Octane Index Applicability over the Pressure-Temperature Domain

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

2.2. Experimental Operating Conditions

2.2.1. Spark Ignited Operation

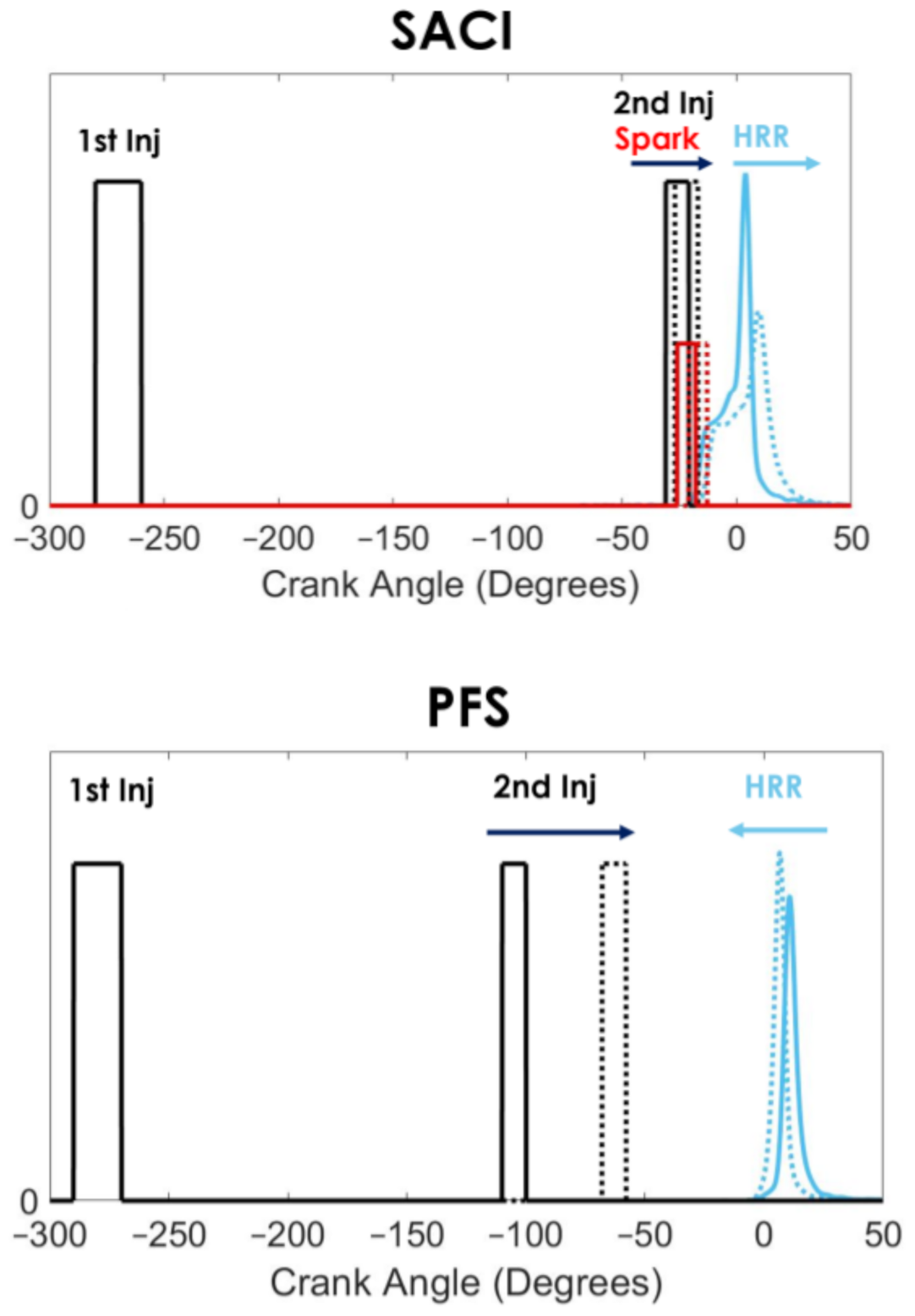

2.2.2. SACI Operation

2.2.3. PFS Operation

2.3. Fuels Investigated

3. Results

3.1. SI Combustion Performance

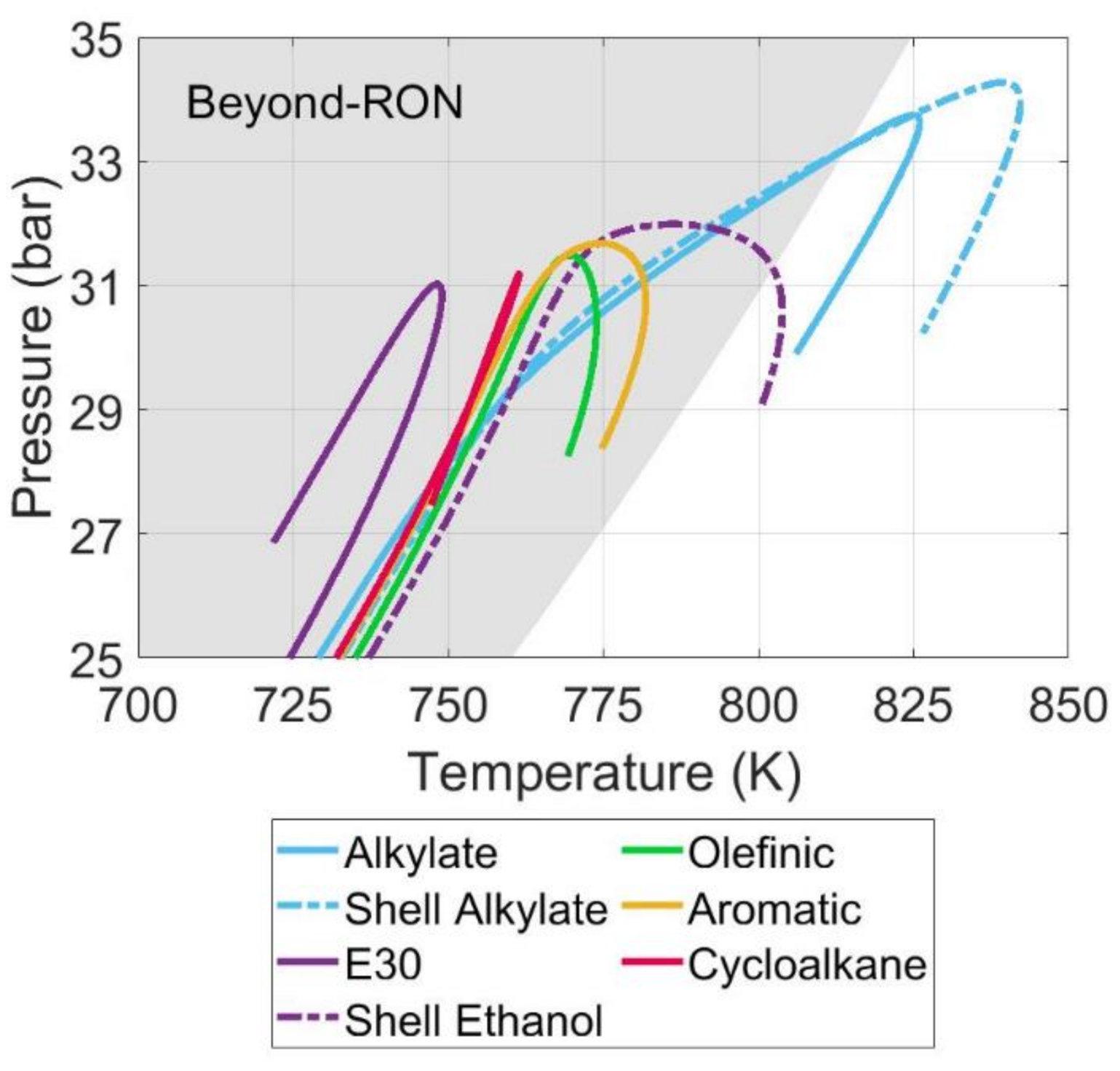

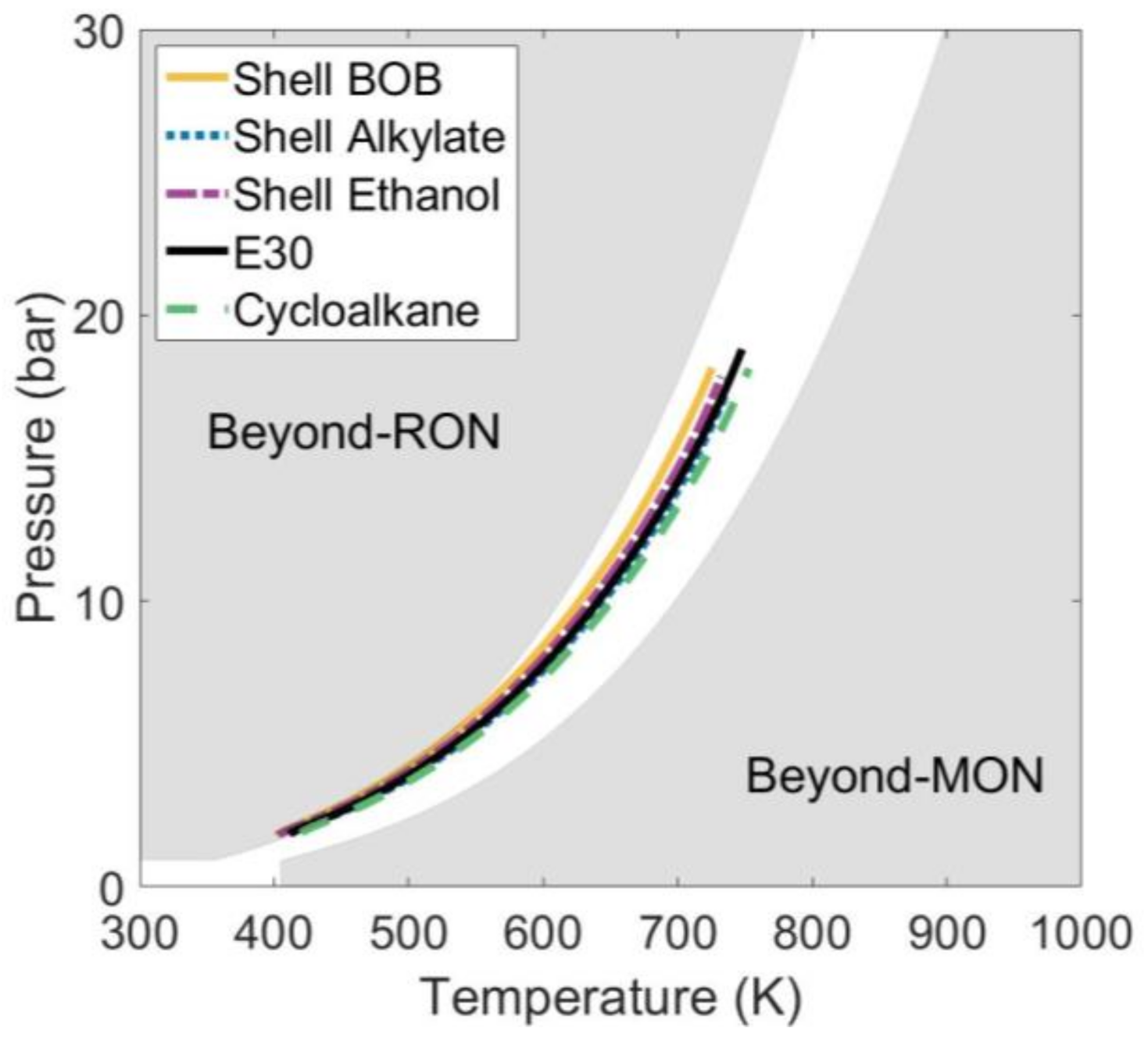

3.2. ACI Combustion Performance

3.3. Octane Index and Measured Fuel Autoignition Resistance

4. Discussion

5. Conclusions

- Fuels with low octane ratings and low Soctane displayed LTHR for ACI operation and PSHR for SI operation. In this investigation, all PSHR that occurred coincided with the 750–850 K temperature range that characterizes LTHR. Higher intake temperatures attenuate the PSHR magnitude by passing through this temperature range at lower pressures, suppressing the oxidation chemistry responsible for LTHR. While low Soctane fuels typically have the greatest levels of LTHR, fuels with Soctane as high as 10.9 exhibited PSHR under boosted SI conditions.

- While the LTHR isn’t observed prior to deflagration during SACI combustion, the post-autoignition combustion rate was highest for the fuels demonstrating the greatest LTHR magnitudes for other combustion modes, thereby providing evidence of LTHR in the end-gas region that is obscured by the deflagration event.

- The LTHR magnitude by fuel chemical family at boosted SI conditions was identical to those at PFS conditions. The ranking from greatest LTHR magnitude to the least is paraffins > aromatic > olefin > cycloalkane > ethanol for a given RON rating.

- The moniker “multimode ACI” encompasses a broad range of combustion strategies and PT trajectories. ACI operation in the prior study had a strongly beyond-MON trajectory, and it showed the importance of chemical composition. The SACI and PFS strategies in the current investigation are closer to the RON trajectory, and exhibited a strong dependence on LTHR, which is similar to the knock dependencies for boosted SI combustion. As a result, the SI and ACI combustion strategies investigated here align much better with OI predictions, illustrating that fuel response is highly dependent on the ACI strategy being used.

- The OI metric is broadly capable of accurately predicting fuel autoignition resistance for SI combustion across a wide range of the PT domain and ACI modes operating at or near RON-like conditions. Similarly, the OI metric is also capable of predicting autoignition resistance ordering for fuels of varying chemical families.

- While the OI metric is adequate for describing autoignition resistance, olefinic fuels were consistently easier to autoignite for ACI operation, but those differences were minor relative to the chemistry-specific differences from the prior investigation [25].

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Disclaimer

Definitions and Abbreviations

| ACI | Advanced compression ignition |

| AFR | Air to fuel ratio |

| AKI | Anti-knock index |

| aTDCf | After firing top dead center |

| BMEP | Brake mean effective pressure |

| BOB | Blendstock for oxygenate blending |

| bTDCf | Before firing top dead center |

| CA | Crank angle |

| CA50 | Crank angle of 50% heat release |

| DHA | Detailed hydrocarbon analysis |

| DI | Direct injection |

| HCCI | Homogeneous charge compression ignition |

| IMEP | Indicated mean effective pressure |

| K | Octane index constant representing engine operating condition |

| LTHR | Low-temperature heat release |

| MON | Motor octane number |

| NOx | Oxides of nitrogen |

| NTC | Negative temperature coefficient |

| OI | Octane index |

| PFS | Partial fuel stratification |

| PMI | Particulate matter index |

| PRR | Pressure rise rate |

| PT | Pressure-temperature |

| R2 | Correlation coefficient |

| RON | Research octane number |

| SACI | Spark-assisted compression ignition |

| Soctane | Octane sensitivity |

| SI | Spark ignited |

| γ | Ratio of specific heats |

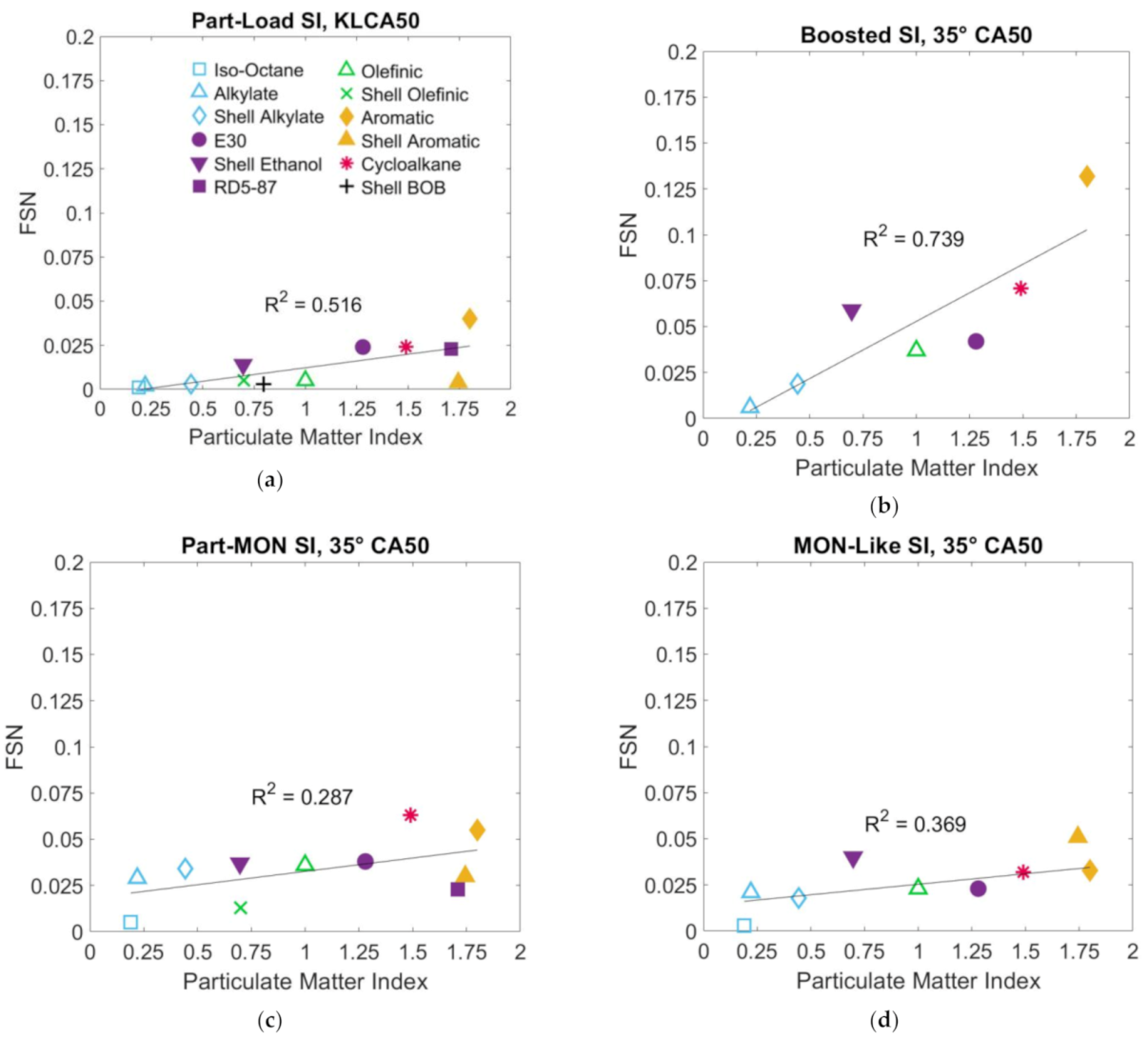

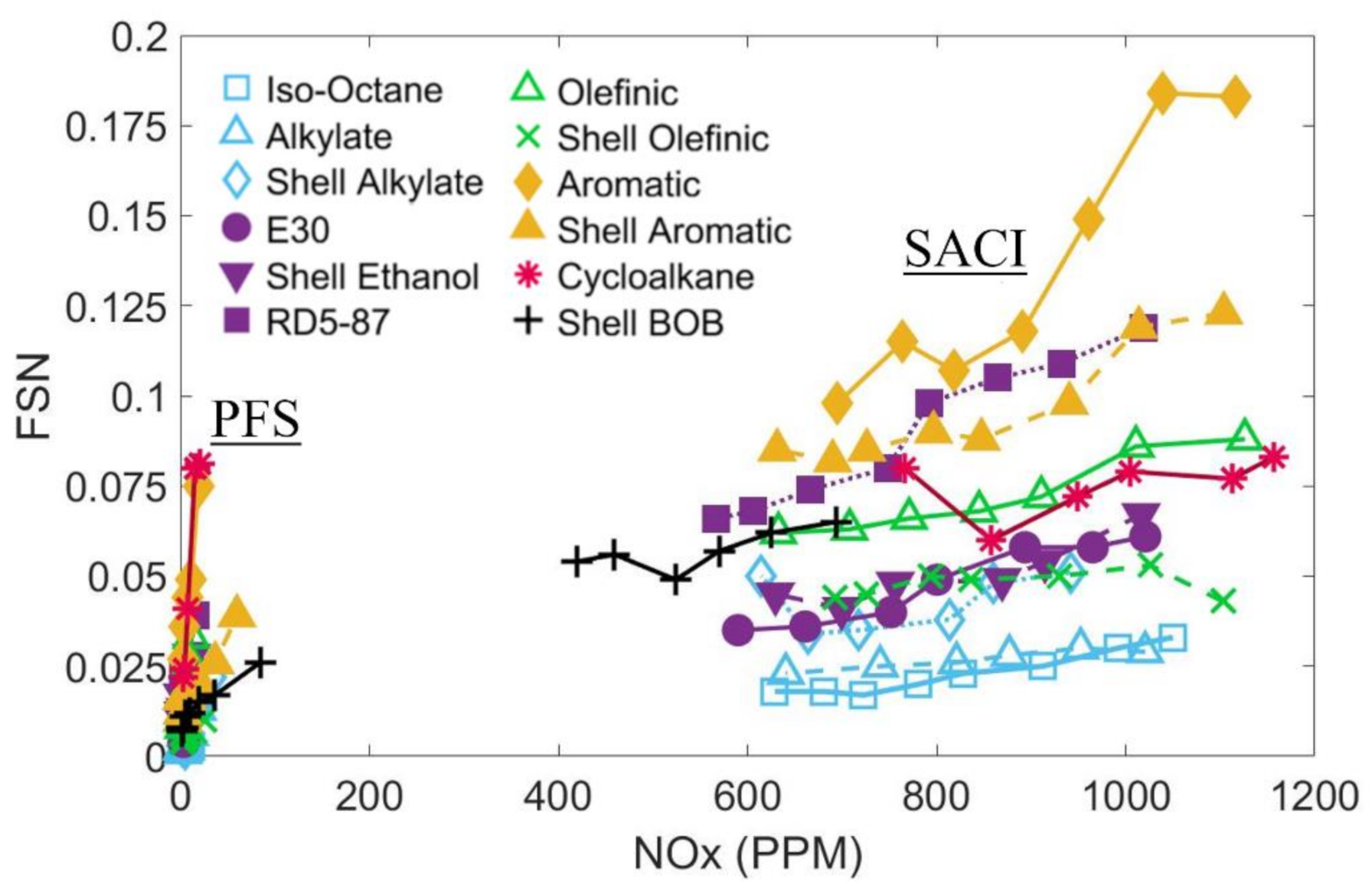

Appendix A. SI Smoke Emissions

References

- Szybist, J.P.; Busch, S.; McCormick, R.L.; Pihl, J.A.; Splitter, D.A.; Ratcliff, M.A.; Kolodziej, C.P.; Storey, J.E.; Moses-Debusk, M.; Vuilleumier, D.; et al. What Fuel Properties Enable Higher Thermal Efficiency in Spark-Ignited Engines? Prog. Energy Combust. Sci. 2021, 82, 100876. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 1st ed.; McGraw-Hill Inc.: New York, NY, USA, 1988. [Google Scholar]

- Jo, Y.S.; Bromberg, L.; Heywood, J. Octane Requirement of a Turbocharged Spark Ignition Engine in Various Driving Cycles. SAE Tech. Pap. 2016. [Google Scholar] [CrossRef]

- Smith, P.; Cheng, W.K. Assessing the Loss Mechanisms Associated with Engine Downsizing, Boosting and Compression Ratio Change. SAE Tech. Pap. 2013. [Google Scholar] [CrossRef]

- Thring, R.H. Homogeneous-Charge Compression-Ignition (HCCI) Engines. SAE Tech. Pap. 1989. [Google Scholar] [CrossRef]

- Dec, J.E. Advanced Compression-Ignition Engines—Understanding the in-Cylinder Processes. Proc. Combust. Inst. 2009, 32, 2727–2742. [Google Scholar] [CrossRef]

- Yang, Y.; Dec, J.; Dronniou, N.; Sjöberg, M.; Cannella, W. Partial Fuel Stratification to Control HCCI Heat Release Rates: Fuel Composition and Other Factors Affecting Pre-Ignition Reactions of Two-Stage Ignition Fuels. SAE Int. J. Engines 2011, 4, 1903–1920. [Google Scholar] [CrossRef]

- Gentz, G.; Dernotte, J.; Ji, C.; Pintor, D.L.; Dec, J. Combustion-Timing Control of Low-Temperature Gasoline Combustion (LTGC) Engines by Using Double Direct-Injections to Control Kinetic Rates. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Chang, J.; Güralp, O.; Filipi, Z.; Assanis, D.N.; Kuo, T.; Najt, P.; Rask, R. New Heat Transfer Correlation for an HCCI Engine Derived from Measurements of Instantaneous Surface Heat Flux. SAE Tech. Pap. 2004. [Google Scholar] [CrossRef]

- Eng, J.A. Characterization of Pressure Waves in HCCI Combustion. SAE Tech. Pap. 2002. [Google Scholar] [CrossRef]

- Dec, J.E.; Yang, Y. Boosted Hcci for High Power without Engine Knock and with Ultra-Low NOx Emissions—Using Conventional Gasoline. SAE Int. J. Engines 2010, 3, 750–767. [Google Scholar] [CrossRef]

- Silke, E.J.; Pitz, W.J.; Westbrook, C.K.; Sjöberg, M.; Dec, J.E. Understanding the Chemical Effects of Increased Boost Pressure under HCCI Conditions. SAE Int. J. Fuels Lubr. 2009, 1, 12–25. [Google Scholar] [CrossRef]

- Sjöberg, M.; Dec, J.E. EGR and Intake Boost for Managing HCCI Low-Temperature Heat Release over Wide Ranges of Engine Speed. SAE Trans. 2007, 116, 65–77. [Google Scholar]

- Dec, J.E.; Yang, Y.; Dronniou, N. Boosted HCCI—Controlling Pressure-Rise Rates for Performance Improvements Using Partial Fuel Stratification with Conventional Gasoline. SAE Int. J. Engines 2011, 4, 1169–1189. [Google Scholar] [CrossRef]

- Boldaji, M.R.; Sofianopoulos, A.; Mamalis, S.; Lawler, B. Effects of Mass, Pressure, and Timing of Injection on the Efficiency and Emissions Characteristics of TSCI Combustion with Direct Water Injection. SAE Tech. Pap. 2018. [Google Scholar] [CrossRef]

- Sjöberg, M.; Dec, J.E.; Babajimopoulos, A.; Assanis, D. Comparing Thermal Stratification Against Retarded Combustion Phasing for Smoothing of HCCI Heat-Release Rates. SAE Trans. 2004, 113, 1557–1575. [Google Scholar]

- Foong, T.M. On the Autoignition of Ethanol/Gasoline Blends in Spark-Ignition Engines. Ph.D. Thesis, University of Melbourne, Melbourne, Australia, 2013. [Google Scholar]

- ASTM D2699-16e1. Standard Test Method for Research Octane Number of Spark-Ignition Engine Fuel; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D2700-16a. Standard Test Method for Motor Octane Number of Spark-Ignition Engine Fuel; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Kalghatgi, G.T. Fuel Anti-Knock Quality-Part I. Engine Studies. SAE Trans. 2001, 110, 1993–2004. [Google Scholar] [CrossRef]

- Szybist, J.P.; Splitter, D.A. Understanding Chemistry-Specific Fuel Differences at a Constant RON in a Boosted SI Engine. Fuel 2018, 217, 370–381. [Google Scholar] [CrossRef]

- Szybist, J.P.; Splitter, D.A. Pressure and Temperature Effects on Fuels with Varying Octane Sensitivity at High Load in SI Engines. Combust. Flame 2017, 177, 49–66. [Google Scholar] [CrossRef]

- Splitter, D.A.; Gilliam, A.; Szybist, J.; Ghandhi, J. Effects of Pre-Spark Heat Release on Engine Knock Limit. Proc. Combust. Inst. 2019, 37, 4893–4900. [Google Scholar] [CrossRef]

- Tao, M.; Zhao, P.; Szybist, J.P.; Lynch, P.; Ge, H. Insights into Engine Autoignition: Combining Engine Thermodynamic Trajectory and Fuel Ignition Delay Iso-Contour. Combust. Flame 2019, 200, 207–218. [Google Scholar] [CrossRef]

- Szybist, J.P.; Splitter, D.A. Impact of Engine Pressure-Temperature Trajectory on Autoignition for Varying Fuel Properties. Appl. Energy Combust. Sci. 2020. [Google Scholar] [CrossRef]

- Fouts, L.A.; Fioroni, G.M.; Christensen, E.D.; Ratcliff, M.A.; McCormick, R.L.; Zigler, B.T.; Sluder, S.; Szybist, J.P.; Dec, J.E.; Miles, P.C.; et al. Co-Optimization of Fuels & Engines: Properties of Co-Optima Core Research Gasolines; Technical Report for NREL/TP-5400-71341; National Renewable Energy Laboratory: Golden, CO, USA, 2018. [Google Scholar]

- Pintor, D.L.; Dec, J.; Gentz, G. φ-Sensitivity for LTGC Engines: Understanding the Fundamentals and Tailoring Fuel Blends to Maximize This Property. SAE Tech. Pap. 2019. [Google Scholar] [CrossRef]

- Manofsky, L.; Vavra, J.; Assanis, D.; Babajimopoulos, A. Bridging the Gap between HCCI and SI: Spark-Assisted Compression Ignition. SAE Tech. Pap. 2011. [Google Scholar] [CrossRef]

- Szybist, J.P.; Nafziger, E.; Weall, A. Load Expansion of Stoichiometric HCCI Using Spark Assist and Hydraulic Valve Actuation. SAE Int. J. Engines 2010, 3, 244–258. [Google Scholar] [CrossRef]

- Weall, A.J.; Szybist, J.P. The Effects of Fuel Characteristics on Stoichiometric Spark-Assisted HCCI. In Proceedings of the ASME 2011 Internal Combustion Engine Division Fall Technical Conference, Morgantown, WV, USA, 2–5 October 2011; pp. 243–259. [Google Scholar]

- Woschni, G.A. Universally Applicable Equation for the Instantaneous Heat Transfer Coefficient in the Internal Combustion Engine. SAE Tech. Pap. 1967, 670931, 3065–3077. [Google Scholar]

- Yun, H.J.; Mirsky, W. Schlieren-Streak Measurements of Instantaneous Exhaust Gas Velocities from a Spark-Ignition Engine. SAE Tech. Pap. 1974, 83, 3143–3158. [Google Scholar]

- Ortiz-Soto, E.; Vavra, J.; Babajimopoulos, A. Assessment of Residual Mass Estimation Methods for Cylinder Pressure Heat Release Analysis of HCCI Engines with Negative Valve Overlap. J. Eng. Gas Turbines Power 2012, 134, 082802. [Google Scholar] [CrossRef]

- Sjöberg, M.; Zeng, W. Combined Effects of Fuel and Dilution Type on Efficiency Gains of Lean Well-Mixed DISI Engine Operation with Enhanced Ignition and Intake Heating for Enabling Mixed-Mode Combustion. SAE Int. J. Engines 2016, 9, 750–767. [Google Scholar] [CrossRef]

- Xu, C.; Pal, P.; Ren, X.; Sjöberg, M.; Van Dam, N.; Wu, Y.; Lu, T.; McNenly, M.; Som, S. Numerical Investigation of Fuel Propertry Effects on Mixed-Mode Combustion in a Spark-Ignition Engine. J. Energy Resour. Technol. 2021, 143, 1–12. [Google Scholar] [CrossRef]

- Olesky, L.K.M.; Middleton, R.J.; Lavoie, G.A.; Wooldridge, M.S.; Martz, J.B. On the Sensitivity of Low Temperature Combustion to Spark Assist near Flame Limit Conditions. Fuel 2015, 158, 11–22. [Google Scholar] [CrossRef]

- Szybist, J.P.; Wagnon, S.W.; Splitter, D.; Pitz, W.J.; Mehl, M. The Reduced Effectiveness of EGR to Mitigate Knock at High Loads in Boosted SI Engines. SAE Int. J. Engines 2017, 10, 2305–2318. [Google Scholar] [CrossRef]

- Vuilleumier, D.; Sjöberg, M. Significance of RON, MON, and LTHR for Knock Limits of Compositionally Dissimilar Gasoline Fuels in a DISI Engine. SAE Int. J. Engines 2017, 10, 938–950. [Google Scholar] [CrossRef]

- Splitter, D.; Kaul, B.; Szybist, J.; Jatana, G. Engine Operating Conditions and Fuel Properties on Pre-Spark Heat Release and SPI Promotion in SI Engines. SAE Int. J. Engines 2017, 10, 1036–1050. [Google Scholar] [CrossRef]

- DelVescovo, D.A.; Splitter, D.A.; Szybist, J.P.; Jatana, G.S. Modeling Pre-Spark Heat Release and Low Temperature Chemistry of Iso-Octane in a Boosted Spark-Ignition Engine. Combust. Flame 2020, 212, 39–52. [Google Scholar] [CrossRef]

- Westbrook, C.K.; Mehl, M.; Pitz, W.J.; Sjöberg, M. Chemical Kinetics of Octane Sensitivity in a Spark-Ignition Engine. Combust. Flame 2017, 175, 2–15. [Google Scholar] [CrossRef]

- Westbrook, C.K.; Mizobuchi, Y.; Poinsot, T.J.; Smith, P.J.; Warnatz, J. Computational Combustion. Proc. Combust. Inst. 2005, 30, 125–157. [Google Scholar] [CrossRef]

- Liang, W.; Law, C.K. Theory of First-Stage Ignition Delay in Hydrocarbon NTC Chemistry. Combust. Flame 2018, 188, 162–169. [Google Scholar] [CrossRef]

- Zhang, P.; Ji, W.; He, T.; He, X.; Wang, Z.; Yang, B.; Law, C.K. First-Stage Ignition Delay in the Negative Temperature Coefficient Behavior: Experiment and Simulation. Combust. Flame 2016, 167, 14–23. [Google Scholar] [CrossRef]

- Leppard, W.R. The Chemical Origin of Fuel Octane Sensitivity. SAE Trans. 1990, 99, 862–876. [Google Scholar]

- Szybist, J.P.; Splitter, D. Effects of Fuel Composition on EGR Dilution Tolerance in Spark Ignited Engines. SAE Int. J. Engines 2016, 9, 819–831. [Google Scholar] [CrossRef]

- Kim, N.; Vuilleumier, D.; Sjöberg, M.; Yokoo, N.; Tomoda, T.; Nakata, K. Using Chemical Kinetics to Understand Effects of Fuel Type and Compression Ratio on Knock-Mitigation Effectiveness of Various EGR Constituents. SAE Int. J. Adv. Curr. Prac. Mobil. 2019, 1, 1560–1580. [Google Scholar]

- Aikawa, K.; Sakurai, T.; Jetter, J.J. Development of a Predictive Model for Gasoline Vehicle Particulate Matter Emissions. SAE Int. J. Fuels Lubr. 2010, 3, 610–622. [Google Scholar] [CrossRef]

- Rockstroh, T.; Floweday, G.; Yates, A. Optimisation of Synthetic Gasoline Blend Recipes for Use in Modern Charge Boosted GDI Engines. Fuel 2016, 186, 800–820. [Google Scholar] [CrossRef]

- Zhou, Z.; Yang, Y.; Brear, M.; Lacey, J.; Leone, T.G.; Anderson, J.E.; Shelby, M.H. A Comparison of Four Methods for Determining the Octane Index and K on a Modern Engine with Upstream, Port or Direct Injection. SAE Tech. Pap. 2017. [Google Scholar] [CrossRef]

- Cracknell, R.; Kassai, M.; Shiraishi, T.; Festa, A.; Gail, S.; Aradi, A.; Shibuya, M. Is the ‘K Value’ of an Engine Truly Fuel Independent? SAE Tech. Pap. 2020. [Google Scholar] [CrossRef]

| Displacement (L) | 0.550 |

|---|---|

| Bore × Stroke (mm) | 86.0 × 94.6 |

| Connecting Rod (m) | 145.5 |

| Compression Ratio | 12.5:1 |

| Cam Phasing | Hydraulic phasing, 60 °CA authority for intake and exhaust |

| Fuel Injector | Centrally-mounted solenoid DI, 8-hole, symmetric 60° included angle |

| Parameter | Part Load SI | Boosted SI | Part-MON | MON-Like | SACI | PFS |

|---|---|---|---|---|---|---|

| Engine Speed (RPM) | 1500 | 1500 | 1500 | 1500 | 1500 | 1200 |

| Gross Indicated Mean Effective Pressure (IMEP) (kPa) | 585–619 | 1055–1163 | 744–898 | 688–833 | 599–651 | 576–635 |

| Air flow (g/min) | 225 | 485 | 350 | 330 | 430 | 500 |

| λ (global) | 1.0 | 1.0 | 1.0 | 1.0 | 2.0 | 3.0 |

| Intake Temperature (°C) | 35 | 35 | 95 | 152 | 35–75 | 61–177 |

| Intake Pressure 1 (kPa) | 73 ± 1 | 120 ± 3 | 102 ± 3 | 103 ± 3 | 159 ± 3 | 177 ± 19 |

| Spark (°CA bTDCf) | 3.2 to 10.9 | −6.5 to −10.8 | −0.2 to −10.7 | −1.6 to −10.8 | 27 to 19.3 | -- |

| Start of Injection 1st/2nd (°CA bTDCf) | 280/-- | 280/-- | 280/-- | 280/-- | 280/32–23.3 | 290/110–48 |

| Injection Split 1st/2nd (% injection duration) | 100/-- | 100/-- | 100/-- | 100/-- | 83/17 | 77/23 |

| CA50 Criteria | KLSA | 35 °CA aTDCf to KLSA, 5° steps | 35 °CA aTDCf to KLSA, 5° steps | 35 °CA aTDCf to KLSA, 5° steps | PRR 10 bar/°CA to 3% COV, 1° steps | PRR 10 bar/°CA to 10° aTDC, 1° steps |

| Intake/Exhaust Cam Advance (°CA) | 35/30 | 35/30 | 35/30 | 35/30 | 0/60 | 35/50 |

| Estimated Residual (mass %) | 4.5–5.1 | 2.7–2.9 | 3.2–3.6 | 3.4–3.9 | 10.0–11.0 | 4.4–5.3 |

| Co-Optima Core Fuels | Shell BOB Fuels | Iso-Octane | RD5-87 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Property | Standard | Olefinic | E30 | Aromatic | Alkylate | Cycloalkane | BOB | Alkylate | Aromatic | Olefinic | Ethanol | ||

| RON | D2699 | 98.2 | 97.4 | 98.1 | 98.0 | 98.0 | 87.3 | 94.6 | 94.8 | 95.4 | 95 | 100 | 92.3 |

| MON | D2700 | 88.0 | 86.6 | 87.8 | 96.6 | 87.1 | 83.3 | 90.6 | 86.8 | 86.6 | 87.1 | 100 | 84.6 |

| Soctane | Calculated | 10.2 | 10.8 | 10.3 | 1.4 | 10.9 | 4 | 4 | 8 | 8.8 | 7.9 | 0 | 7.7 |

| Saturates (V%) | D1319 A/ ISO 22854 B | 58.1 A | 57.1 A | 65 A | 100 A | 70.3 A | 79 B | 91.5 B | 56.9 B | 62.5 B | 68.5 B | 100 A | 47.4 A |

| Aromatic (V%) | D1319 A/ ISO 22854 B | 10.6 A | 8.1 A | 30.8 A | 0 A | 18.1 A | 13.3 B | 5.4 B | 37.5 B | 10.3 B | 11.7 B | 0 A | 23.8 A |

| Olefins (V%) | D1319 A/ ISO 22854 B | 31.3 A | 5 A | 4.2 A | 0 A | 1.5 A | 5.5 B | 2.3 B | 4.1 B | 25.6 B | 4.8 B | 0 A | 5.9 A |

| Oxygenates (V%) | D5589 C/ ISO 22854 B | 0 C | 30.6 C | 0 C | 0 C | 0 C | 0.1 B | 0 B | 0 B | 0 B | 13.1 B | 0 C | 9.1 C |

| Ethanol (V%) | D5589 C/ ISO 22854 B | 0 C | 30.6 C | 0 C | 0 C | 0 C | 0 B | 0 B | 0 B | 0 B | 13.1 B | 0 C | 9.1 C |

| IBP (°C) | D86 | 35.70 | 35.70 | 35.70 | 35.70 | 35.70 | 30.2 | 40.7 | 32.2 | 33.2 | 34 | 99.3 | 40.4 |

| T10 (°C) | D86 | 77.1 | 60.7 | 59.4 | 93.10 | 55.7 | 62.1 | 83.4 | 64.9 | 65.1 | 53.9 | N/A | 57.8 |

| T50 (°C) | D86 | 104.3 | 74.3 | 108.1 | 100.3 | 87.4 | 110.8 | 99.5 | 117.2 | 100.0 | 69.2 | N/A | 101.3 |

| T90 (°C) | D86 | 136.2 | 155.2 | 157.9 | 105.9 | 142.7 | 163.7 | 112.7 | 160.9 | 132.7 | 139.3 | N/A | 157.9 |

| FBP (°C) | D86 | 197.7 | 204.1 | 204.4 | 161.3 | 203.5 | 188.8 | 164.8 | 189.3 | 174.6 | 177.2 | 99.3 | 205 |

| RVP (PSI) | D5191 D/ ISO EN 13016-1 E | 42.1 D | 52.8 D | 49.4 D | 28.6 D | 55.2 D | 68.7 E | 72.5 E | 51.1 E | 55.8 E | 72.5 E | -- | -- |

| LHV (MJ/kg) | D4809 | 44.07 | 38.17 | 42.95 | 44.52 | 43.21 | 44.23 | 44.67 | 43.11 | 44.18 | 41.76 | 44.31 | 41.93 |

| Carbon (W%) | D5291 | 85.40 | 74.78 | 87.22 | 83.75 | 87.08 | 85.18 | 84.56 | 86.82 | 85.27 | 80.45 | 84.28 | 82.67 |

| Hydrogen (W%) | D5291 | 14.50 | 13.79 | 13.12 | 15.80 | 13.24 | 14.81 | 15.44 | 13.18 | 14.73 | 14.56 | 15.91 | 13.66 |

| Oxygen (W%) | D5599 | 0 | 11.19 | 0 | 0 | 0 | 0.01 | 0 | 0 | 0 | 4.99 | 0 | 3.67 |

| H:C | Calculated | 2.02 | 2.2 | 1.79 | 2.25 | 1.81 | 2.09 | 2.19 | 1.82 | 2.07 | 2.17 | 2.25 | 1.97 |

| O:C | Calculated | 0 | 0.11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.047 | 0 | 0.033 |

| PMIF | Calculated | 1.00 | 1.28 | 1.80 | 0.22 | 1.49 | 0.80 | 0.44 | 1.74 | 0.70 | 0.70 | 0.19 | 1.71 |

| AFRstoich | Calculated | 14.85 | 12.92 | 14.52 | 15.17 | 14.55 | 14.91 | 15.06 | 14.54 | 14.89 | 14.06 | 15.14 | 14.05 |

| LHV for stoichiometric mixture per kilogram of air [MJ/kg-air] | Calculated | 2.97 | 2.95 | 2.96 | 2.94 | 2.97 | 2.97 | 2.97 | 2.97 | 2.97 | 2.97 | 2.93 | 2.99 |

| Condition | K | R2 Octane Index | R2 RON |

|---|---|---|---|

| Part-load SI | 0.71 | 0.882 | 0.518 |

| Boosted SI | 0.04 | 0.856 | 0.850 |

| Part-MON | 0.05 | 0.877 | 0.872 |

| MON-Like | 0.33 | 0.729 | 0.476 |

| PFS | −0.41 | 0.856 | 0.725 |

| SACI | −0.33 | 0.777 | 0.697 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Powell, T.R.; Szybist, J.P.; Dal Forno Chuahy, F.; Curran, S.J.; Mengwasser, J.; Aradi, A.; Cracknell, R. Octane Index Applicability over the Pressure-Temperature Domain. Energies 2021, 14, 607. https://doi.org/10.3390/en14030607

Powell TR, Szybist JP, Dal Forno Chuahy F, Curran SJ, Mengwasser J, Aradi A, Cracknell R. Octane Index Applicability over the Pressure-Temperature Domain. Energies. 2021; 14(3):607. https://doi.org/10.3390/en14030607

Chicago/Turabian StylePowell, Tommy R., James P. Szybist, Flavio Dal Forno Chuahy, Scott J. Curran, John Mengwasser, Allen Aradi, and Roger Cracknell. 2021. "Octane Index Applicability over the Pressure-Temperature Domain" Energies 14, no. 3: 607. https://doi.org/10.3390/en14030607

APA StylePowell, T. R., Szybist, J. P., Dal Forno Chuahy, F., Curran, S. J., Mengwasser, J., Aradi, A., & Cracknell, R. (2021). Octane Index Applicability over the Pressure-Temperature Domain. Energies, 14(3), 607. https://doi.org/10.3390/en14030607