The Feasibility of Using Zero-Emission Electric Boats to Enhance the Techno-Economic Performance of an Ocean-Energy-Supported Coastal Hotel Building

Abstract

:1. Introduction and Background

1.1. Background

1.2. Literature Review for ZEB, Electric Mobility and Ocean Renewable Energy System

1.3. Scientific Gaps and Structure of the Study

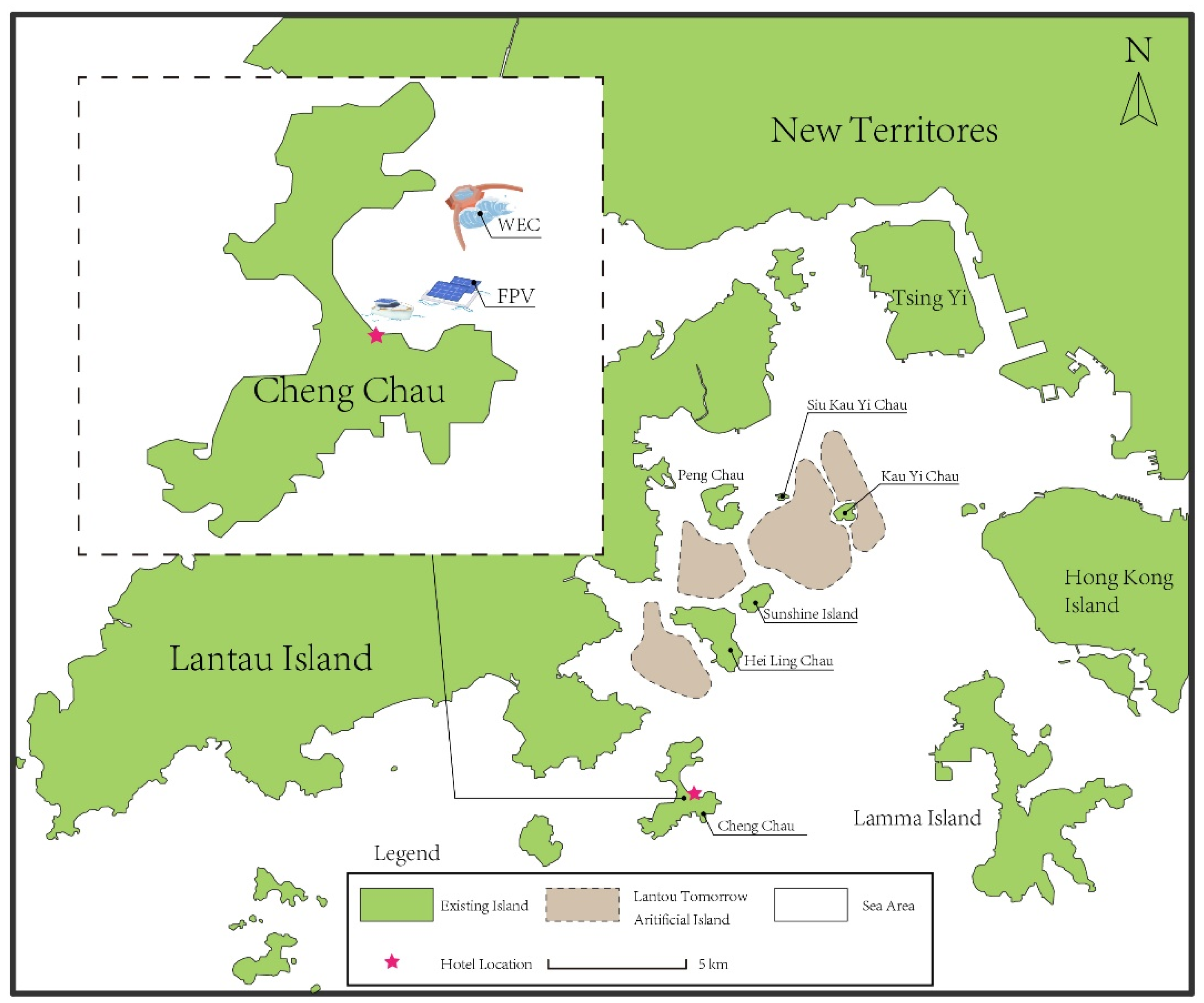

2. System Description and Assumptions

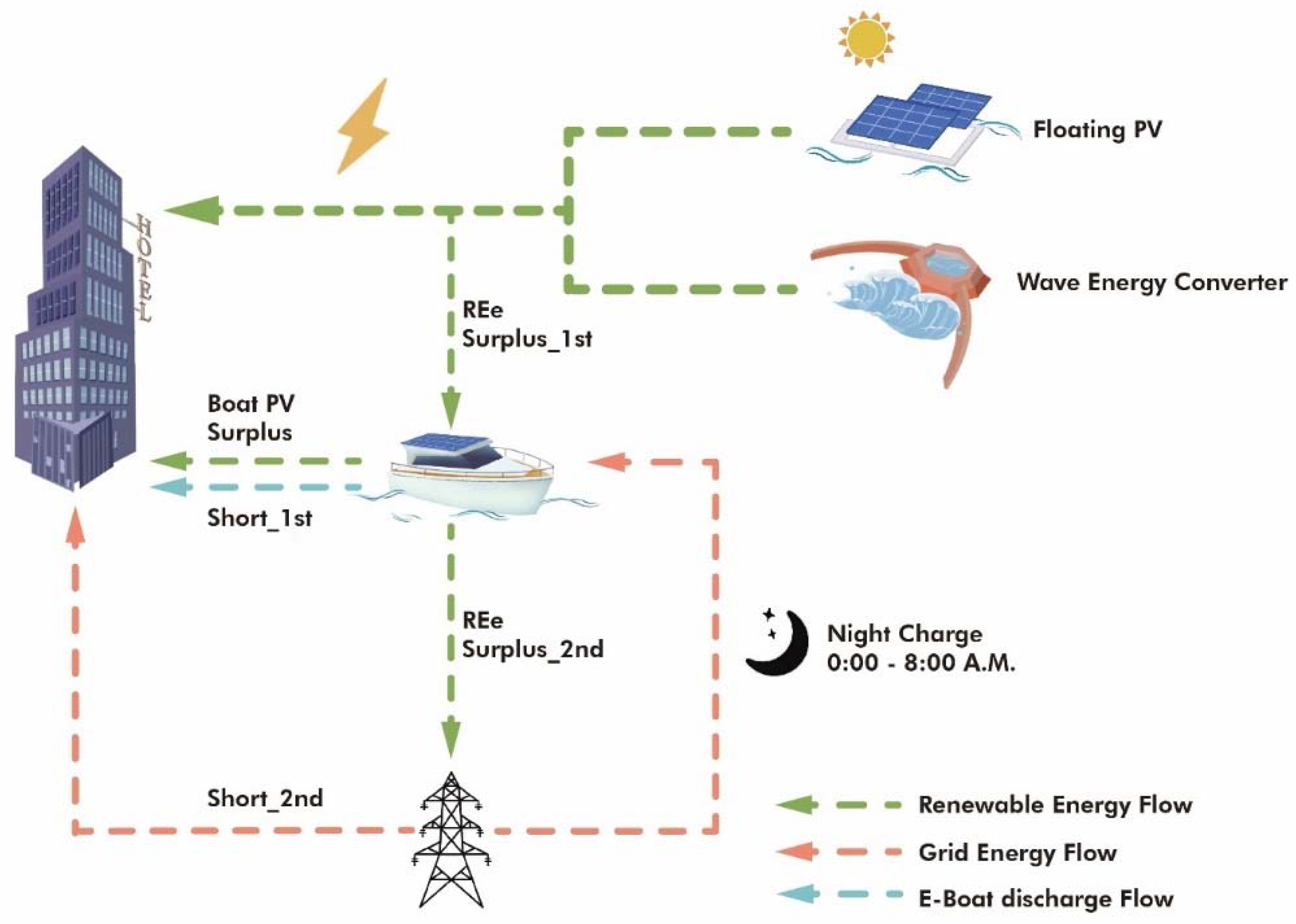

2.1. The Basic Components and Control Principal

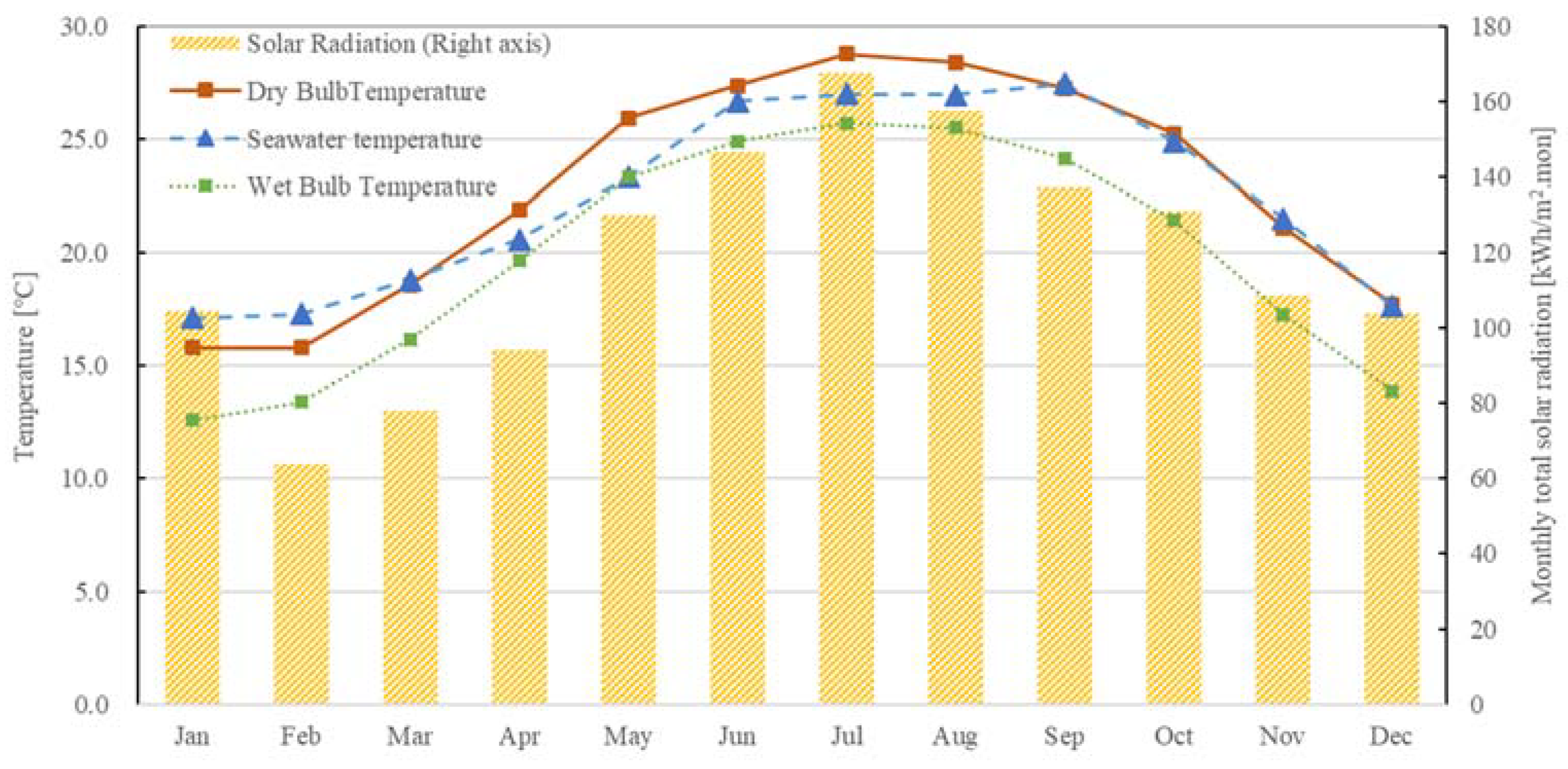

2.2. Weather and Building Service System

2.3. Introduction and Assumptions Regarding the Zero-Emission Boat

3. Integrated Boat and ORE Systems

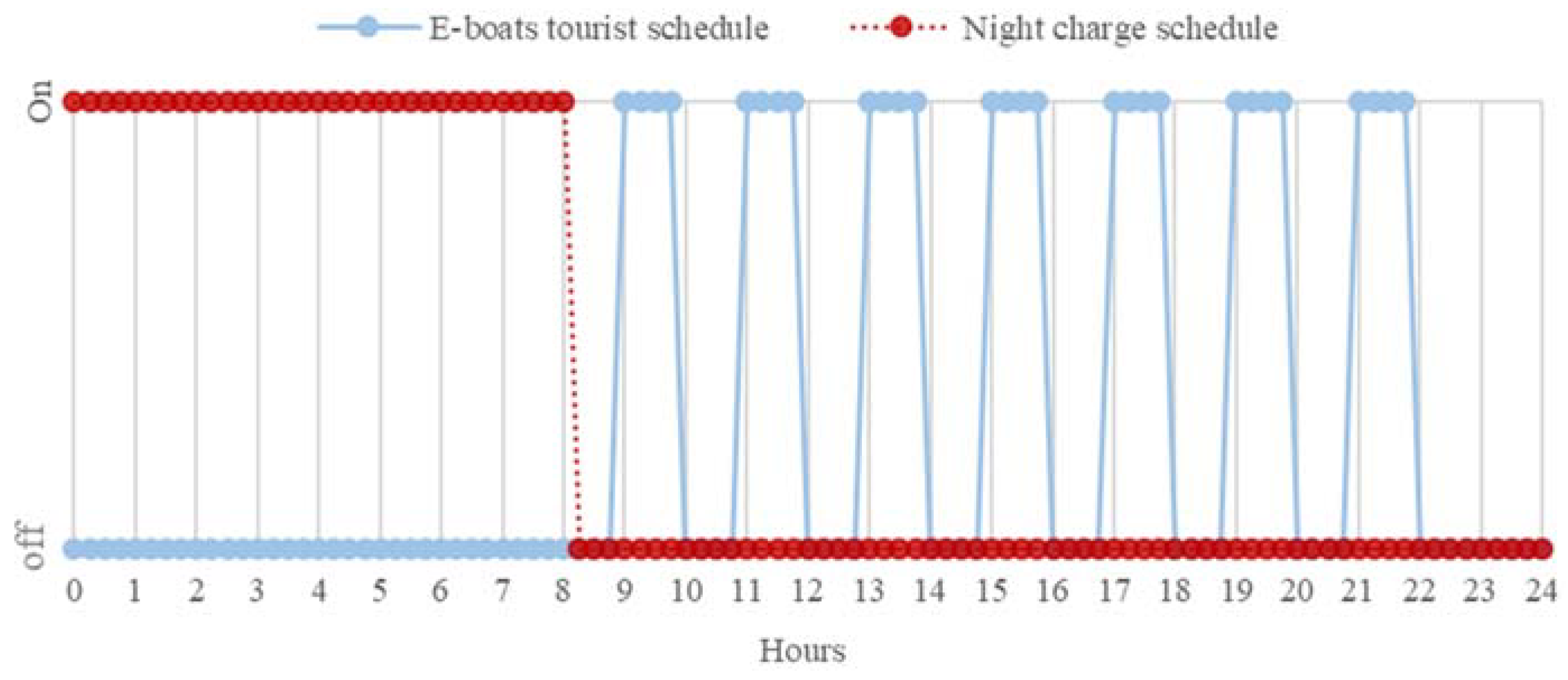

3.1. The Control Principles for Integrating the Zero-Emission Boat

- 1.

- The control strategy for the normal charging mode (building-to-boat function):

- 2.

- The control strategy for night charging mode (building-to-boat function):

- 3.

- The control strategy for discharging mode (boat-to-building function):

3.2. The Integrated Ocean Energy System

3.2.1. Floating PV Panels

3.2.2. Wave Energy Converters

4. Analysis Criteria

5. Simulation Results, Analyses and Discussion

5.1. Structure of Simulation Results and Analysis

5.2. The Impact of Ocean Energy on the Building and Boat Energy Systems

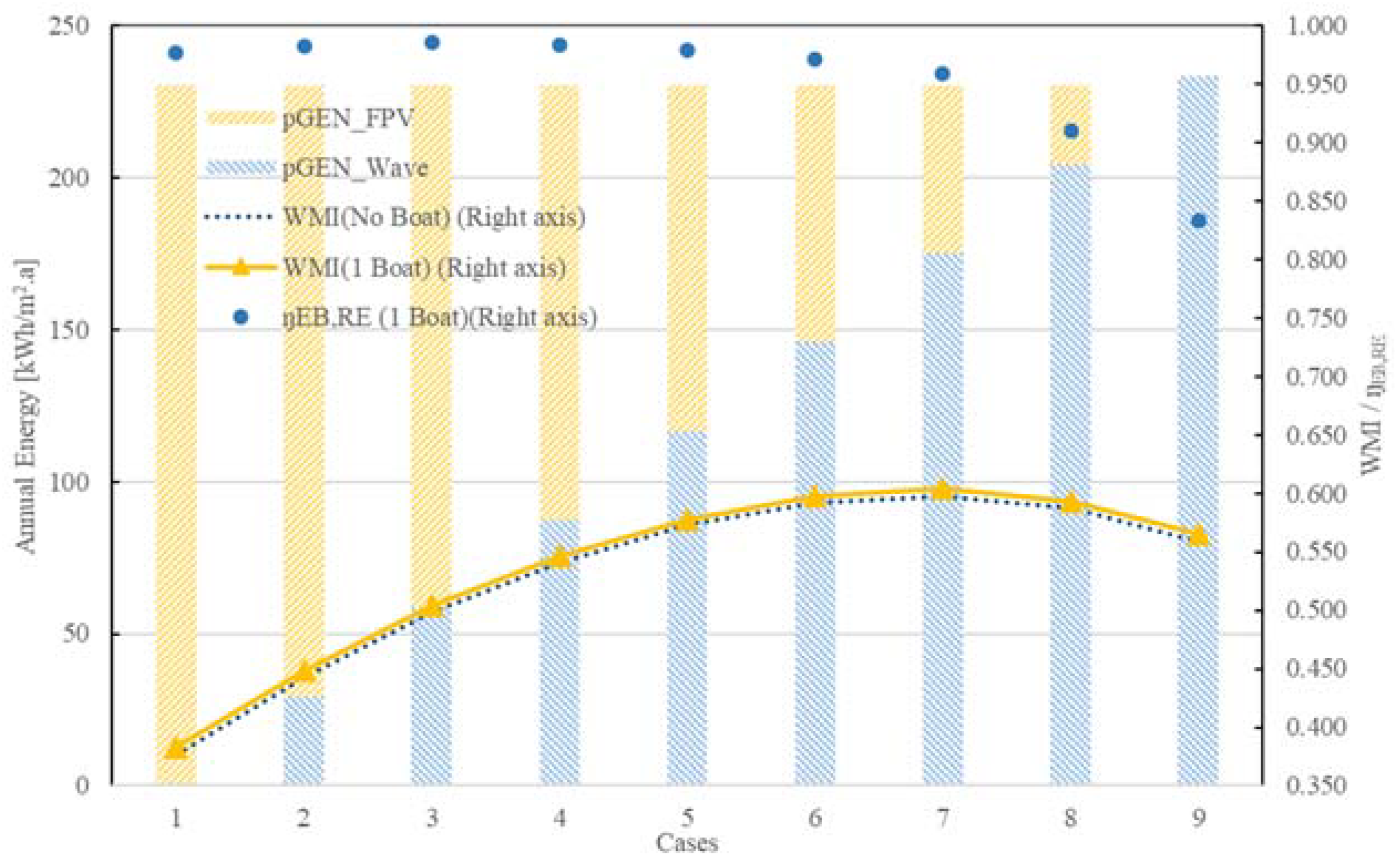

5.2.1. The Impact of the Combined Wave-FPV Energy System on the Technical Performance of the Hybrid System: Mixing Based on Total Generation (Investigation with a Single E-Boat)

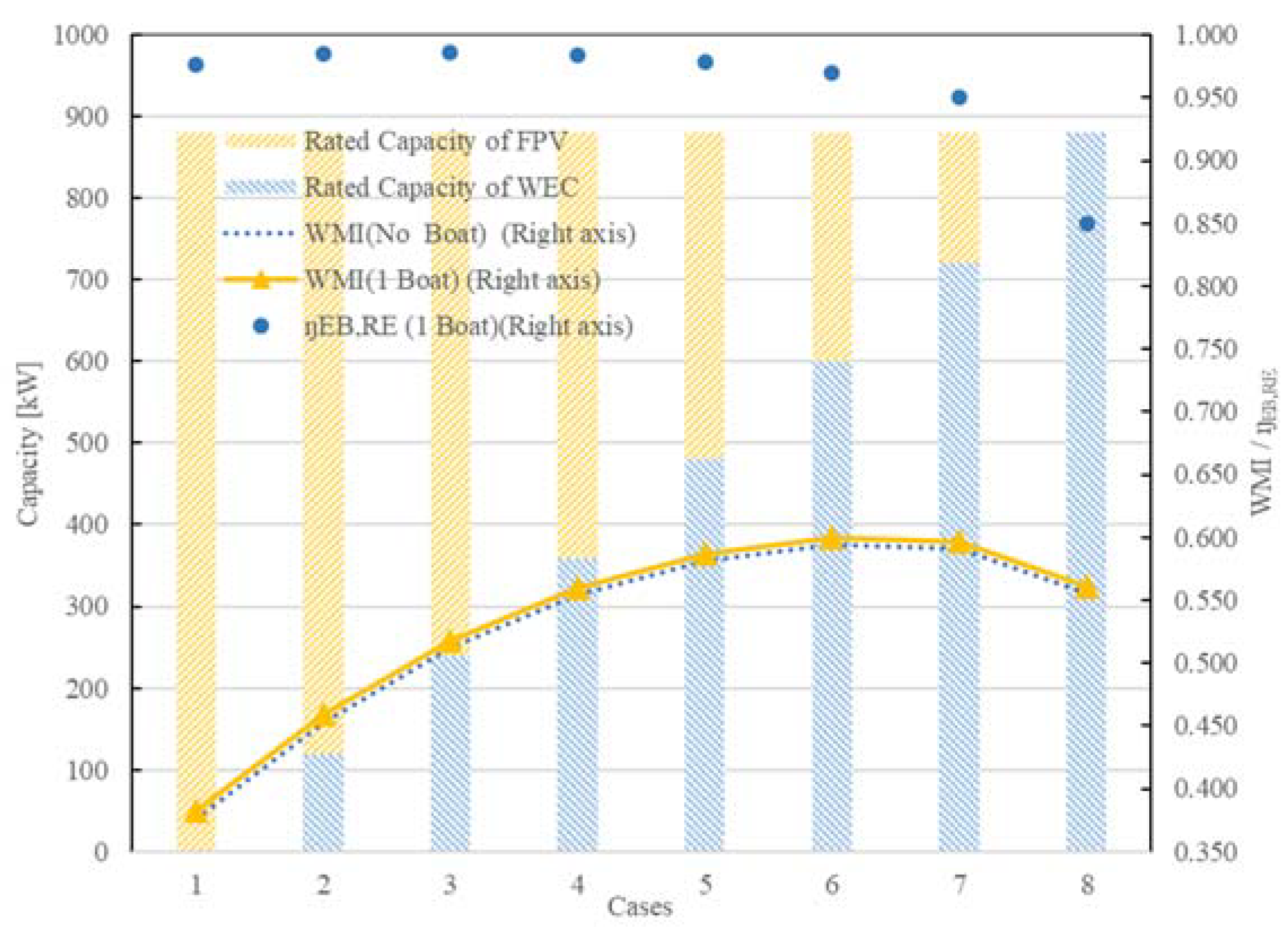

5.2.2. The Impact of the Combined Wave-FPV Energy System on the Technical Performance of the Hybrid System: Mixing Based on Total Rated Capacity (Investigation of a Single E-Boat)

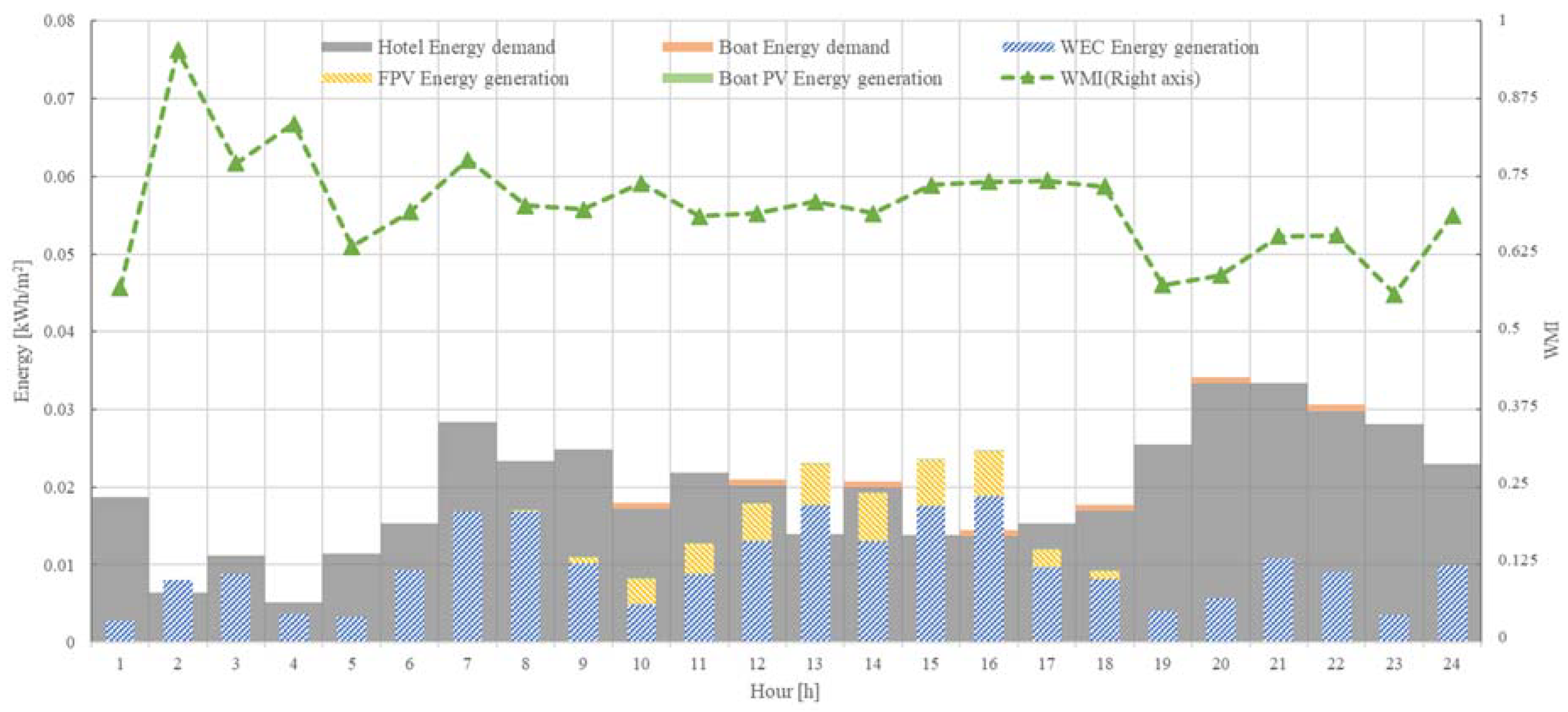

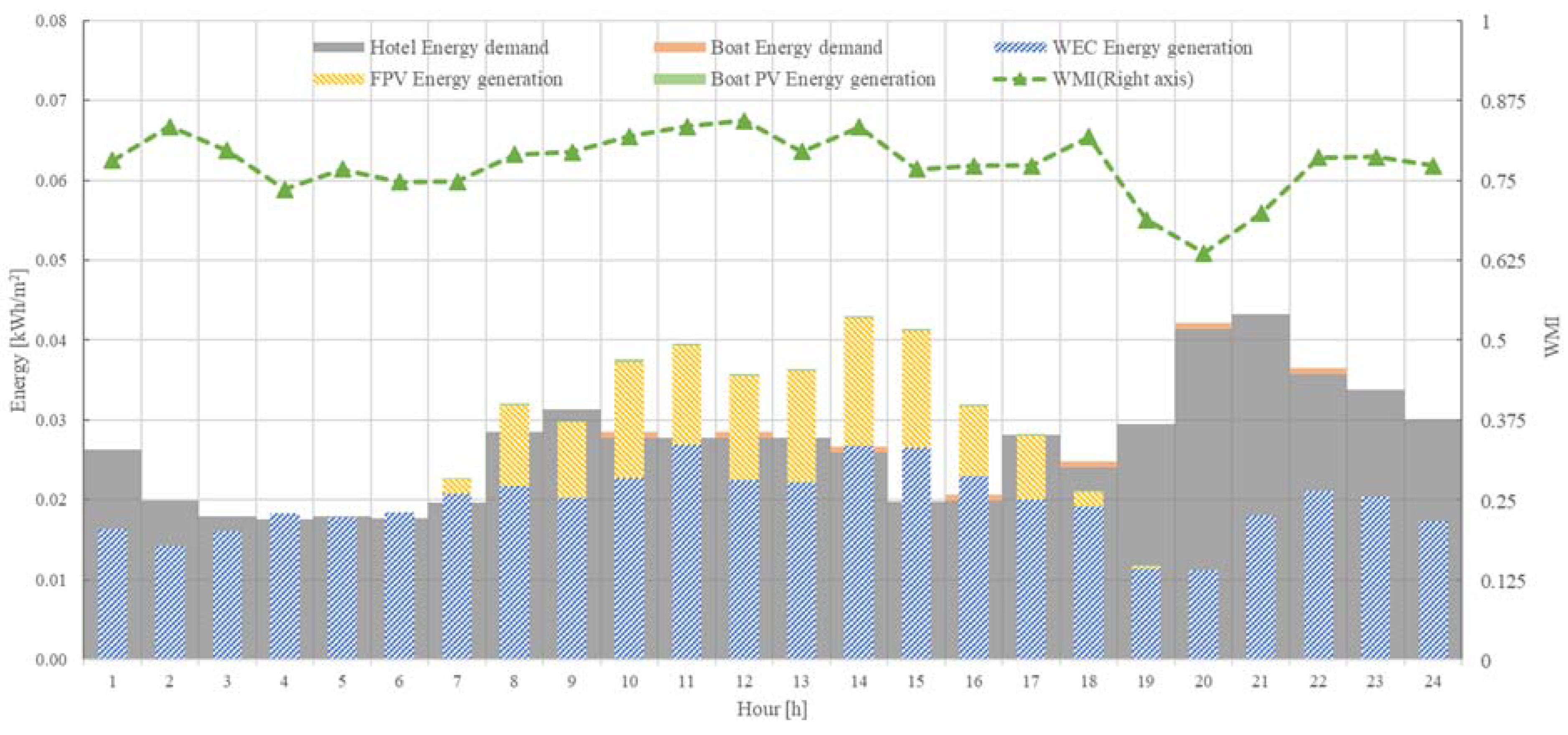

5.2.3. The Monthly and Hourly Technical Performance of the Combined Wave-FPV Energy System (Investigation of a Single E-Boat)

5.3. The Impact of Electric Boats on the Hybrid Zero-Emission System

5.3.1. The Impact of the Cruise Velocity and Cruise Distance on the Technical Performance of the Hybrid System (Investigation of a Single E-Boat)

- Cruise velocity as the variable (Scenario A)

- 2.

- Cruise distance as the variable (Scenario B)

5.3.2. The Impact of Boat Battery Capacity and Cruise Patterns on the Technical Performance of the Hybrid System (Investigation of Multiple E-Boats)

- Cruise velocity as the variable

- 2.

- Cruise distance as the variable

5.4. The Techno-Economic Analysis of the Hybrid Zero-Emission System

5.4.1. The Techno-Economic Analysis for the Integrated Ocean Energy Systems (Investigation of a Single E-Boat)

5.4.2. The Techno-Economic Analysis of the Electric Boat Energy Systems (Investigation of More E-Boats)

5.4.3. Economic Sensitivity Analysis for the Hybrid Zero-Emission System (Investigation of Single E-Boat)

5.5. Environmental and Economic Analysis, Limitations of the Current Study

5.5.1. Environmental and Economic Analysis

5.5.2. Limitations of the Current Study

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AHU | Air handling unit |

| BLT | Beyond the lifetime |

| CEa | The annual operational equivalent CO2 emission |

| CEFeg | The equivalent CO2 emission factor of the electric grid (kg CO2,eq/kWhe) |

| DHW | Domestic hot water |

| E-Boat | Electric boat |

| Eexp,a | The annual exported energy to the electric grid (kWh/m2.a) |

| Edirect,a | The annual net direct energy (kWh/m2.a) |

| Eimp,a | The annual imported energy from the electric grid (kWh/m2.a) |

| CEa | The annual operational equivalent CO2 emissions (kg CO2,eq/m2.a) |

| CS | Cost scenario |

| EVCS | Electric vehicle charging station |

| FPV | floating photovoltaic |

| FSOC | Fractional state of charge |

| Lelec | The total electrical demand power (kW) |

| NPVrel | Relative net present value |

| NOCT | Nominal operating cell temperature |

| NZEB | Nearly zero-energy building |

| neZEH | Nearly zero-energy hotel |

| OEFe | On-site electrical energy fraction |

| OEMe | On-site electrical energy matching |

| ORE | Ocean renewable energy |

| PEBsys | The electrical power sent to drive the E-Boat integrated system (kW) |

| Pexp | The exported power to the electric grid (kW) |

| Pimp | The imported power from the electric grid (kW) |

| Pimp, EBsys | The backup electricity imported from the electric grid for supporting the E-Boat integrated system (kW) |

| POREe | The electrical power generated by the local ocean renewable energy systems (kW) |

| PV | Photovoltaic |

| REe | Renewable electricity |

| SPPrel | Relative simple payback period |

| WEC | Wave energy converter |

| WMI | Weighted matching index |

| ZEB | Zero-emission/energy building |

| ZEV | Zero-emission/energy vehicle |

| The annual local renewable energy ratio in the E-Boat integrated system |

Appendix A

| Insulation (U-Value, W/m2·K) | ||||||

|---|---|---|---|---|---|---|

| Parameters | External roof | External wall | Window glazing | Ground floor layer with soil layer | ||

| Values | 0.345 | 2.308 | 2.78 | 0.609 | ||

| Infiltration (h-1) | ||||||

| Design principal | According to the guideline of the Performance-based Building Energy Code of Hong Kong [43]: (1) When the ventilation is on, the infiltration is 0.306 h-1; (2) When the ventilation in off, the infiltration is 0 h-1. | |||||

| Occupants | ||||||

| Parameters | Number | Activity level MET [64] | ||||

| Values | 19 occupants in each hotel floor [38]. | 1.2 | ||||

| Ventilation | ||||||

| Parameters | Ventilation Type | Total supply flow rate (h − 1) | Fresh air ratio in the total supply air flow rate | Ventilation schedule | ||

| Values | Mechanical supply and exhaust ventilation with return air mixing and rotary heat recovery. | 1.5 (when the fan is on) | 0.475 | Follow the ventilation schedule listed in [43]. | ||

| AHU cooling | ||||||

| Parameters | AHU cooling method | In-blown supply air temperature Tsup (°C) | Specific ventilation fan power (W/(m3/s)) | |||

| Values | 7/12 °C cooling coil | A funcA function with respect to the exhausted indoor air temperature Texh,indoor:

| (1) Supply fan: 800; (2) Exhaust fan: 800 | |||

| AHU heating | ||||||

| Parameters | AHU and reheater heating method | Sensible effectiveness of the rotary heat recovery device | Latent effectiveness of the rotary heat recovery device | |||

| Values | Hydronic heating | 0.85 | 0.5 | |||

| Space cooling | Space heating | |||||

| Parameters | Type | Room air set point (°C) | Cooling schedule | Type | Room air set point (°C) | Heating schedule |

| Values | 15/17 °C hydronic chilled ceiling system | 24 °C for all thermal zones | Follow the cooling schedule listed in [38]. | Electric heating | 21 °C for all thermal zones | Follow the heating schedule listed in [43]. |

| DHW heating | ||||||

| Parameters | Set point (°C) | Daily consumption volume (m3) | DHW Schedule | |||

| Values | 55 | 17.8 | Follow the DHW schedule listed in the [43]. | |||

References

- IEA. 2019 Global Status Report for Buildings and Construction; United Nations Environment Programme: Nairobi, Kenya, 2019. [Google Scholar]

- EMDS. Hong Kong Energy End-Use Data 2020; Electrical and Mechanical Services Department: Hong Kong, China, 2020. [Google Scholar]

- Environment Bureau. Hong Kong’s Climate Action Plan 2030+. Environmental Bureau; The Government of the Hong Kong Special Administrative Region: Hong Kong, China, 2017. [Google Scholar]

- United Nations. The Paris Agreement; United Nations: Brussels, Belgium, 2015. [Google Scholar]

- European Commission. Nearly Zero-Energy Buildings; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Wang, L.; Gwilliam, J.; Jones, P. Case study of zero energy house design in UK. Energy Build. 2009, 41, 1215–1222. [Google Scholar] [CrossRef]

- Attia, S.; Gratia, E.; De Herde, A.; Hensen, J. Simulation-based decision support tool for early stages of zero-energy building design. Energy Build. 2012, 49, 2–15. [Google Scholar] [CrossRef] [Green Version]

- Sobhani, H.; Shahmoradi, F.; Sajadi, B. Optimization of the renewable energy system for nearly zero energy buildings: A future-oriented approach. Energ Convers. Manag. 2020, 224, 113370. [Google Scholar] [CrossRef]

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Arabkoohsar, A.; Behzadi, A.; Alsagri, A.S. Techno-economic analysis and multi-objective optimization of a novel solar-based building energy system; An effort to reach the true meaning of zero-energy buildings. Energy Convers. Manag. 2021, 232, 113858. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Kerinnonta, L. Potential Reconstruction Design of an Existing Townhouse in Washington DC for Approaching Net Zero Energy Building Goal. Sustainability 2019, 11, 6631. [Google Scholar] [CrossRef] [Green Version]

- Gholami, H.; Røstvik, N.H.; Steemers, K. The Contribution of Building-Integrated Photovoltaics (BIPV) to the Concept of Nearly Zero-Energy Cities in Europe: Potential and Challenges Ahead. Energies 2021, 14, 6015. [Google Scholar] [CrossRef]

- Tournaki, S.M.F.; Tsoutsos, R.; Morell, I.; Guerrero, Z.; Urosevic, A.; Derjanecz, C.; Nunez, C.; Rata, M.; Biscan, S.; Pouffary, S.; et al. Towards Nearly Zero Energy Hotels Technical Analysis and Recommendations. In Proceedings of the 5th International Conference on Renewable Energy Sources and Energy Efficiency, Istanbul, Turkey, 21–23 October 2021. [Google Scholar]

- Beccali, M.; Finocchiaro, P.; Ippolito, M.G.; Leone, G.; Panno, D.; Zizzo, G. Analysis of some renewable energy uses and demand side measures for hotels on small Mediterranean islands: A case study. Energy 2018, 157, 106–114. [Google Scholar] [CrossRef]

- Filipe, O.; Cunha, A.C.O. Benchmarking for realistic nZEB hotel buildings. Build. Eng. 2020, 30, 101298. [Google Scholar]

- Nocera, F.; Giuffrida, S.; Trovato, M.R.; Gagliano, A. Energy and New Economic Approach for Nearly Zero Energy Hotels. Entropy 2019, 21, 639. [Google Scholar] [CrossRef] [Green Version]

- Kahn Ribeiro, S.; Kobayashi, S.M.; Beuthe, J.; Gasca, D.; Greene, D.S.; Lee, Y.; Muromachi, P.J.; Newton, S.; Plotkin, D.; Sperling, R.; et al. Transport and Its Infrastructure. In Climate Change 2007, Mitigation; IPCC: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- European Commission. A European Strategy for Low-Emission Mobility; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Hafez, O.; Bhattacharya, K. Optimal design of electric vehicle charging stations considering various energy resources. Renew. Energy 2017, 107, 576–589. [Google Scholar] [CrossRef]

- Sun, B. A multi-objective optimization model for fast electric vehicle charging stations with wind, PV power and energy storage. J. Clean. Prod. 2021, 288, 125564. [Google Scholar] [CrossRef]

- Kumar, G.M.S.; Cao, S. State-of-the-Art Review of Positive Energy Building and Community Systems. Energies 2021, 14, 5046. [Google Scholar] [CrossRef]

- Golla, N.K.; Sudabattula, S.K. Impact of Plug-in electric vehicles on grid integration with distributed energy resources: A comprehensive review on methodology of power interaction and scheduling. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Buonomano, A. Building to Vehicle to Building concept: A comprehensive parametric and sensitivity analysis for decision making aims. Appl. Energy 2020, 261, 114077. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, Y.; Li, X.; Sun, B.; Liao, Q.; Tao, Y.; Wang, Z. Strategic integration of vehicle-to-home system with home distributed photovoltaic power generation in Shanghai. Appl. Energy 2020, 263, 114603. [Google Scholar] [CrossRef]

- Cao, S. The impact of electric vehicles and mobile boundary expansions on the realization of zero-emission office buildings. Appl. Energy 2019, 251, 113347. [Google Scholar] [CrossRef]

- YC Synergy powers electric yachts with fuel cell technology. Fuel Cells Bull. 2014, 2014, 4. [CrossRef]

- Al-Falahi, M.D.A.; Nimma, K.S.; Jayasinghe, S.D.G.; Enshaei, H.; Guerrero, J.M. Power management optimization of hybrid power systems in electric ferries. Energy Convers. Manag. 2018, 172, 50–66. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.-R.; Kim, J.-M.; Jung, J.-J.; Kim, S.-Y.; Choi, J.-H.; Lee, H.-G. Comprehensive Design of DC Shipboard Power Systems for Pure Electric Propulsion Ship Based on Battery Energy Storage System. Energies 2021, 14, 5264. [Google Scholar] [CrossRef]

- Tercan, S.H.; Eid, B.; Heidenreich, M.; Kogler, K.; Akyurek, O. Financial and Technical Analyses of Solar Boats as A Means of Sustainable Transportation. Sustain. Prod. Consump. 2021, 25, 404–412. [Google Scholar] [CrossRef]

- Quirapas, M.A.J.R.; Taeihagh, A. Ocean renewable energy development in Southeast Asia: Opportunities, risks and unintended consequences. Renew. Sustain. Energy Rev. 2021, 137, 110403. [Google Scholar] [CrossRef]

- Boh, S. World’s Largest Floating Solar Photovoltaic Cell Test-Bed Launched in Singapore. The Straits Times. 2016. Available online: https://www.straitstimes.com/singapore/worlds-largest-floating-solar-photovoltaic-cell-test-bed-launched-in-singapore (accessed on 10 December 2021).

- Group, N. NYK to Participate in Demonstration of Tidal Energy in Singapore; NYK: Tokyo, Japan, 2018. [Google Scholar]

- Offshore Energy. Philippines Gives Blessing to Utility Scale Tidal Energy Project. Available online: https://www.offshore-energy.biz/philippines-gives-blessing-to-utility-scale-tidal-energy-project/ (accessed on 10 December 2021).

- Lavidas, G. Developments of energy in EU-unlocking the wave energy potential. Int. J. Sustain. Energy 2019, 38, 208–226. [Google Scholar] [CrossRef]

- Hemer, M.A.; Manasseh, R.; McInnes, K.L.; Penesis, I.; Pitman, T. Perspectives on a way forward for ocean renewable energy in Australia. Renew. Energy 2018, 127, 733–745. [Google Scholar] [CrossRef]

- Jiang, B.; Li, X.; Chen, S.; Xiong, Q.; Chen, B.-f.; Parker, R.G.; Zuo, L. Performance analysis and tank test validation of a hybrid ocean wave-current energy converter with a single power takeoff. Energy Convers. Manag. 2020, 224, 113268. [Google Scholar] [CrossRef]

- Weiss, C.V.C.; Guanche, R.; Ondiviela, B.; Castellanos, O.F.; Juanes, J. Marine renewable energy potential: A global perspective for offshore wind and wave exploitation. Energy Convers. Manag. 2018, 177, 43–54. [Google Scholar] [CrossRef]

- Cao, S. Comparison of the energy and environmental impact by integrating a H2 vehicle and an electric vehicle into a zero-energy building. Energy Convers. Manag. 2016, 123, 153–173. [Google Scholar] [CrossRef]

- TRNSYS 18. Available online: http://sel.me.wisc.edu/trnsys/features/features.html (accessed on 10 December 2021).

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen-Geiger climate classification. Hydrol. Earth Syst. Sci. 2007, 11, 1633–1644. [Google Scholar] [CrossRef] [Green Version]

- The University of Wisconsin-Madison. Solar Energy Laboratory of the University of Wisconsin-Madison, T.E.G., CSTB–Centre Scientifique et Technique du Bâtiment, TESS–Thermal Energy Systems Specialists, Section 8.7 Meteonorm Data. 2017. Volume 8. Available online: https://sel.me.wisc.edu/trnsys/features/trnsys18_0_updates.pdf (accessed on 15 October 2021).

- Meteotest, A.G. Meteonorm. Available online: https://meteonorm.com/en/ (accessed on 10 December 2021).

- E.M.S.D. Performance-Based Building Energy Code; The Government of the Hong Kong Special Administrative Region: Hong Kong, China, 2007. [Google Scholar]

- SOELCAT 12. Available online: https://soelyachts.com/soelcat-12/ (accessed on 10 December 2021).

- 340W NeON®. 2 Black Solar Panel for Home. Available online: https://www.lg.com/us/business/solar-panels/lg-lg340n1k-l5 (accessed on 10 December 2021).

- The University of Wisconsin-Madison. Multizone Building Modeling with Type56 and TRNBuild of the TRNSYS Document Package. Solar Energy Laboratory of the University of Wisconsin-Madison, T.E.G., CSTB–Centre Scientifique et Technique du Bâtiment, TESS–Thermal Energy Systems Specialists. 2017. Volume 5. Available online: https://sel.me.wisc.edu/trnsys/ (accessed on 15 October 2021).

- LLC of Madison. Type 567: Glazed Building-Integrated PV System (Interacts w/Type 56); Section 3.6; TESS–Thermal Energy Systems Specialists; LLC of Madison: Madison, WI, USA, 2013; Volume 3. [Google Scholar]

- FuturaSun. Available online: https://www.futurasun.com/en/ (accessed on 10 December 2021).

- Wave Dragon. Available online: http://www.wavedragon.net/ (accessed on 10 December 2021).

- Hald, T.; Frigaard, P. Forces and Overtopping on 2. Generation Wave Dragon for Nissum Bredning; Hydraulics & Coastal Engineering Laboratory, Department of Civil Engineering, Aalborg University: Aalborg, Denmark, 2001. [Google Scholar]

- Giovanna Bevilacqua, B.Z. Overtopping Wave Energy Converters: General Aspects and Stage of Development. 2011. Available online: http://amsacta.unibo.it/3062/1/overtopping_devicex.pdf (accessed on 10 December 2021).

- Parmeggiani, S.; Chozas, J.F.; Pecher, A.; Friis-Madsen, E.; Sørensen, H.C.; Kofoed, J.P. Performance Assessment of the Wave Dragon Wave Energy Converter Based on the EquiMar Methodology. In Proceedings of the 9th European Wave and Tidal Conference, Southampton, UK, 5–9 September 2011. [Google Scholar]

- Cao, S.; Hasan, A.; Sirén, K. On-site energy matching indices for buildings with energy conversion, storage and hybrid grid connections. Energy Build. 2013, 64, 423–438. [Google Scholar] [CrossRef]

- Cao, S.; Mohamed, A.; Hasan, A.; Sirén, K. Energy matching analysis of on-site micro-cogeneration for a single-family house with thermal and electrical tracking strategies. Energy Build. 2014, 68, 351–363. [Google Scholar] [CrossRef]

- Bank, T.W. Real Interest Rate (%)-Hong Kong SAR, China. Available online: https://data.worldbank.org/indicator/FR.INR.RINR?end=2019&locations=HK&start=2010&view=chart (accessed on 10 December 2021).

- CLP. CLP Sustainability Report 2020; CLP: Hong Kong, China, 2020. [Google Scholar]

- Wave Dragon 1.5 MW. Available online: https://energiforskning.dk/sites/energiforskning.dk/files/slutrapporter/wd15mwv4_efm-17.pdf (accessed on 10 December 2021).

- Martins, B.P. Techno-Economic Evaluation of a Floating PV System for a Wastewater Treatment Facility; KTH School of Industrial Engineering and Management Energy Technology: Stockholm, Sweden, 2019. [Google Scholar]

- NREL. Distributed Generation Energy Technology Capital Costs. Available online: https://www.nrel.gov/analysis/tech-cost-dg.html (accessed on 10 December 2021).

- Hsieh, I.Y.L.; Pan, M.S.; Chiang, Y.-M.; Green, W.H. Learning only buys you so much: Practical limits on battery price reduction. Appl. Energy 2019, 239, 218–224. [Google Scholar] [CrossRef]

- CLP. Tariff and Charges. Available online: https://www.clp.com.hk/en/customer-service/tariff (accessed on 10 December 2021).

- CLP. Renewable Energy Feed-in Tariff. Available online: https://www.clp.com.hk/en/community-and-environment/renewable-schemes/feed-in-tariff (accessed on 10 December 2021).

- Official Exchange Rate (LCU per US$, Period Average)-Hong Kong SAR, China. Available online: https://data.worldbank.org/indicator/PA.NUS.FCRF?end=2019&locations=HK&start=2011 (accessed on 10 December 2021).

- Fanger, P.O. Thermal Comfort. Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

| Heating | Reheater | Electric 1 | Cooling | ||||||

|---|---|---|---|---|---|---|---|---|---|

| AHU Heating 2 | Space Heating | DHW Heating | Total Heating (Excluding Reheater Heating) | Reheater Heating | Electric 1 | AHU Cooling | Space Cooling | Total Cooling | |

| Total Energy (kWh/m2.a) | 0.01 | 0.06 | 67.78 | 67.85 | 15.6 | 102.7 | 164.88 | 41.1 | 205.99 |

| Peak Power (kW) | 22.5 | 7.59 | 68.4 | 75.7 | 14.79 | 100.94 | 146.78 | 98.49 | 227.82 |

| Velocity (Knot) | 3.2 | 4.0 | 5.4 | 6.0 | 7.0 | 8.0 | 8.1 | 9.0 |

|---|---|---|---|---|---|---|---|---|

| Velocity (km/h) | 6.00 | 7.50 | 10.00 | 11.11 | 12.96 | 14.82 | 15.00 | 16.67 |

| Energy consumption (kWh/km) | 0.30 | 0.39 | 0.52 | 0.58 | 0.68 | 1.08 | 1.13 | 1.58 |

| The Variables | The Options of the Variables |

|---|---|

| The on-site ORE | WEC: from 0–800 kW |

| FPV: from 0 to 5524.5 m2 | |

| Cruise Velocity [km/h] | 6, 7.5, 10, 15 |

| Cruise Distance [km] | 5, 7.5, 10, 12.5 |

| The number of electric boats | 0 to 8 (16 boats are the extreme testing case) |

| With building to boat function | Yes |

| With boat-to-building function | Yes, No |

| Variables | Options of the Variables | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Case | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| Scenario 1 | On-Site ORE | WEC [Unit] | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

| FPV [m2] | 5524.5 | 4834.7 | 4124.6 | 3425.4 | 2726.3 | 2027.2 | 1326.4 | 627.3 | 0 | ||

| Cruise Velocity | 7.5 km/h | ||||||||||

| Cruise Distance | 10 km | ||||||||||

| The number of electric boats | 0 or 1 | ||||||||||

| With building to boat function | Yes | ||||||||||

| With boat-to-building function | No | ||||||||||

| Scenario 1 | ||||||

|---|---|---|---|---|---|---|

| Cases | Case 1 (Only FPV) | Case 7 (Mixing) | Case 9 (Only WEC) | |||

| without Boat | with Boat | without Boat | with Boat | without Boat | with Boat | |

| Eimp,a [kWh/m2.a] | 149.51 | 149.46 | 98.36 | 98.15 | 106.60 | 106.33 |

| Eexp,a [kWh/m2.a] | 138.04 | 137.29 | 86.85 | 85.91 | 97.97 | 96.99 |

| Edirect,a [kWh/m2.a] | 11.47 | 12.20 | 11.51 | 12.24 | 8.63 | 9.34 |

| OEFe | 0.351 | 0.357 | 0.573 | 0.578 | 0.537 | 0.543 |

| OEMe | 0.401 | 0.408 | 0.623 | 0.629 | 0.580 | 0.587 |

| WMI | 0.376 | 0.382 | 0.598 | 0.603 | 0.559 | 0.565 |

| ŋEB,RE | - | 0.977 | - | 0.959 | - | 0.833 |

| CEa [kg CO2,eq/m2.a] | 5.57 | 5.93 | 5.59 | 5.95 | 4.19 | 4.54 |

| Variables | Options of the Variables | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Case | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

| Scenario 2 | On-Site ORE | WEC [Unit] | 0 | 6 | 12 | 18 | 24 | 30 | 36 | 44 |

| FPV [m2] | 5528.8 | 4774.8 | 4020.9 | 3267.0 | 2513.1 | 1759.2 | 1005.2 | 0 | ||

| Cruise Velocity | 7.5 km/h | |||||||||

| Cruise Distance | 10 km | |||||||||

| The number of electric boats | 0 or 1 | |||||||||

| With building to boat function | Yes | |||||||||

| With boat-to-building function | No | |||||||||

| Scenario 2 | ||||||

|---|---|---|---|---|---|---|

| Cases | Case 1 (Only FPV) | Case 6 (Mixing) | Case 8 (Only WEC) | |||

| without Boat | with Boat | without Boat | with Boat | without Boat | with Boat | |

| Eimp,a [kWh/m2.a] | 149.49 | 149.44 | 94.14 | 93.98 | 101.62 | 101.34 |

| Eexp,a [kWh/m2.a] | 138.20 | 137.41 | 99.77 | 98.88 | 115.15 | 114.17 |

| Edirect,a [kWh/m2.a] | 11.30 | 12.03 | −5.63 | −4.90 | −13.53 | −12.83 |

| OEFe | 0.351 | 0.357 | 0.591 | 0.596 | 0.559 | 0.564 |

| OEMe | 0.400 | 0.408 | 0.598 | 0.604 | 0.551 | 0.558 |

| WMI | 0.376 | 0.382 | 0.595 | 0.600 | 0.555 | 0.561 |

| ŋEB,RE | - | 0.977 | - | 0.970 | - | 0.850 |

| CEa[kg CO2,eq/m2.a] | 5.49 | 5.85 | −2.74 | −2.38 | −6.58 | −6.23 |

| Simulation Groups | with 1 Boat | with Building to Boat Function | with Boat-to-Building Function | Cruise Distance [km] | Cruise Velocity [km/h] |

|---|---|---|---|---|---|

| Group 2.0 | Yes | Yes | No | 7.5 | 15 |

| Group 2.1 | Yes | Yes | No | 10 | |

| Group 2.2 | Yes | Yes | No | 7.5 | |

| Group 2.3 | Yes | Yes | No | 6 |

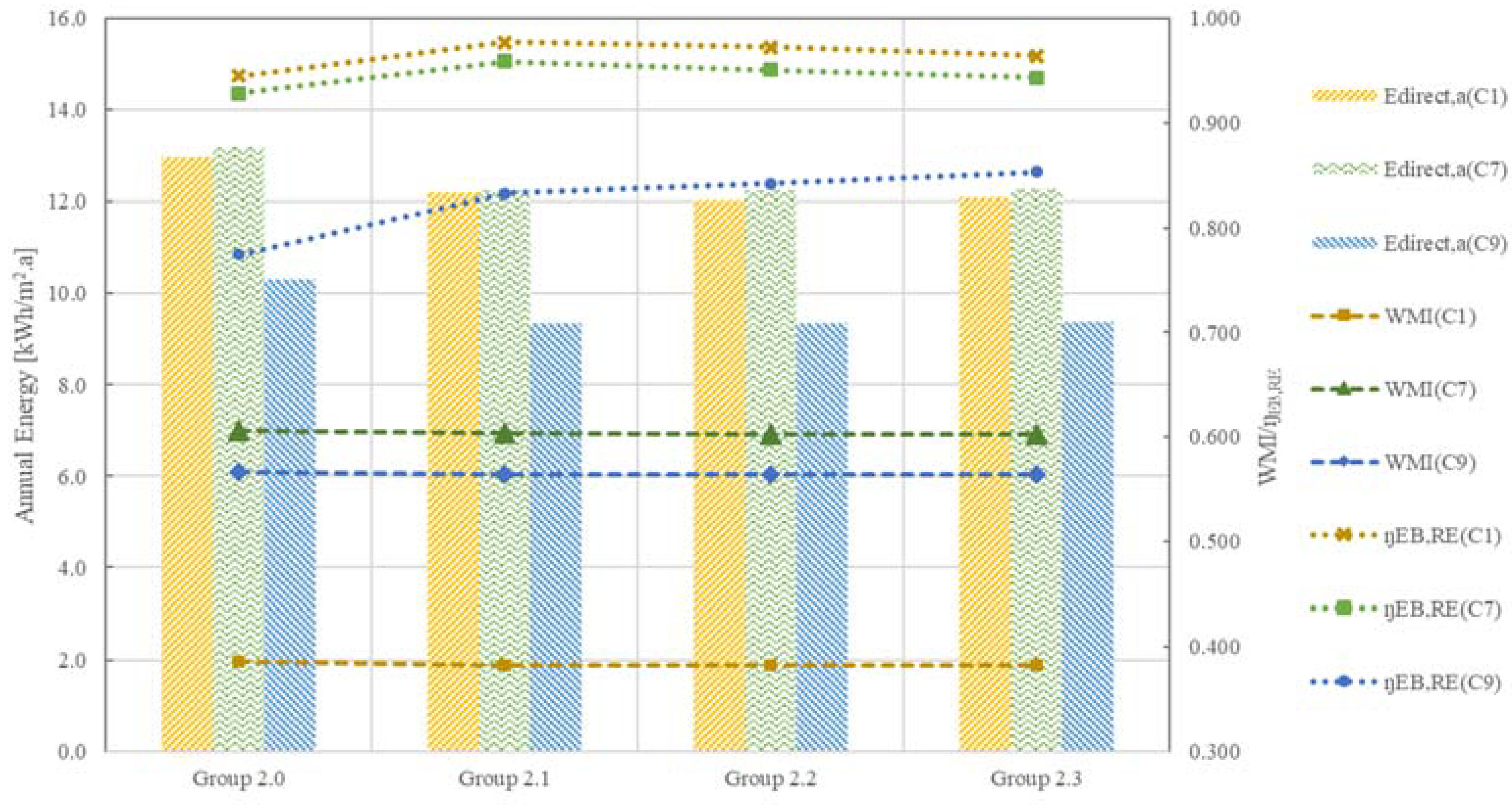

| Simulation Groups | Selected Cases | Edirect,a [kWh/m2.a] | WMI | CEa [kg CO2,eq/m2.a] | |

|---|---|---|---|---|---|

| Group 2.0 (Velocity 15 km/h) | C1 | 12.963 | 0.385 | 0.945 | 6.300 |

| C7 | 13.176 | 0.606 | 0.928 | 6.404 | |

| C9 | 10.397 | 0.567 | 0.775 | 5.005 | |

| Group 2.1 (Velocity 10 km/h) | C1 | 12.204 | 0.382 | 0.977 | 5.931 |

| C7 | 12.239 | 0.603 | 0.959 | 5.948 | |

| C9 | 9.340 | 0.565 | 0.833 | 4.539 | |

| Group 2.2 (Velocity 7.5 km/h) | C1 | 12.040 | 0.382 | 0.972 | 5.851 |

| C7 | 12.240 | 0.603 | 0.951 | 5.949 | |

| C9 | 9.336 | 0.564 | 0.842 | 4.537 | |

| Group 2.3 (Velocity 6 km/h) | C1 | 12.075 | 0.382 | 0.964 | 5.868 |

| C7 | 12.271 | 0.603 | 0.943 | 5.964 | |

| C9 | 9.371 | 0.564 | 0.853 | 4.554 |

| Simulation Groups | With 1 Boat | With Building to Boat Function | With Boat-to-Building Function | Cruise Distance [km] | Cruise Velocity [km/h] |

|---|---|---|---|---|---|

| Group 2.4 | Yes | Yes | No | 5 | 10 |

| Group 2.1 | Yes | Yes | No | 7.5 | |

| Group 2.5 | Yes | Yes | No | 10 | |

| Group 2.6 | Yes | Yes | No | 12.5 |

| Simulation Groups | Selected Groups | Edirect,a [kWh/m2.a] | WMI | CEa [kg CO2,eq/m2.a] | |

|---|---|---|---|---|---|

| Group 2.4 (Distance 5 km) | C1 | 10.9 | 0.378 | 0.971 | 5.300 |

| C7 | 11.1 | 0.600 | 0.991 | 5.399 | |

| C9 | 8.2 | 0.562 | 0.942 | 3.987 | |

| Group 2.1 (Distance 7.5 km) | C1 | 12.2 | 0.382 | 0.977 | 5.931 |

| C7 | 12.2 | 0.603 | 0.959 | 5.948 | |

| C9 | 9.3 | 0.565 | 0.833 | 4.539 | |

| Group 2.5 (Distance 10 km) | C1 | 13.7 | 0.386 | 0.826 | 6.641 |

| C7 | 13.9 | 0.607 | 0.856 | 6.741 | |

| C9 | 11.0 | 0.567 | 0.747 | 5.337 | |

| Group 2.6 (Distance 12.5 km) | C1 | 15.8 | 0.388 | 0.657 | 7.668 |

| C7 | 16.0 | 0.610 | 0.762 | 7.774 | |

| C9 | 13.1 | 0.570 | 0.697 | 6.374 |

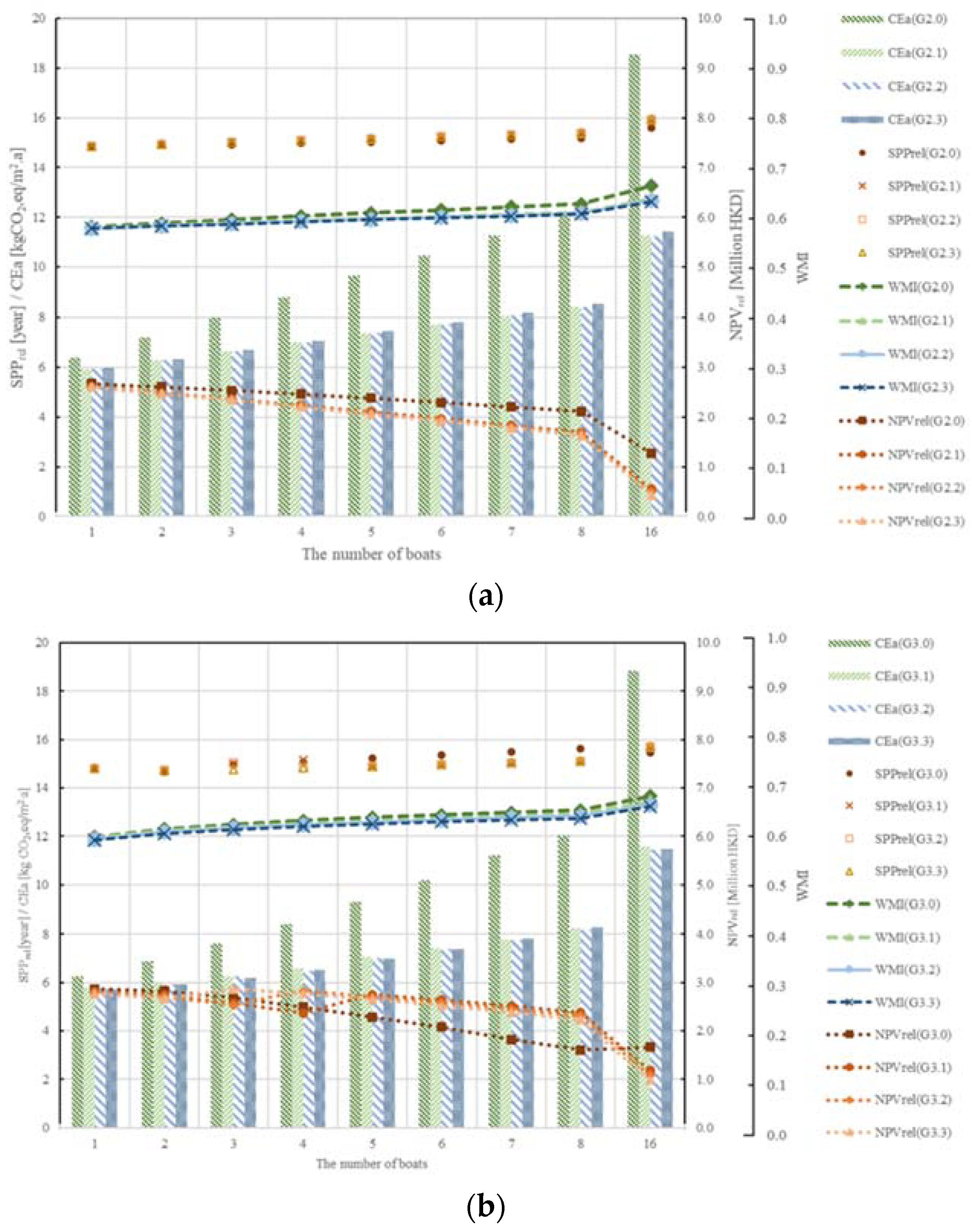

| Simulation Groups | The Number of Boats | With Building to Boat Function | With Boat-to-Building Function | Cruise Distance | Cruise Velocity |

|---|---|---|---|---|---|

| [km] | [km/h] | ||||

| Group 2.0 | 1–8, 16 | Yes | No | 7.5 | 15 |

| Group 2.1 | 1–8, 16 | Yes | No | 10 | |

| Group 2.2 | 1–8, 16 | Yes | No | 7.5 | |

| Group 2.3 | 1–8, 16 | Yes | No | 6 | |

| Group 3.0 | 1–8, 16 | Yes | Yes | 7.5 | 15 |

| Group 3.1 | 1–8, 16 | Yes | Yes | 10 | |

| Group 3.2 | 1–8, 16 | Yes | Yes | 7.5 | |

| Group 3.3 | 1–8, 16 | Yes | Yes | 6 |

| Simulation Groups | The Number of Boats | Edirect,a [kWh/m2.a] | WMI | CEa [kg CO2,eq/m2.a] | |

|---|---|---|---|---|---|

| Group 2.0 (Velocity 15 km/h) | 1 | 13.176 | 0.606 | 0.928 | 6.404 |

| 8 | 24.861 | 0.649 | 0.817 | 12.083 | |

| 16 | 38.204 | 0.680 | 0.745 | 18.567 | |

| Group 2.1 (Velocity 10 km/h) | 1 | 12.239 | 0.603 | 0.959 | 5.948 |

| 8 | 17.320 | 0.635 | 0.874 | 8.417 | |

| 16 | 23.047 | 0.661 | 0.816 | 11.201 | |

| Group 2.2 (Velocity 7.5 km/h) | 1 | 12.240 | 0.603 | 0.951 | 5.949 |

| 8 | 17.299 | 0.633 | 0.862 | 8.407 | |

| 16 | 22.971 | 0.658 | 0.800 | 11.164 | |

| Group 2.3 (Velocity 6 km/h) | 1 | 12.271 | 0.603 | 0.943 | 5.964 |

| 8 | 17.544 | 0.631 | 0.844 | 8.526 | |

| 16 | 23.467 | 0.655 | 0.785 | 11.405 |

| Simulation Groups | The Number of Boats | Edirect,a [kWh/m2.a] | WMI | CEa [kg CO2,eq/m2.a] | |

|---|---|---|---|---|---|

| Group 3.0 (Velocity 15 km/h) | 1 | 12.892 | 0.627 | 0.886 | 6.266 |

| 8 | 24.839 | 0.680 | 0.730 | 12.072 | |

| 16 | 38.715 | 0.703 | 0.664 | 18.815 | |

| Group 3.1 (Velocity 10 km/h) | 1 | 11.846 | 0.624 | 0.894 | 5.757 |

| 8 | 16.814 | 0.673 | 0.747 | 8.171 | |

| 16 | 23.261 | 0.694 | 0.685 | 11.305 | |

| Group 3.2 (Velocity 7.5 km/h) | 1 | 11.797 | 0.622 | 0.885 | 5.733 |

| 8 | 16.707 | 0.669 | 0.732 | 8.119 | |

| 16 | 22.978 | 0.689 | 0.666 | 11.167 | |

| Group 3.3 (Velocity 6 km/h) | 1 | 11.785 | 0.619 | 0.873 | 5.728 |

| 8 | 16.711 | 0.664 | 0.718 | 8.122 | |

| 16 | 23.198 | 0.684 | 0.651 | 11.274 |

| Simulation Groups | The Number of Boats | With Building to Boat Function | With Boat-to-Building Function | Cruise Distance | Cruise Velocity |

|---|---|---|---|---|---|

| [km] | [km/h] | ||||

| Group 2.4 | 1–8, 16 | Yes | No | 5 | 10 |

| Group 2.1 | 1–8, 16 | Yes | No | 7.5 | |

| Group 2.5 | 1–8, 16 | Yes | No | 10 | |

| Group 2.6 | 1–8, 16 | Yes | No | 12.5 | |

| Group 3.4 | 1–8, 16 | Yes | Yes | 5 | 10 |

| Group 3.1 | 1–8, 16 | Yes | Yes | 7.5 | |

| Group 3.5 | 1–8, 16 | Yes | Yes | 10 | |

| Group 3.6 | 1–8, 16 | Yes | Yes | 12.5 |

| Simulation Groups | The Number of Boats | Edirect,a [kWh/m2.a] | WMI | CEa@ [kg CO2,eq/m2.a] | |

|---|---|---|---|---|---|

| Group 2.4 (C7) (Distance 5 km) | 1 | 11.109 | 0.600 | 0.991 | 5.40 |

| 8 | 8.300 | 0.615 | 0.968 | 4.03 | |

| 16 | 5.063 | 0.629 | 0.953 | 2.46 | |

| Group 2.1 (C7) (Distance 7.5 km) | 1 | 12.239 | 0.603 | 0.959 | 5.95 |

| 8 | 17.320 | 0.635 | 0.874 | 8.42 | |

| 16 | 23.047 | 0.661 | 0.816 | 11.20 | |

| Group 2.5 (C7) (Distance 10 km) | 1 | 13.871 | 0.607 | 0.856 | 6.74 |

| 8 | 30.386 | 0.650 | 0.714 | 14.77 | |

| 16 | 49.178 | 0.678 | 0.628 | 23.90 | |

| Group 2.6 (C7) (Distance 12.5 km) | 1 | 15.996 | 0.610 | 0.762 | 7.77 |

| 8 | 47.403 | 0.656 | 0.568 | 23.04 | |

| 16 | 83.194 | 0.673 | 0.455 | 40.43 |

| Simulation Groups | The Number of Boats | Edirect,a [kWh/m2.a] | WMI | CEa [kg CO2,eq/m2.a] | |

|---|---|---|---|---|---|

| Group 3.4 (C7) (Distance 5 km) | 1 | 10.773 | 0.625 | 0.928 | 5.24 |

| 8 | 7.783 | 0.673 | 0.810 | 3.78 | |

| 16 | 5.553 | 0.692 | 0.749 | 2.70 | |

| Group 3.1 (C7) (Distance 7.5 km) | 1 | 11.846 | 0.624 | 0.894 | 5.77 |

| 8 | 16.814 | 0.673 | 0.747 | 8.32 | |

| 16 | 23.261 | 0.694 | 0.685 | 11.36 | |

| Group 3.5 (C7) (Distance 10 km) | 1 | 13.518 | 0.623 | 0.849 | 6.54 |

| 8 | 30.169 | 0.672 | 0.661 | 14.64 | |

| 16 | 49.239 | 0.692 | 0.578 | 23.93 | |

| Group 3.6 (C7) (Distance 12.5 km) | 1 | 15.587 | 0.622 | 0.779 | 7.58 |

| 8 | 47.119 | 0.667 | 0.573 | 22.90 | |

| 16 | 83.177 | 0.677 | 0.466 | 40.42 |

| WEC | FPV | Boat PV | Boat Battery | |

|---|---|---|---|---|

| Capital Cost | 45,630 HKD/kW [57] | 26,520 HKD/kW [58] | 37,331 HKD/kW [59] | 1560 HKD/kWh [60] |

| O&M Cost | 4.80% | 1.92% | 0.86% | / |

| Electricity Fee | 1.22 HKD/kWh [61] | |||

| Feed-in-Tariff | 3.00 HKD/kWh [62] | |||

| Interest Rate | 2.139% [55] | |||

| USD to HKD Exchange rate | 7.80 [63] | |||

| Group | Variables | SPPrel (without FiT) | SPPrel (with FiT) | NPVrel (Million HKD) | WMI | CEa [kg CO2,eq/m2.a] | |

|---|---|---|---|---|---|---|---|

| Scenario 1 | Case 1 (Only FPV) | Without Boat | BLT | 9.59 | 16.04 | 0.376 | 5.57 |

| With Boat | BLT | 9.63 | 16.15 | 0.382 | 5.93 | ||

| Case 5 (Mixing) | Without Boat | BLT | 14.87 | 2.54 | 0.572 | 5.57 | |

| With Boat | BLT | 14.85 | 2.65 | 0.578 | 5.93 | ||

| Case 9 (Only WEC) | Without Boat | BLT | 26.58 | −14.42 | 0.559 | 4.19 | |

| With Boat | BLT | 26.35 | −14.30 | 0.565 | 4.54 |

| Simulation Groups | The Number of Boats | SPPrel (without FiT) | SPPrel (with FiT) | NPVrel [Million HKD] | WMI | CEa [kgCO2,eq/m2.a] |

|---|---|---|---|---|---|---|

| Group 2.0 (C5) (Velocity 15 km/h) | 1 | BLT | 14.83 | 2.67 | 0.580 | 6.386 |

| 8 | BLT | 15.19 | 2.11 | 0.626 | 12.068 | |

| 16 | BLT | 15.61 | 1.28 | 0.663 | 18.552 | |

| Group 2.1 (C5) (Velocity 10 km/h) | 1 | BLT | 14.85 | 2.61 | 0.578 | 5.933 |

| 8 | BLT | 15.36 | 1.69 | 0.610 | 8.433 | |

| 16 | BLT | 15.90 | 0.55 | 0.637 | 11.250 | |

| Group 2.2 (C5) (Velocity 7.5 km/h) | 1 | BLT | 14.85 | 2.61 | 0.577 | 5.935 |

| 8 | BLT | 15.38 | 1.66 | 0.608 | 8.435 | |

| 16 | BLT | 15.93 | 0.49 | 0.634 | 11.226 | |

| Group 2.3 (C5) (Velocity 6 km/h) | 1 | BLT | 14.86 | 2.60 | 0.577 | 5.951 |

| 8 | BLT | 15.39 | 1.63 | 0.606 | 8.549 | |

| 16 | BLT | 15.95 | 0.43 | 0.631 | 11.434 |

| Simulation Groups | The Number of Boats | SPPrel (without FiT) | SPPrel (with FiT) | NPVrel [Million HKD] | WMI | CEa [kgCO2,eq/m2.a] |

|---|---|---|---|---|---|---|

| Group 3.0 (C5) (Velocity 15 km/h) | 1 | BLT | 14.77 | 2.86 | 0.599 | 6.241 |

| 8 | BLT | 15.63 | 1.61 | 0.654 | 12.038 | |

| 16 | BLT | 15.45 | 1.67 | 0.683 | 18.830 | |

| Group 3.1 (C5) (Velocity 10 km/h) | 1 | BLT | 14.80 | 2.81 | 0.596 | 5.787 |

| 8 | BLT | 15.07 | 2.38 | 0.646 | 8.226 | |

| 16 | BLT | 15.64 | 1.18 | 0.671 | 11.580 | |

| Group 3.2 (C5) (Velocity 7.5 km/h) | 1 | BLT | 14.80 | 2.79 | 0.595 | 5.754 |

| 8 | BLT | 15.10 | 2.31 | 0.642 | 8.172 | |

| 16 | BLT | 15.68 | 1.09 | 0.666 | 11.455 | |

| Group 3.3 (C5) (Velocity 6 km/h) | 1 | BLT | 14.82 | 2.77 | 0.593 | 5.725 |

| 8 | BLT | 15.14 | 2.23 | 0.638 | 8.266 | |

| 16 | BLT | 15.72 | 0.99 | 0.661 | 11.500 |

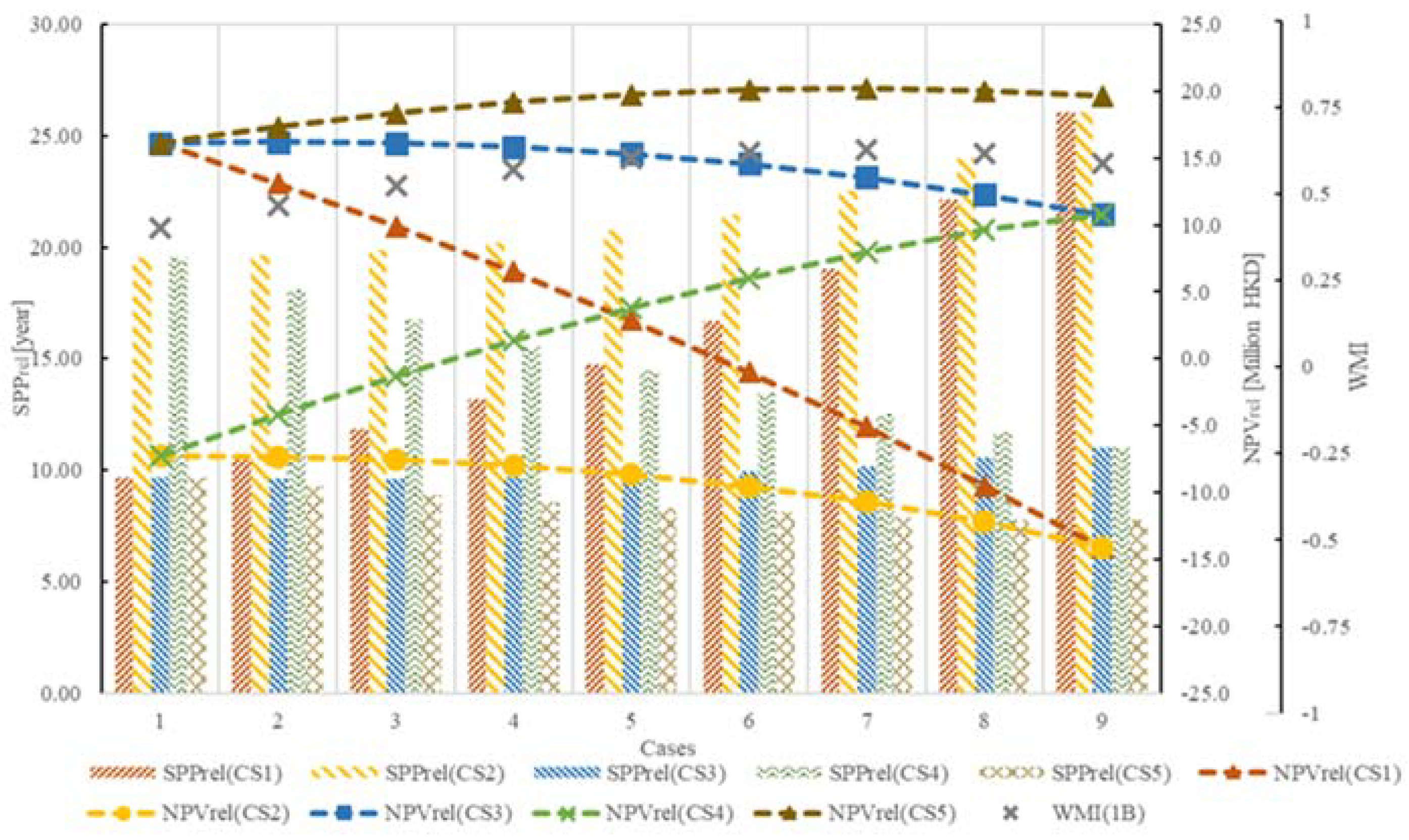

| Selected Group: G3.0 (1 Boat) | WEC (HKD/kW) | FPV (HKD/kW) | Boat PV (HKD/kW) | Boat Battery (HKD/kWh) |

|---|---|---|---|---|

| Capital Cost Scenario 1 | 45,630 | 26,520 | 37,331 | 1560 |

| Capital Cost Scenario 2 | 45,630 | 46,800 | ||

| Capital Cost Scenario 3 | 28,439 | 26,520 | ||

| Capital Cost Scenario 4 | 28,439 | 46,800 | ||

| Capital Cost Scenario 5 | 21,840 | 26,520 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Cao, S.; Xu, Y.; Zhu, X. The Feasibility of Using Zero-Emission Electric Boats to Enhance the Techno-Economic Performance of an Ocean-Energy-Supported Coastal Hotel Building. Energies 2021, 14, 8465. https://doi.org/10.3390/en14248465

Guo X, Cao S, Xu Y, Zhu X. The Feasibility of Using Zero-Emission Electric Boats to Enhance the Techno-Economic Performance of an Ocean-Energy-Supported Coastal Hotel Building. Energies. 2021; 14(24):8465. https://doi.org/10.3390/en14248465

Chicago/Turabian StyleGuo, Xinman, Sunliang Cao, Yang Xu, and Xiaolin Zhu. 2021. "The Feasibility of Using Zero-Emission Electric Boats to Enhance the Techno-Economic Performance of an Ocean-Energy-Supported Coastal Hotel Building" Energies 14, no. 24: 8465. https://doi.org/10.3390/en14248465