Energy and Carbon Emission Efficiency Prediction: Applications in Future Transport Manufacturing

Abstract

:1. Introduction

2. Literature Review

2.1. Transport Manufacturing: Automotive Component Manufacture

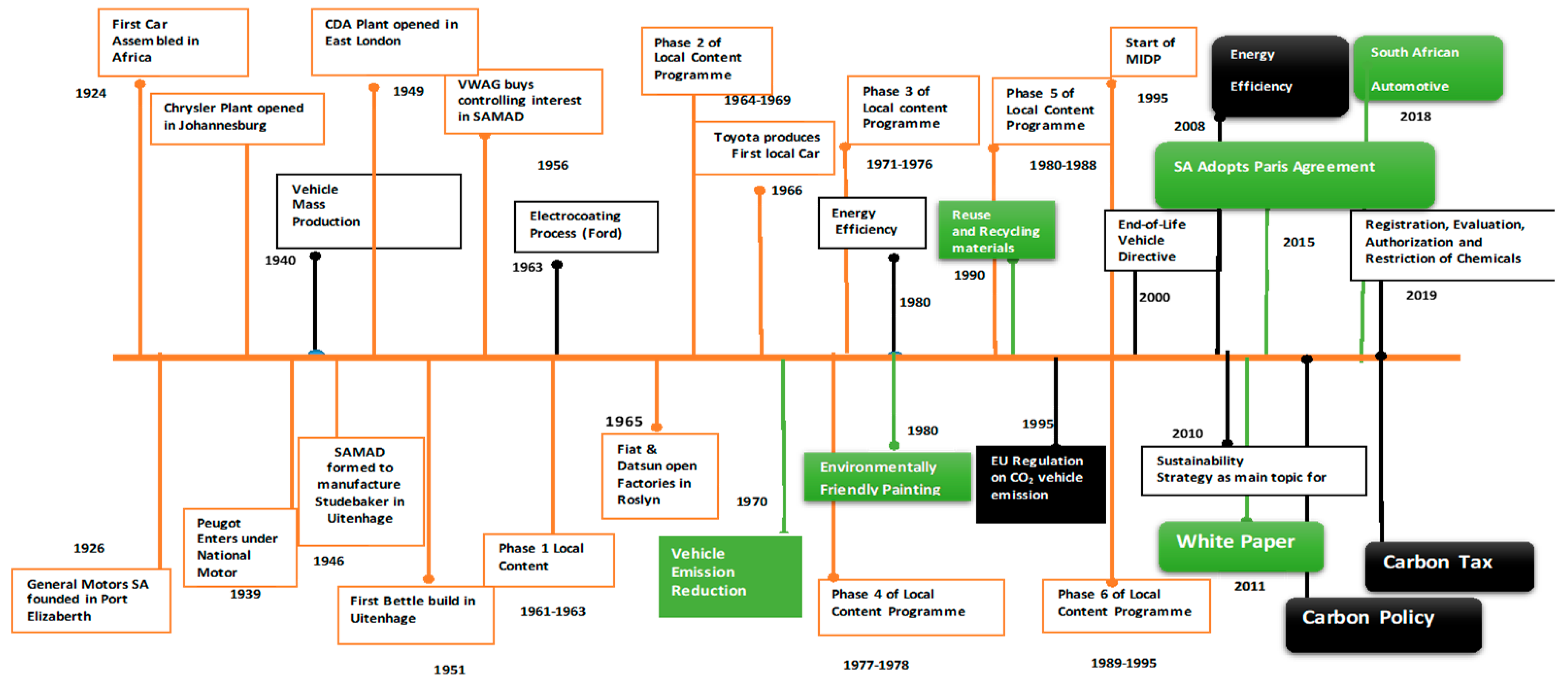

2.2. The South African Automotive Industry

2.2.1. Trends in South African Automotive Industry Energy Consumption and Carbon Emissions

2.2.2. Energy and Carbon Emission Efficiency in Automotive Manufacturing

2.2.3. Application of Time Series in the Prediction of Energy and Carbon Emission Efficiency

3. Materials and Methods

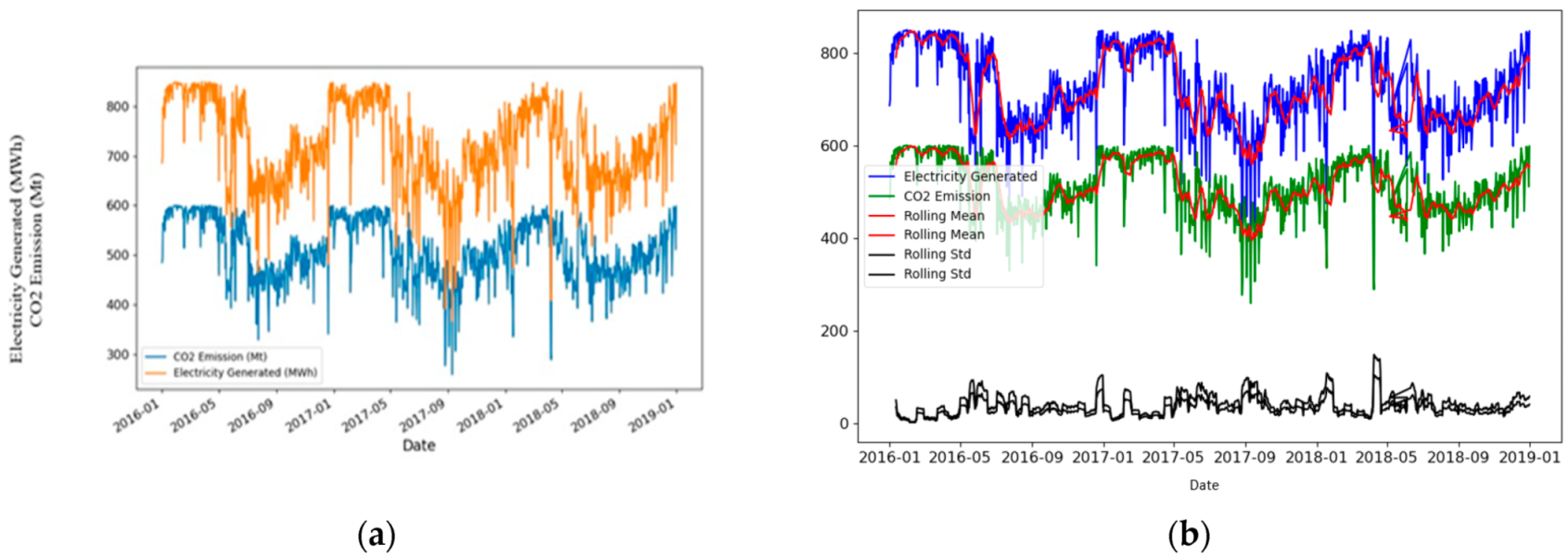

3.1. Secondary Data for This Study

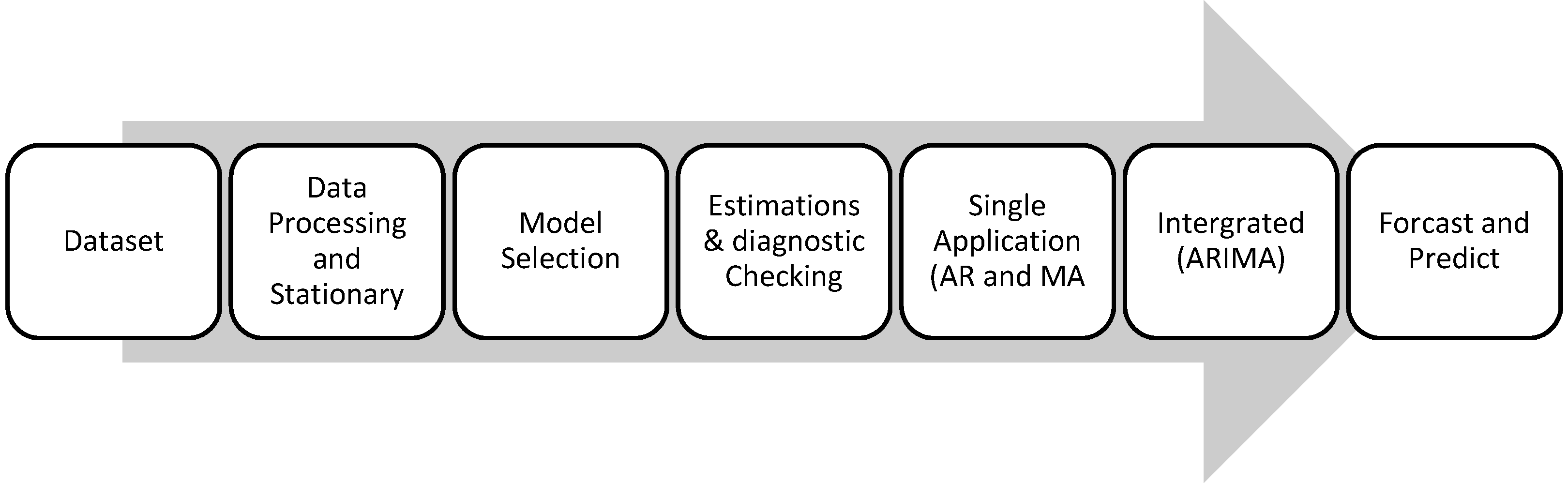

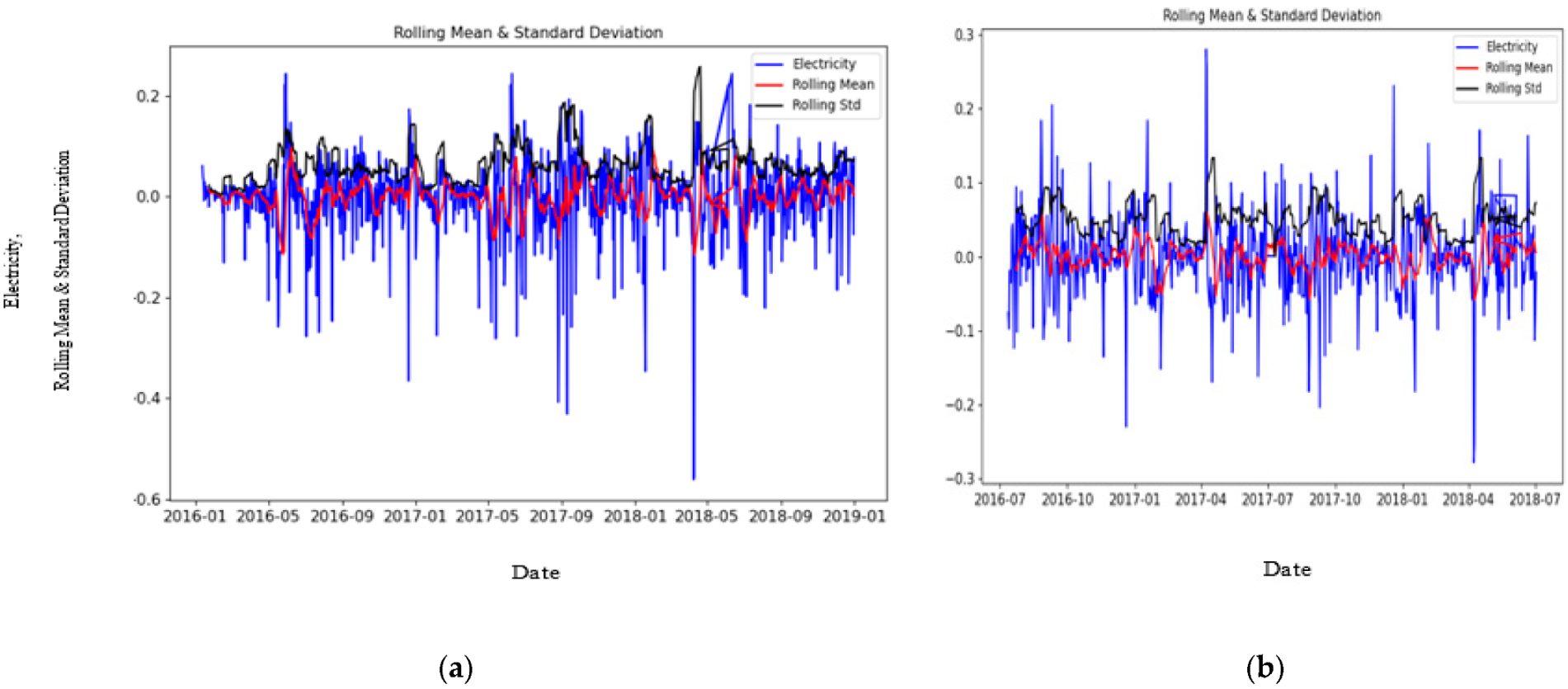

3.2. Methods

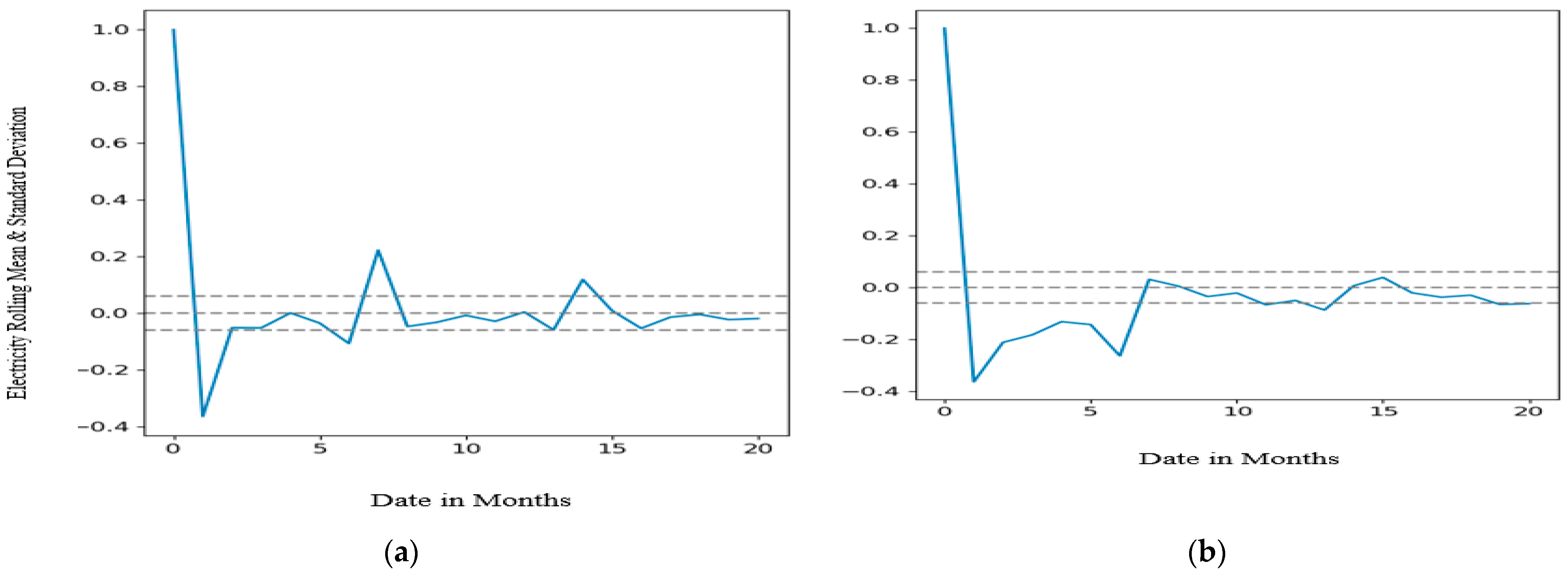

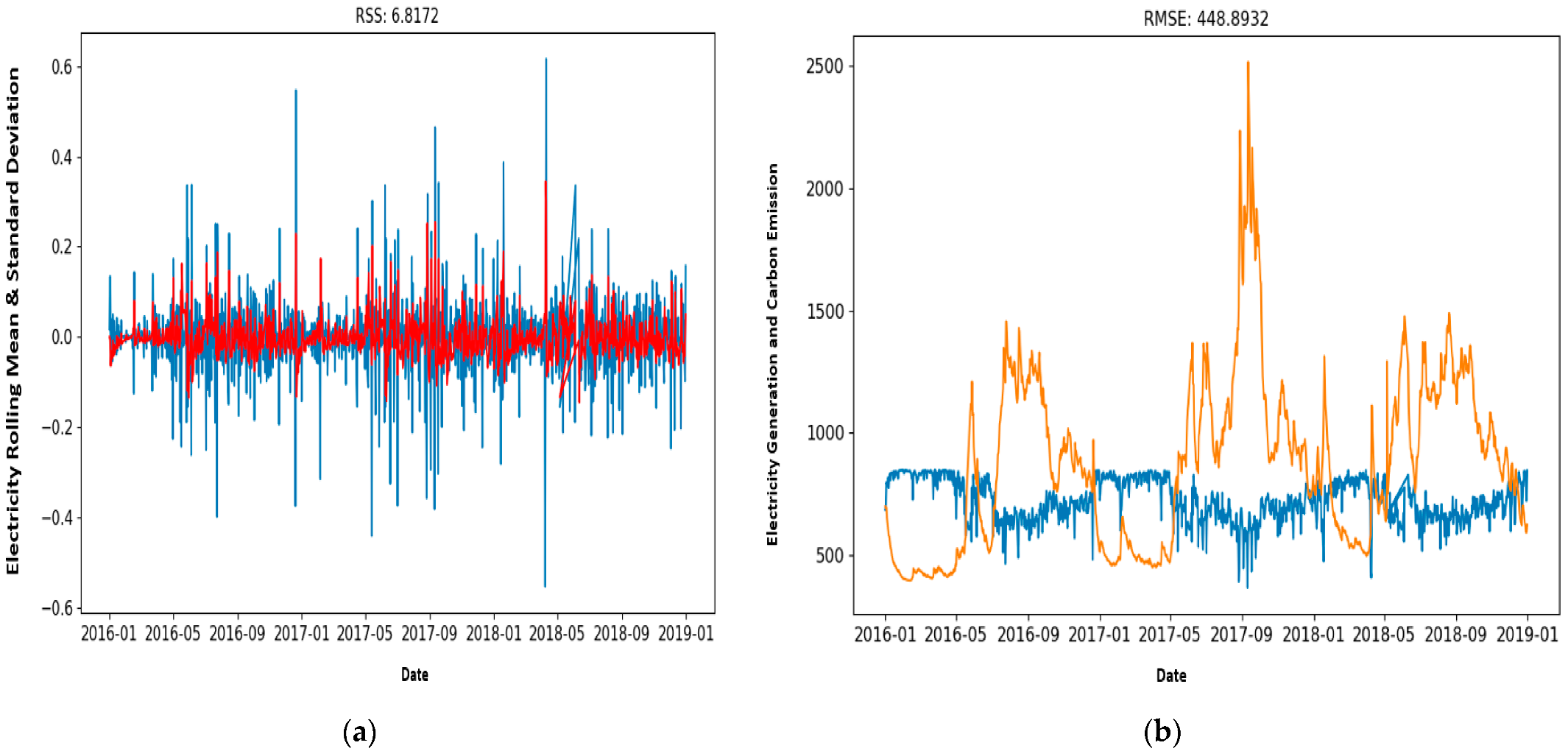

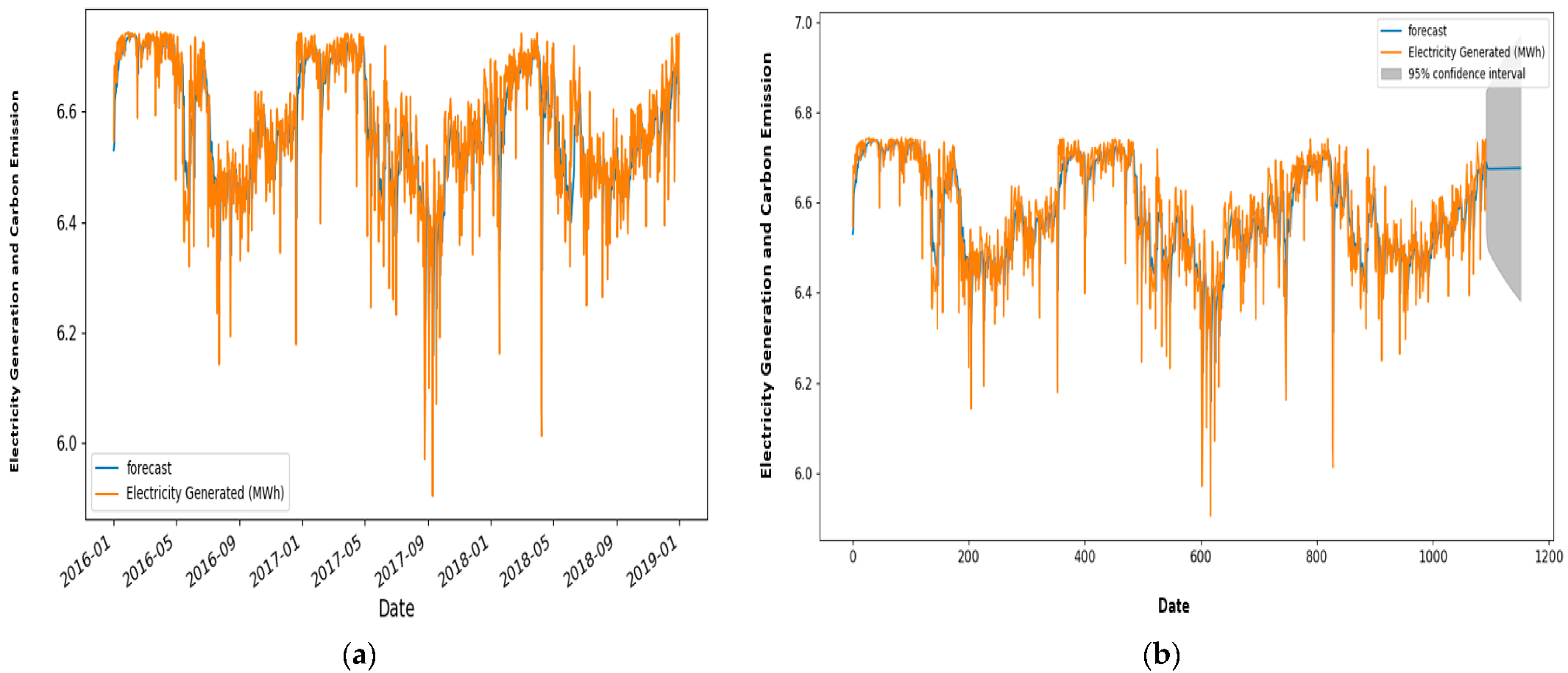

Application of ARIMA Model

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fahmy-Abdullah, M.; Ismail, R.; Sulaiman, N.; Abdul Talib, B. Technical efficiency in transport manufacturing firms: Evidence from Malaysia. Asian Acad. Manag. J. 2017, 22, 57–77. [Google Scholar] [CrossRef]

- Parisa Javadi, P.; Yeganeh, B.; Maryam, A.; Shima, A. Energy assessment and greenhouse gas predictions in the automotive manufacturing industry in Iran. Sustain. Prod. Consum. 2021, 26, 316–330. [Google Scholar] [CrossRef]

- IDC. Developing a Vibrant ESCO Market—Prospects for South Africa’s Energy Efficiency Future; I.D. Corporation, Ed.; IDC: Needham, MA, USA, 2018. [Google Scholar]

- AIEC. South Africa-Automotive Export Manual 2019; Automotive Industry Export Council: South Africa, 2019; Available online: https://aiec.co.za/downloads/AutomotiveExportManual.pdf (accessed on 6 November 2021).

- NAAMSA. South African Economy Manufacturing Presence. 2021. 4. Available online: https://naamsa.net/sa-economy-2021-manufacturing-presence/ (accessed on 6 November 2021).

- Jibhakate, R.A.; Nirwan, N.W.; Rambhad, K.S. Enhancing the effectiveness of green technology in manufacturing industry. Mater. Today Proc. 2021, 47, 4298–4305. [Google Scholar] [CrossRef]

- Al-Tarawneh, H.A. The Main Factors beyond Decision Making. J. Manag. Res. 2011, 4. [Google Scholar] [CrossRef] [Green Version]

- Sallehuddin, R.; Shamsuddin, S.M.; Mohd Hashim, S.Z.; Abraham, A. Forecasting time series data using hybrid grey relational artificial neural network and auto regressive integrated moving average model. Neural Netw. World 2007, 17, 573–605. [Google Scholar]

- Sundarakani, B.; de Souza, R.; Goh, M.; Wagner, S.M.; Manikandan, S. Modeling carbon footprints across the supply chain. Int. J. Prod. Econ. 2010, 128, 43–50. [Google Scholar] [CrossRef]

- Rehman, H.U.; Rafique, R.; Nasir, M.; Zahid Chudhery, M.A. Forecasting CO2 Emissions from Energy, Manufacturing and Transport Sectors in Pakistan: Statistical Vs. Machine Learning Methods. SSRN J. 2018. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3292279 (accessed on 6 November 2021).

- Khandelwal, I.; Adhikari, R.; Verma, G. Time Series Forecasting Using Hybrid ARIMA and ANN Models Based on DWT Decomposition. Procedia Comput. Sci. 2015, 48, 173–179. [Google Scholar] [CrossRef] [Green Version]

- Chou, J.S.; Trans, D. Forecasting energy consumption time series using machine learning techniques based on usage patterns of residential householders. Energy 2018, 165 Pt B, 709–726. [Google Scholar] [CrossRef]

- Hornik, K.; Stinchcombe, M.; White, H. Multilayer feedforward networks are universal approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar] [CrossRef]

- Kandananond, K. Forecasting Electricity Demand in Thailand with an Artificial Neural Network Approach. Energies 2011, 4, 1246–1257. [Google Scholar] [CrossRef]

- Qi, X.; Chen, G.; Li, Y.; Cheng, X.; Li, C. Applying Neural-Network-Based Machine Learning to Additive Manufacturing: Current Applications, Challenges, and Future Perspectives. Engineering 2019, 5, 721–729. [Google Scholar] [CrossRef]

- Gupta, D.; Pratama, M.; Ma, Z.; Li, J.; Prasad, M. Financial time series forecasting using twin support vector regression. PLoS ONE 2019, 14, e0211402. [Google Scholar] [CrossRef]

- Khashei, M.; Bijari, M. A New Hybrid Methodology for Nonlinear Time Series Forecasting. Model. Simul. Eng. 2011, 2011, 379121. [Google Scholar] [CrossRef] [Green Version]

- Kant, G.; Sangwan, K.S. Predictive Modelling for Energy Consumption in Machining Using Artificial Neural Network. Procedia CIRP 2015, 37, 205–210. [Google Scholar] [CrossRef]

- Saleh, C.; Dzakiyullah, N.R.; Nugroho, J.B. Carbon dioxide emission prediction using support vector machine. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012148. [Google Scholar] [CrossRef]

- Sen, P.; Roy, M.; Pal, P. Application of ARIMA for forecasting energy consumption and GHG emission: A case study of an Indian pig iron manufacturing organization. Energy 2016, 116, 1031–1038. [Google Scholar] [CrossRef]

- Shan, K.; Fan, C.; Wang, J. Model predictive control for thermal energy storage assisted large central cooling systems. Energy 2019, 179, 916–927. [Google Scholar] [CrossRef]

- Goudarzi, S.; Anisi, H.; Kama, N.; Doctor, F. Predictive Modelling of Building Energy Consumption based on a Hybrid Nature-Inspired Optimization Algorithm. Energy Build. 2019, 196, 83–93. [Google Scholar] [CrossRef]

- Ji, L.; Zou, Y.; He, K.; Zhu, B. Carbon futures price forecasting based with ARIMA-CNN-LSTM model. Procedia Comput. Sci. 2019, 162, 33–38. [Google Scholar] [CrossRef]

- Fan, D.; Sun, H.; Yao, J.; Zhang, K. Well production forecasting based on ARIMA-LSTM model considering manual operations. Energy 2020, 220, 119708. [Google Scholar] [CrossRef]

- Box, G.E.; Jenkins, G.M.; Reinsel, G.C.; Ljung, G.M. Time Series Analysis: Forecasting and Control; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Giampieri, A.; Ling-Chin, J.; Ma, Z.; Smallbone, A.; RoskillY, A.P. A review of the current automotive manufacturing practice from an energy perspective. Appl. Energy 2020, 261, 114074. [Google Scholar] [CrossRef]

- Kumar, R.; Lamba, K.; Raman, A. Role of zero emission vehicles in sustainable transformation of the Indian automobile industry. Res. Transp. Econ. 2021, 101064, in press. [Google Scholar] [CrossRef]

- Aggelakakis, A.; Bernardino, J.; Boile, M.; Christidis, P.; Condeco Melhorado, A.; Krail, M.; Papanikolaou, A.; Reichenbach, M.; Schippl, J. The future of the transport industry. Publications Office of the European Union: Luxembourg EUR 27085. JRC93544. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC93544 (accessed on 6 November 2021).

- USDOE. Technology Roadmap for Energy Reduction in Automotive Manufacturing; USDOE, Ed.; 2008; pp. 1–81. Available online: https://www1.eere.energy.gov/manufacturing/intensiveprocesses/pdfs/auto_industry_roadmap.pdf (accessed on 6 November 2021).

- Yang, H.K.; Bukkapatnam, S.; Satish, T.; Fugee, S.T. The internet of things for smart manufacturing: A review. IISE Trans. 2019, 51, 1190–1216. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2017, 56, 508–517. [Google Scholar] [CrossRef]

- NCPC. Results and Impact in the Automotive Sector; N.C.P. Centre, Ed.; 2013; pp. 1–40. Available online: http://www.gcpcenvis.nic.in/PDF/Energy_Efficiency_Results_Impact_in_the_Automotive_Sector.pdf (accessed on 6 November 2021).

- DEA. National Climate Change Response White Paper. 2016; pp. 1–50. Available online: https://www.gov.za/sites/default/files/gcis_document/201409/nationalclimatechangeresponsewhitepaper0.pdf (accessed on 6 November 2021).

- DEA. The South African Energy Sector Report. 2019. Available online: http://www.energy.gov.za/files/media/explained/2019-South-African-Energy-Sector-Report.pdf (accessed on 6 November 2021).

- Nedbank. The Energy Efficiency Guide; Nedbank: Thornton, South Africa, 2017; Available online: https://www.nedbank.co.za/content/nedbank/desktop/gt/en/aboutus/green-and-caring/Publications/the-energy-efficiency-guide.html (accessed on 6 November 2021).

- Ramos, D.; Faria, P.; Vale, Z.; Mourinho, J.; Correia, R. Industrial Facility Electricity Consumption Forecast Using Artificial Neural Networks and Incremental Learning. Energies 2020, 13, 4774. [Google Scholar] [CrossRef]

- Liu, W.; Peng, T.; Kishita, Y.; Umeda, Y.; Tang, R.; Tang, W.; Hu, L. Critical life cycle inventory for aluminum die casting: A lightweight-vehicle manufacturing enabling technology. Appl. Energy 2021, 304, 117814. [Google Scholar] [CrossRef]

- Fysikopoulos, A.; Anagnostakis, D.; Salonitis, K.; Chryssolouris, G. An Empirical Study of the Energy Consumption in Automotive Assembly. Procedia CIRP 2012, 3, 477–482. [Google Scholar] [CrossRef] [Green Version]

- Du Plessis, W. Energy efficiency and the law: A multidisciplinary approach. S. Afr. J. Sci. 2015, 111, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Kluczek, A. An energy-led sustainability assessment of production systems—An approach for improving energy efficiency performance. Int. J. Prod. Econ. 2019, 216, 190–203. [Google Scholar] [CrossRef]

- Thollander, P.; Danestig, M.; Rohdin, P. Energy policies for increased industrial energy efficiency: Evaluation of a local energy programme for manufacturing SMEs. Energy Policy 2007, 35, 5774–5783. [Google Scholar] [CrossRef] [Green Version]

- Malinauskaite, J.; Jouhara, H.; Ahmad, L.; Milani, M.; Montorsi, L.; Venturelli, M. Energy efficiency in industry: EU and national policies in Italy and the UK. Energy 2019, 172, 255–269. [Google Scholar] [CrossRef]

- Bonilla, I.; Nieto, N.; Portillo-Valdés, L.; Egilegor, B. Energy efficiency assessment: Process modelling and waste heat recovery analysis. Energy Convers. Manag. 2019, 196, 1180–1192. [Google Scholar] [CrossRef]

- Rue du Can, D.S.; Pudleiner, D.; Pielli, K. Energy efficiency as a means to expand energy access: A Uganda roadmap. Energy Policy 2018, 120, 354–364. [Google Scholar] [CrossRef]

- Gomez Chavez, K.M. Energy Efficiency in Wireless Access Networks: Measurements, Models and Algorithms. Ph.D. Thesis, University of Trento, Trento, Italy, 2013. [Google Scholar]

- Xiong, S.; Ma, X.; Ji, J. The impact of industrial structure efficiency on provincial industrial energy efficiency in China. J. Clean. Prod. 2019, 215, 952–962. [Google Scholar] [CrossRef]

- Pretorius, I.; Piketh, S.J.; Burger, R.P. The Impact of the South African energy Crisis on Emissions. In Air Pollution XXIII; 2015; pp. 255–264. Available online: https://www.researchgate.net/profile/Roelof-Burger/publication/283097663_The_impact_of_the_south_african_energy_crisis_on_emissions/links/56e1381708aee77a15feae92/The-impact-of-the-south-african-energy-crisis-on-emissions.pdf (accessed on 6 November 2021).

- Meng, Z.; Wang, H.; Wang, B. Empirical Analysis of Carbon Emission Accounting and Influencing Factors of Energy Consumption in China. Int. J. Environ. Res. Public Health 2018, 15, 2467. [Google Scholar] [CrossRef] [Green Version]

- Kunda, D.; Phiri, H. An Approach for Predicting CO2 Emissions using Data Mining Techniques. Int. J. Comput. Appl. 2017, 172, 7–10. [Google Scholar] [CrossRef]

- Benedetti, M.C.; Vittorio, I.V. Improving Energy Efficiency in Manufacturing Systems—Literature Review and Analysis of the Impact on the Energy Net-work of Consolidated Practices and Upcoming Opportunities. Energy Efficiency Improvements in Smart Grid Components-IntechOpen Book Series. 2015. Available online: https://www.researchgate.net/profile/Vito-Introna/publication/292124754_Improving_Energy_Efficiency_in_Manufacturing_Systems_-_Literature_Review_and_Analysis_of_the_Impact_on_the_Energy_Network_of_Consolidated_Practices_and_Upcoming_Opportunities/links/5756b5b608ae0405a5782d08/Improving-Energy-Efficiency-in-Manufacturing-Systems-Literature-Review-and-Analysis-of-the-Impact-on-the-Energy-Network-of-Consolidated-Practices-and-Upcoming-Opportunities.pdf (accessed on 6 November 2021).

- Schleich, J.; Fleiter, T. Effectiveness of energy audits in small business organizations. Resour. Energy Econ. 2019, 56, 59–70. [Google Scholar] [CrossRef]

- Javied, T.; Rackow, T.; Franke, J. Implementing Energy Management System to Increase Energy Efficiency in Manufacturing Companies. Procedia CIRP 2015, 26, 156–161. [Google Scholar] [CrossRef] [Green Version]

- Flick, D.; Ji, L.; Dehning, P.; Thiede, S.; Herrmann, C. Energy Efficiency Evaluation of Manufacturing Systems by Considering Relevant Influencing Factor. Procedia CIRP 2017, 63, 586–591. [Google Scholar] [CrossRef]

- Apostolos, F.; Alexios, P.; Georgios, P. Energy efficiency of manufacturing processes: A critical review. Procedia CIRP 2013, 7, 628–633. [Google Scholar] [CrossRef] [Green Version]

- Diaz C, J.L.; Ocampo-Martinez, C. Energy efficiency in discrete-manufacturing systems: Insights, trends, and control strategies. J. Manuf. Syst. 2019, 52, 131–145. [Google Scholar] [CrossRef] [Green Version]

- Adenuga, O.T.; Mpofu, K.; Ramatsetse, B. Energy efficiency analysis modelling system for manufacturing in the context of industry 4.0. Procedia CIRP 2019, 80, 735–740. [Google Scholar] [CrossRef]

- May, G.A.; Dimitris, K. Business Model for Energy Efficiency in Manufacturing. Procedia CIRP 2017, 61, 410–415. [Google Scholar] [CrossRef]

- Mawson, V.J.; Hughes, B.R. The development of modelling tools to improve energy efficiency in manufacturing processes and systems. J. Manuf. Syst. 2019, 51, 95–105. [Google Scholar] [CrossRef]

- Heo, Y.; Zavala, V.M. Gaussian process modeling for measurement and verification of building energy savings. Energy Build. 2012, 53, 7–18. [Google Scholar] [CrossRef]

- Lee, K.H. Carbon accounting for supply chain management in the automobile industry. J. Clean. Prod. 2012, 36, 83–93. [Google Scholar] [CrossRef]

- Siltonen, S. Implication of Energy Efficiency Improvement for CO2 Emission in Energy-Intensive Industry. Doctoral Dissertation, Aalto University, Espoo and Helsinki, Finland, 2010. [Google Scholar]

- Dufour, T.; Hoang, H.M.; Oignet, J.; Osswald, V.; Fournaison, L.; Delahaye, A. Experimental and modelling study of energy efficiency of CO2 hydrate slurry in a coil heat exchanger. Appl. Energy 2019, 242, 492–505. [Google Scholar] [CrossRef]

- Lee, S.; Chong, W.O. Causal relationships of energy consumption, price, and CO2 emissions in the U.S. building sector. Resour. Conserv. Recycl. 2016, 107, 220–226. [Google Scholar] [CrossRef]

- Jalil, A.; Rao, N.H. Time Series Analysis (Stationarity, Cointegration, and Causality). In Environmental Kuznets Curve (EKC), Chapter 8; Özcan, B., Öztürk, I., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 85–99. [Google Scholar]

- Deb, C.; Zhang, F.; Yang, J.; Lee, S.E.; Shah, K.W. A review on time series forecasting techniques for building energy consumption. Renew. Sustain. Energy Rev. 2017, 74, 902–924. [Google Scholar] [CrossRef]

- Pao, H.T.; Fu, H.C.; Tseng, C.L. Forecasting of CO2 emissions, energy consumption and economic growth in China using an improved grey model. Energy 2012, 40, 400–409. [Google Scholar] [CrossRef]

- Lotfalipour, M.R.; Falahi, M.A.; Bastam, M. Prediction of CO2 emission in Iran using grey and ARIMA models. Int. J. Energy Econ. Policy 2013, 3, 9. [Google Scholar]

- Wang, X.; Meng, M. A Hybrid Neural Network and ARIMA Model for Energy Consumption Forcasting. J. Comput. 2012, 7, 1184–1190. [Google Scholar] [CrossRef]

| Period | Duration | Electricity Generated (MWh) | Carbon Emissions (tons) | Period | Duration | Electricity Generated (MWh) | Carbon Emissions (tons) |

|---|---|---|---|---|---|---|---|

| Jan 2016 | 31 | 25,383.9 | 17,991 | Jul 2017 | 31 | 21,314 | 15,991 |

| Feb 2016 | 29 | 24,091.4 | 16,999 | Aug 2017 | 31 | 19,387 | 14,545 |

| Mar 2016 | 31 | 25,732.7 | 18,157 | Sept 2017 | 30 | 17,522 | 13,146 |

| Apr 2016 | 30 | 24,849.9 | 17,534 | Oct 2017 | 31 | 21,607 | 16,211 |

| May 2016 | 15 | 11,679.2 | 8241 | Nov 2017 | 30 | 19,184 | 14,393 |

| Jun 2016 | 30 | 20,346.1 | 14,356 | Dec 2017 | 31 | 22,328 | 16,751 |

| Jul 2016 | 31 | 19,938.9 | 14,069 | Jan 2018 | 31 | 22,095 | 16,576 |

| Aug 2016 | 31 | 19,863.1 | 14,015 | Feb 2018 | 28 | 22,086 | 16,570 |

| Sep 2016 | 30 | 18,708.0 | 13,753 | Mar 2018 | 31 | 25,053 | 18,796 |

| Oct 2016 | 31 | 21,797.6 | 16,354 | Apr 2018 | 30 | 22,065 | 16,554 |

| Nov 2016 | 30 | 2088.3 | 15,667 | May 2018 | 6 | 4487 | 3367 |

| Dec 2016 | 31 | 23,259.3 | 17,450 | Jun 2018 | 20 | 14,308 | 10,735 |

| Jan 2017 | 31 | 25,219.4 | 18,921 | Jul 2018 | 31 | 20,446 | 15,339 |

| Feb 2017 | 28 | 22,019.0 | 16,519 | Aug 2018 | 31 | 20,057 | 15,047 |

| Mar 2017 | 31 | 25,443.0 | 19,089 | Sept 2018 | 30 | 19,575 | 14,686 |

| Apr 2017 | 30 | 24,410.7 | 18,314 | Oct 2018 | 31 | 21,556 | 16,173 |

| May 2017 | 27 | 18,935 | 14,206 | Nov 2018 | 30 | 21,690 | 16,273 |

| Jun 2017 | 13 | 8088 | 6068 | Dec 2018 | 31 | 23,726 | 17,800 |

| Description | Original Data | Post-Estimating and Eliminating Trends | Post-Eliminating Trend and Seasonality |

|---|---|---|---|

| Test statistic | −3.602352 | −9.397422 | −7.793783 |

| p-value | 0.005716 | 6.31922 | 7.815122 |

| Number of #lags used | 6 | 1.5 | 8 |

| Number of observations used | 1086.00000 | 1.066 | 1.084 |

| Critical value (1%) | −3.436386 | −3.436499 | −3.46397 |

| Critical value (5%) | −2.864205 | −2.864255 | −2.86421 |

| Critical value (10%) | −2.568189 | −2.568216 | −2.568961 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modise, R.K.; Mpofu, K.; Adenuga, O.T. Energy and Carbon Emission Efficiency Prediction: Applications in Future Transport Manufacturing. Energies 2021, 14, 8466. https://doi.org/10.3390/en14248466

Modise RK, Mpofu K, Adenuga OT. Energy and Carbon Emission Efficiency Prediction: Applications in Future Transport Manufacturing. Energies. 2021; 14(24):8466. https://doi.org/10.3390/en14248466

Chicago/Turabian StyleModise, Ragosebo Kgaugelo, Khumbulani Mpofu, and Olukorede Tijani Adenuga. 2021. "Energy and Carbon Emission Efficiency Prediction: Applications in Future Transport Manufacturing" Energies 14, no. 24: 8466. https://doi.org/10.3390/en14248466

APA StyleModise, R. K., Mpofu, K., & Adenuga, O. T. (2021). Energy and Carbon Emission Efficiency Prediction: Applications in Future Transport Manufacturing. Energies, 14(24), 8466. https://doi.org/10.3390/en14248466