Solution to Fault of Multi-Terminal DC Transmission Systems Based on High Temperature Superconducting DC Cables

Abstract

:1. Introduction

2. Modeling of the Hybrid MTDC System

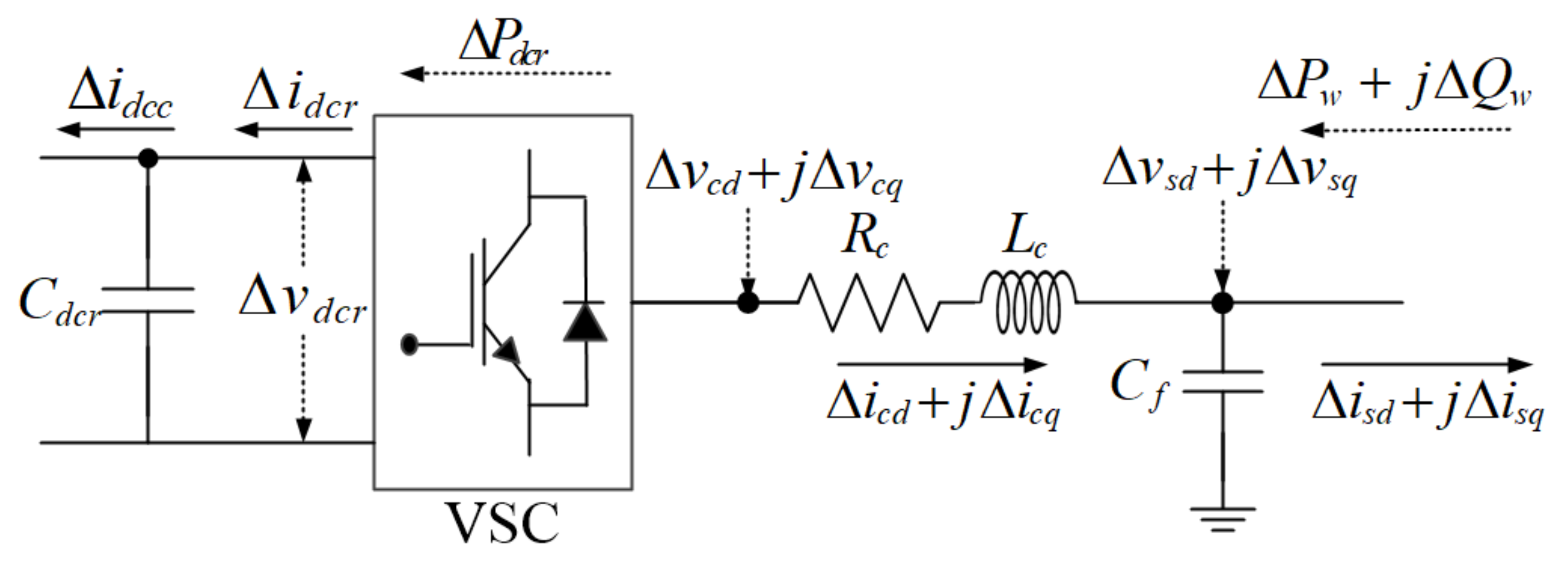

2.1. Wind Farm Side VSC Model

2.2. Four Terminal Dc Network Model

2.3. Grid Side LCC Model

2.3.1. Master–Slave Control Mode

2.3.2. Voltage Droop Control Mode

2.4. Overall State Space Model

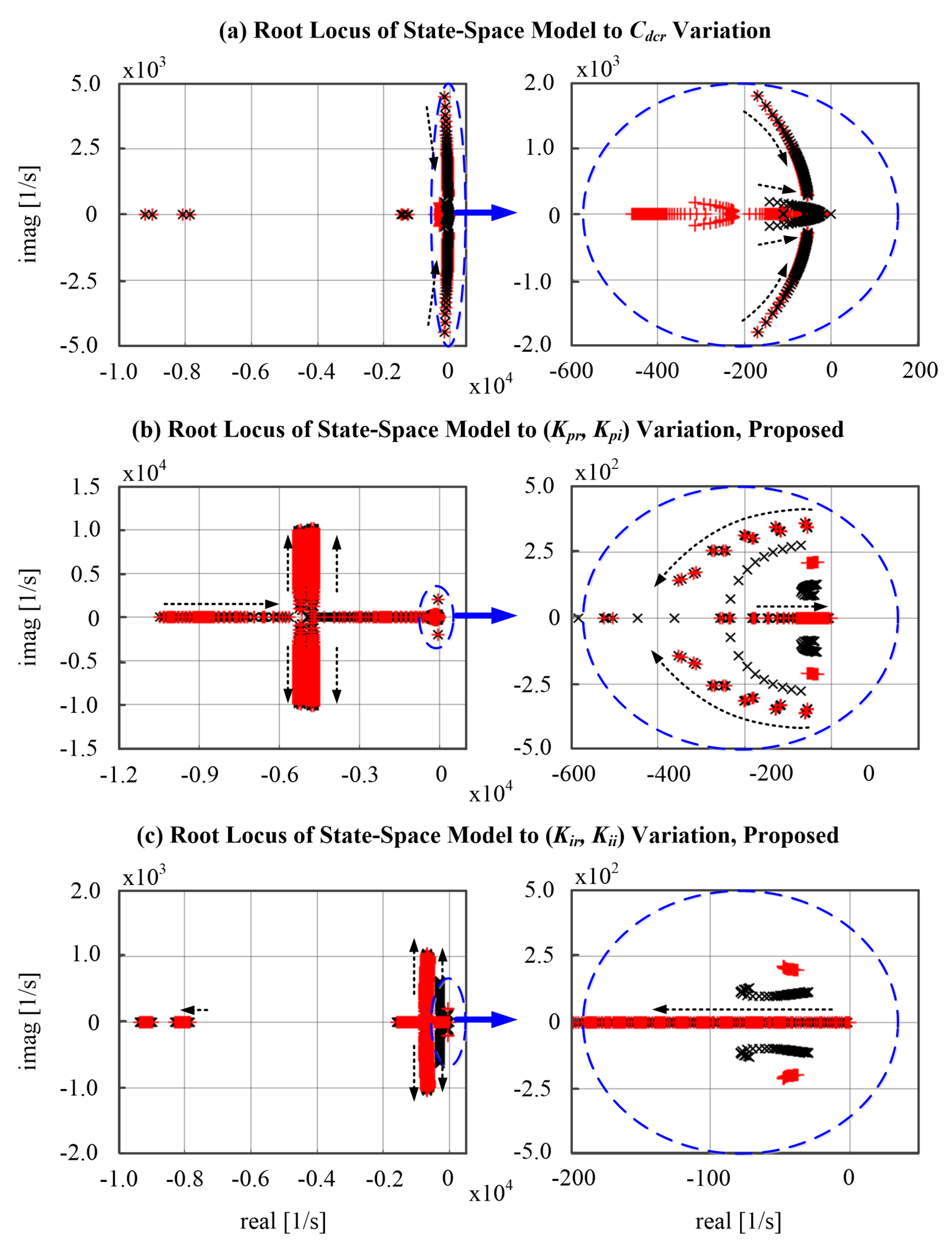

2.5. Root Locus Analysis

3. Grid Monitoring and Fault Localization Method

3.1. Cable System Modeling

3.2. Fault Localization Based on Reflectometry Method

3.2.1. Time Frequency Domain Reflectometry Method

3.2.2. Fault Localization Method on Branch Cable System

| Algorithm 1: Fault Localization Algorithm. |

| if find the fault is located km from the j th section starting point. else the fault is located km from the i th section starting point. end |

4. Discussion

4.1. Operation Control Results

4.2. Fault Localization Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. LCC Model Description

References

- Wu, Y.; Su, P.; Su, Y.; We, T.; Tan, W. Economics- and reliability-based design for an offshore wind farm. IEEE Trans. Ind. Appl. 2017, 53, 5139–5149. [Google Scholar] [CrossRef]

- Hou, P.; Hu, W.; Soltani, M.; Chen, C.; Zhang, B.; Chen, Z. Offshore wind farm layout design considering optimized power dispatch strategy. IEEE Trans. Sustain. Energy 2017, 8, 638–647. [Google Scholar] [CrossRef]

- Wang, L.; Wang, K.; Lee, W.; Chen, Z. Power-flow control and stability enhancement of four parallel-operated wind farms using a line-commutated HVDC link. IEEE Trans. Power Deliv. 2010, 25, 1190–1202. [Google Scholar] [CrossRef]

- Karaagac, U.; Mahseredjian, J.; Cai, L.; Saad, H. Offshore wind farm modeling accuracy and efficiency in MMC-based multiterminal HVDC connection. IEEE Trans. Power Deliv. 2017, 32, 617–627. [Google Scholar] [CrossRef]

- Bianchi, F.D.; Garciá, J.L.D. Coordinated frequency control usint MT-HVDC grids with wind power plants. IEEE Trans. Sustain. Energy 2016, 7, 213–220. [Google Scholar] [CrossRef]

- Preece, R.; Milanović, J.V. Tuning of a damping controller for multiterminal VSC-HVDC grids using the probabilistic collocation method. IEEE Trans. Power Deliv. 2014, 29, 318–326. [Google Scholar] [CrossRef]

- Li, C.; Zhan, P.; Wen, J.; Yao, M.; Li, N.; Lee, W. Offshore wind farm integration and frequency support control utilizing hybrid multiterminal HVDC transmission. IEEE Trans. Ind. Appl. 2014, 50, 2788–2797. [Google Scholar] [CrossRef]

- Han, M.; Xu, D.; Wan, L. Hierarchical optimal power flow control for loss minimization in hybrid multi-terminal HVDC transmission system. CSEE J. Power Energy Syst. 2016, 2, 40–46. [Google Scholar] [CrossRef]

- Li, Z.; Zhan, R.; Li, Y.; He, Y.; Hou, J.; Zhao, X.; Zhang, X. Recent developments in HVDC transmission systems to support renewable energy integration. Glob. Energy Interconnect. 2018, 1, 595–601. [Google Scholar]

- Chang, S.J.; Park, J.B. Wire mismatch detection using a convolutional neural network and fault localization based on time–frequency-domain reflectometry. IEEE Trans. Ind. Electron. 2019, 66, 2102–2110. [Google Scholar] [CrossRef]

- Chang, S.J. Advanced signal sensing method With adaptive threshold curve based on time frequency domain reflectometry compensating the signal attenuation. IEEE OJ. Trans. Ind. Electron. 2020, 1, 22–27. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, H.; Wu, Q.; Zhao, H.; Østergaard, J.; Shahidehpour, M. Enhanced voltage control of VSC-HVDC-connected offshore wind farms based on model predictive control. IEEE Trans. Sustain. Energy 2018, 9, 474–487. [Google Scholar] [CrossRef] [Green Version]

- Karawita, C.; Annakkage, U. Multi-infeed HVDC interaction studies using small-signal stability assessment. IEEE Trans. Power Deliv. 2009, 24, 910–918. [Google Scholar] [CrossRef]

- Wang, L.; Thi, M. Comparisons of damping controllers for stability enhancement of an offshore wind farm fed to an OMIB system through an LCC-HVDC link. IEEE Trans. Power Syst. 2013, 28, 1870–1878. [Google Scholar] [CrossRef]

- Trinh, N.; Zeller, M.; Wuerflinger, K.; Erlich, I. Generic model of MMC-VSC-HVDC for interaction study with ac power system. IEEE Trans. Power Syst. 2016, 31, 27–34. [Google Scholar] [CrossRef]

- Faruque, M.; Zhang, Y.; Dinavahi, V. Detailed modeling of CIGRE HVDC benchmark system using PSCAD/EMTDC and PSB/SIMULINK. IEEE Trans. Power Deliv. 2005, 21, 378–387. [Google Scholar] [CrossRef]

| Symbol | Values | Symbol | Values |

|---|---|---|---|

| , | 1.89 | , | 0.02 |

| , | 4.726 | , | 2 |

| , | 7.935 | 0.004 | |

| 1 | 4 | ||

| 100 | 0.63 | ||

| 1 | 41.3386 | ||

| 0.5 | 0.7 | ||

| , | 0.0125 | , | 0.002 |

| 0.1 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-K.; Lee, G.-S.; Chang, S.-J. Solution to Fault of Multi-Terminal DC Transmission Systems Based on High Temperature Superconducting DC Cables. Energies 2021, 14, 1292. https://doi.org/10.3390/en14051292

Lee C-K, Lee G-S, Chang S-J. Solution to Fault of Multi-Terminal DC Transmission Systems Based on High Temperature Superconducting DC Cables. Energies. 2021; 14(5):1292. https://doi.org/10.3390/en14051292

Chicago/Turabian StyleLee, Chun-Kwon, Gyu-Sub Lee, and Seung-Jin Chang. 2021. "Solution to Fault of Multi-Terminal DC Transmission Systems Based on High Temperature Superconducting DC Cables" Energies 14, no. 5: 1292. https://doi.org/10.3390/en14051292