1. Introduction

Wireless power transfer (WPT) charging technology is superior to plug-in charging systems as it can be used in wet environments and is safe from electric shock [

1]. The recent advancements in power electronics technology have led enterprises such as Qualcomm, Evatran and Witricity to commercialize WPT technology into many products used in daily life that can be charged wirelessly with high efficiency. These products have many industrial [

2] as well as daily life applications, such as the wireless charging of smartphones [

3], EVs [

4,

5] and many biomedical implants [

6,

7].

The increasing carbon footprints and the ever-dwindling oil supply have led vehicle manufacturers to look for alternative options. One of the promising and efficient perspectives is the use of hybrid energy storage system (HESS)-based EVs. The commonly used energy storage units (ESUs) are batteries and supercapacitors (SCs) as they combine the high energy density of batteries and high power density of SCs [

8]. To charge these units, a wired connection is provided at the designated charging stations, which not only has reliability and safety issues but also needs a certain duration to link the vehicle with the charging point. In order to solve these issues, a static WPT system is considered to be a viable option that has no safety concerns regarding sparks caused by contact. A static WPT combined with an HESS can ease the charging process in many types of commercially used EVs such as modern trams, electric scooters, automatic guided vehicles (AGVs) and light rail vehicles (LRVs). In urban areas, trams stop at multiple tourist sites where it would not be appropriate to construct a charging station. As the WPT charging system has high concealment, it can be used in these scenic spots to charge the tram [

9]. Similar to other EVs, charging an electric scooter through a plug-in charging system incurs the problems of possibly getting an electric shock, wire twisting and the lack of a unified charging plug. Therefore, implementing the WPT charging system along with HESS in electric scooters has not only solved the safety concerns but also improved the charging process and propulsion rate [

8]. AGVs are revolutionizing the logistics industry by improving automatic processing and mechanical assembly [

10]. However, to continue their operations, AGVs need to frequently recharged, and using a plug-in charging system decreases their utilization rate and increases the overall cost [

11]. Therefore, the use of a WPT to energize these AGVs has solved the automated charging requirements and security concerns [

12]. Apart from the above-mentioned benefits, an HESS has been implemented in LRVs to lower the power level of WPT charging systems [

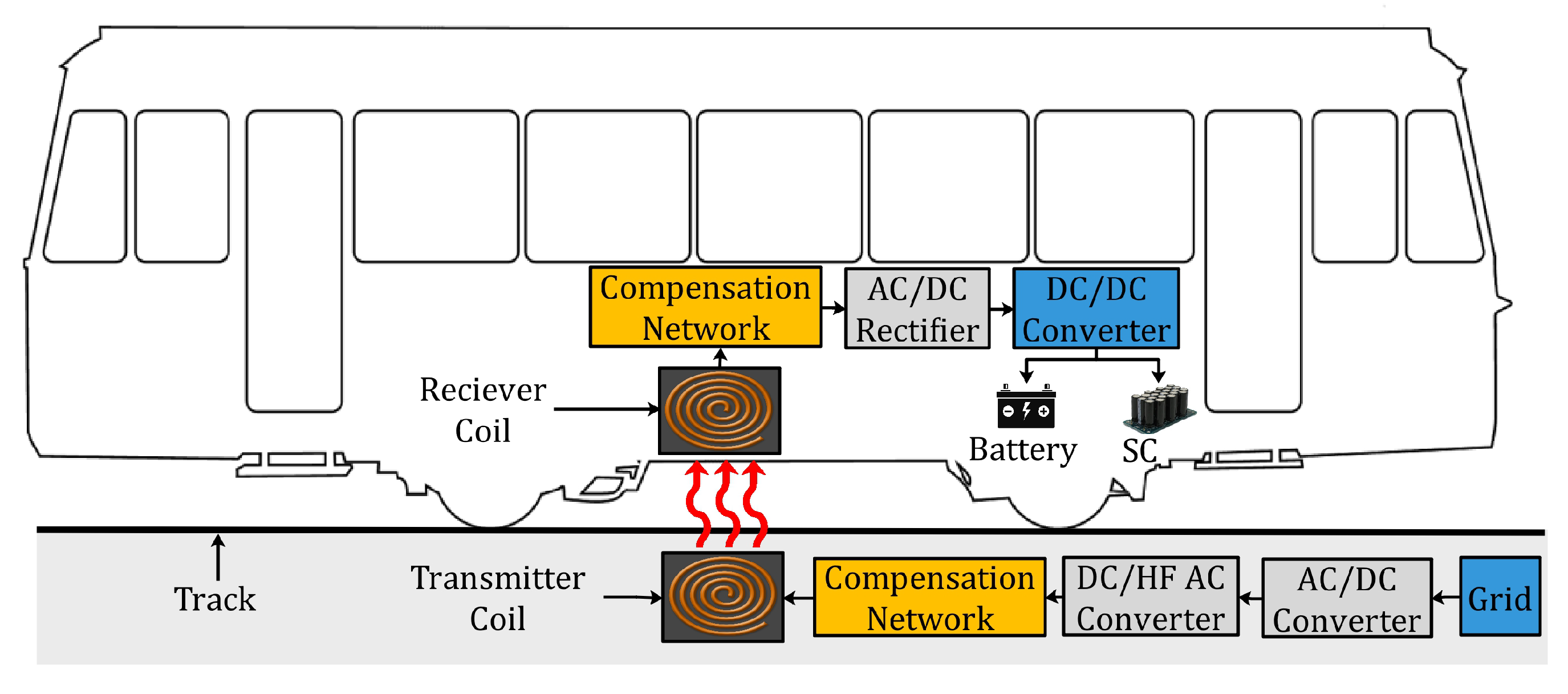

13]. A typical WPT–HESS system implemented in an LRV is shown in

Figure 1.

On the transmitting side, a high frequency (HF) DC/AC inverter converts the DC power into the required HF AC power. The AC/DC rectifier on the receiving side converts the AC voltage back into DC voltage. The compensation networks are implemented on both sides to improve the system efficiency by canceling the leakage inductance and lowering the reactive power transfer [

14,

15]. Finally, the DC–DC converters are interfaced between the rectifier and storage units to control the power flow. Based on this topology, different attempts have been made to integrate an HESS with WPT. In [

8], the author proposed a WPT–HESS system to charge an electric scooter. According to the battery state of charge (SOC), a three-mode strategy is proposed to meet the power demands of the battery and SC. In [

16], an HESS-based WPT system was proposed in which the ESUs—i.e., the battery and SC—were linked to the WPT system by the DC–DC converter, and the implemented WPT system ensured a stable current to these units. The issue with such a configuration is that the power-receiving ability of the SC is wasted. In [

17]; using the same HESS topology, the WPT and HESS system were configured to meet the desired power requirements of the storage devices. However, the article lacks an analysis of the WPT system efficiency, which is a key factor in designing a WPT system.

For the accurate charging of the battery and SC, a stable bus voltage is required. Therefore, the connected WPT system must provide a constant DC bus voltage to the ESUs. To solve this issue, the compensation networks that defines the system transfer characteristics—i.e., a constant current or constant voltage—are utilized [

18]. Based on the inductor–capacitor structure, the compensation networks can be categorized as parallel–series, parallel–parallel, series–parallel and series–series [

18]. The circuit diagrams of these networks are shown in

Figure 2. In parallel–series and parallel–parallel configurations, the source is protected, since there is no power flow from the transmitter coil in the case of the non-availability of the receiver coil. The drawback of these networks is that if the transmitting and receiving coils are misaligned, then high power cannot be transferred [

19]. To solve this problem, the series–parallel network can transfer high power, but its dependence on load variation and high voltage gain make its implementation limited [

20]. The series–series network is widely used because, using this network, the resonant frequency does not vary with coupling-coefficient and load variations. The drawback of this network is that the output current and duty cycle of the connected DC–DC converter are inversely related, making the use of traditional control methods obsolete [

21]. To solve this issue, an LCC-S-based WPT is proposed in [

22] that can maintain a quasi-constant voltage at the output.

Another design element that needs consideration is the system efficiency of WPT and its dependence on the connected load; i.e., the WPT system provides maximum efficiency for a specific load. To operate the WPT system at this maximum efficiency point and control the power flow to the storage devices, DC–DC converters are interfaced between the WPT system and the connected ESUs [

23]. By controlling the DC–DC converter duty cycle, the WPT system equivalent resistance can be altered; i.e., the duty cycle of buck and boost converters can change their input resistance in the range

and

, respectively [

24]. Conventionally, the PID controller is implemented to control the duty cycle [

25,

26]. However, the linear nature of THE PID limits its regulation to a smaller region. A linear model predictive controller (MPC) is designed for a dynamic WPT system in [

27] to control its output voltage. Compared to the PID controller, its response time is faster and it provides better system efficiency. However, the MPC controller needs an accurate dynamic model and an optimization algorithm, which implies high computation cost [

28,

29]. To expand the regulation range of the linear controllers, an SMC is presented in [

30]. Due to its non-linear nature, the SMC not only exhibits faster tracking for different load conditions but also fewer transients. However, the SMC has some of its own shortcomings, such as overshooting and the presence of chattering at the equilibrium point. A high-order SMC based on a super-twisting differentiator is proposed in [

31], enhancing the traditional SMC for a quick transient response. However, the gains of this improved controller should be optimized for various output voltages for a faster response time.

According to the above-mentioned literature, a WPT–HESS system based on the LCC-S compensation topology is presented in this article. The SC and battery are linked to the WPT system by buck and bidirectional buck–boost converters, respectively. To control the converter duty cycles, an integral terminal sliding mode controller (ITSMC) is proposed to overcome the drawbacks of the traditional SMC. Due to LCC-S compensation, the WPT system ensures stable output voltage at the DC bus. Furthermore, to ensure that the WPT system operates at maximum efficiency, the DC–DC converters are controlled to provide optimal power to ESUs. The ITSMC controls the connected bidirectional buck–boost converters to distribute the power flow between the ESUs and ensure that the WPT system provides the injected power at maximum efficiency. In the proposed WPT–HESS system, SC is considered as the main ESU and the battery as an auxiliary ESU. Therefore, the majority of the power is injected into the SC and the remaining power into the battery so that the injected power is equal to the optimal power. During the charging process, the voltage of the SC will rise, due to which its power requirement will increase. When the power requirement increases beyond a threshold, then the power generated from the WPT system will not be optimal; therefore, the battery will be discharged to make sure that the power generated from the WPT system is equal to the optimal power. A detailed energy management system (EMS) is devised to provide the current references for the charging of ESUs, and then the ITSMC is used to track the ESU’s charging currents to the desired references.

The article is structured as follows. The proposed WPT–HESS system and the connected DC–DC converters are modeled in

Section 2. The EMS for the generation of the current references is discussed in

Section 3. The design and closed-loop stability analysis of the proposed controller are discussed in

Section 4.

Section 5 presents the simulation results of the proposed WPT–HESS structure, comparison of the ITSMC with the PID and SMC and the validation of the simulation results by controller hardware in loop (C-HIL) experiments.

Section 6 concludes the article.

4. Designing of Integral Terminal Sliding Mode Controller (ITSMC)

An overall structure of the implemented control strategy is shown in

Figure 9. A centralized ITSMC is proposed in this article, with the main motive of ensuring that the WPT system operates at the optimal power point. To accomplish this task, the ITSMC tracks the SC current

and battery current

to their respective reference currents—i.e.,

and

—which are generated by the proposed EMS. To track

and

to their referenced values, error trajectories are defined for each parameter as follows:

where the errors

and

are used for the regulation of

and

, respectively. Taking the time derivative of Equations (

44) and (

45) and using

and

from Equations (

35) and (

36), we get

To make the error signals equal to zero, the integral terminal sliding mode surfaces

and

are defined as

where

and

are the design parameters of the ITSMC controller, defined as

The integrals of the error signals in the sliding surfaces improve the controller chattering and its dynamic system response for sudden changes in the parameters. Taking the time derivative of these sliding surfaces gives us

Taking the value of

and

from Equations (

46) and (

47) yields

To verify the stability of the proposed controller, a positive definite Lyapunov candidate function

V is defined as follows:

For asymptotic stability, the time derivative of

V—i.e.,

—must be negative semi-definite, derived as

To make the

negative semi-definite, the following condition must be satisfied for

:

where

is the controller gain used to converge the states towards the sliding surface; i.e., the higher its value, the faster the converging speed and vice versa. Meanwhile,

is the signum function used to bind the states to remain on the sliding surface. Both of these controlling parameters are defined as

Substituting the values of

and

from Equation (

57) and into (

56) yield

As (

) > 0, the

is negative semi-definite; therefore, the asymptotic convergence of the designed controller is verified by the Lyapunov stability criteria. Furthermore, the chosen sliding surfaces should also satisfy the existence condition, which is stated as follows:

According to the existence condition presented in Equation (

61), the surfaces can be derived as follows:

For (

,

) > 0 and (

,

) = 1, we get:

For (

,

) < 0 and (

,

) = 0, we get

Satisfying the necessary condition of Equations (

62)–(

65), the control laws

and

are obtained as follows:

where

, and

are the duty cycles of the converters linked to the battery and SC, respectively. The boundary conditions for these control signals are defined as

and

. Furthermore, based on the referenced current value, the control input

is split before feeding into the PWM of the respective switches. Utilizing

and

, the generation of

and

is shown in

Figure 9.

5. Results and Discussion

The performance of the ITSMC was verified by simulating the proposed WPT–HESS system for different

levels in the MATLAB/Simulink platform. The uncontrolled rectifier was interfaced with the battery and SC through the DC–DC converters controlled by the ITSMC. The references for

and

were generated for different

levels from EMS, and then the ITSMC was used to track these currents to their required references; i.e.,

and

. The parameter of the WPT system and the compensation network were designed and are listed in

Table 1. The specifications of the HESS system are listed in

Table 2, and the components of the DC–DC converters and ITSMC are shown in

Table 3. The nomenclature used in this manuscript is listed in Abbreviations.

To validate the proposed controller and power allocation strategy, the charging of SC was initialized with four different voltage levels; i.e., 5, 12, 22, and 35 V. The reference currents for these different levels of were generated by the EMS and then tracked by the proposed ITSMC.

In the first scenario, the charging began with the lowest

level—i.e., 5 V—as shown in

Figure 10a. It can be deduced that the SC was charged to its rated voltage—i.e., 50 V—in the required time of 45 s, satisfying rule 1. According to the power allocation strategy, the ITSMC tracked

to

of 10 A for the whole charging process; i.e., the charging was done with a constant current. Observing the

, it can be seen that initially, when the charging requirement of the SC was lower, the ITSMC charged the battery with the maximum current by tracking

to

of

A. However, the

gradually decreased due to the increment in the charging requirement of the SC. Furthermore, when the charging requirements of SC exceeded the optimal power of the WPT, the bidirectional buck–boost converter operated in boost mode to discharge the battery and, together with WPT, catered for the charging requirements. This discharging phenomenon can be observed at approximately 25 s as the

was negative afterward. The power curves of this charging cycle are shown in

Figure 10b. It can be realized from the mentioned Figure that the SC charging power

increased linearly to its maximum value of 500 W. Furthermore, when the

exceeded the

, the

was negative afterward, showing the discharging of the battery to the SC, realizing rule 2. Observing the WPT power curve

, it can be deduced that until the

reached

, the

was not optimal, but afterwards for the remaining charging process, the

was at its optimal value of 310 W, satisfying rule 3.

In the next scenario, the initial voltage of the SC was increased to 12 V, i.e.,

= 12 V. Utilizing Equation (

41), the turning power was calculated to be 296 W; therefore, according to the power allocation strategy, a two-step charging mode was used; i.e., the initial charging of SC by a constant current and then constant power. This charging phenomenon is shown in

Figure 11a,b. It can be seen that until 17 s, the SC was charged by a constant current of 10 A until its power reached the turning power point; i.e., 296 watts. Afterward, the SC was charged with a constant power of 296 watts. Furthermore, the charging curves of ESUs and the WPT system shown in

Figure 11a,b show that during the whole charging process, the battery charging power ensured that the WPT system generated the optimal power of 310 Watts.

When

was increased to 22 V, using Equation (

41),

was calculated to be 224 W. Following the power allocation strategy, only the constant power mode was utilized to charge the SC. The remaining power from the WPT was used to charge the battery to ensure the optimal power generation from the WPT system.

Figure 12a,b depicts this charging process.

Following the trend, when

was equal to 35 V, the constant power mode was used again. The turning power

for this

was calculated as 175 W. However, in this scenario, the SC was fully charged in less time; i.e., 35 s. This charging process is shown in

Figure 13a,b where it can be seen that the charging was completed quicker than the rated time of 45 s. To summarize all the scenarios, the turning power for each initial voltage is shown in

Table 4.

To verify the performance of the ITSMC,

Figure 14 shows the WPT system efficiency of the above four scenarios. Furthermore, the efficiency of non-HESS was also calculated by charging the SC from 5 to 50 V with a constant current of 10 A. The efficiency of the non-HESS is shown as

. The efficiency in all of these cases was considered from the HF inverter input to the rectifier output. From

Figure 14, it can be deduced that the ITSMC kept the proposed system at maximum efficiency; i.e., approximately 92%. It can also be observed that the efficiency of non-HESS depended upon the SC charging power

; i.e., it increased until

and then decreased afterward.

5.1. Comparison with PID and SMC Techniques

To verify the robustness of the ITSMC and the previously used control techniques—i.e., PID and SMC—against the load variations, the connected load resistance

was abruptly varied with the perturbation frequency of 20 Hz; i.e., after every 0.05 s. Furthermore, fluctuations in the load were set at 40%. According to the mentioned perturbation conditions, the load was initially set at 5

; afterwards, it was incremented to 7

and finally decremented to 5

. The mentioned perturbation scheme can be defined as

Under the aforementioned load variations, the controllers were used to track a constant output current of 5 A. This regulation of the output current by the ITSMC, PID and SMC is shown in

Figure 15. It can be seen that, compared to PID and SMC, the ITSMC tracked the current quicker with better accuracy. Under the perturbation at 0.05 s and 0.1 s, the ITSMC recovered much quicker compared to other controllers. Furthermore, the PID and SMC exhibited overshoots and a large settling time compared to the ITSMC.

To check the performance of the ITSMC, SMC and PID when tracking different current levels, the reference currents were abruptly varied after each 0.05 s. The variation in the reference current level with respect to time is shown below:

The tracking of

for the above-mentioned perturbation in

by ITSMC, SMC and PID is shown in

Figure 16. It can be observed that, during the perturbations at 0.05 s and 0.1 s, compared to PID and SMC, the ITSMC tracked the reference current much quicker with no overshoot. The detailed comparison analysis of ITSMC with PID and SMC is listed in

Table 5, consisting of the rise time, settling time, percentage overshoot and steady state error. It can be observed that the ITSMC outperformed PID and SMC in terms of robustness and less steady-state error, therefore reaching the maximum efficiency point in less time with greater accuracy [

30].

5.2. Controller Hardware in Loop Results

To validate the simulation results, a controller hardware in loop (C-HIL) setup of the proposed WPT–HESS system for cost-effective real-time experiments is shown in

Figure 17. For the C-HIL, MCU F28379D launchpads were utilized, comprised of TMS320F28379D dual core CPUs operating at 200 MHz. The launchpads were connected with a MATLAB embedded coder using Texas Instruments C2000 Delfino support library. The proposed WPT–HESS model which included a DC voltage source, HF inverter, compensation network, transmitting and receiving coils, power converters, a battery and an SC was modeled on MATLAB and translated into MCU F28379D launchpad 1 through the embedded coder. The proposed EMS and ITSMC control laws were implemented on MCU F28379D launchpad 2 with a switching frequency of 100 KHz. The PWM ports of launchpad 2 were linked with the GPIO ports of launchpad 1. Using the built-in analog-to-digital and digital-to-analog converters, a closed-loop system was formed. Utilizing the C-HIL setup, all the simulated scenarios were repeated and compared.

Figure 18a,

Figure 19a,

Figure 20a and

Figure 21a shows the performance analysis of

,

,

and

for different

levels. It can be seen in

Figure 18a that when

was initialized with 5 V, a constant value of 10 A was applied to fully charge the SC. Furthermore. when the

crossed over

, the battery was discharged to cater for the SC’s extra power. The second scenario for

= 12 V is shown in

Figure 19a. In this case, the segmented charging strategy—i.e., an initial constant current and then constant power—was applied. The third scenario shown in

Figure 20a depicts the

= 22 V in which constant power was applied to fully charge the SC. Finally, the last scenario is shown in

Figure 21a, in which the SC was initialized with 35 V. In this case, again constant power was applied; however, the charging process was completed a little earlier. The power curves of the SC, battery and WPT system for all the mentioned scenarios are shown in

Figure 18b,

Figure 19b,

Figure 20b and

Figure 21b. It can be seen that for different levels of

, the WPT system always generated

, thus ensuring operation at the maximum efficiency. Furthermore, it can be observed that, in all these scenario, the C-HIL results were consistent with the simulation results, validating the adequate performance of the ITSMC.