Study on Thermo-Hydro-Mechanical Coupling and the Stability of a Geothermal Wellbore Structure

Abstract

1. Introduction

2. THM Coupling Models of the Wellbore in the Process of Water Injection

3. Numerical Analysis of the Geothermal Wellbore Structure during Water Injection

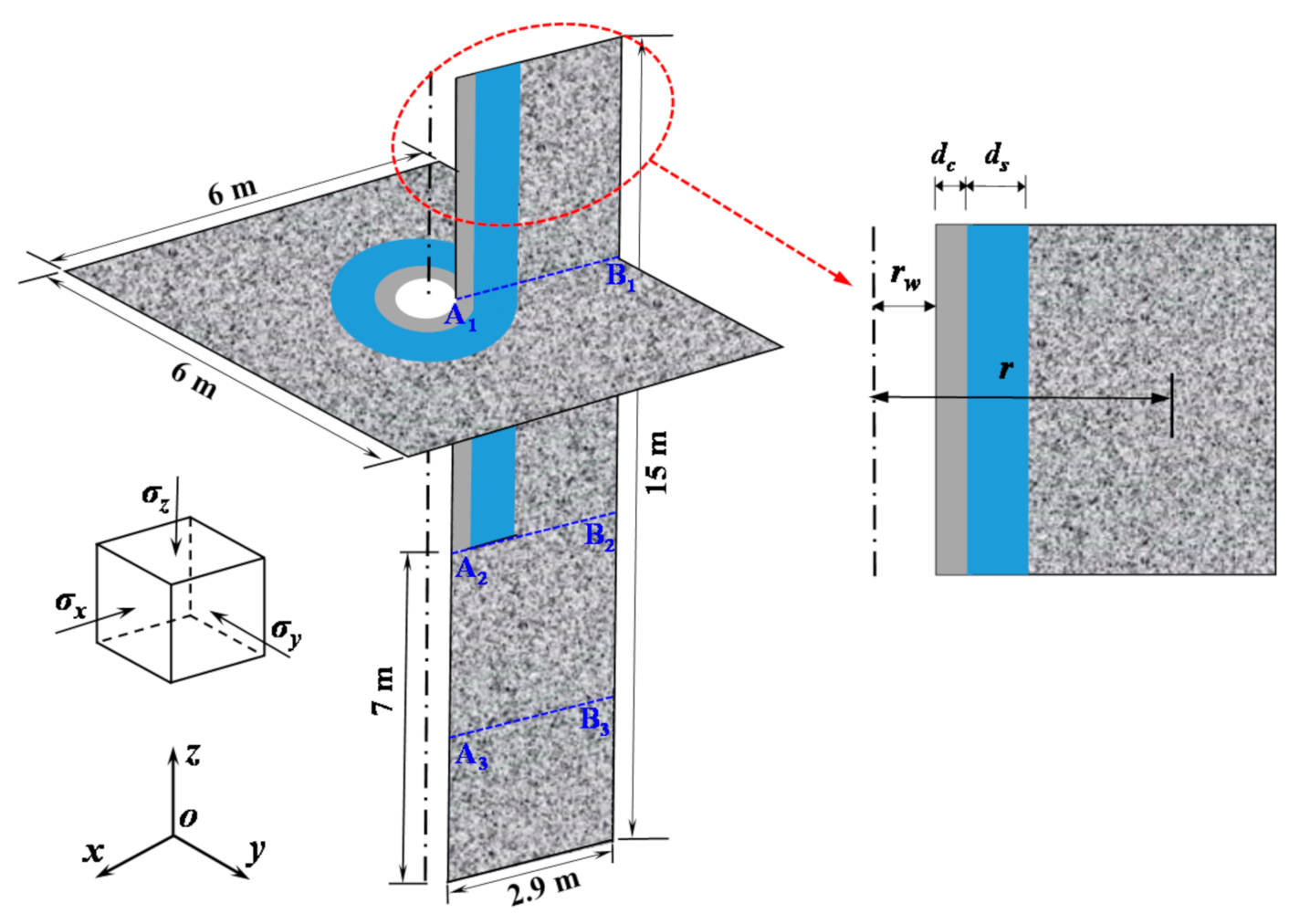

3.1. Wellbore Geometry Model

3.2. Procedures of Numerical Simulation

- (1)

- Stress equilibrium at the initial deformation state

- (2)

- Thermal and fluid loading during cold water injection

- (3)

- THM coupling simulation of water injection

- Steady and static thermal analysis was carried out to determine the temperature fields around the wellbore. As the main driving mechanism, it is of great importance to capture the thermal load correctly.

- The thermal loads achieved from temperature fields were applied to the hydro-mechanical model.

- THM coupling analysis was conducted to study the thermal stress accumulation and failure process of the geothermal wellbore structure.

4. Results and Discussion

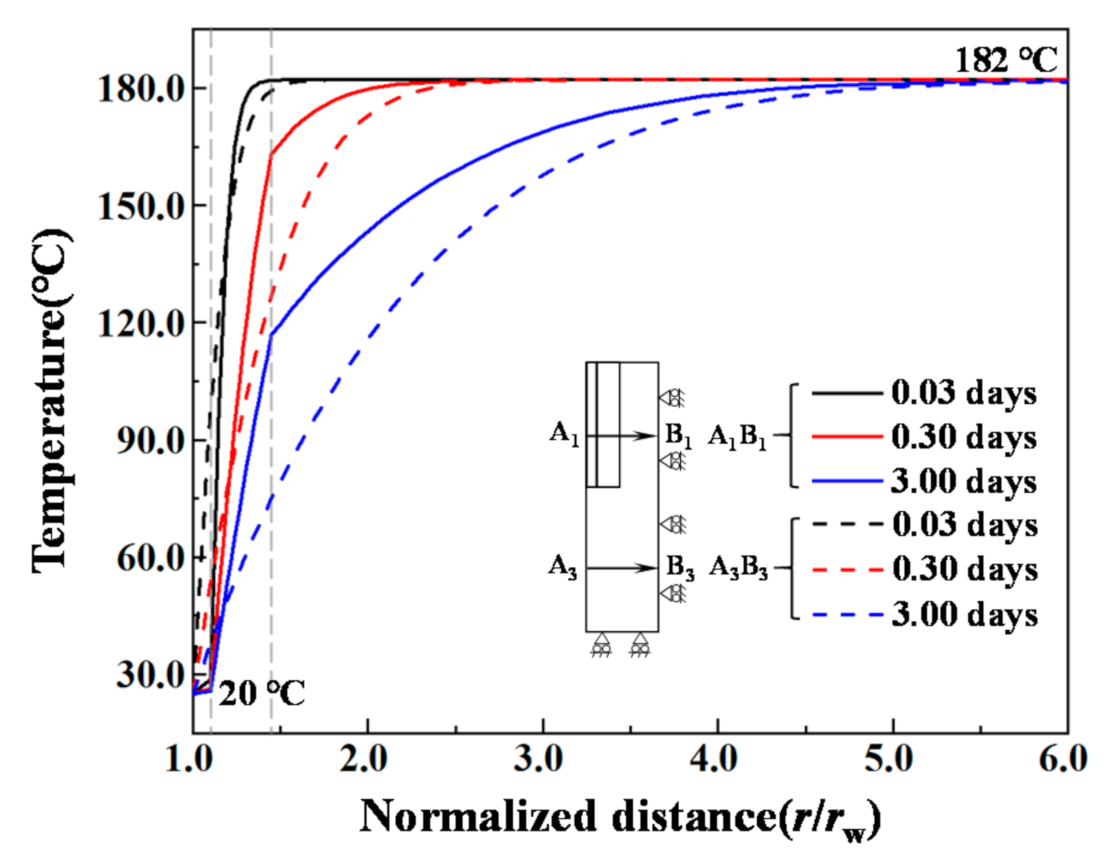

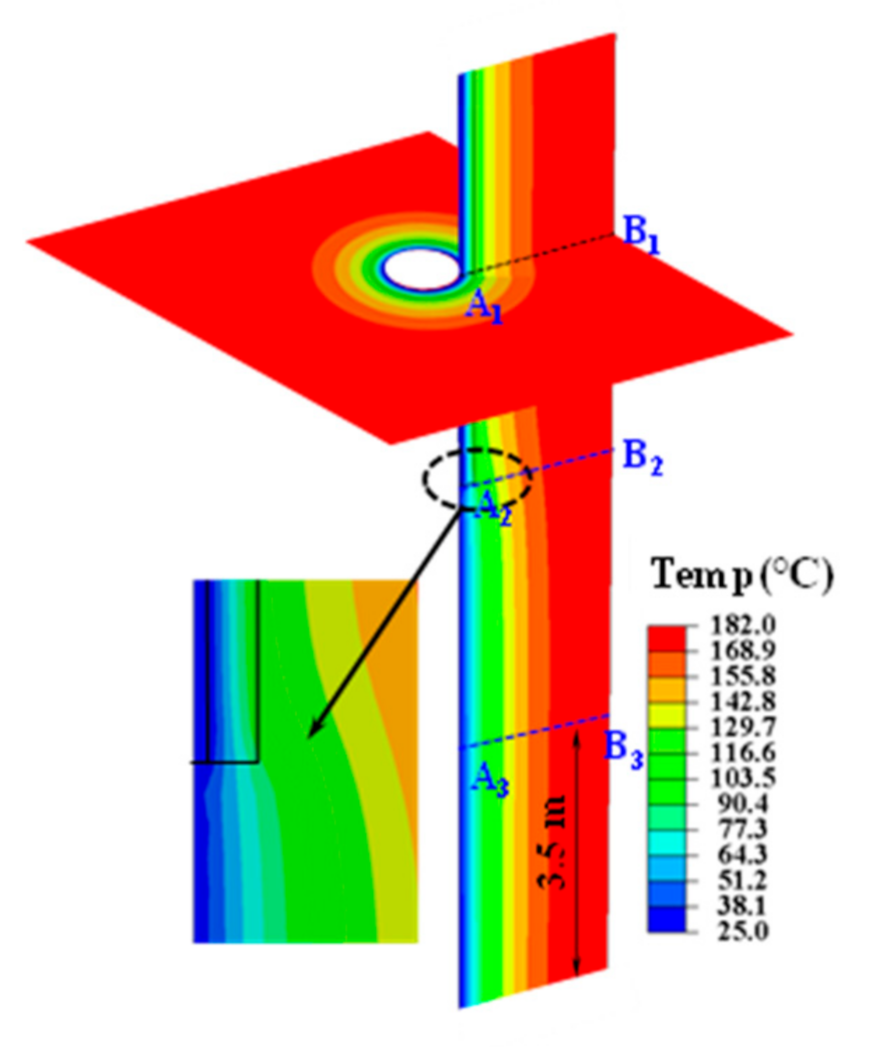

4.1. Temperature Distribution of the Geothermal Wellbore during the Water Injection

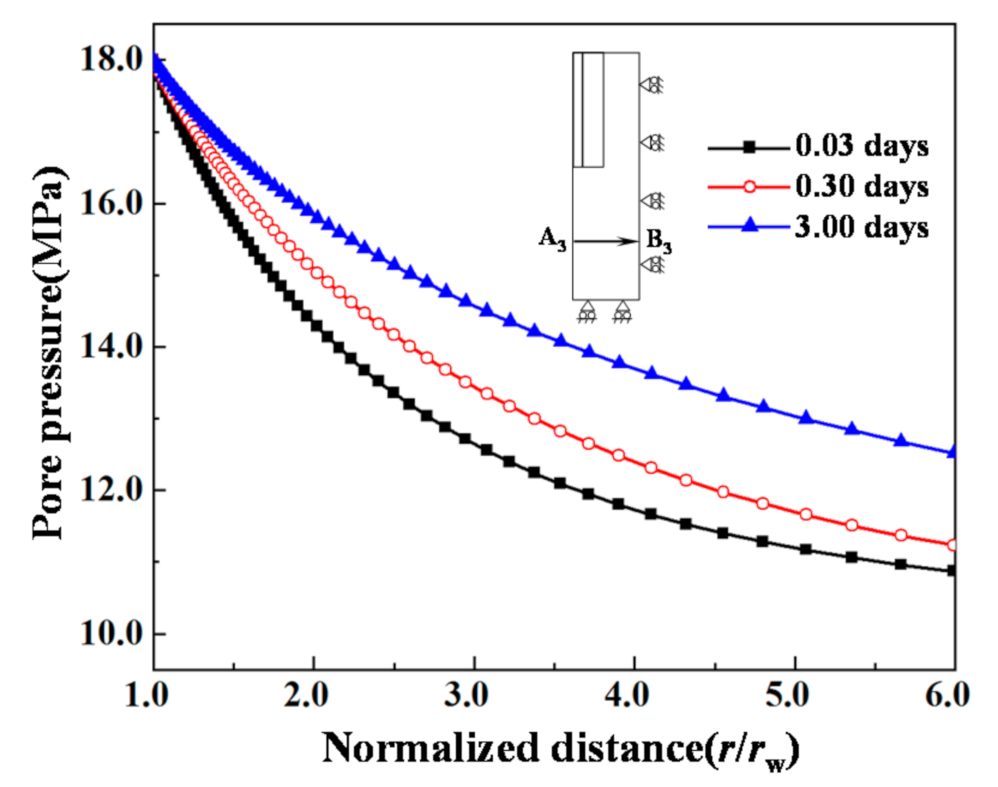

4.2. Pore Pressure of Near-Wellbore Formations during Water Injection

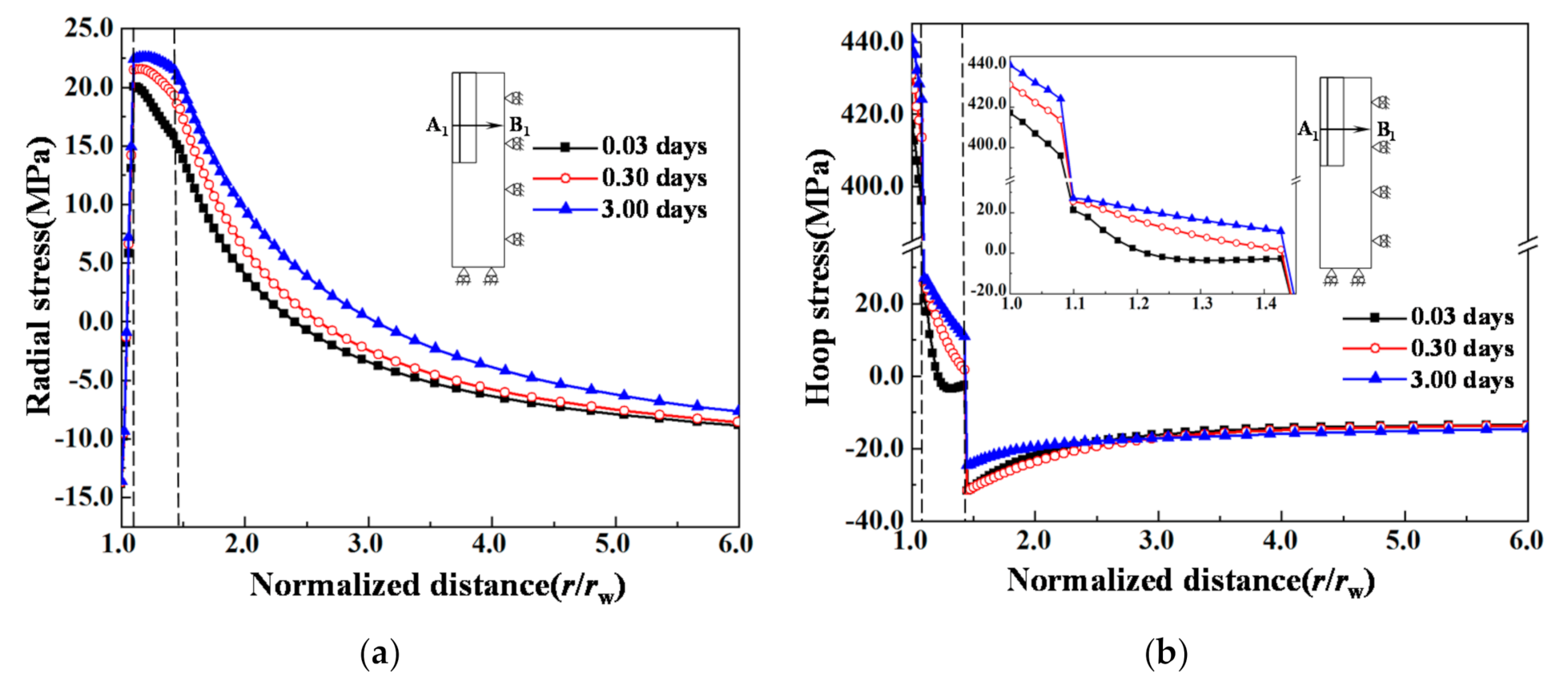

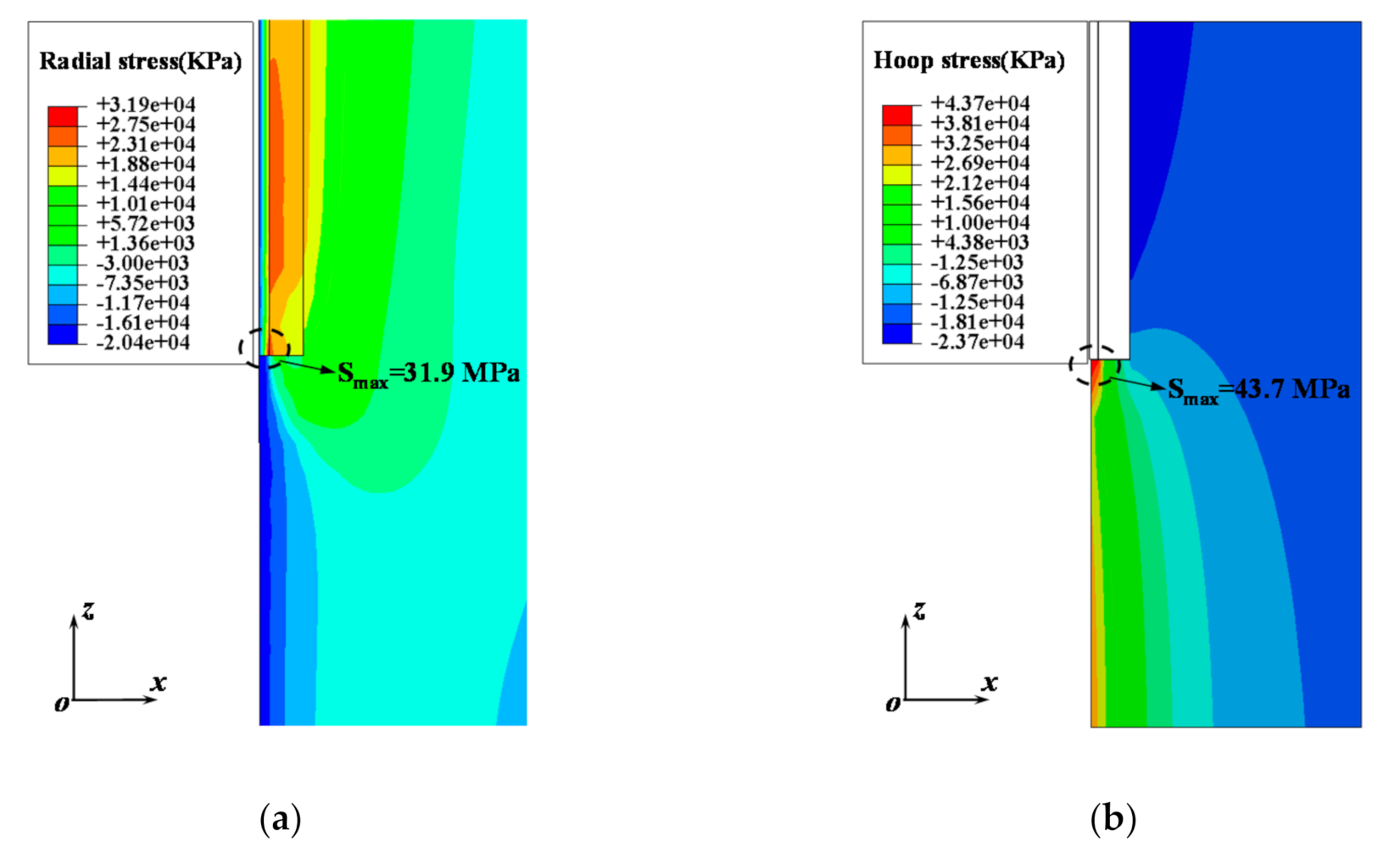

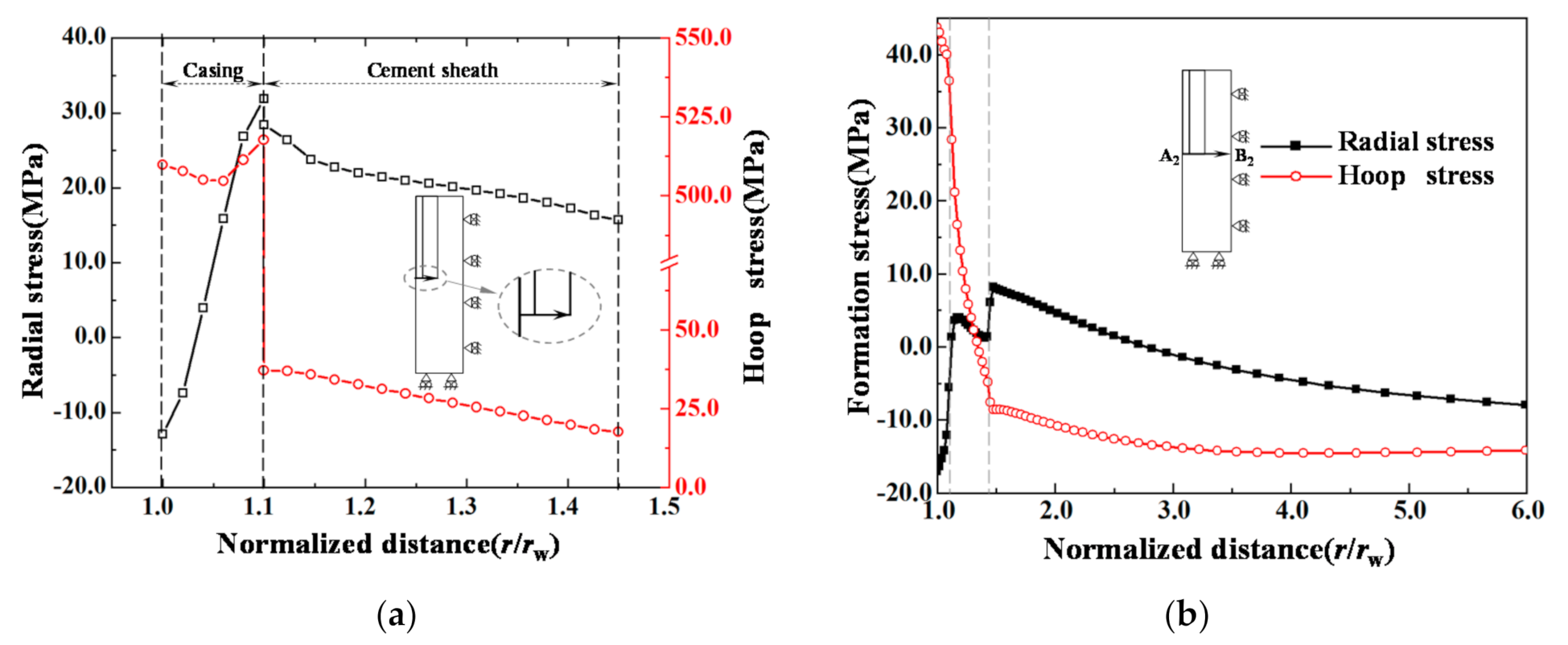

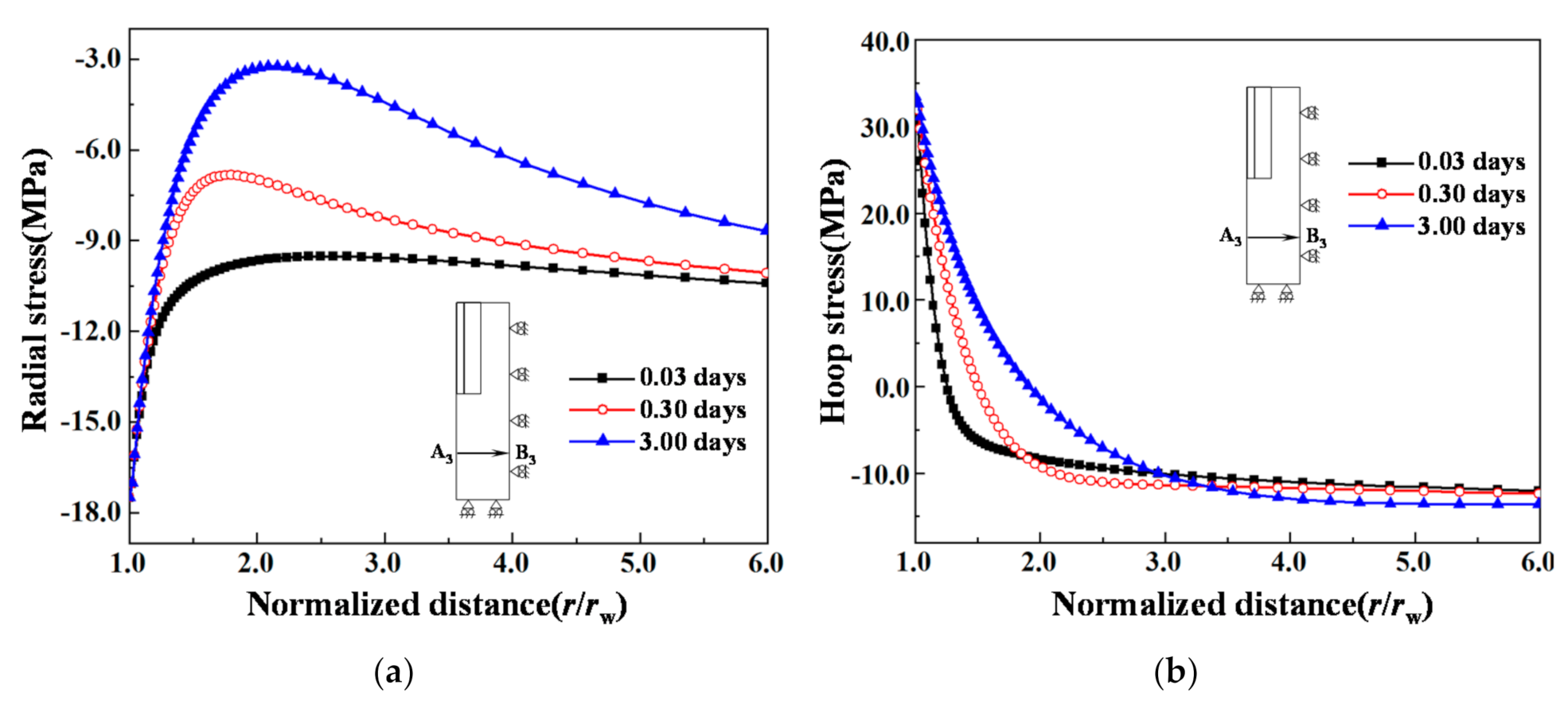

4.3. THM Coupling Stress Near the Wellbore during the Water Injection

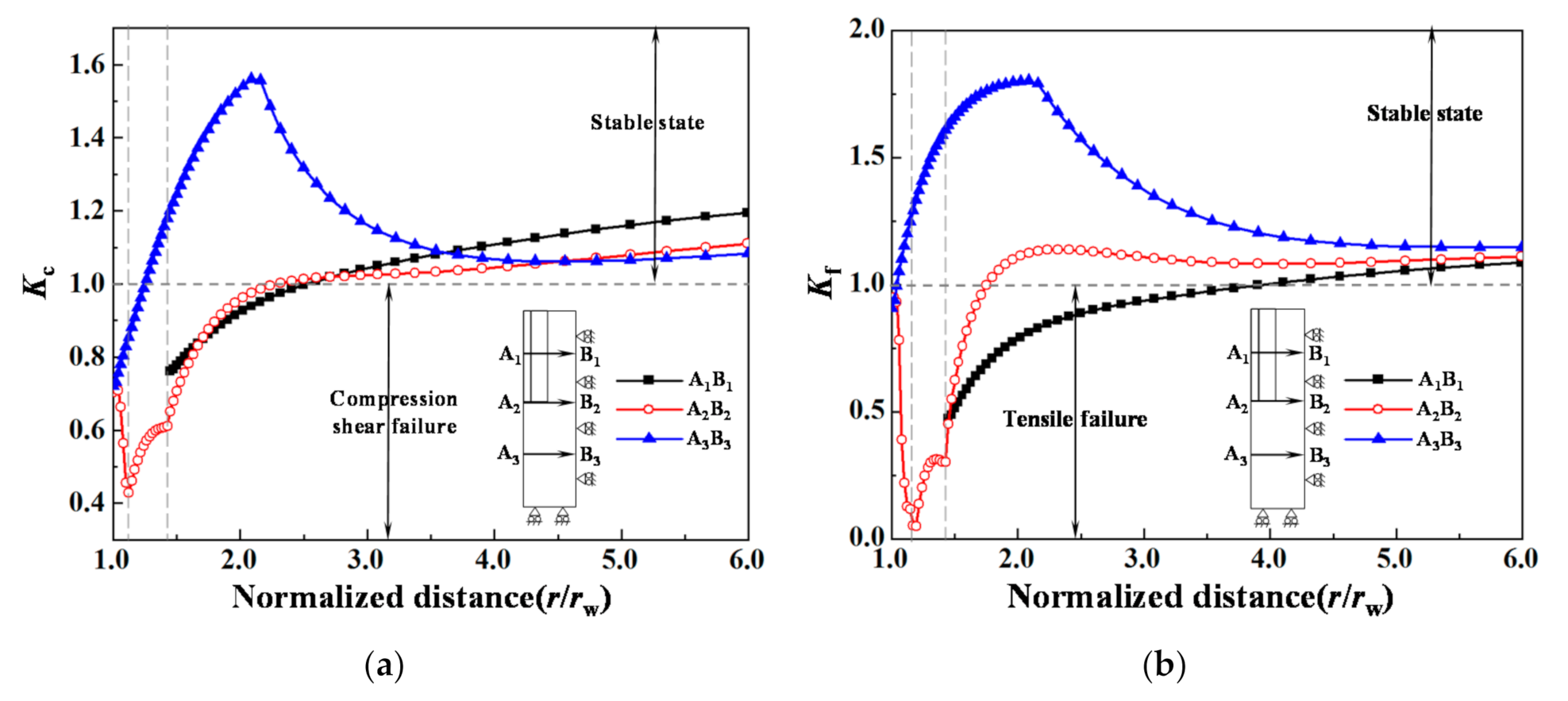

4.4. Instability Coefficient of the Wellbore Structure

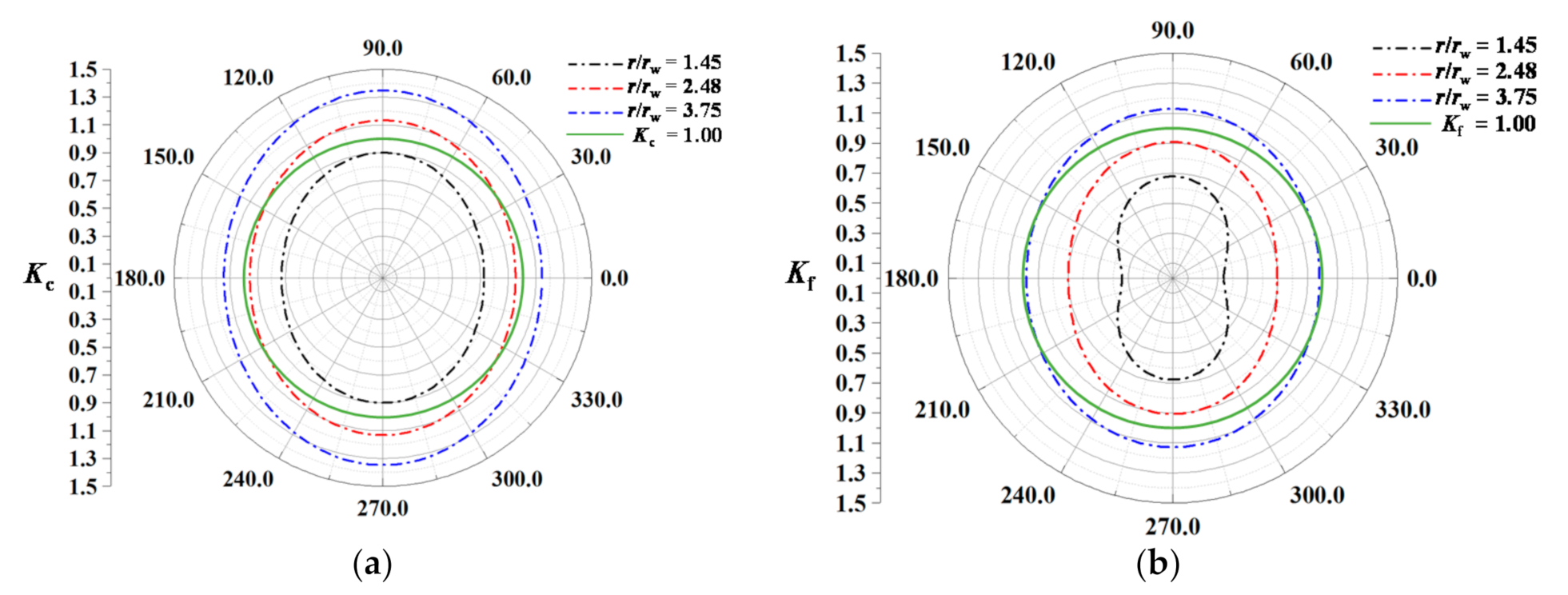

4.5. Stability Coefficient Evaluation of Wellbore

5. Conclusions

- (1)

- The injected fluid diffused from the open-hole wall to the distal end along the radial and axial directions of the well, simultaneously. The stress caused by the excess pore pressure led to debonding of the interface between the cement sheath and the formations, which greatly shortened the service life of the geothermal well.

- (2)

- During the cold water injection, the thermal stress concentration appeared at two interfaces of the geothermal wellbore structure, i.e., section A1B1 of the casing–cement sheath cementation surface and section A2B2 of the local open-hole completion segment. The radial tensile stress concentration mainly occurred at section A1B1. The radial tensile stress was up to 31.9 MPa, which was likely to cause debonding at the casing–cement sheath interface. While at section A2B2 the stress concentration was dominated by the hoop tensile stress, which was up to 43.7 MPa, about 2.08 times the tensile strength of the cement sheath.

- (3)

- Due to the partial casing completion, the collapses and fractures of the wellbore were severe in the formations at section A2B2. The wellbore collapse and the rupture in section A1B1 were relatively small; however, the damaged region was wider. The wellbore structure at the open-hole completion A3B3 section was less affected by the variations of temperature and pore pressure. Therefore, both the collapse damage degree and damage region were much smaller than at sections A1B1 and A2B2.

- (4)

- The method presented in this study was effective for the THM coupling analysis of the wellbore structure. This method can provide a mechanical basis for wellbore structural failure control and the safety evaluation of a geothermal wellbore.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Pang, M.; Han, J.; Li, Y.; Wang, C. Geothermal power in China: Development and performance evaluation. Renew. Sustain. Energy Rev. 2019, 116, 109431. [Google Scholar] [CrossRef]

- Lu, S.-M. A global review of enhanced geothermal system (EGS). Renew. Sustain. Energy Rev. 2018, 81, 2902–2921. [Google Scholar] [CrossRef]

- Tester, J.W. The Future of Geothermal Energy—Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century; MIT-Massachusetts Institute of Technology: Cambridge, MA, USA, 2006; pp. 50–52. [Google Scholar]

- Pandey, S.; Chaudhuri, A.; Kelkar, S. A coupled thermo-hydro-mechanical modeling of fracture aperture alteration and reservoir deformation during heat extraction from a geothermal reservoir. Geothermics 2017, 65, 17–31. [Google Scholar] [CrossRef]

- Wei, G.; Meng, J.; Du, X.; Yang, Y. Performance Analysis on a Hot Dry Rock Geothermal Resource Power Generation System Based on Kalina Cycle. Energy Procedia 2015, 75, 937–945. [Google Scholar] [CrossRef]

- Rawal, C. 3D Modeling of Coupled Rock Deformation and Thermo-Poro-Mechanical Processes in Fractures. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, May 2012. [Google Scholar]

- Ye, Z.; Janis, M.; Ghassemi, A. In Injection-Driven Shear Slip and The Coupled Permeability Evolution of Granite Fractures for EGS Stimulation, American Rock Mechanics Association, 51st US Rock Mechanics/Geomechanics Symposium. 2017. Available online: https://agupubs.onlinelibrary.wiley.com/doi/10.1029/2018JB016045 (accessed on 27 January 2021).

- Anderson, A.; Rezaie, B. Geothermal technology: Trends and potential role in a sustainable future. Appl. Energy 2019, 248, 18–34. [Google Scholar] [CrossRef]

- Kumari, W.; Ranjith, P. Sustainable development of enhanced geothermal systems based on geotechnical research—A review. Earth-Sci. Rev. 2019, 199, 102955. [Google Scholar] [CrossRef]

- Pandey, S.; Vishal, V.; Chaudhuri, A. Geothermal reservoir modeling in a coupled thermo-hydro-mechanical-chemical approach: A review. Earth-Sci. Rev. 2018, 185, 1157–1169. [Google Scholar] [CrossRef]

- Liu, Q.S.; Xu, X.C.; Yamaguchi, T.; Cho, A. Testing study on mechanical properties of the three gorges granite concern-ing temperature and time. Chin. J. Rock Mech. Eng. 2001, 20, 715–719. [Google Scholar]

- Xi, B.; Zhao, Y.; Wan, Z.; Dong, F.; Zhang, N. Rheological experimental investigation on surrounding rock mass of gran-ite under high temperature and hydrostatic stress. Chin. J. Rock Mech. Eng. 2008, 27, 1659–1666. [Google Scholar]

- Xi, B.P.; Zhao, Y.S.; Wan, Z.J.; Zhao, J.C.; Wang, Y. Study of constitutive equation of granite rheological model with thermo-mechanical coupling effects. Chin. J. Rock Mech. Eng. 2009, 28, 956–967. [Google Scholar]

- Dusseault, M.B. In Stress Changes in Thermal Operations, Spe International Thermal Operations Symposium; Society of Petroleum Engineers, Inc.: 1993. Available online: https://onepetro.org/SPEITOHOS/proceedings-abstract/93ITOS/All-93ITOS/SPE-25809-MS/55797 (accessed on 27 January 2021).

- Hosseini, S.M.; Kord, S.; Hashemi, A.; Dashti, H. Mechanistic Modeling of Low Salinity Water Injection under Fracturing Condition in Carbonate Reservoirs: Coupled Geochemical and Geomechanical Simulation Study. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 23–25 October 2018. [Google Scholar]

- Maury, V.; Idelovici, J.L. Safe Drilling of HP/HT Wells, The Role of the Thermal Regime in Loss and Gain Phenomenon. Soc. Pet. Eng. 1995, 29428, 819–829. [Google Scholar]

- Tao, Q.; Ghassemi, A. Poro-thermoelastic borehole stress analysis for determination of the in situ stress and rock strength. Geothermics 2010, 39, 250–259. [Google Scholar] [CrossRef]

- Ge, J.; Ghassemi, A. Analysis of Failure Potential around a Hydraulic Fracture in Jointed Rock. In Proceeding of the 42nd US Rock Mechanics Symposium and 2nd U.S.-Canada Rock Mechanics Symposium, San Francisco, CA, USA, 29 June–2 July 2008. [Google Scholar]

- Xi, B.; Zhao, J.; Zhao, Y.; Zhu, H.; Wu, J. Key technologies of hot dry rock drilling during construction. Chin. J. Rock Mech. Eng. 2011, 30, 2234–2243. [Google Scholar]

- Jeanne, P.; Rutqvist, J.; Dobson, P.F.; Garcia, J.; Walters, M.; Hartline, C.; Borgia, A. Geomechanical simulation of the stress tensor rotation caused by injection of cold water in a deep geothermal reservoir. J. Geophys. Res. Solid Earth 2015, 120, 8422–8438. [Google Scholar] [CrossRef]

- Rutqvist, J.; Jeanne, P.; Dobson, P.F.; Garcia, J.; Hartline, C.; Hutchings, L.; Singh, A.; Vasco, D.W.; Walters, M. The Northwest Geysers EGS Demonstration Project, California—Part 2: Modeling and interpretation. Geothermics 2016, 63, 120–138. [Google Scholar] [CrossRef]

- Zhu, Z.X.; Du, H.T.; Zhang, W.B. Analysis of thermal stress on wellbore stability during gas drilling. Chin. J. Drill. Prod. Technol. 2017, 40, 25–27. [Google Scholar]

- Huang, X.; Zhu, J.; Li, J.; Lan, C.; Jin, X. Parametric study of an enhanced geothermal system based on thermo-hydro-mechanical modeling of a prospective site in Songliao Basin. Appl. Therm. Eng. 2016, 105, 1–7. [Google Scholar] [CrossRef]

- Li, W.; Soliman, M.; Han, Y. Microscopic numerical modeling of Thermo-Hydro-Mechanical mechanisms in fluid injection process in unconsolidated formation. J. Pet. Sci. Eng. 2016, 146, 959–970. [Google Scholar] [CrossRef]

- De Simone, S.; Vilarrasa, V.; Carrera, J.; Alcolea, A.; Meier, P. Thermal coupling may control mechanical stability of geothermal reservoirs during cold water injection. Phys. Chem. Earth Parts A/B/C 2013, 64, 117–126. [Google Scholar] [CrossRef]

- Salimzadeh, S.; Nick, H.; Zimmerman, R. Thermoporoelastic effects during heat extraction from low-permeability reservoirs. Energy 2018, 142, 546–558. [Google Scholar] [CrossRef]

- Salimzadeh, S.; Paluszny, A.; Nick, H.M.; Zimmerman, R.W. A three-dimensional coupled thermo-hydro-mechanical model for deformable fractured geothermal systems. Geothermics 2018, 71, 212–224. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, J.; Qu, Z.Q. Thermo-hydro-mechanical coupling model and comprehensive evaluation method of high temperature geothermal extraction. Prog. Geophys. 2019, 34, 0668–0675. [Google Scholar] [CrossRef]

- Meng, M.; Chen, P.; Ren, R. Statistic evaluation of failure criteria in wellbore stability with temperature effects. Fuel 2019, 252, 730–752. [Google Scholar] [CrossRef]

- Ding, J.F.; Wang, S.M. Multi-region and multi-physics coupled 3D numerical simulation of enhanced geothermal system. J. Univ. Chin. Acad. Sci. 2019, 36, 694–701. [Google Scholar]

- Zhao, Z.H.; Liu, G.H.; Xu, H.R. A robust numerical modeling framework for coupled thermo-hydro-mechanical process in deep geo-energy engineering. Eng. Mech. 2020, 37, 1–18. [Google Scholar] [CrossRef]

- Bazyrov, I.; Glazyrina, A.; Lukin, S.; Alchibaev, D.; Salishchev, M.; Ovcharenko, Y. Time-dependent hydro-geomechanical res-ervoir simulation of field production. Procedia Struct. Integr. 2017, 6, 228–235. [Google Scholar] [CrossRef]

- Rutqvist, J.; Wu, Y.-S.; Tsang, C.-F.; Bodvarsson, G. A modeling approach for analysis of coupled multiphase fluid flow, heat transfer, and deformation in fractured porous rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 429–442. [Google Scholar] [CrossRef]

- Pang, M.; Xu, G.; Sun, F.; Xue, S.; Wang, Y.; Incorparated, C.P.-G. Formation Damage and Wellbore Stability of Soft Mudstone Subjected to Thermal–Hydraulic–Mechanical Loading. J. Eng. Sci. Technol. Rev. 2019, 12, 95–102. [Google Scholar] [CrossRef]

- Hu, L.; Winterfeld, P.H.; Fakcharoenphol, P.; Wu, Y.-S. A novel fully-coupled flow and geomechanics model in enhanced geothermal reservoirs. J. Pet. Sci. Eng. 2013, 107, 1–11. [Google Scholar] [CrossRef]

- Renaud, T.; Verdin, P.; Falcone, G. Numerical simulation of a Deep Borehole Heat Exchanger in the Krafla geothermal system. Int. J. Heat Mass Transf. 2019, 143, 118496. [Google Scholar] [CrossRef]

- Yang, X.C.; Kang, F.X.; Wang, X.P. Hydrochmical features of geothermal reservoir geotemperature field in sand-stone porosity and enrichment mechanism of geothermal water: A case study of geothermal reservoir of Guantao For-mation in the Lubei. Acta Geol. Sin. 2019, 93, 738–750. [Google Scholar]

- Xue, S.; Wong, R.; Du, J. Maintaining Hydraulic Integrity of Structural Shale around a Thermal Well under Steam Stimulation. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 13–15 June 2006; p. 7. [Google Scholar]

- Wei, K.; Guan, Z.C.; Liao, H.L. Assessment method of borehole instability risk. J. China Univ. Pet. 2013, 37, 62–66. [Google Scholar]

| Parameters | Casing | Cement Sheath |

|---|---|---|

| Density (kg/m3) | 7800 | 3100 |

| Young’s modulus (GPa) | 230 | 13.5 |

| Poisson’s ratio (-) | 0.3 | 0.286 |

| Thermal expansion coefficient (1/°C) | 1.3 × 10−5 | 1.1 × 10−5 |

| Specific heat (J/kg·°C) | 461 | 837 |

| Thermal conductivity (W/m·°C) | 45 | 0.98 |

| Parameters | Value |

|---|---|

| Rock mass density (kg/m3) | 2600 |

| Young’s modulus (GPa) | 30 |

| Poisson’s ratio (-) | 0.25 |

| Cohesion (MPa) | 39 |

| Internal friction angle (°) | 52 |

| Tensile strength (MPa) | 21 |

| Rock mass permeability coefficient (m/s) | 1.2 × 10−13 |

| Porosity | 0.01 |

| Rock mass thermal conductivity (W/m·°C) | 3.5 |

| Rock mass specific heat (J/kg·°C) | 900 |

| Rock mass thermal expansion coefficient (1/°C) | 5 × 10−6 |

| Density of water (kg/m3) | 1000 |

| Bulk modulus of water (GPa) | 2.5 |

| Thermal conductivity of water (W/m·°C) | 11.9 |

| Specific heat of water (J/kg·°C) | 40 |

| Thermal expansion coefficient of water (1/°C) | 2.08 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huan, X.; Xu, G.; Zhang, Y.; Sun, F.; Xue, S. Study on Thermo-Hydro-Mechanical Coupling and the Stability of a Geothermal Wellbore Structure. Energies 2021, 14, 649. https://doi.org/10.3390/en14030649

Huan X, Xu G, Zhang Y, Sun F, Xue S. Study on Thermo-Hydro-Mechanical Coupling and the Stability of a Geothermal Wellbore Structure. Energies. 2021; 14(3):649. https://doi.org/10.3390/en14030649

Chicago/Turabian StyleHuan, Xiaolin, Gao Xu, Yi Zhang, Feng Sun, and Shifeng Xue. 2021. "Study on Thermo-Hydro-Mechanical Coupling and the Stability of a Geothermal Wellbore Structure" Energies 14, no. 3: 649. https://doi.org/10.3390/en14030649

APA StyleHuan, X., Xu, G., Zhang, Y., Sun, F., & Xue, S. (2021). Study on Thermo-Hydro-Mechanical Coupling and the Stability of a Geothermal Wellbore Structure. Energies, 14(3), 649. https://doi.org/10.3390/en14030649