Experimental and Numerical Results of LIFUS5/Mod3 Series E Test on In-Box LOCA Transient for WCLL-BB

Abstract

:1. Introduction

2. Materials and Methods: LIFUS5/Mod3 Facility

- the generation of detailed and reliable experimental data;

- the investigation of the dynamic effects of energy release, chemical reaction, and hydrogen production on the structures;

- the broadening of the current knowledge of physicochemical behavior of PbLi eutectic alloys, and the understanding of relevant phenomena associated with its use;

- the expansion of the database used for code verification.

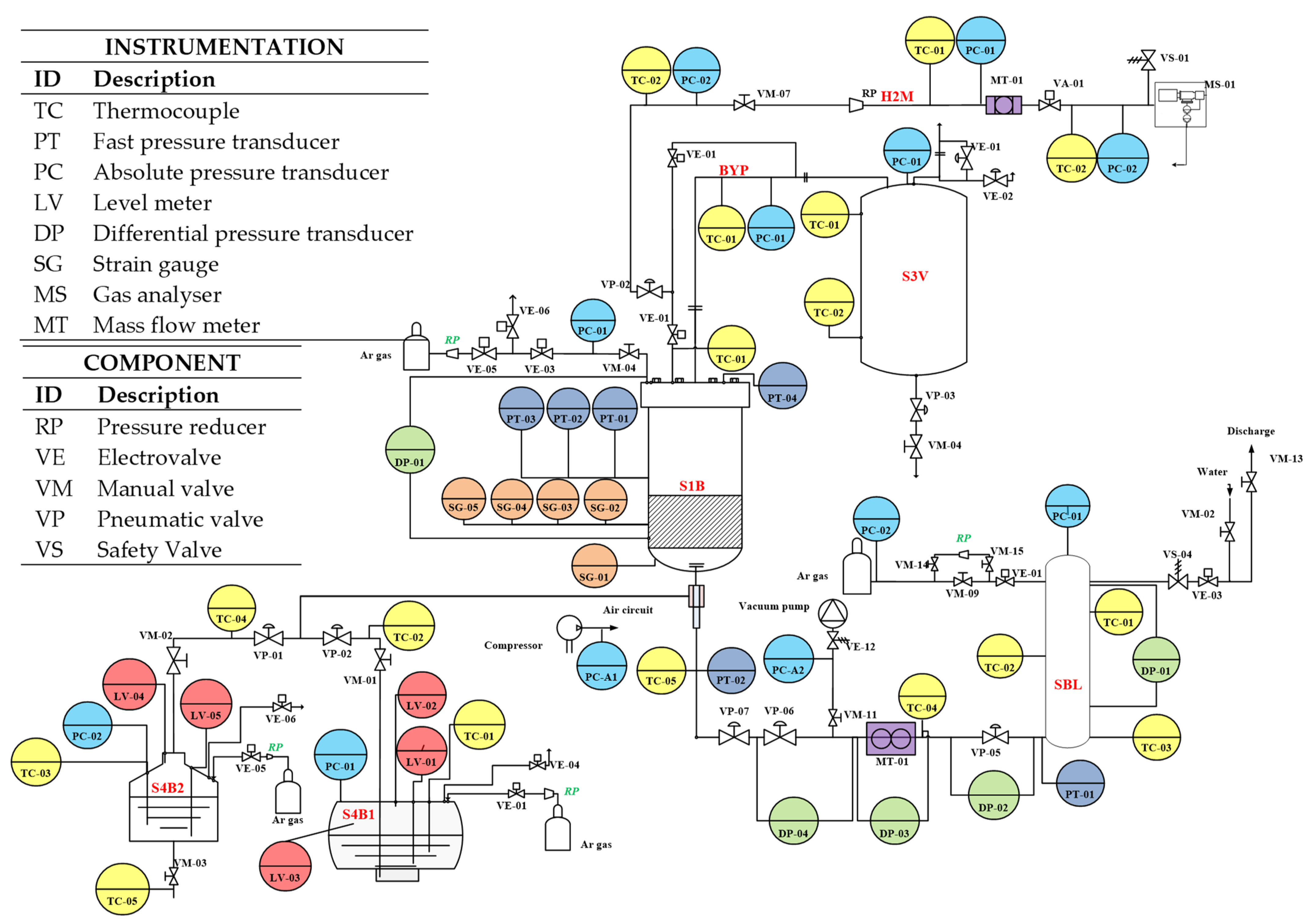

2.1. Facility Description

- The main reaction vessel, S1B, where the water–PbLi interaction takes place;

- The water tank SBL and the injection line, which is used to bring water to test conditions. This is built out of an enlarged section of pipe, connected by a line to the bottom of S1B; pressure is maintained inside this tank by the action of an argon cylinder connected to its top;

- The safety expansion vessel, S3V, connected to S1B by means of two in-series rupture disks, to avoid damaging the rest of the facility in case of overpressure;

- The PbLi storage tanks, S4B1 and S4B2, holding, respectively, fresh and exploited alloys;

- The hydrogen extraction and analysis system.

2.1.1. Reaction Vessel S1B

- A gooseneck seal to allow thermocouples cables passage;

- The housing for the fast pressure transducer;

- The hydrogen extraction line connection;

- The expansion line connecting the vessel to S3V via the rupture disks;

- The housing of a differential pressure meter for level-monitoring and a pressure transducer for absolute pressure-measurement.

2.1.2. Test Section

2.1.3. Injection Line

- In the SBL vertical section to measure the water level before each test;

- Across valve VP-SBL-05, named: DP-SBL-02;

- Across the Coriolis mass flow meter, named: DP-SBL-03;

- Across valve number VP-SBL-06, named: DP-SBL-03.

2.1.4. Expansion Line

2.1.5. Hydrogen Extraction Line

2.1.6. Instrumentation and Control Units

2.1.7. Test Matrix

- The pressure difference between the water circuit and the PbLi, which is the driving parameter of the transient: once pressures in the two systems come into equilibrium, the injection stops;

- The size of the break;

- Water flow condition: the instauration of choked flow limits the velocity of water itself, while the void fraction of the jet will affect the actual injected mass.

2.2. Code Nodalizations

- ○

- Coupled calculation: fully nodalized with RELAP5;

- ○

- Standalone calculation: reduced to a short vertical section below the S1B;

- The reaction vessel S1B (including Test Section);

- The expansion line (including the first rupture disk);

- The hydrogen extraction line (up to the collecting valve);

- The thermocouple supporting passage (gooseneck).

2.2.1. Reaction Vessel S1B

2.2.2. Test Section

2.2.3. Injection Line

2.2.4. Expansion Line

2.2.5. Hydrogen Extraction Line

2.2.6. Boundary and Initial Conditions (BIC)

3. Results

3.1. Test E4.1 Experimental Results

- Pressurization of water injection line (0 ms to 229.4 ms), from the pressure rise in the injection line (valve VP-SBL-06 starts to open, start of test) to the rupture cap occurrence (start of injection).

- Water–PbLi interaction (229.4 ms to 1156.8 ms), from the cap rupture occurrence to the full closure of valve VP-SBL-06 (end of injection). This phase can be divided into three different sub-phases:

- Flashing of injected water (229.4 ms to 245 ms), from cap rupture occurrence to the ending of the first pressure peaks.

- Pressurization dominated by the two-phase thermodynamic interaction (245 ms to 420 ms), from the ending of the first pressure peaks to the pressure slope change.

- Pressurization dominated by the single-phase thermodynamic interaction (420 ms to 1156.8 ms), from the pressure slope change to valve VP-SBL-06 fully closed.

- Pressurization dominated by the chemical reaction (1156.8 ms to ~20,000 ms), from the full closure of valve VP-SBL-06 to the S1B pressure stabilization.

- Ending phase (~20,000 ms to the End of Test), from the S1B pressure stabilization to the End of Test.

3.1.1. Pressure Time Trends

3.1.2. Strain Time Trends

3.1.3. Temperature Time Trends

3.1.4. Hydrogen Production

- At SoT, the facility condition was: valve VP-SBL-05 opened, and valve VP-SBL-06 closed; DP-SBL-01 (Figure 13b) measured 90.8 mbar, which corresponded to an amount of water in the SBL line equal to 944 g;

- During the injection, DP-SBL-01 measured 0.0 bar; therefore, all the water was injected through the line;

- At the end of the test, a part of the water that remained trapped in all the injection lines was collected and weighted, with a result of 750 g;

- This result, considering the differential pressure sensor measurement, permitted the obtaining of the injected water, with a result of 944 − 750 g = 194 g;

- The Coriolis mass flow meter measured an integral value of 395 g;

- Some of the water remained trapped between valve VP-SBL-06 and valve VP-SBL-07. The volume of this section of the line is equal to 0.14 L, which corresponds to a mass of 111 g (at 250 °C, temperature effectively recorded);

- The amount of injected water, considering the Coriolis mass flow meter measure, permitted the obtaining of the injected water, with a result of 395 − 111 = 284 g;

- Considering the double-check of the injected water, the estimation gave a range between 194 and 284 g.

3.2. Numerical Results in Standalone and Coupled Configurations

3.2.1. Pressure Evolution

3.2.2. Temperature Evolution

3.2.3. Mass Flow Rate and Hydrogen Production

| # | LIFUS5/Mod3 | Test E4.1 | ||||

|---|---|---|---|---|---|---|

| Parameter | ID | Unit | Experiment | Standalone | Coupled | |

| SYSTEM S1B | ||||||

| S1-1 | P @ SoT | PC-S1B-01 | bar | 0.7 | 1.00 | 1.28 |

| S1-2 | TPbLi @ SoT | average | °C | 333.9 | 337.00 | 337.00 |

| S1-3 | PbLi LVL (from S1B top flange) | TC-S1B-L1/L2 | mm | −50 | −50 | −50 |

| S1-4 | Vol. gas | -- | l | 4.073 | 4.6 | 4.1 |

| S1-5 | First P peak at the injector cap rupture | PT-S1B-03 | bar | 217.7 | 19.84 | 14.76 |

| S1-6 | Second delayed P peak | PT-S1B-01 | bar | 74.2 | 16.04 | 9.40 |

| S1-7 | Ratio between Ppeak1 and Pinjection_line at the injector cap rupture | -- | -- | 1.49 | 0.15 | 0.11 |

| S1-8 | Ratio between Ppeak2 and Pinjection_line at the injector cap rupture | -- | -- | 0.51 | 0.12 | 0.07 |

| S1-9 | P at EoT | PT-S1B-01/03 | bar | 94.0 | 44.33 | 62.43 |

| S1-10 | Rupture disk open time | PC-BYP-01 | s | -- | -- | 0.00 |

| S1-11 | Min TPbLi | -- | °C | -- | 508.00 | 235.00 |

| S1-12 | Max TPbLi | TC-R61-L3 | °C | 439.67 | 1210.42 | 1709.87 |

| S1-13 | TPbLi at EoT (Level 6) | TC-RXY-L6 | °C | 345–384 | 750.61 | 527.29 |

| SYSTEM SBL | ||||||

| S2-1 | P in gas line at SoT | PC-SBL-02 | bar | 158.8 | 158.70 | 158.70 |

| S2-2 | P at SoT | PC-SBL-01 | bar | 158.7 | 158.70 | 158.70 |

| S2-3 | T at SoT | TC-SBL-04 | °C | 274.7 | 304.78 | 302.51 |

| S2-4 | Min. P during injection | PT-SBL-01 | bar | 115.73 | 117.01 | 110.00 |

| S2-5 | P at EoT | PC-SBL-01 | bar | 163.5 | 155.00 | 155.00 |

| S2-6 | T at EoT | TC-SBL-01/05 | °C | 263.0 | 319.72 | 277.02 |

| S2-7 | Mass of water injected | MT-SBL-01 | g | 194–285 | 300 | 202.08 |

| INJECTION SYSTEM | ||||||

| I-1 | Start of injection (valve opening instant) | -- | s | 0 | 0 | 0 |

| I-2 | Injection time (from cap rupture) | -- | s | 0.9274 | 0.92 | 0.93 |

| I-3 | Injector cap rupture instant | -- | s | 0.2294 | 0.23 | 0.22 |

| I-4 | Pressure of cap rupture | PT-SBL-02 | bar | 146.3 | 132.03 | 134.98 |

| I-5 | Pressurization rate | PT-SBL-02 | bar/s | 633.3 | 571.18 | 698.51 |

| I-6 | Injection valve fully closed instant | -- | s | 1.1568 | 1.148 | 1.150 |

| SYSTEM H2 | ||||||

| H-1 | H2 generated | -- | g | 22.91 | 30.73 | 15.05 |

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Del Nevo, A.; Arena, P.; Caruso, G.; Chiovaro, P.; Di Maio, P.; Eboli, M.; Edemetti, F.; Forgione, N.; Forte, R.; Froio, A.; et al. Recent progress in developing a feasible and integrated conceptual design of the WCLL BB in EUROfusion project. Fusion Eng. Des. 2019, 146, 1805–1809. [Google Scholar] [CrossRef] [Green Version]

- Martelli, E.; Del Nevo, A.; Arena, P.; Bongiovì, G.; Caruso, G.; Di Maio, P.A.; Eboli, M.; Mariano, G.; Marinari, R.; Moro, F.; et al. Advancements in DEMO WCLL breeding blanket design and integration. Int. J. Energy Res. 2017, 42, 27–52. [Google Scholar] [CrossRef] [Green Version]

- Del Nevo, A.; Martelli, E.; Agostini, P.; Arena, P.; Bongiovì, G.; Caruso, G.; Di Gironimo, G.; Di Maio, P.; Eboli, M.; Giammusso, R.; et al. WCLL breeding blanket design and integration for DEMO 2015: Status and perspectives. Fusion Eng. Des. 2017, 124, 682–686. [Google Scholar] [CrossRef]

- Tassone, A.; Del Nevo, A.; Arena, P.; Bongiovi, G.; Caruso, G.; Di Maio, P.A.; Di Gironimo, G.; Eboli, M.; Forgione, N.; Forte, R.; et al. Recent Progress in the WCLL Breeding Blanket Design for the DEMO Fusion Reactor. IEEE Trans. Plasma Sci. 2018, 46, 1446–1457. [Google Scholar] [CrossRef]

- Cismondi, F.; Spagnuolo, G.; Boccaccini, L.; Chiovaro, P.; Ciattaglia, S.; Cristescu, I.; Day, C.; Del Nevo, A.; Di Maio, P.; Federici, G.; et al. Progress of the conceptual design of the European DEMO breeding blanket, tritium extraction and coolant purification systems. Fusion Eng. Des. 2020, 157, 111640. [Google Scholar] [CrossRef] [Green Version]

- Eboli, M.; Forgione, N.; Del Nevo, A. Implementation of the chemical PbLi/water reaction in the SIMMER code. Fusion Eng. Des. 2016, 109-111, 468–473. [Google Scholar] [CrossRef]

- Eboli, M.; Forgione, N.; Del Nevo, A. Assessment of SIMMER-III code in predicting Water Cooled Lithium Lead Breeding Blanket “in-box-Loss of Coolant Accident”. Fusion Eng. Des. 2020, 163, 112127. [Google Scholar] [CrossRef]

- D’Auria, F.; Galassi, G.M. Code Assessment Methodology and Results; IAEA Technical Workshop/Committee on Computer Aided Safety Analyses: Moscow, Russia, 1990. [Google Scholar]

- Bonuccelli, M.; D’Auria, F.; Debrecin, N.; Galassi, G.M. A Methodology for the Qualification of Thermalhydraulic Code Nodalizations. In Proceedings of the NURETH-6 Conference, Grenoble, France, 5–8 October 1993. [Google Scholar]

- Eboli, M.; Del Nevo, A.; Pesetti, A.; Forgione, N.; Sardain, P. Simulation study of pressure trends in the case of loss of coolant accident in Water Cooled Lithium Lead blanket module. Fusion Eng. Des. 2015, 98–99, 1763–1766. [Google Scholar] [CrossRef]

- Eboli, M.; Del Nevo, A.; Forgione, N.; Porfiri, M.T. Post-test analyses of LIFUS5 Test#3 experiment. Fusion Eng. Des. 2017, 124, 856–860. [Google Scholar] [CrossRef]

- Eboli, M.; Moghanaki, S.K.; Martelli, D.; Forgione, N.; Porfiri, M.T.; Del Nevo, A. Experimental activities for in-box LOCA of WCLL BB in LIFUS5/Mod3 facility. Fusion Eng. Des. 2019, 146, 914–919. [Google Scholar] [CrossRef]

- Eboli, M.; Crugnola, R.M.; Cammi, A.; Khani, S.; Forgione, N.; Del Nevo, A. Test Series D experimental results for SIMMER code validation of WCLL BB in-box LOCA in LIFUS5/Mod3 facility. Fusion Eng. Des. 2020, 156, 111582. [Google Scholar] [CrossRef]

- Moghanaki, S.K.; Eboli, M.; Forgione, N.; Martelli, D.; Del Nevo, A. Validation of SIMMER-III code for in-box LOCA of WCLL BB: Pre-test numerical analysis of Test D1.1 in LIFUS5/Mod3 facility. Fusion Eng. Des. 2019, 146, 978–982. [Google Scholar] [CrossRef]

- Moghanaki, S.K.; Galleni, F.; Eboli, M.; Del Nevo, A.; Paci, S.; Forgione, N. Analysis of Test D1.1 of the LIFUS5/Mod3 facility for In-box LOCA in WCLL-BB. Fusion Eng. Des. 2020, 160, 111832. [Google Scholar] [CrossRef]

- Moghanaki, S.K.; Galleni, F.; Eboli, M.; Del Nevo, A.; Paci, S.; Forgione, N. Post-test analysis of Series D experiments in LIFUS5/Mod3 facility for SIMMER code validation of WCLL-BB In-box LOCA. Fusion Eng. Des. 2021, 165, 112268. [Google Scholar] [CrossRef]

- Gonfiotti, B.; Moghanaki, S.K.; Eboli, M.; Barone, G.; Del Nevo, A.; Martelli, D. Development of a SIMMER-III/RELAP5 coupling tool. Fusion Eng. Des. 2019, 146 Pt B, 1993–1997. [Google Scholar] [CrossRef]

- Galleni, F.; Moghanaki, S.; Eboli, M.; Del Nevo, A.; Paci, S.; Ciolini, R.; Frano, R.L.; Forgione, N. RELAP5/SIMMER-III code coupling development for PbLi-water interaction. Fusion Eng. Des. 2020, 153, 111504. [Google Scholar] [CrossRef]

- Galleni, F.; Moscardini, M.; Eboli, M.; Del Nevo, A.; Martelli, D.; Forgione, N. Preliminary analysis of an in-box LOCA in the breeding unit of the WCLL TBM for the ITER reactor with SIMMER-IV code. Fusion Eng. Des. 2021, 169, 112472. [Google Scholar] [CrossRef]

- Moscardini, M.; Galleni, F.; Pucciarelli, A.; Eboli, M.; Del Nevo, A.; Paci, S.; Forgione, N. Thermo-hydraulic analysis of PbLi ancillary system of WCLL TBM undergoing in-box LOCA. Fusion Eng. Des. 2021, 168, 112614. [Google Scholar] [CrossRef]

- Pucciarelli, A.; Toti, A.; Castelliti, D.; Belloni, F.; Van Tichelen, K.; Moscardini, M.; Galleni, F.; Forgione, N. Coupled system thermal Hydraulics/CFD models: General guidelines and applications to heavy liquid metals. Ann. Nucl. Energy 2020, 153, 107990. [Google Scholar] [CrossRef]

- Eboli, M.; Del Nevo, A.; Forgione, N.; Giannetti, F.; Mazzi, D.; Ramacciotti, M. Experimental Characterization of Leak Detection Systems in HLM Pool Using LIFUS5/Mod3 Facility. Nucl. Technol. 2020, 206, 1409–1420. [Google Scholar] [CrossRef]

- Pesetti, A.; Del Nevo, A.; Forgione, N. Experimental investigation and SIMMER-III code modelling of LBE–water interaction in LIFUS5/Mod2 facility. Nucl. Eng. Des. 2015, 290, 119–126. [Google Scholar] [CrossRef]

- PED Directive. Available online: https://ec.europa.eu/growth/sectors/pressure-equipment-and-gas-appliances/pressure-equipment-sector/pressure-equipment_en (accessed on 27 October 2021).

- AA.VV. SIMMER-III (Version3.F) Input Manual; O-arai Engineering Center, Japan Nuclear Cycle Development Institute: Ibaraki, Japan, May 2012. [Google Scholar]

- AA.VV. SIMMER-IV (Version 3.F) Input Manual; O-arai Engineering Center, Japan Nuclear Cycle Development Institute: Ibaraki, Japan, May 2012. [Google Scholar]

- Green Rot Effects. Available online: https://blog.wika.us/products/temperature-products/green-rot-affects-type-k-thermocouples/ (accessed on 27 October 2021).

| Component | Parameter | Value |

|---|---|---|

| S1B reaction vessel | Volume (L) | 30 |

| Inner diameter (m) | 0.28 | |

| Height (m) | 0.56 | |

| Design pressure (bar) | 200 | |

| Design temperature (°C) | 500 | |

| SBL water pipe | Volume (L) | 4.05 |

| Inner diameter (m) | 0.04 | |

| Design pressure (bar) | 200 | |

| Design temperature (°C) | 350 | |

| S3V dump vessel | Volume (L) | 2000 |

| Inner diameter (m) | 1 | |

| Design pressure (bar) | 10 | |

| Design temperature (°C) | 400 | |

| S4B1 fresh PbLi | Volume (L) | 400 |

| Inner diameter (m) | 0.54 | |

| Length (m) | 1.56 | |

| Design temperature (°C) | 450 | |

| S4B2 depleted PbLi | Volume (L) | 400 |

| Inner diameter (m) | 0.54 | |

| Length (m) | 1.56 | |

| Design temperature (°C) | 450 |

| Position | N° | Utilization | Component ID |

|---|---|---|---|

| A | 1 | Water injection and PbLi charging/discharging system | Steel pipe |

| B | 1 | Connection to S3V-expansion/dump vessel | Steel pipe |

| C | 1 | Gooseneck sealing system to TC passage | Test section TCs |

| D | 1 | Hydrogen measurement system | MS-H2M-01 |

| E | 1 | DP meter and PC pressure transducer | DP-S1B-01 PC-S1B-01 |

| F | 1 | PT fast pressure transducer | PT-S1B-04 |

| G-H-I | 3 | PT on cylindrical shell | PT-S1B-01/02/03 |

| L | 1 | DP meter | DP-S1B-01 |

| On shell | 3 | Strain gages (circumferential) | SG-S1B-02/03/04 |

| On shell | 1 | Strain gages (axial) | SG-S1B-05 |

| On bottom | 1 | Strain gages (radial) | SG-S1B-01 |

| Test Series E | D Orifice (mm) | Water T (°C) | PbLi T (°C) | Injection Time (s) | Injection Pressure (bar) |

|---|---|---|---|---|---|

| #1 | 4 | 295 | 330 | 1 | 155 |

| #2 | 4 | 295 | 430 | 1 | 155 |

| #3 | 1 | 295 | 330 | 0.5 | 155 |

| #4 | 2 | 295 | 330 | 1 | 155 |

| #5 | 1 | 295 | 330 | 1.5 | 155 |

| #6 | 4 | 295 | 380 | 1 | 155 |

| #7 | 2 | 295 | 380 | 1.3 | 155 |

| #8 | 1 | 295 | 380 | 2 | 155 |

| Region | Dimension | SIII | L5/M3 Facility | SIII Cells |

|---|---|---|---|---|

| S1B | H (m) | 0.575 | 0.555 | 22–52 |

| D (m) | 0.2614 | 0.257 | 1–50 | |

| V (L) | 26.575 | 26.590 | - | |

| Free gas (in S1B) | H (m) | - | −0.04 | NN-52 |

| V (L) | 3.4 | 3.554 | - | |

| Inj-device | H (m) | 0.02 | 0.02 | 22 |

| D (m) | 0.0094 | 0.0094 | 1–3 | |

| Dorifice (m) | 0.002 | 0.002 | 1 | |

| Inj-line | H (m) | (variable) | ~6.8 | 1–22 |

| D (m) | 0.0094 | 0.0094 | 1–3 | |

| D (m) | 0.0094 | 1–3 |

| Installed (TCs), Inside S1B | |||||||

|---|---|---|---|---|---|---|---|

| Ring 1 | Ring 2 | Ring 3 | Ring 4 | Ring 5 | Ring 6 | ||

| Level 1 | (12,28) | - | (26,28) | (28,28) | - | (35,28) | - |

| TC-R11-L1 TC-R13-L1 | TC-R31-L1 TC-R32-L1 TC-R33-L1 | TC-R34-L1 TC-R35-L1 TC-R36-L1 | TC-R53-L1 | ||||

| Level 2 | (12,31) | (19,31) | (28,31) | (31,31) | - | - | |

| TC-R11-L2 TC-R12-L2 TC-R13-L2 | TC-R21-L2 TC-R22-L2 | TC-R32-L2 TC-R33-L2 | TC-R41-L2 TC-R42-L2 TC-R43-L2 | ||||

| Level 3 | (12,34) | - | (26,34) | (31,34) | - | (41,34) | |

| TC-R12-L3 TC-R13-L3 | TC-R31-L3 TC-R33-L3 | TC-R41-L3 TC-R42-L3 TC-R43-L3 | TC-R61-L3 TC-R62-L3 TC-R63-L3 | ||||

| Level 4 | - | (19,36) | (28,36) | (31,36) | (37,36) | - | |

| TC-R21-L4 TC-R22-L4 TC-R23-L4 | TC-R31-L4 TC-R32-L4 TC-R33-L4 | TC-R41-L4 TC-R42-L4 TC-R43-L4 | TC-R52-L4 TC-R53-L4 | ||||

| Level 5 | (12,38) | - | (26,38) | (31,38) | - | (41,38) | |

| TC-R11-L5 TC-R13-L5 | TC-R31-L5 TC-R32-L5 TC-R33-L5 | TC-R41-L5 TC-R43-L5 | TC-R61-L5 TC-R62-L5 TC-R63-L5 | ||||

| Level 6 | (12,40) | - | (26,40) | (28,40) | - | - | (41,40) |

| TC-R11-L6 TC-R12-L6 | TC-R31-L6 TC-R33-L6 | TC-R34-L6 TC-R35-L6 TC-R36-L6 | TC-R61-L6 TC-R62-L6 TC-R63-L6 | ||||

| Installed (TC, PTs) | |||||||

| Location | Cell | ||||||

| Injection line—vacuum part, TC-SBL-05 | (1–3,17) | ||||||

| Injection line—pressurized part, TC-SBL-01, @ temperature BC | (1–3,1) | ||||||

| Injection line—pressurized part, PC-SBL-01, @ pressure BC | (1–3,1) | ||||||

| Injection line—vacuum part, PT-SBL-02 | (3,17) | ||||||

| Expansion line, rupture disk, PT-S1B-04 | (30,52) | ||||||

| Reaction vessel (S1B), PT-S1B-01/03 | (50,33) | ||||||

| Reaction vessel (S1B), PC-S1B-01 | (47,53) | ||||||

| Component Number | Hydrodynamic Component | Description | Length (m) | Area (m2) |

|---|---|---|---|---|

| 100 | Time-dependent volume | Argon tank | (-) | (-) |

| 200 | Pipe | SBL | 2.8 | 9.069 × 10−4 |

| 205 | Single junction | (-) | ||

| 206 | Pipe | 1.096 | 6.936 × 10−5 | |

| 207 | Motor valve | VP-SBL-05 | (-) | 6.93 × 10−5 |

| 208 | Pipe | Normal section | 2.094 | 6.936 × 10−5 |

| Coriolis section | 1.48 | 6.12 × 10−4 | ||

| 213 | Motor valve | VP-SBL-06 | (-) | 6.93 × 10−5 |

| 214 | Pipe | 1.742 | 6.936 × 10−5 | |

| 215 | Motor valve | VP-SBL-07 | (-) | 6.93 × 10−5 |

| 216 | Pipe | 0.518 | 6.936 × 10−5 | |

| 217 | Single junction | (-) | ||

| 216 | Pipe | 1.4 | 6.936 × 10−5 | |

| 260 | Time-dependent volume | Coupling interface | (-) | (-) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eboli, M.; Galleni, F.; Forgione, N.; Badodi, N.; Cammi, A.; Del Nevo, A. Experimental and Numerical Results of LIFUS5/Mod3 Series E Test on In-Box LOCA Transient for WCLL-BB. Energies 2021, 14, 8527. https://doi.org/10.3390/en14248527

Eboli M, Galleni F, Forgione N, Badodi N, Cammi A, Del Nevo A. Experimental and Numerical Results of LIFUS5/Mod3 Series E Test on In-Box LOCA Transient for WCLL-BB. Energies. 2021; 14(24):8527. https://doi.org/10.3390/en14248527

Chicago/Turabian StyleEboli, Marica, Francesco Galleni, Nicola Forgione, Nicolò Badodi, Antonio Cammi, and Alessandro Del Nevo. 2021. "Experimental and Numerical Results of LIFUS5/Mod3 Series E Test on In-Box LOCA Transient for WCLL-BB" Energies 14, no. 24: 8527. https://doi.org/10.3390/en14248527

APA StyleEboli, M., Galleni, F., Forgione, N., Badodi, N., Cammi, A., & Del Nevo, A. (2021). Experimental and Numerical Results of LIFUS5/Mod3 Series E Test on In-Box LOCA Transient for WCLL-BB. Energies, 14(24), 8527. https://doi.org/10.3390/en14248527