1. Introduction

Solar thermal systems with pressurized circuits for heating, domestic hot water preparation and process heat applications generally use water-glycol mixtures as a frost-resistant heat carrier. In order to prevent the storage tank from overheating, the circulation pump is switched off as soon as the temperature reaches a pre-defined maximum value. Hence, the collector array is no longer actively cooled, and the process of stagnation begins.

Solar thermal systems for the above-mentioned applications are usually operated at a system overpressure below three bar which corresponds to saturation temperatures below 140 °C. The maximum stagnation temperature of flat-plate collectors with single glazing and selective absorber coatings can reach above 200 °C. Therefore, stagnation is always associated with the vaporization of the heat carrier. Stagnation is a transient process during which several phenomena occur. After pump shutdown, solar irradiation heats the absorber, thus increasing its temperature and heat losses. The saturation temperature normally is reached near the top of the absorber. In this state, the absorbed solar irradiation is still higher than the heat losses. As a result, the collector turns the excess absorbed energy with a certain efficiency into vaporization and displacement of the liquid. The rate of these processes depends on the optical and thermal properties of the collector, the boundary conditions and the size of the absorber region at saturation. The major part of the liquid content is displaced into the pipes of the circuit, mostly by volumetric displacement but also by interfacial friction between the increasing steam flow and the liquid. The growing vapor volume displaces an equivalent liquid volume from the circuit into the expansion vessel. The residual liquid within the absorber steadily vaporizes and propagates into the pipes of the circuit. Condensing vapor heats the exposed pipe walls from their initial temperature up to saturation temperature. The vapor propagation into the circuit increases until the enthalpy flow rate of vapor from the collector field drops below the heat losses of the pipes.

The following historical overview (see also Eismann [

1]) shows why stagnation became a research topic relatively late, when solar thermal technology was already well established. Three qualitative ranges of the stagnation phenomenon can be associated with the corresponding collector technologies.

Up to the middle of the 1970s, the vast majority of flat-plate collectors were equipped with nonselective absorbers. The maximum stagnation temperature was about 140 °C, which is below the permissible operation temperature of water-glycol mixtures. This allowed suppression of vaporization by setting the system pressure above saturation pressure.

With the introduction of selective coatings like black-chrome and black-nickel, the efficiency at elevated temperatures was significantly increased. As a result, flat-plate collectors reached a maximum stagnation temperature of up to 180 °C. In most cases, the system pressure was set to values in such a way that the saturation temperature was significantly below the actual temperature during dry stagnation. Vaporization of the liquid and compensation of the vapor volume by a sufficiently large expansion vessel was an accepted strategy to limit the pressure rise during stagnation. Because of the low efficiency in saturation conditions, the steam range was correspondingly small. For this reason and because the market volume was small at the time, the number of failures due to the excessive steam range was too low to merit scientific interest. Pioneering companies solved stagnation problems based on their own expertise and subsequently devised measures, like rules for the arrangement of check valves and the sizing of membrane expansion vessels. Some suppliers proposed suppression of vaporization by a high concentration of glycol and a sufficiently high system pressure.

The adoption of cost-effective, highly selective thin-film absorber coatings in the 1990s and the ensuing market growth led to a dramatic increase in failures caused by the excessive steam range. Typical cases of damage are the loss of liquid caused by the opening of the safety valve, pumps destroyed by the passage of vapor, deformed and thus leaking membranes of expansion vessels due to excessive temperatures and water hammer induced by rapid condensation within the heat exchangers. These phenomena initiated a considerable amount of research dedicated to understanding the stagnation process, to develop measures to limit the steam range and derive theoretical models capable of predicting maximum pressure and steam range.

Terschueren [

2] firstly described the stagnation phenomenon qualitatively and recommended useful practical conclusions from observations. In the subsequent years, several experimental studies were carried out. The main objective of these studies was to understand and characterize the stagnation process qualitatively and to derive practical rules for the design of collectors and solar thermal systems. Eismann and von Felten [

3] conducted experiments on a real system with 52 m

2 flat-plate collectors. Stagnation was triggered by manually switching off the pump. From the results, they deduced that stagnation is manageable if the piping is routed in such a way that the steam forms a continuous volume and propagates monotonously downward. They provided rules for pipe routing resulting in the best possible emptying of the collector field. As another rule, they define the location of the check valve, which must be upstream from the connection point of the pressure maintenance. This allows displacement of liquid from the collector field in both the supply and return lines. Based on the measurement data from experiments on a real system with two 22 m

2 flat-plate collectors, Hausner and Fink [

4] described stagnation as a sequence of five successive phases as (1) liquid expansion, (2) displacement of liquid by steam (3) emptying by boiling (phase with saturated steam), (4) emptying by boiling (phase with saturated and superheated steam) and (5) refilling of the collectors. From experimental data and qualitative considerations, they classified the hydraulic designs of collectors and their connections by external pipes according to their emptying behavior. This and the practical rules derived from it were published also by Hausner and Fink [

5]. Streicher [

6] addressed the danger of water hammer induced by rapid condensation of steam during stagnation. He explained, with examples, that those hydraulic designs in which the steam forms a continuous volume are to be preferred. Lustig [

7] conducted experiments on systems with flat-plate collectors and vacuum-tube collectors focusing on the processes in the absorber. He recognized that the displacement of the liquid and the spreading of the vapor takes the form of a two-phase flow. For a collector with a meander type absorber tube, he identified the various flow patterns in all the tube sections. He used a plug-flow model to simulate the propagation of steam into a single pipe. The residual liquid was predefined as a fraction of the absorber volume. By adjusting the residual amount and the absorber volume, a fairly good agreement with the experiments could be achieved.

Good emptying behavior, characterized by a small quantity of residual liquid within the absorbers, was identified as a decisive prerequisite for a small steam range. However, there was no way to predict the steam range as a function of system properties and boundary conditions. Hausner, et al. [

8] were the first who came up with a correlation for the maximum steam range, based on a comprehensive experimental study on the effect of hydraulic collector design and collector arrangement on the steam range. The location of the steam front was deduced from the signals of equidistant temperature sensors attached to the pipe walls. They introduced the experimental quantity of steam production power, defined as the product of vapor mass flow and the enthalpy of vaporization at the moment of maximum steam range. Their results provided a valuable insight into the influence of hydraulic design and pipe routing on the steam range. However, application of their empirical correlation is limited to the design and operational conditions of the arrangements investigated. In subsequent research projects the influence of collector efficiency and hydraulic design on maximum steam range was further investigated by Rommel, et al. [

9] who used their indoor test facility to conduct experiments on a system of vacuum tube collectors made entirely of glass by Schott. On some absorber tubes, a narrow strip remained uncoated. As a result, the evaporation process was directly observable. Rommel, et al. [

10] discussed measures to limit the steam range and control strategies to reduce stagnation events. They presented a sophisticated measurement method to determine the steam range, steam volume, and the amount of liquid remaining in the collector. Building on these results Scheuren et al. [

11] designed and built an experimental facility with collector fields of different hydraulic design with up to 25.2 m

2 aperture area. Their experiments showed the strong influence of the emptying behavior on the steam range. Based on these experiments Scheuren [

12] derived a more general empirical correlation for the steam range. He distinguished three classes of collector fields characterized by good, average and poor emptying behavior and provided a corresponding set of two parameters for the correlation. However, the class needs to be determined initially, based on qualitative considerations and practical experience.

Harrison and Cruickshank [

13] and Frank, et al. [

14] provided a literature review on measures to prevent excessive steam range, covering control strategies, condensers as well as other devices capable of reducing stagnation temperature. They also provided practical examples such as cooling devices, sunshades and collectors with automatic devices such as thermochromic absorber coatings.

Thus far, research has considered stagnation as a succession of five distinguishable processes: heating-up, liquid displacement, vaporization of residual liquid, overheating of the dried-out absorber regions and the re-filling of the collectors.

Eismann [

1] used the thermal hydraulic system code TRACE, specifically developed for the safety analysis of nuclear systems [

15], to model a solar system consisting of eight flat-plate collectors with meander-type absorbers. The representation of the two-phase states is essentially based on the material data of water and steam. The two-fluid model of TRACE [

16] describes both the gas and liquid phases by three one-dimensional conservation equations for mass, momentum and energy. This enables the simulation of two-phase flows in thermodynamic imbalance, for example subcooled boiling and condensation.

Simulation results showed that the processes of liquid displacement, vaporization and overheating of dried-out parts of the absorber are, in fact, overlapping. The simulation showed that the phases of displacement and evaporation occur at the same time and that the maximum steam range is reached in an early phase when far less than half of the liquid has evaporated. It was concluded that the maximum steam range can be approximately calculated based on the properties of water and steam, neglecting the effect of fractioned distillation of the water propylene glycol mixture used in the real system. Based on the insight gained, a simplified model was derived. Contrary to the findings of the TRACE simulations, displacement and evaporation were considered as separate processes. These simplifications made it possible to solve the differential equation describing the propagation of steam into the pipes analytically. For the generation of the vapor, only the residual amount of liquid that remained in the absorbers after displacement was considered. This residual quantity was calculated beforehand by a drift-flux model. This model was incorporated in the first version of the open source tool THD [

17]. However, experimental validation of the model was not possible at the time. Furthermore, the two-phase model of TRACE is based on the properties of water and steam while the real heat carrier is a mixture of water and propylene glycol. This leads to a considerable uncertainty in the determination of the steam range which motivated further research resulting in the present article. The aim of this article is to derive a model that foregoes the simplifications undertaken earlier.

The new model accounts for the different heat capacities of the steam- and liquid-filled parts of the absorbers and the rise of the saturation temperature as the water content of the water-glycol mixture decreases during evaporation. The new model allows for the fact that displacement and evaporation occur at the same time. The model was calibrated on the basis of stagnation experiments on two real-size solar systems.

Section 2 describes the experimental facility and the models to calculate heat losses and state variables not covered by measurements. In

Section 3, the thermal-hydraulic model for the displacement of liquid from the collector array and the propagation of vapor into the circuit is described. Care has been taken to ensure that the derivations are fully comprehensible, without the need to consult the literature cited.

3. Derivation of the Model

3.1. Residual Liquid

Calculation of the amount of residual liquid is decoupled from the transient model. It is determined on the basis of state variables and boundary conditions that occur when the saturation temperature is reached, and the following simplifying assumptions:

The meander and header tubes are completely wetted. All parts of the absorber contribute to vaporization according to their efficiency.

Only steam leaves the wetted and steam-filled parts of the absorber. The residual liquid is considered stationary, which is expressed by a liquid superficial velocity of everywhere in the absorber.

The influence of two-phase pressure losses on the saturation temperature is neglected. Consequently, each absorber within the collector array undergoes the same process and the saturation temperature is the same everywhere.

The steam flow distributions in the upper and lower parts of the absorber are symmetrical.

Meander and header tubes are treated separately. The length and the volume of the pipe bends in the meander tube are added to the straight parts. A meander with a total length, , is nodalized into straight, horizontal pipe sections. The numbering of absorber pipe sections starts at the middle of the meander tube from to in both upstream and downstream direction. It follows from assumptions 2, 3 and 4 that the steam flow distributions in the upper and lower parts of the absorber are symmetrical.

The superficial velocity of the steam flow is proportional to the section number,

k, as calculated from the mass and energy balance,

The efficiency of the meander region is,

Inserting into Equation (37) and using Equation (41) yields the liquid holdup of the water-glycol mixture,

The total amount of residual water in the meander tube is calculated using the initial mass fraction of water,

xm0, and summing up over all the meander tube sections,

Because the absorber area associated with a header is small compared to the meander region, their contribution to the vaporization is also small. It is therefore sufficient to describe each header tube by a single node. The superficial velocity in the

kth upper header tube results from the sum of steam flows in the upper half of one to

k meanders and the steam flows in one to

k header tubes,

Inserting Equation (48) into Equation (37) yields the void fraction. The residual mass is calculated using Equation (47). The residual mass of the water-glycol mixture in the kth bottom header tube is calculated analogously.

3.1.1. Corrections for the Residual Mass of Water

The simplifying assumptions two and four stated in the section above were a pre-requisite for the calculation of the initial residual mass. However, the liquid content will move during the stagnation process under the influence of gravity and friction between the steam flow and the liquid. A fraction of the initial residual quantity will leave the absorber in liquid form and therefore not contribute to the steam flow entering the pipes. The magnitude of this fraction is estimated considering the following effects:

Eismann [

1] found by thermal-hydraulic simulation of a system with flat-plate collectors featuring meander absorbers with highly selective coatings that about 80% of the displaced liquid flows downwards into the return line, which is in accordance with experimental results of Hausner, Fink, Wagner, Riva and Hillerns [

8]. The complementary fraction is displaced from the region above the origin of evaporation in upward direction into the supply line. It can be concluded that with a relatively high efficiency at stagnation conditions, the vaporization rate and the steam velocity soon become so high that interfacial friction dominates, and the effect of gravity on the liquid content within the pipe bends can be neglected.

At low efficiencies at stagnation conditions, e.g., in the case of thermochromic absorber coating, the vaporization rate hence the interfacial friction increase only slowly. In consequence, a larger part of the liquid above the origin of evaporation is allowed to flow against the upward flowing steam and collect in the lower parts of the meander where the heat losses are higher. As a result, phase separation is more pronounced and nearly all the displaced liquid leaves the collector array via the return line. During the much longer evaporation phase a considerable amount of residual liquid does not evaporate but eventually flows into the return line, driven by the weak interfacial friction and gravity. Based on this hypothesis and the procedure outlined in

Section 3.6, the following distribution function was derived, which describes the ratio of the liquid mass that evaporates during stagnation to the initial residual mass as calculated by the drift-flux correlation.

The same distribution function is used to correlate the probable center of the residual liquid with the corresponding local heat loss coefficient,

The relevant part of the residual water contributing to the steam range is,

3.2. Temperature Rise

After pump shutdown the absorber is heated up by the solar gain. The temperature rise is not uniform, due to the increased heat losses across the edges of the collector and along the flow path. However, the model for the displacement phase, which is derived in

Section 3.2, requires the assumption of a linear absorber temperature distribution within the liquid-filled part, which simplifies the modelling tremendously. It follows from this simplification that boiling commences as soon as the outlet reaches saturation temperature,

Ts. The temperature rise during the heating-up period is described by Equation (52), where

T is the temperature of the absorber at an arbitrary location along the flow path.

When dimensioning solar thermal systems, the maximum steam range should be determined for extremal but constant values of solar irradiation and ambient temperature. The elapsed time between pump shutdown and the onset of boiling is irrelevant. For comparison of simulations and experiments under varying boundary conditions, however, onset of boiling should coincide with experimental data, because the boundary conditions are time-dependent. A correction factor,

, accounts for the fact that the temperature within the meander region rises faster than the average temperature.

It is sufficient to solve this equation numerically using the Euler method. For , the temperature at the absorber outlet, , reaches saturation temperature, Ts, within a finite time interval.

With the onset of boiling three processes start to run in parallel. The growing steam volume displaces the liquid content from the absorber into the connecting pipes. The regions below saturation temperature are heated up by the solar gain and the displaced liquid from regions with higher temperature. At the same time, steam leaves the absorber and enters the pipes. Describing these combined processes using the two-phase mixture model requires further simplifications. Time evolution of the state variables is assumed as identical in each collector of the collector array. In consequence, the mass flows of displaced liquid and of steam entering the adjoining pipes are proportional to the number,

n, of collectors. It is adequate to describe liquid displacement and steam generation independently, based on the following definitions and simplifications illustrated by

Figure 7.

Liquid displacement happens simultaneously in the upper header, the lower header and the meander tube. It is therefore not necessary to distinguish between these three regions. This allows the description of the processes of displacement and steam generation in one dimension as a function of the volume, V.

The temperature gradient within the region below saturation temperature results from normal operation prior to pump shutdown,

and is defined as a constant during the whole displacement process. The sizes of three volume fractions and the corresponding absorber areas are defined using parameters,

and

, between 0 and 1.

The volume part, , contains steam and residual water. The solar gain of the corresponding absorber area, , causes vaporization and, if the pressure increases, a corresponding increase in temperature. Only saturated steam generated in this region contributes to the steam flow from the collector into the adjoining pipes.

The volume part,

, contains saturated water. Steam generated in this region of the absorber only contributes to the displacement of liquid. The simplifying assumption of a constant heat loss allows the definition of the parameter,

, as a function of the time dependent inlet temperature,

.

The temperature rises linearly along the coordinate,

V, from the actual temperature,

, at the collector inlet,

, to saturation temperature at

.

By using the definitions stated by Equations (54) and (55), Equation (30) can be represented by two coupled equations describing liquid displacement and steam generation as follows.

3.3. Liquid Displacement

Equation (56) is the one-dimensional representation of Equation (30) describing liquid displacement.

The first term on the right-hand side represents the part of the solar gain transferred to the saturated liquid within the region,

, of the absorber content, which causes steam generation. By application of the one-dimensional form of the mass conservation equation,

the derivative of the void fraction can be replaced by the mass flow of displaced liquid.

In order to integrate this equation analytically over short time periods, the heat capacity of the collector is set as a constant and the derivative of the saturation temperature of steam is replaced by the finite difference ratio of values from the preceding time step.

The growth rate of the overall void fraction r can be obtained from the mass balance applied on the whole absorber.

Integration over time yields the void fraction and, finally, the actual steam volume,

. The parameter,

, describing the steam-filled part of the collector array is defined as a function of the steam volume and the total residual mass of water:

3.4. Steam Generation

The model for steam generation is based on the following considerations. The vaporization rate, , of residual liquid depends on the solar gain at saturation temperature and the change of enthalpy of the absorber due to change of the saturation temperature of the residual liquid, . The time evolutions of the vaporization rate within the absorber and the header tubes are different because the initial residual masses and the respective absorber areas are not the same. It is therefore necessary to calculate the vaporization rate for the meander and the upper and lower headers separately, while the same parameter, , is used for all regions. In order to simplify mathematical expressions, the model will be derived for an unspecified region, , of one single absorber.

Displacement of liquid is usually accompanied by an increase in pressure, hence an increase in saturation temperature. Therefore, part of the absorbed energy within the region,

, is used for the heating-up of the absorber. The steam generation rate within the absorber region depends on the current mass of residual water within this region,

. If

, the absorber region is assumed to be fully wetted and the whole steam-filled region contributes to steam generation. Steam generation decreases with a decreasing residual mass of water. It is therefore reasonable to quantify the fraction of the steam-filled region contributing to steam generation as a function of the current mass related to the initial mass of the residual water,

. The value of the exponent,

, is defined later. Thus, the total power attributed to vaporization is,

The goal is to find a formula for the steam power, i.e., the enthalpy flow of steam leaving the absorber, as a function of time. By definition, steam generated within the volume fraction of the region,

, contributes only to the outflow of steam from the collector field. Therefore, the surface integral on the left-hand side of Equation (30) reduces to

and the surface integral on the right-hand side of the same equation to

. Thus, the one-dimensional form of Equation (30) becomes,

Integration and replacing specific inner energies by specific enthalpies,

, yields,

The void fraction and its derivative are defined by the residual mass and the mass fraction of water.

Since the densities of water and propylene glycol above 100 °C differ by less than 2%, it is sufficient to base the void fraction on the density of the saturated water. The mass flow of steam can be expressed by the derivative of the residual liquid by applying the mass balance, Equation (31), to the region,

X.

Inserting into Equation (64) yields the differential equation for the residual liquid mass.

Since the saturation temperature varies only slowly with pressure, the equation can be integrated over a sufficiently short time interval,

. The derivative of stored heat is replaced by the finite difference with values from the previous interval. The specific enthalpies of steam are evaluated at the saturation temperature of the liquid.

It is reasonable to assume that dry out is reached within a finite time interval, which requires an exponent α < 1. Solving Equation (67) by the separation of variables and integration yields,

Differentiation and using Equation (64) and multiplication by the enthalpy of vaporization results in the enthalpy flow of saturated steam from the region,

.

The total enthalpy flow from the collector array is,

Figure 8 shows the normalized enthalpy flow of steam in the isothermal case as a function of the dimensionless time. The choice of

is justified as follows.

For a short time interval of

, the second term within the square brackets of Equation (70) could be neglected because the magnitude of

is

times smaller than the initial residual mass. This would allow the differential equation for the steam propagation derived in the next section to be solved analytically and result in Equation (80). However, the choice of the exponent,

, is not critical, as will be explained in

Section 3.6. For

Equation (70) is a linear function of time, which allows to solve Equation (80) analytically for any time interval, as long as the saturation temperature can be considered as a constant. This is beneficial in two ways. In practical applications of this model, where the steam range is determined under constant but extremal conditions, the time interval can be considerably extended, which results in a short simulation time. Due to the analytical solution, no convergence issues occur.

3.5. Steam Propagation into the Circuit

Steam propagation into the circuit is described by the energy Equation (30), applied to a control volume defined by a finite section,

, of pipe. The index,

, is omitted where possible. Heat conduction in axial direction is neglected. A sharp phase boundary across the pipe cross-section is assumed. The flow across any pipe cross-section is therefore either steam or liquid. The liquid holdup,

, of the steam-filled part of a pipe section is considered as zero. The void fraction of a pipe section is interpreted as the dimensionless location,

x, of a virtual steam front.

With these simplifications, the left-hand side of Equation (30) can be integrated and rearranged as follows:

The first term of the right-hand side of Equation (30),

consists of three parts. The first part describes the enthalpy flow into the pipe wall as it is exposed by the moving steam front. This term contributes only to positive velocities of the steam front. The second part accounts for the heat losses to the ambient. The third part describes the enthalpy flow due to change of saturation temperature. The time derivative of the enthalpy is replaced by the finite difference analogous to Equation (68). The heat capacity per unit length of a pipe section,

Ck, depends on the specific heat capacities of the pipe and the steam.

The heat capacity of the insulating layer is ignored. The second term on the right-hand side of Equation (30) describes the rate of work exercised by the steam entering and the liquid leaving the control volume,

Combining Equations (73), (74) and (76), and substituting the phasic velocities by the mass flows

and the inner energies with enthalpies,

, leads to the following representation of the energy equation.

From the mass conservation applied to the same control volume one gets an expression for the liquid mass flow across the boundary.

Substituting into Equation (77) and replacing the enthalpies of saturated steam and water with the enthalpy of vaporization,

hv, results in a differential equation for the location,

x, of the steam front within the control volume defined by the pipe section,

k.

The enthalpy flow,

, of saturated steam entering the pipe section,

k, is equal to the enthalpy flow of steam leaving the collector,

, with the mass flow of steam from Equation (71), reduced by the heat flux,

c, dissipated from the steam into the pipe walls.

Inserting this equation into Equation (79) and substituting Equation (71) for the steam power results in a differential equation for the location,

x, of the steam front.

The quantities,

e, and,

f, are defined for the whole collector array consisting of

nC collectors and regions

as follows:

Because the pressure losses and the influence of check valves are ignored, the height levels of the steam front in the supply and return lines are equal. If the phase boundaries of both the supply and return line are located in horizontal pipe sections, both steam fronts are assumed to propagate at the same speed. These rules are formally implemented by parameters,

and

, according to

Table 1 and the coefficients,

a,

b and

c, defined as follows:

An increase in steam volume usually accompanies an increase in pressure. Therefore, all coefficients become time-dependent. However, within a sufficiently short time step the coefficients can be considered as constant, which allows the derivation of an analytical solution. The solution of the homogeneous part of Equation (81) is,

The solution of the inhomogeneous equation has the form,

Comparing of coefficients yields,

Inserting the initial condition,

, yields the constant,

, of the homogeneous solution.

Finally, the location of the steam front, starting at the initial time,

, is,

Of interest are also the heat losses from the pipes to the ambient,

, and the total dissipated heat from the steam to the pipes,

, which are calculated using Equation (84).

The change rate of heat,

, accumulated by the steam filled parts of the collectors is,

3.6. Numerical Procedure

The equations describing the states of the MEV, the steam-filled parts of the circuit and the absorber regions are formally coupled by shared state variables. Therefore, stepwise calculation can lead to oscillations of these variables. Some of these oscillations, like the pressure transients observed in reality [

8], p. 67 are caused by the physical processes. Others, which could be limited by a sufficiently short time step, are caused by the numerical procedure. A time step of 0.2 s proved to be a good compromise between computing time and time resolution. Inexplicable peaks and oscillations are sufficiently canceled out by taking the average of new and previous values of pressure, saturation temperature and the change rates of heat, where the previous values are weighted by a factor of 20. The consequently resulting infringement of the law of conservation of energy is negligible.

The residual mass of the system with standard selective absorbers is calculated based on a 5 min average of solar irradiation. For the system with thermochromic absorbers the solar irradiation is averaged over 10 min. The starting point of the time series is taken as the moment when saturation conditions are reached.

Eleven experimental data sets for both solar thermal systems were available. According to the properties of the model only four data sets from experiments with inactive check valves were used for model calibration. The unknown parameters were determined iteratively by a qualitative procedure displayed in

Figure 9.

An initial value for the parameter, KS, for the effective stagnation temperature in Equation (2), was chosen. The distribution parameter, δ, was varied until the measured and simulated steam ranges matched. The corresponding efficiency of the meander region, ηM, was stored for curve fitting. The time evolutions of the measured and simulated steam ranges were compared. If the gradients of the simulated steam range, which depend on the efficiency, were too small, the value of the parameter, KS, was increased and vice versa. This procedure was repeated until the steam ranges and the time evolutions matched. Finally, the parameters of the distribution function, Equation (49), were determined, based on the final values δ(ηM).

5. Conclusions

A transient model for the stagnation of solar thermal systems was developed based on the integral form of a two-phase mixture model. Based on scientific articles, and the author’s own experience that fast pressure transients with large amplitudes do not occur, the momentum conservation equation was replaced with a simple pressure balance and a drift flux model. With successive simplifications, it was possible to derive at a one-dimensional representation of the mixture model. The resulting differential equation for the steam range could be analytically integrated over short time periods. Thus, stability problems were avoided, and efficient computing was achieved.

The fact that displacement and steam generation occur at the same time has been considered by defining two time-dependent volume fractions, one completely liquid-filled, the other containing steam and residual liquid. Steam generation within the liquid-filled volume fraction is attributed to liquid displacement, whereas evaporation of the residual mass is linked to steam generation. This made it possible to formulate liquid displacement and steam expansion into the circuit by two sets of energy and mass conservation equations. Heat losses from collectors and pipes to the ambient are modelled by well-established correlations for convective and radiative heat transfer. A transient model for the gas temperature inside the membrane expansion vessel was also derived. The model leaves only four parameters unknown, which were determined by comparison of experimental and simulated data. One parameter, in Equation (2), accounts for the fact that the effective stagnation temperature of a collector lies between the temperature of dry stagnation and the temperature where the solar gain at normal operating conditions is zero. The other three parameters are numerical values within Equation (49), which defines the ratio of residual mass relevant for steam expansion into the circuit to the residual mass calculated by the drift flux model. The model is applicable to solar systems with flat-plate collectors and meander-type absorbers with tube diameters ≤9 mm. Application to other hydraulic concepts and larger diameters of absorber tube requires different correlations for the residual mass and calibration experiments with collectors of the particular hydraulic concept.

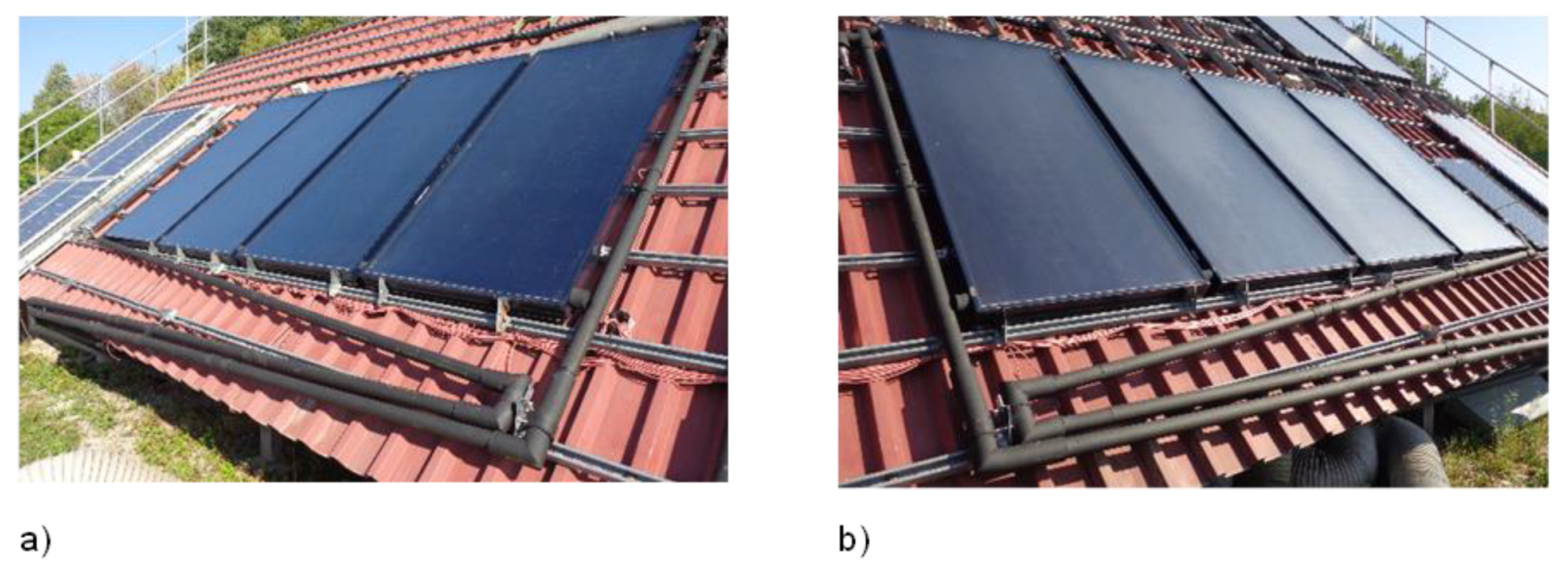

In order to calibrate the model, an experimental facility was designed and built, dedicated to the performance of well-defined stagnation tests under real conditions. The facility consists of two solar thermal systems, the one with standard selective absorbers, the other with thermochromic absorbers. Two spring-loaded check valves prevent natural circulation in the circuit and protect the pump from hot liquid and/or steam during stagnation. Experiments with active and deactivated check valves were carried out. Because the model does not account for the effects of the check valves, only experiments with deactivated check valves were used to determine the unknown parameters.

In the experiments where the check valves were deactivated, i.e., opened immediately after pump shutdown, the experimental values of the liquid levels in the supply and return lines were almost equal. Therefore the simulated progression of the steam ranges in the supply and return lines correspond well to the experimental values.

The experiments with active check valves show a distinct difference of the liquid levels due to the opening pressure of the check valves. The simulation result of the system with standard selective absorbers correspond well to data from experiments with active as well as deactivated check valves. Thus, check valves have practically no effect on the total steam range. It can be concluded that the magnitude of the pressure losses within the meander tube is larger than the opening pressure of the check valves.

The simulation results of the system with thermochromic absorbers correspond well to data from experiments with deactivated check valves. With activated check valves, both the progression of the steam range and its total maximum differ considerably. Due to the much lower velocities of steam and liquid in the system with thermochromic absorbers, the associated pressure losses are lower than the opening pressure of the check valves. Therefore, phase separation is more pronounced, and a larger amount of liquid is displaced via the return line, resulting in a smaller amount of residual liquid and, in consequence, a smaller steam range. Because the model does not account for the effects of the check valves, the simulation tends to overestimate the steam range.

It is important to note that the effect of the check valves must be considered when dimensioning a solar system. It is suggested that the steam range in the supply and return line should be corrected in accordance to Equations (94), which are functions of the inclination angle and the number,

n, of the check valves and their opening pressure, ∆

p.

In general, the model is capable of predicting the maximum steam range well within the accuracy needed for system design. Due to the complexity of the experimental facility, which represents two real systems, as well as the transient ambient conditions and the limited number of sensors, it is not possible to attribute experimental data accurately to certain effects.

The model is implemented into the open-source simulation tool THD, dedicated to the thermal-hydraulic dimensioning of solar systems up to about 100 m

2 collector area [

17,

36]. The actual size is limited mainly by the validity of the assumption that pressure losses during stagnation are negligible. Tools of this kind will become increasingly important as the key to designing both cost effective and operationally safe solar systems.