SPEAR (Solar Pyrolysis Energy Access Reactor): Theoretical Design and Evaluation of a Small-Scale Low-Cost Pyrolysis Unit for Implementation in Rural Communities

Abstract

:1. Introduction

1.1. Regional Context and Call for Action

1.2. Pyrolysis

1.3. Solar-Powered Pyrolysis

1.4. Research Objectives and Structure

2. Materials and Methods

2.1. Potential Feedstocks and Reactor Sizing

2.2. Pyrolysis Heat Transfer Approach and Modeling

2.3. Solar Unit

2.4. Financial Feasibility Assessment

2.5. Provision of Electrification Services

3. Results

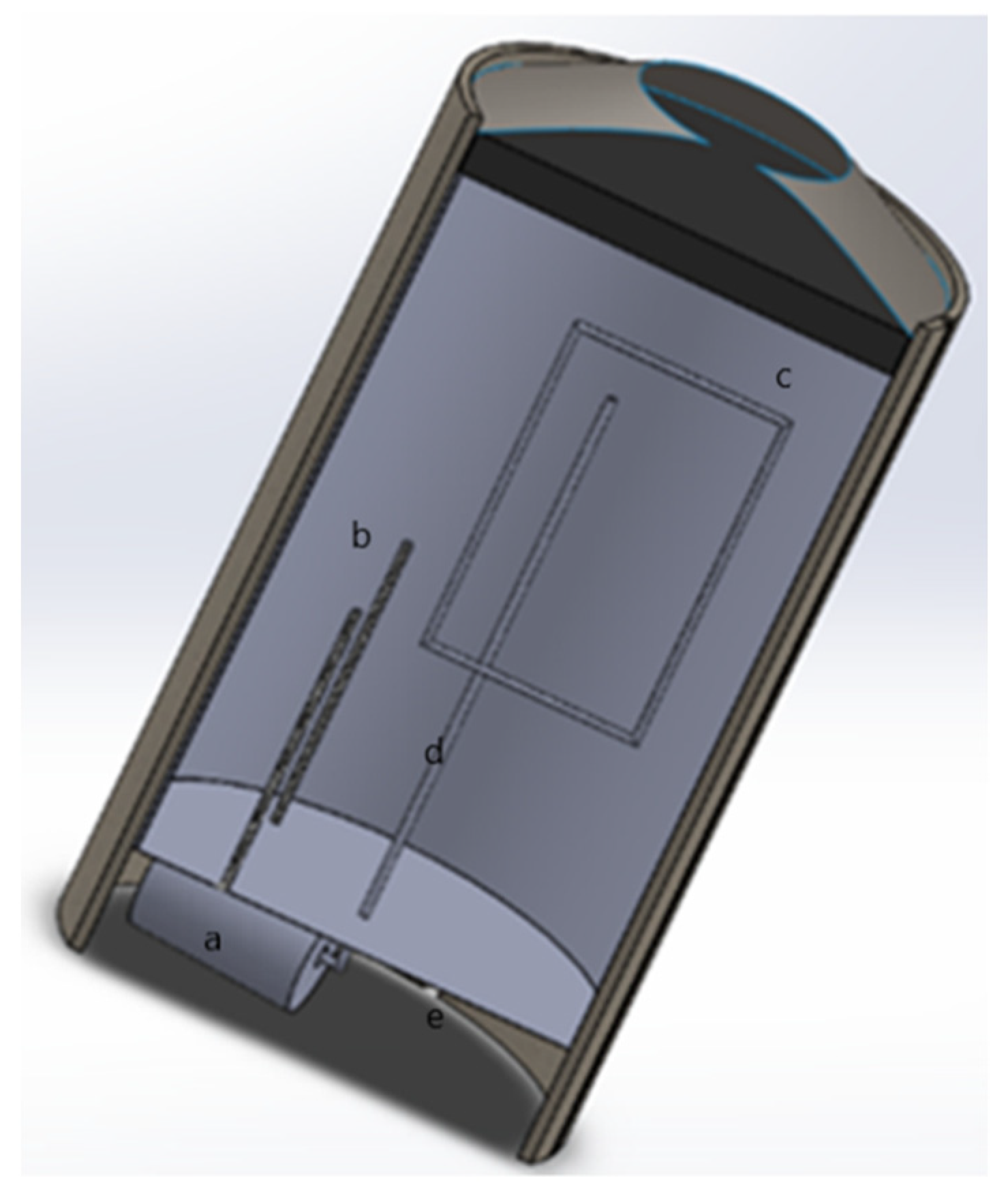

3.1. Reactor Design

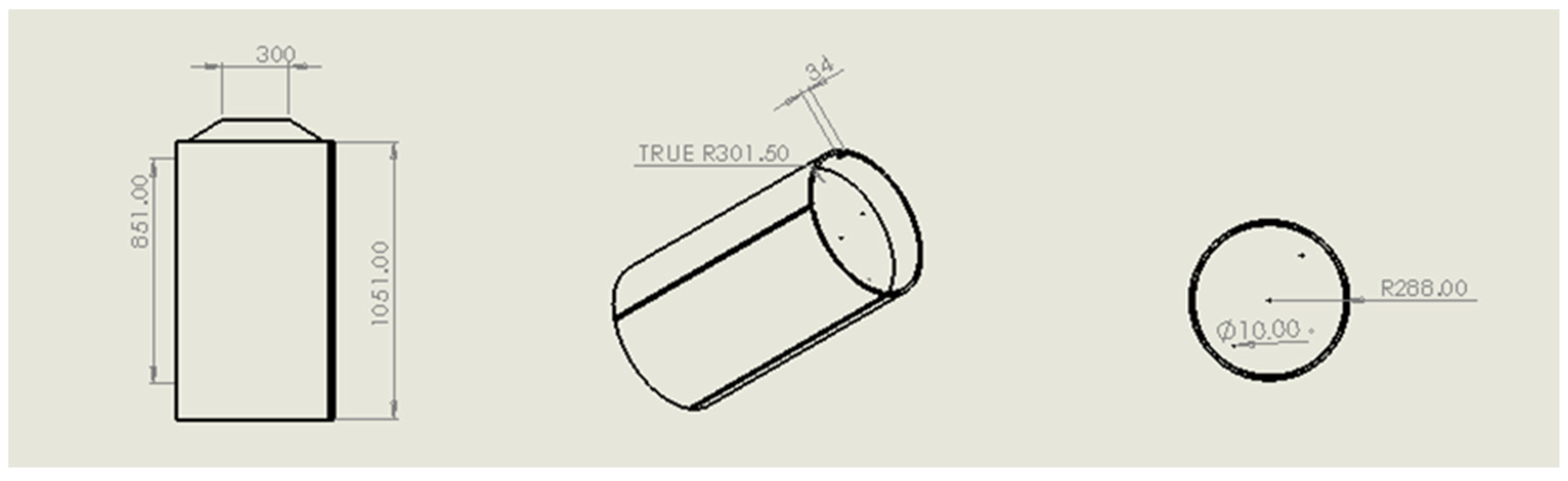

3.2. Heat Pipes

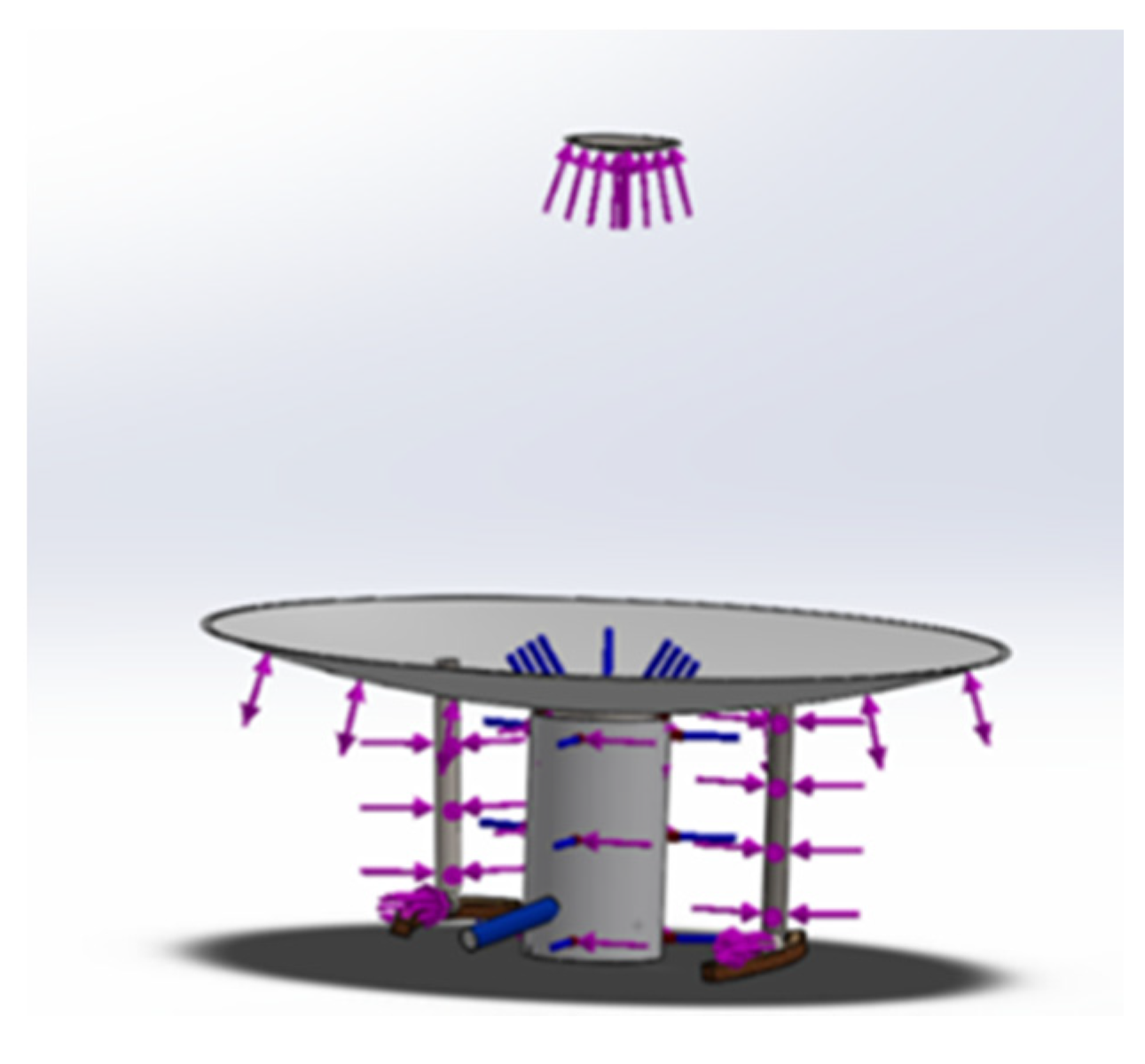

3.3. Solar Unit

3.4. Biochar Yield and Provision of Electrification Services

3.5. Financial Feasibility Evaluation

4. Discussion

4.1. Biomass Feedstock

4.2. Design Considerations and Potential Improvements

4.3. Financial Feasibility

4.4. Environmental and Social Impact

4.5. Comparison to Alternatives

4.6. Potential for Scale Up

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Unit Cost Breakdown for the System

| Component | Cost Per Unit | Number Needed | Reference |

|---|---|---|---|

| Battery 220 Wh | 95 | 1 | [90] |

| TE 5.7 W | 19.94/unit | 5 | [99] |

| DC connection cable (d = 4 mm, L = 95 mm) | 0.49$/unit | 10 | [107] |

| Cement for insulation | 7.4$ for a 50 kg bag | 1 | [108] |

| 55-gallon (220 L) drum | 10$ for new unit | 1 | [109] |

| Glass Steel PU sandwich mirror panel | 39.1$/m2 | 9.62 m2 | [110] |

| Faceted secondary reflector | 49.7$/m2 | 0.4016 m2 | [110] |

| 30 cm diameter quartz window | 29.95$ | 1 | [111] |

| SiC Coated ceramic emitter plate | 25.8$/plate | 2 | [112] |

| Char collection Drainage PVC pipe (d = 100 mm, L = 3 m) | 9.36$ | 1 | [113] |

| HRS 1573 K resistant silicon mix | 7.99$ for 315 mL | [114] | |

| 843 K resistant Aluminum gasket for reactor top 550 mm | 42.25$ | [115] | |

| Gasket clips and installation tools | 15.4$ | [115] | |

| Perforated steel piping for gas collection (D = 32 mm, L = 500 mm) | 7.5$ | 1 | [116] |

| High skilled labor cost for 1 day | 46.9$ | 1 | [117] |

| FLOX™ Unit | 56.68$/kWth | 1.696 kWth | [118] |

| Stainless steel Ball Valve | 2.2$/unit | 1 | [119] |

| Loop heat pipe | 0.2$/W | 575 | [120] |

| Capillary heat pipe | 0.1245$/W | 750 | [121] |

| 5 W LEDs | 1.99$/light | 2 | [69] |

| Dowtherm A HTF | 4$/liter | 1 | [122] |

| Secondary reflector support telescopic poles (D = 6 mm, L = 1 m) | 4.93$/piece | 2 | [123] |

| Primary concentrator aluminum telescopic poles (D = 25 mm, L = 1 m) | 6.07$/piece | 2 | [123] |

| Telescopic tube connectors | 3.12$/piece | 4 | [124] |

| Primary concentrator thermoplastic wheels (100 mm diameter) | 3.64$/wheel | 2 | [125] |

References

- Gasser, T.; Luderer, G. Mitigation Pathways Compatible with 1.5 C in the Context of Sustainable Development. 2018. Available online: https://www.ipcc.ch/site/assets/uploads/sites/2/2019/05/SR15_Chapter2_Low_Res.pdf (accessed on 10 July 2019).

- IEA. WEO-2017 Special Report: Energy Access Outlook. 2017. Available online: www.iea.org/t&c/ (accessed on 30 July 2019).

- Hirmer, S.; Cruickshank, H. The user-value of rural electrification: An analysis and adoption of existing models and theories. Renew. Sustain. Energy Rev. 2014, 34, 145–154. [Google Scholar] [CrossRef] [Green Version]

- Mertz, O.; Halsnæs, K.; Olesen, J.E.; Rasmussen, K. Adaptation to Climate Change in Developing Countries. Environ. Manag. 2009, 43, 743–752. [Google Scholar] [CrossRef] [Green Version]

- PwC. Electricity beyond the Grid: Accelerating Access to Sustainable Power for All. 2016. Available online: www.pwc.com/utilities (accessed on 13 August 2019).

- Lynd, L.R.; Sow, M.; Chimphango, A.F.; Cortez, L.A.; Brito Cruz, C.H.; Elmissiry, M.; Laser, M.; Mayaki, I.A.; Moraes, M.A.; Nogueira, L.A.; et al. Bioenergy and African transformation. Biotechnol. Biofuels 2015, 8, 18. [Google Scholar] [CrossRef] [Green Version]

- Tucho, G.; Nonhebel, S.; Tucho, G.T.; Nonhebel, S. Bio-Wastes as an Alternative Household Cooking Energy Source in Ethiopia. Energies 2015, 8, 9565–9583. [Google Scholar] [CrossRef] [Green Version]

- Das, K.C.; Singh, K.; Bibens, B.R.; Hilten, S.A.; Baker, W.D.; Greene, J.D. Peterson Pyrolysis Characteristics of Forest Residues Obtained from Different Harvesting Methods. Appl. Eng. Agric. 2013, 27, 107–113. [Google Scholar] [CrossRef]

- World Bank. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. 2018, pp. 2–6. Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 9 August 2019).

- IEA. Biofuel Potential in Sub-Saharan Africa: Raising Food Yields, Reducing Food Waste and Utilising Residues. 2017. Available online: www.irena.org (accessed on 3 August 2019).

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.-T.; Show, P.-L. Waste to bioenergy: A review on the recent conversion technologies. BMC Energy 2019, 1, 4. [Google Scholar] [CrossRef]

- Sharma, A.; Pareek, V.; Zhang, D. Biomass pyrolysis—A review of modelling, process parameters and catalytic studies. Renew. Sustain. Energy Rev. 2015, 50, 1081–1096. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Rony, A.H.; Kong, L.; Lu, W.; Dejam, M.; Adidharma, H.; Gasem, K.A.M.; Zheng, Y.; Norton, U.; Fan, M. Kinetics, thermodynamics, and physical characterization of corn stover (Zea mays) for solar biomass pyrolysis potential analysis. Bioresour. Technol. 2019, 284, 466–473. [Google Scholar] [CrossRef]

- Antal, M.J.; Várhegyi, G.; Jakab, E. Cellulose Pyrolysis Kinetics: Revisited. Ind. Eng. Chem. Res. 1998, 37, 1267–1275. [Google Scholar] [CrossRef] [Green Version]

- Gao, X.; Lu, L.; Shahnam, M.; Rogers, W.A.; Smith, K.; Gaston, K.; Robichaud, D.; Brennan Pecha, M.; Crowley, M.; Ciesielski, P.N.; et al. Assessment of a detailed biomass pyrolysis kinetic scheme in multiscale simulations of a single-particle pyrolyzer and a pilot-scale entrained flow pyrolyzer. Chem. Eng. J. 2021, 418, 129347. [Google Scholar] [CrossRef]

- Yang, S.; Wang, S.; Wang, H. Particle-scale evaluation of the pyrolysis process of biomass material in a reactive gas-solid spouted reactor. Chem. Eng. J. 2020, 21, 127787. [Google Scholar] [CrossRef]

- Lu, L.; Gao, X.; Gel, A.; Wiggins, G.M.; Crowley, M.; Pecha, B.; Shahnam, M.; Rogers, W.A.; Parks, J.; Ciesielski, P.N. Investigating biomass composition and size effects on fast pyrolysis using global sensitivity analysis and CFD simulations. Chem. Eng. J. 2020, 21, 127789. [Google Scholar] [CrossRef]

- Mohan, D.; Abhishek, K.; Sarswat, A.; Patel, M.; Singh, P.; Pittman, C.U. Biochar production and applications in soil fertility and carbon sequestration–a sustainable solution to crop-residue burning in India. RSC Adv. 2018, 8, 508–520. Available online: http://xlink.rsc.org/?DOI=C7RA10353K9 (accessed on 10 August 2019). [CrossRef] [Green Version]

- Galinato, S.P.; Yoder, J.K.; Granatstein, D. The economic value of biochar in crop production and carbon sequestration. Energy Policy 2011, 39, 6344–6350. Available online: https://www.sciencedirect.com/science/article/pii/S0301421511005672 (accessed on 10 August 2019). [CrossRef]

- Archontoulis, S.V.; Huber, I.; Miguez, F.E.; Thorburn, P.J.; Rogovska, N.; Laird, D.A. A model for mechanistic and system assessments of biochar effects on soils and crops and trade-offs. GCB Bioenergy 2016, 8, 1028–1045. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Ryu, C.; Park, Y.K. Slow pyrolysis of rice straw: Analysis of products properties, carbon and energy yields. Bioresour. Technol. 2014, 155, 63–70. [Google Scholar] [CrossRef]

- Woolf, D.; Lehmann, J.; Lee, D.R. Optimal bioenergy power generation for climate change mitigation with or without carbon sequestration. Nat. Commun. 2016, 7, 13160. [Google Scholar] [CrossRef] [Green Version]

- Roberts, K.G.; Gloy, B.A.; Joseph, S.; Scott, N.R.; Lehmann, J. Life cycle assessment of biochar systems: Estimating the energetic, economic, and climate change potential. Environ. Sci. Technol. 2010, 44, 827–833. [Google Scholar] [CrossRef] [PubMed]

- Brown, T.R.; Wright, M.M.; Brown, R.C. Estimating profitability of two biochar production scenarios: Slow pyrolysis vs. fast pyrolysis. Biofuels Bioprod. Biorefining 2011, 5, 54–68. 4. [Google Scholar] [CrossRef]

- Crombie, K.; Mašek, O. Investigating the potential for a self-sustaining slow pyrolysis system under varying operating conditions. Bioresour. Technol. 2014, 162, 148–156. [Google Scholar] [CrossRef] [Green Version]

- Pereira, E.G.; Marchtins, M.A.; Pecenka, R.; Angélica de Cássia, O.C. Pyrolysis gases burners: Sustainability for integrated production of charcoal, heat and electricity. Renew. Sustain. Energy Rev. 2017, 75, 592–600. [Google Scholar] [CrossRef]

- Wünning, J.A.; Wünning, J.G. Flameless oxidation to reduce thermal no-formation. Prog. Energy Combust. Sci. 1997, 23, 81–94. [Google Scholar] [CrossRef]

- Blurock, E.; Battin-Leclerc, F. Modeling combustion with detailed kinetic mechanisms. In Green Energy and Technology; Springer: London, UK, 2013; pp. 17–57. Available online: https://www.springer.com/gp/book/9781447153061 (accessed on 15 July 2019). [CrossRef]

- Yadav, D.; Banerjee, R. A review of solar thermochemical processes. Renew. Sustain. Energy Rev. 2016, 54, 497–532. [Google Scholar] [CrossRef]

- Wieckert, C.; Obrist, A.; Von Zedtwitz, P.; Maag, G.; Steinfeld, A. Syngas Production by Thermochemical Gasification of Carbonaceous Waste Materials in a 150 kW th Packed-Bed Solar Reactor. Energy Fuels 2013, 27, 4770–4776. [Google Scholar] [CrossRef]

- Morales, S.; Miranda, R.; Bustos, D.; Cazares, T.; Tran, H. Solar biomass pyrolysis for the production of bio-fuels and chemical commodities. J. Anal. Appl. Pyrolysis 2014, 109, 65–78. [Google Scholar] [CrossRef]

- Garcia-Nunez, J.A.; Pelaez-Samaniego, M.R.; Garcia-Perez, M.E.; Fonts, I.; Abrego, J.; M Westerhof, R.J.; Garcia-Perez, M. Historical Developments of Pyrolysis Reactors: A Review. Energy Fuels 2017, 31, 5751–5775. Available online: https://pubs.acs.org/sharingguidelines (accessed on 17 July 2019). [CrossRef]

- Chen, Q.; Yang, R.; Zhao, B.; Li, Y.; Wang, S.; Wu, H.; Zhuo, Y.; Chen, C. Investigation of heat of biomass pyrolysis and secondary reactions by simultaneous thermogravimetry and differential scanning calorimetry. Fuel 2014, 134, 467–476. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels production through biomass pyrolysis—A technological review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Zeng, K.; Gauthier, D.; Soria, J.; Mazza, G.; Flamant, G. Solar pyrolysis of carbonaceous feedstocks: A review. Sol. Energy 2017, 156, 73–92. [Google Scholar] [CrossRef]

- Adinberg, R.; Epstein, M.; Karni, J. Solar Gasification of Biomass: A Molten Salt Pyrolysis Study. J. Sol. Energy Eng. 2004, 126, 850. Available online: http://solarenergyengineering.asmedigitalcollection.asme.org/article.aspx?articleid=1457062 (accessed on 9 August 2019). [CrossRef]

- Rony, A.H.; Mosiman, D.; Sun, Z.; Qin, D.; Zheng, Y.; Boman, J.H.; Fan, M. A novel solar powered biomass pyrolysis reactor for producing fuels and chemicals. J. Anal. Appl. Pyrolysis 2018, 132, 19–32. Available online: https://www-sciencedirect-com.ezproxy.is.ed.ac.uk/science/article/pii/S016523701830038X (accessed on 27 February 2019). [CrossRef] [Green Version]

- Khairnasov, S.M.; Naumova, A.M. Heat pipes application to solar energy systems. Appl. Sol. Energy (Engl. Transl. Geliotekhnika) 2016, 52, 47–60. Available online: https://link.springer.com/article/10.3103/S0003701X16010060 (accessed on 29 January 2021). [CrossRef]

- Steinfeld, A. Solar thermochemical production of hydrogen. In Handbook of Hydrogen Energy; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Joardder, M.U.H.; Halder, P.K.; Rahim, M.A.; Masud, M.H. Solar Pyrolysis: Converting Waste Into Asset Using Solar Energy. Clean Energy Sustain. Dev. 2017, 213–235. [Google Scholar]

- Kodama, T. High-temperature solar chemistry for converting solar heat to chemical fuels. Prog. Energy Combust. Sci. 2003, 29, 567–597. Available online: https://www.sciencedirect.com/science/article/pii/S0360128503000595 (accessed on 11 July 2019). [CrossRef]

- Zeaiter, J.; Ahmad, M.N.; Rooney, D.; Samneh, B.; Shammas, E. Design of an automated solar concentrator for the pyrolysis of scrap rubber. Energy Convers. Manag. 2015, 101, 118–125. [Google Scholar] [CrossRef]

- Chintala, V.; KuMarch, S.; Pandey, J.K.; Sharma, A.K.; KuMarch, S. Solar thermal pyrolysis of non-edible seeds to biofuels and their feasibility assessment. Energy Convers. Manag. 2017, 153, 482–492. [Google Scholar] [CrossRef]

- Li, R.; Zeng, K.; Soria, J.E.; Gauthier, D.; Rodriguez, R.; Flamant, G. Product distribution from solar pyrolysis of agricultural and forestry biomass residues. Renew. Energy 2015, 89, 27–35. Available online: doi.org/10.1016/j.renene.2015.11.071 (accessed on 9 August 2019).

- Zeng, K.; Gauthier, D.; Li, R.; Flamant, G. Solar pyrolysis of beech wood: Effects of pyrolysis parameters on the product distribution and gas product composition. Energy 2015, 93, 1648–1657. [Google Scholar] [CrossRef]

- Daugaard, D.E.; Brown, R.C. Enthalpy for Pyrolysis for Several Types of Biomass Enthalpy for Pyrolysis for Several Types of Biomass Enthalpy for Pyrolysis for Several Types of Biomass. Energy Fuels 2003, 17, 934–939. [Google Scholar] [CrossRef] [Green Version]

- World Bank. Global Wind Atlas. 2019. Available online: https://globalwindatlas.info/ (accessed on 1 August 2019).

- World Bank. Global Solar Atlas. 2019. Available online: https://globalsolaratlas.info/ (accessed on 30 July 2019).

- World Bank. Inflation, consumer prices (annual %)-Sub-Saharan Africa, Middle East & North Africa. 2021. Available online: https://data.worldbank.org/indicator/FP.CPI.TOTL.ZG?locations=ZG-ZQ (accessed on 10 August 2019).

- Titiloye, J.O.; Abu Bakar, M.S.; Odetoye, T.E. Thermochemical characterisation of agricultural wastes from West Africa. Ind. Crops Prod. 2013, 47, 199–203. [Google Scholar] [CrossRef]

- Ackerman, P.; Ham, C.; Dovey, S.; Du Toit, B.; De Wet, J.; Kunneke, A.; Seifert, T.; Meincken, M.; Von Doderer, C. The Use of Forest Residue for Bioenergy in Southern Africa. 2013. Available online: https://www.icfr.ukzn.ac.za/sites/default/files/pubs/Bulletin03-2013.pdf (accessed on 4 August 2019).

- Dasappa, S. Potential of biomass energy for electricity generation in sub-Saharan Africa. Energy Sustain. Dev. 2014, 15, 203–213. Available online: https://www.sciencedirect.com/science/article/pii/S0973082611000524 (accessed on 22 November 2018). [CrossRef]

- Onsree, T.; Tippayawong, N.; Zheng, A.; Li, H. Pyrolysis behavior and kinetics of corn residue pellets and eucalyptus wood chips in a macro thermogravimetric analyzer. Case Stud. Therm. Eng. 2018, 12, 546–556. Available online: https://www.sciencedirect.com/science/article/pii/S2214157X18301424 (accessed on 4 August 2019). [CrossRef]

- The Cary Company. Specs: 55 Gallon Blue Tight Head Plastic Drum, UN Rated, 2“NPS & 2” Buttress Fittings. 2019. Available online: https://www.thecarycompany.com/media/pdf/specs/56W55D.pdf (accessed on 3 August 2019).

- Mohammad, S.T.; Al-Kayiem, H.H.; Assadi, M.K.; Kananda, K.; Nazir, R.; Jadhav, S. Thermal losses in central receiver solar thermal power plant Related content Performance and Simulation of a Stand-alone Parabolic Trough Solar Thermal Power Plant Numerical Investigation on Trapezoidal Cavity Receiver Used In LFR with Water Flow in Absor. 2018. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/377/1/012008/pdf (accessed on 1 August 2019).

- Steinfeld, A.; Schubnell, M. Optimum aperture size and operating temperature of a solar cavity-receiver. Sol. Energy 1993, 50, 19–25. [Google Scholar] [CrossRef]

- Shuai, Y.; Xia, X.L.; Tan, H.P. Radiation performance of dish solar concentrator/cavity receiver systems. Sol. Energy 2008, 82, 13–21. [Google Scholar] [CrossRef]

- Steinfeld, A.; Brack, M.; Meier, A.; Weidenkaff, A.; Wuillemin, D. A solar chemical reactor for co-production of zinc and synthesis gas. Energy 1998, 23, 803–814. [Google Scholar] [CrossRef]

- Jouhara, H.; Nannou, T.K.; Anguilano, L.; Ghazal, H.; Spencer, N. Heat pipe based municipal waste treatment unit for home energy recovery. Energy 2017, 139, 1210–1230. [Google Scholar] [CrossRef]

- Yang, H.; Kudo, S.; Kuo, H.-P.; Norinaga, K.; Mori, A.; Mašek, O.; Hayashi, J. Estimation of Enthalpy of Bio-Oil Vapor and Heat Required for Pyrolysis of Biomass. Energy Fuels 2013, 27, 2675–2686. Available online: http://pubs.acs.org/doi/10.1021/ef400199z (accessed on 28 July 2019). [CrossRef]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Ferrer-Rodríguez, J.P.; Fernández, E.F.; Almonacid, F.; Pérez-Higueras, P. Geometric Optical Design; (350.6050) Solar Energy; (220.1770) Concentrators; (220.4298) Nonimaging Optics. 2016. Available online: http://dx.doi.org/10.1364/OL.41.001985 (accessed on 30 July 2019).

- Shanks, K.; Sarmah, N.; Ferrer-Rodriguez, J.P.; Senthilarasu, S.; Reddy, K.S.; Fernández, E.F.; Mallick, T. Theoretical investigation considering manufacturing errors of a high concentrating photovoltaic of cassegrain design and its experimental validation. Sol. Energy 2016, 131, 235–245. Available online: https://www.sciencedirect.com/science/article/pii/S0038092X16001596#b0110 (accessed on 16 July 2019). [CrossRef] [Green Version]

- TracePro TracePro Tutorials Archives|Lambdares.com. Available online: https://www.lambdares.com/su/tracepro-tutorials/ (accessed on 30 July 2019).

- SunEarthTools Sun-Earth Tools: Calculation of Sun’s Position in the Sky for Each Location on the Earth at Any Time of Day. Available online: https://www.sunearthtools.com/dp/tools/pos_sun.php (accessed on 1 August 2019).

- Borchers, A.M.; Duke, J.M.; Parsons, G.R. Does willingness to pay for green energy differ by source? Energy Policy 2007, 35, 3327–3334. [Google Scholar] [CrossRef]

- ESMAP. Measuring Energy Access Introduction to the Multi-Tier Framework. 2015. Available online: https://www.seforall.org/sites/default/files/MTFpresentation_SE4ALL_April5.PDF (accessed on 10 August 2019).

- Amazon 25 Year Life Philips My Vision LED 5w Light Bulb BC B22 Bayonet Cap Warm White 2700k GLS Standard Shape Instant Low Energy Saving 250 Lumen Lamps L.E.D. [Energy Class A]. Available online: https://www.amazon.co.uk/Philips-Vision-Bayonet-Standard-Instant/dp/B0083WDMPW (accessed on 10 August 2019).

- Toolbox, E. Fuels-Higher and Lower Calorific Values. Available online: https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 10 August 2019).

- WorldBank. Pump Price for Diesel Fuel (US$ per liter)|Data. Available online: https://data.worldbank.org/indicator/EP.PMP.DESL.CD (accessed on 10 August 2019).

- Reber, T.; Booth, S.; Cutler, D.; Li, X.; Salasovich, J. Tariff Considerations for Micro-Grids in Sub-Saharan Africa. 2018. Available online: www.nrel.gov/publications (accessed on 10 August 2019).

- Rosnes, O.; Vennemo, H. The cost of providing electricity to Africa. Energy Econ. 2012, 34, 1318–1328. [Google Scholar] [CrossRef]

- IDS. The Costs and Benefits of Lighting and Electricity Services for Off-Grid Populations in Sub-Sahara Africa. 2018. Available online: https://assets.publishing.service.gov.uk/media/5af96657ed915d0df4e8cdea/Costs_Benefits_Off-Grid_Electricity_Lighting_Systems.pdf (accessed on 10 August 2019).

- Megan, D. South Africa’s Ramaphosa Signs Carbon Tax into Law. Available online: https://www.climatechangenews.com/2019/05/28/south-africas-ramaphosa-signs-carbon-tax-law/ (accessed on 15 July 2019).

- Stig, S. The MSR: Impact on Marchket balance and prices. Point Carbon Thomson Reuters 2019. Available online: https://ec.europa.eu/clima/sites/clima/files/docs/0094/thomson_reuters_point_carbon_en.pdf (accessed on 15 July 2019).

- Mondal, M.A.H.; Bryan, E.; Ringler, C.; Rosegrant, M. Ethiopian power sector development: Renewable based universal electricity access and export strategies. Renew. Sustain. Energy Rev. 2017, 75, 11–20. Available online: https://www-sciencedirect-com.ezproxy.is.ed.ac.uk/science/article/pii/S1364032116306979 (accessed on 25 November 2018). [CrossRef]

- Gwenzi, W.; Chaukura, N.; Mukome, F.N.D.; Machado, S.; Nyamasoka, B. Biochar production and applications in sub-Saharan Africa: Opportunities, constraints, risks and uncertainties. J. Environ. Manag. 2015, 150, 250–261. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0301479714005684 (accessed on 13 June 2019). [CrossRef] [PubMed]

- Weitzman, M.L. A Review of the Stern Review on the Economics of Climate Change. J. Econ. Lit. 2007, 45, 703–724. Available online: http://pubs.aeaweb.org/doi/10.1257/jel.45.3.703 (accessed on 11 August 2019). [CrossRef]

- TEG. Thermoelectric Gencell Technology. Available online: www.Tecteg.com (accessed on 4 August 2019).

- Stewart, M.; Stewart, M. Piping system components. Surf. Prod. Oper. 2016, 193–300. Available online: https://www.sciencedirect.com/science/article/pii/B9781856178082000043 (accessed on 4 August 2019).

- Ghosh, A.; Ghosh, A.; Neogi, S. Evaluation of physical and thermal properties of coal combustion residue blended concrete for energy efficient building application in India. Adv. Build. Energy Res. 2018, 1–22. Available online: https://www.tandfonline.com/doi/full/10.1080/17512549.2018.1557076 (accessed on 1 August 2019).

- Narendra Babu, N.; Kamath, H.C. Materials used in Heat Pipe. Mater. Today Proc. 2015, 2, 1469–1478. Available online: https://linkinghub.elsevier.com/retrieve/pii/S221478531500317X (accessed on 3 August 2019). [CrossRef]

- Tang, Y.; Zhou, R.; Lu, L.; Xie, Z. Anti-Gravity Loop-shaped heat pipe with graded pore-size wick. Appl. Therm. Eng. 2012, 36, 78–86. Available online: https://www.sciencedirect.com/science/article/pii/S135943111100723X#bib14 (accessed on 19 July 2019). [CrossRef]

- A Product Technical Data DOWTHERM A Heat Transfer Fluid. Available online: http://www.dow.com/heattrans (accessed on 3 August 2019).

- Jouhara, H.; Chauhan, A.; Nannou, T.; Almahmoud, S.; Delpech, B.; Wrobel, L.C. Heat pipe based systems—Advances and applications. Energy 2017, 128, 729–754. Available online: https://www.sciencedirect.com/science/article/pii/S0360544217305935 (accessed on 22 July 2019). [CrossRef]

- Pihl, E.; Kushnir, D.; Sandén, B.; Johnsson, F. Material Constraints for Concentrating Solar Thermal Power. Energy 2012, 44, 944–954. Available online: http://fossilhub.org/wp-content/uploads/2014/03/Pihl_etal2012_ConcSolarPower_materials.pdf (accessed on 12 August 2019).

- Hijazi, H.; MokhiaMarch, O.; Elsamni, O. Mechanical design of a low cost parabolic solar dish concentrator. Alex. Eng. J. 2016, 55, 1–11. Available online: https://www.sciencedirect.com/science/article/pii/S111001681600034X (accessed on 14 July 2019). [CrossRef] [Green Version]

- Lertsatitthanakorn, C.; Jamradloedluk, J.; Rungsiyopas, M. Electricity generation from a solar parabolic concentrator coupled to a thermoelectric module. Energy Procedia 2014, 52, 150–158. Available online: http://dx.doi.org/10.1016/j.egypro.2014.07.065 (accessed on 19 July 2019). [CrossRef] [Green Version]

- Alibaba Portable Power Station 220wh Emergency Backup Lithium Battery 200w Ac Inverter Outlet Solar Generator-Buy Rechargable Batteries, Solar Power Bank, Camping Back Up Power Product on Alibaba.com. Available online: https://www.alibaba.com/product-detail/Portable-Power-Station-220Wh-Emergency-Backup_62055629175.html?spm=a2700.7724857.normalList.34.2747d8c4VueH1R (accessed on 12 August 2019).

- Rueda-Ordóñez, Y.J.; Tannous, K.; Olivares-Gómez, E. An empirical model to obtain the kinetic parameters of lignocellulosic biomass pyrolysis in an independent parallel reactions scheme. Fuel Process. Technol. 2015, 140, 222–230. Available online: https://www.sciencedirect.com/science/article/pii/S0378382015301557 (accessed on 12 August 2019). [CrossRef]

- Supin, S.; Buathong, C.; Sirisak, S. High-energy conversion efficiency of drum kiln with heat distribution pipe for charcoal and biochar production. Energy Sustain. Dev. 2019, 59, 1–7. [Google Scholar]

- Jouhara, H.; Ahmad, D.; van den Boogaert, I.; Katsou, E.; Simons, S.; Spencer, N. Pyrolysis of domestic based feedstock at temperatures up to 300 °C. Therm. Sci. Eng. Prog. 2018, 5, 117–143. Available online: https://www.sciencedirect.com/science/article/pii/S2451904917303980#b0165 (accessed on 24 July 2019). [CrossRef]

- Busch, J.; Lubowski, R.N.; Godoy, F.; Steininger, M.; Yusuf, A.A.; Austin, K.; Hewson, J.; Juhn, D.; Farid, M.; Boltz, F. Structuring economic incentives to reduce emissions from deforestation within Indonesia. Proc. Natl. Acad. Sci. USA 2012, 109, 1062–1067. Available online: http://www.ncbi.nlm.nih.gov/pubmed/22232665 (accessed on 29 November 2018). [CrossRef] [PubMed] [Green Version]

- IRENA. Solar PV in Africa: Costs and Marchkets. 2016. Available online: www.irena.org (accessed on 29 January 2021).

- Alston, S.M.; Arnold, J.C. Environmental Impact of Pyrolysis of Mixed WEEE Plastics Part 2: Life Cycle Assessment. Environ. Sci. Technol. 2011, 45, 9386–9392. Available online: https://pubs.acs.org/doi/10.1021/es2016654 (accessed on 13 August 2019). [CrossRef]

- Mcelligott, K.M.; Coleman, M. Biochar Amendments to Forest Soils: Effects on Soil Properties and Tree Growth. 2011. Available online: https://forest.moscowfsl.wsu.edu/smp/solo/documents/GTs/McElligott-Kristin_Thesis.pdf (accessed on 14 August 2019).

- Acumen. How Affordable is Off-Grid Energy Access in Africa? An Evidence Review. 2017. Available online: https://acumen.org/wp-content/uploads/2017/07/Evidence-Review-On-Affordability.pdf (accessed on 10 August 2019).

- TEG. Recycling Waste Heat for a Cooler Tomorrow Recycling Waste Heat for a Cooler Tomorrow Product Overview Geometric Characteristics. 2015. Available online: www.tegpro.com (accessed on 4 August 2019).

- Mitchell, E.J.S.; Ting, Y.; Allan, J.; Lea-Langton, A.R.; Spracklen, D.V.; McFiggans, G.; Coe, H.; Routledge, M.N.; Williams, A.; Jones, J.M. Pollutant Emissions from Improved Cookstoves of the Type Used in Sub-Saharan Africa. Combust. Sci. Technol. 2020, 192, 1582–1602. Available online: https://www.tandfonline.com/doi/full/10.1080/00102202.2019.1614922 (accessed on 17 February 2021). [CrossRef] [Green Version]

- Kshirsagar, M.P.; Kalamkar, V.R. A comprehensive review on biomass cookstoves and a systematic approach for modern cookstove design. Renew. Sustain. Energy Rev. 2014, 30, 580–603. [Google Scholar] [CrossRef]

- Champier, D.; Bédécarrats, J.P.; Kousksou, T.; Rivaletto, M.; Strub, F.; Pignolet, P. Study of a TE (thermoelectric) generator incorporated in a multifunction wood stove. Energy 2011, 36, 1518–1526. [Google Scholar] [CrossRef] [Green Version]

- Torres-Rojas, D.; Lehmann, J.; Hobbs, P.; Joseph, S.; Neufeldt, H. Biomass availability, energy consumption and biochar production in rural households of Western Kenya. Biomass Bioenergy 2011, 35, 3537–3546. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, C.Y. A review of solar collectors and thermal energy storage in solar thermal applications. Appl. Energy 2013, 104, 538–553. [Google Scholar] [CrossRef] [Green Version]

- Renewable Energy Agency I. Renewable Energy Technologies: Cost Analysis Series Concentrating Solar Power Volume 1: Power Sector Issue 2/5 Acknowledgement. 2012. Available online: www.irena.org/Publications (accessed on 14 July 2019).

- Schöniger, F.; Thonig, R.; Resch, G.; Lilliestam, J. Making the sun shine at night: Comparing the cost of dispatchable concentrating solar power and photovoltaics with storage. Energy Sources Part B Econ. Plan. Policy 2021, 1–20. Available online: https://www.tandfonline.com/doi/full/10.1080/15567249.2020.1843565 (accessed on 17 February 2021).

- 4 mm Black PV Solar Cable. Available online: https://quickbit.co.uk/4mm-solar-cable?language=en¤cy=GBP&gclid=CjwKCAjw1rnqBRAAEiwAr29II8-PhcQYS49G8X_dpH6XJDvedi9kJkYY15CVQPUMHydetsfP9i9khRoCbo0QAvD_BwE (accessed on 10 August 2019).

- Cement: Constructing Africa—CAHF|Centre for Affordable Housing Finance Africa. Available online: http://housingfinanceafrica.org/cement-constructing-africa/ (accessed on 10 August 2019).

- Gallon Steel Drums For Sale—Buy 55 Gallon Steel Drums For Sale, 55 Gallon Steel Drums For Sale, 55 Gallon Steel Drums For Sale Product on Alibaba.com. Available online: https://www.alibaba.com/product-detail/55-gallon-steel-drums-for-sale_62022559768.html?spm=a2700.7724857.main07.10.53947624kGFb9A (accessed on 10 August 2019).

- Dish systems for CSP. Available online: https://www.osti.gov/pages/servlets/purl/1356835 (accessed on 10 August 2019).

- Quartz Windows|Fluorescence Applications|UV Fused Silica. Available online: https://www.knightoptical.com/stock/optical-components/uvvisnir-optics/windows/quartz-uv-fused-silica-ir-quartz-windows/quartz-windows/ (accessed on 10 August 2019).

- Silicon Carbide Plates High Temperature and Corrosion Resistance Ceramic Plate Boards—Buy Silicon Carbide Plates, Ceramic Plate, Ceramic Plate Boards Product on Alibaba.com. Available online: https://www.alibaba.com/product-detail/Silicon-Carbide-Plates-High-Temperature-And_62022936406.html?spm=a2700.7724857.normalList.11.3fde6ecdRWXDCO&s=p (accessed on 10 August 2019).

- Drainage Pipe Plain Ended—110mm x 3mtr. Available online: https://www.drainagepipe.co.uk/drainage-pipe-plain-ended-110mm-x-3mtr-p-D043/ (accessed on 10 August 2019).

- Heat Resistant Sealant 310 mL in Cartridge Gun Tube|VITCAS. Available online: https://shop.vitcas.com/vitcas-heat-resistant-sealant-1300.html (accessed on 10 August 2019).

- Kurt, J. Lesker Company|Aluminum Gaskets for CF Flanges|Vacuum Science Is Our Business. Available online: https://www.lesker.com/newweb/flanges/hardware_cf_gaskets.cfm?pgid=aluminum (accessed on 10 August 2019).

- Perforated Pipes Exhaust Tube T304 Stainless Steel All Sizes Pipe Length Tubes|eBay. Available online: https://www.ebay.co.uk/itm/Perforated-Pipes-Exhaust-Tube-T304-Stainless-Steel-All-Sizes-Pipe-Length-Tubes-/233013535235 (accessed on 10 August 2019).

- 3.4 Malawi Manual Labor Costs—Logistics Capacity Assessment—Digital Logistics Capacity Assessments. Available online: https://dlca.logcluster.org/display/public/DLCA/3.4+Malawi+Manual+Labor+Costs (accessed on 10 August 2019).

- A techno-economic analysis of the application of continuous staged-combustion and flameless oxidation to the combustor design in gas turbines. Fuel Process. Technol. 2006, 87, 727–736. Available online: https://www-sciencedirect-com.ezproxy.is.ed.ac.uk/science/article/pii/S037838200600035X (accessed on 10 August 2019). [CrossRef]

- Stainless Steel Cf8 100 mm 1000 Wog Bspt Screw End Ball Valve With Limit Switch—Buy Ball Valve with Limit Switch, Bspt Screw End Ball Valve, Bspt Screw End Ball Valve With Limit Switch Product on Alibaba.com. Available online: https://www.alibaba.com/product-detail/Stainless-steel-cf8-100mm-1000-wog_60690079515.html?spm=a2700.7724857.normalList.38.56d52ef0M6ylmO (accessed on 10 August 2019).

- Huang, B.J.; Chuang, Y.H.; Yang, P.E. Low-cost manufacturing of loop heat pipe for commercial applications. Appl. Therm. Eng. 2017, 126, 1091–1097. Available online: http://dx.doi.org/10.1016/j.applthermaleng.2016.12.062 (accessed on 9 August 2019). [CrossRef]

- CCI Copper Heat Pipe and Sink Specifications. Available online: http://www.farnell.com/datasheets/317989.pdf?_ga=2.156455410.857736183.1565447970-136742991.1565447970&_gac=1.79837925.1565447970.CjwKCAjw1rnqBRAAEiwAr29II_DFeKwUcwYinKkQXa-stZJvD2RXvSLAbOV__o8QKxXfoFZMmP0shxoCJvoQAvD_BwE (accessed on 10 August 2019).

- Dowtherm A—Buy Dowtherm A Biphenyl Diphenyl Oxide Eutectic, Dowtherm A Oem Diphenyl And Diphenylether, Dowtherm A Oem Heat Transfer Fluid Polyester Production Use Product on Alibaba.com. Available online: https://www.alibaba.com/product-detail/Equal-to-Dowtherm-A_60599873147.html?spm=a2700.7724857.normalList.1.61741db1zvofVc (accessed on 12 August 2019).

- 1/2in OD Telescopic Tube|Aluminium|metals4U. Available online: https://www.metals4u.co.uk/aluminium/c1/telescopic-tube/c177/12.7mm-(-12-)-od/p3051 (accessed on 14 August 2019).

- 1in to 7/8in Adjustable Tube Connector|Aluminium|metals4U. Available online: https://www.metals4u.co.uk/aluminium/c1/telescopic-tube/c177/1-to-78-adjustable-connector/p3061 (accessed on 14 August 2019).

- 100 mm Grey non Marchking Thermoplastic Rubber Wheel. Available online: https://www.rosscastors.co.uk/100mm-grey-non-Marchking-thermoplastic-rubber-wheel.html?utm_source=google_shopping&gclid=Cj0KCQjw4s7qBRCzARIsAImcAxZuJB3hdSxwRfav_ukKFYkbf0BhauKTv5My7ME8m-3jgA6ltU8IMWUaAvW3EALw_wcB (accessed on 14 August 2019).

| Property | Rice Husks | Sugarcane Bagasse | Corn Straw | Timber Residue | Eucalyptus Residue |

|---|---|---|---|---|---|

| Residue: Crop ratio | 1:0.67 | 1:3.3 | 1:0.77 | 1:2.3 | 1:1.8 |

| Pyrolysis Onset Temperature range (K) | 473–823 | 473–723 | 473–823 | 498–823 | 483–903 |

| Recorded Weight Loss (%) | 50 | 65 | 70 | 75 | 80 |

| Bulk Density Dry Basis (kg/m3) | 100 | 120 | 130 | 220 | 480 |

| Parameter | Heat Pipe A | Heat Pipe B |

|---|---|---|

| Heat Pipe Type | Anti–gravity loop | Vertical Capillary Wick |

| Number of Pipes | 1 | 2 |

| Evaporator Energy Source | Radiative, Emitter plate | Convective, Gas combustion |

| Working Fluid | Water | Dowtherm A™ |

| Fill Level (%) | 25 | 40 |

| Optimal Temperature Operating Range (K) | 303–560 | 423–668 |

| Density at 25 °C (kg/m3) | 997 | 1056 |

| Pipe Diameter(mm) | 8 | 10 |

| Pipe Material | Stainless Steel | Stainless Steel |

| Pipe Total Length | 400 mm (height) × 250 mm (width) | 350 mm |

| Wick Material | Sintered Copper Powder | Nickel Powder |

| Wick Permeability | 54% | 64% |

| Evaporator Wick Size | 75 μm | NA |

| Liquid Line Wick Size | 100 μm | 15 μm |

| Average Thermal Resistance | 0.15° K/W | 0.1171° K/W |

| Maximum Deliverable Heat | 575 W | 375 W per pipe |

| F1 (m) | D2 (m) | F2 (m) | H1 (m) | H2 (m) | SD (m) | A (°) | ηoptideal % | ηopt 1.5°TE % | Qcavity Ideal (kW) |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 0.5 | 0.2857 | 0.3828 | 0.0547 | 1.77 | 47.26 | 85 | 72 | 6.5 |

| Parameter | Rice Husk | Sugarcane Bagasse | Corn Straw | Pine Residue | Eucalyptus Residue |

|---|---|---|---|---|---|

| Mmax (kg) | 17.7 | 21.3 | 23.0 | 39.1 | 85.13 |

| Qminimum (kW) | 1.147 | 1.33 | 1.43 | 2.55 | 5.59 |

| Char Yield After 2 h (kg) | 6.03 | 6.17 | 5.31 | 12.09 | 15.32 |

| Char Yield (% wt) | 34 | 29 | 23 | 30 | 18 |

| Scenario | Rice Husk | Sugarcane Bagasse | Corn Straw | Pine Residue | Eucalyptus Residue |

|---|---|---|---|---|---|

| A: NPV (2019$) | 223.63 | 273.07 | 298.72 | 526.01 | 1181.35 |

| B: NPV (2019$) | 484.85 | 586.67 | 753.67 | 1295.85 | 2860.85 |

| C: NPV (2019$) | 1258.11 | 1514.44 | 1643.69 | 2802.0 | 6147.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caputo, C.; Mašek, O. SPEAR (Solar Pyrolysis Energy Access Reactor): Theoretical Design and Evaluation of a Small-Scale Low-Cost Pyrolysis Unit for Implementation in Rural Communities. Energies 2021, 14, 2189. https://doi.org/10.3390/en14082189

Caputo C, Mašek O. SPEAR (Solar Pyrolysis Energy Access Reactor): Theoretical Design and Evaluation of a Small-Scale Low-Cost Pyrolysis Unit for Implementation in Rural Communities. Energies. 2021; 14(8):2189. https://doi.org/10.3390/en14082189

Chicago/Turabian StyleCaputo, Cesare, and Ondřej Mašek. 2021. "SPEAR (Solar Pyrolysis Energy Access Reactor): Theoretical Design and Evaluation of a Small-Scale Low-Cost Pyrolysis Unit for Implementation in Rural Communities" Energies 14, no. 8: 2189. https://doi.org/10.3390/en14082189

APA StyleCaputo, C., & Mašek, O. (2021). SPEAR (Solar Pyrolysis Energy Access Reactor): Theoretical Design and Evaluation of a Small-Scale Low-Cost Pyrolysis Unit for Implementation in Rural Communities. Energies, 14(8), 2189. https://doi.org/10.3390/en14082189