Potassium Hydroxyde Pre-Treatment Enhances Methane Yield from Giant Reed (Arundo donax L.)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock

2.2. Experimental Design

2.3. Pre-Treatments without Washing Step

2.4. Pre-Treatments with Washing Step

2.5. Anaerobic Digestion

2.6. Parameters of the Cumulative Methane Production Curves (Gompertz Parameters)

2.7. Analytical Methods

2.8. Enzymatic Saccharification of the Pre-Treated Samples and Reducing Sugar Determination

2.9. Statistical Analysis

3. Results and Discussion

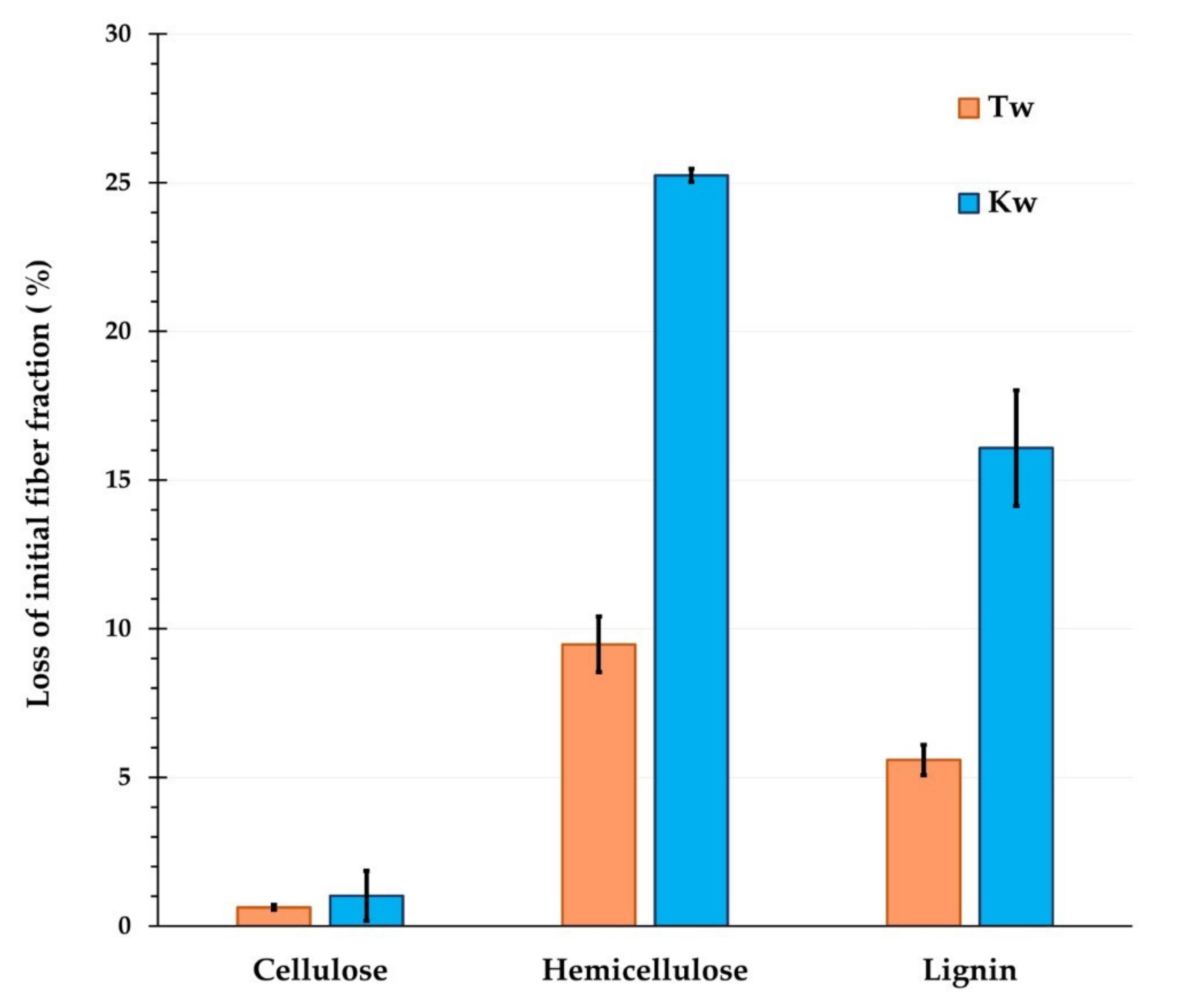

3.1. Pre-Treatment Efficiency and Effects on the Biomass

3.2. Washing Effects

3.3. Effects of the Pre-Treatments on Anaerobic Digestion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gunes, B.; Stokes, J.; Davis, P.; Connolly, C.; Lawler, J. Optimisation of anaerobic digestion of pot ale after thermochemical pre-treatment through Response Surface Methodology. Biomass Bioenergy 2021, 144, 105902. [Google Scholar] [CrossRef]

- Wagner, A.O.; Lackner, N.; Mutschlechner, M.; Prem, E.M.; Markt, R.; Illmer, P. Biological pretreatment strategies for second-generation lignocellulosic resources to enhance biogas production. Energies 2018, 11, 1797. [Google Scholar] [CrossRef] [Green Version]

- Edwiges, T.; Bastos, J.A.; Alino, J.H.L.; d’Avila, L.; Mantovani Frare, L.; Somer, J.-G. Comparison of various pretreatment techniques to enhance biodegradability of lignocellulosic biomass for methane production. J. Environ. Chem. Eng. 2019, 7, 103495. [Google Scholar] [CrossRef]

- Novakovic, J.; Kontogianni, N.; Barampouti, E.M.; Mai, S.; Moustakas, K.; Malamis, D.; Loizidou, M. Towards upscaling the valorization of wheat straw residues: Alkaline pretreatment using sodium hydroxide, enzymatic hydrolysis and biogas production. Environ. Sci. Pollut. Res. 2020. [Google Scholar] [CrossRef] [PubMed]

- Scordia, D.; Cosentino, S.L. Perennial Energy Grasses: Resilient Crops in a Changing European Agriculture. Agriculture 2019, 9, 169. [Google Scholar] [CrossRef] [Green Version]

- Kovačić, Đ.; Kralik, D.; Rupcic, S.; Jovicic, D.; Spajić, R.; Tišma, M. Soybean straw, corn stover and sunflower stalk as possible substrates for biogas production in Croatia: A review. Chem. Biochem. Eng. Q. 2017, 31, 187–198. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A technological overview of biogas production from biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Cianchetta, S.; Di Maggio, B.; Burzi, P.L.; Galletti, S. Evaluation of selected white-rot fungal isolates for improving the sugar yield from wheat straw. Appl. Biochem. Biotechnol. 2014, 173, 609–623. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Xu, F.; Ge, X.; Li, Y. Challenges and strategies for solid-state anaerobic digestion of lignocellulosic biomass. Renew. Sust. Energ. Rev. 2015, 44, 824–834. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Monlau, F.; Barakat, A.; Steyer, J.P.; Carrere, H. Comparison of seven types of thermo-chemical pretreatments on the structural features and anaerobic digestion of sunflower stalks. Bioresour. Technol. 2012, 120, 241–247. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Ge, X.; Zhang, Q.; Li, Y. Comparison of liquid hot water and alkaline pretreatments of giant reed for improved enzymatic digestibility and biogas energy production. Bioresour. Technol. 2016, 216, 60–68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Surendra, K.C.; Sawatdeenarunat, C.; Shrestha, S.; Sung, S.; Khanal, S.K. Anaerobic digestion-based biorefinery for bioenergy and biobased products. Ind. Biotechnol. 2015, 11, 103–112. [Google Scholar] [CrossRef]

- D’Imporzano, G.; Pilu, R.; Corno, L.; Adani, F. Arundo donax L. can substitute traditional energy crops for more efficient, environmentally-friendly production of biogas: A Life Cycle Assessment approach. Bioresour. Technol. 2018, 267, 249–256. [Google Scholar] [CrossRef]

- Ceotto, E.; Castelli, F.; Moschella, A.; Diozzi, M.; Di Candilo, M. Cattle slurry fertilization to giant reed (Arundo donax L.): Biomass yield and nitrogen use efficiency. BioEnergy Res. 2015, 8, 1252–1262. [Google Scholar] [CrossRef]

- Cianchetta, S.; Bregoli, L.; Galletti, S. Microplate-based evaluation of the sugar yield from giant reed, giant Miscanthus and switchgrass after mild chemical pre-treatments and hydrolysis with tailored Trichoderma enzymatic blends. Appl. Biochem. Biotech. 2017, 183, 876–892. [Google Scholar] [CrossRef]

- Di Girolamo, G.; Bertin, L.; Capecchi, L.; Ciavatta, C.; Barbanti, L. Mild alkaline pre-treatments loosen fibre structure enhancing methane production from biomass crops and residues. Biomass Bioenergy 2014, 71, 318–329. [Google Scholar] [CrossRef]

- Thomas, H.L.; Arnoult, S.; Brancourt-Hulmel, M.; Carrère, H. Methane production variability according to Miscanthus genotype and alkaline pretreatments at high solid content. Bioenerg. Res. 2019, 12, 325–337. [Google Scholar] [CrossRef]

- Jaffar, M.; Pang, Y.; Yuan, H.; Zou, D.; Liu, Y.; Zhu, B.; Korai, R.M.; Li, X. Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion. Chin. J. Chem. Eng. 2016, 24, 404–409. [Google Scholar] [CrossRef]

- Jiang, D.; Ge, X.; Zhang, Q.; Zhou, X.; Chen, Z.; Keener, H.; Li, Y. Comparison of sodium hydroxide and calcium hydroxide pretreatments of giant reed for enhanced enzymatic digestibility and methane production. Bioresour. Technol. 2017, 244, 1150–1157. [Google Scholar] [CrossRef]

- Vasmara, C.; Cianchetta, S.; Marchetti, R.; Galletti, S. Biogas production from wheat straw pre-treated with ligninolytic fungi and co-digestion with pig slurry. Environ. Eng. Manag. J. 2015, 14, 1751–1760. [Google Scholar] [CrossRef]

- Vasmara, C.; Marchetti, R. Biogas production from biodegradable bioplastics. Environ. Eng. Manag. J. 2016, 15, 2041–2048. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; van’t Riet, K. Modeling of the bacterial growth curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- APHA. Standard Methods for the Examination of Water and Wastewater, 18th ed.; American Public Health Association: Washington, DC, USA, 1992. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral-detergent fiber and non-starch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Cianchetta, S.; Galletti, S.; Burzi, P.L.; Cerato, C. Hydrolytic potential of Trichoderma sp. strains evaluated by microplate-based screening followed by switchgrass saccharification. Enzyme Microb. Technol. 2012, 50, 304–310. [Google Scholar] [CrossRef] [PubMed]

- SAS Institute. SAS/STAT™ Guide for Personal Computers, Version 6, 2nd ed.; SAS Institute: Cary, NC, USA, 1987. [Google Scholar]

- Littell, R.C.; Milliken, G.A.; Stroup, W.W.; Wolfinger, R.D. SAS system for Mixed Models; SAS Institute Inc.: Cary, NC, USA, 1996. [Google Scholar]

- Cianchetta, S.; Nota, M.; Polidori, N.; Galletti, S. Alkali pre-treatment and enzymatic hydrolysis of Arundo donax for single cell oil production. Environ. Eng. Manag. J. 2019, 18, 1693–1701. [Google Scholar]

- Lemões, J.S.; e Silva, C.F.L.; Avila, S.P.F.; Montero, C.R.S.; e Silva, S.D.D.A.; Samios, D.; Peralba, M.D.C.R. Chemical pretreatment of Arundo donax L. for second-generation ethanol production. Electron. J. Biotechn. 2018, 31, 67–74. [Google Scholar] [CrossRef]

- Xiao, B.; Sun, X.F.; Sun, R. Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw. Polym. Degrad. Stab. 2001, 74, 307–319. [Google Scholar] [CrossRef]

- Liu, X.; Zicari, S.M.; Liu, G.; Li, Y.; Zhang, R. Pretreatment of wheat straw with potassium hydroxide for increasing enzymatic and microbial degradability. Bioresour. Technol. 2015, 185, 150–157. [Google Scholar] [CrossRef]

- Asghar, U.; Irfan, M.; Nadeem, M.; Nelofer, R.; Syed, Q. Effect of KOH pretreatment on lignocellulosic waste to be used as for ethanol production. Iran. J. Sci. Technol. Trans. Sci. 2017, 41, 659–663. [Google Scholar] [CrossRef]

- Sharma, R.; Palled, V.; Sharma-Shivappa, R.R.; Osborne, J. Potential of potassium hydroxide pretreatment of Switchgrass for fermentable sugar Production. Appl. Biochem. Biotechnol. 2013, 169, 761–772. [Google Scholar] [CrossRef] [PubMed]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Shilpi, S.; Lamb, D.; Bolan, N.; Seshadri, B.; Choppala, G.; Naidu, R. Waste to watt: Anaerobic digestion of wastewater irrigated biomass for energy and fertiliser production. J. Environ. Manag. 2019, 239, 73–83. [Google Scholar] [CrossRef] [PubMed]

- Ceotto, E.; Vasmara, C.; Marchetti, R.; Cianchetta, S.; Galletti, S. Biomass and methane yield of giant reed (Arundo donax L.) as affected by single and double annual harvest. GCB Bioenergy 2021, 1–15. [Google Scholar] [CrossRef]

- Li, L.; Chen, C.; Zhang, R.; He, Y.; Wang, W.; Liu, G. Pretreatment of corn stover for methane production with the combination of potassium hydroxide and calcium hydroxide. Energ. Fuel. 2015, 29, 5841–5846. [Google Scholar] [CrossRef]

- Moset, V.; Xavier, C.d.A.N.; Feng, L.; Wahid, R.; Møller, H.B. Combined low thermal alkali addition and mechanical pre-treatment to improve biogas yield from wheat straw. J. Clean Prod. 2018, 172, 1391–1398. [Google Scholar] [CrossRef]

- Sawatdeenarunat, C.; Surendra, K.C.; Takara, D.; Oechsner, H.; Khanal, S.K. Anaerobic digestion of lignocellulosic biomass: Challenges and opportunities. Bioresour. Technol. 2015, 178, 178–186. [Google Scholar] [CrossRef]

- Field, J.A.; Lettinga, G. The methanogenic toxicity and anaerobic degradability of a hydrolyzable tannin. Water Res. 1987, 21, 367–374. [Google Scholar] [CrossRef]

- Kayembe, K.; Basosila, L.; Mpiana, P.T.; Sikulisimwa, P.C.; Mbuyu, K. Inhibitory ffects of phenolic monomers on methanogenesis in anaerobic digestion. Br. Microbiol. Res. J. 2013, 3, 32–41. [Google Scholar] [CrossRef]

- Vasmara, C.; Marchetti, R. Spent coffee grounds from coffee vending machines as feedstock for biogas production. Environ. Eng. Manag. J. 2018, 17, 2813–2821. [Google Scholar]

| Trait | Mean (SD) | |

|---|---|---|

| Total solids (TS), %FW 1 | 94.81 | (0.02) |

| Volatile solids (VS), %FW | 89.62 | (1.80) |

| Ash, %FW | 5.19 | (0.01) |

| pH in water | 5.40 | (0.30) |

| Total N, %DM 2 | 0.39 | (0.05) |

| Total C, %DM | 46.70 | (0.60) |

| Total P, %DM | 0.05 | (0.00) |

| C/N, mol/mol | 142 | (21) |

| Cellulose, %DM | 43.1 | (1.5) |

| Hemicellulose, %DM | 23.6 | (0.8) |

| Lignin, %DM | 11.4 | (0.5) |

| Reducing Sugar Yield | ||||

|---|---|---|---|---|

| Pre-Treatment 1 | mg g−1 Pre-Treated Dry Biomass | mg g−1 Initial Dry Biomass | ||

| GR | 72 | d 2 | 72 | d |

| T | 129 | c | 129 | c |

| Tw | 54 | d | 49 | d |

| K | 336 | a | 336 | a |

| Kw | 301 | b | 277 | b |

| Pre-Treatment 1 | ||

|---|---|---|

| Tw | Kw | |

| Trait | Mean (SD) | Mean (SD) |

| TS, % retained 2 | 94.67 (0.19) | 81.20 (0.06) |

| VS, % retained | 95.00 (0.23) | 83.90 (0.13) |

| Cellulose, %DM 3 | 45.23 (0.03) | 52.68 (0.45) |

| Hemicellulose, %DM | 22.58 (0.23) | 21.81 (0.06) |

| Lignin, %DM | 11.32 (0.06) | 11.77 (0.22) |

| Parameters 2 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SMY | Rmax | λ | Time Mmax | CH4 max | AMP | |||||||

| mL CH4 g−1 VS | mL CH4 d−1 | d | d | % | mL CH4 g−1 VS | |||||||

| Pre-Treatment 1 | ||||||||||||

| GR | 192 | b 3 | 4.26 | b | 1.70 | b | 46.8 | a | 47 | c | 192 | b |

| T | 198 | b | 4.95 | b | 2.38 | b | 42.4 | b | 49 | bc | 198 | b |

| Tw | 203 | b | 5.02 | b | 2.66 | b | 43.5 | ab | 48 | bc | 193 | b |

| K | 231 | a | 6.03 | a | 4.20 | a | 42.5 | b | 58 | a | 231 | a |

| Kw | 232 | a | 5.23 | ab | 1.69 | b | 46.1 | a | 52 | b | 195 | b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasmara, C.; Cianchetta, S.; Marchetti, R.; Ceotto, E.; Galletti, S. Potassium Hydroxyde Pre-Treatment Enhances Methane Yield from Giant Reed (Arundo donax L.). Energies 2021, 14, 630. https://doi.org/10.3390/en14030630

Vasmara C, Cianchetta S, Marchetti R, Ceotto E, Galletti S. Potassium Hydroxyde Pre-Treatment Enhances Methane Yield from Giant Reed (Arundo donax L.). Energies. 2021; 14(3):630. https://doi.org/10.3390/en14030630

Chicago/Turabian StyleVasmara, Ciro, Stefano Cianchetta, Rosa Marchetti, Enrico Ceotto, and Stefania Galletti. 2021. "Potassium Hydroxyde Pre-Treatment Enhances Methane Yield from Giant Reed (Arundo donax L.)" Energies 14, no. 3: 630. https://doi.org/10.3390/en14030630