Error Analysis of the Normative Calculation Method of the Exhaust Emissions and Fuel Consumption in the Vehicles Fueled with Gaseous Fuels

Abstract

:1. Introduction

- a.

- for vehicles with a spark ignition engine fueled with petrol (E5):

- b.

- for vehicles with a spark ignition engine fueled with LPG:

- c.

- for vehicles with a spark ignition engine fueled with natural gas (CNG) or biomethane (CBG):

- factor “a” in the Equation (4);

- total hydrocarbon density ρTHC in the Equation (1);

- fuel density used in formulas to calculate the fuel consumption in Equations (6)–(8);

- factor in Equations (6)–(8) depends on the structure of the fuel molecule in the case of hydrocarbon emissions.

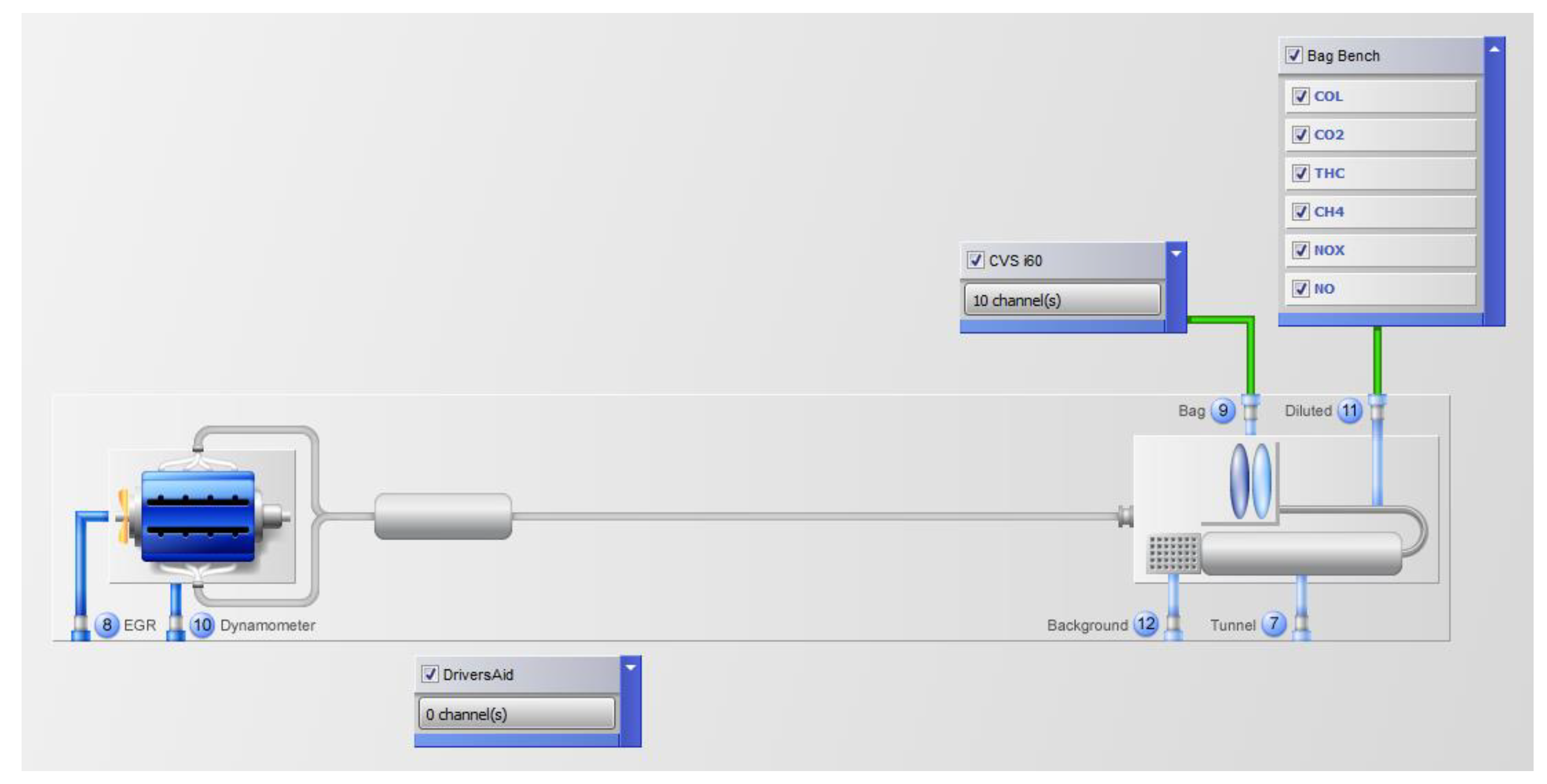

2. Methodology

- type RPL 1220/12 C 221 113/GPM 200 one roller chassis dynamometer with adjustable resistance curve by AVL-Zoellner,

- exhaust sampling and emissions analysis system by AVL consisting of:

- type CVS i60 LD S2 full-flow CFV-CVS exhaust gas sampling system by AVL with critical flow Venturis allowing for flow rates from 2 to 30 m3/min,

- set of AMA i60 D1-CD LE analyzers by AVL equipped with two-range analyzers for analyzing the diluted exhaust, consisting of:

- type AVL IRD i60 CO2 L/CO SL two-channel analyzer by ABB operating on the principle of infrared absorption (NDIR), measuring the low CO2 concentration and very low CO concentration in the dry exhaust gases;

- type AVL CLD i60 LHD two-channel, heated analyzer by AVL operating on the principle of chemiluminescence, equipped with two detectors enabling the simultaneous measurement of low NOx and NO concentrations;

- type CUTTER FID i60 CLD two-channel analyzer by AVL operating on the principle of flame ionization detection (FID), equipped with two detectors enabling the simultaneous measurement of low total hydrocarbons (THC) and CH4 concentrations;

- a set of calibration gases with accuracy of 1%, used for calibration of the analyzers,

- VAISALA PTU303 weather station for measuring air temperature, pressure, and humidity in a chassis dynamometer room,

- iGEM Vehicle measurement automation system produced by AVL, which was responsible for controlling the operation of measuring devices, analyzing exhaust gas samples and recording selected parameters in the database.

- -

- for gasoline (E5): C1H1.89O0.016 and ρTHC = 0.631 g/dm3;

- -

- for LPG: C1H2.522 and ρTHC = 0.649 g/dm3.

3. Results

3.1. Exhaust Emissions

3.2. Fuel Consumption

4. Discussion

- Hydrocarbon density in Equation (1)—only for emissions of total THC;

- Factor “a” in Equation (2).

- fuel density in Formulas (6)–(8);

- THC emissions factor, which depends on the structure of the fuel molecule.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | concentration of carbon dioxide in undiluted, wet exhaust gas, determined with the assumption that the combustion is complete and perfect and the fuel-air mixture has a stoichiometric composition (% vol.); |

| CCO | measured concentration of carbon monoxide in the diluted exhaust gas (ppm); |

| CCO2 | measured concentration of carbon dioxide in the diluted exhaust gas (% vol.); |

| concentration of pollutant in the diluted exhaust gas corrected according to its content in the dilution air (ppm); | |

| CCVS | concentration of pollutant in the diluted exhaust gas; |

| Cdil | concentration of pollutant in the dilution air, |

| CNG | compressed natural gas; |

| CTHC | measured concentration of total hydrocarbons in the diluted exhaust gas (ppm); |

| d | distance traveled during the test (km); |

| DF | dilution factor; |

| ECO | measured emission of carbon monoxide (g/km); |

| ECO2 | measured emission of carbon dioxide (g/km); |

| Ecorrected | corrected emission, taking into account the gasoline supplying phase in the calculations; |

| ECU | electronic control unit; |

| EHC | measured emission of hydrocarbons (g/km); |

| Enormative | emissions calculated in accordance with Regulation 83 and European regulation 2017/1151, i.e., without taking into account that part of the emissions results from gasoline consumption; |

| FC | fuel consumption in dm3 per 100 km (in the case of gasoline, LPG, diesel or biodiesel) or in m3 per 100 km (in the case of natural gas); |

| H/C | hydrogen to carbon ratio for specific fuel CxHyOz; |

| kh | correction factor depending on air humidity (only for nitrogen oxides NOx); |

| LPG | liquefied petroleum gas; |

| m | mass of the pollutant’s emission (g/km); |

| MWC | molar mass of carbon (12,011 g/mol); |

| MW | molar mass of hydrogen (1008 g/mol); |

| MWO | molar mass of oxygen (15,999 g/mol); |

| NOx | nitrogen oxides that are most relevant for air pollution (NO and NO2); |

| O/C | oxygen to carbon ratio for specific fuel CxHyOz; |

| THC | total hydrocarbons; |

| VCVS | volume of diluted exhaust gas, corrected for reference conditions (dm3); |

| VM | molar volume of an ideal gas at 273.15 K and 1013.25 hPa (22,413 dm3/mol); |

| WLTC | world harmonized light-duty test cycle; |

| ρCNG/CBG | CNG/biomethane density. |

| ρgasoline | gasoline density; |

| ρ | density of pollutant under the reference conditions (g/dm3); |

| ρLPG | LPG density; |

| ρTHC | the density of total hydrocarbons including non-methane hydrocarbons (g/dm3); |

Appendix A

| Pollutant | Normative [g/km] | Corrected | |||

|---|---|---|---|---|---|

| Lowgas [g] | LowLPG [g] | Total [g] | EmissionLow [g/km] | ||

| CO2 | 175.7 | 96.2 | 502.2 | 598.4 | 188.7 |

| CO | 1.271 | 3.790 | 0.530 | 4.320 | 1.362 |

| NOx | 0.247 | 0.404 | 0.443 | 0.847 | 0.267 |

| NO | 0.153 | 0.266 | 0.281 | 0.547 | 0.172 |

| THC | 0.323 | 0.977 | 0.130 | 1.107 | 0.349 |

| CH4 | 0.021 | 0.038 | 0.036 | 0.074 | 0.023 |

| Pollutant | Normative [g/km] | Corrected | |||

|---|---|---|---|---|---|

| Lowgas [g] | LowLPG [g] | Total [g] | EmissionLow [g/km] | ||

| CO2 | 177.9 | 102.7 | 495.3 | 598.0 | 190.7 |

| CO | 1.348 | 3.822 | 0.716 | 4.538 | 1.447 |

| NOx | 0.242 | 0.349 | 0.466 | 0.815 | 0.260 |

| NO | 0.149 | 0.299 | 0.290 | 0.589 | 0.188 |

| THC | 0.291 | 0.874 | 0.111 | 0.985 | 0.314 |

| CH4 | 0.021 | 0.038 | 0.043 | 0.081 | 0.026 |

| Pollutant | Normative [g/km] | Corrected | |||

|---|---|---|---|---|---|

| Lowgas [g] | LowLPG [g] | Total [g] | EmissionLow [g/km] | ||

| CO2 | 176.2 | 100.8 | 487.2 | 588.0 | 189.1 |

| CO | 2.113 | 4.278 | 2.761 | 7.039 | 2.264 |

| NOx | 0.145 | 0.373 | 0.114 | 0.487 | 0.157 |

| NO | 0.091 | 0.247 | 0.072 | 0.319 | 0.103 |

| THC | 0.320 | 0.947 | 0.119 | 1.066 | 0.343 |

| CH4 | 0.024 | 0.038 | 0.042 | 0.080 | 0.026 |

| Pollutant | Normative [g/km] | Corrected | |||

|---|---|---|---|---|---|

| Lowgas [g] | LowLPG [g] | Total [g] | EmissionLow [g/km] | ||

| CO2 | 185.0 | 140.5 | 468.1 | 608.6 | 197.9 |

| CO | 1.884 | 5.741 | 0.455 | 6.196 | 2.014 |

| NOx | 0.157 | 0.361 | 0.158 | 0.519 | 0.169 |

| NO | 0.098 | 0.235 | 0.084 | 0.319 | 0.104 |

| THC | 0.350 | 1.074 | 0.078 | 1.152 | 0.375 |

| CH4 | 0.022 | 0.046 | 0.019 | 0.065 | 0.021 |

| Pollutant | Normative [g/km] | Corrected | |||

|---|---|---|---|---|---|

| Lowgas [g] | LowLPG [g] | Total [g] | EmissionLow [g/km] | ||

| CO2 | 180.3 | 110.5 | 483.5 | 594.0 | 192.7 |

| CO | 1.959 | 5.836 | 0.614 | 6.450 | 2.093 |

| NOx | 0.542 | 0.251 | 1.541 | 1.792 | 0.581 |

| NO | 0.307 | 0.167 | 0.962 | 1.129 | 0.366 |

| THC | 0.281 | 0.761 | 0.144 | 0.905 | 0.294 |

| CH4 | 0.027 | 0.041 | 0.033 | 0.074 | 0.024 |

References

- Regulation No. 83 ONZ “Uniform Provisions Concerning the Approval of Vehicles with Regard to the Emission of Pollutants According to Engine Fuel Requirements", Revision 5, 07 Series of Amendments to the Regulation—Date of entry into force: 22 January 2015. 2: E/ECE/324/Rev.1/Add.82/Rev.5-E/ECE/TRANS/505/Rev.1/Add.82/Rev.5; United Nations: New York, NY, USA, 2015.

- Regulation No. 101 ONZ “Uniform Provisions Concerning the Approval of Passenger Cars Powered by an Internal Combustion Engine Only, or Powered by a Hybrid Electric Power Train with Regard to the Measurement of the Emission of Carbon Dioxide and Fuel Consumption and/or the Measurement of Electric Energy Consumption and Electric Range, and of Categories M1 and N1 Vehicles Powered by an Electric Power Train only with Regard to the Measurement of Electric Energy Consumption and Electric Range”, Revision 3, Supplement 1 to the 01 Series of Amendments to the Regulation—Date of Entry Into Force: 27 January 2013: E/ECE/324/Rev.2/Add.100/Rev.3-E/ECE/TRANS/505/Rev.2/Add.100/Rev.3.; Geneva, Switzerland. 2013. Available online: https://unece.org/transport/vehicle-regulations-wp29/standards/addenda-1958-agreement-regulations-101-120 (accessed on 9 February 2021).

- Commission Regulation (EU) 2017/1151 of 1 June 2017 Supplementing Regulation (EC) No. 715/2007 of the European Parliament and of the Council on Type-approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No. 1230/2012 and Repealing Commission Regulation (EC) No. 692/2008 (Text with EEA relevance) (OJ L 175, 7.7.2017, p. 1); The European Parliament: Brussels, Belgium, 2017.

- Regulation No. 115 ONZ “Uniform Provisions Concerning the Approval of: I. Specific LPG (Liquefied Petroleum Gases) Retrofit Systems to be Installed in Motor Vehicles for the Use of LPG in Their Propulsion System, II. Specific CNG (Compressed Natural Gas) Retrofit Systems to be Installed in Motor Vehicles for the Use of CNG in Their Propulsion System”, Revision 1, Supplement 5 to the Original Version of the Regulation—Date of Entry into Force: 15 July 2013: E/ECE/324/Rev.2/Add.114/Rev.1-E/ECE/TRANS/505/Rev.2/Add.114/Rev.1; Economic Commission for Europe of the United Nations: Geneva, Switzerland, 2013.

- Majerczyk, A.; Taubert, S. Układy Zasilania Gazem Propan-Butan, 1st ed.; Wydawnictwa Komunikacji i Łączności: Warszawa, Poland, 2004; ISBN 8320615259. [Google Scholar]

- Merkisz, J.; Bielaczyc, P.; Pielecha, J.; Woodburn, J. RDE Testing of Passenger Cars: The Effect of the Cold Start on the Emissions Results; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Satlawa, M.; Pajdowski, P.; Pietras, D. The Impact of the Driver’s Driving Style on the Exhaust Emissions of a Passenger Car during a Real Road Cycle; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Menes, M.; Wiśniowski, P. The Profitability of Disposing of Vehicles Fulfilling the Older Euro Standards in Terms of CO2 Emission. J. KONES 2019, 26, 89–94. [Google Scholar] [CrossRef] [Green Version]

- Jaworski, A.; Mądziel, M.; Kuszewski, H.; Lejda, K.; Balawender, K.; Jaremcio, M.; Jakubowski, M.; Wojewoda, P.; Lew, K.; Ustrzycki, A. Analysis of Cold Start Emission from Light Duty Vehicles Fuelled with Gasoline and LPG for Selected Ambient Temperatures; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Szczotka, A.; Puchałka, B.; Bielaczyc, P.; Adamiak, B. Influence of the chassis dynamometer regulation on the exhaust emission results. AUTOBUSY Tech. Eksploat. Syst. Transp. 2019, 24. [Google Scholar] [CrossRef]

- Merkisz, J.; Pielecha, J.; Radzimirski, S. New Trends in Emission Control in the European Union; Springer Science and Business Media LLC: Berlin, Germany, 2014. [Google Scholar]

- Behrendt, H.; Moersch, O.; Seiferth, C.T.; Seifert, G.E.; Wiebrecht, J.W. Studies on Enhanced CVS Technology to Achieve SULEV Certification; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

- Szczotka, A.; Puchałka, B.; Bielaczyc, P.; Adamiak, B. Influence of the dilution factor on the uncertainty of the exhaust gas emission results obtained during testing on the chassis dynamometer. AUTOBUSY Tech. Eksploat. Syst. Transp. 2018, 737–742. [Google Scholar] [CrossRef]

- Sherman, M.T.; Lennon, K.; Chase, R.E. Error Analysis of Various Sampling Systems; SAE Technical Paper: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Ohtsuki, S.; Inoue, K.; Yamagishi, Y.; Namiyama, K. Studies on Emission Measurement Techniques for Super-Ultra Low Emissions Vehicles; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

- Silvis, W.M.; Chase, R.E. Proportional Ambient Sampling: A CVS Improvement for ULEV and Lean Engine Operation; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Tayama, A.; Kanetoshi, K.; Tsuchida, H.; Morita, H. A Study of a Gasoline-Fueled Near-Zero-Emission Vehicle Using an Improved Emission Measurement System; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Hawley, J.; Brace, C.; Cox, A.; Ketcher, D.; Stark, R. Influence of Time-Alignment on the Calculation of Mass Emissions on a Chassis Rolls Dynamometer; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Hawley, J.G.; Bannister, C.D.; Brace, C.J.; Cox, A.; Ketcher, D.; Stark, R. Vehicle modal emissions measurement—techniques and issues. Proceedings of the Institution of Mechanical Engineers, Part D. J. Automob. Eng. 2004, 218, 859–873. [Google Scholar] [CrossRef]

- Wiers, W.W.; Scheffler, C.E. Carbon Dioxide (CO2) Tracer Technique for Modal Mass Exhaust Emission Measurement. SAE Trans. 1972, 81, 441–455. [Google Scholar] [CrossRef]

- Silvis, W.; Williamson, J.; Kreft, N.; Alajbegovic, A. DVE—Direct Vehicle Exhaust Flow Measurement Using Head-Type Flowmeters. SAE Trans. 2003, 112, 461–473, JSTOR. [Google Scholar]

- Austin, T.C.; Caretto, L.S. Improving the Calculation of Exhaust Gas Dilution During Constant Volume Sampling; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Fu, J.G.; Wang, W.G.; Lyons, D.W. Development of Continuous Dilution Factor for CVS Emissions Sampling and Calculation; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Szczotka, A.; Bielaczyc, P.; Woodburn, J. Źródła błędów przy pomiarach emisji związków szkodliwych spalin na hamowni podwoziowej—Analiza bilansu masy (Error sources during exhaust emission measurements on chassis dynamometer—mass balance analysis). AUTOBUSY Tech. Eksploat. Syst. Transp. 2017, 529–534. [Google Scholar] [CrossRef]

- Inoue, K.; Ishihara, M.; Akashi, K.; Adachi, M.; Ishida, K. Numerical Analysis of Mass Emission Measurement Systems for Low Emission Vehicles; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Silvis, W.; Harvey, R.; Dageforde, A. A CFV Type Mini-Dilution Sampling System for Vehicle Exhaust Emissions Measurement; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Silvis, W.; Lewis, G. The Control of TP Pressure in Emissions Sampling Systems; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Guenther, M.; Henney, T.; Silvis, W.; Nakatani, S.; Wu, D.Y.; Wu, D.Y. Improved Bag Mini-Diluter Sampling System for Ultra-Low Level Vehicle Exhaust Emissions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Nagy, D.B.; Loo, J.; Tulpa, J.; Schroeder, P.; Middleton, R.; Morgan, C. Evaluation of the Bag Mini-Diluter and Direct Vehicle Exhaust Volume System for Low Level Emissions Measurement; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- McLeod, J.; Nagy, D.; Schroeder, P.; Thiel, S.; Dearth, M.A.; Colvin, A.D.; Webb, T.; Carduner, K.R.; Schuetzle, D.; Middleton, R.; et al. A Sampling System for the Measurement of PreCatalyst Emissions from Vehicles Operating Under Transient Conditions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1993. [Google Scholar] [CrossRef]

- Park, G.; Mun, S.; Hong, H.; Chung, T.; Jung, S.; Kim, S.; Seo, S.; Kim, J.; Lee, J.; Kim, K.; et al. Characterization of Emission Factors Concerning Gasoline, LPG, and Diesel Vehicles via Transient Chassis-Dynamometer Tests. Appl. Sci. 2019, 9, 1573. [Google Scholar] [CrossRef] [Green Version]

- Majerczyk, A.; Radzimirski, S. Analysis of measurement errors of CVS method used for tests of pollutant emissions from light-duty vehicles. J. KONES Powertrain Transp. 2015, 20. [Google Scholar] [CrossRef]

- Regulation (EU) 2019/631 of the Europan Parliament and of the Council of 17 April 2019 Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/2011 (Text with EEA Relevance); European Parliament: Brussels, Belgium, 2019.

| Hydrocarbons | Density [g/m3] |

|---|---|

| Gasoline E5 (C1H1.89O0.016) | 0.631 |

| Gasoline E10 (C1H1.93O0.033) | 0.646 |

| Diesel B5 (C1H1.86O0.005) | 0.622 |

| Diesel B7 (C1H1.86O0.007) | 0.625 |

| LPG (C1H2.525) | 0.649 |

| CNG / Biomethane (CH4) | 0.716 |

| Ethanol E85 (C1H2.74O0.385) | 0.934 |

| Fuel | Factor “a” |

|---|---|

| Gasoline E5 | 13.4 |

| Gasoline E10 | 13.4 |

| Diesel B5 | 13.5 |

| Diesel B7 | 13.5 |

| LPG | 11.9 |

| CNG/Biomethane | 9.5 |

| Ethanol E85 | 12.5 |

| Fuel | Density |

|---|---|

| Gasoline E5 (C1H1.89O0.016) | 0.743–0.756 |

| LPG (C1H2.525) | 0.538 |

| CNG / Biomethane (CH4) | 0.654 |

| Parameter | Value/Description |

|---|---|

| Engine | Four stroke spark ignition engine |

| Engine capacity | 1598 cm3 |

| Maximum engine power | 81 kW at 6000 min−1 |

| Fuel system | Bi-fuel; gasoline or LPG |

| Gasoline injection system | Multipoint indirect gasoline injection |

| LPG injection system | Multipoint indirect sequential injection in the gas phase |

| After-treatment system | Three-way catalytic converter |

| Measured Parameter | Measuring Equipment | Accuracy |

|---|---|---|

| Flow | Exhaust dilution system | ±0.5% |

| Speed | Chassis dynamometer | ±0.025% |

| Distance | Chassis dynamometer | ±0.1% |

| Concentration | Analyzers | ±2% |

| Tgas [s] | Distance [km] |

|---|---|

| 68 | 3.172 |

| 73 | 3.136 |

| 73 | 3.109 |

| 91 | 3.076 |

| 72 | 3.082 |

| Pollutant | Normative [g/km] | Corrected | |||

|---|---|---|---|---|---|

| Lowgas [g] | LowLPG [g] | Total [g] | EmissionLow [g/km] | ||

| CO2 | 175.7 | 96.2 | 502.2 | 598.4 | 188.7 |

| CO | 1.271 | 3.790 | 0.530 | 4.320 | 1.362 |

| NOx | 0.247 | 0.404 | 0.443 | 0.847 | 0.267 |

| NO | 0.153 | 0.266 | 0.281 | 0.547 | 0.172 |

| THC | 0.323 | 0.977 | 0.130 | 1.107 | 0.349 |

| CH4 | 0.021 | 0.038 | 0.036 | 0.074 | 0.023 |

| Pollutant | ∆E1 | ∆E2 | ∆E3 | ∆E4 | ∆E5 | ∆Eaverage |

|---|---|---|---|---|---|---|

| CO2 | −6.9% | −6.7% | −6.9% | −6.5% | −6.5% | −6.7% |

| CO | −6.7% | −6.8% | −6.7% | −6.5% | −6.4% | −6.6% |

| NOx | −7.5% | −6.9% | −7.4% | −6.9% | −6.8% | −7.1% |

| NO | −11.3% | −20.7% | −11.3% | −5.5% | −16.2% | −13.0% |

| THC | −7.4% | −7.4% | −6.7% | −6.5% | −4.3% | −6.5% |

| CH4 | −10.0% | −18.7% | −6.7% | 4.1% | 12.5% | −3.8% |

| Lp. | Normative | Corrected | ΔFCLPG | |

|---|---|---|---|---|

| Gasoline | LPG | |||

| 1 | 10.99 | 11.85 | 11.49 | 4.5% |

| 2 | 11.13 | 11.71 | 11.61 | 4.3% |

| 3 | 11.10 | 12.16 | 11.53 | 3.9% |

| 4 | 11.63 | 11.74 | 11.89 | 2.2% |

| 5 | 11.33 | 13.61 | 11.46 | 1.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzelak, P.; Taubert, S. Error Analysis of the Normative Calculation Method of the Exhaust Emissions and Fuel Consumption in the Vehicles Fueled with Gaseous Fuels. Energies 2021, 14, 1916. https://doi.org/10.3390/en14071916

Grzelak P, Taubert S. Error Analysis of the Normative Calculation Method of the Exhaust Emissions and Fuel Consumption in the Vehicles Fueled with Gaseous Fuels. Energies. 2021; 14(7):1916. https://doi.org/10.3390/en14071916

Chicago/Turabian StyleGrzelak, Paulina, and Sławomir Taubert. 2021. "Error Analysis of the Normative Calculation Method of the Exhaust Emissions and Fuel Consumption in the Vehicles Fueled with Gaseous Fuels" Energies 14, no. 7: 1916. https://doi.org/10.3390/en14071916

APA StyleGrzelak, P., & Taubert, S. (2021). Error Analysis of the Normative Calculation Method of the Exhaust Emissions and Fuel Consumption in the Vehicles Fueled with Gaseous Fuels. Energies, 14(7), 1916. https://doi.org/10.3390/en14071916