Design of Clean Steel Production with Hydrogen: Impact of Electricity System Composition

Abstract

:1. Introduction

1.1. CO2 Emissions Reduction Options

1.2. Hydrogen Direct Reduction Steelmaking Process

1.3. Research Gap

2. Method

2.1. Data

2.2. Steel Process Model

2.3. Electricity Price Profiles

3. Results and Discussion

3.1. Investments in Steel Production and Storage Capacities

3.2. Operational Time and Operational Level of the Steel Production Capacity

3.3. Sensitivity Analysis: Impact of Solar Power

3.4. Implications

3.5. Limitations

4. Conclusions

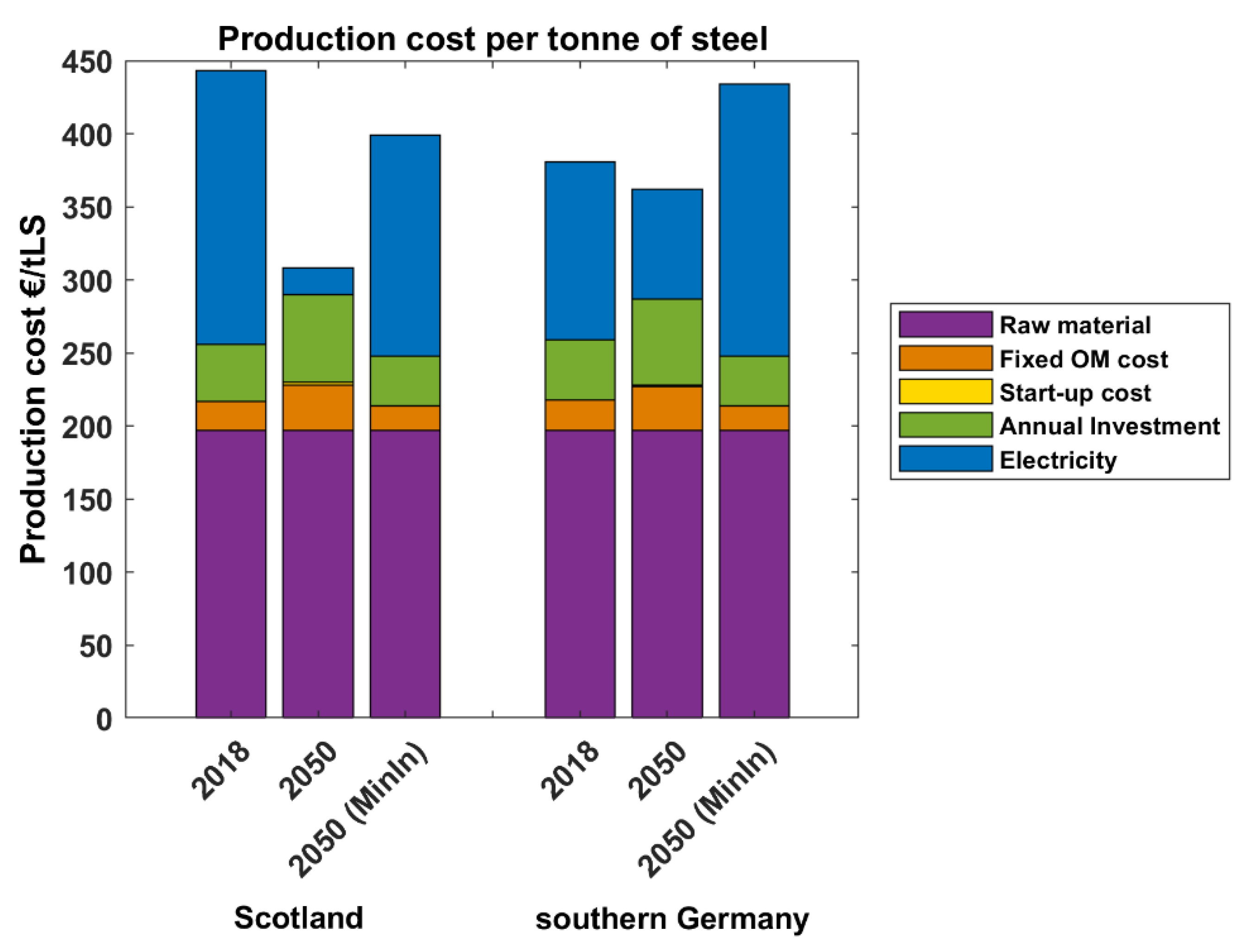

- The cost-optimal investments in the steel production capacities of the modelled process are higher compared to investment in a process in which all the production units are operated at full capacity for all hours of the year, i.e., a “minimum investment level” design, for the electricity price profiles applied in this work. Such a process design, enabling a price-following operation, results in a reduction in electricity costs by up to 88% and a reduction in the cost per tonne of steel by up to 23% compared to the “minimum investment level” design.

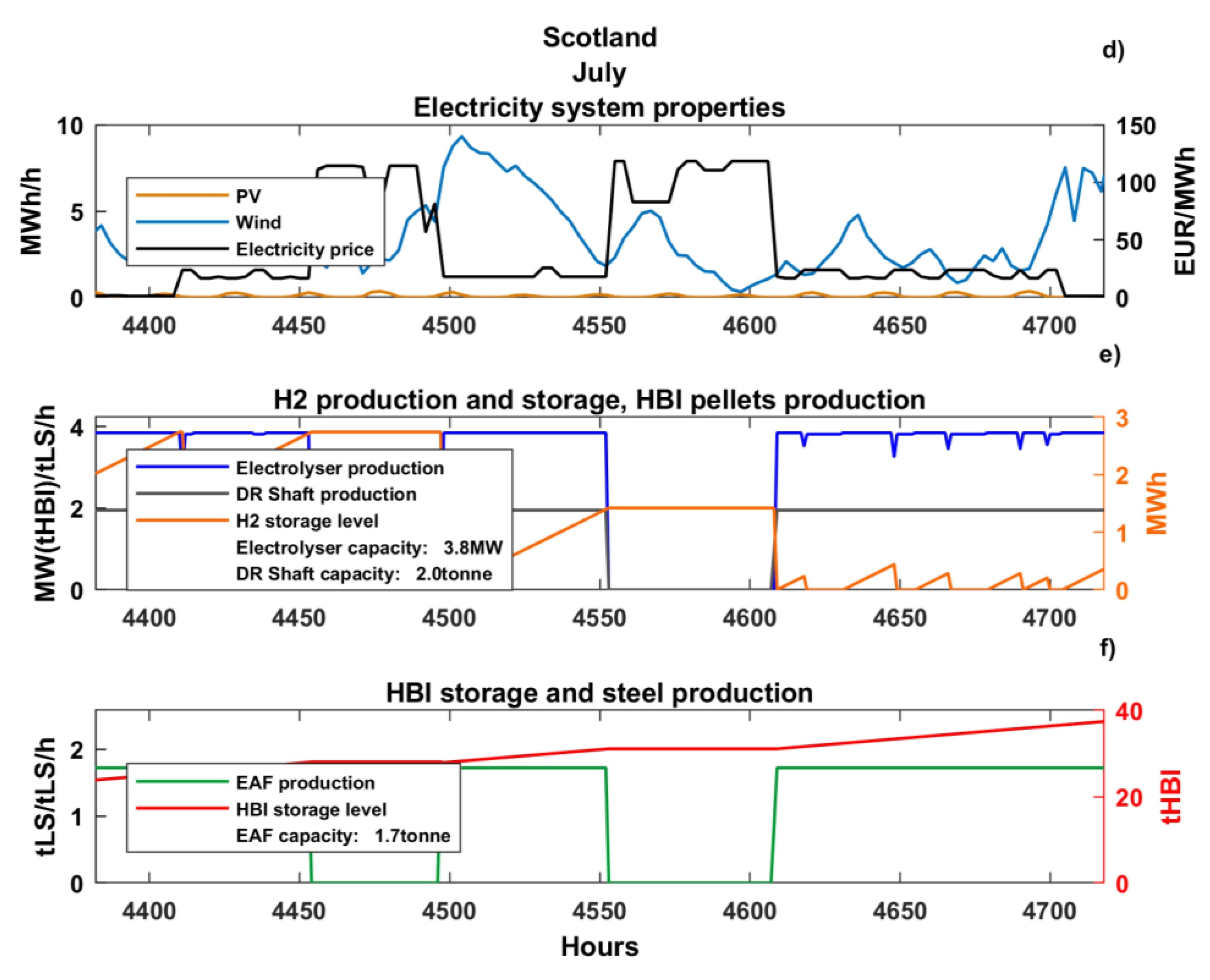

- The cost-optimal design of the steelmaking process is highly dependent upon the electricity system mix. For example, the hot-briquetted iron storage unit is sized to manage wind variation, of up to several days, for the wind-dominated region and to manage diurnal solar variation for the solar PV-dominated region.

- The benefits of cost-optimal investments in steel-production capacities depend on the electricity system composition. The results indicate that the benefits are greater in wind-dominated Scotland than in solar-dominated southern Germany since the flexibility offered by the steel process is more relevant in the days to week timescale than the seasonal timescale needed to compensate for the low solar PV production in south Germany during wintertime. Based on the findings of the sensitivity analysis, it is found that in a solar PV-dominated electricity system with good conditions for solar PV throughout the year, the potential to decrease the total steelmaking cost through cost-minimized sizing of the production capacity of the steelmaking process is higher, as compared to the wind-dominated electricity system.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| approx. | approximately |

| BF-CCS | blast furnace with carbon capture and storage |

| CCS | carbon capture and storage |

| DR | direct reduction |

| DRI | direct reduced iron |

| EAF | electric arc furnace |

| EU | European Union |

| h | hour |

| HBI | hot-briquetted iron |

| H-DR | hydrogen-direct reduction |

| LS | liquid steel |

| RE | renewable energy |

| SP | Steel Process |

| t | tonne |

| VRE | variable renewable electricity |

| Sets | |

| T | time-steps, [h] |

| P | steel production capacities (electrolyser, [MW/tLS/h]; DR shaft furnace, [tHBI/tLS/h]; EAF, [tLS/tLS/h]) |

| storage technologies (hydrogen storage, [MWh]; HBI pellets storage, [tHBI]) | |

| Parameters | |

| total annual steel production demand, [t] | |

| efficiency of the storage technology | |

| Variables | |

| cycling cost of the steel production capacity () in time-step t, [€] | |

| investment cost of the production capacity, [€/unit of production capacity (see units of the set P)] | |

| running cost of the production capacity in time-step t, [€/unit of production capacity (see units of the set P)] | |

| total steel production cost, [€] | |

| investments in production capacity, [unit of production capacity (see units of the set P)] | |

| yield of the steel production capacity in time-step t, [unit of production capacity (see units of the set P)] | |

| products stored in the storage technology at time-step t, [unit of storage technologies (see units of the set )] | |

| product with which the storage is charged at time-step t, [unit of storage technologies (see units of the set )] | |

| product that is discharged from the storage at time-step t, [unit of storage technologies (see units of the set )]] | |

| Superscripts | |

| an | annual |

| ch | charged |

| cycl | cycling |

| dis | discharged |

| inv | investment |

| run | running |

| STR | storage |

| tot | total |

Appendix A

| Production Capacity | Investment Cost | Investment Cost Unit | Technical Lifetime [years] | Fixed O&M Cost 1 [%] | Discount Rate [%] |

|---|---|---|---|---|---|

| Production capacity | |||||

| Electrolyser | 0.50 | M€/MW | 25 | 3 | 5 |

| DR shaft furnace | 230 | €/tonne per year | 40 | 3 | 5 |

| EAF | 184 | €/tonne per year | 40 | 3 | 5 |

| Storage technology | |||||

| Hydrogen storage | 0.011 | M€/MWh | 30 | - | 5 |

| Commodity | Input Level | Input Level Unit | Cost | Cost Unit |

|---|---|---|---|---|

| Alloys | 11 | kg/tLS | 1777 | €/tonne |

| Electricity EAF | 494 | kWh/tLS | Var 1 | €/MWh |

| Electricity electrolyser | 2200 | kWh/tLS | Var | €/MWh |

| Electricity DR shaft furnace | 322 | kWh/tLS | Var | €/MWh |

| Graphite electrode | 2 | kg/tLS | 4000 | €/tonne |

| Iron ore pellets | 1650 | tonne/tLS | 100 | €/tonne |

| Lime | 50 | kg/tLS | 90 | €/tonne |

| Low Investment Cost of Hydrogen Storage | |||||

| Production Capacity | Storage Capacity | ||||

| Electrolyser [MW/tLS/h] | DR Shaft Furnace [tHBI/tLS/h] | EAF [tLS/tLS/h] | Hydrogen [MWh] | HBI Pellets [tHBI] | |

| Scotland | |||||

| 2050 | 3.9 | 1.9 | 1.7 | 14.6 | 104 |

| southern Germany | |||||

| 2050 | 3.9 | 1.8 | 1.7 | 18.4 | 40 |

| High Investment Cost of Hydrogen Storage | |||||

| Production Capacity | Storage Capacity | ||||

| Electrolyser [MW/tLS/h] | DR Shaft Furnace [tHBI/tLS/h] | EAF [tLS/tLS/h] | Hydrogen [MWh] | HBI Pellets [tHBI] | |

| Scotland | |||||

| 2050 | 3.8 | 2.0 | 1.7 | 0 | 94 |

| southern Germany | |||||

| 2050 | 3.7 | 1.9 | 1.7 | 0 | 13 |

References

- Höhne, N.; de Villafranca, M.J.; Nascimento, L.; Kuramochi, T.; Hans, F.; Luna, L.; Fekete, H.; Warnecke, C. A Possible 2050 Climate Target for the EU; NewClimate Institute: Cologne, Germany, 2019; pp. 1–17. [Google Scholar]

- EC. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- IEA. Renewables 2019; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Åhman, M.; Nilsson, L.J.; Johansson, B. Global climate policy and deep decarbonization of energy-intensive industries. Clim. Policy 2016, 17, 634–649. [Google Scholar] [CrossRef] [Green Version]

- Philibert, C. Renewable Energy for Industry; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Worldsteel. Steel’s Contribution to a Low Carbon Future and Climate Resilient Societies—Worldsteel Position Paper; Worldsteel: Brussels, Belgium, 2020. [Google Scholar]

- Fais, B.; Sabio, N.; Strachan, N. The critical role of the industrial sector in reaching long-term emission reduction, energy efficiency and renewable targets. Appl. Energy 2016, 162, 699–712. [Google Scholar] [CrossRef] [Green Version]

- Norgate, T.; Haque, N.; Somerville, M.; Jahanshahi, S. Biomass as a Source of Renewable Carbon for Iron and Steelmaking. ISIJ Int. 2012, 52, 1472–1481. [Google Scholar] [CrossRef] [Green Version]

- Bataille, C.; Åhman, M.; Neuhoff, K.; Nilsson, L.J.; Fischedick, M.; Lechtenböhmer, S.; Solano-Rodriquez, B.; Denis-Ryan, A.; Stiebert, S.; Waisman, H.; et al. A review of technology and policy deep decarbonization pathway options for making energy-intensive industry production consistent with the Paris Agreement. J. Clean. Prod. 2018, 187, 960–973. [Google Scholar] [CrossRef] [Green Version]

- Muslemani, H.; Liang, X.; Kaesehage, K.; Ascui, F.; Wilson, J. Opportunities and challenges for decarbonizing steel production by creating markets for ‘green steel’ products. J. Clean. Prod. 2021, 315, 128127. [Google Scholar] [CrossRef]

- Material Economics. Industrial Transformation 2050—Pathways to Net-Zero Emissions from EU Heavy Industry; Material Economics: Stockholm, Sweden, 2019. [Google Scholar]

- IEA. Material Efficiency in Clean Energy Transitions; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Milford, R.L.; Allwood, J.M.; Cullen, J.M. Assessing the potential of yield improvements, through process scrap reduction, for energy and CO2 abatement in the steel and aluminium sectors. Resour. Conserv. Recycl. 2011, 55, 1185–1195. [Google Scholar] [CrossRef]

- Chunbao Charles, X.U.; Cang, D. A brief overview of low CO2 emission technologies for iron and steel making. J. Iron Steel Res. Int. 2010, 17, 1–7. [Google Scholar]

- Van der Stel, J.; Louwerse, G.; Sert, D.; Hirsch, A.; Eklund, N.; Pettersson, M. Top gas recycling blast furnace developments for ‘green’and sustainable ironmaking. Ironmak. Steelmak. 2013, 40, 483–489. [Google Scholar] [CrossRef]

- Arasto, A.; Tsupari, E.; Kärki, J.; Pisilä, E.; Sorsamäki, L. Post-combustion capture of CO2 at an integrated steel mill—Part I: Technical concept analysis. Int. J. Greenh. Gas Control 2013, 16, 271–277. [Google Scholar] [CrossRef]

- Tsupari, E.; Kärki, J.; Arasto, A.; Pisilä, E. Post-combustion capture of CO2 at an integrated steel mill–Part II: Economic feasibility. Int. J. Greenh. Gas Control 2013, 16, 278–286. [Google Scholar] [CrossRef]

- Chisalita, D.-A.; Petrescu, L.; Cobden, P.; van Dijk, H.A.J.; Cormos, A.-M.; Cormos, C.-C. Assessing the environmental impact of an integrated steel mill with post-combustion CO2 capture and storage using the LCA methodology. J. Clean. Prod. 2019, 211, 1015–1025. [Google Scholar] [CrossRef]

- Rootzén, J.; Johnsson, F. CO2 emissions abatement in the Nordic carbon-intensive industry–an end-game in sight? Energy 2015, 80, 715–730. [Google Scholar] [CrossRef] [Green Version]

- Fick, G.; Mirgaux, O.; Neau, P.; Patisson, F. Using biomass for pig iron production: A technical, environmental and economical assessment. Waste Biomass Valorization 2014, 5, 43–55. [Google Scholar] [CrossRef] [Green Version]

- Suopajärvi, H.; Kemppainen, A.; Haapakangas, J.; Fabritius, T. Extensive review of the opportunities to use biomass-based fuels in iron and steelmaking processes. J. Clean. Prod. 2017, 148, 709–734. [Google Scholar] [CrossRef]

- Wang, C.; Mellin, P.; Lövgren, J.; Nilsson, L.; Yang, W.; Salman, H.; Hultgren, A.; Larsson, M. Biomass as blast furnace injectant —Considering availability, pretreatment and deployment in the Swedish steel industry. Energy Convers. Manag. 2015, 102, 217–226. [Google Scholar] [CrossRef] [Green Version]

- Mandova, H.; Leduc, S.; Wang, C.; Wetterlund, E.; Patrizio, P.; Gale, W.; Kraxner, F. Possibilities for CO2 emission reduction using biomass in European integrated steel plants. Biomass Bioenergy 2018, 115, 231–243. [Google Scholar] [CrossRef]

- Arasto, A.; Onarheim, K.; Tsupari, E.; Kärki, J. Bio-CCS: Feasibility comparison of large scale carbon-negative solutions. Energy Procedia 2014, 63, 6756–6769. [Google Scholar] [CrossRef] [Green Version]

- Fischedick, M.; Marzinkowski, J.; Winzer, P.; Weigel, M. Techno-economic evaluation of innovative steel production technologies. J. Clean. Prod. 2014, 84, 563–580. [Google Scholar] [CrossRef] [Green Version]

- Lechtenböhmer, S.; Nilsson, L.J.; Åhman, M.; Schneider, C. Decarbonising the energy intensive basic materials industry through electrification—Implications for future EU electricity demand. Energy 2016, 115, 1623–1631. [Google Scholar] [CrossRef] [Green Version]

- HYBRIT. HYBRIT—A Swedish Prefeasibility Study Project for Hydrogen Based CO2—Free Ironmaking; SSAB: Stockholm, Sweden, 2016. [Google Scholar]

- Zhang, X.; Jiao, K.; Zhang, J.; Guo, Z. A review on low carbon emissions projects of steel industry in the World. J. Clean. Prod. 2021, 306, 127259. [Google Scholar] [CrossRef]

- ArcelorMittal ArcelorMittal Commissions Midrex to Design Demonstration Plant for Hydrogen Steel Production in Hamburg. Available online: https://corporate.arcelormittal.com/media/news-articles/2019-sep-16-arcelormittal-commissions-midrex-to-design-demonstration-plant (accessed on 5 April 2020).

- Salzgitter AG Salzgitter AG und Tenova Unterzeichnen Absichtserklärung für das SALCOS-Projekt: CO2-arme Stahlproduktion auf Wasserstoffbasis. Available online: https://www.salzgitter-ag.com/de/newsroom/pressemeldungen/pressemeldung-der-salzgitter-ag/2019-04-03-1/salzgitter-ag-und-tenova-unterzeichnen-absichtserklrung-fr-das-salcosprojekt-co2arme-stahlproduktion-auf-wasserstoffbasis.html (accessed on 10 December 2021).

- Voestalpine The Three Pillars of Decarbonization. Available online: https://www.voestalpine.com/blog/en/innovation-en/the-three-pillars-of-decarbonization/ (accessed on 5 April 2020).

- Rechberger, K.; Spanlang, A.; Sasiain Conde, A.; Wolfmeir, H.; Harris, C. Green Hydrogen-Based Direct Reduction for Low-Carbon Steelmaking. Steel Res. Int. 2020, 91, 2000110. [Google Scholar] [CrossRef]

- Fruehan, R.J. Research on Sustainable Steelmaking. Met. Mater. Trans. A 2009, 40, 123–133. [Google Scholar] [CrossRef]

- Buschow, K.H.J.; Cahn, R.W.; Flemings, M.C.; Ilschner, B.; Kramer, E.J.; Mahajan, S. The Science and Technology of Materials: An Introduction. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2009; pp. 1–4. [Google Scholar]

- Zervas, T. Gas-based direct reduction processes for iron and steel production. Fuel Energy Abstr. 1996, 37, 212. [Google Scholar] [CrossRef]

- Atsushi, M.; Uemura, H.; Sakaguchi, T. MIDREX processes. Kobelco Technol. Rev. 2010, 29, 50–57. [Google Scholar]

- Caglayan, D.G.; Weber, N.; Heinrichs, H.U.; Linßen, J.; Robinius, M.; Kukla, P.A.; Stolten, D. Technical potential of salt caverns for hydrogen storage in Europe. Int. J. Hydrogen Energy 2020, 45, 6793–6805. [Google Scholar] [CrossRef]

- Cihlar, J.; Mavins, D.; van der Leun, K. Picturing the Value of Underground Gas Storage to the European Hydrogen System; Guidehouse: Chicago, IL, USA, 2021. [Google Scholar]

- FCH, J.U. Fuel Cells and Hydrogen Joint Undertaking. Available online: https://www.fch.europa.eu/page/fch-ju-projects (accessed on 10 December 2021).

- Paulus, M.; Borggrefe, F. The potential of demand-side management in energy-intensive industries for electricity markets in Germany. Appl. Energy 2011, 88, 432–441. [Google Scholar] [CrossRef]

- Bennett, D.; Lewis, C. Achieving Competitive Edge: Getting Ahead Through Technology and People Proceedings of the OMA-UK Sixth International Conference; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 1447119045. [Google Scholar]

- Anameric, B.; Kawatra, S.K. Properties and features of direct reduced iron. Miner. Process. Extr. Met. Rev. 2007, 28, 59–116. [Google Scholar] [CrossRef]

- Kushnir, D.; Hansen, T.; Vogl, V.; Åhman, M. Adopting hydrogen direct reduction for the Swedish steel industry: A technological innovation system (TIS) study. J. Clean. Prod. 2020, 242, 118185. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2019; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Ballester, C.; Furió, D. Effects of renewables on the stylized facts of electricity prices. Renew. Sustain. Energy Rev. 2015, 52, 1596–1609. [Google Scholar] [CrossRef]

- Brée, L.C.; Perrey, K.; Bulan, A.; Mitsos, A. Demand side management and operational mode switching in chlorine production. AIChE J. 2019, 65, e16352. [Google Scholar] [CrossRef]

- Roh, K.; Brée, L.C.; Perrey, K.; Bulan, A.; Mitsos, A. Flexible operation of switchable chlor-alkali electrolysis for demand side management. Appl. Energy 2019, 255, 113880. [Google Scholar] [CrossRef]

- Vogl, V.; Åhman, M.; Nilsson, L.J. Assessment of hydrogen direct reduction for fossil-free steelmaking. J. Clean. Prod. 2018, 203, 736–745. [Google Scholar] [CrossRef]

- Mayer, J.; Bachner, G.; Steininger, K. Macroeconomic implications of switching to process-emission-free iron and steel production in Europe. J. Clean. Prod. 2019, 210, 1517–1533. [Google Scholar] [CrossRef]

- Arens, M.; Worrell, E.; Eichhammer, W.; Hasanbeigi, A.; Zhang, Q. Pathways to a low-carbon iron and steel industry in the medium-term—the case of Germany. J. Clean. Prod. 2017, 163, 84–98. [Google Scholar] [CrossRef]

- Otto, A.; Robinius, M.; Grube, T.; Schiebahn, S.; Praktiknjo, A.; Stolten, D. Power-to-Steel: Reducing CO2 through the Integration of Renewable Energy and Hydrogen into the German Steel Industry. Energies 2017, 10, 451. [Google Scholar] [CrossRef] [Green Version]

- Weigel, M.; Fischedick, M.; Marzinkowski, J.; Winzer, P. Multicriteria analysis of primary steelmaking technologies. J. Clean. Prod. 2016, 112, 1064–1076. [Google Scholar] [CrossRef] [Green Version]

- Göransson, L.; Lehtveer, M.; Nyholm, E.; Taljegard, M.; Walter, V. The Benefit of Collaboration in the North European Electricity System Transition—System and Sector Perspectives. Energies 2019, 12, 4648. [Google Scholar] [CrossRef] [Green Version]

- Göransson, L.; Johnsson, F. A comparison of variation management strategies for wind power integration in different electricity system contexts. Wind. Energy 2018, 21, 837–854. [Google Scholar] [CrossRef]

- Johansson, V.; Göransson, L. Impacts of variation management on cost-optimal investments in wind power and solar photovoltaics. Renew. Energy Focus 2020, 32, 10–22. [Google Scholar] [CrossRef]

- Pimm, A.J.; Cockerill, T.T.; Gale, W.F. Energy system requirements of fossil-free steelmaking using hydrogen direct reduction. J. Clean. Prod. 2021, 312, 127665. [Google Scholar] [CrossRef]

- Energistyrelsen, E. Technology Data. Renewable Fuels: Danish Energy Agency and Energinet; Denmark and Fredericia: Esbjerg, Denmark, 2017. [Google Scholar]

- Johansson, F.; Spross, J.; Damasceno, D.; Johansson, J.; Stille, H. Investigation of Research Needs Regarding the Storage of Hydrogen Gas in Lined Rock Caverns: Prestudy for Work Package 2.3 in HYBRIT Research Program 1; KTH Royal Institute of Technology: Stockholm, Sweden, 2018. [Google Scholar]

- Wörtler, M.; Schuler, F.; Voigt, N.; Schmidt, T.; Dahlmann, P.; Lüngen, H.B.; Ghenda, J.-T. Steel’s Contribution to a Low-Carbon Europe 2050: Technical and Economic Analysis of the Sector’s CO2 Abatement Potential; Boston Consulting Group: Boston, MA, USA, 2013. [Google Scholar]

- Statista Iron Ore Prices from 2003 to 2019. Available online: https://www.statista.com/statistics/282830/iron-ore-prices-since-2003/ (accessed on 5 April 2020).

- Remus, R.; Monsonet, M.A.A.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for Iron and Steel Production; Publications Office of the European Union: Luxembourg, 2013; p. 621. [Google Scholar]

- Göransson, L.; Goop, J.; Odenberger, M.; Johnsson, F. Impact of thermal plant cycling on the cost-optimal composition of a regional electricity generation system. Appl. Energy 2017, 197, 230–240. [Google Scholar] [CrossRef]

- Epexspot Market Data. Available online: https://www.epexspot.com/en/market-data?data_mode=table&modality=Auction&sub_modality=DayAhead&market_area=DE-LU&product=60&delivery_date=2020-04-06&trading_date=2020-04-05 (accessed on 5 April 2020).

- NordPool Nord Pool UK. Available online: https://www.nordpoolgroup.com/Market-data1/GB/Auction-prices/UK/Hourly/?view=table (accessed on 5 April 2020).

- IEA. What Is behind Soaring Energy Prices and What Happens Next? Available online: https://www.iea.org/commentaries/what-is-behind-soaring-energy-prices-and-what-happens-next (accessed on 10 December 2021).

- EC Questions and Answers: Commission Communication on Energy Prices. Available online: https://ec.europa.eu/commission/presscorner/detail/en/QANDA_21_5202 (accessed on 10 December 2021).

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future cost and performance of water electrolysis: An expert elicitation study. Int. J. Hydrogen Energy 2017, 42, 30470–30492. [Google Scholar] [CrossRef]

- Saba, S.M.; Müller, M.; Robinius, M.; Stolten, D. The investment costs of electrolysis—A comparison of cost studies from the past 30 years. Int. J. Hydrogen Energy 2018, 43, 1209–1223. [Google Scholar] [CrossRef]

- Adams, S.; Schnittger, S.; Kockar, I.; Kelly, N.; Xu, H.; Monari, F.; Edrah, M.; Zhang, J.; Bell, G. Impact of Electrolysers on the Network; Scottish & Southern Electricity Networks: Perth, UK, 2016. [Google Scholar]

- Moreno-Leiva, S.; Haas, J.; Junne, T.; Valencia, F.; Godin, H.; Kracht, W.; Nowak, W.; Eltrop, L. Renewable energy in copper production: A review on systems design and methodological approaches. J. Clean. Prod. 2020, 246, 118978. [Google Scholar] [CrossRef]

- Röben, F.T.C.; Schöne, N.; Bau, U.; Reuter, M.A.; Dahmen, M.; Bardow, A. Decarbonizing copper production by power-to-hydrogen: A techno-economic analysis. J. Clean. Prod. 2021, 306, 127191. [Google Scholar] [CrossRef]

- Xylia, M.; Silveira, S.; Duerinck, J.; Meinke-Hubeny, F. Weighing regional scrap availability in global pathways for steel production processes. Energy Effic. 2018, 11, 1135–1159. [Google Scholar] [CrossRef] [Green Version]

| CO2 Emissions Reduction Options | Abatement Potential | Reference |

|---|---|---|

| Increased process efficiency 1 | 16% | [11] |

| Material efficiency | approx. 20% | [12] |

| Steel reuse and recycling | 17% | [13] |

| Top gas recycling blast furnace | 5–10% 15% | [14] [15] |

| CO2 capture technology 2 | 50–75% | [16,17,18] |

| CO2 capture technology + Top gas recycling blast furnace | 60% | [15,19] |

| Biomass 3 | 7–15% 23% 20–42% 31–57% | [20] [21] [22,23] [8] |

| Biomass + CO2 capture technology + Top gas recycling blast furnace | over 80% | [14,24] |

| Hydrogen direct reduction (H-DR) 4 | ~100% 5 | [25,26,27] |

| Electrowinning | ~100% 5 | [25] |

| Electricity Price Profile | Region | Year | Solar Power [TWh] (Penetration Level [%]) | Wind Power [TWh] (Penetration Level [%]) | Average Electricity Price, €/MWh |

|---|---|---|---|---|---|

| 1 | Germany | 2018 | 46 (~8%) | 112 (~19%) | 45 |

| 2 | Southern Germany | 2050 | 152 (~22%) | 135 (~20%) | 61 |

| 3 | The UK | 2018 | 13 (~4%) | 57 (~16%) | 65 |

| 4 | Scotland | 2050 | 0.5 (~1%) | 45 (~94%) | 49 |

| Production Capacity | Storage Capacity | ||||

|---|---|---|---|---|---|

| Electrolyser | DR Shaft Furnace | EAF | Hydrogen | HBI Pellets | |

| [MW/tLS/h] | [tHBI/tLS/h] | [tLS/tLS/h] | [MWh] | [tHBI] | |

| Minimum Investment level (MinIn) | 2.2 | 1.1 | 1.0 | 0 | 0 |

| Scotland | |||||

| 2018 | 2.5 | 1.3 | 1.2 | 0 | 0 |

| 2050 | 3.8 | 2.0 | 1.7 | 2.7 | 108 |

| southern Germany | |||||

| 2018 | 2.6 | 1.3 | 1.2 | 0 | 0 |

| 2050 | 3.7 | 1.9 | 1.7 | 4.4 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toktarova, A.; Göransson, L.; Johnsson, F. Design of Clean Steel Production with Hydrogen: Impact of Electricity System Composition. Energies 2021, 14, 8349. https://doi.org/10.3390/en14248349

Toktarova A, Göransson L, Johnsson F. Design of Clean Steel Production with Hydrogen: Impact of Electricity System Composition. Energies. 2021; 14(24):8349. https://doi.org/10.3390/en14248349

Chicago/Turabian StyleToktarova, Alla, Lisa Göransson, and Filip Johnsson. 2021. "Design of Clean Steel Production with Hydrogen: Impact of Electricity System Composition" Energies 14, no. 24: 8349. https://doi.org/10.3390/en14248349

APA StyleToktarova, A., Göransson, L., & Johnsson, F. (2021). Design of Clean Steel Production with Hydrogen: Impact of Electricity System Composition. Energies, 14(24), 8349. https://doi.org/10.3390/en14248349