Challenges and Opportunities for End-of-Life Coal Mine Sites: Black-to-Green Energy Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Temporal Horizon of Hard Coal Mines

- Mines with a high risk of hampering exploitation, comprising the mines where the number of hazard events related to natural hazards in the analyzed period was in the third (upper) quartile;

- Mines with an average risk of hampering exploitation, comprising the mines where the number of hazard events related to natural hazards in the analyzed period was in the second (average) quartile;

- Mines with a low risk of hampering exploitation, comprising the mines where the number of hazard events related to natural hazards in the analyzed period was in the first (lower) quartile.

- Amount of coal reserves, defined as coal reserves identified in the highest recognition categories, possible to be exploited without undertaking significant investments to make them available, assuming their use at the level of 30%, based on results of the use of coal deposits in active mines presented in [45,52] and on the size of coal resources in Polish mines based on [53].

2.2. Alternative Uses of Hard Coal Mines

2.2.1. Production of Geothermal Energy

- Mine water inflow—defined as the average annual water inflow to the mine. The water inflow to the mine is a value variable with time, and it depends not only on the hydrogeological conditions, but also on the exploitation depth and the size of the extraction. The mines located in the eastern part of the USCB in the Vistula region are characterized by the largest inflow to the mine, with the highest average inflow value of about 60 m3/min occurring in the Sobieski mine [65].

- Mining water temperature—defined as the temperature of rocks at the deepest exploitation level corresponding to water temperature. Mining water pumped to the surface, under conditions of the USCB, typically has a much lower temperature, ranging from 13 to 23 °C [67].

- Mining water quality—defined as the content of mineral substances in mining water (chemistry of mining water). The mineralization of water in the USCB area is variable and depends on the depth and the type of overburden. Generally, it can be assumed that mineralization increases with depth and in regions where the overburden is impermeable and there is no freshwater inflow from the surface. In mining water, apart from large amounts of sulfates and chlorides, also barium and metal compounds can be found, mainly iron and manganese [70], the presence of which may necessitate water treatment, for the proper functioning of the geothermal installation.

- Shaft depth and technical condition—defined as the maximum mine depth resulting from the shaft depth and the maintenance conditions of the shafts (as an effect of age, durability of the used materials, the manner of usage and exploitation conditions). The production of energy from mine waters with the use of mine shafts requires maintenance of the shaft infrastructure. It should be emphasized that the largest number of shafts in history in the area of the USCB were dug in the 1950s, so for at least several dozen years, they have been subjected to the aggressive action of salty groundwater, temperature changes, and rock mass pressure [71]. As a result, the number of shafts that can serve as parts of installation for the production of geothermal energy will be limited.

- Distance to the potential customers—defined as the distance of the shaft from the geothermal energy development sites. It should be as small as possible; hence, it seems reasonable to conduct such projects in highly urbanized areas. According to [72], the optimal distances do not exceed 1000 m.

2.2.2. Energy Production from Coalbed Methane

2.2.3. Energy Production from Underground Coal Gasification (UCG) Process

- The overburden thickness (UCG1), defined as the thickness of the rocks on the coal seam intended for gasification [77];

- The coal seam thickness (UCG2), defined as the minimum average thickness of the coal seam intended for gasification [77];

- The coal ash content (UCG3), defined as the maximum coal ash content [77];

- The sulfur content in coal (UCG4), defined as the maximum content of sulfur and its compounds in coal [77];

- The degree of coalification (UGC5), defined as the dominant type of coal in the bed intended for gasification [77];

- Rock tightness (UCG6), defined as the impermeability of floor and roof rocks in the vicinity of the coal seam [78];

- The deposit fault (UCG7), defined as the number and nature of faults crossing the coal seam to be converted into gas [79];

- The gasification area (UCG8), defined as the size of the plot in the coal seam intended for gasification [27];

- The methane bearing capacity (UCG9), defined as the average methane content in the deposit intended for gasification [80];

- The safe distance (UCG10), defined as the minimum distance of the plot (separated part of the coal seam) intended for gasification from the goaf and underground workings [27].

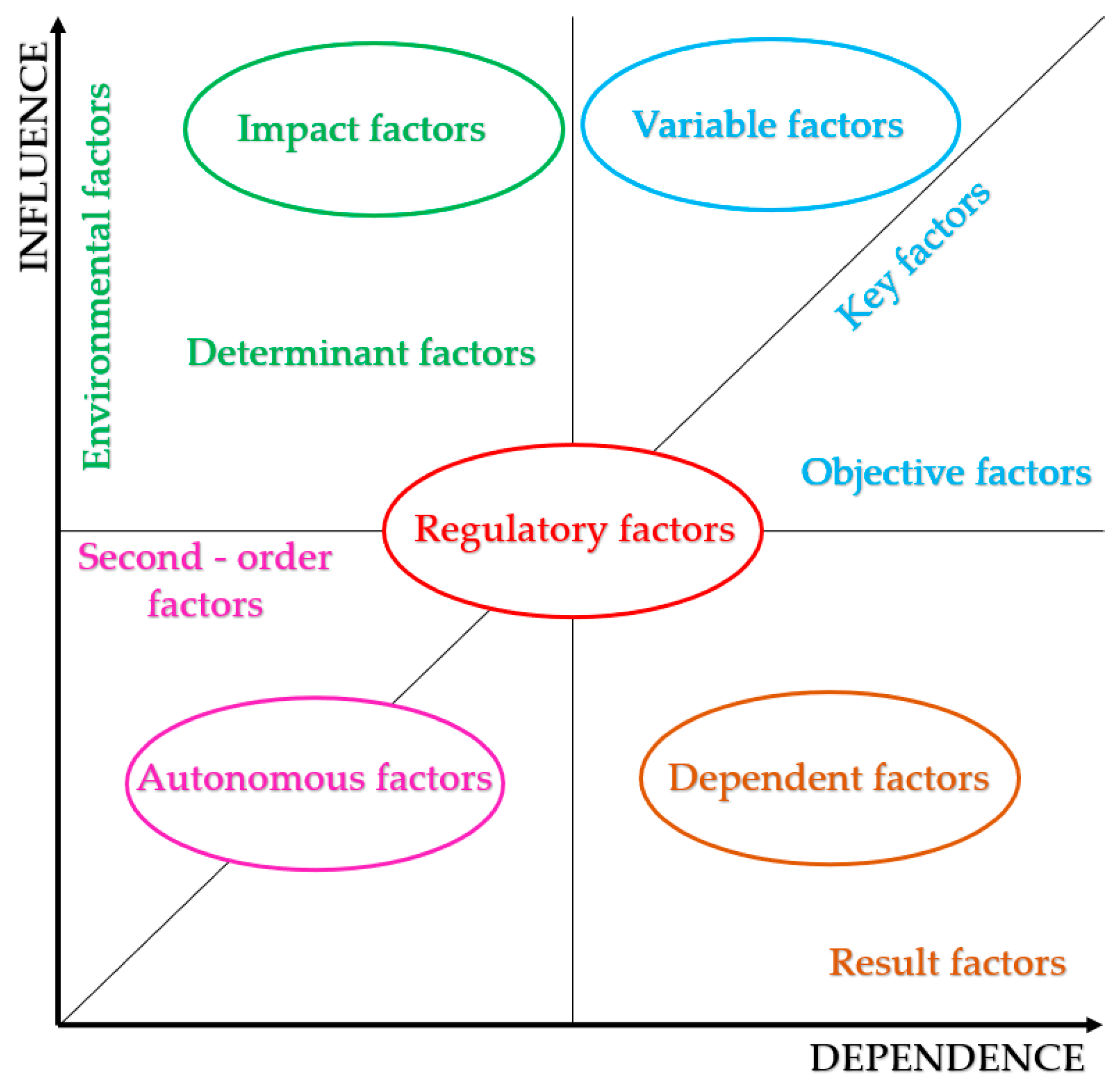

2.3. MICMAC METHOD

- The first quadrant (upper right)—variable factors, characterized by both the highest influences on others and the highest degree of dependencies, among which key factors and objective factors can be distinguished. The objective variables depend on them more than the key variables, rather than influencing them by themselves.

- The second quadrant (upper left)—the criteria referred to as the impact factors which are characterized by high impact and, at the same time, a limited relationship (determinant factors—mainspring and barrier) or absence (environmental factors).

- The third quadrant (bottom left)—autonomous factors which do not directly affect the system, and variables of medium and low impact on the equation (second-order factors).

- The fourth quadrant (bottom right)—the criteria having a medium/low influence on the others but medium/high dependence (dependent factors). There are also result factors that have a low impact on others and a high degree of dependence on others.

- Central area of the matrix—it contains regulatory factors that are characterized by both medium influence and medium dependence.

3. Results and Discussion

3.1. Estimated Temporal Horizon of Mines

3.2. Potential Geothermal Energy Production

3.3. Opportunities for Energy Production from Coalbed Methane

3.4. Possibilities for Conducting UCG and MICMAC Analysis

3.4.1. Possibilities for Conducting UCG

3.4.2. MICMAC Analysis

- UCG10 (safe distance) has been transferred from the central area of the matrix (regulatory factors) to the first quadrant (variable factors—key factor).

- UCG8 (gasification area) has been transferred from the fourth quadrant (dependent factors) to the first quadrant (variable factors—objective factor).

- UCG9 (methane bearing capacity) has been transferred from the third quadrant (autonomous factors) to the second quadrant (impact factors).

- UCG2 (coal seam thickness) has been transformed from the third quadrant (autonomous factors) to the central area of the matrix (regulatory factor).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oei, P.-Y.; Brauers, H.; Herpich, P. Lessons from Germany’s hard coal mining phase-out: Policies and transition from 1950 to 2018. Clim. Policy 2020, 20, 963–979. [Google Scholar] [CrossRef] [Green Version]

- Bódis, K.; Kougias, I.; Taylor, N.; Jäger-Waldau, A. Solar Photovoltaic Electricity Generation: A Lifeline for the European Coal Regions in Transition. Sustainability 2019, 11, 3703. [Google Scholar] [CrossRef] [Green Version]

- Langer, P. “Post-mining reality” in Western Europe: Selected Collieries in Belgium and France Following Discontinuation of Coal Mining. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 112003. [Google Scholar] [CrossRef]

- Rabanal, N.G. Coal restructuring in Spain: Continuity and uncertainty? Energy Policy 2009, 37, 4373–4378. [Google Scholar] [CrossRef]

- Anderson, K. The political economy of coal subsidies in Europe. Energy Policy 1995, 23, 485–496. [Google Scholar] [CrossRef]

- BP p.l.c. BP Statistical Review of World Energy, 69th ed.; BP p.l.c.: London, UK, 2020; Volume 66. [Google Scholar]

- Siddi, M. The European Green Deal: Assessing its current state and future implementation. Clim. Policy 2020, 16, 543–547. [Google Scholar]

- European Commission. The EU Circular Economy Action Plan; European Union: Brussels, Belgium, 2020; pp. 1–2. [Google Scholar]

- Tomaszewski, K. The Polish road to the new European Green Deal—Challenges and threats to the national energy policy. Polityka Energetyczna Energy Policy J. 2020, 23, 5–18. [Google Scholar] [CrossRef]

- Pactwa, K.; Woźniak, J.; Dudek, M. Sustainable Social and Environmental Evaluation of Post-Industrial Facilities in a Closed Loop Perspective in Coal-Mining Areas in Poland. Sustainability 2021, 13, 167. [Google Scholar] [CrossRef]

- Kretschmann, J.; Melchers, C.; Goerke-Mallet, P.; Hegemann, M.; Brueggerhoff, S. Done for Good. Challenges of Post-Mining; Technische Hochschule Georg Agricola: Bochum, Germany, 2016. [Google Scholar]

- Frejowski, A.; Kabiesz, J. Criteria for Assessing the Longevity of Hard Coal Mines. Arch. Min. Sci. 2020, 65, 433–452. [Google Scholar] [CrossRef]

- Kretschmann, J. Post-mining excellence: Strategy and transfer. J. South. Afr. Inst. Min. Met. 2018, 118, 853–859. [Google Scholar] [CrossRef]

- Kretschmann, J.; Efremenkov, A.B.; Khoreshok, A.A. From Mining to Post-Mining: The Sustainable Development Strategy of the German Hard Coal Mining Industry. IOP Conf. Ser. Earth Environ. Sci. 2017, 50. [Google Scholar] [CrossRef]

- Kretschmann, J. Sustainable Change of Coal-Mining Regions. Min. Met. Explor. 2020, 37, 167–178. [Google Scholar] [CrossRef]

- Strambo, C.; Burton, J.; Atteridge, A. The End of Coal? Planning a “Just Transition” in South Africa; Stockholm Environment Institute: Stockholm, Sweden, 2019. [Google Scholar]

- Menéndez, J.; Ordóñez, A.; Álvarez, R.; Loredo, J. Energy from closed mines: Underground energy storage and geothermal applications. Renew. Sustain. Energy Rev. 2019, 108, 498–512. [Google Scholar] [CrossRef]

- Jardón, S.; Ordóñez, A.; Álvarez, R.; Cienfuegos, P.; Loredo, J. Mine Water for Energie-und Wasserversorgung in der Central Coal Basin von Asturien (Spanien). Mine Water Environ. 2013, 32, 139–151. [Google Scholar] [CrossRef]

- Wang, X.; Tang, Y.; Wang, S.; Schobert, H.H. Clean coal geology in China: Research advance and its future. Int. J. Coal Sci. Technol. 2020, 7, 299–310. [Google Scholar] [CrossRef]

- UNECE—United Nations Economic Commission for Europe (Methane to Markets Partnership). Best Practice Guidance for Effective Methane Drainage and Use in Coal Mines; ECE Energy Series No.31; United Nations: New York, NY, USA; Geneva, Switzerland, 2010; Volume 86. [Google Scholar]

- Rahimzadeh, A.; Mohammadi, A.H.; Kamari, A. An Overview of Coal Bed Methane (CBM) Reservoirs: Production and Recovery Advancements. Adv. Energy Res. 2016, 23, 1–27. [Google Scholar]

- Xin, L.; Wang, Z.-T.; Wang, G.; Nie, W.; Zhou, G.; Cheng, W.-M.; Xie, J. Technological aspects for underground coal gasification in steeply inclined thin coal seams at Zhongliangshan coal mine in China. Fuel 2017, 191, 486–494. [Google Scholar] [CrossRef]

- Nieć, M.; Sermet, E.; Chećko, J.; Górecki, J. Evaluation of coal resources for underground gasification in Poland. Selection of possible UCG sites. Fuel 2017, 208, 193–202. [Google Scholar] [CrossRef]

- Jafarpour, A.; Najafi, M. Evaluating the Criteria affecting Methane Drainage in Underground Coal Mines Using Interpretive Structural Modeling. J. Miner. Resour. Eng. 2020, 4, 12–15. [Google Scholar]

- Pivnyak, G.; Falshtynskyi, V.; Dychkovskyi, R.; Saik, P.; Lozynskyi, V.; Cabana, E.; Koshka, O. Conditions of Suitability of Coal Seams for Underground Coal Gasification. Key Eng. Mater. 2020, 844, 38–48. [Google Scholar] [CrossRef]

- Mohanty, D. An overview of the geological controls in underground coal gasification. IOP Conf. Ser. Earth Environ. Sci. 2017, 76, 012010. [Google Scholar] [CrossRef] [Green Version]

- Drzewiecki, J. The basic technological conditions of Underground Coal Gasification (UCG). AGH J. Min. Geoengin. 2012, 36, 117–124. [Google Scholar]

- Al-Habaibeh, A.; Athresh, A.P.; Parker, K. Performance analysis of using mine water from an abandoned coal mine for heating of buildings using an open loop based single shaft GSHP system. Appl. Energy 2018, 211, 393–402. [Google Scholar] [CrossRef] [Green Version]

- Kabiesz, J. Annual Report on the State of Basic Natural and Technical Hazards in Hard Coal Mining, 2008th–2020th ed.; GIG: Katowice, Poland, 2020. [Google Scholar]

- State Mining Authority. Assessment of Safety, Mine Rescue and Public Safety in Connection with the Activities of Mining and Geology in 2019; Wyższy Urząd Górniczy—State Mining Authority: Katowice, Poland, 2020. (In Polish)

- Shadrin, A.V. Geophysical criterion of pre-outburst crack propagation in coal beds. J. Min. Sci. 2016, 52, 670–682. [Google Scholar] [CrossRef]

- Bai, C.; Gong, G.; Liu, Q.; Chen, Y.; Niu, G. The explosion overpressure field and flame propagation of methane/air and methane/coal dust/air mixtures. Saf. Sci. 2011, 49, 1349–1354. [Google Scholar] [CrossRef]

- Broder, J.C.; Gao, C.X.; Campbell, T.C.; Berger, E.; Maybery, D.; McFarlane, A.; Tsoutsoulis, J.; Ikin, J.; Abramson, M.J.; Sim, M.R.; et al. The factors associated with distress following exposure to smoke from an extended coal mine fire. Environ. Pollut. 2020, 266, 115131. [Google Scholar] [CrossRef] [PubMed]

- Szurgacz, D.; Tutak, M.; Brodny, J.; Sobik, L.; Zhironkina, O. The Method of Combating Coal Spontaneous Combustion Hazard in Goafs—A Case Study. Energies 2020, 13, 4538. [Google Scholar] [CrossRef]

- Portola, V.A.; Ovchinnikov, A.E.; Zhadanov, A.N. Evaluation of endogenous fire precautions in coal mines. Min. Inf. Anal. Bull. 2020, 2020, 205–214. [Google Scholar] [CrossRef]

- He, S.; Song, D.; Li, Z.; He, X.; Chen, J.; Zhong, T.; Lou, Q. Mechanism and Prevention of Rockburst in Steeply Inclined and Extremely Thick Coal Seams for Fully Mechanized Top-Coal Caving Mining and Under Gob Filling Conditions. Energies 2020, 13, 1362. [Google Scholar] [CrossRef] [Green Version]

- Cui, F.; Dong, S.; Lai, X.; Chen, J.; Cao, J.; Shan, P. Study on Rule of Overburden Failure and Rock Burst Hazard under Repeated Mining in Fully Mechanized Top-Coal Caving Face with Hard Roof. Energies 2019, 12, 4780. [Google Scholar] [CrossRef] [Green Version]

- Shen, W.; Wang, M.; Cao, Z.; Su, F.; Nan, H.; Li, X. Mining-induced failure criteria of interactional hard roof structures: A case study. Energies 2019, 12, 3016. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Jiang, F. Rock burst criteria and control based on an abutment-stress-transfer model in deep coal roadways. Energy Sci. Eng. 2020, 8, 2966–2975. [Google Scholar] [CrossRef]

- Linming, D.O.U.; Yaodong, J.I.A.N.G.; Anye, C.A.O. Monitoring and pre-warning of rockburst hazard with technology of stress field and wave field in underground coalmines. Chin. J. Rock Mech. Eng. 2017, 36, 803–811. [Google Scholar]

- Cao, A.; Dou, L.; Cai, W.; Gong, S.; Liu, S.; Jing, G. Case study of seismic hazard assessment in underground coal mining using passive tomography. Int. J. Rock Mech. Min. Sci. 2015, 78, 1–9. [Google Scholar] [CrossRef]

- De Smith, M. Statistical Analysis Handbook a Comprehensive Handbook of Statistical Concepts, Techniques and Software Tools, 2018th ed.; Drumlin Security Ltd: London, UK, 2018. [Google Scholar]

- Bobowski, Z. Wybrane Metody Statystyki Opisowej I Wnioskowania Statystycznego; Wydawnictwo WWSZiP: Wałbrzych, Poland, 2004. [Google Scholar]

- Sermet, E.; Nieć, M.; Chećko, J. Hard (bituminous) coal resources in Poland—Expectations and reality. Gospod. Surowcami Miner. 2017, 33, 5–26. [Google Scholar] [CrossRef] [Green Version]

- Nieć, M.; Salamon, E. Variation of fossil fuels resources in Poland during the last half century (Zmiany zasobów paliw kopalnych (kopalin energetycznych) w Polsce w ostatnim półwieczu). Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią PAN 2016, 96, 201–228. [Google Scholar]

- Mark, C.; Stephan, R.C.; Agioutantis, Z. Analysis of Mine Roof Support (AMRS) for US Coal Mines. Min. Met. Explor. 2020, 37, 1899–1910. [Google Scholar] [CrossRef]

- Li, T.; Cai, M. A review of mining-induced seismicity in China. Int. J. Rock Mech. Min. Sci. 2007, 44, 1149–1171. [Google Scholar] [CrossRef]

- Xie, H.; Zhou, H.; Xue, D.; Wang, H.; Zhang, R.; Gao, F. Research and consideration on deep coal mining and critical depth. J. China Coal Soc. 2012, 37, 535–542. [Google Scholar]

- Ranjith, P.G.; Zhao, J.; Ju, M.; De Silva, R.V.; Rathnaweera, T.D.; Bandara, A.K. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Brauers, H.; Oei, P.-Y. The political economy of coal in Poland: Drivers and barriers for a shift away from fossil fuels. Energy Policy 2020, 144, 111621. [Google Scholar] [CrossRef]

- Dubiński, J.; Prusek, S.; Turek, M.; Wachowicz, J. Hard Coal Production Competitiveness in Poland. J. Min. Sci. 2020, 56, 322–330. [Google Scholar] [CrossRef]

- Nieć, M.; Młynarczyk, M. Management of Hard Coal Deposits in Poland; IGSMiE PAN Kraków: Kraków, Poland, 2014. [Google Scholar]

- Szuflicki, M.; Malon, A.; Tymiński, M. Balance of Mineral Resources in Poland as of December 31 2019; Państwowy Instytut Geologiczny—Państwowy Instytut Badawczy: Warszawa, Poland, 2020. (In Polish) [Google Scholar]

- Abraham, J. Just Transitions for the Miners: Labor Environmentalism in the Ruhr and Appalachian Coalfields. New Political Sci. 2017, 39, 218–240. [Google Scholar] [CrossRef]

- Nel, E.L.; Hill, T.R.; Aitchison, K.C.; Buthelezi, S. The closure of coal mines and local development responses in Coal-Rim Cluster, northern KwaZulu-Natal, South Africa. Dev. South. Afr. 2003, 20, 369–385. [Google Scholar] [CrossRef]

- Limpitlaw, D.; Aken, M.; Lodewijks, H. Post-mining rehabilitation, land use and pollution at collieries in South Africa. In Colloquium: Sustainable Development in the Life of Coal Mining; South African Institute of Mining and Metallurgy: Boksburg, South Africa, 2005; pp. 1–10. [Google Scholar]

- Wirth, P.; Černič-Mali, B.; Fischer, W. Problems and Potentials of Post-Mining Regions. In Post-Mining Regions in Central Europe—Problems, Potentials, Possibilities; Oekom Verlag: München, Germany, 2012. [Google Scholar]

- Wieber, G.; Pohl, S. Mine Water: A Source of Geothermal Energy—Examples from the Rhenish Massif. In Proceedings of the 10th International Mine Water Association Congress–Mine Water and the Environment, Karlsbad, Czech Republic, 2–5 June 2008; pp. 113–116. [Google Scholar]

- Díez, R.R.; Diaz-Aguado, M.B. Estimating Limits for the Geothermal Energy Potential of Abandoned Underground Coal Mines: A Simple Methodology. Energies 2014, 7, 4241–4260. [Google Scholar] [CrossRef] [Green Version]

- Menéndez, J.; Loredo, J. Use of closured open pit and underground coal mines for energy generation: Application to the Asturias Central Coal Basin (Spain). E3S Web Conf. 2019, 80, 01005. [Google Scholar] [CrossRef]

- Loredo, C.; Roqueñí, N.; Ordóñez, A. Modelling flow and heat transfer in flooded mines for geothermal energy use: A review. Int. J. Coal Geol. 2016, 164, 115–122. [Google Scholar] [CrossRef]

- Jessop, A. Geothermal Energy from Old Mines at Springhill, Nova Scotia, Canada. In Proceedings of the World Geotherm Congress, Florence, Italy, 18–31 May 1995; pp. 463–468. [Google Scholar]

- Watzlaf, G.R.; Ackman, T.E. Underground Mine Water for Heating and Cooling using Geothermal Heat Pump Systems. Mine Water Environ. 2006, 25, 1–14. [Google Scholar] [CrossRef]

- Patsa, E.; Van Zyl, D.; Zarrouk, S.J.; Arianpoo, N. Geothermal Energy in Mining Developments: Synergies and Opportunities Throughout a Mine ’ s Operational Life Cycle. In Proceedings of the World Geothermal Congress, Florence, Italy, 18–31 May 1995; pp. 19–25. [Google Scholar]

- Karpiński, M.; Batko, R.; Kmiecik, E.; Tomaszewska, B.; Zdechlik, R. Time variability of the volume of underground water inflows to the workings of the Sobieski Mining Plant. Tech. Poszuk. Geol. 2017, 56, 49–60. (In Polish) [Google Scholar]

- Solik-Heliasz, E.; Małolepszy, Z. The possibilities of utilisation of geothermal energy from mine waters in the Upper Silesian Coal Basin (Możliwości wykorzystania energii geotermalnej z wód kopalnianych w Górnośląskim Zagłebiu Weglowym). In Proceedings of the International Scientific Conderence Geothermal Energy in Underground Mines, Ustron, Poland, 21–23 November 2001; pp. 81–88. [Google Scholar]

- Solik-Heliasz, E. Geothermals Waters of the Upper Silesian Region and Their Energy Resources; Główny Instytut Górnictwa w Katowicach: Katowice, Poland, 2012. [Google Scholar]

- Małolepszy, Z. Geosyntopic model of geothermics in the Upper Silesian Coal Basin (Geosynoptyczny model pola geotermicznego Górnośląskiego Zagłebia Weglowego). Tech. Poszuk. Geol. 2000, 39, 3–33. [Google Scholar]

- Karwasiecka, M. Geothermal Atlas of the Upper Silesian Coal Basin; Wydawnictwa Katrograficzne Polskiej Agencji Ekologicznej SA: Warszawa, Poland, 1996. (In Polish) [Google Scholar]

- Bondaruk, J.; Janson, E.; Wysocka, M.; Chałupnik, S. Identification of hazards for water environment in the Upper Silesian Coal Basin caused by the discharge of salt mine water containing particularly harmful substances and radionuclides. J. Sustain. Min. 2015, 14, 179–187. [Google Scholar] [CrossRef] [Green Version]

- Stasica, J. Modern methods of testing and evaluation of the technical state of mining shafts lining (Nowoczesne metody badań i oceny stanu technicznego obudów szybów górniczych). Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią PAN, 101, Kraków 2017, 85–100. [Google Scholar]

- Solik-Heliasz, E.; Skrzypczak, M. The technological design of geothermal plant for producing energy from mine waters. Arch. Min. Sci. 2009, 54, 563–572. [Google Scholar]

- Chećko, J.; Urych, T.; Magdziarczyk, M.; Smoliński, A. Resource Assessment and Numerical Modeling of CBM Extraction in the Upper Silesian Coal Basin, Poland. Energies 2020, 13, 2153. [Google Scholar] [CrossRef]

- Krzemien, A. Dynamic fire risk prevention strategy in underground coal gasification processes by means of artificial neural networks. Arch. Min. Sci. 2019, 64, 3–19. [Google Scholar] [CrossRef]

- Frejowski, A.; Koteras, A. Criteria for location conditions of UCG generator in the Carboniferous rockmass disturbed by mining operations. Wiadomości Górnicze 2016, 67, 29–38. (In Polish) [Google Scholar]

- Krzemień, A. Fire risk prevention in underground coal gasification (UCG) within active mines: Temperature forecast by means of MARS models. Energy 2019, 170, 777–790. [Google Scholar] [CrossRef]

- Frejowski, A.; Myszkowski, J. Selected geological criteria determining the use of available mining technologies for underground hard coal gasification. Górnicze Zagrożenia Nat. 2012. (In Polish) [Google Scholar]

- Merta, G.; Frejowski, A. Evaluation of the cracks of the rocks mass in the area of UCG geo-reactor. Wiadomości Górnicze 2015, 66, 281–286. [Google Scholar]

- Marcisz, M. Degree of Faulting of Hard Coal Deposits of Upper Silesian Coal Basin. Gospod. Surowcami Miner. 2017, 33, 97–112. [Google Scholar] [CrossRef] [Green Version]

- Frejowski, A. Selected Aerological Criteria Determining the Conduct of Underground Coal Gasification under the Conditions of USCB; Central MIning Institute: Katowice, Poland, 2013; pp. 70–79. (In Polish) [Google Scholar]

- Duperrin, J.; Godet, M. SMIC 74—A method for constructing and ranking scenarios. Futures 1975, 7, 302–312. [Google Scholar] [CrossRef]

- Villacorta, P.J.; Masegosa, A.D.; Castellanos, D.; Lamata, M.T. A Linguistic Approach to Structural Analysis in Prospective Studies. In International Conference on Information Processing and Management of Uncertainty in Knowledge-Based Systems; Springer: Berlin/Heidelberg, Germany, 2012; pp. 150–159. [Google Scholar]

- Agrawal, N. A framework for Crosby’s quality principles using ISM and MICMAC approaches. TQM J. 2019, 32, 305–330. [Google Scholar] [CrossRef]

- Dhir, S.; Dhir, S. Modeling of strategic thinking enablers: A modified total interpretive structural modeling (TISM) and MICMAC approach. Int. J. Syst. Assur. Eng. Manag. 2020, 11, 175–188. [Google Scholar] [CrossRef]

- Krause, E.; Krzemień, K. Methane Risk Assessment in Underground Mines by Means of a Survey by the Panel of Experts (Sope). J. Sustain. Min. 2014, 13, 6–13. [Google Scholar] [CrossRef] [Green Version]

| Seismic Hazard—Number of High-Energy Tremors | Rock Burst Hazard—Number of Rock Bursts | Fire Hazard—Number of Endogenous Fires | Gas Hazard—Number of Methane Ignitions or Explosions | Depth of the Mine—The Deepest Level of Exploitation | Temporal Horizon | |

|---|---|---|---|---|---|---|

| Group size | 18 | 18 | 18 | 18 | 18 | 18 |

| Significance level | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Variance | 9871.79 | 3.08 | 8.87 | 3.55 | 37,591.58 | 132.29 |

| Standard deviation | 98.9 | 1.75 | 2.97 | 1.88 | 193.88 | 11.5 |

| Coefficient of the variability | 1.24 | 1.5 | 1.01 | 1.30 | 0.24 | 0.01 |

| Interquartile range | 115.25 | 2 | 2.75 | 2.75 | 250 | 17 |

| Minimum | 0 | 0 | 0 | 0 | 500 | 2024 |

| Maximum | 346 | 6 | 11 | 6 | 1150 | 2062 |

| Lower quartile | 3 | 0 | 1 | 0 | 650 | 2034 |

| Median | 46.5 | 0 | 2 | 0.5 | 795 | 2043 |

| Upper quartile | 118.25 | 2 | 3.75 | 2.75 | 900 | 2051 |

| Skewness | 1.49 | 1.54 | 1.54 | 1.22 | 0.13 | 0.14 |

| Std. err. of the skewness | 0.53 | 0.53 | 0.53 | 0.53 | 0.53 | 0.53 |

| Kurtosis | 1.819 | 2.04 | 1.98 | 0.68 | −0.87 | −1.01 |

| Std. err. of the kurtosis | 1.037 | 1.03 | 1.03 | 1.03 | 1.03 | 1.03 |

| Years of Experience in Coal Mining | Number of Experts from Scientific Entity | Number of Experts from Coal Mining Industry |

|---|---|---|

| 10–20 | 6 | 5 |

| 21–30 | 4 | 5 |

| 31–40 | 4 | 2 |

| >40 | 2 | 0 |

| Indicator of Experts’ Competence | Number of Experts from Scientific Entity | Number of Experts from Coal Mining Industry |

| 0.5–0.6 | 3 | 4 |

| 0.7–0.8 | 8 | 6 |

| 0.9–1.0 | 5 | 2 |

| Quadrant Number | Factors | Matrix Direct Influences Analysis | Matrix Indirect Influences Analysis | Evaluation of Factors on the Possibility of UCG |

|---|---|---|---|---|

| I | Variable (Key and objective) | - | UCG10 (safe distance)—key factor | Priority factors for the evaluation |

| UCG8 (gasification area)—objective factor | ||||

| II | Impact (Determinant and environmental) | UCG1 (overburden thickness) UCG7 (deposit faults) | UCG1 (overburden thickness)—environmental factor | Factors determining the evaluation |

| UCG7 (deposit faults)—environmental factor | ||||

| UCG9 (methane bearing capacity)—determinant factor | ||||

| III | Autonomous | UCG2 (coal seam thickness) | Factors with low influence on the evaluation | |

| UCG3 (coal ash content) | ||||

| UCG4 (sulfur content in coal) | UCG3 (coal ash content) | |||

| UCG5 (degree of coalification) | UCG4 (sulfur content in coal) | |||

| UCG6 (rock tightness) | UCG5 (degree of coalification) | |||

| UCG9 (methane bearing capacity) | UCG6 (rock tightness) | |||

| IV | Dependent (Result) | UCG8 (gasification area) | - | Factors with high dependency and low impact on the evaluation |

| Central area of the matrix | Regulatory | UCG10 (safe distance) | UCG2 (coal seam thickness) | Factors with medium dependency and medium impact on the evaluation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frejowski, A.; Bondaruk, J.; Duda, A. Challenges and Opportunities for End-of-Life Coal Mine Sites: Black-to-Green Energy Approach. Energies 2021, 14, 1385. https://doi.org/10.3390/en14051385

Frejowski A, Bondaruk J, Duda A. Challenges and Opportunities for End-of-Life Coal Mine Sites: Black-to-Green Energy Approach. Energies. 2021; 14(5):1385. https://doi.org/10.3390/en14051385

Chicago/Turabian StyleFrejowski, Aleksander, Jan Bondaruk, and Adam Duda. 2021. "Challenges and Opportunities for End-of-Life Coal Mine Sites: Black-to-Green Energy Approach" Energies 14, no. 5: 1385. https://doi.org/10.3390/en14051385