The Effect of Heat Removal during Thermophilic Phase on Energetic Aspects of Biowaste Composting Process

Abstract

:1. Introduction

1.1. Composting as an Exothermic Method of Biowaste Processing

1.2. Materials for Composting

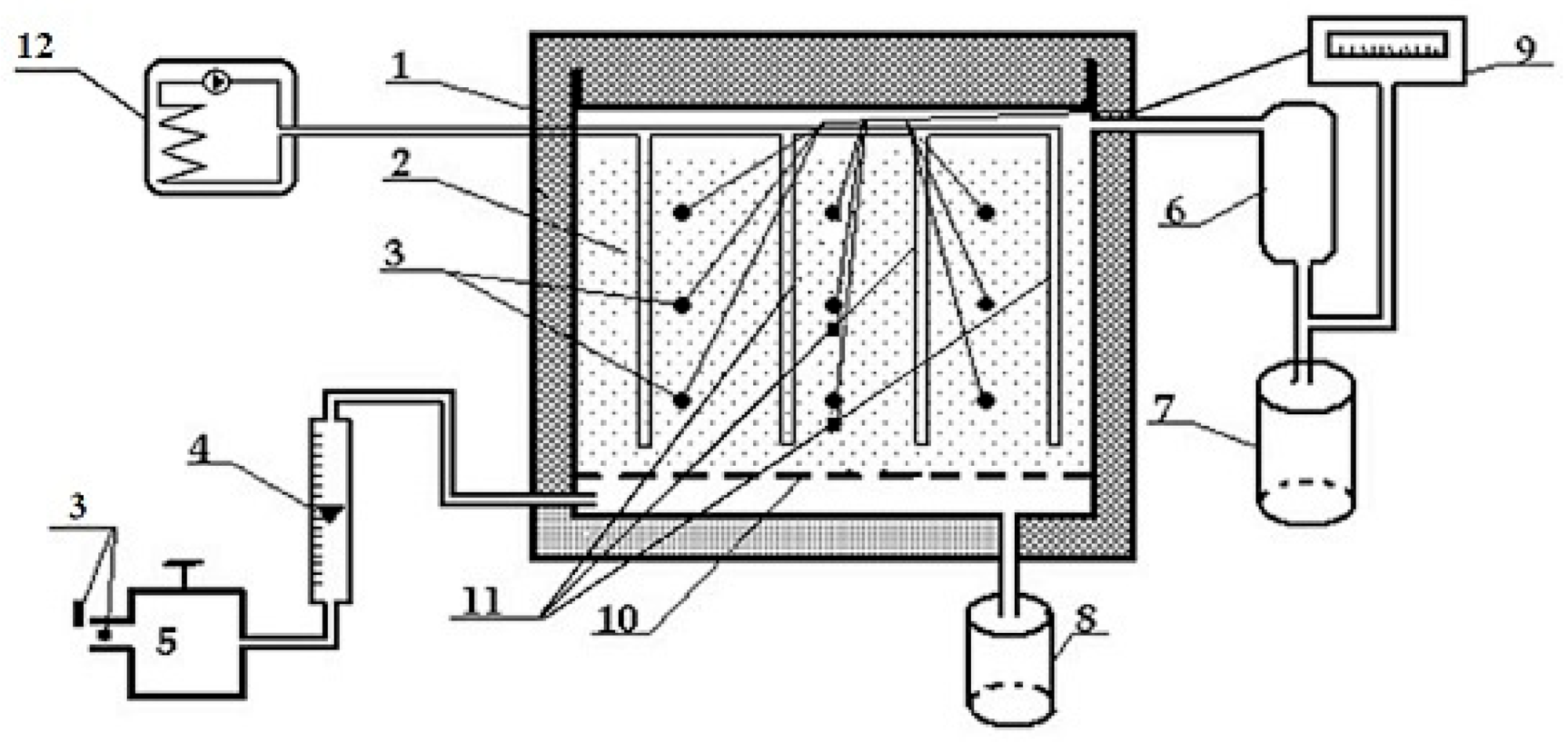

2. Materials and Methods

3. Results

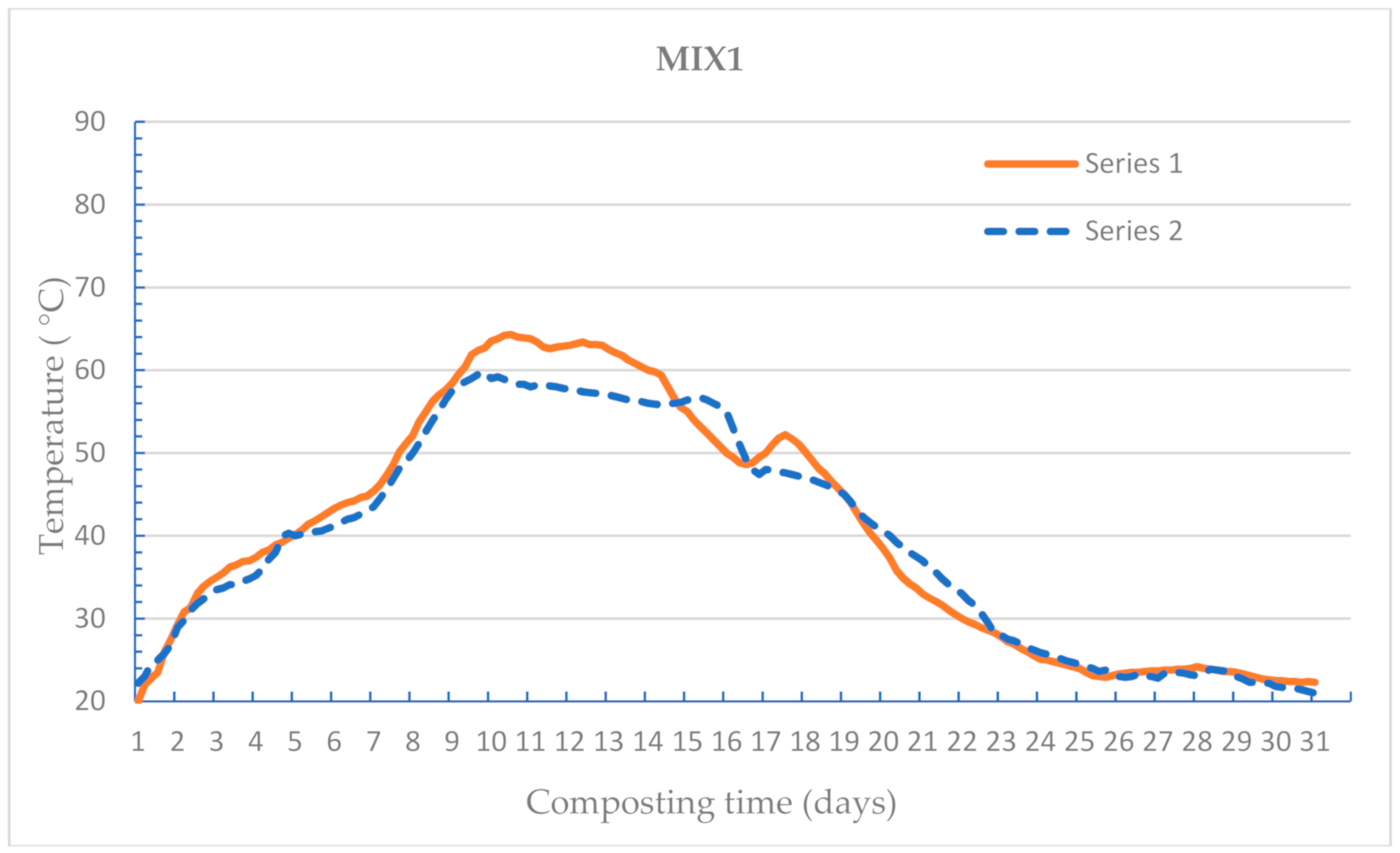

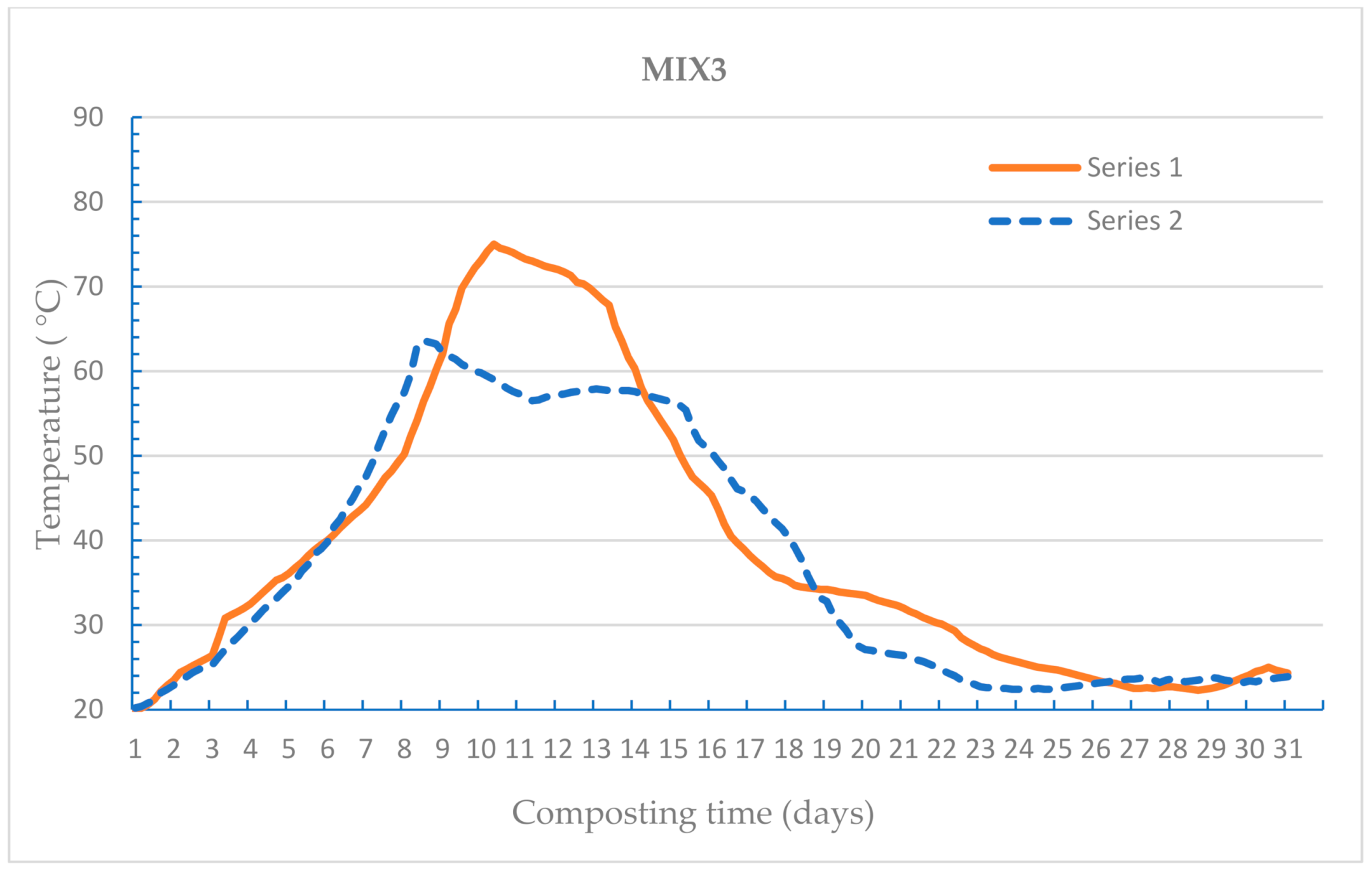

3.1. Temperature

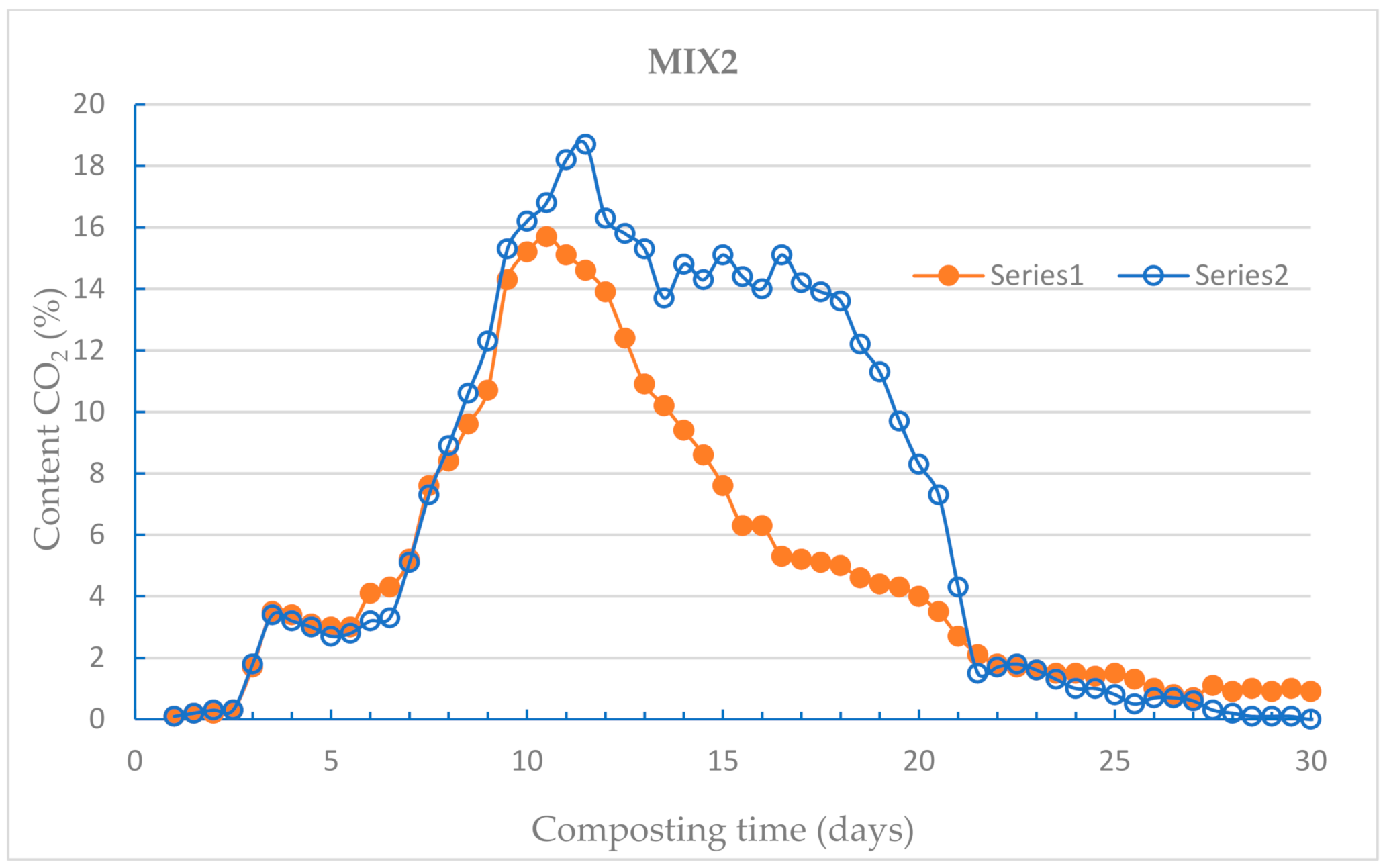

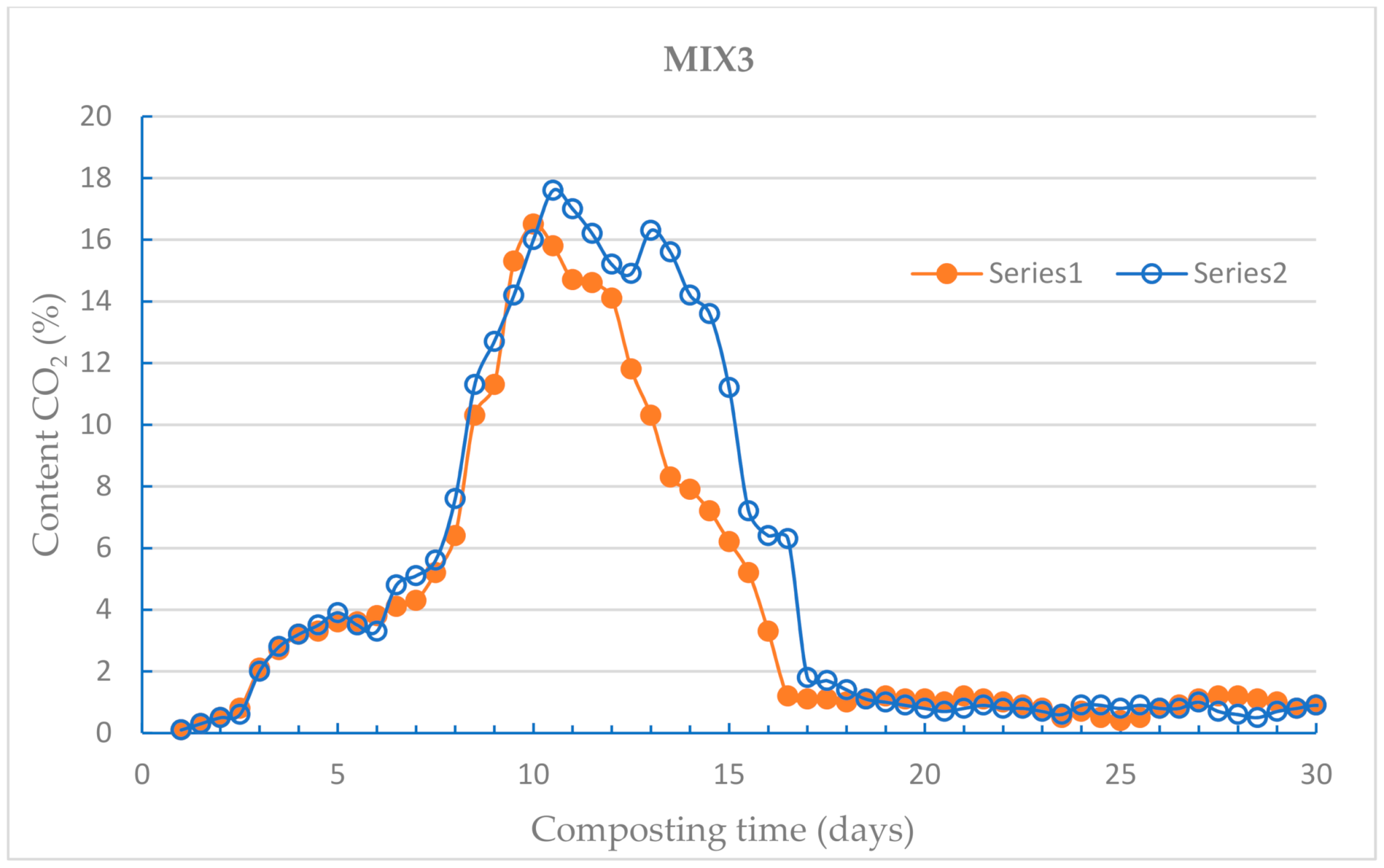

3.2. Carbon Dioxide Emissions

3.3. Heat Recovery

4. Discussion

5. Conclusions

- The addition of spent coffee grounds (10%) for the composting of green bio-waste materials (cabbage leaves with straw addition) increases the effectiveness of the composting process.

- In each of all the investigated cases, the discharge of heat excess by the refrigeration system caused a prolongation of the thermophilic phase. Presumably, this shows that temperatures in the range 55–65 °C create the best thermal comfort for the growth of the microorganisms and decomposition of organic material, which was also confirmed by the increased emission of carbon dioxide from the cooled composts with added coffee grounds (MIX2 and MIX3).

- Heat recovery during the most intense part of the thermophilic phase has provided thermal comfort for the microorganisms by keeping the temperature in the range of 55–65 °C. The effect was the higher CO2 emission from cooled materials, which is an effect of higher microbial activity.

- The amount of heat recovered, even in the case of MIX2 (1950 kJ · kg−1 dry matter), is not high, but for large installations for biological waste composting, it can be used, for example, to heat the batch in the following bioreactors in winter conditions or for other similar purposes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baran, S.; Wójcikowska-Kapusta, A.; Zukowska, G.; Bik-Małodzińska, M.; Wesołowska-Dobruk, S. Influence of sludge-ash composts on some properties of reclaimed land. Arch. Environ. Prot. 2015, 41, 82–88. [Google Scholar] [CrossRef] [Green Version]

- Piotrowska-Cyplik, A.; Chrzanowski, Ł.; Cyplik, P.; Dach, J.; Olejnik, A.; Staninska, J.; Czarny, J.; Lewicki, A.; Marecik, R.; Powierska-Czarny, J. Composting of oiled bleaching earth: Fatty acids degradation, phytotoxicity and mutagenicity changes. Int. Biodeterior. Biodegrad. 2013, 78, 49–57. [Google Scholar] [CrossRef]

- Bohacz, J. Composts and Water Extracts of Lignocellulosic Composts in the Aspect of Fertilization, Humus-Forming, Sanitary, Phytosanitary and Phytotoxicity Value Assessment. Waste Biomass Valorization 2019, 10, 2837–2850. [Google Scholar] [CrossRef] [Green Version]

- Dach, J.; Mazurkiewicz, J.; Janczak, D.; Pulka, J.; Pochwatka, P.; Kowalczyk-Jusko, A. Cow Manure Anaerobic Digestion or Composting—Energetic and Economic Analysis. In Proceedings of the 2020 4th International Conference on Green Energy and Applications, Singapore, 7–9 March 2020; pp. 143–147. [Google Scholar] [CrossRef]

- Ayilara, M.; Olanrewaju, O.; Babalola, O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Maroušek, J.; Bartoš, P.; Filip, M.; Kolář, L.; Konvalina, P.; Maroušková, A.; Moudrý, J.; Peterka, J.; Šál, J.; Šoch, M.; et al. Advances in the agrochemical utilization of fermentation residues reduce the cost of purpose-grown phytomass for biogas production. Energy Sources Part A Recover. Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

- Al-Alawi, M.; Szegi, T.; El Fels, L.; Hafidi, M.; Simon, B.; Gulyas, M. Green waste composting under GORE(R) cover membrane at industrial scale: Physico-chemical properties and spectroscopic assessment. Int. J. Recycl. Org. Waste Agric. 2019, 8, 385–397. [Google Scholar] [CrossRef] [Green Version]

- Lohri, C.R.; Diener, S.; Zabaleta, I.; Mertenat, A.; Zurbrügg, C. Treatment technologies for urban solid biowaste to create value products: A review with focus on low- and middle-income settings. Rev. Environ. Sci. Biotechnol. 2017, 16, 81–130. [Google Scholar] [CrossRef] [Green Version]

- Manyi-Loh, C.; Mamphweli, S.; Meyer, E.; Okoh, A. Antibiotic use in agriculture and its consequential resistance in environmental sources: Potential public health implications. Molecules 2018, 23, 795. [Google Scholar] [CrossRef] [Green Version]

- Nakasaki, K.; Ohtaki, A.; Takemoto, M.; Fujiwara, S. Production of well-matured compost from night-soil sludge by an extremely short period of thermophilic composting. Waste Manag. 2011, 31, 495–501. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Liu, K.; Price, G.W. Evaluation of three composting systems for the management of spent coffee grounds. Bioresour. Technol. 2011, 102, 7966–7974. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, S.; Yuan, Z. Adoption of solid organic waste composting products: A critical review. J. Clean. Prod. 2020, 272, 122712. [Google Scholar] [CrossRef]

- Agnew, J.M.; Leonard, J.J. The physical properties of compost. Compost Sci. Util. 2003, 11, 238–264. [Google Scholar] [CrossRef]

- Blazy, V.; De-Guardia, A.; Benoist, J.C.; Daumoin, M.; Lemasle, M.; Wolbert, D.; Barrington, S. Process conditions influence on pig slaughter house compost quality under forced aeration. Waste Biomass Valorization 2014, 5, 451–468. [Google Scholar] [CrossRef]

- Sołowiej, P.; Neugebauer, M.; Dach, J.; Czekała, W.; Janczak, D. The influence of substrate C: N ratios on heat generation during the composting process of sewage sludge. Int. J. Smart Grid Clean Energy 2017. [Google Scholar] [CrossRef]

- Li, X.; Shi, X.S.; Yang, Z.M.; Xu, X.H.; Guo, R.B. Effects of recyclable ceramsite as the porous bulking agent during the continuous thermophilic composting of dairy manure. J. Clean. Prod. 2019, 217, 344–351. [Google Scholar] [CrossRef]

- Xu, J.; Lu, Y.; Shan, G.; He, X.S.; Huang, J.; Li, Q. Inoculation with Compost-Born Thermophilic Complex Microbial Consortium Induced Organic Matters Degradation While Reduced Nitrogen Loss During Co-Composting of Dairy Manure and Sugarcane Leaves. Waste Biomass Valorization 2019, 10, 2467–2477. [Google Scholar] [CrossRef]

- Neugebauer, M.; Solowiej, P.; Nalepa, K.; Janczak, D.; Czechlowski, M. The dependence on the dynamics of the composting process and greenhouse gas emissions from the amount of maize straw addition to sewage sludge. Int. Multidiscip. Sci. GeoConf. SGEM 2016, 3, 39–46. [Google Scholar] [CrossRef]

- Hogland, W.; Bramryd, T.; Persson, I. Physical, biological and chemical effects of unsorted fractions of industrial solid waste in waste fuel storage. Waste Manag. Res. 1996, 14, 197–210. [Google Scholar] [CrossRef]

- Neugebauer, M. The use of biological waste as a source of low-temperature heat for hotbeds in spring in north-eastern Poland. J. Environ. Manag. 2018, 225, 133–138. [Google Scholar] [CrossRef]

- Smith, M.M.; Aber, J.D.; Rynk, R. Heat Recovery from Composting: A Comprehensive Review of System Design, Recovery Rate, and Utilization. Compost Sci. Util. 2017, 25, S11–S22. [Google Scholar] [CrossRef]

- Schmaltz, K. Bio-generated greenhouse heating project. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Seattle, WA, USA, 11–15 November 2007; Volume 15, pp. 235–243. [Google Scholar] [CrossRef]

- Bajko, J.; Fišer, J.; Jícha, M. Condenser-Type Heat Exchanger for Compost Heat Recovery Systems. Energies 2019, 12, 1583. [Google Scholar] [CrossRef] [Green Version]

- Smith, M.M.; Aber, J.D. Energy recovery from commercial-scale composting as a novel waste management strategy. Appl. Energy 2018, 211, 194–199. [Google Scholar] [CrossRef]

- Wolna-Maruwka, A.; Dach, J. Effect of type and proportion of different structure-creating additions on the inactivation rate of pathogenic bacteria in sewage sludge composting in a cybernetic bioreactor. Arch. Environ. Prot. 2009, 35, 87–100. [Google Scholar]

- Maroušek, J.; Strunecký, O.; Kolář, L.; Vochozka, M.; Kopecký, M.; Maroušková, A.; Batt, J.; Poliak, M.; Šoch, M.; Bartoš, P.; et al. Advances in nutrient management make it possible to accelerate biogas production and thus improve the economy of food waste processing. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–10. [Google Scholar] [CrossRef]

- Jakubowski, T.; Giełżecki, J. The Use of Compost Produced with the Addition of Wastes from a Poultry Farm in Potato-Growing. In Renewable Energy Sources: Engineering, Technology, Innovation: ICORES 2018; Wróbel, M., Jewiarz, M., Szlęk, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 735–741. [Google Scholar] [CrossRef]

- Cecchi, F.; Cavinato, C. Smart Approaches to Food Waste Final Disposal. Int. J. Environ. Res. Public Health 2019, 16, 2860. [Google Scholar] [CrossRef] [Green Version]

- Janczak, D.; Malińska, K.; Czekała, W.; Cáceres, R.; Lewicki, A.; Dach, J. Biochar to reduce ammonia emissions in gaseous and liquid phase during composting of poultry manure with wheat straw. Waste Manag. 2017, 66, 36–45. [Google Scholar] [CrossRef] [PubMed]

- Morales, A.B.; Bustamante, M.A.; Marhuenda-Egea, F.C.; Moral, R.; Ros, M.; Pascual, J.A. Agri-food sludge management using different co-composting strategies: Study of the added value of the composts obtained. J. Clean. Prod. 2016, 121, 186–197. [Google Scholar] [CrossRef]

- Al-Rumaihi, A.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Environmental Impact Assessment of Food Waste Management Using Two Composting Techniques. Sustainability 2020, 12, 1595. [Google Scholar] [CrossRef] [Green Version]

- Maroušek, J.; Rowland, Z.; Valášková, K.; Král, P. Techno-economic assessment of potato waste management in developing economies. Clean Technol. Environ. Policy 2020, 22, 937–944. [Google Scholar] [CrossRef]

- Barthod, J.; Rumpel, C.; Dignac, M.F. Composting with additives to improve organic amendments. A review. Agron. Sustain. Dev. 2018, 38, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Czekała, W.; Malińska, K.; Cáceres, R.; Janczak, D.; Dach, J.; Lewicki, A. Co-composting of poultry manure mixtures amended with biochar—The effect of biochar on temperature and C-CO2 emission. Bioresour. Technol. 2016, 200, 921–927. [Google Scholar] [CrossRef] [PubMed]

- Aviani, I.; Laor, Y.; Medina, S.; Krassnovsky, A.; Raviv, M. Co-composting of solid and liquid olive mill wastes: Management aspects and the horticultural value of the resulting composts. Bioresour. Technol. 2010, 101, 6699–6706. [Google Scholar] [CrossRef]

- Yang, Y.; Du, W.; Ren, X.; Cui, Z.; Zhou, W.; Lv, J. Effect of bean dregs amendment on the organic matter degradation, humification, maturity and stability of pig manure composting. Sci. Total Environ. 2020, 708, 134623. [Google Scholar] [CrossRef]

- Hashemi, S.; Boudaghpour, S.; Han, M. Evaluation of different natural additives effects on the composting process of source separated feces in resource-oriented sanitation systems. Ecotoxicol. Environ. Saf. 2019, 185. [Google Scholar] [CrossRef] [PubMed]

- Kopeć, M.; Baran, A.; Mierzwa-Hersztek, M.; Gondek, K.; Chmiel, M.J. Effect of the Addition of Biochar and Coffee Grounds on the Biological Properties and Ecotoxicity of Composts. Waste Biomass Valorization 2018, 9, 1389–1398. [Google Scholar] [CrossRef] [Green Version]

- Murthy, P.S.; Madhava Naidu, M. Sustainable management of coffee industry by-products and value addition—A review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- ICO, 2020. International Coffee Organization. Coffee Market Report 2020. Available online: http://www.ico.org/historical/1990%20onwards/PDF/1a-total-production.pdf (accessed on 28 August 2020).

- Zuorro, A.; Lavecchia, R. Spent coffee grounds as a valuable source of phenolic compounds and bioenergy. J. Clean. Prod. 2012, 34, 49–56. [Google Scholar] [CrossRef]

- Hue, N.V.; Bittenbender, H.C.; Ortiz-Escobar, M.E. Managing coffee processing water in Hawaii. J. Hawaii. Pac. Agric. 2006, 13, 15–21. [Google Scholar]

- Melo, G.; Melo, V.; Melo, W. Compostagem (Composting). Faculdade de Ciȇncas Agrárias e Veterinarinárias Jaboticabal, Brasil. 2007, pp. 1–3. Available online: http://www.ambientenet.eng.br/TEXTOS/COMPOSTAGEM.pdf (accessed on 30 August 2020). (In Portuguese).

- Mussatto, S.I.; Carneiro, L.M.; Silva, J.P.A.; Roberto, I.C.; Teixeira, J.A. A study on chemical constituents and sugars extraction from spent coffee grounds. Carbohydr. Polym. 2011, 83, 368–374. [Google Scholar] [CrossRef] [Green Version]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef] [Green Version]

- Nogueira, W.A.; Nogueira, F.N.; Devens, D.C. Temperature and pH control in composting of coffee and agricultural wastes. Water Sci. Technol. 1999, 40, 113–119. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, Composition, and Application of Coffee and Its Industrial Residues. Food Bioprocess Technol. 2011, 4, 661–672. [Google Scholar] [CrossRef] [Green Version]

- Caetano, N.; Silva, V.; Mata, T.M. Valorization of Coffee Grounds for Biodiesel Production. Chem. Eng. Trans. 2012, 26, 267–272. [Google Scholar] [CrossRef]

- Bizzo, W. Geração, Distribuição e Utilização de Vapor (Generation, Distribution, and Use of Steam), Apostila de Curso, UNICAMP, Brasil. 2003. Available online: http://www.fem.unicamp.br/~em672/GERVAP1.pdf (accessed on 30 August 2020). (In Portuguese).

- Santos, C.; Fonseca, J.; Aires, A.; Coutinho, J.; Trindade, H. Effect of different rates of spent coffee grounds (SCG) on composting process, gaseous emissions and quality of end-product. Waste Manag. 2017, 59, 37–47. [Google Scholar] [CrossRef] [PubMed]

- Hachicha, R.; Rekik, O.; Hachicha, S.; Ferchichi, M.; Woodward, S.; Moncef, N.; Cegarra, J.; Mechichi, T. Co-composting of spent coffee ground with olive mill wastewater sludge and poultry manure and effect of Trametes versicolor inoculation on the compost maturity. Chemosphere 2012, 88, 677–682. [Google Scholar] [CrossRef]

- Karmee, S.K. A spent coffee grounds based biorefinery for the production of biofuels, biopolymers, antioxidants and biocomposites. Waste Manag. 2018, 72, 240–254. [Google Scholar] [CrossRef] [PubMed]

- Haile, M. Integrated volarization of spent coffee grounds to biofuels. Biofuel Res. J. 2014, 1, 65–69. [Google Scholar] [CrossRef]

- Seco, A.; Espuelas, S.; Marcelino, S.; Echeverría, A.M.; Prieto, E. Characterization of Biomass Briquettes from Spent Coffee Grounds and Xanthan Gum Using Low Pressure and Temperature. Bioenergy Res. 2020, 13, 369–377. [Google Scholar] [CrossRef]

- Sołowiej, P.; Neugebauer, M. Impact of Coffee Grounds Addition on the Calorific Value of the Selected Biological Materials. Agric. Eng. 2016, 20, 177–183. [Google Scholar] [CrossRef] [Green Version]

- Limousy, L.; Jeguirim, M.; Dutournié, P.; Kraiem, N.; Lajili, M.; Said, R. Gaseous products and particulate matter emissions of biomass residential boiler fired with spent coffee grounds pellets. Fuel 2013, 107, 323–329. [Google Scholar] [CrossRef]

- Kante, K.; Nieto-Delgado, C.; Rangel-Mendez, J.R.; Bandosz, T.J. Spent coffee-based activated carbon: Specific surface features and their importance for H 2S separation process. J. Hazard. Mater. 2012, 201–202, 141–147. [Google Scholar] [CrossRef] [PubMed]

- Tsai, W.T.; Liu, S.C.; Hsieh, C.H. Preparation and fuel properties of biochars from the pyrolysis of exhausted coffee residue. J. Anal. Appl. Pyrolysis 2012, 93, 63–67. [Google Scholar] [CrossRef]

- Liu, C.; Pujol, D.; Olivella, M.; De La Torre, F.; Fiol, N.; Poch, J.; Villaescusa, I. The Role of Exhausted Coffee Compounds on Metal Ions Sorption. Water Air Soil Pollut. 2015, 226, 1–10. [Google Scholar] [CrossRef]

- Oliveira, W.E.; Franca, A.S.; Oliveira, L.S.; Rocha, S.D. Untreated coffee husks as biosorbents for the removal of heavy metals from aqueous solutions. J. Hazard. Mater. 2008, 152, 1073–1081. [Google Scholar] [CrossRef]

- Kwon, E.E.; Yi, H.; Jeon, Y.J. Sequential co-production of biodiesel and bioethanol with spent coffee grounds. Bioresour. Technol. 2013, 136, 475–480. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Carneiro, L.M.; Teixeira, J.A. Sugars metabolism and ethanol production by different yeast strains from coffee industry wastes hydrolysates. Appl. Energy 2012, 92, 763–768. [Google Scholar] [CrossRef] [Green Version]

- Carrasco-Cabrera, C.P.; Bell, T.L.; Kertesz, M.A. Caffeine metabolism during cultivation of oyster mushroom (Pleurotus ostreatus) with spent coffee grounds. Appl. Microbiol. Biotechnol. 2019, 103, 5831–5841. [Google Scholar] [CrossRef]

- Barreto, S.M.; López, M.V.; Levin, L. Effect of culture parameters on the production of the edible mushroom Grifola frondosa (maitake) in tropical weathers. World J. Microbiol. Biotechnol. 2008, 24, 1361–1366. [Google Scholar] [CrossRef]

- Silva, M.A.; Nebra, S.A.; Machado Silva, M.J.; Sanchez, C.G. The Use of Biomass Residues in The Brazilian Soluble Coffee Industry. Biomass Bioenergy 1998, 14, 457–467. [Google Scholar] [CrossRef]

- Küçük, Ç.; Tekgül, Y.T. Effects of cotton stalk, maize stalk and almond bark on some soil microbial activities. Arch. Environ. Prot. 2017, 43, 91–96. [Google Scholar] [CrossRef] [Green Version]

- Viel, M.; Sayag, D.; Peyre, A.; André, L. Optimization of In-vessel Co-composting through heat recovery. Biol. Wastes 1987, 20, 167–185. [Google Scholar] [CrossRef]

- Solowiej, P.; Neugebauer, M.; Nalepa, K.; Czekala, W.; Zbytek, Z. Energy efficiency of composting sewage sludge with the addition of maize straw. Int. Multidiscip. Sci. GeoConf. SGEM 2016. [Google Scholar] [CrossRef]

- Neugebauer, M.; Sołowiej, P.; Piechocki, J. Fuzzy control for the process of heat removal during the composting of agricultural waste. J. Mater. Cycles Waste Manag. 2014, 16, 291–297. [Google Scholar] [CrossRef] [Green Version]

- Błaszczyk, M.; Fit, M. Sukcesja mikroorganizmów w czasie kompostowania odpadów organicznych (The succession of microorganisms during composting of organic waste). In Proceedings of the VII Scientific and Technological Conference Water Sewage Waste in the Environment “Biological Treatment of Solid Biological Waste”, Zielona Góra, Poland, 9–10 September 2004; pp. 24–29. (In Polish). [Google Scholar]

- Guo, R.; Li, G.; Jiang, T.; Schuchardt, F.; Chen, T.; Zhao, Y.; Shen, Y. Effect of aeration rate, C/N ratio and moisture content on the stability and maturity of compost. Bioresour. Technol. 2012, 112, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Żukowska, G.; Mazurkiewicz, J.; Myszura, M.; Czekała, W. Heat Energy and Gas Emissions during Composting of Sewage Sludge. Energies 2019, 12, 4782. [Google Scholar] [CrossRef] [Green Version]

- Shemekite, F.; Gómez-Brandón, M.; Franke-Whittle, I.H.; Praehauser, B.; Insam, H.; Assefa, F. Coffee husk composting: An investigation of the process using molecular and non-molecular tools. Waste Manag. 2014, 34, 642–652. [Google Scholar] [CrossRef] [Green Version]

- Meng, L.; Li, W.; Zhang, X.; Zhao, Y.; Chen, L.; Zhang, S. Influence of spent mushroom substrate and molasses amendment on nitrogen loss and humification in sewage sludge composting. Heliyon 2020, 6, e04988. [Google Scholar] [CrossRef]

- Kliestik, T.; Misankova, M.; Valaskova, K.; Svabova, L. Bankruptcy Prevention: New Effort to Reflect on Legal and Social Changes. Sci. Eng. Ethics 2018, 24, 791–803. [Google Scholar] [CrossRef] [PubMed]

- Pochwatka, P.; Kowalczyk-Juśko, A.; Sołowiej, P.; Wawrzyniak, A.; Dach, J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies 2020, 13, 6058. [Google Scholar] [CrossRef]

- Xu, Z.; Li, G.; Huda, N.; Zhang, B.; Wang, M.; Luo, W. Effects of moisture and carbon/nitrogen ratio on gaseous emissions and maturity during direct composting of cornstalks used for filtration of anaerobically digested manure centrate. Bioresour. Technol. 2020, 298, 122503. [Google Scholar] [CrossRef]

- Calabi-Floody, M.; Medina, J.; Suazo, J.; Ordiqueo, M.; Aponte, H.; de Mora, M.L.L.; Rumpel, C. Optimization of wheat straw co-composting for carrier material development. Waste Manag. 2019, 98, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Siles-Castellano, A.B.; López, M.J.; Jurado, M.M.; Suárez-Estrella, F.; López-González, J.A.; Estrella-González, M.J.; Moreno, J. Industrial composting of low carbon/nitrogen ratio mixtures of agri-food waste and impact on compost quality. Bioresour. Technol. 2020, 316, 123946. [Google Scholar] [CrossRef] [PubMed]

- Kujawa, S.; Janczak, D.; Mazur, A. Image Analysis of Sewage Sludge and Barley Straw as Biological Materials Composted under Different Conditions. Materials 2019, 12, 3644. [Google Scholar] [CrossRef] [Green Version]

- Czekała, W.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kwiatkowska, A.; Kozłowski, K. Influence of maize straw content with sewage sludge on composting process. J. Water Land Dev. 2016, 30, 43–49. [Google Scholar] [CrossRef]

- Golbaz, S.; Zamanzadeh, M.Z.; Pasalari, H.; Farzadkia, M. Assessment of co-composting of sewage sludge, woodchips, and sawdust: Feedstock quality and design and compilation of computational model. Environ. Sci. Pollut. Res. 2020, 1–14. [Google Scholar] [CrossRef]

- Cai, H.; Chen, T.; Liu, H.; Gao, D.; Zheng, G.; Zhang, J. The effect of salinity and porosity of sewage sludge compost on the growth of vegetable seedlings. Sci. Hortic. 2010, 124, 381–386. [Google Scholar] [CrossRef]

- Li, Y.; Liu, T.; Song, J.; Lv, J.; Jiang, J. Effects of chemical additives on emissions of ammonia and greenhouse gas during sewage sludge composting. Process Saf. Environ. Prot. 2020, 143, 129–137. [Google Scholar] [CrossRef]

- Fillingham, M.A.; VanderZaag, A.C.; Burtt, S.; Baldé, H.; Ngwabie, N.M.; Smith, W.; Hakami, A.; Wagner-Riddle, C.; Bittman, S.; MacDonald, D. Greenhouse gas and ammonia emissions from production of compost bedding on a dairy farm. Waste Manag. 2017, 70, 45–52. [Google Scholar] [CrossRef]

- Bai, M.; Impraim, R.; Coates, T.; Flesch, T.; Trouvé, R.; van Grinsven, H.; Cao, Y.; Hill, J.; Chen, D. Lignite effects on NH3, N2O, CO2 and CH4 emissions during composting of manure. J. Environ. Manag. 2020, 271, 110960. [Google Scholar] [CrossRef]

- Chen, J.; Hou, D.; Pang, W.; Nowar, E.E.; Tomberlin, J.K.; Hu, R.; Chen, H.; Xie, J.; Zhang, J.; Yu, Z.; et al. Effect of moisture content on greenhouse gas and NH3 emissions from pig manure converted by black soldier fly. Sci. Total Environ. 2019, 697, 133840. [Google Scholar] [CrossRef]

- Bohacz, J. Microbial strategies and biochemical activity during lignocellulosic waste composting in relation to the occurring biothermal phases. J. Environ. Manag. 2018, 206, 1052–1062. [Google Scholar] [CrossRef] [PubMed]

- Antizar-Ladislao, B.; Irvine, G.; Lamont, E.R. Energy from waste: Reuse of compost heat as a source of renewable energy. Int. J. Chem. Eng. 2010. [Google Scholar] [CrossRef] [Green Version]

- Keil, C.; Plura, S.; Radspieler, M.; Schweigler, C. Application of customized absorption heat pumps for utilization of low-grade heat sources. Appl. Therm. Eng. 2008, 28, 2070–2076. [Google Scholar] [CrossRef]

- Rodrigues, C.R.S.; Machado, T.; Pires, A.L.; Chaves, B.; Carpinteiro, F.S.; Pereira, A.M. Recovery of thermal energy released in the composting process and their conversion into electricity utilizing thermoelectric generators. Appl. Therm. Eng. 2018, 138, 319–324. [Google Scholar] [CrossRef]

| TS (% FM) | VS (%TS) | Nitrogen (g/kg TS) | pH | C/N Ratio (-) | |

|---|---|---|---|---|---|

| Cabbage leaves | 9.11 | 90.3 | 21.0 | 5.91 | 20 |

| Wheat straw | 95.3 | 88.9 | 3.4 | 6.96 | 125 |

| Coffee grounds | 49.3 | 48.4 | 27.3 | 6.20 | 21 |

| Cabbage Leaves (kg) | Wheat Straw (kg) | Coffee Grounds (kg) | C/N Ratio (-) | |

|---|---|---|---|---|

| MIX1 | 10.0 | 1.0 | 0.0 | 35 |

| MIX2 | 10.0 | 1.0 | 1.0 | 29 |

| MIX3 | 10.0 | 1.0 | 2.0 | 27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sołowiej, P.; Pochwatka, P.; Wawrzyniak, A.; Łapiński, K.; Lewicki, A.; Dach, J. The Effect of Heat Removal during Thermophilic Phase on Energetic Aspects of Biowaste Composting Process. Energies 2021, 14, 1183. https://doi.org/10.3390/en14041183

Sołowiej P, Pochwatka P, Wawrzyniak A, Łapiński K, Lewicki A, Dach J. The Effect of Heat Removal during Thermophilic Phase on Energetic Aspects of Biowaste Composting Process. Energies. 2021; 14(4):1183. https://doi.org/10.3390/en14041183

Chicago/Turabian StyleSołowiej, Piotr, Patrycja Pochwatka, Agnieszka Wawrzyniak, Krzysztof Łapiński, Andrzej Lewicki, and Jacek Dach. 2021. "The Effect of Heat Removal during Thermophilic Phase on Energetic Aspects of Biowaste Composting Process" Energies 14, no. 4: 1183. https://doi.org/10.3390/en14041183

APA StyleSołowiej, P., Pochwatka, P., Wawrzyniak, A., Łapiński, K., Lewicki, A., & Dach, J. (2021). The Effect of Heat Removal during Thermophilic Phase on Energetic Aspects of Biowaste Composting Process. Energies, 14(4), 1183. https://doi.org/10.3390/en14041183