Performance Analysis and Optimization of a Vertical-Axis Wind Turbine with a High Tip-Speed Ratio

Abstract

1. Introduction

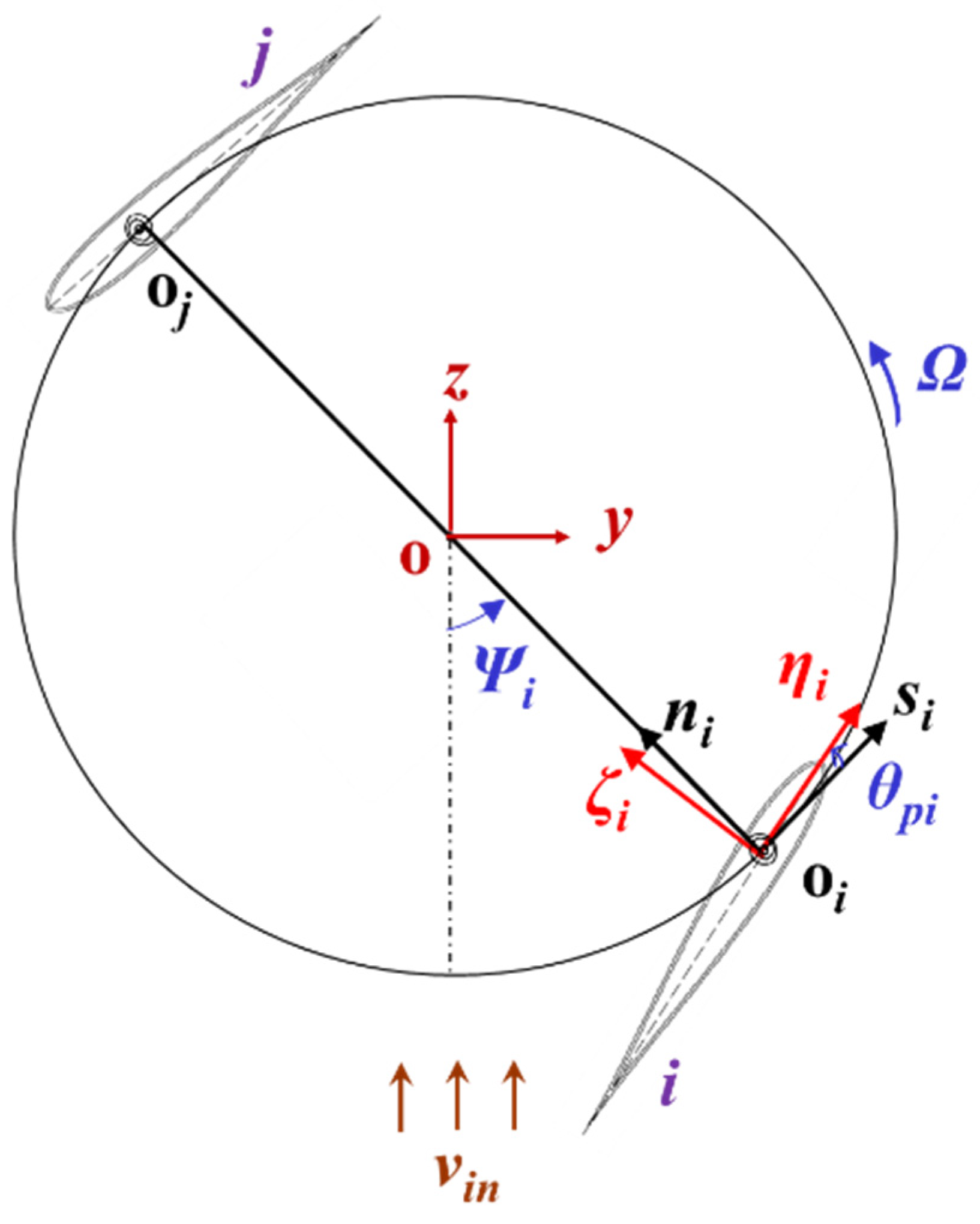

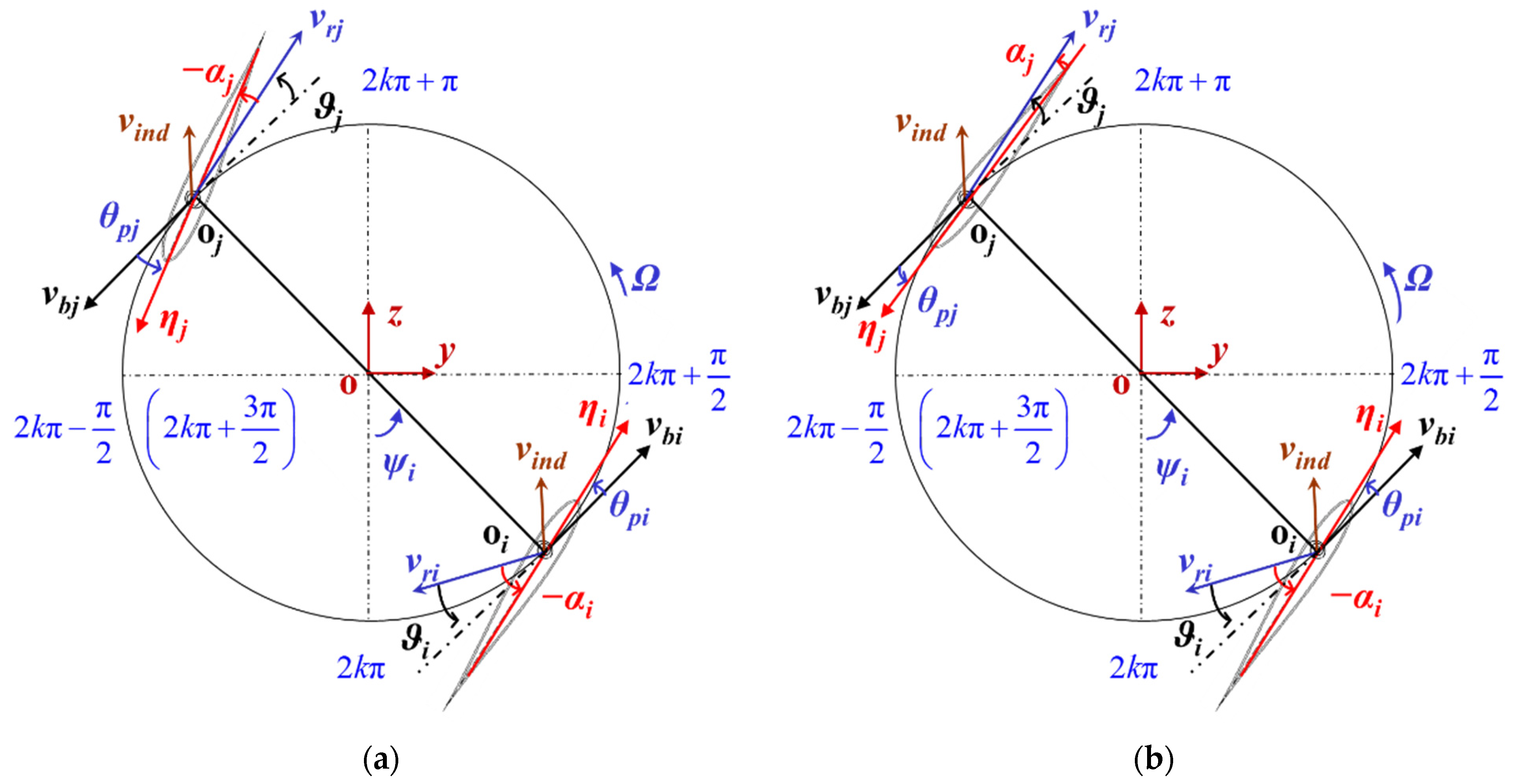

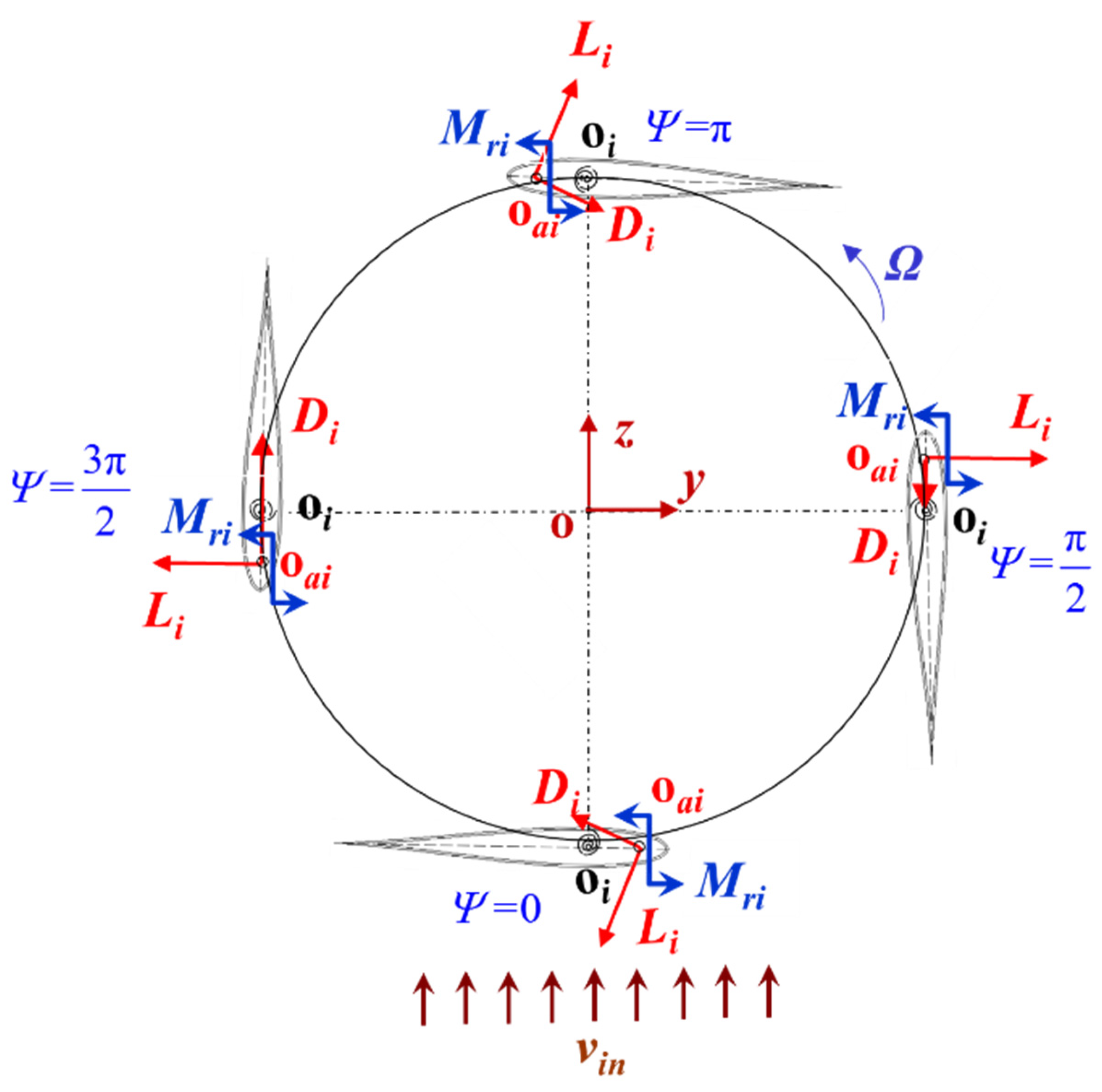

2. Analysis of Aerodynamic Loads

- (1)

- Upwind Area: (k = 0, 1, 2….)

- (2)

- Downwind Area: (k = 0, 1, 2….)

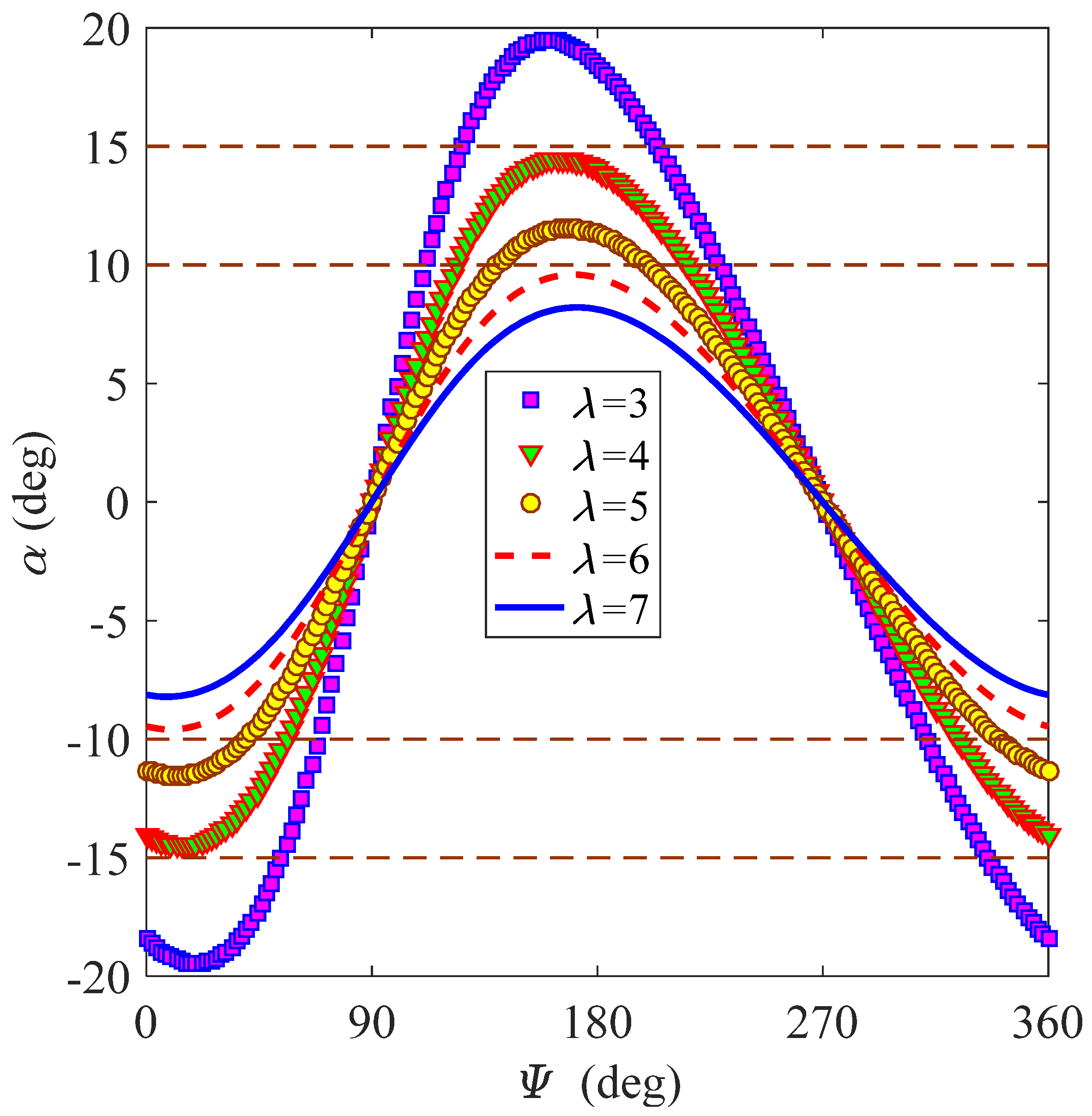

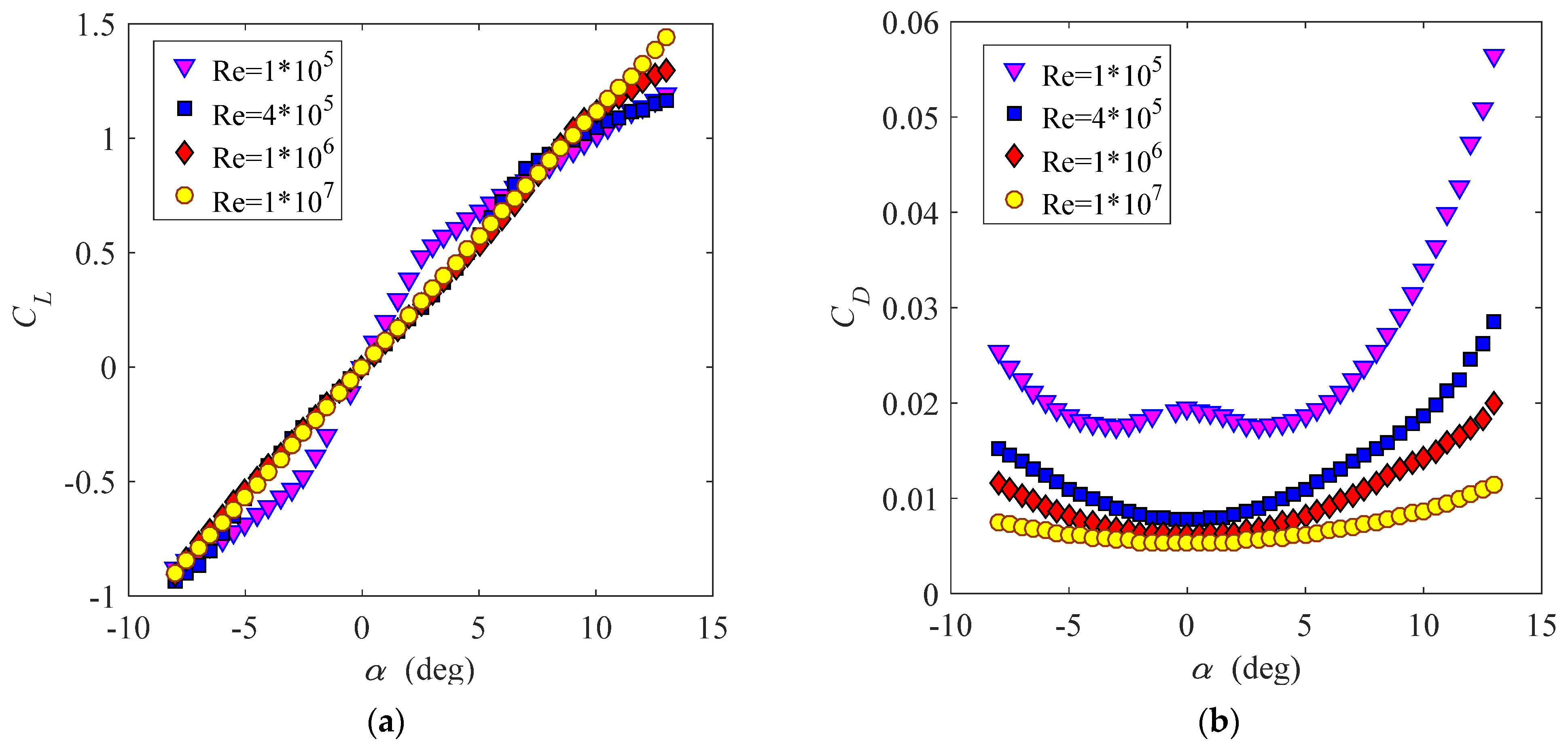

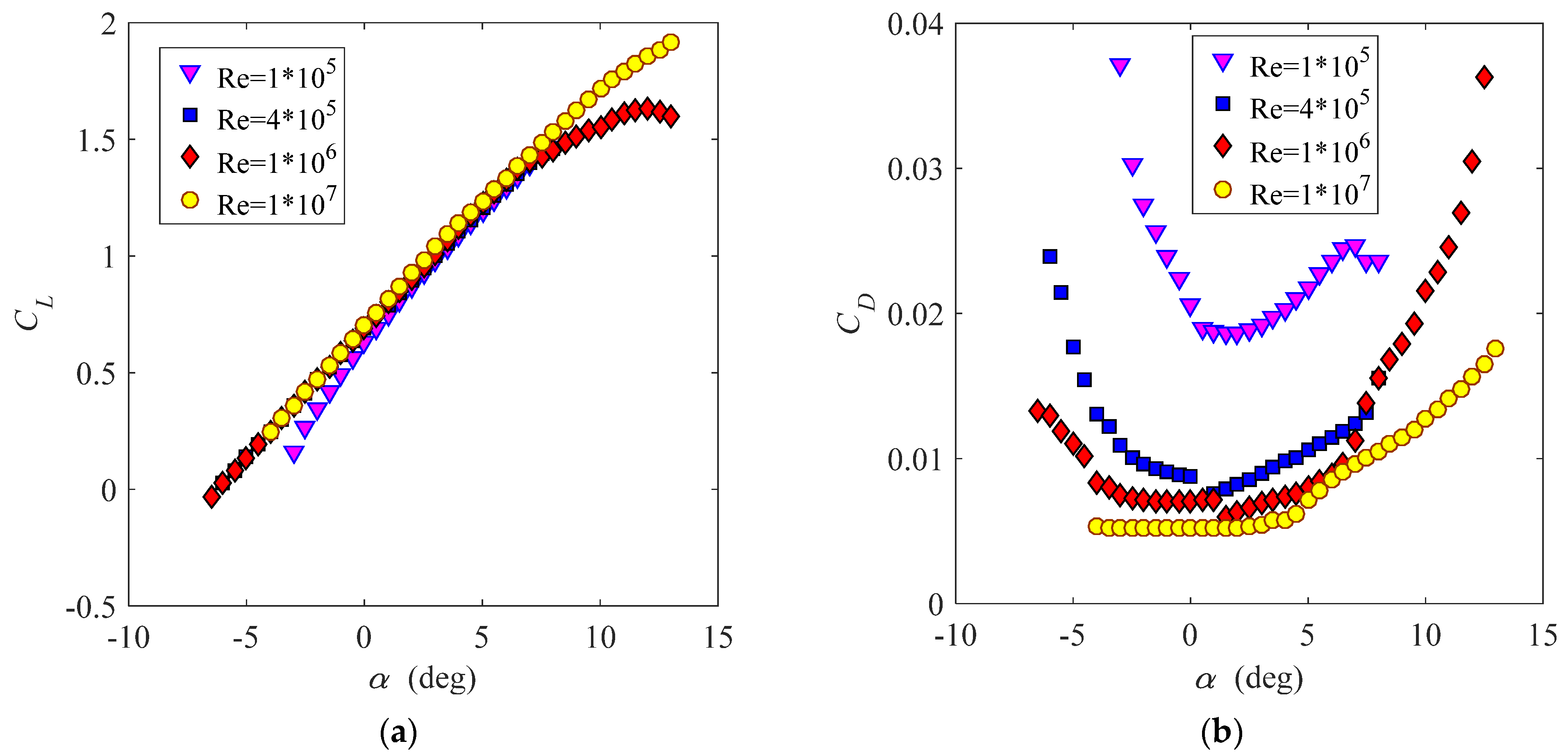

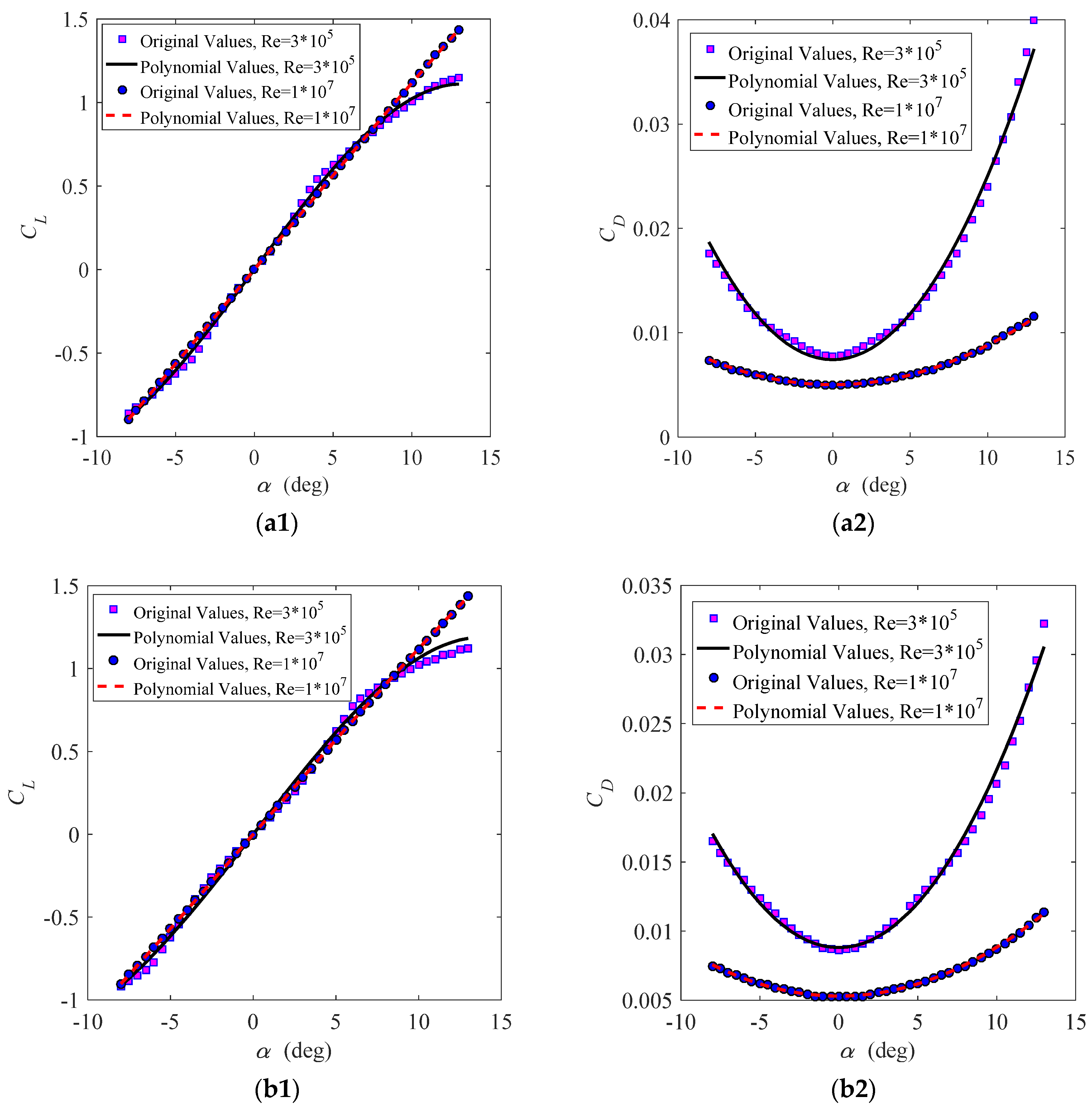

3. Performance Analysis of a Fixed-Pitch VAWT

3.1. Analytical Method for the Turbine Performance

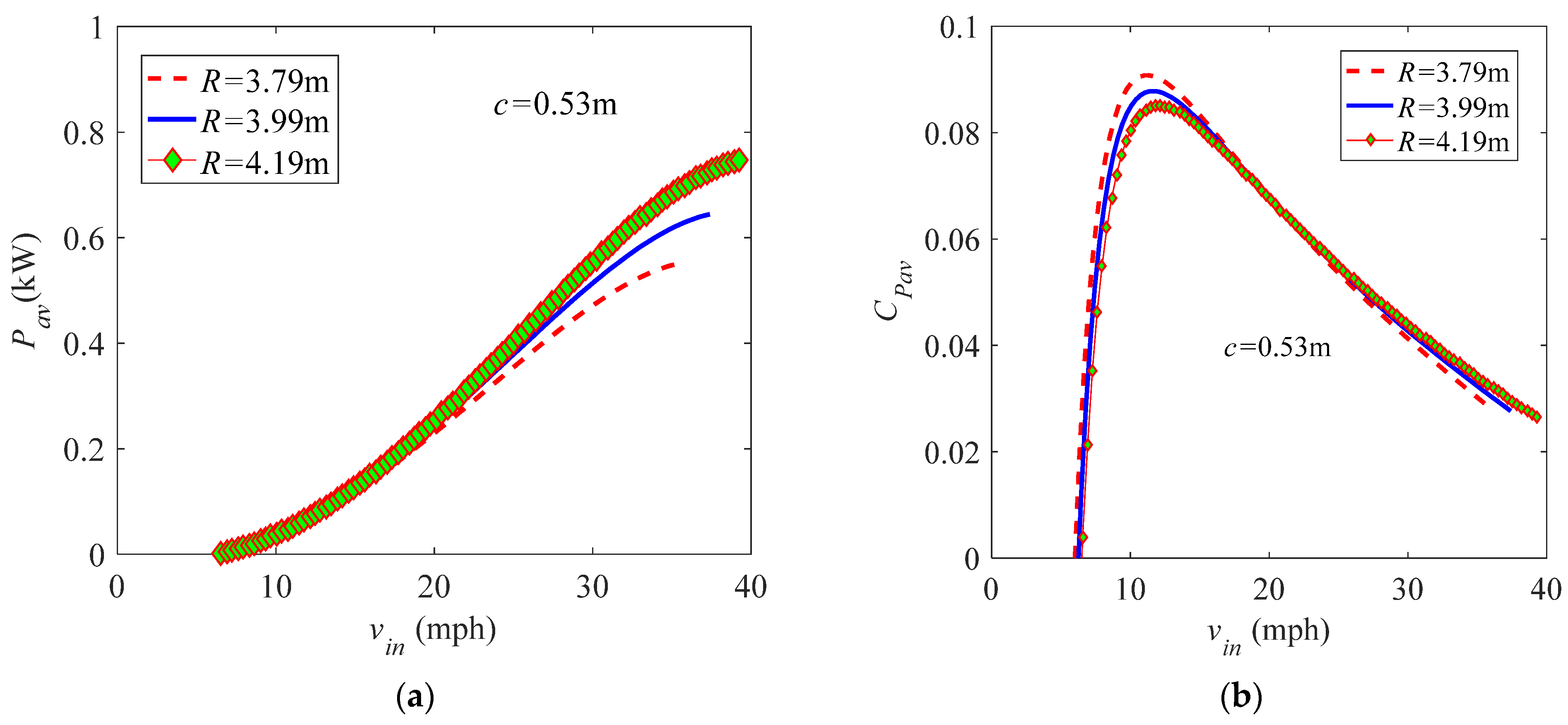

3.2. Performance of a Fixed-Pitch Turbine

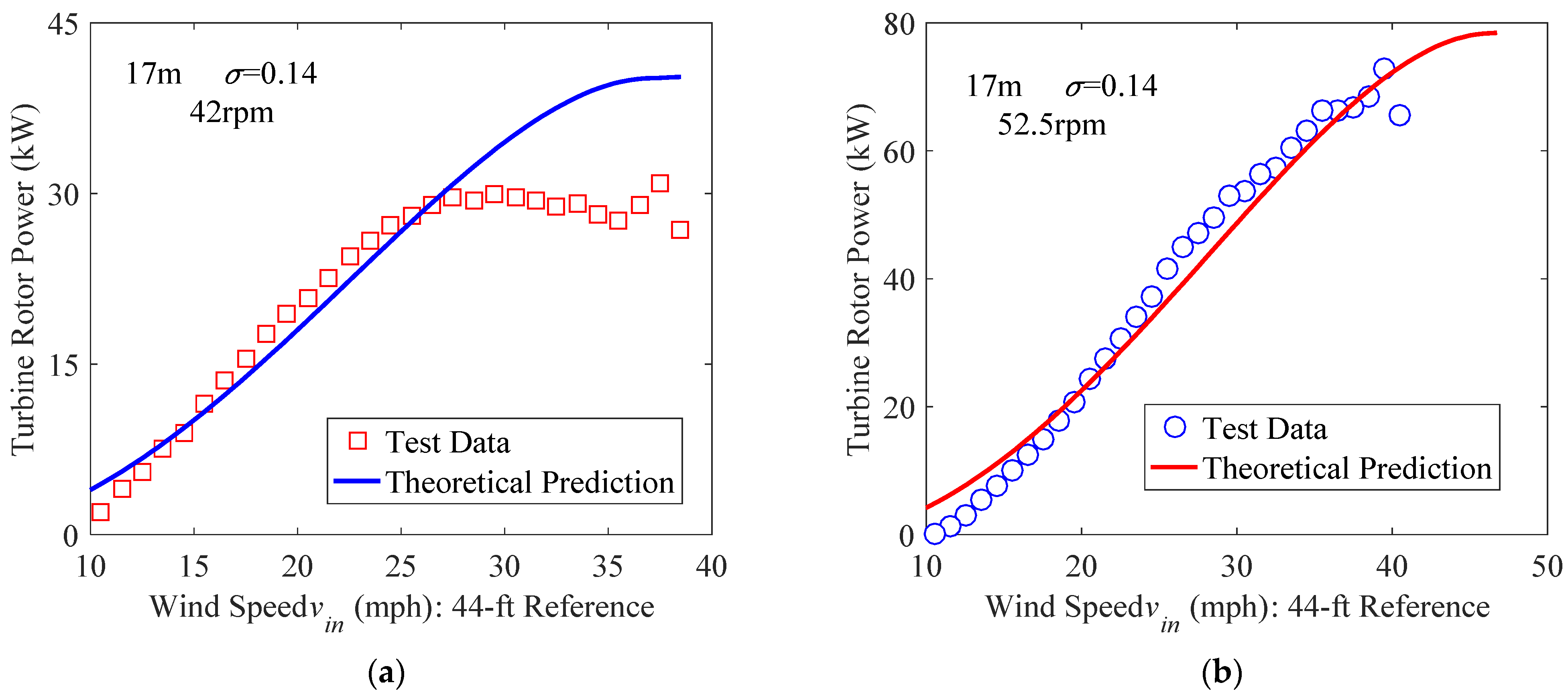

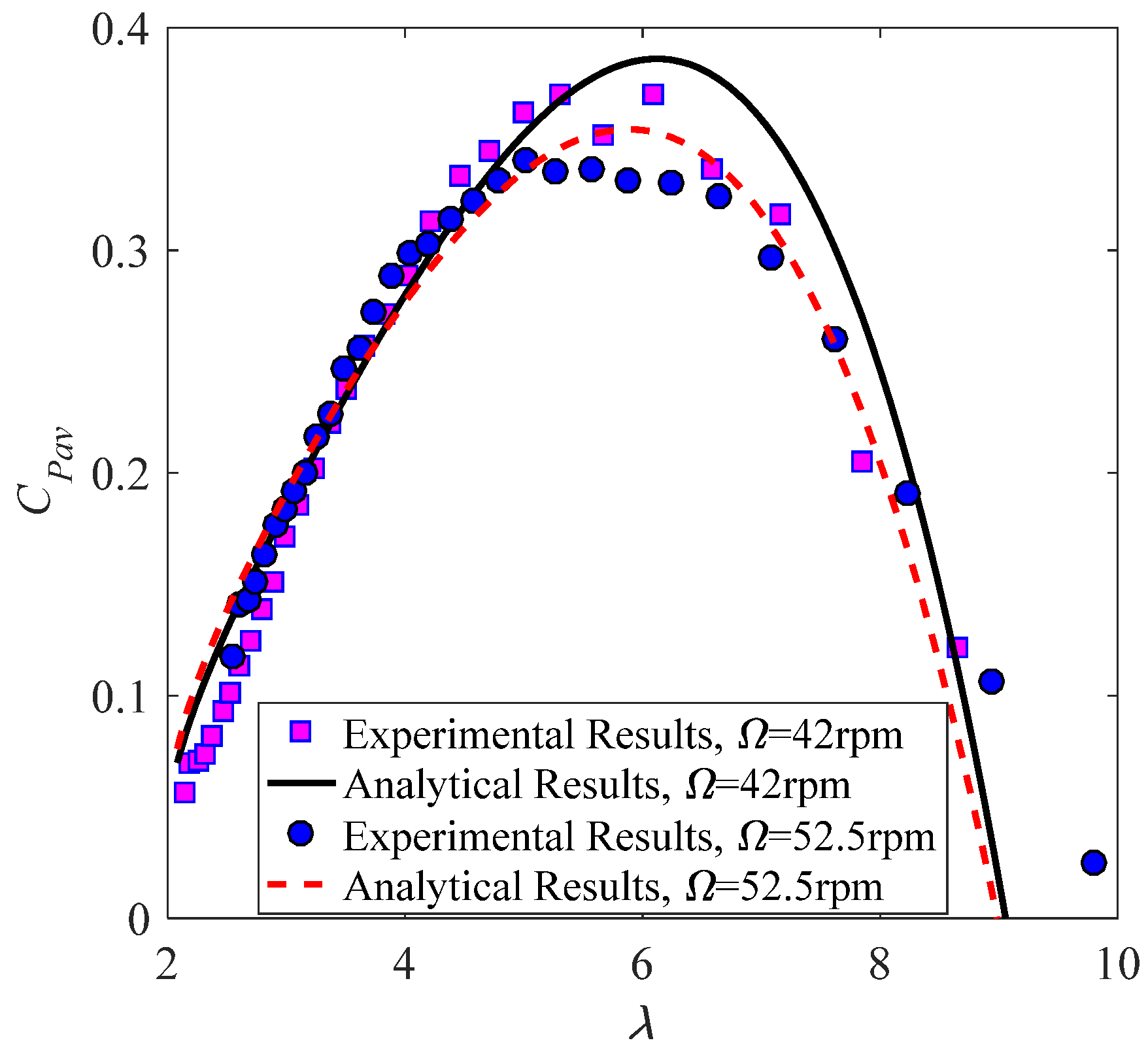

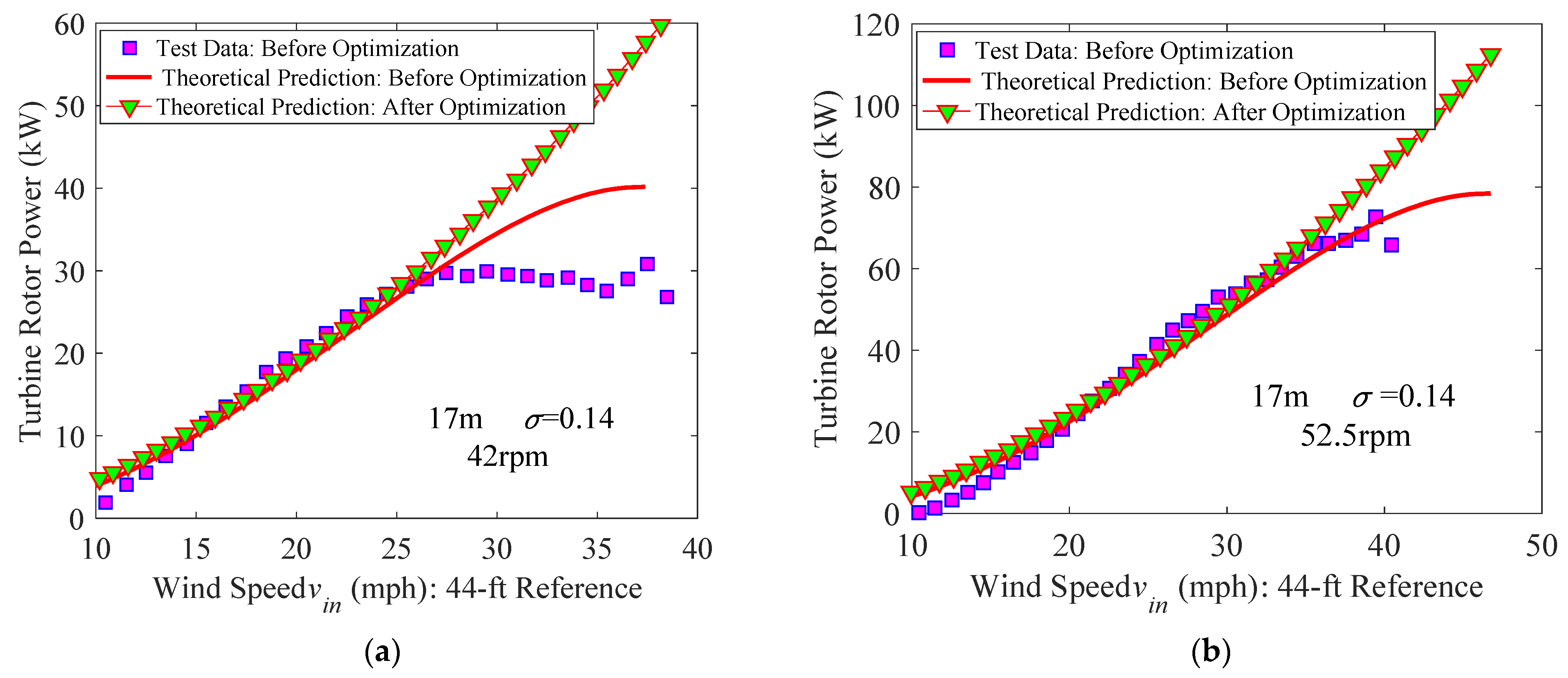

3.2.1. Validation of Results

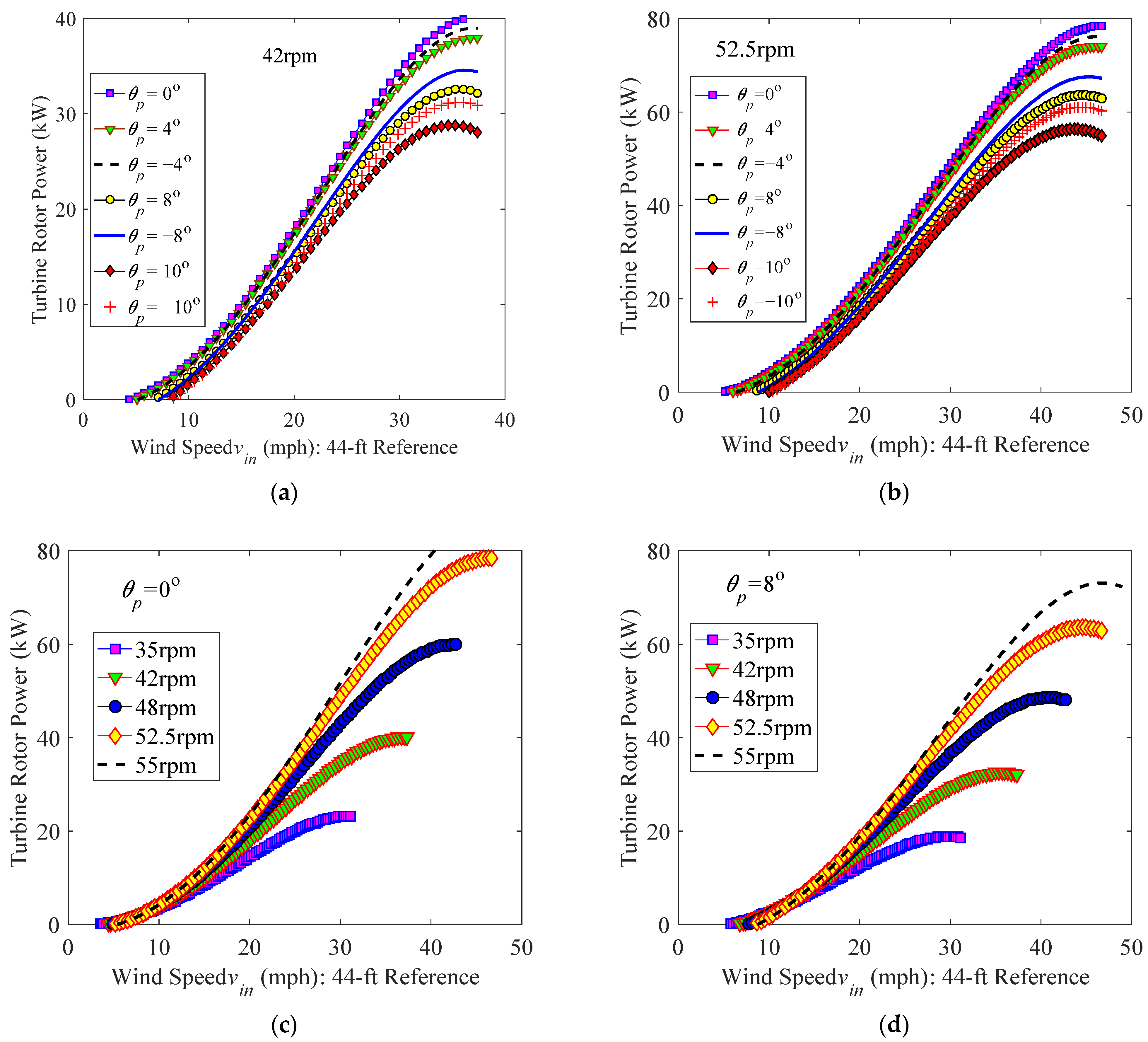

3.2.2. Performance of a Constant-Speed Blade

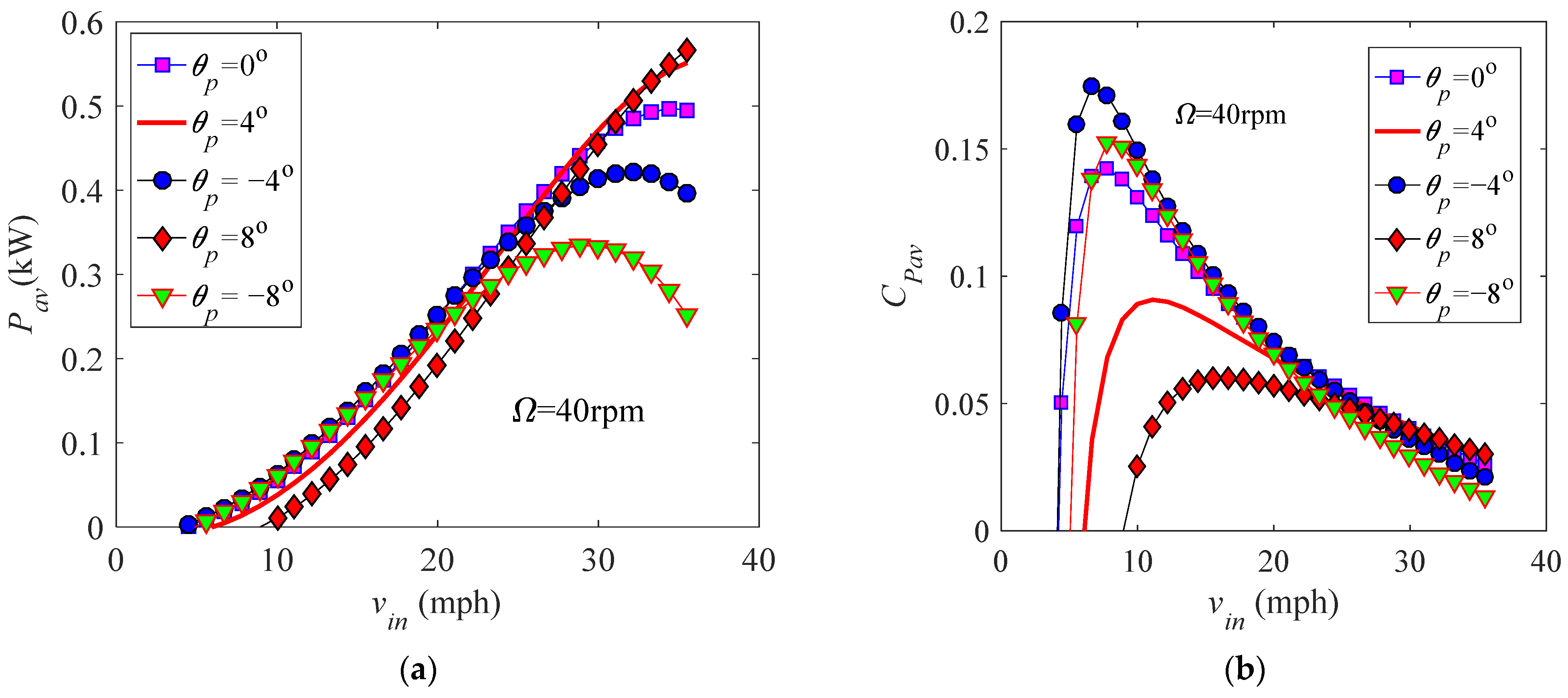

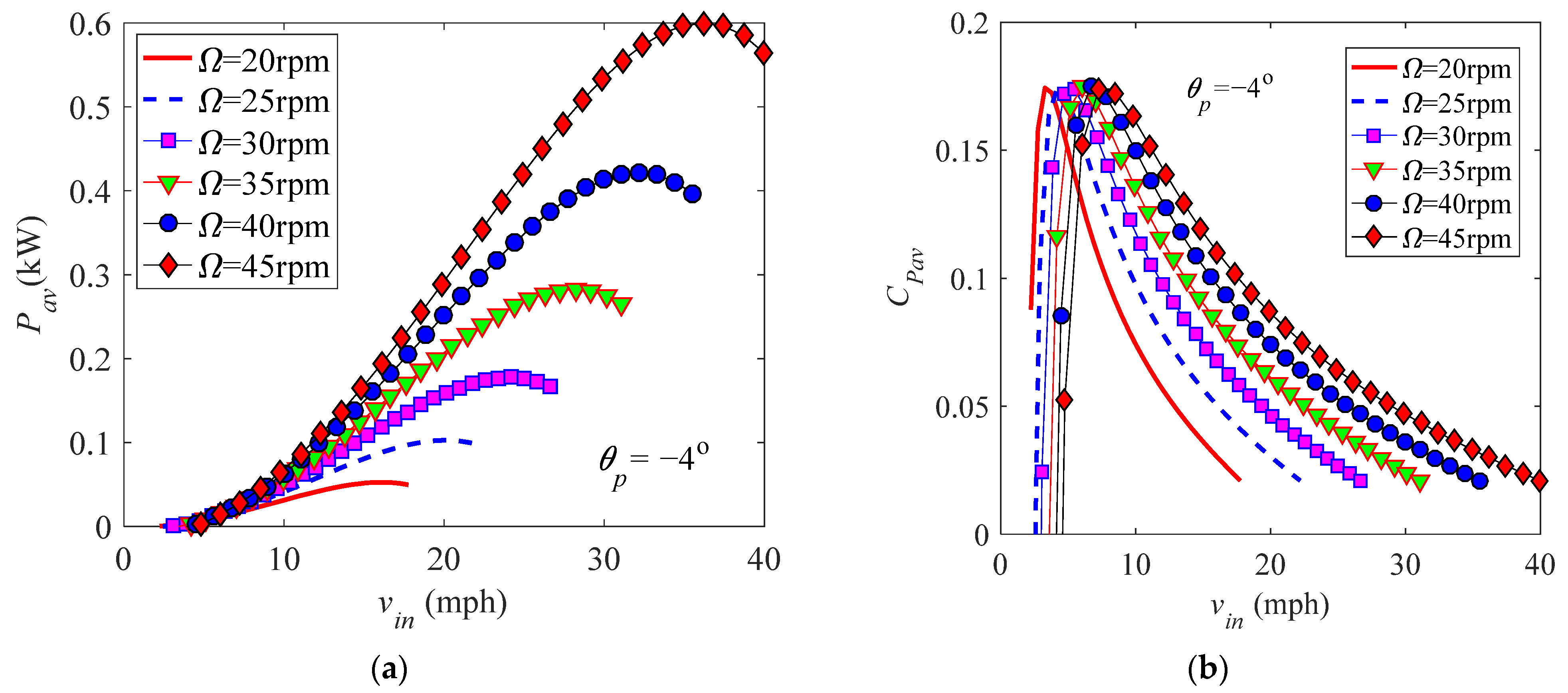

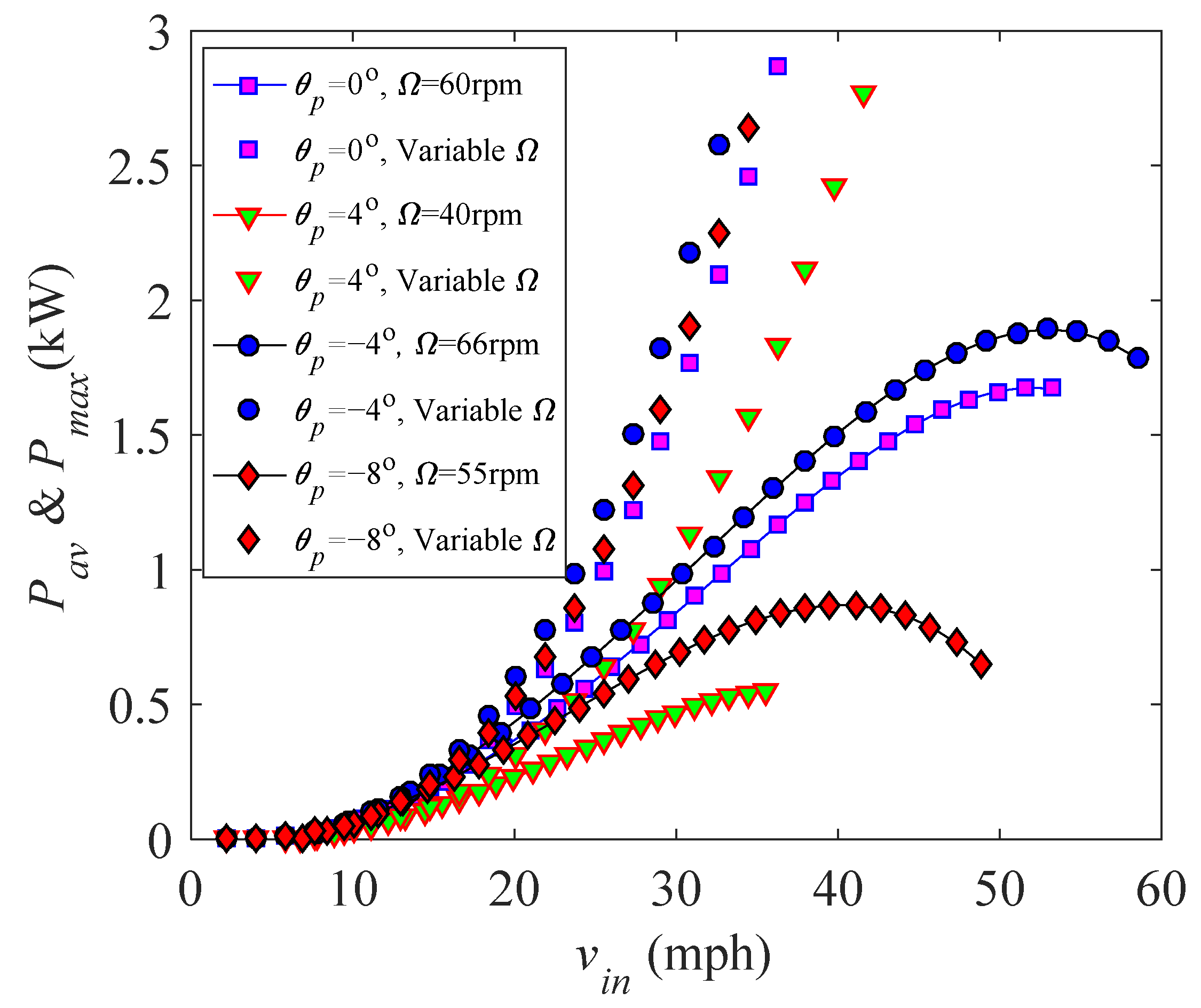

3.2.3. Performance of a Variable-Speed Blade

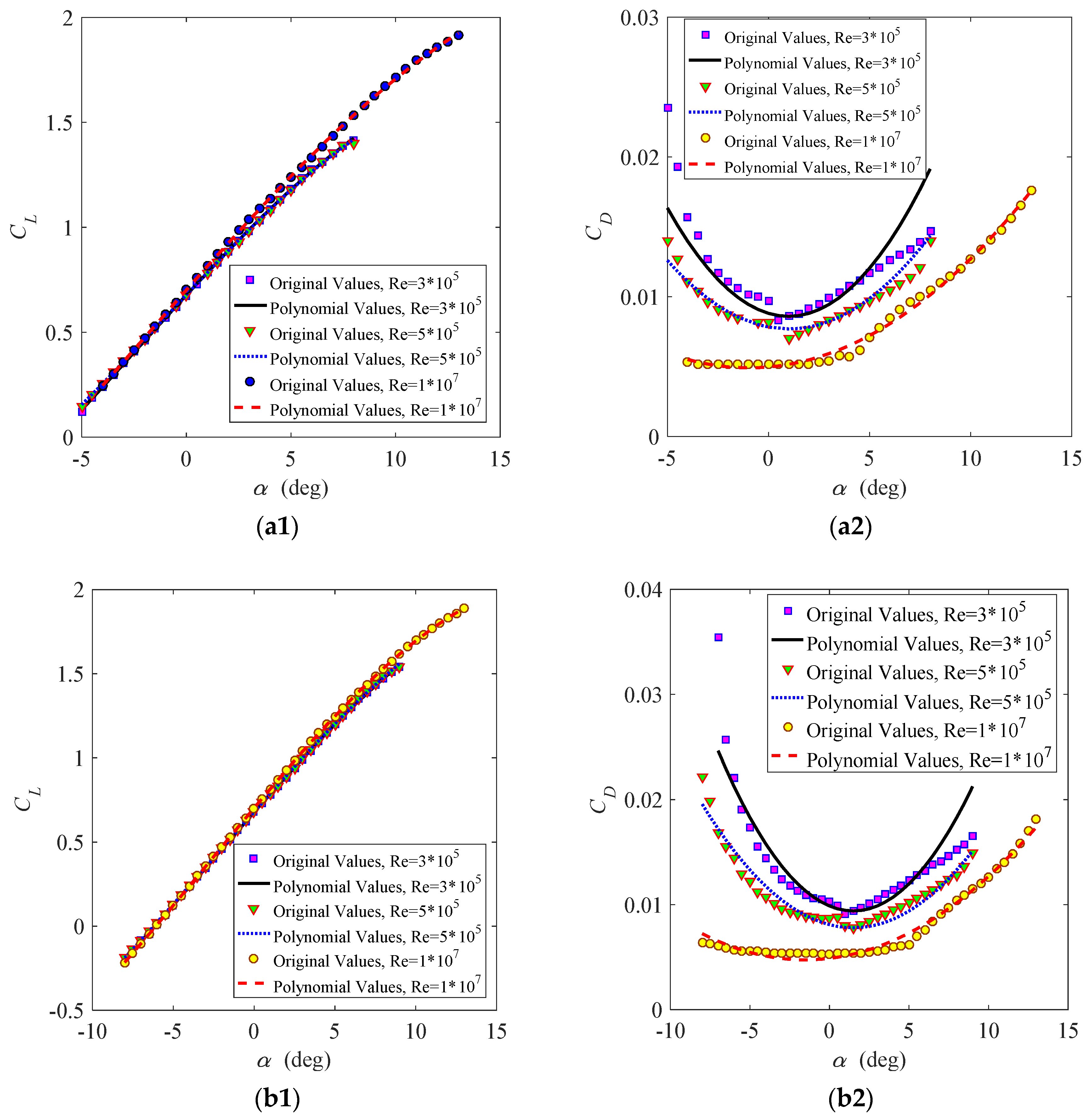

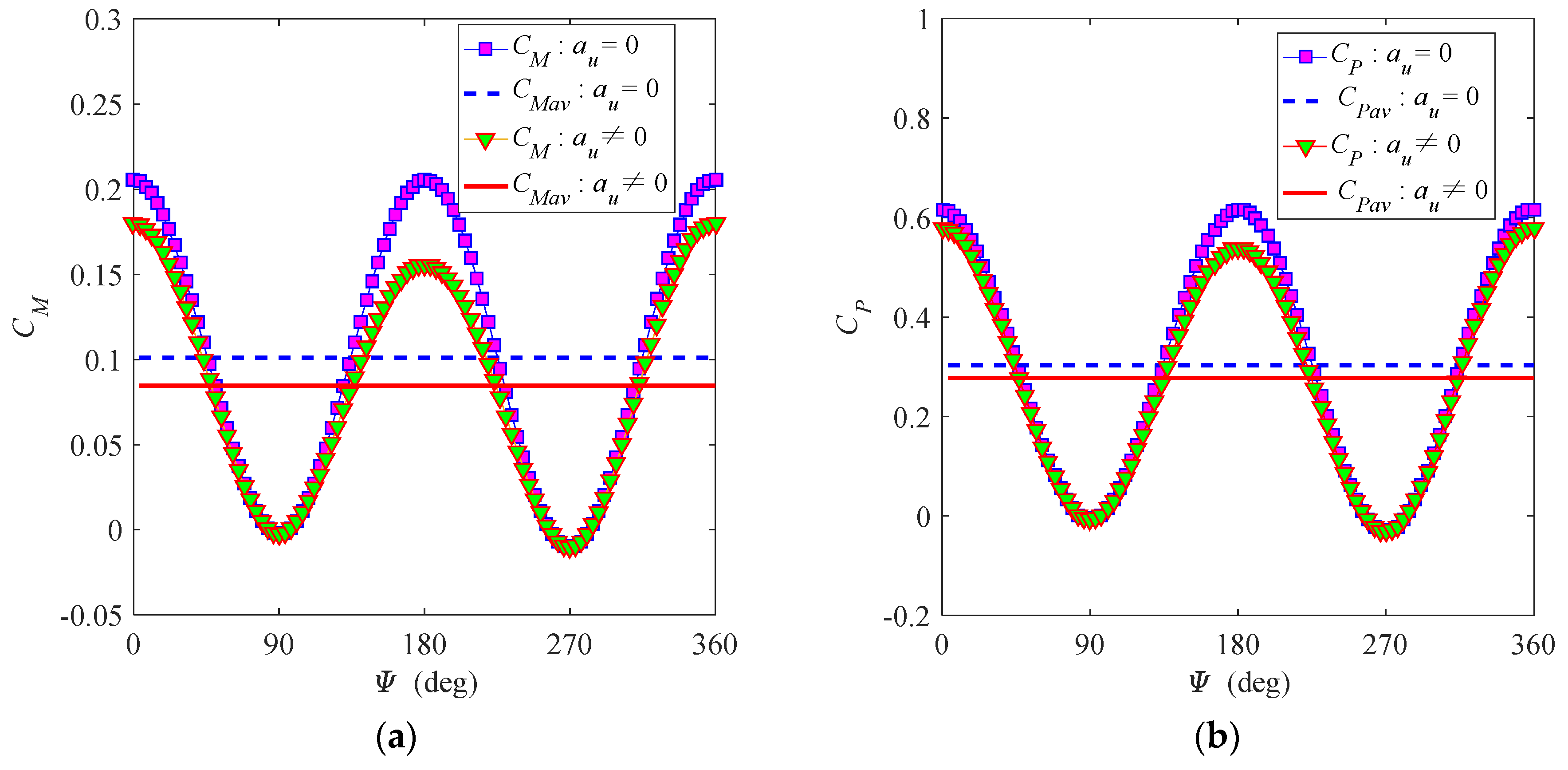

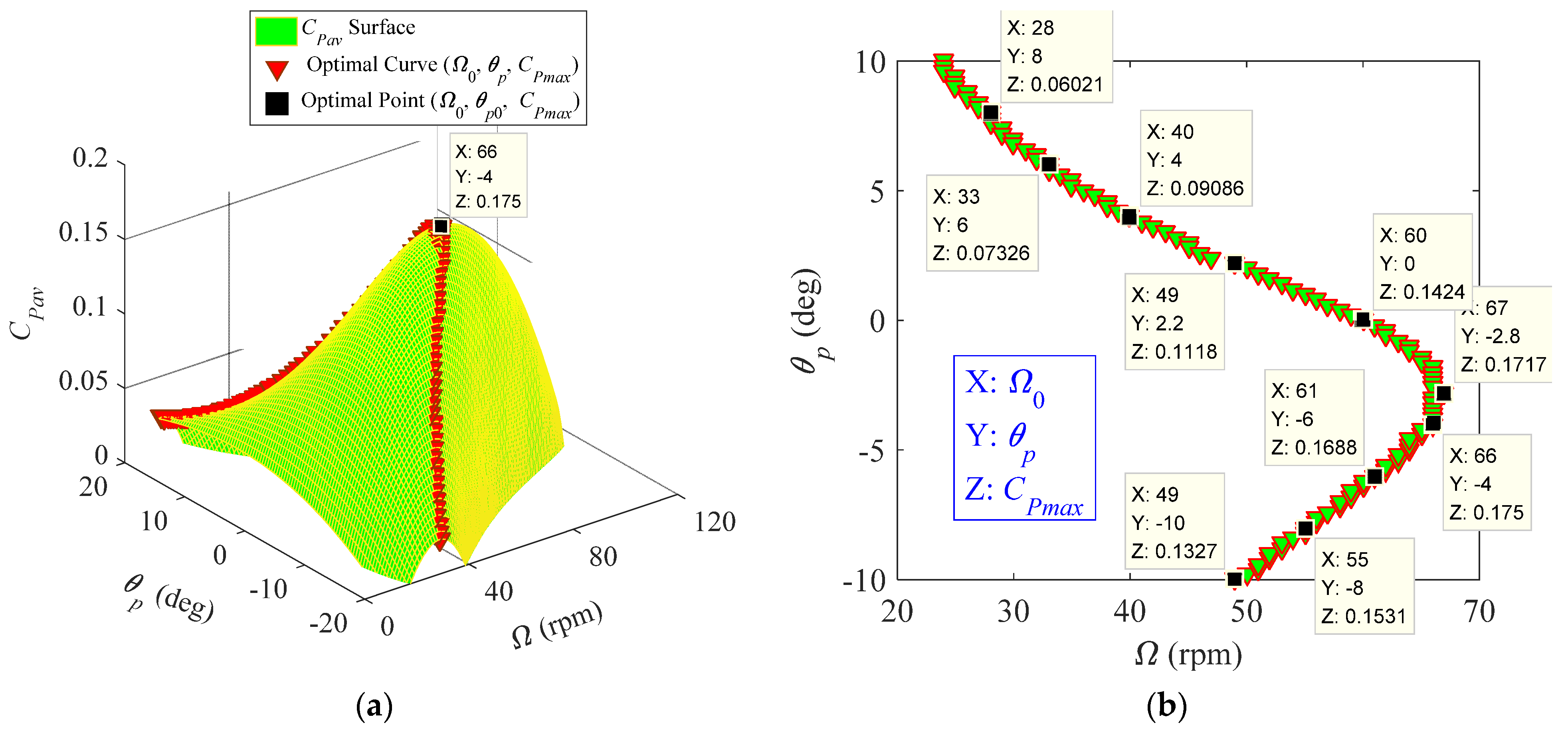

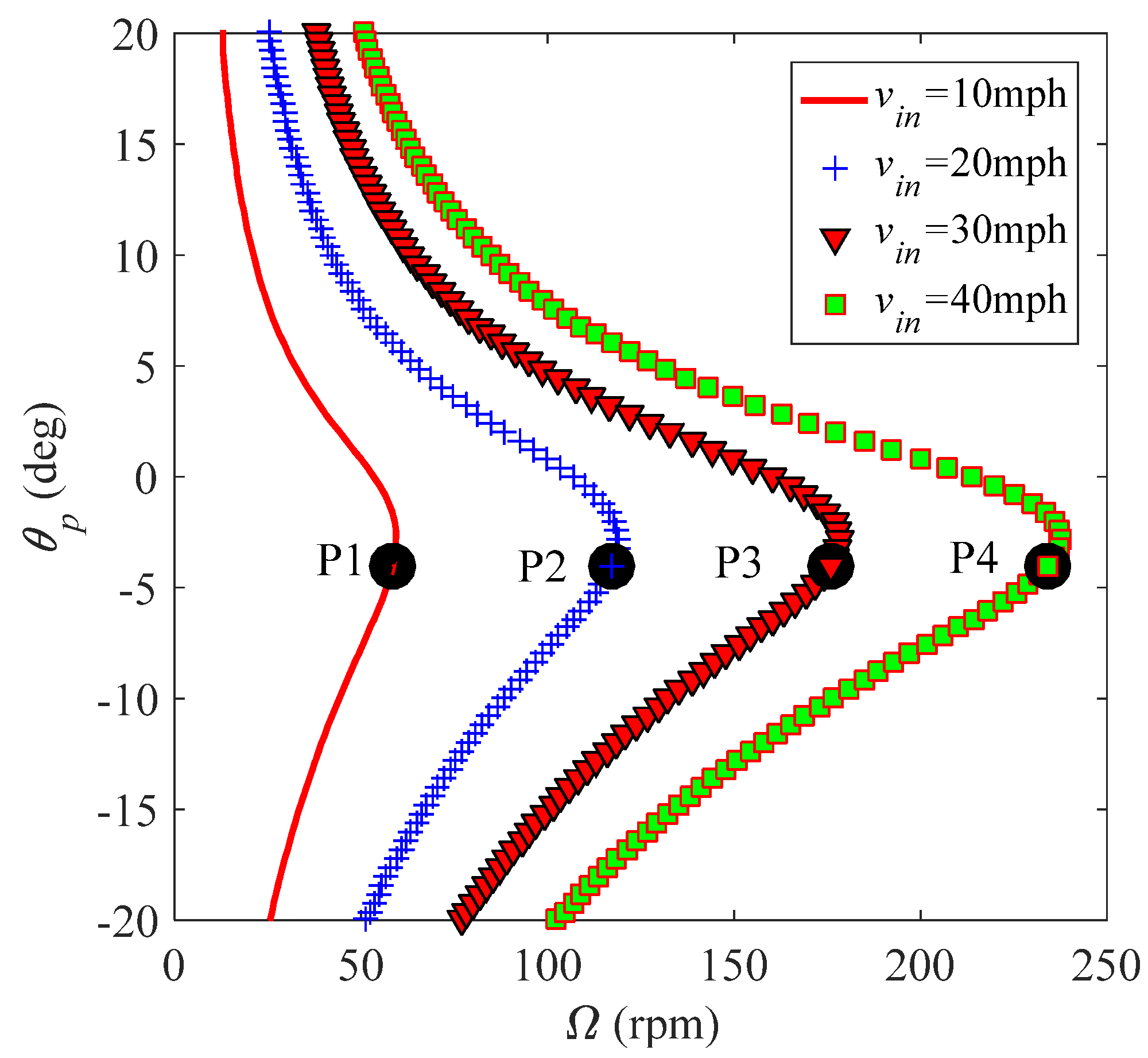

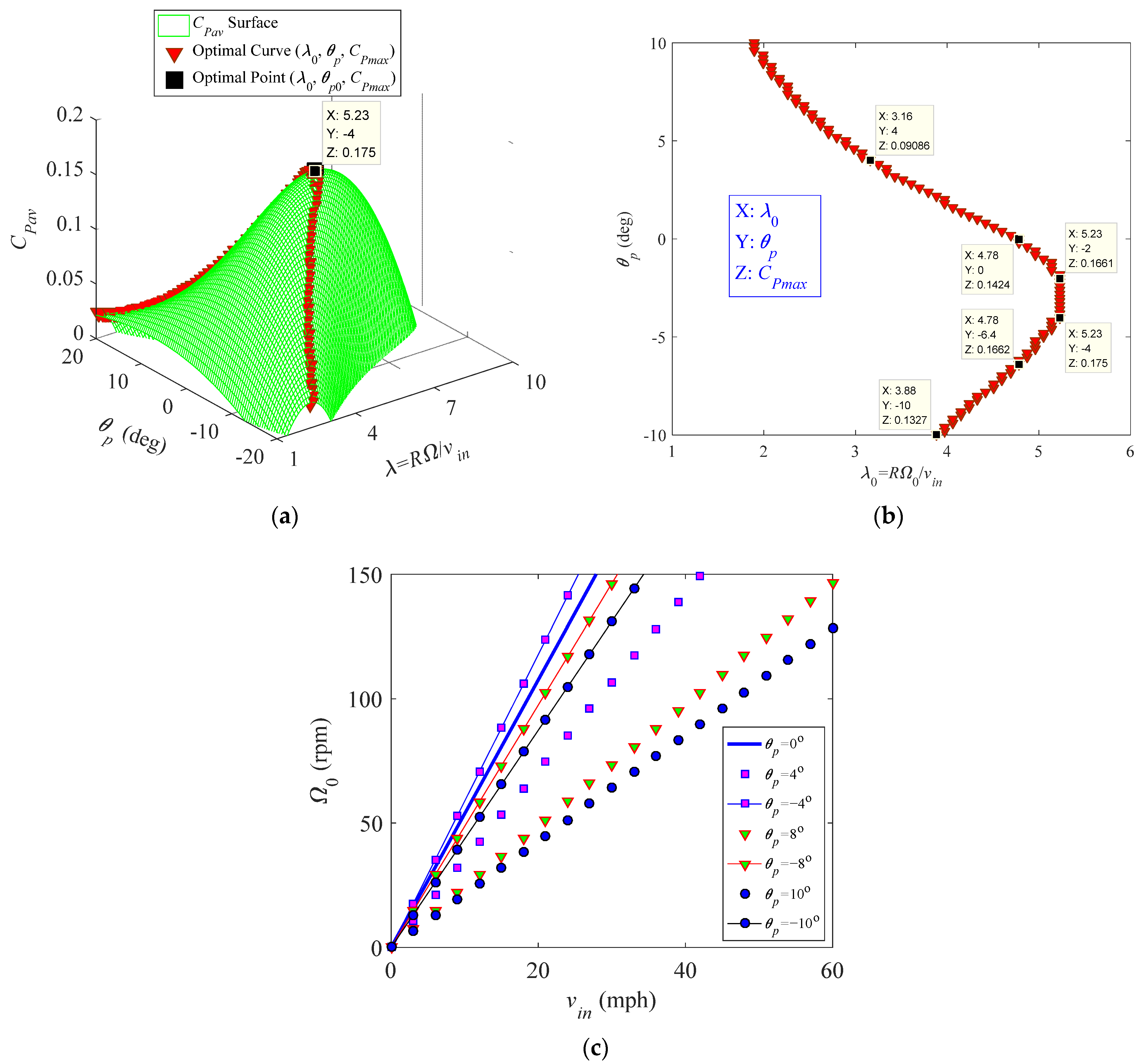

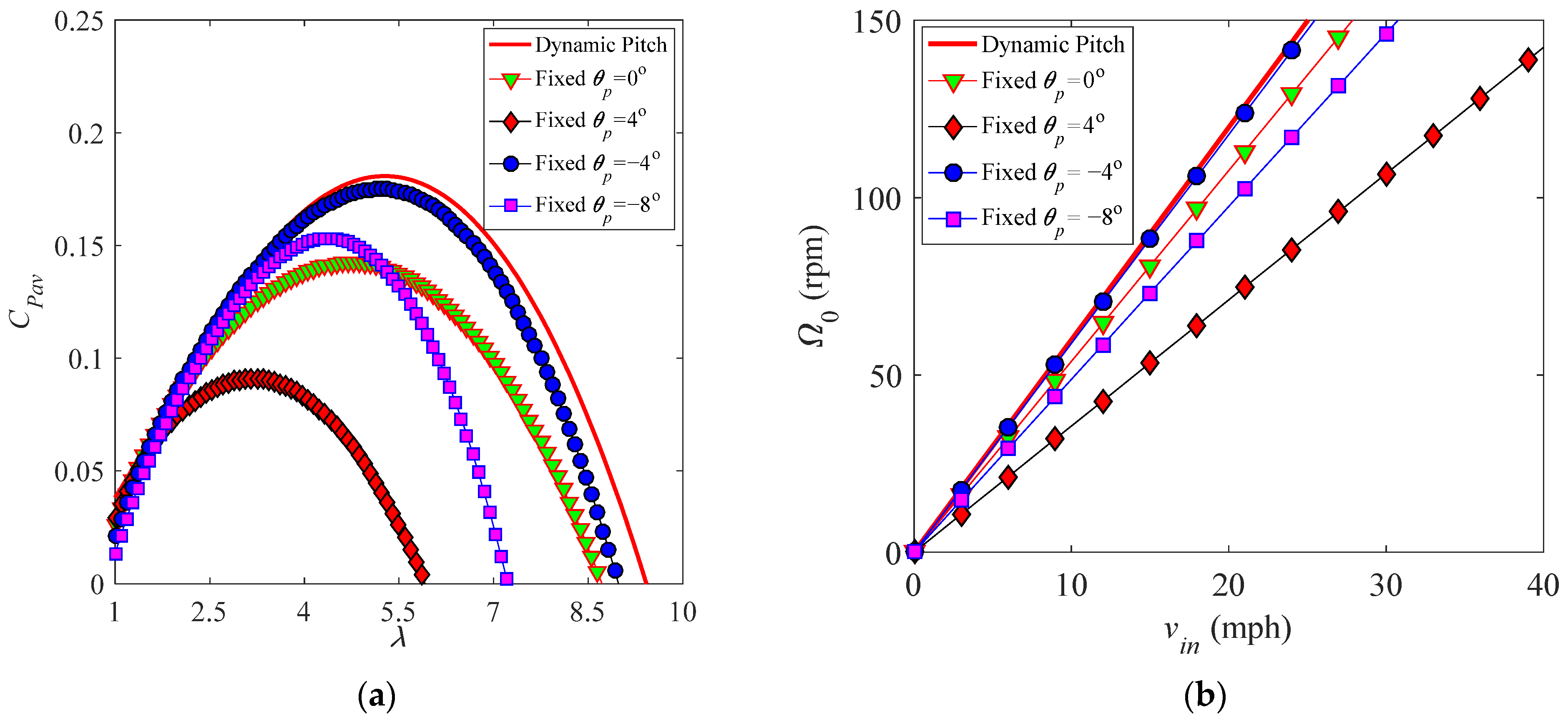

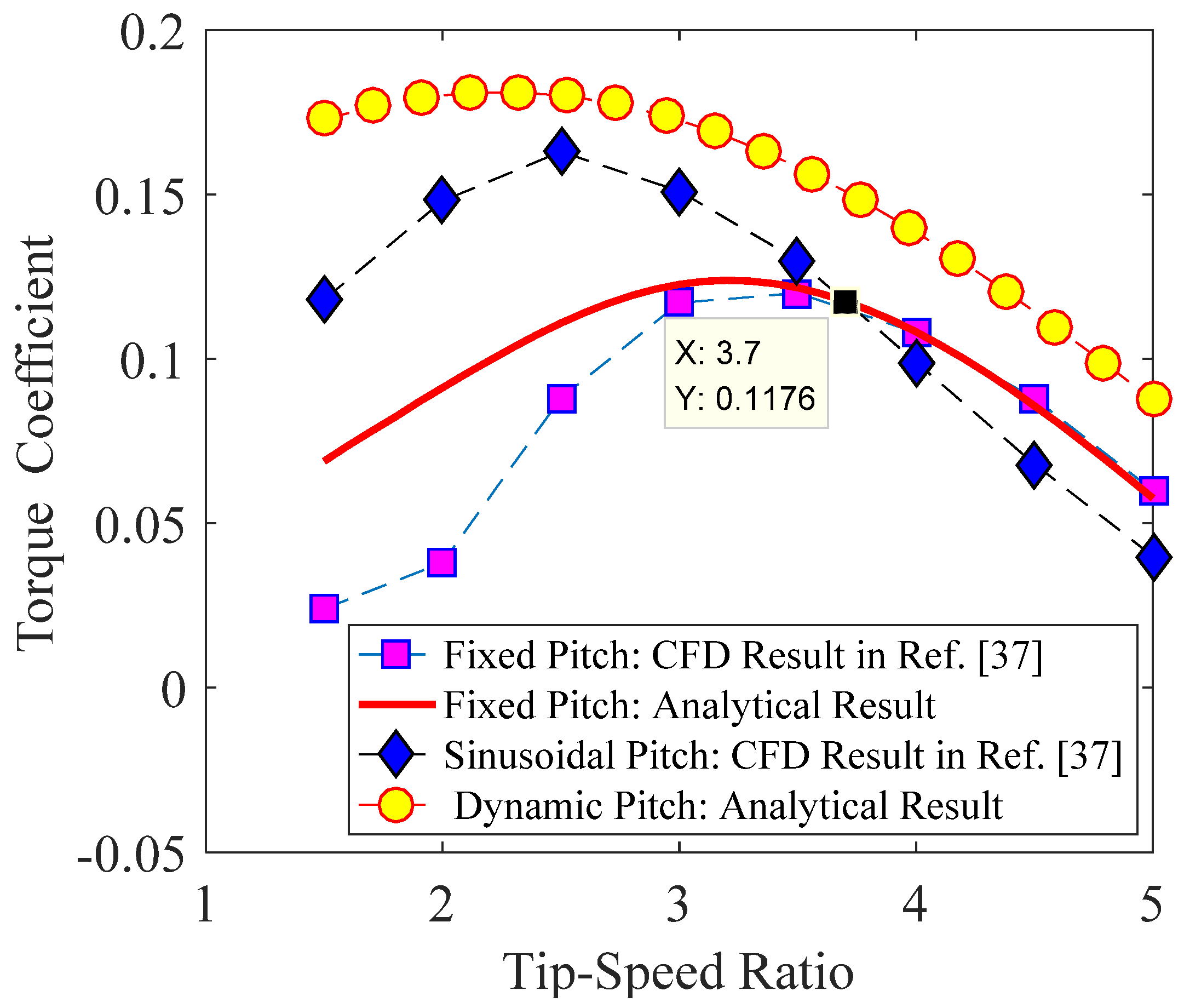

4. Performance Optimization Based on a Dynamic-Pitch Method

- (1)

- Upwind Area: (k = 0, 1, 2….)

- (2)

- Downwind Area: (k = 0, 1, 2….)For these two cases, one can obtain the same changing rule of the optimized pitch angle as , which reveals that the optimized pitch angle rule of symmetric airfoils depends on the tip-speed ratio λ, azimuth Ψi, induced factor a, and three coefficients c1, c2, and c3. Neglecting the subscript i, the dynamic-pitch rule of the symmetric airfoils at a fixed Reynolds number is obtained aswhere .

- (1)

- Upwind Area: (k = 0, 1, 2….)

- (2)

- Downwind Area: (k = 0, 1, 2….)The dynamic-pitch rule at a fixed Reynolds number can be obtained aswhere Γi and Γ are the same as those for symmetric airfoils. This reveals that the dynamic-pitch rule of an asymmetric airfoil depends on the tip-speed ratio λ, azimuth Ψ, induced factor a, and five aerodynamic coefficients c1, c2, c3, bL, and bD.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ad | Induction factor in the downwind area |

| au | Induction factor in the upwind area |

| A | Swept area, m2 |

| c | Chord length, m |

| c0L, c1, c3, bL | Coefficients of CL as a function of α |

| c0, c0D, c2, bD | Coefficients of CD as a function of α |

| CL | Lift coefficient |

| CD | Drag coefficient |

| CM | Instantaneous torque coefficient |

| CMav | Average torque coefficient in one revolution |

| Cp | Instantaneous power coefficient |

| CPav | Average power coefficient in one revolution |

| CPmax | Optimal power coefficient |

| D | Rotor diameter, m |

| Di | Drag force of the i-th airfoil, N |

| l | Length of the airfoil element, m |

| Li | Lift force of the i-th airfoil, N |

| M | Instantaneous torque, N·m |

| Mav | Average torque in one revolution, N·m |

| Mr | Residual aerodynamic moment, N·m |

| N | Number of blades |

| o-yz | Inertial coordinate system with unit vectors (j, k) |

| oi-sini | Body coordinate system of the i-th airfoil with unit vectors (jsi, kni) |

| oi-ηiζi | Section coordinate system of the i-th airfoil with unit vectors (jηi, kζi) |

| P | Instantaneous power, W |

| Pav | Average power in one revolution, W |

| Pmax | Optimal power, W |

| R | Rotor radius, m |

| Re | Reynolds number |

| t | Time, s |

| vb | Blade velocity, vb = RΩ, mph = 0.447 m/s |

| ve | Equilibrium incoming wind velocity in the downwind area, mph |

| vin | Incoming wind velocity, mph |

| vr | Resultant wind velocity, mph |

| vd | Downstream velocity in the downwind area, mph |

| vu | Upstream velocity in the upwind area, mph |

| α | Angle of attack, ° or rad |

| λ = vb/vin | Tip-speed ratio |

| λ0 | Optimal tip-speed ratio |

| λd | Tip-speed ratio in the downwind area |

| λu | Tip-speed ratio in the upwind area |

| ρa | Air density, kg/m3 |

| σ = Ncl/A=Nc/D | Solidity for a straight uniform blade with zero tilt angle |

| ϑ | Acute angle between vr and vb, °or rad |

| Ω | Rotational speed, rpm |

| Ω 0 | Optimal rotational speed, rpm |

| Ψ, Ψ0 | Azimuth and the initial azimuth of the airfoil, °or rad |

| θp | Pitch angle, °or rad |

References

- Blackwell, B.F.; Sheldahl, R.E.; Feltz, L.V. Wind Tunnel Performance Data for the Darrieus Wind Turbine with NACA 0012 Blades; Sandia Laboratories: Washington, DC, USA, 1976; ISBN SAND76-0130. [Google Scholar]

- Worstell, M.H. Aerodynamic Performance of the 17-Meter-Diameter Darrieus Wind Turbine; Sandia Laboratories: Washington, DC, USA, 1978; ISBN SAND78-1737. [Google Scholar]

- Reuter, R.C.; Worstell, M.H. Torque Ripple in a Vertical Axis Wind Turbine; Sandia Laboratories: Washington, DC, USA, 1978; ISBN SAND78-0577. [Google Scholar]

- Ashwill, T.D.; Leonard, T.M. Developments in Blade Shape Design for a Darrieus Vertical Axis Wind Turbine; Sandia National Laboratories: Albuquerque, NM, USA, 1986; ISBN SAND86-1085. [Google Scholar]

- Sutherland, H.J.; Stephenson, W.A. Rotor Instrumentation Circuits for the Sandia 34-Meter Vertical Axis Wind Turbine; Sandia National Laboratories: Albuquerque, NM, USA, 1988; ISBN SAND88-1144. [Google Scholar]

- Ashwill, T.D. Measured Data for the Sandia 34-Meter Vertical Axis Wind Turbine; Sandia National Laboratories: Albuquerque, NM, USA, 1991; ISBN SAND91-2228. [Google Scholar]

- Kooiman, S.; Tullis, S. Response of a vertical axis wind turbine to time varying wind conditions found within the urban environment. Wind. Eng. 2010, 34, 389–401. [Google Scholar] [CrossRef]

- Danao, L.A.; Eboibi, O.; Howell, R. An experimental investigation into the influence of unsteady wind on the performance of a vertical axis wind turbine. Appl. Energy 2013, 107, 403–411. [Google Scholar] [CrossRef]

- Mertens, S.; van Kuik, G.; van Bussel, G. Performance of an H-Darrieus in the skewed flow on a roof. J. Sol. Energy Eng. 2003, 125, 433–440. [Google Scholar] [CrossRef]

- Möllerström, E.; Ottermo, F.; Goude, A.; Eriksson, S.; Hylander, J.; Bernhoff, H. Turbulence influence on wind energy extraction for a medium size vertical axis wind turbine. Wind. Energy 2016, 19, 1963–1973. [Google Scholar] [CrossRef]

- Li, Q.; Maeda, T.; Kamada, Y.; Murata, J.; Yamamoto, M.; Ogasawara, T.; Shimizu, K.; Kogaki, T. Study on power performance for straight-bladed vertical axis wind turbine by field and wind tunnel test. Renew. Energy 2016, 90, 291–300. [Google Scholar] [CrossRef]

- Wekesa, D.W.; Wang, C.; Wei, Y.; Danao, L.A.M. Influence of operating conditions on unsteady wind performance of vertical axis wind turbines operating within a fluctuating free-stream: A numerical study. J. Wind. Eng. Ind. Aerodyn. 2014, 135, 76–89. [Google Scholar] [CrossRef]

- Lei, H.; Zhou, D.; Lu, J.; Chen, C.; Han, Z.; Bao, Y. The impact of pitch motion of a platform on the aerodynamic performance of a floating vertical axis wind turbine. Energy 2017, 119, 369–383. [Google Scholar] [CrossRef]

- Mohamed, M. Impacts of solidity and hybrid system in small wind turbines performance. Energy 2013, 57, 495–504. [Google Scholar] [CrossRef]

- Joo, S.; Choi, H.; Lee, J. Aerodynamic characteristics of two-bladed H-Darrieus at various solidities and rotating speeds. Energy 2015, 90, 439–451. [Google Scholar] [CrossRef]

- Shahizare, B.; Nik-Ghazali, N.-N.; Chong, W.T.; Tabatabaeikia, S.; Izadyar, N.; Esmaeilzadeh, A. Novel investigation of the different Omni-direction-guide-vane angles effects on the urban vertical axis wind turbine output power via three-dimensional numerical simulation. Energy Convers. Manag. 2016, 117, 206–217. [Google Scholar] [CrossRef]

- Chen, W.-H.; Chen, C.-Y.; Huang, C.-Y.; Hwang, C.-J. Power output analysis and optimization of two straight-bladed vertical-axis wind turbines. Appl. Energy 2017, 185, 223–232. [Google Scholar] [CrossRef]

- Chen, J.; Yang, H.; Yang, M.; Xu, H. The effect of the opening ratio and location on the performance of a novel vertical axis Darrieus turbine. Energy 2015, 89, 819–834. [Google Scholar] [CrossRef]

- Fiedler, A.J.; Tullis, S. Blade offset and pitch effects on a high solidity vertical axis wind turbine. Wind. Eng. 2009, 33, 237–246. [Google Scholar] [CrossRef]

- Liu, K.; Yu, M.; Zhu, W. Enhancing wind energy harvesting performance of vertical axis wind turbines with a new hybrid design: A fluid-structure interaction study. Renew. Energy 2019, 140, 912–927. [Google Scholar] [CrossRef]

- Orlandi, A.; Collu, M.; Zanforlin, S.; Shires, A. 3D URANS analysis of a vertical axis wind turbine in skewed flows. J. Wind. Eng. Ind. Aerodyn. 2015, 147, 77–84. [Google Scholar] [CrossRef]

- Peng, Y.-X.; Xu, Y.-L.; Zhan, S. A hybrid DMST model for pitch optimization and performance assessment of high-solidity straight-bladed vertical axis wind turbines. Appl. Energy 2019, 250, 215–228. [Google Scholar] [CrossRef]

- Zhao, Z.; Yan, C.; Wang, T.; Xu, B.; Zheng, Y. Study on approach of performance improvement of VAWT employing double multiple stream tubes model. J. Renew. Sustain. Energy 2017, 9, 023305. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, S.; Tagawa, K.; Feng, F. Starting performance effect of a truncated-cone-shaped wind gathering device on small-scale straight-bladed vertical axis wind turbine. Energy Convers. Manag. 2018, 167, 70–80. [Google Scholar] [CrossRef]

- Greenblatt, D.; Schulman, M.; Ben-Harav, A. Vertical axis wind turbine performance enhancement using plasma actuators. Renew. Energy 2012, 37, 345–354. [Google Scholar] [CrossRef]

- Ma, N.; Lei, H.; Han, Z.; Zhou, D.; Bao, Y.; Zhang, K.; Zhou, L.; Chen, C. Airfoil optimization to improve power performance of a high-solidity vertical axis wind turbine at a moderate tip speed ratio. Energy 2018, 150, 236–252. [Google Scholar] [CrossRef]

- Chen, J.; Chen, L.; Xu, H.; Yang, H.; Ye, C.; Liu, D. Performance improvement of a vertical axis wind turbine by comprehensive assessment of an airfoil family. Energy 2016, 114, 318–331. [Google Scholar] [CrossRef]

- Ismail, M.F.; Vijayaraghavan, K. The effects of aerofoil profile modification on a vertical axis wind turbine performance. Energy 2015, 80, 20–31. [Google Scholar] [CrossRef]

- Antar, E.; El Cheikh, A.; ElKhoury, M. A dynamic rotor vertical-axis wind turbine with a blade transitioning capability. Energies 2019, 12, 1446. [Google Scholar] [CrossRef]

- Kirke, B.K.; Lazauskas, L. Enhancing the performance of vertical axis wind turbine using a simple variable pitch system. Wind Eng. 1991, 15, 187–195. [Google Scholar]

- Benedict, M.; Lakshminarayan, V.; Pino, J.; Chopra, I. Aerodynamics of a small-scale vertical-axis wind turbine with dynamic blade pitching. Aiaa J. 2016, 54, 924–935. [Google Scholar] [CrossRef]

- ElKhoury, M.; Kiwata, T.; Aoun, E. Experimental and numerical investigation of a three-dimensional vertical-axis wind turbine with variable-pitch. J. Wind. Eng. Ind. Aerodyn. 2015, 139, 111–123. [Google Scholar] [CrossRef]

- Paraschivoiu, I.; Trifu, O.; Saeed, F. H-Darrieus wind turbine with blade pitch control. Int. J. Rotating Mach. 2009, 2009, 1–7. [Google Scholar] [CrossRef]

- Li, C.; Xiao, Y.; Xu, Y.-L.; Peng, Y.-X.; Hu, G.; Zhu, S. Optimization of blade pitch in H-rotor vertical axis wind turbines through computational fluid dynamics simulations. Appl. Energy 2018, 212, 1107–1125. [Google Scholar] [CrossRef]

- Kiwata, T.; Yamada, T.; Kita, T.; Takata, S.; Komatsu, N.; Kimura, S. Performance of a vertical axis wind turbine with variable-pitch straight blades utilizing a linkage mechanism. J. Environ. Eng. 2010, 5, 213–225. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, S.; Wang, K.; Liu, X.; Liang, Y. Study on Synchronous Variable-Pitch Vertical Axis Wind Turbine. In Proceedings of the 2011 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011; pp. 1–5. [Google Scholar]

- Kirke, B.K.; Paillard, B. Predicted and measured performance of a vertical axis wind turbine with passive variable pitch compared to fixed pitch. Wind. Eng. 2017, 41, 74–90. [Google Scholar] [CrossRef]

- Horb, S.; Fuchs, R.; Immas, A.; Silvert, F.; Deglaire, P. Variable pitch control for vertical-axis wind turbines. Wind. Eng. 2018, 42, 128–135. [Google Scholar] [CrossRef]

- Jacobs, N.E.; Ward, K.E.; Pinkerton, R.M. The Characteristics of 78 Related Airfoil Sections from Tests in the Variable-Density Wind Tunnel. In NACA Report 460; Langley Memorial Aeronautical Laboratory: Hampton, Virginia, USA, 1933; ISBN NACA-460. [Google Scholar]

- Sheldahl, E.R.; Klimas, P.C. Aerodynamic Characteristics of Seven Symmetrical Airfoil Sections through 180-Degree Angle of Attack for Use in Aerodynamic Analysis of Vertical Axis Wind Turbines; Sandia National Laboratories: Albuquerque, NM, USA, 1981; ISBN SAND80-2114. [Google Scholar]

- Afzali, F.; Kapucu, O.; Feeny, B.F. Vibration Analysis of Vertical-Axis Wind-Turbine Blades. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; pp. 1–13. [Google Scholar]

- Templin, R.J. Aerodynamic Performance Theory for the NRC Vertical-Axis Wind Turbine; NASA STI/RECON technical report; NASA: Washington, DC, USA, 1974. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Chopra, I.; Zhu, W.; Yu, M. Performance Analysis and Optimization of a Vertical-Axis Wind Turbine with a High Tip-Speed Ratio. Energies 2021, 14, 996. https://doi.org/10.3390/en14040996

Li L, Chopra I, Zhu W, Yu M. Performance Analysis and Optimization of a Vertical-Axis Wind Turbine with a High Tip-Speed Ratio. Energies. 2021; 14(4):996. https://doi.org/10.3390/en14040996

Chicago/Turabian StyleLi, Liang, Inderjit Chopra, Weidong Zhu, and Meilin Yu. 2021. "Performance Analysis and Optimization of a Vertical-Axis Wind Turbine with a High Tip-Speed Ratio" Energies 14, no. 4: 996. https://doi.org/10.3390/en14040996

APA StyleLi, L., Chopra, I., Zhu, W., & Yu, M. (2021). Performance Analysis and Optimization of a Vertical-Axis Wind Turbine with a High Tip-Speed Ratio. Energies, 14(4), 996. https://doi.org/10.3390/en14040996