A New Lumped Approach for the Simulation of the Magnetron Injection Gun for MegaWatt-Class EU Gyrotrons

Abstract

:1. Introduction

2. The MIG of the 1MW European Gyrotron for ITER

2.1. Geometry and Materials

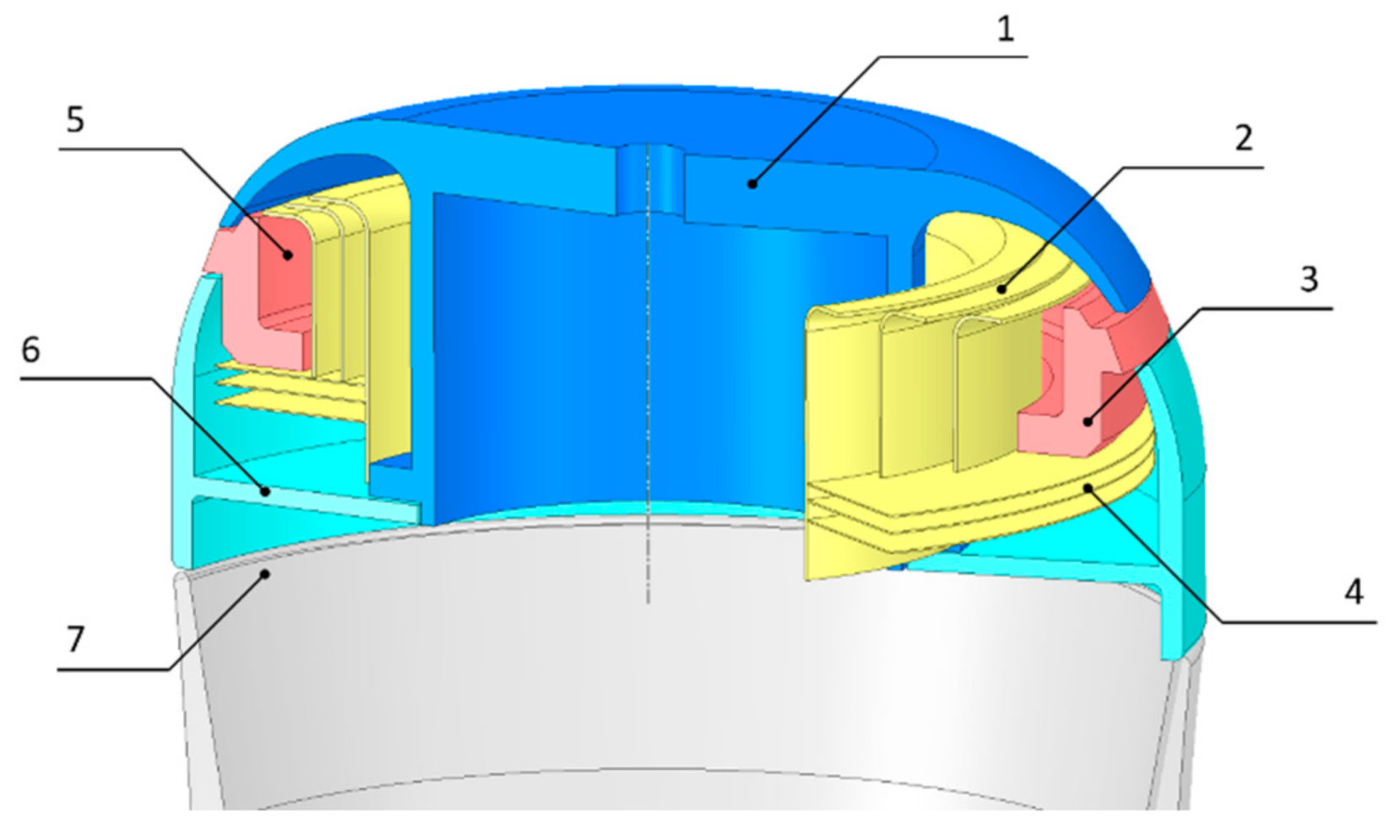

- The main component responsible for the electron emission is the emitter ring, which, in Figure 3, is labeled as element #3. The beam current generation occurs on its external surface, due to the thermionic effect. Here, due to their thermal agitation, electrons are able to overcome the material-vacuum potential barrier and leave the surface. To promote this phenomenon, the material of which the emitter ring is composed must be characterized by a low metal-vacuum work function. For this reason, this component is built using a sintered tungsten substrate which is impregnated with barium-calcium aluminate.

- To direct all the heat injected into the system towards the emitter ring, a set of thermal shields are mounted around the heating element, contained in the cavity formed by the emitter ring and the shields, labeled as #5 in Figure 3. The thermal shields themselves, labeled as #2 and #4, respectively, are made of polished and highly reflective material. This is due to the fact that the main mechanism of heat transfer between components is radiative heat transfer, since the cavity of the gyrotron is evacuated.

- Parts #1 (the nose cone) and #6 (the prolongator) in Figure 3 are used as a support for the emitter ring and for the thermal shields. Their shape and alignment are crucial for obtaining high efficiency in the RF power production, since they modify the electric field configuration inside the MIG. The electric field, together with the magnetic field, determine the direction of the electrons towards the resonant cavity and the shaping of the beam.

2.2. Working Conditions

- A potential of −50 kV is applied to the MIG’s cathode, which, in Figure 5, is la-beled as #3.

- A potential of +30 kV is applied to the MIG’s anode, which is labeled as #2.

- On the flat top and bottom surfaces, labeled as #1 and #4, no boundary conditions are specified.

3. A Lumped Model for the MIG’s Cathode Thermal Behavior and Current Emission

3.1. Justification for a Lumped-Parameter Model

3.2. Implementation of the Lumped Model

- Thermal diffusion through the emitter, modeled for two generic adjacent zones i and j, using geometrical thermal resistances, according to Equation (4):if the two masses are adjacent along the radial direction, and:if they are adjacent in the vertical direction. Here, is the contact area between two adjacent regions, and is the distance between their barycenter.

- Radiative heat transfer to the surroundings, modeled for the generic mass i according to the following equation:where is the area of the exposed area of zone i, is the Stefan–Boltzmann constant and K is a constant parameter calculated numerically, to keep into account the geometry of the surroundings.

- Electron emission and subsequent cooling effect modeled through the Richardson–Dushman equation, which applies only to the zone M4 and isdefined according to Equation (3).

4. Validation of the Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wesson, J.; Campbell, D.J. Tokamaks; Oxford University Press: Oxford, UK, 2011; Volume 149. [Google Scholar]

- Organization, ITER Organization Website. Available online: https://www.iter.org/ (accessed on 5 October 2020).

- Barabaschi, P.; Kamada, Y.; Shirai, H. Progress of the JT-60SA project. Nucl. Fusion 2019, 59, 112005. [Google Scholar] [CrossRef]

- Wakatani, M. Stellarator and Heliotron Devices; Oxford University Press on Demand: Oxford, UK, 1998; Volume 95. [Google Scholar]

- Wolf, R.C.; Alonso, A.; Äkäslompolo, S.; Baldzuhn, J.; Beurskens, M.; Beidler, C.D.; Biedermann, C.; Bosch, H.-S.; Bozhenkov, S.; Brakel, R.; et al. Performance of Wendelstein 7-X stellarator plasmas during the first divertor operation phase. Phys. Plasmas 2019, 26, 082504. [Google Scholar] [CrossRef] [Green Version]

- Thumm, M.K.A.; Denisov, G.G.; Sakamoto, K.; Tran, M.Q. High-power gyrotrons for electron cyclotron heating and current drive. Nucl. Fusion 2019, 59, 073001. [Google Scholar] [CrossRef]

- Ioannidis, Z.C.; Albajar, F.; Alberti, S.; Avramidis, K.A.; Bin, W.; Bonicelli, T.; Bruschi, A.; Chelis, J.; Fanale, F.; Gantenbein, G.; et al. Recent experiments with the European 1MW, 170GHz industrial CW and short-pulse gyrotrons for ITER. Fusion Eng. Des. 2019, 146, 349–352. [Google Scholar] [CrossRef] [Green Version]

- Hogge, J.-P.; Albajar, F.; Alberti, S.; Avramidis, K.; Bin, W.; Bonicelli, T.; Braunmueller, F.; Bruschi, A.; Chelis, J.; Frigot, P.-E.; et al. Status and Experimental Results of the European 1 MW, 170 GHz Industrial CW Prototype Gyrotron for ITER. In Proceedings of the 2016 41st International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz), Copenhagen, Denmark, 25–30 September 2016. [Google Scholar]

- Jelonnek, J.; Aiello, G.; Albaiar, F.; Alberti, S.; Avramidis, K.A.; Bertinetti, A.; Brucker, P.T.; Bruschi, A.; Chclis, I.; Dubray, J.; et al. From W7-X Towards ITER and Beyond: 2019 Status on EU Fusion Gyrotron Developments. In Proceedings of the 2019 International Vacuum Electronics Conference (IVEC), Busan, Korea, 28 April–1 May 2019. [Google Scholar]

- Sakamoto, K.; Kajiwara, K.; Takahashi, K.; Oda, Y.; Kasugai, A.; Kobayashi, T.; Kobayashi, N.; Henderson, M.; Darbos, C. Development of High Power Gyrotron for ITER Application. In Proceedings of the 35th International Conference on Infrared, Millimeter, and Terahertz Waves, Rome, Italy, 5–10 September 2010. [Google Scholar]

- Kasugai, A.; Minami, R.; Takahashi, K.; Kobayashi, N.; Sakamoto, K. Long pulse operation of 170GHz ITER gyrotron by beam current control. Fusion Eng. Des. 2006, 81, 2791–2796. [Google Scholar] [CrossRef]

- Rozier, Y.; Albajar, F.; Alberti, S.; Avramidis, K.A.; Bonicelli, T.; Cismondi, F.; Frigot, P.-E.; Gantenbein, G.; Hermann, V.; Hogge, J.-P.; et al. Manufacturing and Tests of the European 1 MW, 170 GHz CW Gyrotron Prototype for ITER. In Proceedings of the 2016 IEEE International Vacuum Electronics Conference (IVEC), Monterey, CA, USA, 19–21 April 2016. [Google Scholar]

- Idehara, T.; Kuleshov, A.; Ueda, K.; Khutoryan, E. Power-stabilization of high frequency gyrotrons using a double PID feedback control for applications to high power THz spectroscopy. J. InfraredMillim. Terahertz Waves 2014, 35, 159–168. [Google Scholar] [CrossRef]

- Khutoryan, E.; Idehara, T.; Kuleshov, A.; Ueda, K. Gyrotron output power stabilization by PID feedback control of heater current and anode voltage. In Proceedings of the 2014 39th International Conference on Infrared, Millimeter, and Terahertz waves (IRMMW-THz), Tucson, AZ, USA, 14–19 September 2014. [Google Scholar]

- Bakunin, V.L.; Denisov, G.G.; Novozhilova, Y.V. Frequency and phase stabilization of a multimode gyrotron with megawatt power by an external signal. Tech. Phys. Lett. 2014, 40, 382–385. [Google Scholar] [CrossRef]

- Ogawa, I.; Idehara, T.; Ui, M.; Mitsudo, S.; Förster, W. Stabilization and modulation of the output power of submillimeter wave gyrotron. Fusion Eng. Des. 2001, 53, 571–576. [Google Scholar] [CrossRef]

- Langmuir; Blodgett, K.B. Currents Limited by Space Charge between Coaxial Cylinders. Phys. Rev. 1923, 22, 347–356. [Google Scholar] [CrossRef]

- Dushman, S. Thermionic Emission. Rev. Mod. Phys. 1930, 2, 381–476. [Google Scholar] [CrossRef]

- Cronin, J.L. Modern Dispenser Cathodes. IEEE Proc. 1981, 128, 19–32. [Google Scholar] [CrossRef]

- Petrin, B. Thermionic field emission of electrons from metals and explosive electron emission from micropoints. J. Exp. Theor. Phys. 2009, 109, 314–321. [Google Scholar] [CrossRef]

- Charbonnier, F.M.; Strayer, R.W.; Swanson, L.W.; Martin, E.E. Nottingham Effect in Field and T—F Emission: Heating and Cooling Domains, and Inversion Temperature. Phys. Rev. Lett. 1964, 13, 397–401. [Google Scholar] [CrossRef]

- OpenCFD Ltd. OpenFOAM®-Official Home of The Open Source Computational Fluid Dynamics (CFD) Toolbox. 2019. Available online: https://openfoam.com/ (accessed on 20 October 2020).

- Siegel, R.; Howell, J.R.; Menguc, M.P. Thermal Radiation Heat Transfer, 5th ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- OpenCFD Ltd. OpenFOAM API Guide: FvDOM Class Reference. 2019. Available online: https://www.openfoam.com/documentation/guides/latest/api/classFoam_1_1radiation_1_1fvDOM.html (accessed on 20 October 2020).

- OpenCFD Ltd. OpenFOAM: Manual Pages: CheckMesh. OpenCFD Ltd. Available online: https://www.openfoam.com/documentation/guides/latest/man/checkMesh.html (accessed on 11 November 2020).

- Ioannidis, Z.C.; Rzesnicki, T.; Albajar, F.; Alberti, S.; Avramidis, K.A.; Bin, W.; Bonicelli, T.; Bruschi, A.; Chelis, I.; Frigot, P.-E.; et al. CW experiments with the EU 1-MW, 170-GHz industrial prototype gyrotron for ITER at KIT. IEEE Trans. Electron. Devices 2017, 64, 3885–3892. [Google Scholar] [CrossRef]

- Bonicelli, T.; Alberti, S.; Cirant, S.; Dormicchi, O.; Fasel, D.; Hogge, J.P.; Illy, S.; Jin, J.; Lievin, C.; Mondino, P.L.; et al. EC power sources: European technological developments towards ITER. Fusion Eng. Des. 2007, 82, 619–626. [Google Scholar] [CrossRef]

- Rzesnicki, T.; Albajar, F.; Alberti, S.; Avramidis, K.A.; Bin, W.; Bonicelli, T.; Braunmueller, F.; Bruschi, A.; Chelis, J.; Frigot, P.-E.; et al. Experimental verification of the European 1 MW, 170 GHz industrial CW prototype gyrotron for ITER. Fusion Eng. Des. 2017, 123, 490–494. [Google Scholar] [CrossRef]

- Avramides, K.A.; Pagonakis, I.G.; Iatrou, C.T.; Vomvoridis, J.L. EURIDICE: A code-package for gyrotron interaction simulations and cavity design. Epj Web Conf. 2012, 32, 04016. [Google Scholar] [CrossRef] [Green Version]

- Bertinetti, A.; Albajar, F.; Avramidis, K.A.; Cau, F.; Cismondi, F.; Gantenbein, G.; Jelonnek, J.; Kalaria, P.C.; Ruess, S.; Rzesnicki, T.; et al. Analysis of an actively-cooled coaxial cavity in a 170 GHz 2 MW gyrotron using the multi-physics computational tool MUCCA. Fusion Eng. Des. 2019, 146, 74–77. [Google Scholar] [CrossRef]

- Braunmueller, F.; Tran, T.M.; Vuillemin, Q.; Alberti, S.; Genoud, J.; Hogge, J.-P.; Tran, M.Q. TWANG-PIC, a novel gyro-averaged one-dimensional particle-in-cell code for interpretation of gyrotron experiments. Phys. Plasmas 2015, 22, 063115. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badodi, N.; Cammi, A.; Leggieri, A.; Sanchez, F.; Savoldi, L. A New Lumped Approach for the Simulation of the Magnetron Injection Gun for MegaWatt-Class EU Gyrotrons. Energies 2021, 14, 2068. https://doi.org/10.3390/en14082068

Badodi N, Cammi A, Leggieri A, Sanchez F, Savoldi L. A New Lumped Approach for the Simulation of the Magnetron Injection Gun for MegaWatt-Class EU Gyrotrons. Energies. 2021; 14(8):2068. https://doi.org/10.3390/en14082068

Chicago/Turabian StyleBadodi, Nicolò, Antonio Cammi, Alberto Leggieri, Francisco Sanchez, and Laura Savoldi. 2021. "A New Lumped Approach for the Simulation of the Magnetron Injection Gun for MegaWatt-Class EU Gyrotrons" Energies 14, no. 8: 2068. https://doi.org/10.3390/en14082068