Pulsed LED-Lighting as an Alternative Energy Savings Technique for Vertical Farms and Plant Factories

Abstract

:1. Introduction

2. Materials and Methods

2.1. Lighting System Characteristics

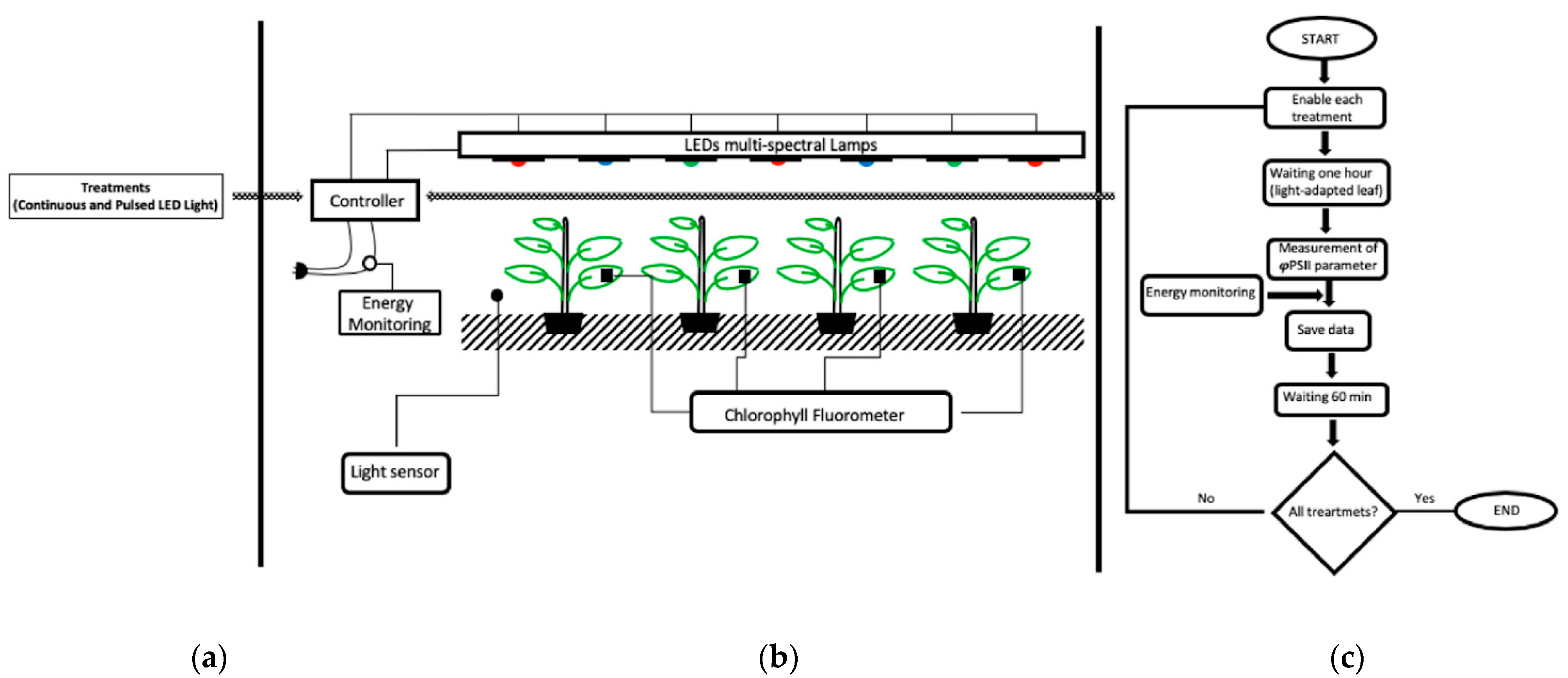

2.2. Continuous and Pulsed LED Light Effects in φPSII

LED Light Treatments (Pulsed and Continuous Light)

2.3. Continuous and Pulsed LED Light Effects in Energy Consumption

2.4. Mathematical Model: Continuous and Pulsed Light Modes

3. Results

3.1. Continuous and Pulsed LED Light Effects in Photochemical Efficiency of Photosystem II (φPSII)

3.2. Energy Consumption in CONTINUOUS and Pulsed LED Light

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, S.M.; Radhakrishnan, R.; Lee, K.-E.; You, Y.-H.; Ko, J.-H.; Kim, J.-H.; Lee, I.-J. Mechanism of plant growth promotion elicited by Bacillus sp. LKE15 in oriental melon. Acta Agric. Scand. B 2015, 65, 637–647. [Google Scholar]

- Li, J.S.; Xia, X.H.; Chen, G.Q.; Alsaedi, A.; Hayat, T. Optimal embodied energy abatement strategy for Beijing economy: Based on a three-scale input-output analysis. J. Renew. Sustain. Energy Rev. 2016, 53, 1602–1610. [Google Scholar] [CrossRef]

- Benke, K.; Tomkins, B. Future food-production systems: Vertical farming and controlled-environment agriculture. SSPP 2017, 13, 13–26. [Google Scholar] [CrossRef] [Green Version]

- Eaves, J.; Eaves, S. Comparing the profitability of a greenhouse to a vertical farm in Quebec: Profitability of a greenhouse and a vertical farm. Can. J. Agric. Econ. 2018, 66, 43–54. [Google Scholar] [CrossRef]

- Kalantari, F.; Tahir, O.M.; Lahijani, A.M.; Kalantari, S. A review of vertical farming technology: A guide for implementation of building integrated agriculture in cities. Adv. Eng. Forum 2017, 24, 76–91. [Google Scholar] [CrossRef]

- Rabara, R.C.; Behrman, G.; Timbol, T.; Rushton, P.J. Effect of Spectral Quality of Monochromatic LED Lights on the Growth of Artichoke Seedlings. Front. Plant Sci. 2017, 8, 190. [Google Scholar] [CrossRef] [Green Version]

- Massa, G.D.; Kim, H.-H.; Wheeler, R.M.; Mitchell, C.A. Plant productivity in response to LED lighting. HortScience 2008, 43, 1951–1956. [Google Scholar] [CrossRef]

- Ata, K.; Urano, M.; Takahashi, A. Thermal analysis of pulsed LED lighting in plant factory. IMFEDK 2017, 56–57. [Google Scholar] [CrossRef]

- Kozai, T. Smart Plant Factory: The Next Generation Indoor Vertical Farms, 1st ed.; Springer: Singapore, 2018. [Google Scholar]

- Kozai, T. Led Lighting for Urban Agriculture; Springer: Singapore, 2016. [Google Scholar]

- Shimizu, H.; Saito, Y.; Nakashima, H.; Miyasaka, J.; Ohdoi, K. Light Environment Optimization for Lettuce Growth in Plant Factory. IFAC Proc. 2011, 44, 605–609. [Google Scholar] [CrossRef] [Green Version]

- Son, K.-H.; Jeon, Y.-M.; Oh, M. Application of supplementary white and pulsed light-emitting diodes to lettuce grown in a plant factory with artificial lighting. Hortic. Environ. Biotechnol. 2016, 57, 560–572. [Google Scholar] [CrossRef]

- D’Souza, C.; Yuk, H.-G.; Khoo, G.H.; Zhou, W. Application of light-emitting diodes in food production, postharvest preservation, and microbiological food safety: LEDs in food production and preservation. Rev. Food Sci. Food Saf. 2015, 14, 719–740. [Google Scholar] [CrossRef]

- Dou, H.; Niu, G.; Gu, M.; Masabni, J. Effects of light quality on growth and phytonutrient accumulation of herbs under controlled environments. Acta Hortic. 2017, 3, 36. [Google Scholar] [CrossRef] [Green Version]

- Han, T.; Vaganov, V.; Cao, S.; Li, Q.; Ling, L.; Cheng, X.; Tu, M. Improving “Color Rendering” of LED lighting for the growth of lettuce. Sci. Rep. 2017, 7, 45944. [Google Scholar] [CrossRef]

- Muneer, S.; Kim, E.; Park, J.; Lee, J. Influence of green, red and blue light emitting diodes on multiprotein complex proteins and photosynthetic activity under different light intensities in lettuce leaves (Lactuca sativa L.). Int. J. Mol. Sci. 2014, 15, 4657–4670. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruangrak, E.; Khummueng, W. Effects of artificial light sources on accumulation of phytochemical contents in hydroponic lettuce. J. Hortic. Sci. Biotechnol. 2019, 94, 378–388. [Google Scholar] [CrossRef]

- Barta, D.J.; Tibbitts, T.W.; Bula, R.J.; Morrow, R.C. Evaluation of light emitting diode characteristics for a space-based plant irradiation source. Adv. Space Res. 1992, 12, 141–149. [Google Scholar] [CrossRef]

- Bula, R.J.; Morrow, R.C.; Tibbitts, T.W.; Barta, D.J.; Ignatius, R.W.; Martin, T.S. Light-emitting diodes as a radiation source for plants. HortScience 1991, 26, 203–205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dougher, T.A.O.; Bugbee, B. Evidence for yellow light suppression of lettuce growth. Photochem. Photobiol. 2007, 73, 208–212. [Google Scholar] [CrossRef]

- Dougher, T.A.O.; Bugbee, B. Differences in the response of wheat, soybean and lettuce to reduced blue radiation. Photochem. Photobiol. 2001, 73, 199–207. [Google Scholar] [CrossRef]

- Hoenecke, M.E.; Bula, R.J.; Tibbitts, T.W. Importance of “blue” photon levels for lettuce seedlings grown under red-light-emitting diodes. HortScience 1992, 27, 427–430. [Google Scholar] [CrossRef] [Green Version]

- Okamoto, K.; Yanagi, T.; Takita, S. Development of plant growth apparatus using blue and red LED as artificial light source. Acta Hortic. 1996, 440, 111–116. [Google Scholar] [CrossRef] [PubMed]

- Olvera-Gonzalez, E.; Alaniz-Lumbreras, D.; Ivanov-Tsonchev, R.; Villa-Hernández, J.; De la Rosa-Vargas, I.; López-Cruz, I.; Lara-Herrera, A. Chlorophyll fluorescence emission of tomato plants as a response to pulsed light-based LEDs. Plant Growth Regul. 2013, 69, 117–123. [Google Scholar] [CrossRef] [Green Version]

- Yorio, N.C.; Goins, G.D.; Kagie, H.R.; Wheeler, R.M.; Sager, J.C. Improving Spinach, Radish, and Lettuce Growth under Red Light-emitting Diodes (LEDs) with Blue Light Supplementation. HortScience 2001, 36, 380–383. [Google Scholar] [CrossRef] [Green Version]

- Brumfield, R. Dealing with rising energy cost. GNP 2007, 33, 24–31. [Google Scholar]

- National Aeronautics and Space Administration. Growing Plants in Space. 2019. Available online: https://www.nasa.gov/content/growing-plants-in-space (accessed on 3 March 2021).

- Anpo, M.; Fukuda, H.; Wada, T. Plant Factory Using Artificial Light Adapting to Environmental Disruption and Clues to Agricultural Innovation, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Despommier, D.; Carter, M. The Vertical Farm: Feeding the World in the 21st Century; Macmillan: New York, NY, USA, 2010. [Google Scholar]

- Schubert, E.F. Solid-State Light Sources Getting Smart. Science 2005, 308, 1274–1278. [Google Scholar] [CrossRef]

- Sanford, S. Energy-Efficient Agricultural Lighting; University of Wisconsin: Madison, WI, USA, 2004; Volume 14, pp. 1–12. [Google Scholar]

- Bian, Z.-H.; Cheng, R.-F.; Yang, Q.-C.; Wang, J.; Lu, C. Continuous light from red, blue, and green light-emitting diodes reduces nitrate content and enhances phytochemical concentrations and antioxidant capacity in lettuce. J. Am. Soc. Hortic. Sci. 2016, 141, 186–195. [Google Scholar] [CrossRef] [Green Version]

- Gupta, S.D. Light Emitting Diodes for Agriculture; Springer: Singapore, 2017. [Google Scholar]

- Ballaré, C.L.; Scopel, A.L.; Sánchez, R.A. On the opportunity cost of the photosynthate invested in stem elongation reactions mediated by phytochrome. Oecologia 1991, 86, 561–567. [Google Scholar] [CrossRef]

- Domurath, N.; Schroeder, F.-G.; Glatzel, S. Light response curves of selected plants under different light conditions. Acta Hortic. 2012, 291–298. [Google Scholar] [CrossRef] [Green Version]

- Goto, E. Effects of Light Quality on Growth of Crop Plants under Artificial Lighting. Environ. Control Biol. 2003, 41, 121–132. [Google Scholar] [CrossRef] [Green Version]

- Stenitz, B.; Poff, K.L. A single positive phototropic response induced with pulsed light in hypocotyls of Arabidopsis thaliana seedlings. Planta 1986, 168, 305–315. [Google Scholar] [CrossRef]

- Tennessen, D.J.; Bula, R.J.; Sharkey, T.D. Efficiency of photosynthesis in continuous and pulsed light emitting diode irradiation. Photosynth. Res. 1995, 44, 261–269. [Google Scholar] [CrossRef]

- Jao, R.-C.; Fang, W. Effects of frequency and duty ratio on the growth of potato plantlets in vitro using light-emitting diodes. HortScience 2004, 39, 375–379. [Google Scholar] [CrossRef] [Green Version]

- Jao, R.-C.; Fang, W. Growth of potato plantlets in vitro is different when provided concurrent versus alternating blue and red-light photoperiods. HortScience 2004, 39, 380–382. [Google Scholar] [CrossRef] [Green Version]

- Jao, R.-C.; Fang, W. An adjustable light source for photo–phyto related research and young plant production. Appl. Eng. Agric. 2003, 19. [Google Scholar] [CrossRef]

- Yoneda, M.Y. Method of Cultivating Plant and Illuminator for Cultivating Plant. European Patent Office Patent No. EP1374665A1, 2 January 2004. [Google Scholar]

- Olvera-Gonzalez, E.; Alaniz-Lumbreras, D.; Ivanov-Tsonchev, R.; Villa-Hernández, J.; Olvera-Olvera, C.; González-Ramírez, E.; Castaño, V. Intelligent lighting system for plant growth and development. Comput. Electron. Agric. 2012, 92, 48–53. [Google Scholar] [CrossRef]

- Senol, R.; Kilic, S.; Tasdelen, K. Pulse timing control for LED plant growth unit and effects on carnation. Comput. Electron. Agric. 2016, 123, 125–134. [Google Scholar] [CrossRef]

- Kanechi, M.; Maekawa, A.; Nishida, Y.; Miyashita, E. Effects of pulsed lighting-based light-emitting diodes on the growth and photosynthesis of lettuce leaves. Acta Hortic. 2016, 207–214. [Google Scholar] [CrossRef]

- Pardo, G.P.; Velázquez, S.T.; Cruz, A.; Aguilar, C.H.; Pacheco, F.A.D.; Martínez, F.R. Pulsed led light in germination and growth of lettuce seeds. BOTHALIA 2016, 46, 15. [Google Scholar]

- Vaštakaitė, V. Pulsed Light-Emitting Diodes for a Higher Phytochemical Level in Microgreens. J. Agric. Food Chem. 2017, 65, 6529–6534. [Google Scholar] [CrossRef]

- Son, K.; Lee, S.; Oh, M. Comparison of Lettuce Growth under Continuous and Pulsed Irradiation Using Light-Emitting Diodes. Korean J. Hortic. Sci. Technol. 2018, 36, 542–551. [Google Scholar]

- Genty, B.; Briantais, J.-M.; Baker, N.R. The relationship between the quantum yield of photosynthetic electron transport and quenching of chlorophyll fluorescence. Biochim. Biophys. Acta Gen. Subj. 1989, 990, 87–92. [Google Scholar] [CrossRef]

- Maxwell, K.; Johnson, G.N. Chlorophyll fluorescence—a practical guide. J. Exp. Bot. 2000, 51, 659–668. [Google Scholar] [CrossRef]

- Meng, Q.; Kelly, N.; Runkle, E.S. Substituting green or far-red radiation for blue radiation induces shade avoidance and promotes growth in lettuce and kale. Environ. Exp. Bot. 2019, 162, 383–391. [Google Scholar] [CrossRef]

- Mickens, M.A. A strategic approach for investigating light recipes for ‘Outredgeous’ red romaine lettuce using white and monochromatic LEDs. Life Sci. Space Res. 2018, 19, 53–62. [Google Scholar] [CrossRef]

- Naznin, M.; Lefsrud, M.; Gravel, V.; Azad, M. Blue Light added with Red LEDs Enhance Growth Characteristics, Pigments Content, and Antioxidant Capacity in Lettuce, Spinach, Kale, Basil, and Sweet Pepper in a Controlled Environment. Plants 2019, 8, 93. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Quality (Color) | Maximum PPFD (μmol) | Irradiated Surface (m2) |

|---|---|---|

| White | 150 | 0.19 (37 × 50 cm) |

| Blue | 90 | 0.19 (37 × 50 cm) |

| Green | 55 | 0.19 (37 × 50 cm) |

| Red | 150 | 0.19 (37 × 50 cm) |

| Total | 445 | 0.19 (37 × 50 cm) |

| Recipes | Red | Green | Blue | White |

|---|---|---|---|---|

| 95R5B | 95% | 0% | 5% | 0% |

| 83R17B | 83% | 0% | 17% | 0% |

| 60R40B | 60% | 0% | 40% | 0% |

| 57W43B | 0% | 0% | 43% | 57% |

| 67R11B22G | 67% | 22% | 11% | 0% |

| 67R33G | 67% | 33% | 0% | 0% |

| 100W | 0% | 0% | 0% | 100% |

| 50R50B | 50% | 0% | 50% | 0% |

| 70R30B | 70% | 0% | 30% | 0% |

| 30R70B | 30% | 0% | 70% | 0% |

| Fc (Hz) | ton (s) | |||||

|---|---|---|---|---|---|---|

| Duty Cycle (%) | ||||||

| 40 | 50 | 60 | 70 | 80 | 90 | |

| 1 × 102 | 0.004 | 0.005 | 0.006 | 0.007 | 0.008 | 0.009 |

| 5 × 102 | 0.0008 | 0.001 | 0.0012 | 0.0014 | 0.0016 | 0.0018 |

| 1 × 103 | 0.0004 | 0.0005 | 0.0006 | 0.0007 | 0.0008 | 0.0009 |

| Initial Parameters | * Calculated Parameters | Measured Parameters | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Light Treatments (Recipes) | PPFDc (µmol m−2 s−1) | Photoperiod | Fc (Hz) | * T | * Np | * PPFDp (µmol m−2 s−1) | Energy Equivalence (mol m−2 d−1) | Energy Consumption ± 0.1 (W/h) | ||||||||||||

| Duty Cycle (%) | Duty Cycle (%) | |||||||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | * DLIp | * DLIc | Continuous | 40 | 50 | 60 | 70 | 80 | 90 | ||||||

| 95R5B | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 3.24 | 3.24 | 23.8 | 21.3 | 21.6 | 22.2 | 22.7 | 23.0 | 23.7 |

| 500 | 0.002 | 3.24 × 107 | 22.1 | 23.1 | 23.1 | 23.4 | 23.7 | 23.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 23.0 | 23.1 | 23.4 | 23.5 | 23.5 | 23.7 | ||||||||||||

| 83R17B | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 24.0 | 21.4 | 21.7 | 22.1 | 22.7 | 23.1 | 23.8 | ||

| 500 | 0.002 | 3.24 × 107 | 22.8 | 23.1 | 23.2 | 23.5 | 23.8 | 24.0 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 23.0 | 23.3 | 23.3 | 23.7 | 23.9 | 24.0 | ||||||||||||

| 60R40B | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 24.8 | 21.7 | 22.3 | 22.7 | 23.1 | 23.5 | 24.3 | ||

| 500 | 0.002 | 3.24 × 107 | 22.3 | 23.3 | 23.8 | 23.9 | 24.1 | 24.5 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 23.7 | 23.7 | 24.1 | 24.2 | 24.4 | 24.5 | ||||||||||||

| 57W43B | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 26.0 | 23.1 | 23.7 | 24.2 | 24.6 | 25.0 | 25.6 | ||

| 500 | 0.002 | 3.24× 107 | 23.2 | 23.2 | 23.7 | 25.4 | 25.5 | 26.0 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 25.4 | 26.5 | 25.6 | 25.8 | 25.8 | 26.0 | ||||||||||||

| 67R11B22G | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 25.4 | 21.9 | 22.4 | 22.9 | 23.4 | 23.9 | 24.7 | ||

| 500 | 0.002 | 3.24 × 107 | 23.4 | 23.7 | 24.0 | 24.3 | 24.5 | 24.7 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 23.7 | 23.9 | 24.1 | 24.3 | 24.5 | 24.8 | ||||||||||||

| 67R33G | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 24.0 | 21.3 | 21.6 | 22.1 | 22.4 | 22.8 | 23.5 | ||

| 500 | 0.002 | 3.24 × 107 | 22.6 | 22.8 | 23.0 | 23.1 | 23.4 | 23.7 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 23.1 | 23.2 | 23.3 | 23.3 | 23.6 | 24.0 | ||||||||||||

| 100W | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 25.5 | 23.4 | 23.8 | 24.2 | 24.4 | 24.5 | 25.1 | ||

| 500 | 0.002 | 3.24 × 107 | 22.8 | 23.0 | 23.3 | 23.6 | 25.2 | 25.5 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 25.7 | 25.6 | 25.7 | 25.4 | 25.4 | 25.5 | ||||||||||||

| 50R50B | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 24.8 | 22.0 | 22.3 | 22.6 | 23.1 | 23.6 | 24.4 | ||

| 500 | 0.002 | 3.24 × 107 | 22.1 | 22.8 | 23.7 | 24.0 | 24.1 | 24.4 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 23.5 | 23.8 | 23.9 | 24.3 | 24.5 | 24.6 | ||||||||||||

| 70R30B | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 24.4 | 21.6 | 22.0 | 22.4 | 22.8 | 23.2 | 23.9 | ||

| 500 | 0.002 | 3.24 × 107 | 23.2 | 23.3 | 23.4 | 23.7 | 23.8 | 24.1 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 23.5 | 23.6 | 23.6 | 23.8 | 24.0 | 24.2 | ||||||||||||

| 30R70B | 50 | 18/6 | 100 | 0.01 | 6.48 × 106 | 125 | 100 | 83 | 71 | 63 | 56 | 25.0 | 22.4 | 22.7 | 23.2 | 23.6 | 23.9 | 24.6 | ||

| 500 | 0.002 | 3.24 × 107 | 22.4 | 22.7 | 23.3 | 24.3 | 24.7 | 24.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 24.5 | 24.4 | 24.5 | 24.6 | 24.9 | 24.8 | ||||||||||||

| 95R5B | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 7.13 | 7.13 | 30.1 | 27.5 | 27.4 | 28.1 | 28.4 | 28.9 | 29.5 |

| 500 | 0.002 | 3.24 × 107 | 26.6 | 26.6 | 26.9 | 28.0 | 29.4 | 29.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 30.3 | 30.0 | 29.9 | 29.9 | 29.9 | 30.0 | ||||||||||||

| 83R17B | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 30.2 | 27.5 | 27.4 | 28.1 | 28.6 | 29.1 | 29.7 | ||

| 500 | 0.002 | 3.24 × 107 | 26.7 | 26.6 | 27.9 | 27.8 | 29.4 | 29.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 30.4 | 30.0 | 30.0 | 29.9 | 30.3 | 30.2 | ||||||||||||

| 60R40B | 110 | 18/6 | 100 | 0.01 | 6.48× 106 | 275 | 220 | 183 | 157 | 138 | 122 | 31.0 | 28.2 | 28.3 | 28.8 | 29.1 | 29.6 | 30.3 | ||

| 500 | 0.002 | 3.24 × 107 | 27.2 | 27.1 | 27.1 | 27.7 | 30.0 | 30.6 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 31.1 | 30.8 | 30.6 | 30.7 | 30.7 | 30.6 | ||||||||||||

| 57W43B | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 34.4 | 32.2 | 32.0 | 32.1 | 32.3 | 32.8 | 33.4 | ||

| 500 | 0.002 | 3.24 × 107 | 30.6 | 30.2 | 30.3 | 30.9 | 33.5 | 33.9 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 35.0 | 34.3 | 34.1 | 34.0 | 34.1 | 34.1 | ||||||||||||

| 67R11B22G | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 31.2 | 27.5 | 27.8 | 28.3 | 28.9 | 29.6 | 30.3 | ||

| 500 | 0.002 | 3.24 × 107 | 27.0 | 27.1 | 27.6 | 28.6 | 29.9 | 30.4 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 30.3 | 30.3 | 30.3 | 30.4 | 30.7 | 30.8 | ||||||||||||

| 67R33G | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 29.8 | 27.6 | 27.6 | 28.0 | 28.2 | 27.5 | 29.2 | ||

| 500 | 0.002 | 3.24 × 107 | 26.8 | 26.4 | 26.6 | 26.9 | 29.0 | 29.3 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 30.4 | 29.9 | 29.9 | 29.7 | 29.9 | 29.7 | ||||||||||||

| 100W | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 35.1 | 34.7 | 34.1 | 33.9 | 33.5 | 33.8 | 34.3 | ||

| 500 | 0.002 | 3.24 × 107 | 33.1 | 32.1 | 32.2 | 34.5 | 34.8 | 34.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 37.7 | 36.4 | 35.9 | 35.4 | 35.0 | 34.9 | ||||||||||||

| 50R50B | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 31.2 | 28.8 | 28.6 | 28.8 | 29.1 | 29.9 | 30.7 | ||

| 500 | 0.002 | 3.24 × 107 | 27.6 | 27.5 | 27.6 | 28.0 | 30.3 | 30.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 31.6 | 31.3 | 30.9 | 31.0 | 30.8 | 31.1 | ||||||||||||

| 70R30B | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 30.2 | 27.4 | 27.7 | 28.3 | 28.5 | 28.9 | 29.5 | ||

| 500 | 0.002 | 3.24 × 107 | 26.6 | 26.6 | 26.8 | 27.1 | 29.3 | 29.7 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 30.3 | 30.1 | 30.0 | 30.1 | 30.1 | 30.0 | ||||||||||||

| 30R70B | 110 | 18/6 | 100 | 0.01 | 6.48 × 106 | 275 | 220 | 183 | 157 | 138 | 122 | 32.2 | 31.0 | 30.6 | 30.6 | 30.5 | 30.8 | 31.5 | ||

| 500 | 0.002 | 3.24 × 107 | 29.8 | 29.1 | 29.2 | 29.5 | 31.4 | 31.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 33.8 | 33.1 | 32.6 | 32.2 | 32.2 | 32.3 | ||||||||||||

| 95R5B | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257.1 | 225 | 200 | 11.66 | 11.66 | 36.9 | 36.8 | 36.1 | 36.0 | 35.6 | 35.7 | 36.2 |

| 500 | 0.002 | 3.24 × 107 | 35.4 | 34.4 | 35.8 | 37.1 | 36.9 | 36.9 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 40.1 | 38.7 | 37.8 | 37.6 | 37.0 | 36.8 | ||||||||||||

| 83R17B | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 37.1 | 36.1 | 35.8 | 35.7 | 35.4 | 35.6 | 36.1 | ||

| 500 | 0.002 | 3.24 × 107 | 34.7 | 33.8 | 33.7 | 36.1 | 36.7 | 36.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 39.3 | 38.4 | 37.9 | 37.4 | 37.0 | 36.9 | ||||||||||||

| 60R40B | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 37.8 | 37.6 | 37.1 | 37.0 | 36.6 | 36.8 | 37.2 | ||

| 500 | 0.002 | 3.24 × 107 | 36.1 | 35.2 | 35.2 | 38.0 | 38.1 | 38.1 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 41.1 | 39.5 | 38.8 | 38.6 | 38.3 | 38.0 | ||||||||||||

| 57W43B | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 43.5 | 45.5 | 44.1 | 43.3 | 43.2 | 43.4 | 43.5 | ||

| 500 | 0.002 | 3.24 × 107 | 43.7 | 42.1 | 45.2 | 44.8 | 44.4 | 43.8 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 48.6 | 46.9 | 45.7 | 45.1 | 44.3 | 44.2 | ||||||||||||

| 67R11B22G | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 37.3 | 36.0 | 35.7 | 35.9 | 35.9 | 36.0 | 36.7 | ||

| 500 | 0.002 | 3.24 × 107 | 34.9 | 34.0 | 34.0 | 36.5 | 37.1 | 37.4 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 39.5 | 38.4 | 37.8 | 37.6 | 37.4 | 37.3 | ||||||||||||

| 67R33G | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 36.9 | 37.7 | 36.8 | 36.4 | 35.8 | 35.9 | 36.5 | ||

| 500 | 0.002 | 3.24 × 107 | 36.4 | 35.2 | 34.7 | 37.3 | 37.2 | 37.2 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 41.4 | 39.5 | 38.4 | 37.8 | 37.5 | 37.1 | ||||||||||||

| 100W | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 46.7 | 53.2 | 50.2 | 48.1 | 47.0 | 47.1 | 47.0 | ||

| 500 | 0.002 | 3.24 × 107 | 52.4 | 48.6 | 50.6 | 49.2 | 48.1 | 47.3 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 56.6 | 51.8 | 49.7 | 49.3 | 48.3 | 47.5 | ||||||||||||

| 50R50B | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 38.4 | 39.6 | 38.4 | 38.2 | 37.8 | 37.8 | 38.0 | ||

| 500 | 0.002 | 3.24 × 107 | 38.3 | 36.8 | 36.5 | 39.2 | 39.0 | 38.9 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 43.6 | 41.4 | 40.2 | 39.7 | 39.5 | 38.9 | ||||||||||||

| 70R30B | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 37.1 | 36.3 | 35.8 | 35.7 | 35.5 | 35.8 | 36.4 | ||

| 500 | 0.002 | 3.24 × 107 | 34.7 | 34.0 | 33.9 | 36.5 | 36.9 | 37.1 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 39.4 | 38.3 | 37.8 | 37.5 | 37.1 | 37.0 | ||||||||||||

| 30R70B | 180 | 18/6 | 100 | 0.01 | 6.48 × 106 | 450 | 360 | 300 | 257 | 225 | 200 | 40.6 | 46.5 | 43.6 | 41.8 | 41.2 | 40.9 | 40.7 | ||

| 500 | 0.002 | 3.24 × 107 | 45.4 | 41.9 | 43.3 | 42.8 | 42.1 | 41.4 | ||||||||||||

| 1000 | 0.001 | 6.48 × 107 | 50.3 | 47.0 | 44.6 | 43.1 | 42.3 | 41.7 | ||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olvera-Gonzalez, E.; Escalante-Garcia, N.; Myers, D.; Ampim, P.; Obeng, E.; Alaniz-Lumbreras, D.; Castaño, V. Pulsed LED-Lighting as an Alternative Energy Savings Technique for Vertical Farms and Plant Factories. Energies 2021, 14, 1603. https://doi.org/10.3390/en14061603

Olvera-Gonzalez E, Escalante-Garcia N, Myers D, Ampim P, Obeng E, Alaniz-Lumbreras D, Castaño V. Pulsed LED-Lighting as an Alternative Energy Savings Technique for Vertical Farms and Plant Factories. Energies. 2021; 14(6):1603. https://doi.org/10.3390/en14061603

Chicago/Turabian StyleOlvera-Gonzalez, Ernesto, Nivia Escalante-Garcia, Deland Myers, Peter Ampim, Eric Obeng, Daniel Alaniz-Lumbreras, and Victor Castaño. 2021. "Pulsed LED-Lighting as an Alternative Energy Savings Technique for Vertical Farms and Plant Factories" Energies 14, no. 6: 1603. https://doi.org/10.3390/en14061603