Research on Model Predictive Control for Automobile Active Tilt Based on Active Suspension

Abstract

:1. Introduction

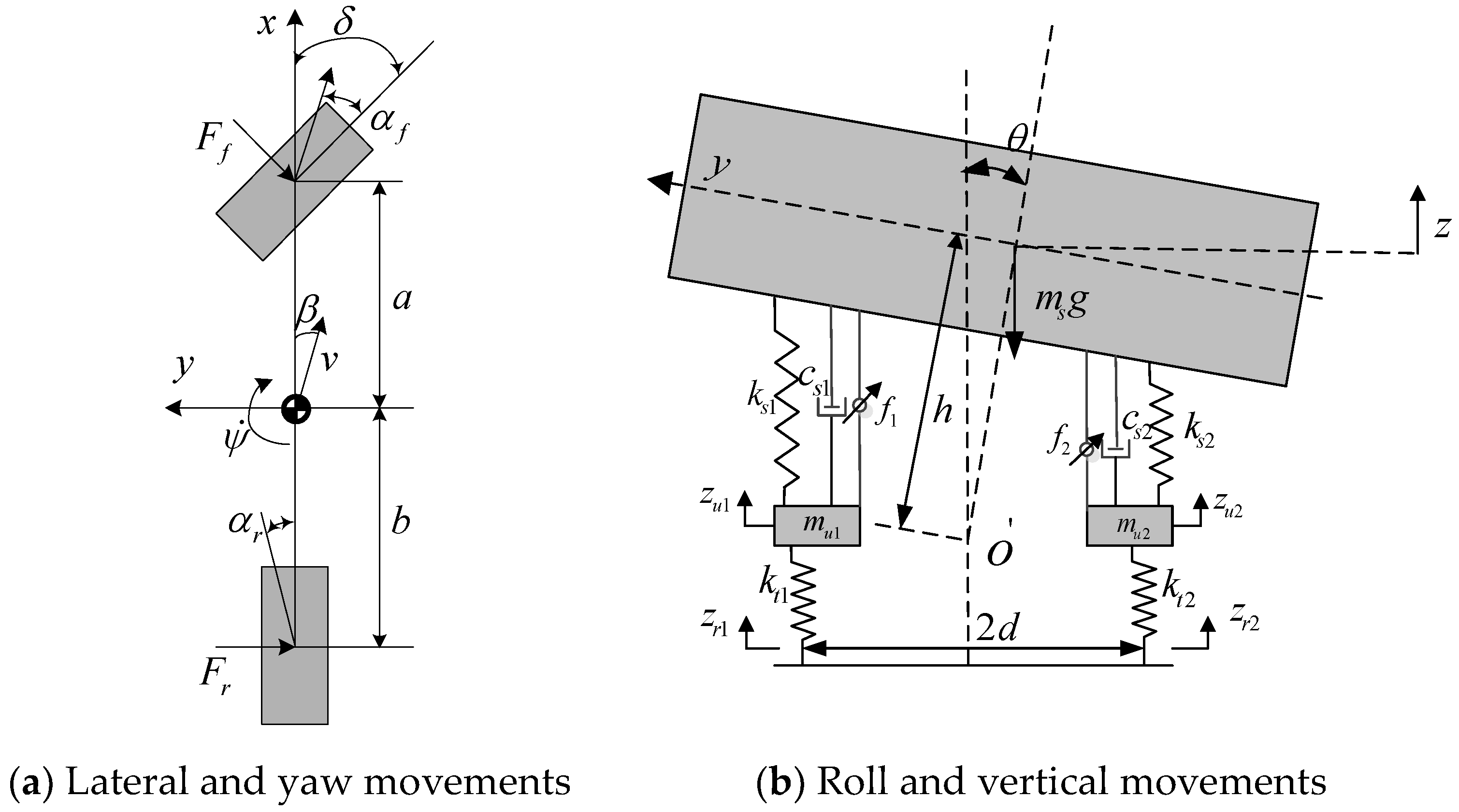

2. Vehicle Steer–Roll Dynamic Model Based on Active Suspension

3. Design of the Model Predictive Controller

3.1. Desired Tilt Angle for Active Tilt Control

3.2. Design of the Controller

4. Simulation Results and Analyses

4.1. Step-Steering Input Maneuver

4.2. Double-Lane Change Maneuver

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. Parameters of Matrices

References

- Zou, J.; Guo, X.; Abdelkareem, M.A.; Xu, L.; Zhang, J. Modelling and ride analysis of a hydraulic interconnected suspension based on the hydraulic energy regenerative shock absorbers. Mech. Syst. Signal Process. 2019, 127, 345–369. [Google Scholar] [CrossRef]

- Yao, J.; Taheri, S.; Tian, S.; Zhang, Z.; Shen, L. A novel semi-active suspension design based on decoupling skyhook control. J. Vibroeng. 2014, 16, 873–880. [Google Scholar]

- Jing, H.; Wang, R.; Li, C.; Bao, J. Robust finite-frequency H∞ control of full-car active suspension. J. Sound Vib. 2019, 441, 221–239. [Google Scholar] [CrossRef]

- Muniandy, V.; Samin, P.M.; Jamaluddin, H.; Rahman, R.A.; Bakar, S.A.A. Double anti-roll bar hardware-in-loop experiment for active anti-roll control system. J. Vibroeng. 2017, 19, 2886–2909. [Google Scholar]

- Goodall, R. Tilting trains and beyond-the future for active railway suspensions. Part 1: Improving passenger comfort. Comput. Control Eng. J. 1999, 10, 153–160. [Google Scholar] [CrossRef]

- Halikias, G.D.; Goodall, R.M.; Zolotas, A.C. Recent results in tilt control design and assessment of high-speed railway vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2007, 221, 291–312. [Google Scholar]

- Colombo, E.F.; Gialleonardo, E.; Facchinetti, A.; Bruni, S. Active carbody roll control in railway vehicles using hydraulic actuation. Control Eng. Pract. 2014, 31, 24–34. [Google Scholar] [CrossRef]

- Piyabongkarn, D.; Keviczky, T.; Rajamani, R. Active direct tilt control for stability enhancement of a narrow commuter vehicle. Int. J. Automot. Technol. 2004, 5, 77–88. [Google Scholar]

- Tang, C.; Ataei, M.; Khajepour, A. A Reconfigurable Integrated Control for Narrow Tilting Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 234–244. [Google Scholar] [CrossRef]

- So, S.G.; Karnopp, D. Switching strategies for narrow ground vehicles with dual mode automatic tilt control. Int. J. Veh. Des. 1997, 18, 518–532. [Google Scholar]

- Rajamani, R.; Gohl, J.; Alexander, L.; Starr, P. Dynamics of Narrow Tilting Vehicles. Math. Comput. Model. Dyn. Syst. 2003, 9, 209–231. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Chevrel, P.; Claveau, F. LPV Static Output Feedback for Constrained Direct Tilt Control of Narrow Tilting Vehicles. IEEE Trans. Control Syst. Technol. 2020, 28, 661–670. [Google Scholar] [CrossRef]

- Berote, J.; Darling, J.; Plummer, A. Development of a tilt control method for a narrow-track three-wheeled vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2011, 226, 48–69. [Google Scholar] [CrossRef] [Green Version]

- Kidane, S.; Alexander, L.; Rajamani, R.; Starr, P.; Donath, M. A fundamental investigation of tilt control systems for narrow commuter vehicles. Veh. Syst. Dyn. 2008, 46, 295–322. [Google Scholar] [CrossRef]

- Robertson, J.W.; Darling, J.; Plummer, A.R. Combined steering-direct tilt control for the enhancement of narrow tilting vehicle stability. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 847–862. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Shen, S. Integrated vehicle ride and roll control via active suspensions. Veh. Syst. Dyn. 2008, 46, 495–508. [Google Scholar] [CrossRef]

- Ling, J. Research and Simulation on the Active Roll Control System Based on a Slow-Active Suspension; Beijing Institute of Technology: Beijing, China, 2016. [Google Scholar]

- Youn, I.; Wu, L.; Youn, E.; Tomizuka, M. Attitude motion control of the active suspension system with tracking controller. Int. J. Automot. Technol. 2015, 16, 593–601. [Google Scholar] [CrossRef]

- Youn, I.; Youn, E.; Khan, M.A.; Wu, L.; Tomizuka, M. Combined effect of electronic stability control and active tilting control based on full-car nonlinear model. In The Dynamics of Vehicles on Roads and Tracks: Proceedings of the 24th Symposium of the International Association for Vehicle System Dynamics (IAVSD 2015), Graz, Austria, 17–21 August 2015; CRC Press: Boca Raton, FL, USA, 2016; pp. 345–353. [Google Scholar]

- Zhu, Q.; Ayalew, B. Predictive roll, handling and ride control of vehicles via active suspensions. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 2102–2107. [Google Scholar]

- Rajamani, R.; Piyabongkarn, D.N. New paradigms for the integration of yaw stability and rollover prevention functions in vehicle stability control. IEEE Trans. Intell. Transp. Syst. 2013, 14, 249–261. [Google Scholar] [CrossRef]

- Cars-Data. Available online: https://www.cars-data.com/en/technical-terms/atc-active-tilt-control.html (accessed on 19 January 2021).

- Robertson, J.W.; Darling, J.; Plummer, A.R. Path following performance of narrow tilting vehicles equipped with active steering. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2–4 July 2012; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2012; pp. 679–686. [Google Scholar]

- Hibbard, R.; Karnopp, D. The dynamics of small, relatively tall and narrow tilting ground vehicles. Adv. Automot. Technol. ASME Publ. DSC 1993, 52, 397–417. [Google Scholar]

- Yao, J.; Li, Z.; Wang, M.; Yao, F.; Tang, Z. Automobile active tilt control based on active suspension. Adv. Mech. Eng. 2018, 10, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Ding, S.; Li, S. Second-order sliding mode controller design subject to mismatched term. Automatica 2017, 77, 388–392. [Google Scholar] [CrossRef]

- Chang, X.; Liu, Y.; Shen, M. Resilient Control Design for Lateral Motion Regulation of Intelligent Vehicle. IEEE/ASME Trans. Mechatron. 2019, 24, 2488–2497. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Wang, J. Sideslip Angle Estimation of an Electric Ground Vehicle via Finite-Frequency H-infinity Approach. IEEE Trans. Transp. Electrif. 2015, 2, 200–209. [Google Scholar] [CrossRef]

- Abe, M. Vehicle Handling Dynamics: Theory and Application; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Jin, Z.; Zhang, L.; Zhang, J.; Khajepour, A. Stability and optimised H∞ control of tripped and untripped vehicle rollover. Veh. Syst. Dyn. 2016, 54, 1405–1427. [Google Scholar] [CrossRef]

- ISO 8608. Mechanical Vibration–Road Surface Profiles–Reporting of Measured Data; International Organization for Standardization: Geneva, Switzerland, 1995. [Google Scholar]

- Yao, J.; Lv, G.; Qv, M.; Li, Z.; Ren, S.; Taheri, S. Lateral stability control based on the roll moment distribution using a semiactive suspension. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2017, 231, 1627–1639. [Google Scholar] [CrossRef] [Green Version]

- Tanifuji, K.; Koizumi, S.; Shimamune, R.H. Mechatronics in Japanese rail vehicles: Active and semi-active suspensions. Control Eng. Pract. 2002, 10, 999–1004. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| 1500 | 120 | ||

| 2500 | 35,000 | ||

| 460 | 2000 | ||

| 380,000 | 9.81 | ||

| 1.4 | 0.45 | ||

| 1.7 | 0.74 | ||

| 76,339 | 70,351 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Wang, M.; Li, Z.; Jia, Y. Research on Model Predictive Control for Automobile Active Tilt Based on Active Suspension. Energies 2021, 14, 671. https://doi.org/10.3390/en14030671

Yao J, Wang M, Li Z, Jia Y. Research on Model Predictive Control for Automobile Active Tilt Based on Active Suspension. Energies. 2021; 14(3):671. https://doi.org/10.3390/en14030671

Chicago/Turabian StyleYao, Jialing, Meng Wang, Zhihong Li, and Yunyi Jia. 2021. "Research on Model Predictive Control for Automobile Active Tilt Based on Active Suspension" Energies 14, no. 3: 671. https://doi.org/10.3390/en14030671