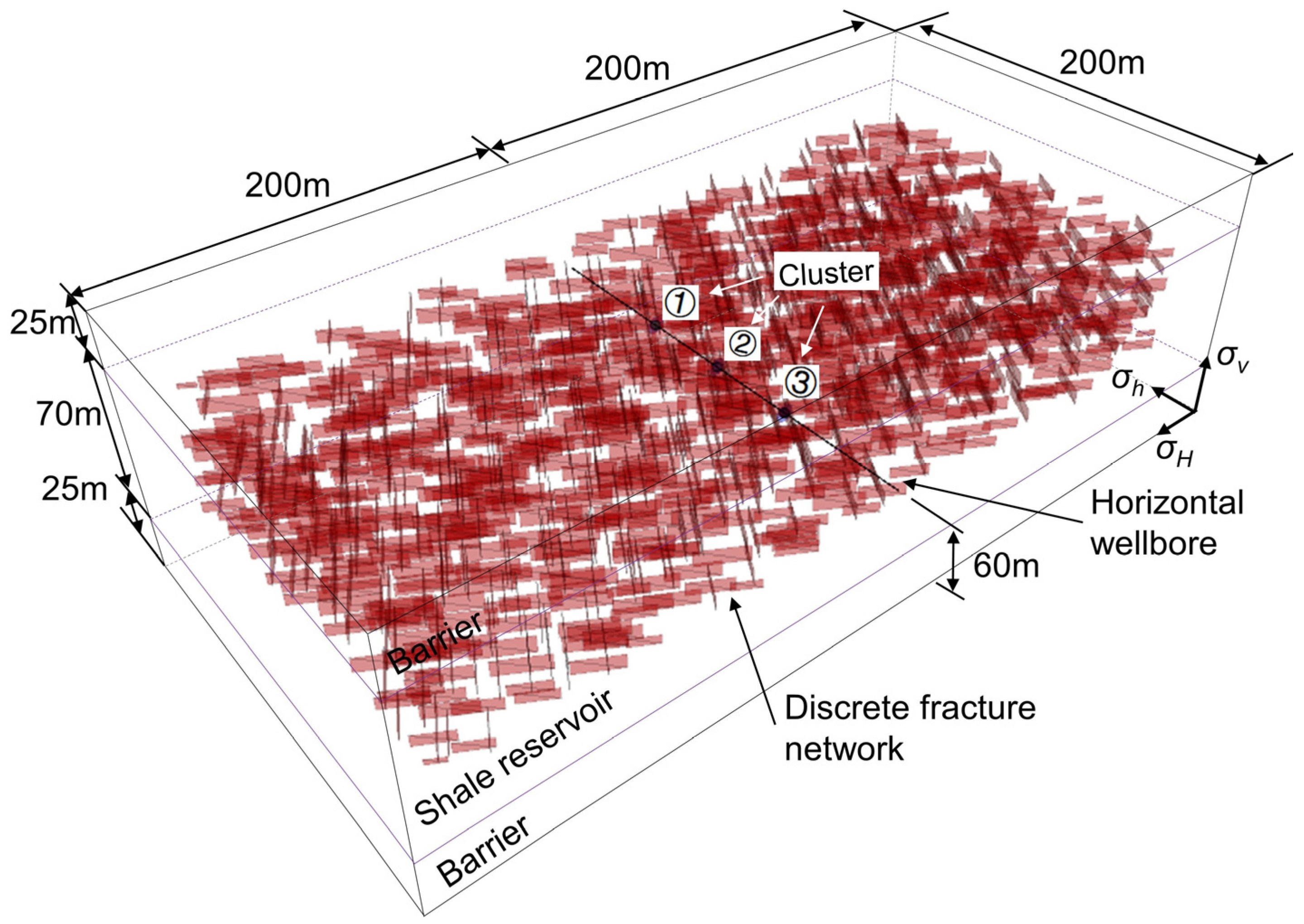

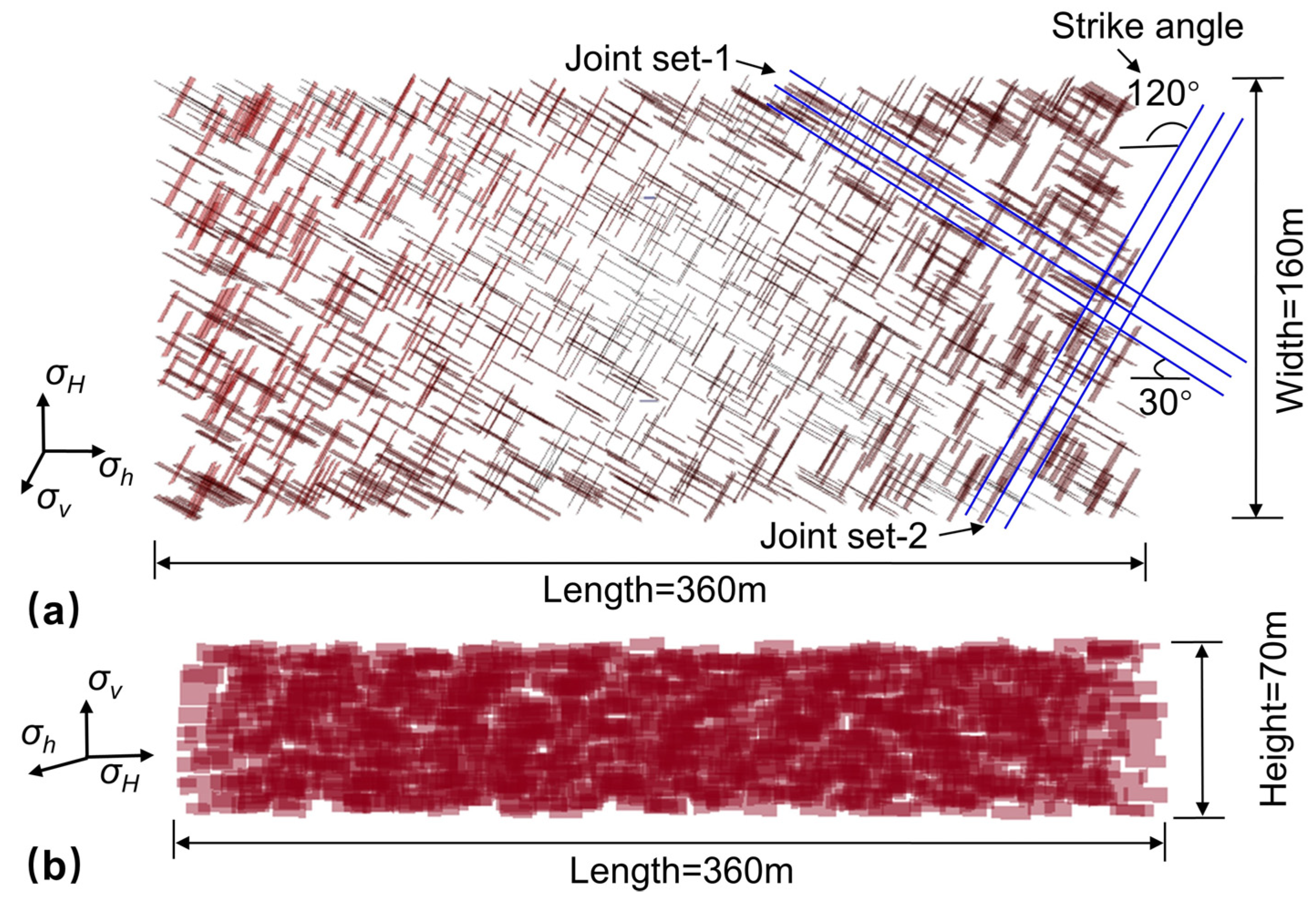

3. Three-Dimensional Numerical Model of Hydraulic Fracture Network

3.1. Engineering Background

3.2. Establishment of the Three-Dimensional Fracture Network Model

| Parameters | Shale Reservoir |

|---|---|

| Formation pore pressure (MPa) | 29.4 |

| Maximum horizontal principal stress (MPa) | 52.5 |

| Minimum horizontal principal stress (MPa) | 47.5 |

| Overburden stress (MPa) | 57.5 |

| Uniaxial compressive strength (MPa) | 200.1 |

| Tensile strength (MPa) | 13.16 |

| Poisson’s ratio | 0.26 |

| Elastic modulus (GPa) | 52.89 |

| Fracture toughness (MPa/m0.5) | 0.96 |

| Leak-off coefficient (m/s0.5) | 1.2 × 10−4 |

| Matrix permeability (mD) | 0.002 |

| Porosity (%) | 5 |

| Parameters | Value |

|---|---|

| Number of clusters | 3 |

| Cluster spacing (m) | 40 |

| Injection rate (m3/min) | 13 |

| Fluid viscosity (mPa.s) | 3 |

| Fluid density (kg/m3) | 1010 |

| Fracturing fluid type | Newtonian fluid |

| Injection time (s) | 6300 |

| Perforation phase angle (°) | 60 |

| Perforation density (holes/m) | 16 |

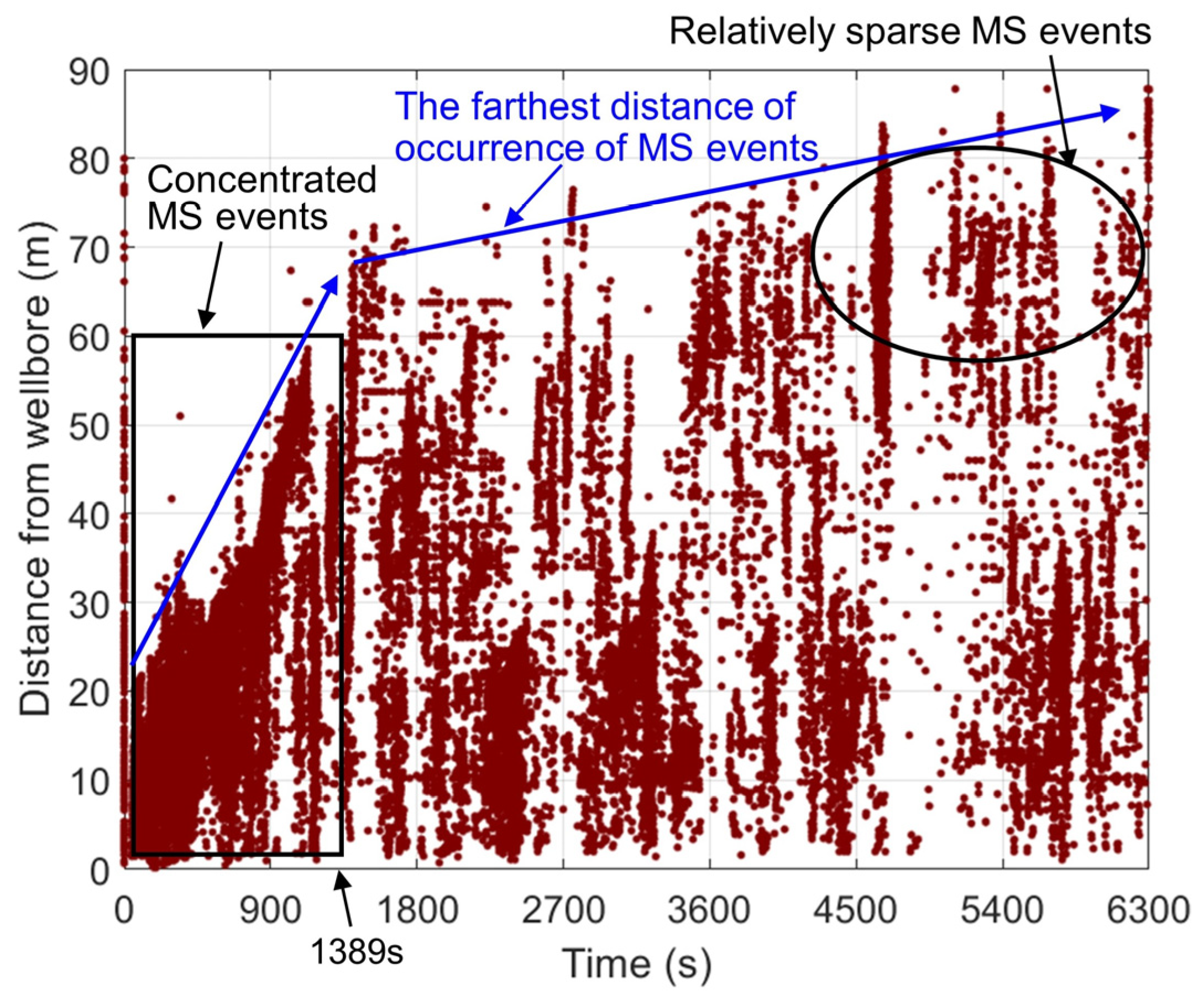

3.3. Numerical Simulation Results and Model Verification

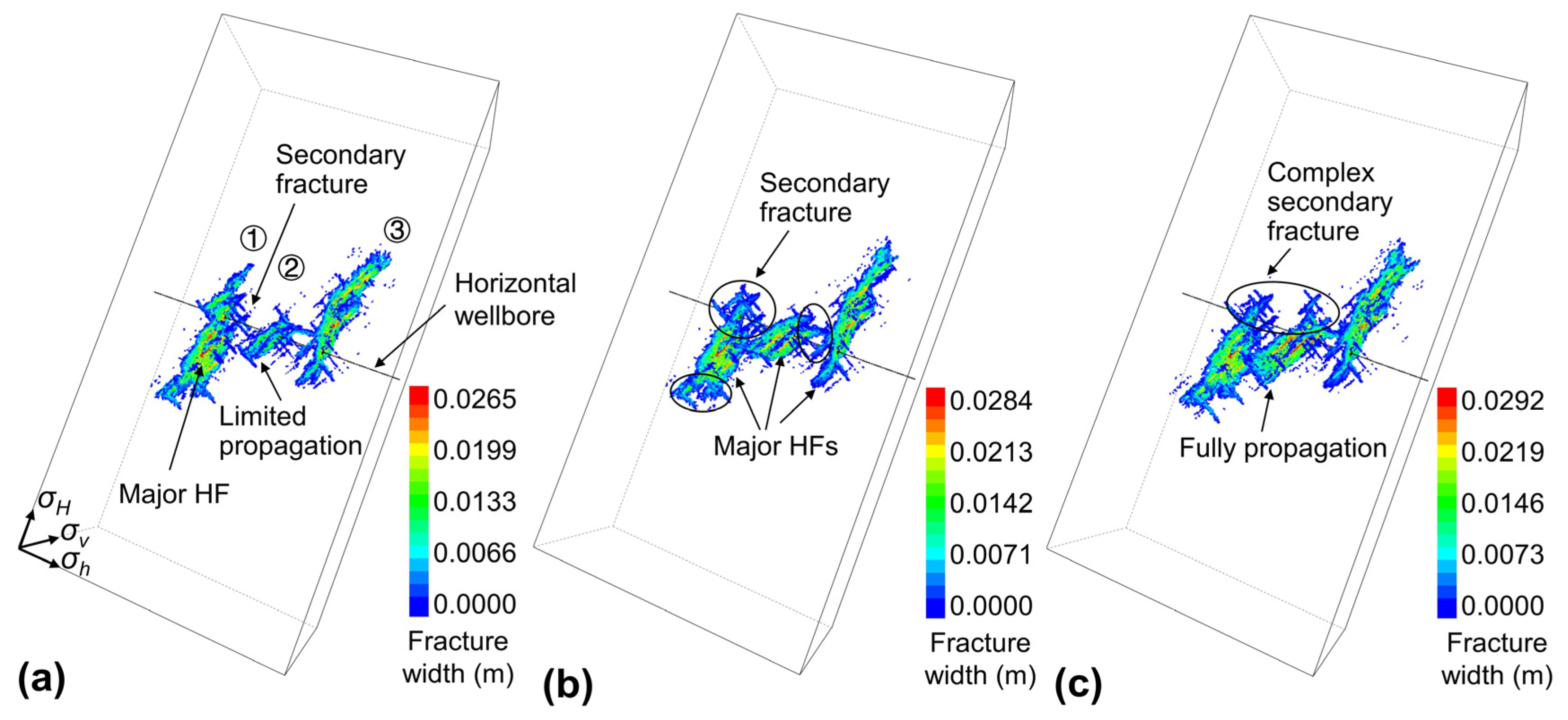

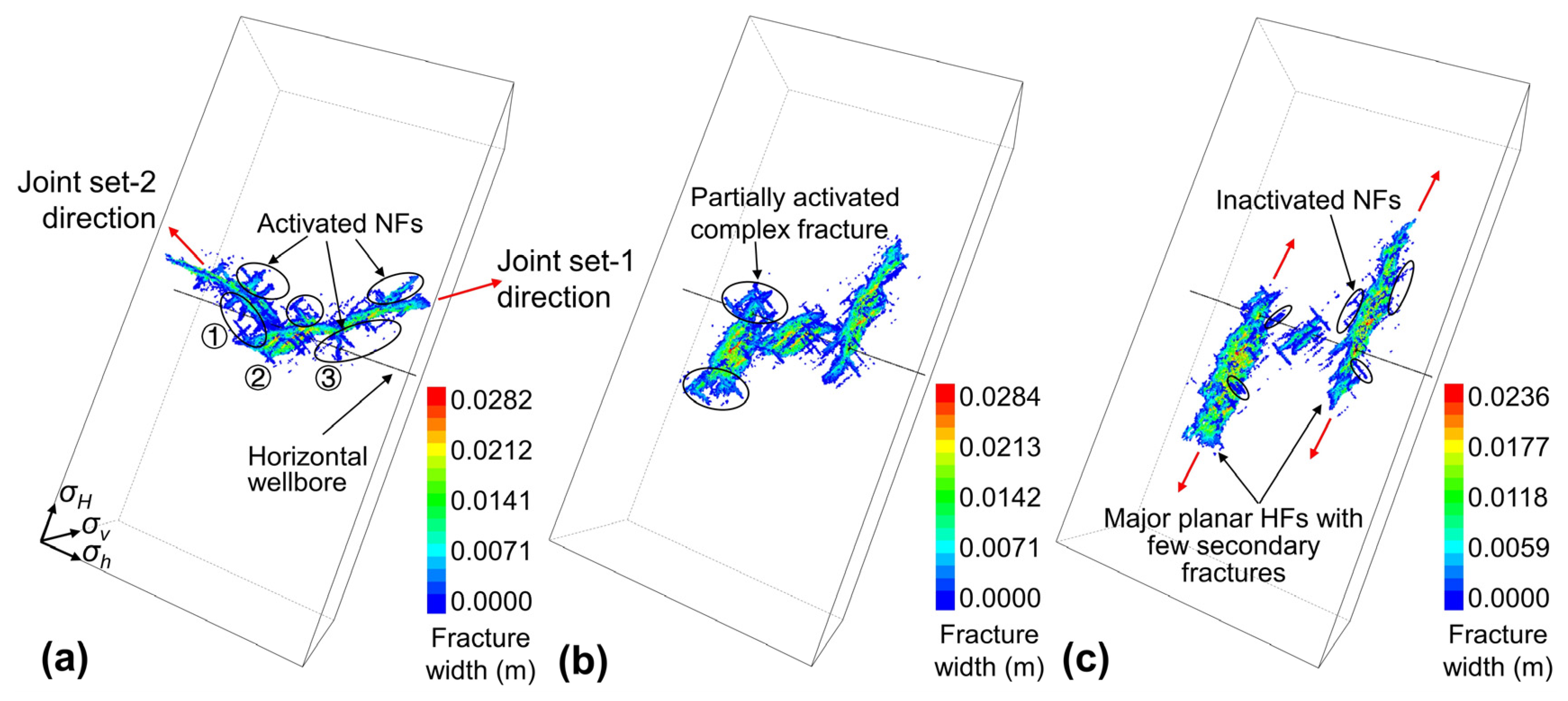

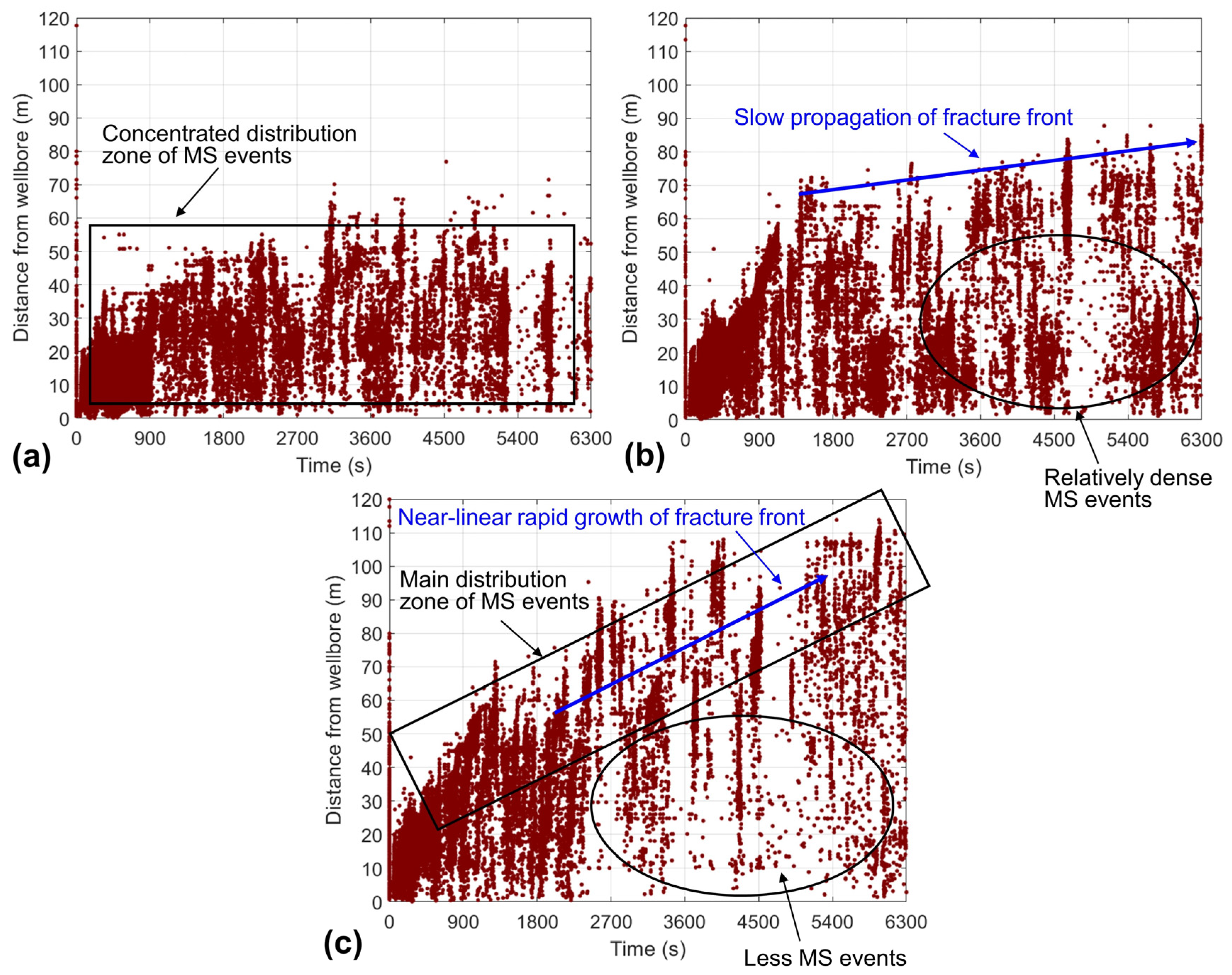

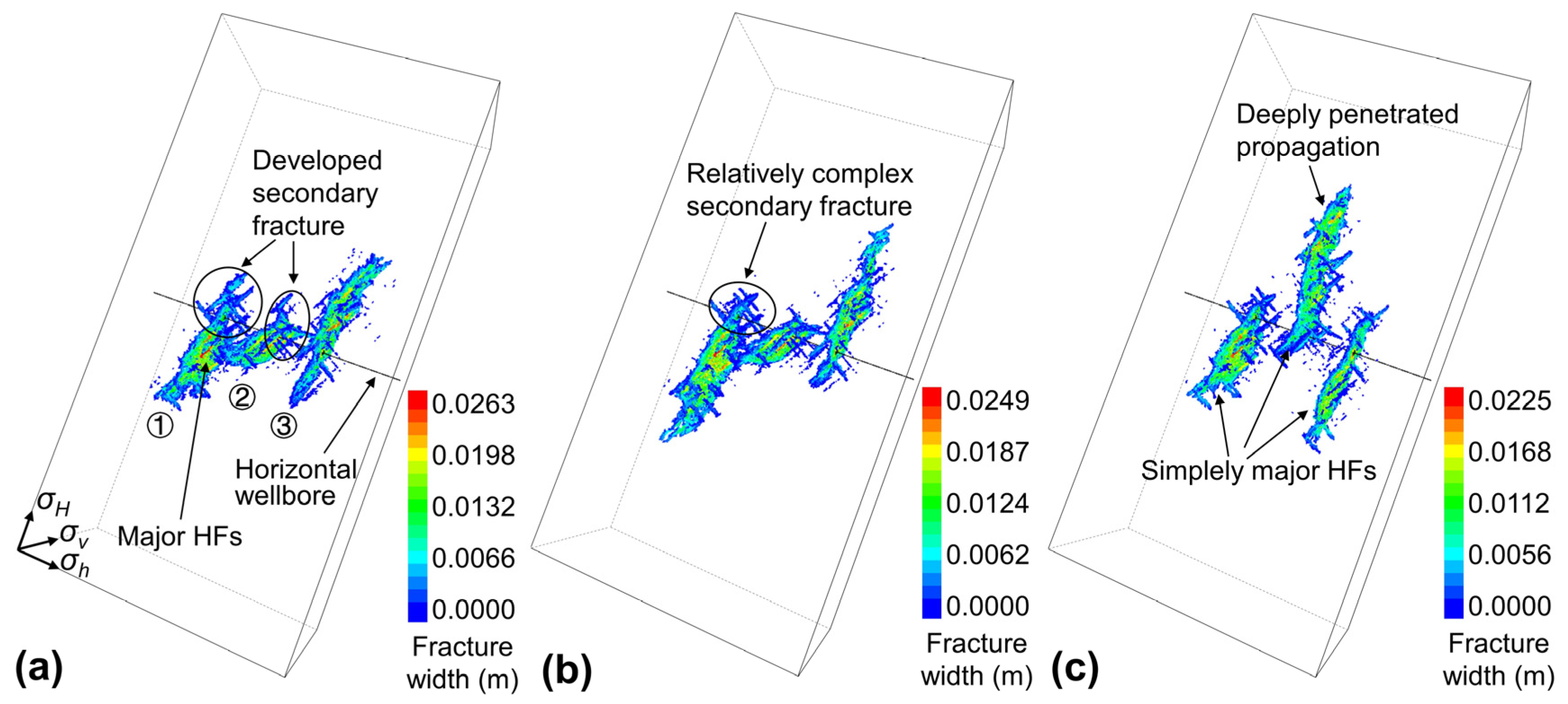

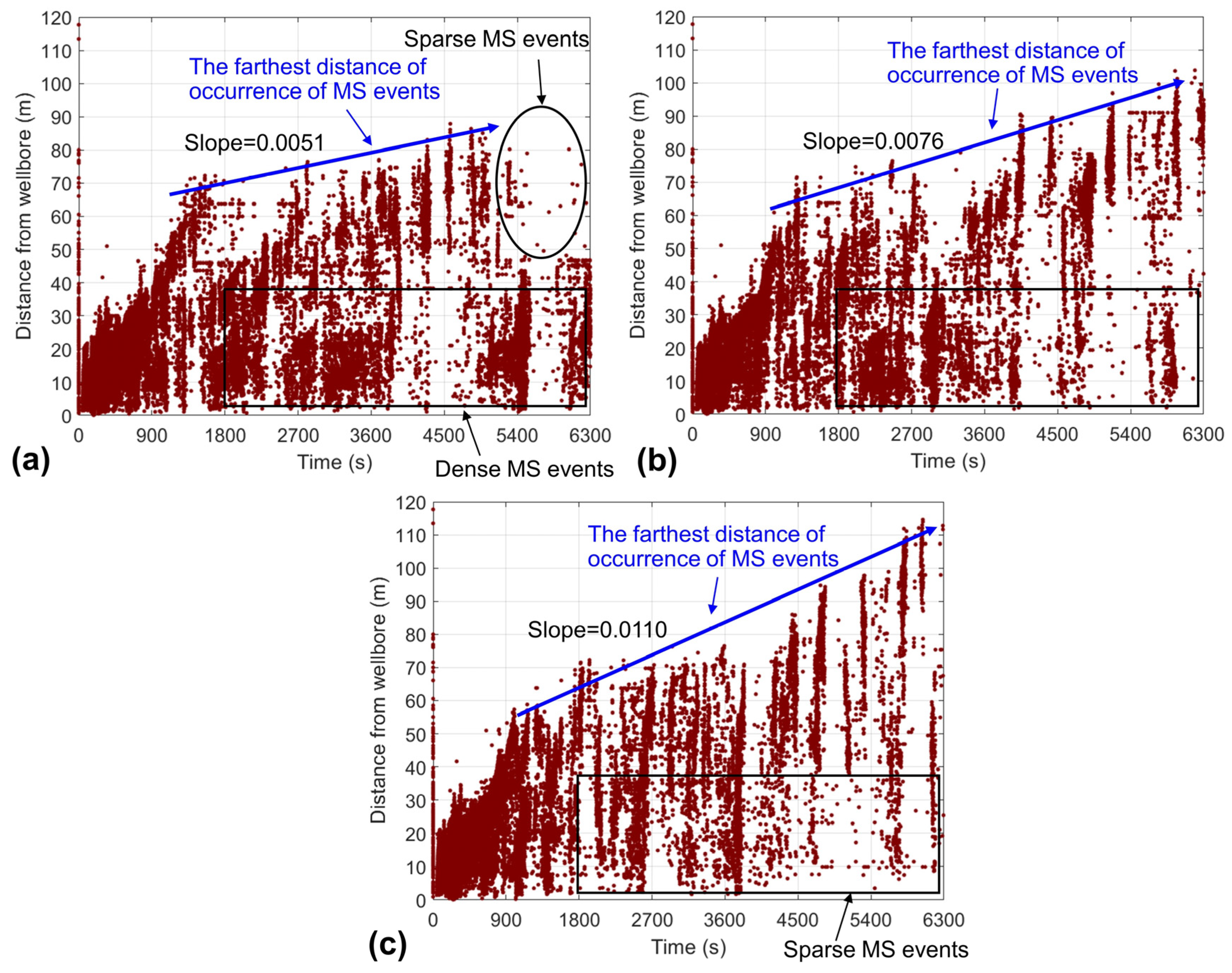

4. Propagation Behaviors of Three-Dimensional Fracture Network

4.1. Injection Rate

4.2. Horizontal Stress Difference

4.3. Fluid Viscosity

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, D.-J.; Tang, H.; Shen, P.; Su, X.; Huang, L. Co-effects of bedding planes and parallel flaws on fracture evolution in anisotropic rocks. Eng. Geol. 2020, 264, 105382. [Google Scholar] [CrossRef]

- Elizalde, C.; Griffith, W.A.; Miller, T. Thrust fault nucleation due to heterogeneous bedding plane slip: Evidence from an Ohio coal mine. Eng. Geol. 2016, 206, 1–17. [Google Scholar] [CrossRef]

- Ma, G.; Li, M.; Wang, H.; Chen, Y. Equivalent discrete fracture network method for numerical estimation of deformability in complexly fractured rock masses. Eng. Geol. 2020, 277, 105784. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, X.; Liu, Z. Experimental investigation of hydraulic sand fracturing on fracture propagation under the influence of coal macrolithotypes in Hancheng block, China. J. Pet. Sci. Eng. 2019, 175, 60–71. [Google Scholar] [CrossRef]

- Tang, J.; Wu, K.; Zuo, L.; Xiao, L.; Sun, S.; Ehlig–Economides, C. Investigation of rupture and slip mechanisms of hydraulic fracture in multiple-layered formation. SPE J. 2019, 24, 2292–2307. [Google Scholar] [CrossRef]

- Xie, J.; Tang, J.; Yong, R.; Fan, Y.; Zuo, L.; Chen, X.; Li, Y. A 3-D hydraulic fracture propagation model applied for shale gas reservoirs with multiple bedding planes. Eng. Fract. Mech. 2020, 228, 106872. [Google Scholar] [CrossRef]

- Tan, P.; Jin, Y.; Pang, H. Hydraulic fracture vertical propagation behavior in transversely isotropic layered shale formation with transition zone using XFEM-based CZM method. Eng. Fract. Mech. 2021, 248, 107707. [Google Scholar] [CrossRef]

- Haddad, M.; Du, J.; Vidal-Gilbert, S. Integration of dynamic microseismic data with a true 3d modeling of hydraulic-fracture propagation in the Vaca Muerta shale. SPE J. 2017, 22, 1714–1738. [Google Scholar] [CrossRef]

- Mejía Camones, L.A.; Vargas, E.d.A.; Velloso, R.Q.; Paulino, G.H. Simulation of hydraulic fracturing processes in rocks by coupling the lattice Boltzmann model and the Park-Paulino-Roesler potential-based cohesive zone model. Int. J. Rock Mech. Min. Sci. 2018, 112, 339–353. [Google Scholar] [CrossRef]

- Ouchi, H.; Katiyar, A.; Foster, J.T.; Sharma, M.M. A peridynamics model for the propagation of hydraulic fractures in naturally fractured reservoirs. SPE J. 2017, 22, 1082–1102. [Google Scholar] [CrossRef]

- Tan, P.; Pang, H.; Zhang, R.; Jin, Y.; Zhou, Y.; Kao, J.; Fan, M. Experimental investigation into hydraulic fracture geometry and proppant migration characteristics for southeastern Sichuan deep shale reservoirs. J. Pet. Sci. Eng. 2020, 184, 106517. [Google Scholar] [CrossRef]

- Li, M.; Zhang, F.; Zhuang, L.; Zhang, X.; Ranjith, P. Micromechanical analysis of hydraulic fracturing in the toughness-dominated regime: Implications to supercritical carbon dioxide fracturing. Comput. Geosci. 2020, 24, 1815–1831. [Google Scholar] [CrossRef]

- Maity, D.; Ciezobka, J. Digital fracture characterization at hydraulic fracturing test site hfts-midland: Fracture clustering, stress effects and lithologic controls. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Virtual, 4–6 May 2021. [Google Scholar]

- Ru, Z.; Hu, J.; Madni, A.S.; An, K. A study on the optimal conditions for formation of complex fracture networks in fractured reservoirs. J. Struct. Geol. 2020, 135, 104039. [Google Scholar] [CrossRef]

- Guo, Z.; Tian, S.; Liu, Q.; Ma, L.; Yong, Y.; Yang, R. Experimental investigation on the breakdown pressure and fracture propagation of radial borehole fracturing. J. Pet. Sci. Eng. 2022, 208, 109169. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, X.; Liu, Z.; Yan, Y.; Yang, H. Investigation on the hydraulic fracture propagation of multilayers-commingled fracturing in coal measures. J. Pet. Sci. Eng. 2018, 167, 774–784. [Google Scholar] [CrossRef]

- Yang, B.; Wang, H.; Wang, B.; Shen, Z.; Zheng, Y.; Jia, Z.; Yan, W. Digital quantification of fracture in full-scale rock using micro-CT images: A fracturing experiment with N2 and CO2. J. Pet. Sci. Eng. 2021, 196, 107682. [Google Scholar] [CrossRef]

- Zhai, L.; Zhang, H.; Pan, D.; Zhu, Y.; Zhu, J.; Zhang, Y.; Chen, C. Optimisation of hydraulic fracturing parameters based on cohesive zone method in oil shale reservoir with random distribution of weak planes. J. Nat. Gas Sci. Eng. 2020, 75, 103130. [Google Scholar] [CrossRef]

- Wang, H. Hydraulic fracture propagation in naturally fractured reservoirs: Complex fracture or fracture networks. J. Nat. Gas Sci. Eng. 2019, 68, 102911. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Dahi Taleghani, A.; Lian, Z. On how pumping hesitations may improve complexity of hydraulic fractures, a simulation study. Fuel 2019, 249, 294–308. [Google Scholar] [CrossRef]

- Zou, J.; Jiao, Y.-Y.; Tan, F.; Lv, J.; Zhang, Q. Complex hydraulic-fracture-network propagation in a naturally fractured reservoir. Comput. Geotech. 2021, 135, 104165. [Google Scholar] [CrossRef]

- Fan, H.; Li, S.; Feng, X.-T.; Zhu, X. A high-efficiency 3D boundary element method for estimating the stress/displacement field induced by complex fracture networks. J. Pet. Sci. Eng. 2020, 187, 106815. [Google Scholar] [CrossRef]

- Ren, L.; Su, Y.; Zhan, S.; Hao, Y.; Meng, F.; Sheng, G. Modeling and simulation of complex fracture network propagation with SRV fracturing in unconventional shale reservoirs. J. Nat. Gas Sci. Eng. 2016, 28, 132–141. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, R.; Jiang, G.; Xie, J. Modelling hydraulic fracturing in a complex-fracture-network reservoir with the DDM and graph theory. J. Nat. Gas Sci. Eng. 2017, 47, 73–82. [Google Scholar] [CrossRef]

- Shakiba, M.; de Araujo Cavalcante Filho, J.S.; Sepehrnoori, K. Using embedded discrete fracture model (EDFM) in numerical simulation of complex hydraulic fracture networks calibrated by microseismic monitoring data. J. Nat. Gas Sci. Eng. 2018, 55, 495–507. [Google Scholar] [CrossRef]

- Li, J.; Yu, W.; Guerra, D.; Wu, K. Modeling wettability alteration effect on well performance in Permian basin with complex fracture networks. Fuel 2018, 224, 740–751. [Google Scholar] [CrossRef]

- Shi, F.; Wang, X.; Liu, C.; Liu, H.; Wu, H. An XFEM-based method with reduction technique for modeling hydraulic fracture propagation in formations containing frictional natural fractures. Eng. Fract. Mech. 2017, 173, 64–90. [Google Scholar] [CrossRef]

- Dong, Y.; Li, P.; Tian, W.; Xian, Y.; Lu, D. An equivalent method to assess the production performance of horizontal wells with complicated hydraulic fracture network in shale oil reservoirs. J. Nat. Gas Sci. Eng. 2019, 71, 102975. [Google Scholar] [CrossRef]

- Qin, M.; Yang, D.; Chen, W.; Xia, X. Hydraulic fracturing network modeling based on peridynamics. Eng. Fract. Mech. 2021, 247, 107676. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Pan, Y.; Wang, X.; Yan, M.; Shi, X.; Zhou, X.; Li, H. Experiments and analysis on the influence of multiple closed cemented natural fractures on hydraulic fracture propagation in a tight sandstone reservoir. Eng. Geol. 2021, 281, 105981. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, S.; Zhao, H.; Wang, L.; Li, W.; Geng, Y.; Tao, S.; Zhang, G.; Chen, M. Effect of random natural fractures on hydraulic fracture propagation geometry in fractured carbonate rocks. Rock Mech. Rock Eng. 2018, 51, 491–511. [Google Scholar] [CrossRef]

- Tan, P.; Jin, Y.; Han, K.; Hou, B.; Chen, M.; Guo, X.; Gao, J. Analysis of hydraulic fracture initiation and vertical propagation behavior in laminated shale formation. Fuel 2017, 206, 482–493. [Google Scholar] [CrossRef]

- Damjanac, B.; Detournay, C.; Cundall, P.A. Application of particle and lattice codes to simulation of hydraulic fracturing. Comput. Part. Mech. 2016, 3, 249–261. [Google Scholar] [CrossRef]

- Benouadah, N.; Djabelkhir, N.; Song, X.; Rasouli, V.; Damjanac, B. Simulation of competition between transverse notches versus axial fractures in open hole completion hydraulic fracturing. Rock Mech. Rock Eng. 2021, 54, 2249–2265. [Google Scholar] [CrossRef]

- Bakhshi, E.; Rasouli, V.; Ghorbani, A.; Fatehi Marji, M.; Damjanac, B.; Wan, X. Lattice numerical simulations of lab-scale hydraulic fracture and natural interface interaction. Rock Mech. Rock Eng. 2019, 52, 1315–1337. [Google Scholar] [CrossRef]

- Damjanac, B.; Cundall, P. Application of distinct element methods to simulation of hydraulic fracturing in naturally fractured reservoirs. Comput. Geotech. 2016, 71, 283–294. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, X.; Tang, M.; Du, X.; Xu, C.; Tang, J.; Damjanac, B. Numerical investigation on hydraulic fracturing of extreme limited entry perforating in plug-and-perforation completion of shale oil reservoir in Changqing oilfield, China. Rock Mech. Rock Eng. 2021, 54, 2925–2941. [Google Scholar] [CrossRef]

- Zhang, F.; Wu, J.; Huang, H.; Wang, X.; Luo, H.; Yue, W.; Hou, B. Technological parameter optimization for improving the complexity of hydraulic fractures in deep shale reservoirs. Nat. Gas Ind. 2021, 41, 125–135. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, F.; Tang, M.; Du, X.; Tang, J. Effect of stress shadow caused by multi-stage fracturing from multiple well pads on fracture initiation and near-wellbore propagation from infill wells. SPE J. 2021, 1–22. [Google Scholar] [CrossRef]

- Zhang, F.; Mack, M. Integrating fully coupled geomechanical modeling with microsesmicity for the analysis of refracturing treatment. J. Nat. Gas Sci. Eng. 2017, 46, 16–25. [Google Scholar] [CrossRef]

- Zou, Y.; Ma, X.; Zhang, S.; Zhou, T.; Li, H. Numerical investigation into the influence of bedding plane on hydraulic fracture network propagation in shale formations. Rock Mech. Rock Eng. 2016, 49, 3597–3614. [Google Scholar] [CrossRef]

- Heng, S.; Li, X.; Liu, X.; Chen, Y. Experimental study on the mechanical properties of bedding planes in shale. J. Nat. Gas Sci. Eng. 2020, 76, 103161. [Google Scholar] [CrossRef]

- Nagel, N.B.; Garcia, X.; Sanchez Nagel, M.; Lee, B. Understanding “SRV”: A numerical investigation of “wet” vs. “dry” microseismicity during hydraulic fracturing. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Maxwell, S.C.; Mack, M.; Zhang, F.; Chorney, D.; Goodfellow, S.D.; Grob, M. Differentiating wet and dry microseismic events induced during hydraulic fracturing. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar]

- Li, S.; Zhang, D.; Li, X. A new approach to the modeling of hydraulic-fracturing treatments in naturally fractured reservoirs. SPE J. 2017, 22, 1064–1081. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, S.; Ma, X.; Zhou, T.; Zeng, B. Numerical investigation of hydraulic fracture network propagation in naturally fractured shale formations. J. Struct. Geol. 2016, 84, 1–13. [Google Scholar] [CrossRef]

- Maxwell, S.C.; Zhang, F.; Damjanac, B. Geomechanical modeling of induced seismicity resulting from hydraulic fracturing. Lead. Edge 2015, 34, 678–683. [Google Scholar] [CrossRef] [Green Version]

- Kresse, O.; Weng, X.; Chuprakov, D.; Prioul, R.; Cohen, C. Effect of flow rate and viscosity on complex fracture development in UFM model. In Proceedings of the ISRM International Conference for Effective and Sustainable Hydraulic Fracturing, Brisbane, Australia, 20–22 May 2013. [Google Scholar]

- Zhao, H.; Wang, X.; Wang, W.; Mu, E. A simulation method based on energy criterion for network fracturing in shale gas reservoirs. J. Nat. Gas Sci. Eng. 2018, 52, 295–303. [Google Scholar] [CrossRef]

- Meyer, B.R.; Bazan, L.W. A discrete fracture network model for hydraulically induced fractures: Theory, parametric and case studies. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

- Li, S.; Zhang, D. How effective is carbon dioxide as an alternative fracturing fluid? SPE J. 2019, 24, 857–876. [Google Scholar] [CrossRef]

- Ni, L.; Zhang, X.; Zou, L.; Huang, J. Phase-field modeling of hydraulic fracture network propagation in poroelastic rocks. Comput. Geosci. 2020, 24, 1767–1782. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Huang, H.; Xu, E.; Li, J.; Wang, X. Numerical Investigation on Propagation Behaviors of a Three-Dimensional Fracture Network Coupled with Microseismicity in Fractured Shale Reservoirs. Energies 2021, 14, 8297. https://doi.org/10.3390/en14248297

Wu J, Huang H, Xu E, Li J, Wang X. Numerical Investigation on Propagation Behaviors of a Three-Dimensional Fracture Network Coupled with Microseismicity in Fractured Shale Reservoirs. Energies. 2021; 14(24):8297. https://doi.org/10.3390/en14248297

Chicago/Turabian StyleWu, Jianfa, Haoyong Huang, Ersi Xu, Junfeng Li, and Xiaohua Wang. 2021. "Numerical Investigation on Propagation Behaviors of a Three-Dimensional Fracture Network Coupled with Microseismicity in Fractured Shale Reservoirs" Energies 14, no. 24: 8297. https://doi.org/10.3390/en14248297