Emissions Effects of Energy Storage for Frequency Regulation: Comparing Battery and Flywheel Storage to Natural Gas

Abstract

:1. Introduction

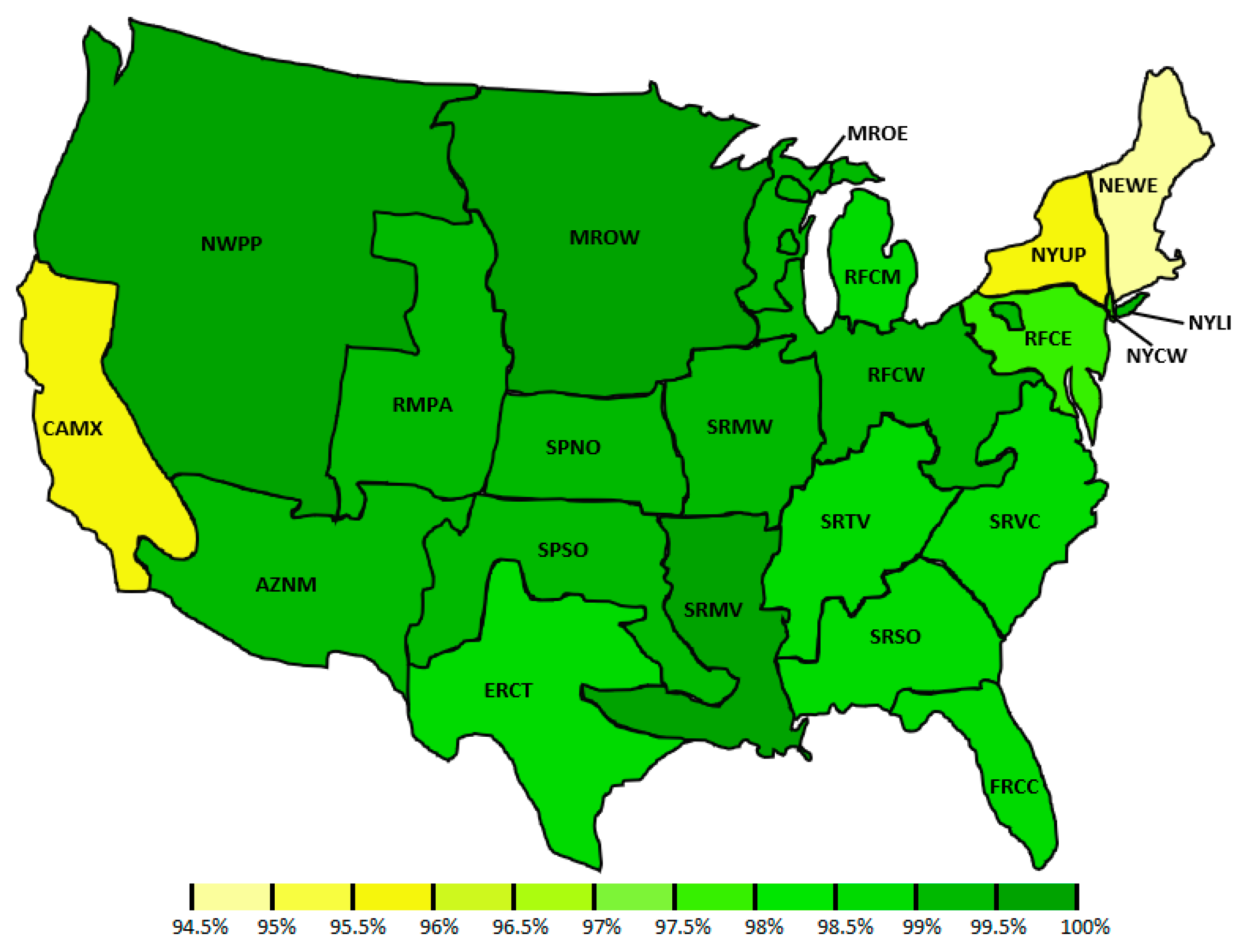

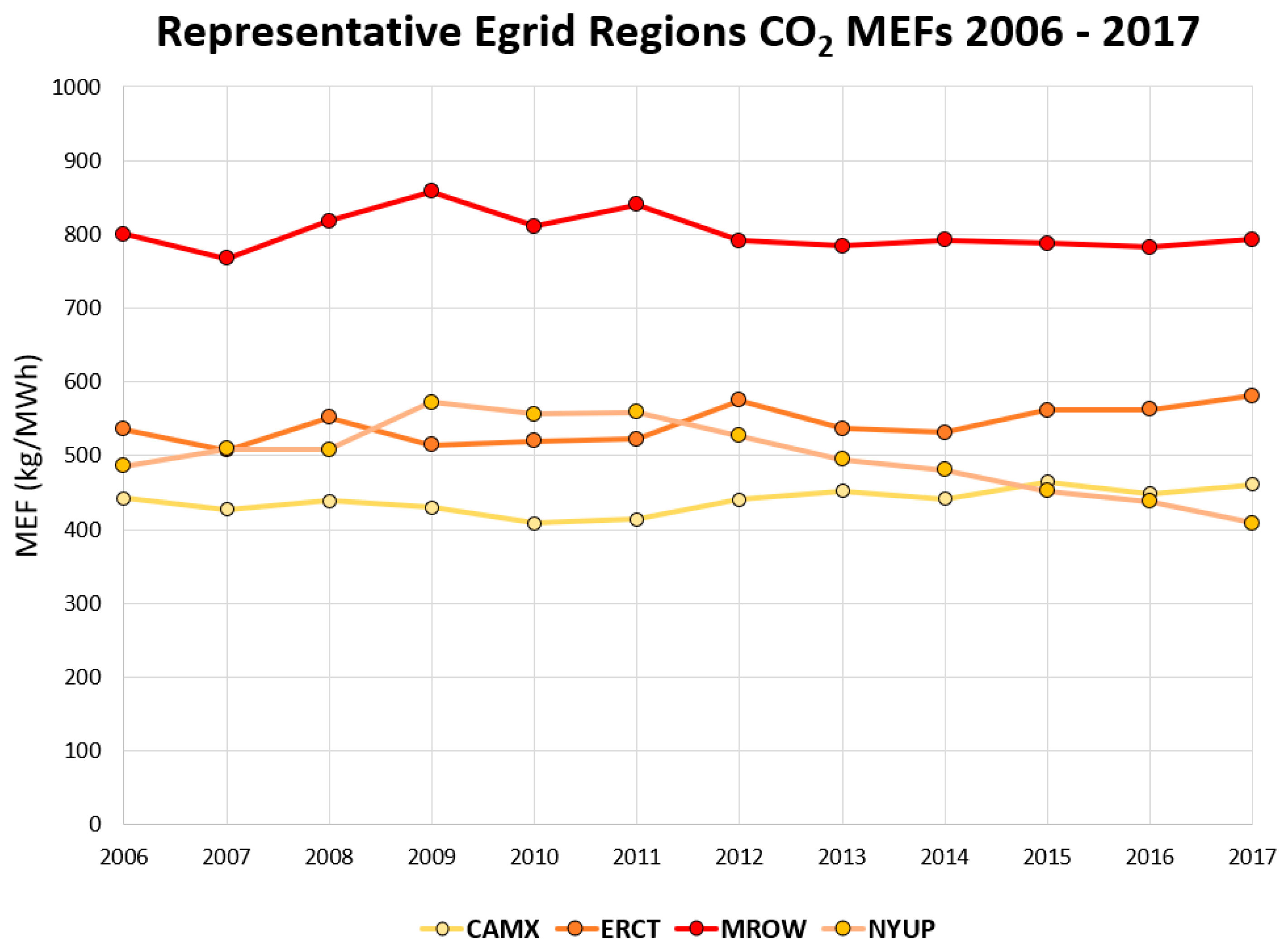

2. Materials and Methods

2.1. Natural Gas Operation and Emissions

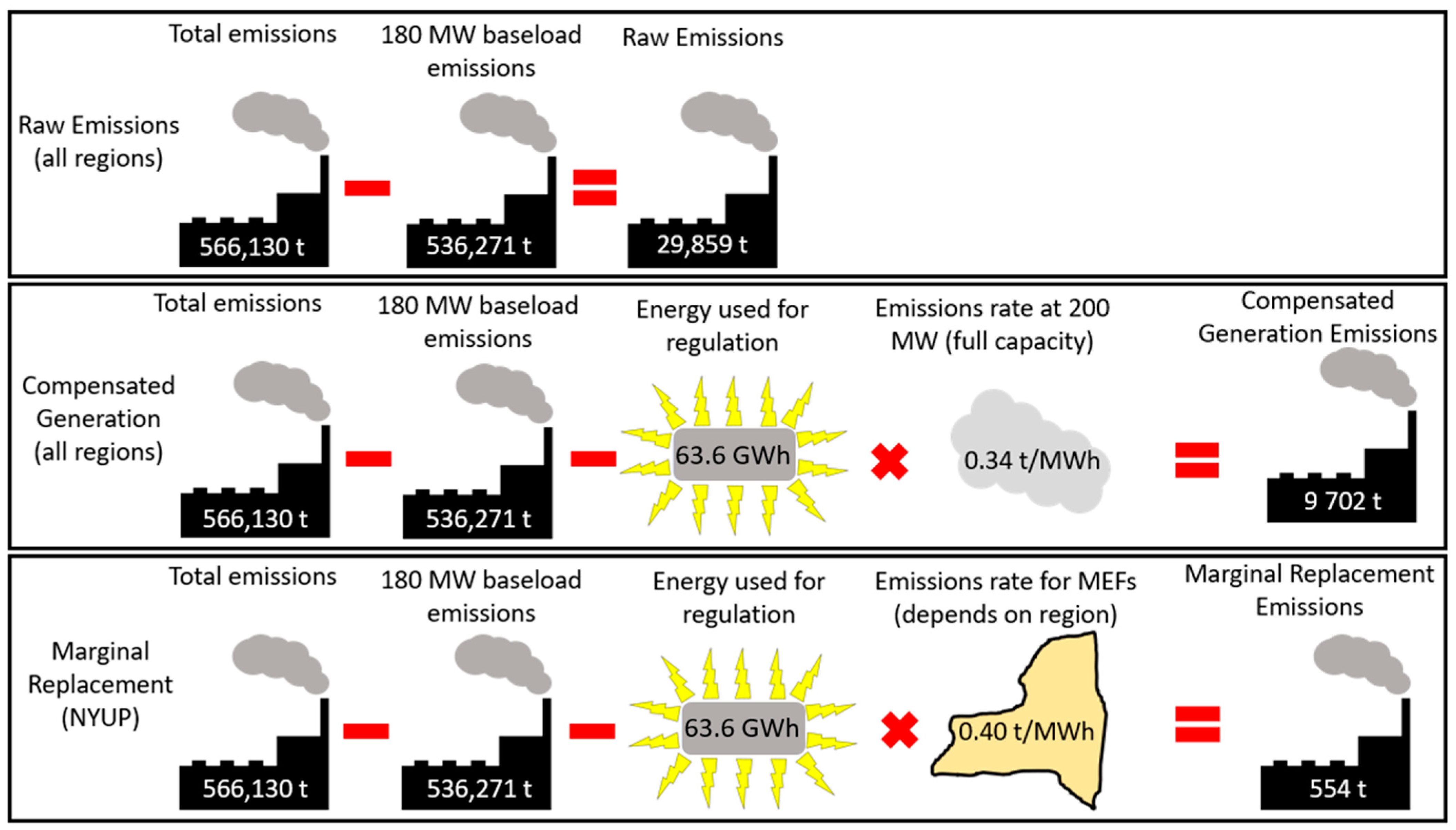

2.2. Attributing Natural Gas Emissions

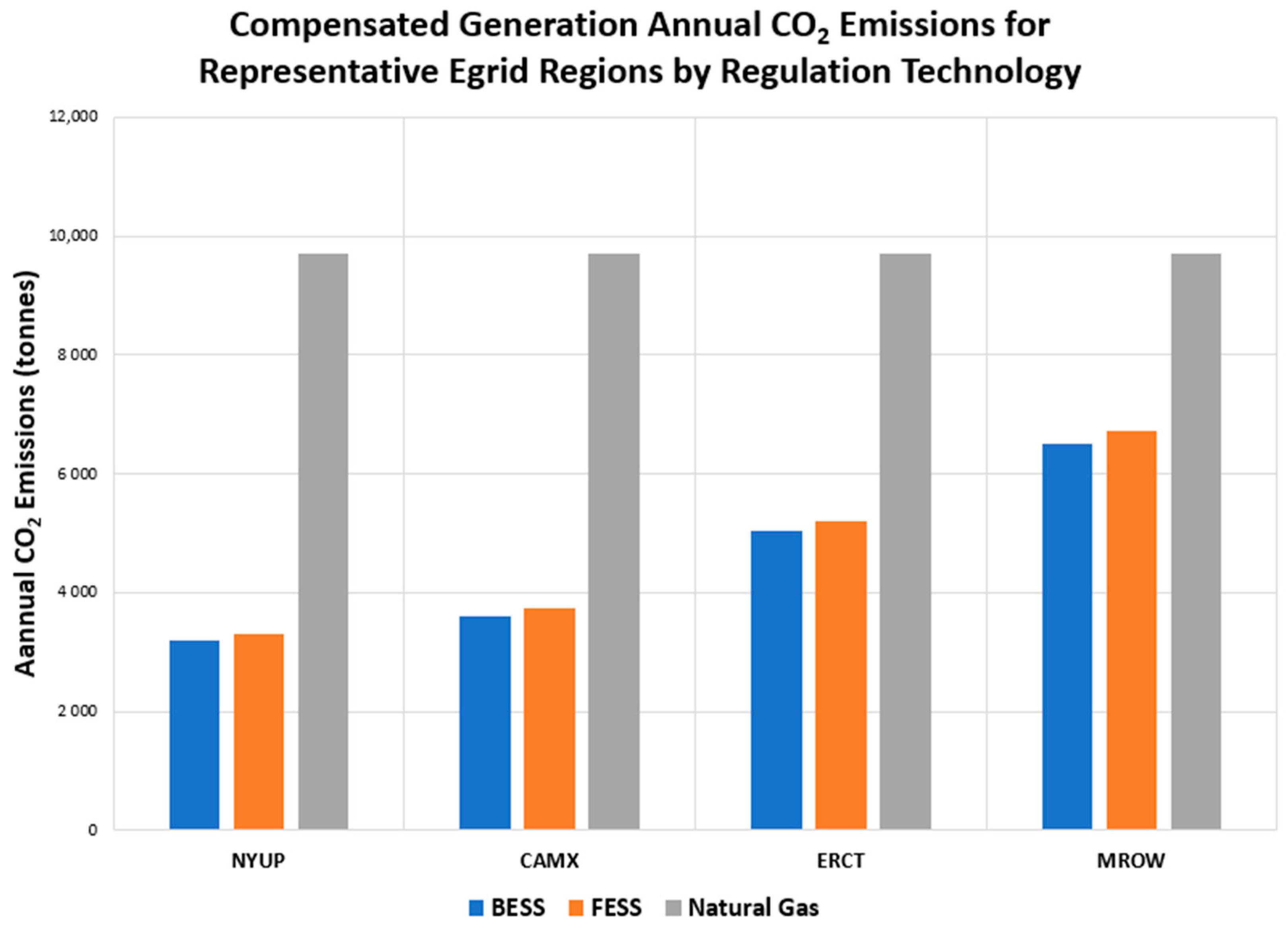

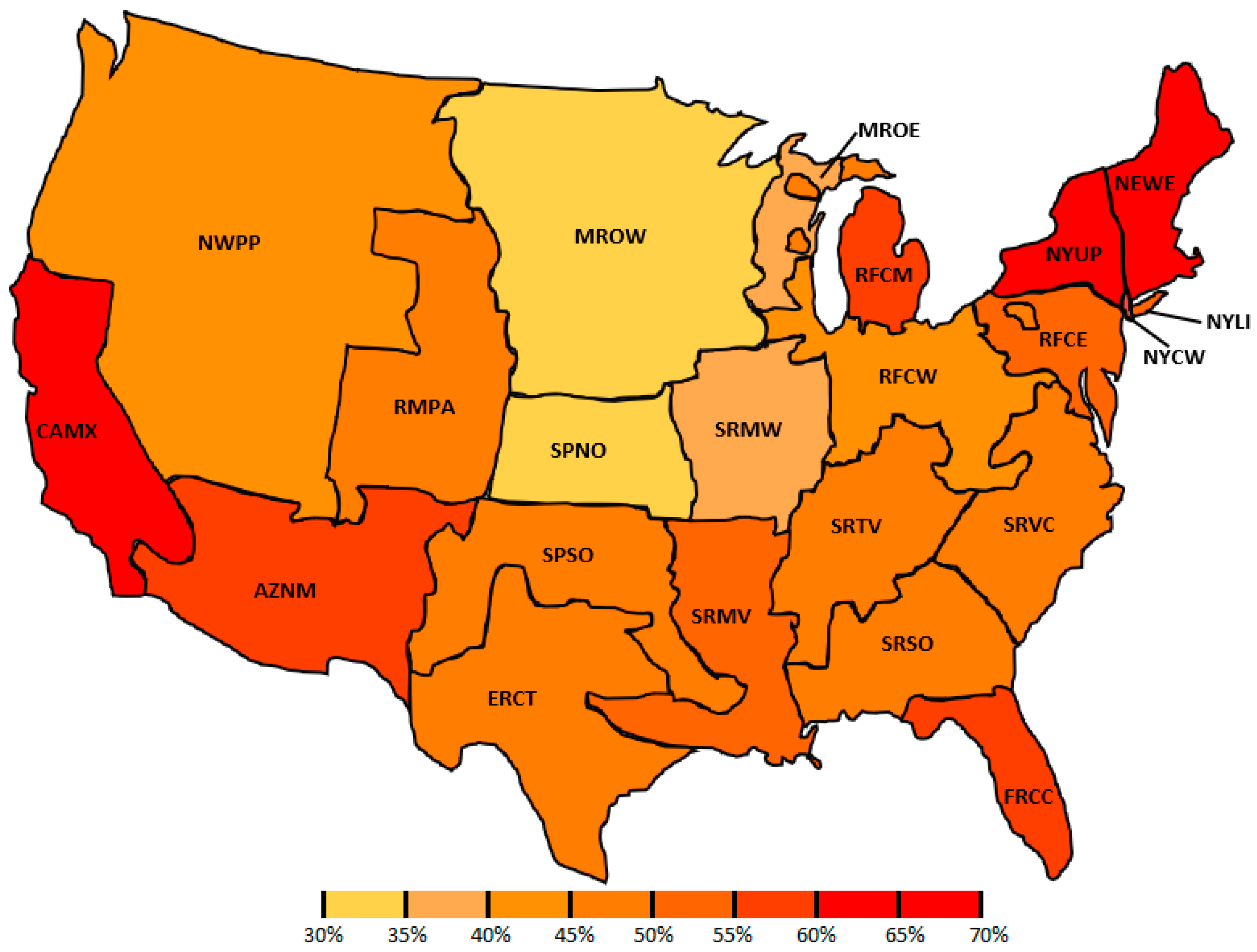

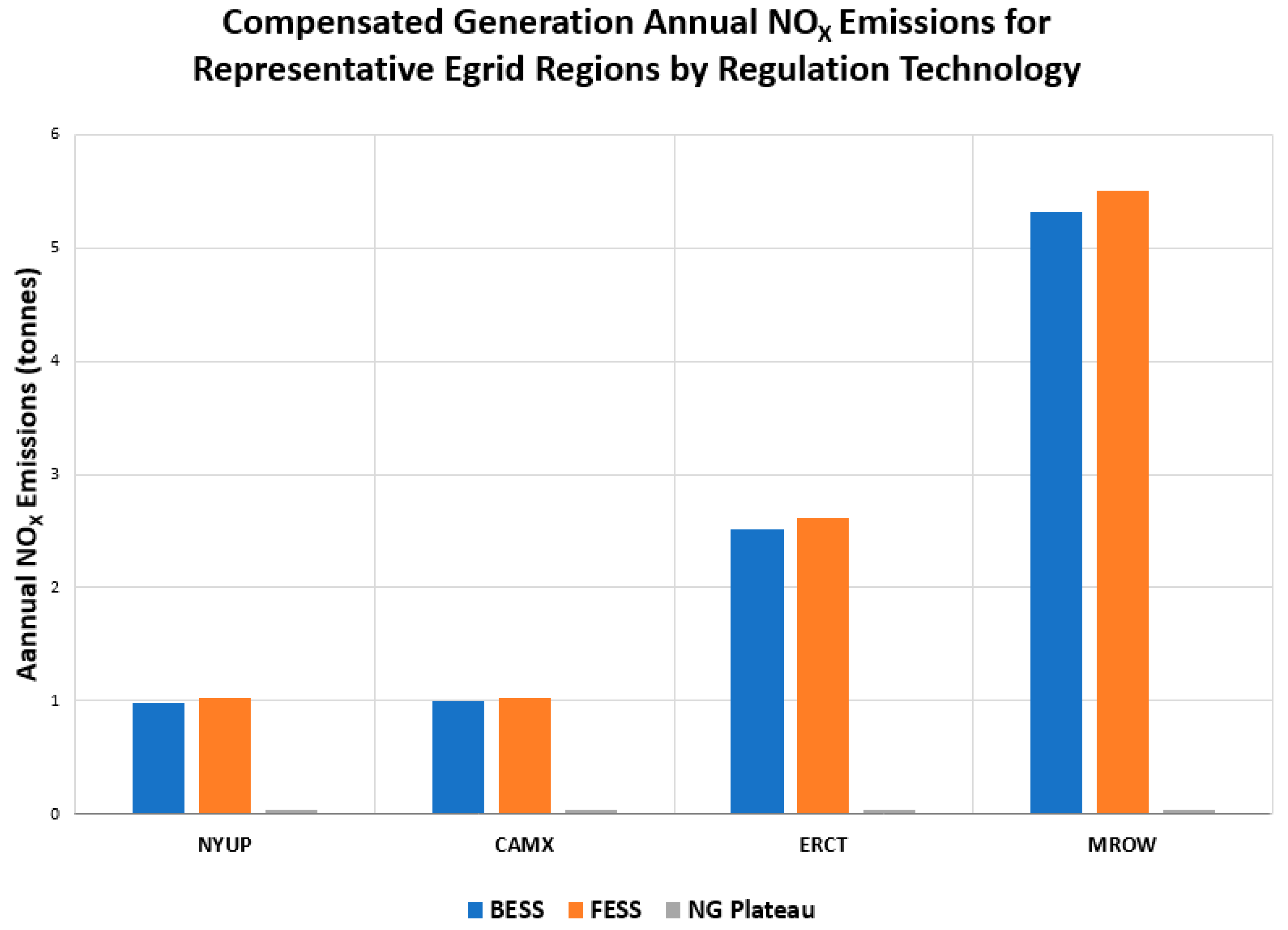

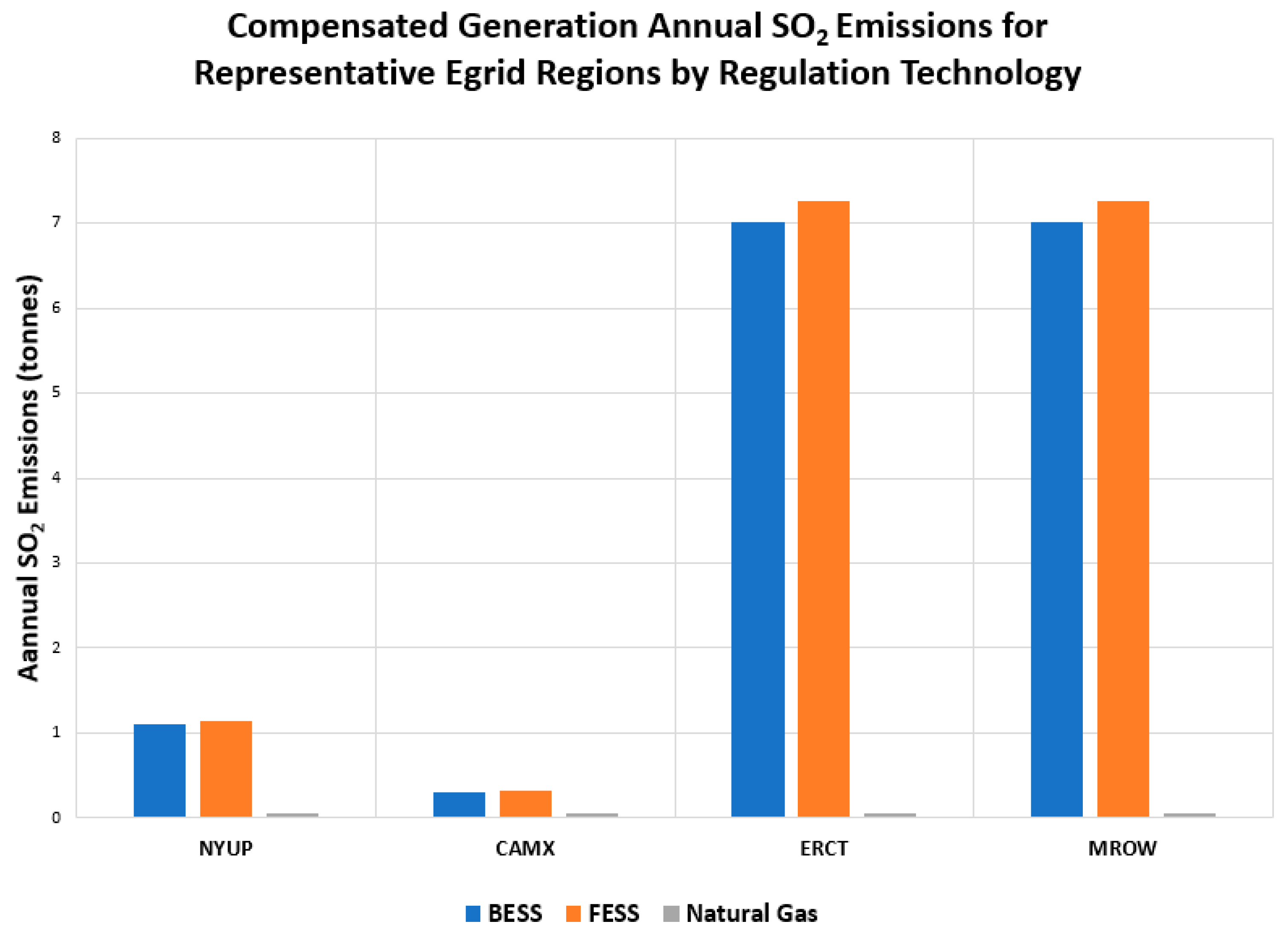

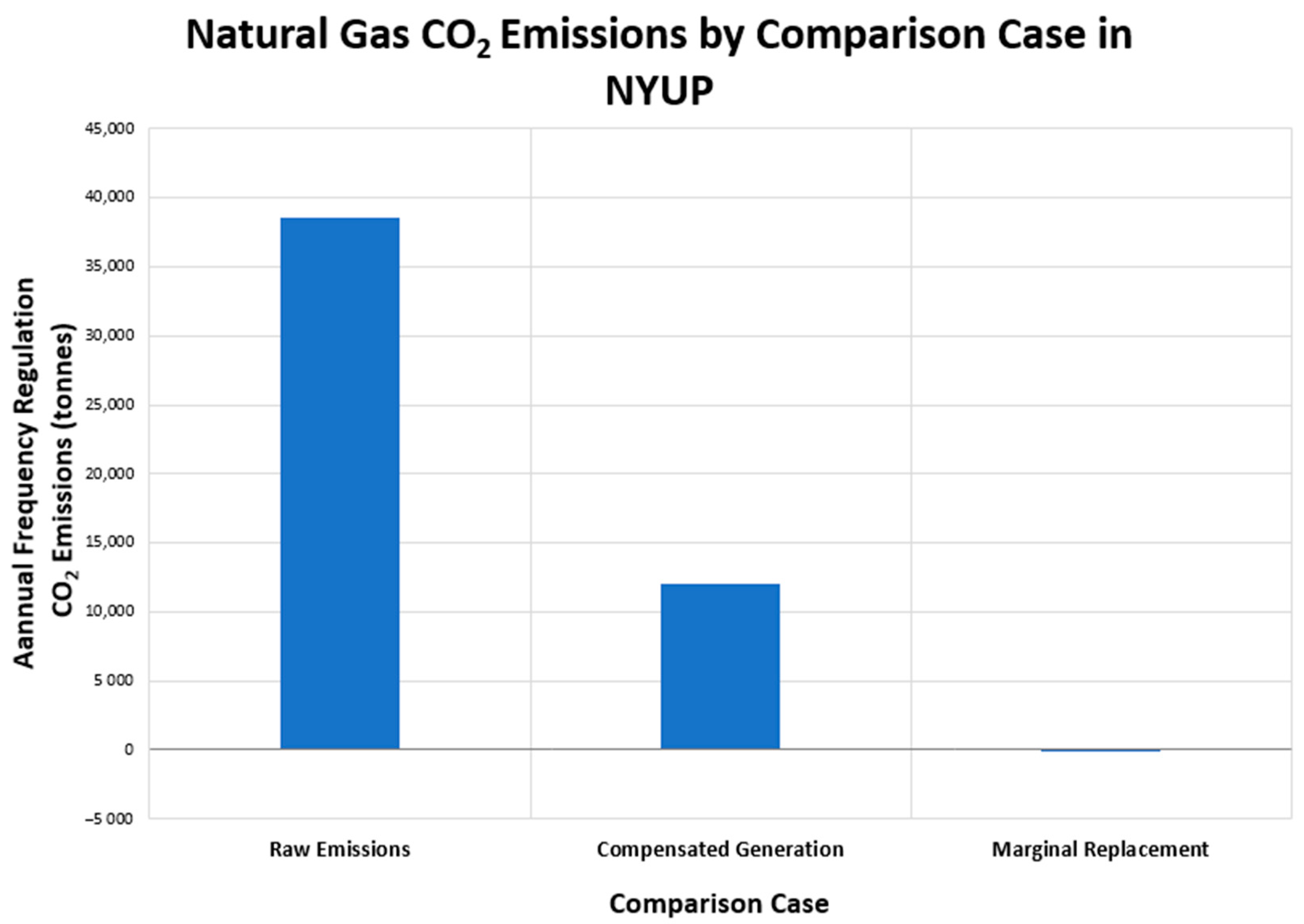

3. Results

Sensitivity Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Denchak, M. Are the Effects of Global Warming Really that Bad? Available online: https://www.nrdc.org/stories/are-effects-global-warming-really-bad (accessed on 12 November 2017).

- The New York State Energy Research and Development Authority. Advances Framework to Implement the State’s Climate Law and Decarbonize its Power Sector. Available online: https://www.nyserda.ny.gov/About/Newsroom/2020-Announcements/2020-06-18-New-York-Advances-Framework-to-Implement-the-States-Climate-Law-and-Decarbonize-its-Power-Sector. (accessed on 7 September 2020).

- Bae, H.; Tsuji, T.; Oyama, T.; Uchida, K. Frequency regulation method with congestion management using renewable energy curtailment. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016. [Google Scholar]

- General Electric. What Every Generation Executive Should Know About the Impact of Ancillary Services on Plant Economics. Available online: https://www.ge.com/power/transform/article.transform.articles.2019.aug.ancillary-services-gas-power-plants (accessed on 19 January 2021).

- Cannon, G.; White, J.M.; Whites, S. FERC Orders on PJM’s Frequency Regulation Market Give Energy Storage Providers Another Recent Win. Available online: https://www.akingump.com/en/experience/industries/energy/speaking-energy/ferc-orders-on-pjm-s-frequency-regulation-market-give-energy.html (accessed on 3 December 2020).

- PJM. Regulation Market. Available online: https://learn.pjm.com/three-priorities/buying-and-selling-energy/ancillary-services-market/regulation-market.aspx (accessed on 3 December 2020).

- Frequency Regulation Basics and Trends. Available online: https://www.osti.gov/biblio/885974-frequency-regulation-basics-trends (accessed on 19 January 2021).

- Deign, J. When batteries beat traditional power. Available online: http://energystoragereport.info/frequency-regulation-battery-energy-storage/#sthash.ddRcwygr.ujsFnv1W.dpbs (accessed on 3 November 2018).

- Lucas, A.; Chondrogiannis, S. Smart grid energy storage controller for frequency regulation and peak shaving, using a vanadium redox flow battery. Int. J. Electr. Power Energy Syst. 2016, 80, 26–36. [Google Scholar] [CrossRef]

- Du, P. Application of Energy Storage for Fast Regulation Service in Energy Market. In Energy Storage for Smart Grids: Planning and Operation for Renewable and Variable Energy Resources (VERs); Academic Press: London, UK, 2015; pp. 97–113. [Google Scholar]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Keuring van Elektrotechnische Materialen te Arnhem (KEMA). Emissions Comparison for a 20 MW Flywheel-based Frequency Regulation Power Plant. Available online: https://jointventure.org/images/stories/pdf/kema_flywheel_report_co2_reductions.pdf (accessed on 1 December 2020).

- Ryan, N.A.; Lin, Y.; Mitchell-Ward, N.; Mathieu, J.L.; Johnson, J.X. Use-Phase Drives Lithium-Ion Battery Life Cycle Environmental Impacts When Used for Frequency Regulation. Environ. Sci. Technol. 2018, 52, 10163–10174. [Google Scholar] [CrossRef] [PubMed]

- Katzenstein, W.; Apt, J. Air Emissions Due To Wind And Solar Power. Environ. Sci. Technol. 2009, 43, 253–258. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- PJM. Ancillary Services. Available online: https://www.pjm.com/markets-and-operations/ancillary-services.aspx (accessed on 25 February 2018).

- Siler-Evans, K.; Azevedo, I.L.; Morgan, M.G. Marginal Emissions Factors for the U.S. Electricity System. Environ. Sci. Technol. 2012, 46, 4742–4748. [Google Scholar] [CrossRef] [PubMed]

- Azevedo, I.L.; Deetjen, T.A.; Donti, P.L.; Horner, N.C.; Siler-Evans, K.; Vaishnav, P.T. Electricity Marginal Factor Estimates. Available online: https://cedm.shinyapps.io/MarginalFactors/ (accessed on 19 January 2021).

- Electric Power Research Institute. Handbook of Energy Storage for Transmission or Distribution Applications. Available online: https://www.epri.com/#/pages/product/1007189/?lang=en (accessed on 17 April 2018).

- Darrow, K.; Tidball, R.; Wang, J.; Hampson, A. Combined Heat and Power Partnership. Available online: https://www.epa.gov/chp/catalog-chp-technologies (accessed on 17 October 2018).

- PJM. Regulation. Available online: https://www.pjm.com/-/media/training/nerc-certifications/markets-exam-materials/mkt-optimization-wkshp/regulation-market.ashx?la=en (accessed on 20 October 2018).

- PJM. Capacity by Fuel Type. Available online: https://www.pjm.com/-/media/markets-ops/ops-analysis/capacity-by-fuel-type-2017.ashx?la=en (accessed on 20 October 2018).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pareis, E.; Hittinger, E. Emissions Effects of Energy Storage for Frequency Regulation: Comparing Battery and Flywheel Storage to Natural Gas. Energies 2021, 14, 549. https://doi.org/10.3390/en14030549

Pareis E, Hittinger E. Emissions Effects of Energy Storage for Frequency Regulation: Comparing Battery and Flywheel Storage to Natural Gas. Energies. 2021; 14(3):549. https://doi.org/10.3390/en14030549

Chicago/Turabian StylePareis, Eric, and Eric Hittinger. 2021. "Emissions Effects of Energy Storage for Frequency Regulation: Comparing Battery and Flywheel Storage to Natural Gas" Energies 14, no. 3: 549. https://doi.org/10.3390/en14030549