The Degree of Polymerization in a Prediction Model of Insulating Paper and the Remaining Life of Power Transformers

Abstract

:1. Introduction

2. Experimental Work

3. Correlation and Multilinear Regression

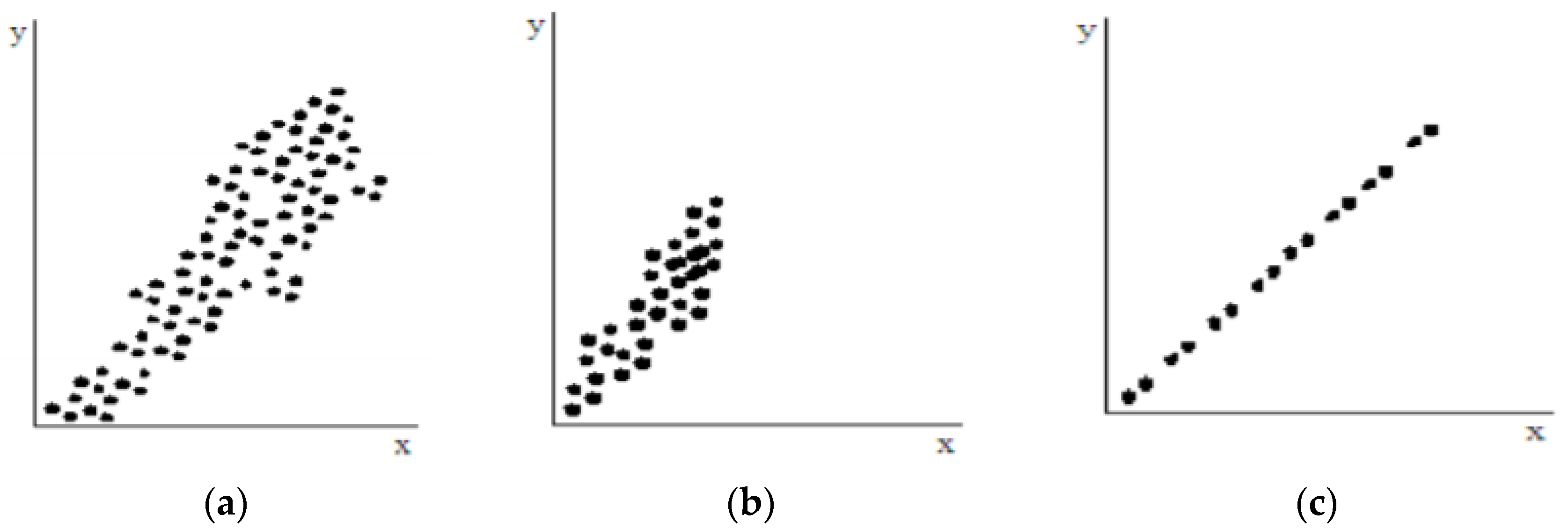

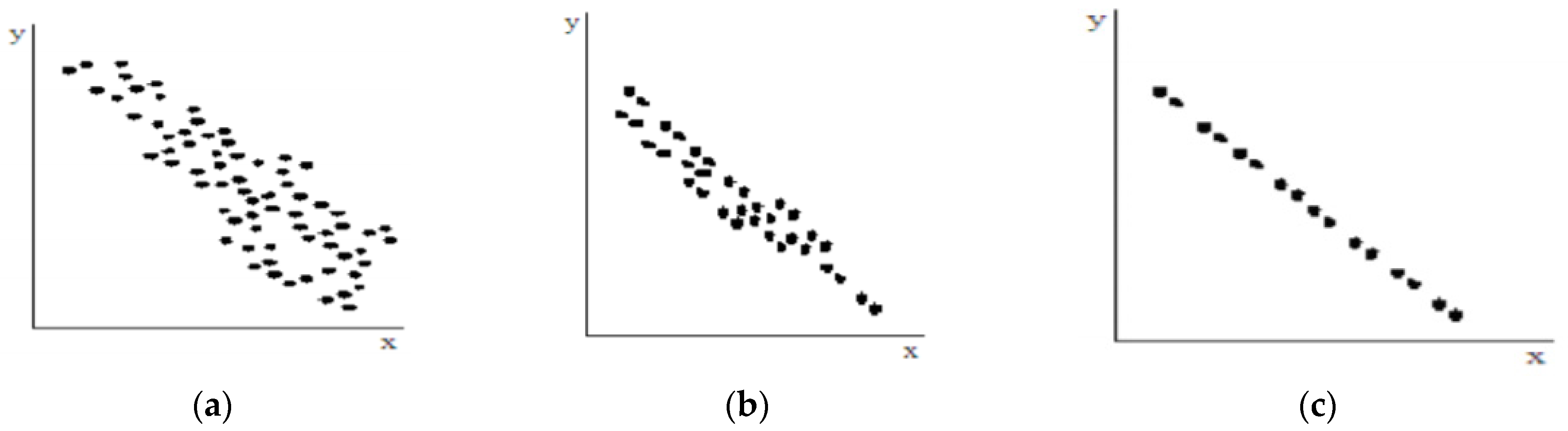

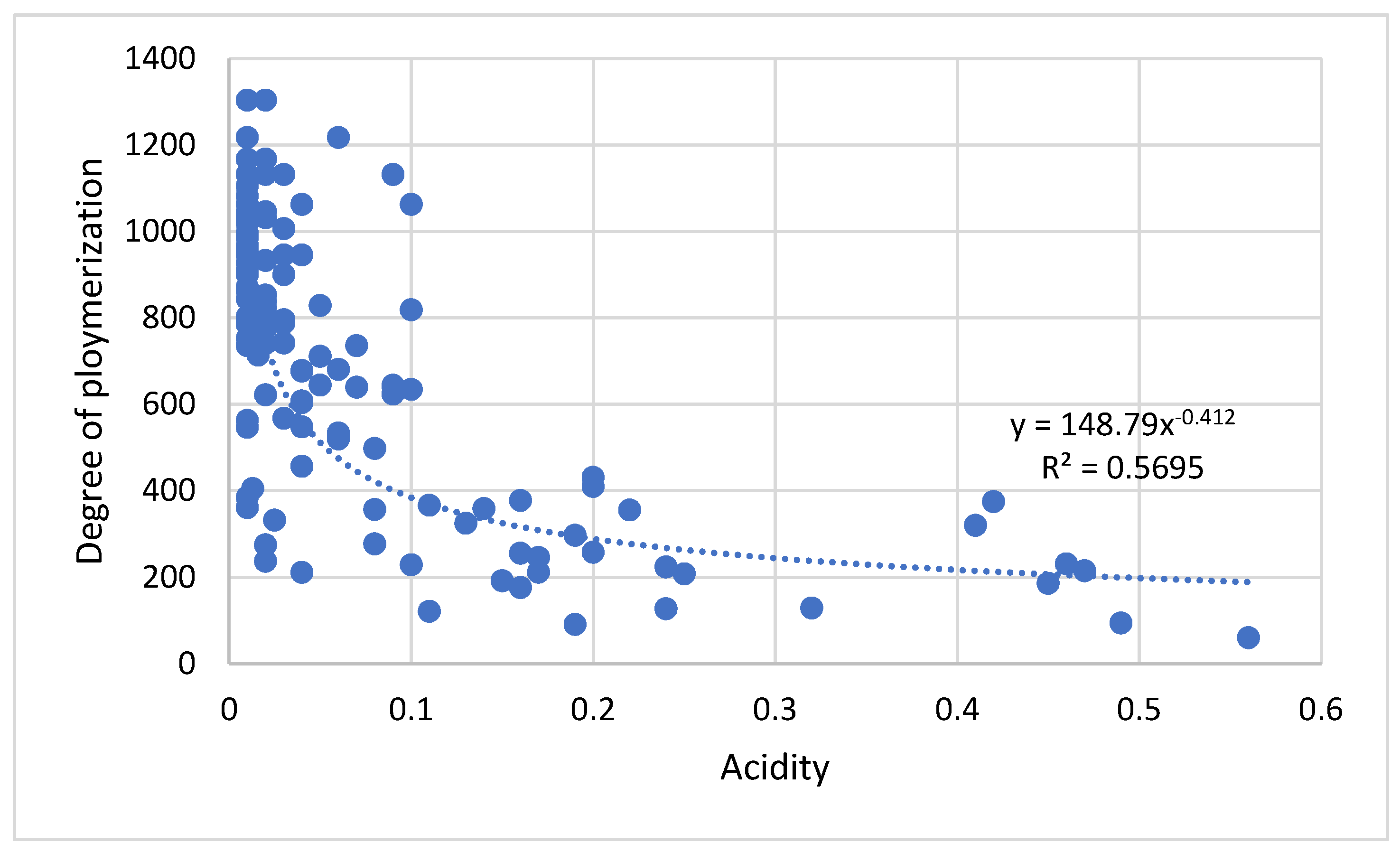

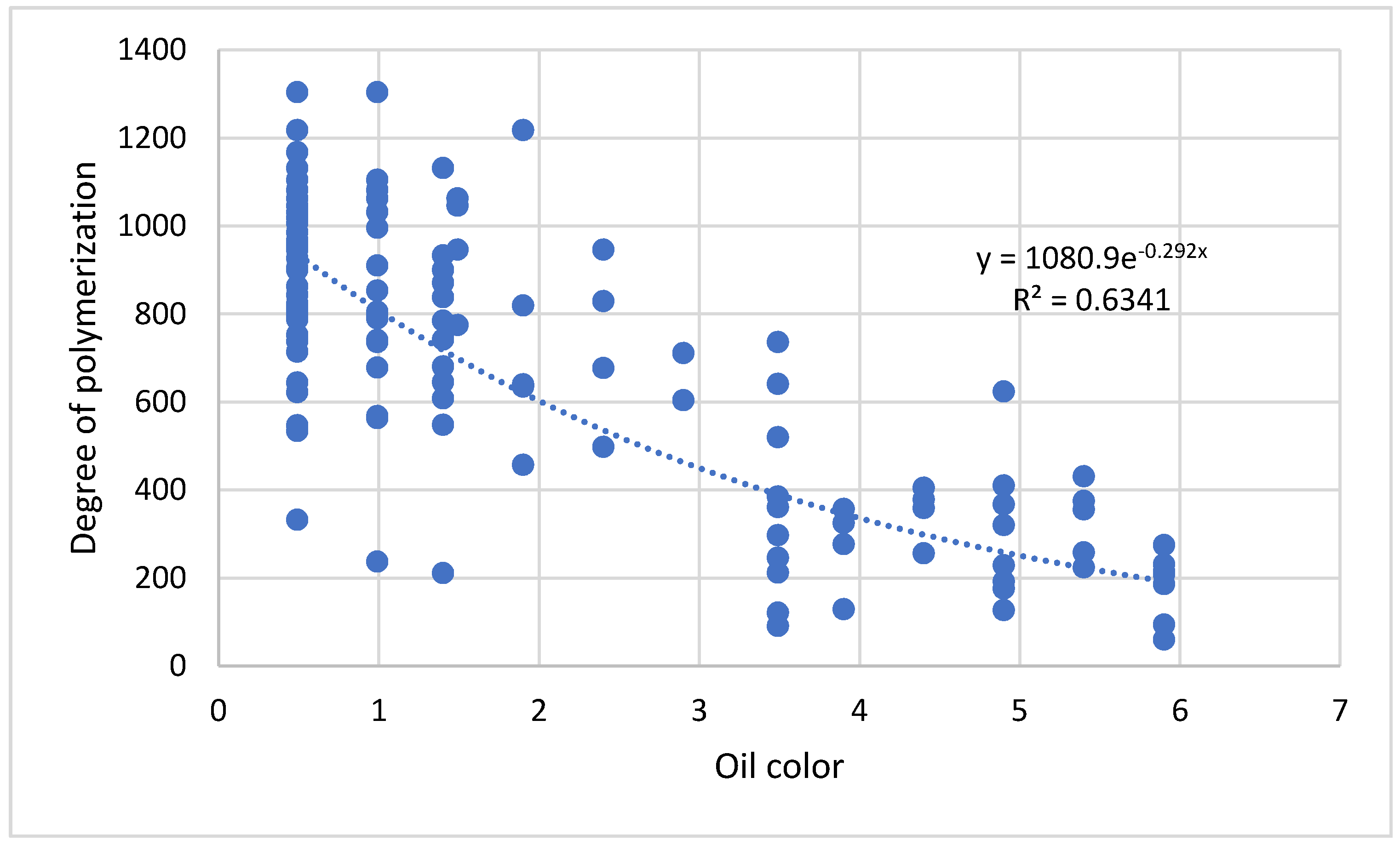

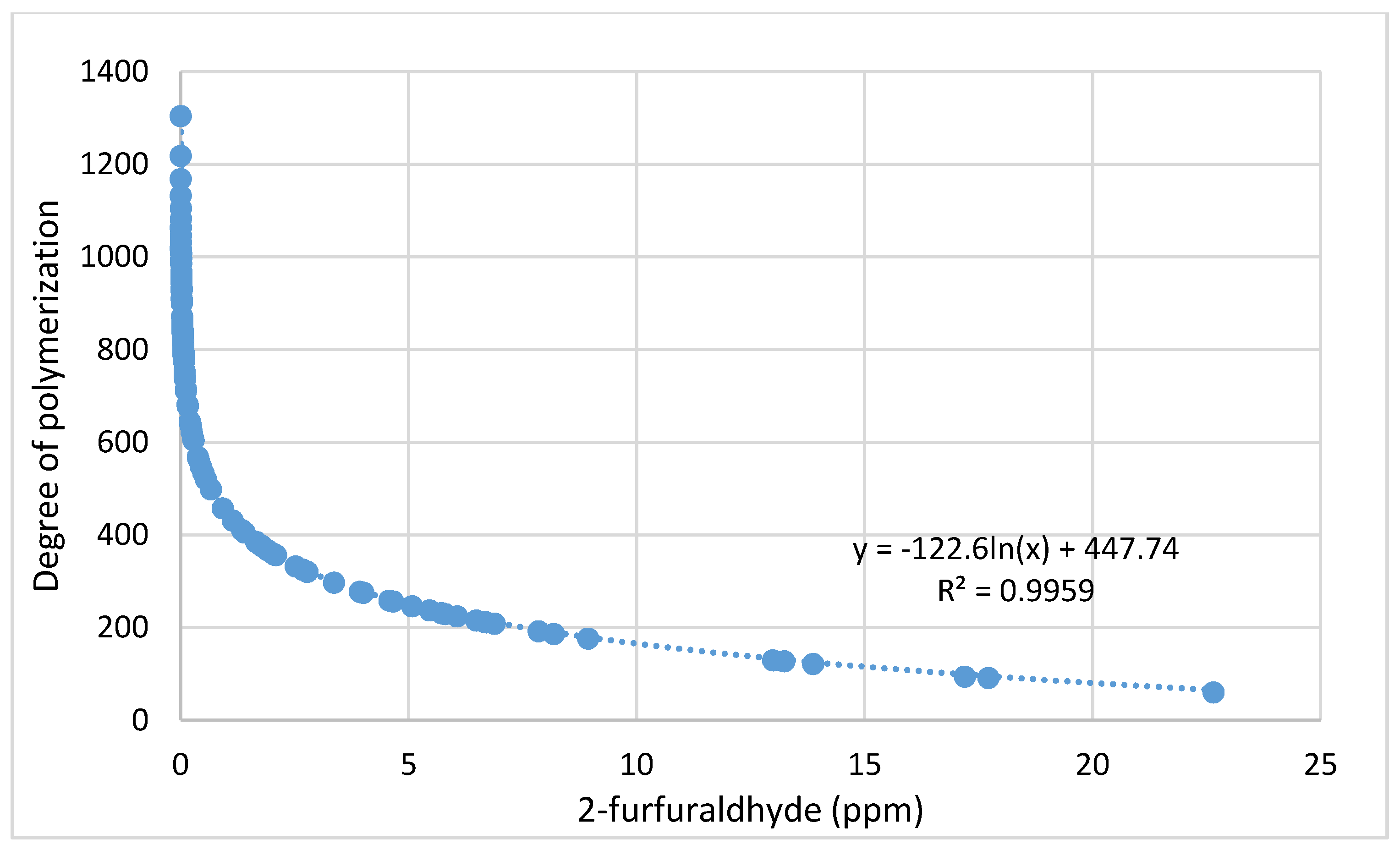

3.1. Correlation

3.2. Multilinear Regression

3.3. Statistical Parameters

4. Statistical Results and Discussions

| DP Empirical Formula | FA | Ref. | ||

|---|---|---|---|---|

| 1 | De Pablo 1 | ppm | [3,26] | |

| 2 | De Pablo 2 | ppm | [3,26] | |

| 3 | Chendong | ppm | [3,25] | |

| 4 | Burton | ppm | [26] | |

| 5 | Vuarchex | ppm | [26] | |

| 6 | Proposed Equation (9) | ppb |

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Prasojo, R.A.; Maulidevi, N.U.; Soedjarno, B.A.; Suwarno, S. Health Index Analysis of Power Transformer with Incomplete Paper Condition Data. In Proceedings of the 4th International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Chennai, India, 21–23 November 2019; pp. 1–4. [Google Scholar]

- Meissner, M.; Darmann, M.; Schober, S.; Mittelbach, M.; Sumereder, C. Reliability Study of Furan Level Analysis for Trans-former Health Prediction. In Proceedings of the 20th International Conference on Dielectric Liquids (ICDL), Roma, Italy, 23–27 June 2019. [Google Scholar]

- El-Aal, R.A.A.; Helal, K.; Hassan, A.M.M.; Dessouky, S.S. Prediction of transformers conditions and lifetime using furan compounds analysis. IEEE Access 2019, 7, 102264–102273. [Google Scholar] [CrossRef]

- Gouda, O.E.; El Dein, A.Z. Prediction of aged transformer oil and paper insulation. Electr. Power Compon. Syst. 2019, 47, 406–419. [Google Scholar] [CrossRef]

- Ghoneim, S.S.M.; Taha, I.B.M.; Elkalashy, N.I. Integrated ANN-based proactive fault diagnostic scheme for power trans-formers using dissolved gas analysis. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1838–1845. [Google Scholar] [CrossRef]

- Nugraha, B.H.; Kinkeldey, T.; Munster, T.; Werle, P. Algorithm for Estimating the Degree of Polymerization of Paper Insulation Impregnated with Inhibited Insulating Oil. In Proceedings of the 2nd International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Denpasar, Bali, Indonesia, 1–4 October 2019. [Google Scholar]

- Saha, T.K. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef] [Green Version]

- Pradhan, M. Assessment of the status of insulation during thermal stress accelerated experiments on transformer prototypes. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 227–237. [Google Scholar] [CrossRef]

- Abu Bakar, N.; Abu-Siada, A.; Islam, S. A Review on Chemical Diagnosis Techniques for Transformer Paper Insulation Deg-radation. In Proceedings of the Australasian Universities Power Engineering Conference, (AUPEC), Hobart, TAS, Australia, 29 September–3 October 2013. [Google Scholar]

- Allan, D. Recent Advances in the Analysis and Interpretation of Aged Insulation from Operating Power Transformers. In Proceedings of the 5th International Conference on Properties and Applications of Dielectric Materials, Seoul, Korea, 25–30 May 2002. [Google Scholar]

- Poniran, Z.; Abdul-Malek, Z.; Zalizah, P.; Abdul, M.Z. Life Assessment of Power Transformers via Paper Ageing Analysis. In Proceedings of the International Conference on Power Engineering, Energy and Electrical Drives, Setubal, Portugal, 12–14 April 2007; pp. 460–465. [Google Scholar]

- Shkolnik, A.B.; Rasor, R.T. Statistical insights into furan interpretation using a large dielectric fluid testing database. In Proceedings of the PES T&D, Orlando, FL, USA, 7–10 May 2012; pp. 1–8. [Google Scholar]

- Cheim, L.; Platts, D.; Prevost, T.; Xu, S. Furan analysis for liquid power transformers. IEEE Electr. Insul. Mag. 2012, 28, 8–21. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Furanic Compounds in Electrical Insulating Liquids by High Performance Liquid Chromatography (HPLC); ASTM: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Makowski, D.; Ben-Shachar, M.S.; Patil, I.; Lüdecke, D. Methods and algorithms for correlation analysis in R. J. Open Source Softw. 2020, 5, 2306. [Google Scholar] [CrossRef]

- Prasojo, R.A.; Diwyacitta, K.; Gumilang, H.S. Correlation of Transformer Paper Deterioration to Oil Characteristics and Dissolved Gases. In Proceedings of the International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Sanur, Indonesia, 2–5 October 2017; pp. 40–45. [Google Scholar]

- Farias-Basulto, G.; Reyes-Figueroa, P.; Ulbrich, C.; Szyszka, B.; Schlatmann, R.; Klenk, R. Validation of a multiple linear regression model for CIGSSe photovoltaic module performance and Pmpp prediction. Sol. Energy 2020, 208, 859–865. [Google Scholar] [CrossRef]

- Wu, J.; Lian, Z.; Zheng, Z.; Zhang, H. A method to evaluate building energy consumption based on energy use index of different functional sectors. Sustain. Cities Soc. 2020, 53, 101893. [Google Scholar] [CrossRef]

- Hillary, W.; Jayarathna, K.; Ranasinghe, L.; Samarakoon, S.; Rathnayake, N.; Lucas, J.R.; Samarasinghe, R. A Tool for Estimating Remaining Life Time of a Power Transformer. In Proceedings of the 2017 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 29–31 May 2017; pp. 373–378. [Google Scholar]

- Li, S.; Ge, Z.; Abu-Siada, A.; Yang, L.; Li, S.; Wakimoto, K. A new technique to estimate the degree of polymerization of in-sulation paper using multiple aging parameters of transformer oil. IEEE Access 2019, 7, 157471–157479. [Google Scholar] [CrossRef]

- Ghoneim, S.S.; Dessouky, S.S.; Elfaraskoury, A.A.; Sharaf, A.B.A.; Dessouki, S.S. Modelling and experimental verification of barrier effect on breakdown voltage of transformer oil using Box-Behnken Design. Measurement 2019, 147, 106829. [Google Scholar] [CrossRef]

- Doble Engineering Company. Tutorial on Electrical-Grade Insulating Papers in Power Transformers. In Proceedings of the 1993 Doble Client Committees Fall Meeting, Chicago, IL, USA, 4–7 October 1993. [Google Scholar]

- Kanumuri, D.; Sharma, V.; Rahi, O.P. Analysis using various aproaches for residual life estimation of power transformers. Int. J. Electr. Eng. Inform. 2019, 11, 389–407. [Google Scholar]

- Chairul, I.S.; Ab Ghani, S.; Khiar, M.A.; Thayoob, Y.M.; Ghazali, Y.Y. Kraft Paper Insulation’s Life Assess-ment and Effects of Oxygen and Moisture to Paper Insulation’s Deterioration Rate. In Proceedings of the IEEE International Conference on Power and Energy (PECon), Kota Kinabalu Sabah, Malaysia, 2–5 December 2012. [Google Scholar]

- Chendong, X.; Qiming, F.; Shiheng, X. To Estimate the Ageing Status of Transformers by Furfural Concentration in the Oil. In Proceedings of the CIGRE Study Committee 33 Colloquium, Leningrad, Moscow; 1991. [Google Scholar]

- De Pablo, A. Furfural and ageing: How are they related. In Proceedings of the IEE Colloquium Insulating Liquids, Leatherhead, UK, 27 May 1999. [Google Scholar]

| The Correlation Value | Description of the Relationship |

|---|---|

| +1 | Complete positive correlation |

| 0.7–0.99 | Strong positive correlation |

| 0.5–0.69 | Moderate positive correlation |

| 0.01–0.49 | Weak positive correlation |

| 0 | No correlation |

| H2 | CH4 | C2H6 | C2H4 | C2H2 | CO | CO2 | CO2/CO | BDV | IF | ACI | MC | OC | FA | Tan δ | DP | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H2 | 1.0 | |||||||||||||||

| CH4 | 0.27 | 1.0 | ||||||||||||||

| C2H6 | 0.22 | 0.44 | 1.0 | |||||||||||||

| C2H4 | 0.12 | 0.44 | 0.22 | 1.0 | ||||||||||||

| C2H2 | 0.06 | −0.06 | −0.06 | 0.13 | 1.0 | |||||||||||

| CO | 0.19 | 0.17 | −0.00 | 0.09 | −0.11 | 1.0 | ||||||||||

| CO2 | 0.23 | 0.03 | −0.11 | 0.16 | 0.030 | 0.453 | 1.0 | |||||||||

| CO2/CO | −0.02 | −0.04 | −0.03 | −0.05 | −0.01 | −0.14 | −0.05 | 1.0 | ||||||||

| BDV | 0.11 | 0.03 | −0.21 | −0.10 | −0.11 | 0.01 | 0.05 | 0.02 | 1.0 | |||||||

| IF | −0.14 | −0.00 | −0.11 | −0.08 | −0.15 | 0.37 | −0.08 | −0.04 | 0.04 | 1.0 | ||||||

| ACI | 0.06 | −0.05 | 0.02 | −0.01 | 0.08 | −0.07 | 0.21 | −0.05 | 0.03 | −0.73 | 1.0 | |||||

| MC | 0.23 | 0.08 | 0.20 | 0.00 | −0.03 | 0.03 | 0.18 | −0.02 | −0.10 | −0.55 | 0.67 | 1.0 | ||||

| OC | 0.16 | 0.04 | 0.18 | 0.07 | 0.09 | −0.13 | 0.12 | −0.07 | −0.08 | −0.86 | 0.79 | 0.59 | 1.0 | |||

| FA | 0.26 | −0.06 | −0.06 | −0.03 | 0.13 | −0.01 | 0.36 | −0.03 | 0.07 | −0.60 | 0.72 | 0.68 | 0.63 | 1.0 | ||

| Tan δ | 0.26 | 0.24 | 0.39 | 0.05 | −0.02 | 0.15 | −0.01 | −0.04 | −0.08 | −0.52 | 0.55 | 0.59 | 0.66 | 0.4 | 1.0 | |

| DP | −0.17 | −0.02 | −0.07 | −0.02 | −0.19 | 0.24 | −0.2 | 0.09 | −0.01 | 0.79 | −0.64 | −0.54 | −0.76 | −0.68 | −0.46 | 1.0 |

| Coefficients | Standard Error | t Stat | p-Value | |

|---|---|---|---|---|

| Intercept | 499.029 | 176.986 | 2.820 | 0.006 |

| H2 | 0.311 | 0.489 | 0.635 | 0.527 |

| CH4 | −0.237 | 0.206 | −1.148 | 0.253 |

| C2H6 | 0.046 | 0.141 | 0.328 | 0.743 |

| C2H4 | 1.072 | 0.834 | 1.285 | 0.201 |

| C2H2 | −1.030 | 0.588 | −1.751 | 0.083 |

| CO | 0.111 | 0.063 | 1.755 | 0.082 |

| CO2 | −0.016 | 0.008 | −1.964 | 0.052 |

| CO2/CO | 0.169 | 0.090 | 1.874 | 0.063 |

| BDV | −1.924 | 2.259 | −0.852 | 0.396 |

| IF | 13.362 | 3.873 | 3.450 | 0.001 |

| ACI | 640.530 | 290.556 | 2.205 | 0.029 |

| MC | −1.938 | 2.947 | −0.657 | 0.512 |

| OC | −60.504 | 22.715 | −2.664 | 0.009 |

| FA | −25.842 | 7.618 | −3.392 | 0.001 |

| Tan δ | −1.649 | 3.681 | −0.448 | 0.655 |

| IF | ACI | OC | FA | DP | |

|---|---|---|---|---|---|

| IF | 1.000 | ||||

| ACI | −0.732 | 1.000 | |||

| OC | −0.856 | 0.792 | 1.000 | ||

| FA | −0.595 | 0.720 | 0.628 | 1.000 | |

| DP | 0.789 | −0.637 | −0.760 | −0.679 | 1.000 |

| Coefficients | Standard Error | t Stat | p-Value | |

|---|---|---|---|---|

| Intercept | 328.002 | 127.202 | 2.579 | 0.011 |

| IF | 16.034 | 3.128 | 5.125 | 0.000 |

| ACI | 573.576 | 267.419 | 2.145 | 0.034 |

| OC | −52.457 | 19.654 | −2.669 | 0.009 |

| FA | −31.854 | 6.166 | −5.166 | 0.000 |

| Case | 2-FAL (ppm) | Measured DP | Equation (9) | Error % (9) | De Pablo 1 [3,23] | Error % De Pablo 1 | De Pablo 2 [3,23] | Error % De Pablo 2 | Chendong [3,24] | Error% Chendong | Burton [23] | Error% Burton | Vuarchex [23] | Error% Vuarchex | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.045 | 801 | 827.70 | 3.33 | 795.52 | 0.68 | 793.36 | 0.95 | 816.22 | 1.90 | 769.36 | 3.95 | 805.47 | 0.56 | [23] |

| 2 | 0.097 | 720 | 732.91 | 1.79 | 790.87 | 9.84 | 785.75 | 9.13 | 720.28 | 0.04 | 702.20 | 2.47 | 736.94 | 2.35 | [23] |

| 3 | 1.222 | 500 | 422.93 | 15.41 | 702.83 | 40.57 | 651.84 | 30.37 | 406.55 | 18.69 | 482.59 | 3.48 | 512.84 | 2.57 | [23] |

| 4 | 0.416 | 604 | 555.04 | 8.11 | 763.77 | 26.45 | 742.54 | 22.94 | 540.26 | 10.55 | 576.18 | 4.61 | 608.35 | 0.72 | [23] |

| 5 | 0.492 | 589 | 534.47 | 9.26 | 757.58 | 28.62 | 732.93 | 24.44 | 519.44 | 11.81 | 561.61 | 4.65 | 593.48 | 0.76 | [23] |

| 6 | 0.447 | 599 | 546.23 | 8.81 | 761.23 | 27.08 | 738.59 | 23.30 | 531.34 | 11.30 | 569.94 | 4.85 | 601.98 | 0.50 | [23] |

| 7 | 0.058 | 800 | 796.59 | 0.43 | 794.36 | 0.70 | 791.46 | 1.07 | 784.73 | 1.91 | 747.31 | 6.59 | 782.97 | 2.13 | [24] |

| 8 | 0.130 | 70 | 697.64 | 0.34 | 788.01 | 12.57 | 781.11 | 11.59 | 684.59 | 2.20 | 677.21 | 3.26 | 711.44 | 1.63 | [24] |

| 9 | 0.292 | 600 | 598.43 | 0.26 | 774.10 | 29.02 | 758.79 | 26.46 | 584.18 | 2.64 | 606.92 | 1.15 | 639.72 | 6.62 | [24] |

| 10 | 0.654 | 500 | 499.57 | 0.09 | 744.70 | 48.94 | 713.24 | 42.65 | 484.12 | 3.18 | 536.88 | 7.38 | 568.25 | 13.65 | [24] |

| 11 | 1.464 | 400 | 400.78 | 0.19 | 686.39 | 71.60 | 628.78 | 57.20 | 384.13 | 3.97 | 466.89 | 16.72 | 496.83 | 24.21 | [24] |

| 12 | 1.720 | 380 | 381.02 | 0.27 | 669.81 | 76.27 | 606.10 | 59.50 | 364.13 | 4.18 | 452.89 | 19.18 | 482.55 | 26.99 | [24] |

| 13 | 2.021 | 360 | 361.25 | 0.35 | 651.32 | 80.92 | 581.44 | 61.51 | 344.12 | 4.41 | 438.89 | 21.91 | 468.25 | 30.07 | [24] |

| 14 | 2.374 | 340 | 341.51 | 0.44 | 630.89 | 85.55 | 554.95 | 63.22 | 324.15 | 4.66 | 424.90 | 24.97 | 453.98 | 33.52 | [24] |

| 15 | 2.789 | 320 | 321.76 | 0.55 | 608.45 | 90.14 | 526.75 | 64.61 | 304.16 | 4.95 | 410.91 | 28.41 | 439.70 | 37.41 | [24] |

| 16 | 3.277 | 300 | 301.99 | 0.66 | 584.03 | 94.68 | 497.04 | 65.68 | 284.15 | 5.28 | 396.90 | 32.30 | 425.41 | 41.80 | [24] |

| 17 | 3.851 | 280 | 282.20 | 0.79 | 557.69 | 99.18 | 466.12 | 66.47 | 264.12 | 5.67 | 382.89 | 36.74 | 411.11 | 46.82 | [24] |

| 18 | 4.524 | 260 | 262.46 | 0.95 | 529.69 | 103.73 | 434.44 | 67.09 | 244.14 | 6.10 | 368.90 | 41.88 | 396.83 | 52.63 | [24] |

| 19 | 5.315 | 240 | 242.70 | 1.13 | 500.18 | 108.41 | 402.30 | 67.62 | 224.14 | 6.61 | 354.90 | 47.87 | 382.55 | 59.40 | [24] |

| 20 | 6.245 | 220 | 222.93 | 1.33 | 469.42 | 113.37 | 370.10 | 68.23 | 204.13 | 7.21 | 340.89 | 54.95 | 368.26 | 67.39 | [24] |

| 21 | 7.337 | 200 | 203.18 | 1.59 | 437.81 | 118.91 | 338.31 | 69.16 | 184.14 | 7.93 | 326.90 | 63.45 | 353.98 | 76.99 | [24] |

| FA (ppm) | FA (ppb) | Actual PD | Estimated PD Based on Equation (9) | Error % | Percentage Remaining Life |

|---|---|---|---|---|---|

| 0.045 | 45.00 | 801.00 | 827.70 | 3.33 | 102.66 |

| 0.097 | 97.50 | 720.00 | 732.91 | 1.79 | 93.88 |

| 1.222 | 1222.00 | 500.00 | 422.93 | 15.41 | 54.22 |

| 0.416 | 416.00 | 604.00 | 555.04 | 8.11 | 73.83 |

| 0.492 | 492.00 | 589.00 | 534.47 | 9.26 | 71.11 |

| 0.447 | 447.00 | 599.00 | 546.23 | 8.81 | 72.68 |

| 0.058 | 58.00 | 800.00 | 796.59 | 0.43 | 99.90 |

| 0.130 | 130.00 | 700.00 | 697.64 | 0.34 | 90.32 |

| 0.292 | 292.00 | 600.00 | 598.43 | 0.26 | 79.26 |

| 0.654 | 654.00 | 500.00 | 499.57 | 0.09 | 66.24 |

| 1.464 | 1464.00 | 400.00 | 400.78 | 0.19 | 50.34 |

| 1.720 | 1720.00 | 380.00 | 381.02 | 0.27 | 46.70 |

| 2.021 | 2021.00 | 360.00 | 361.25 | 0.35 | 42.85 |

| 2.374 | 2374.00 | 340.00 | 341.51 | 0.44 | 38.80 |

| 2.789 | 2789.00 | 320.00 | 321.76 | 0.55 | 34.50 |

| 3.277 | 3277.00 | 300.00 | 301.99 | 0.66 | 29.93 |

| 3.851 | 3851.00 | 280.00 | 282.20 | 0.79 | 25.04 |

| 4.524 | 4524.00 | 260.00 | 262.46 | 0.95 | 19.81 |

| 5.315 | 5315.00 | 240.00 | 242.70 | 1.13 | 14.16 |

| 6.245 | 6245.00 | 220.00 | 222.93 | 1.33 | 8.03 |

| 7.337 | 7337.00 | 200.00 | 203.18 | 1.59 | 1.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghoneim, S.S.M. The Degree of Polymerization in a Prediction Model of Insulating Paper and the Remaining Life of Power Transformers. Energies 2021, 14, 670. https://doi.org/10.3390/en14030670

Ghoneim SSM. The Degree of Polymerization in a Prediction Model of Insulating Paper and the Remaining Life of Power Transformers. Energies. 2021; 14(3):670. https://doi.org/10.3390/en14030670

Chicago/Turabian StyleGhoneim, Sherif S. M. 2021. "The Degree of Polymerization in a Prediction Model of Insulating Paper and the Remaining Life of Power Transformers" Energies 14, no. 3: 670. https://doi.org/10.3390/en14030670