Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector

Abstract

1. Introduction

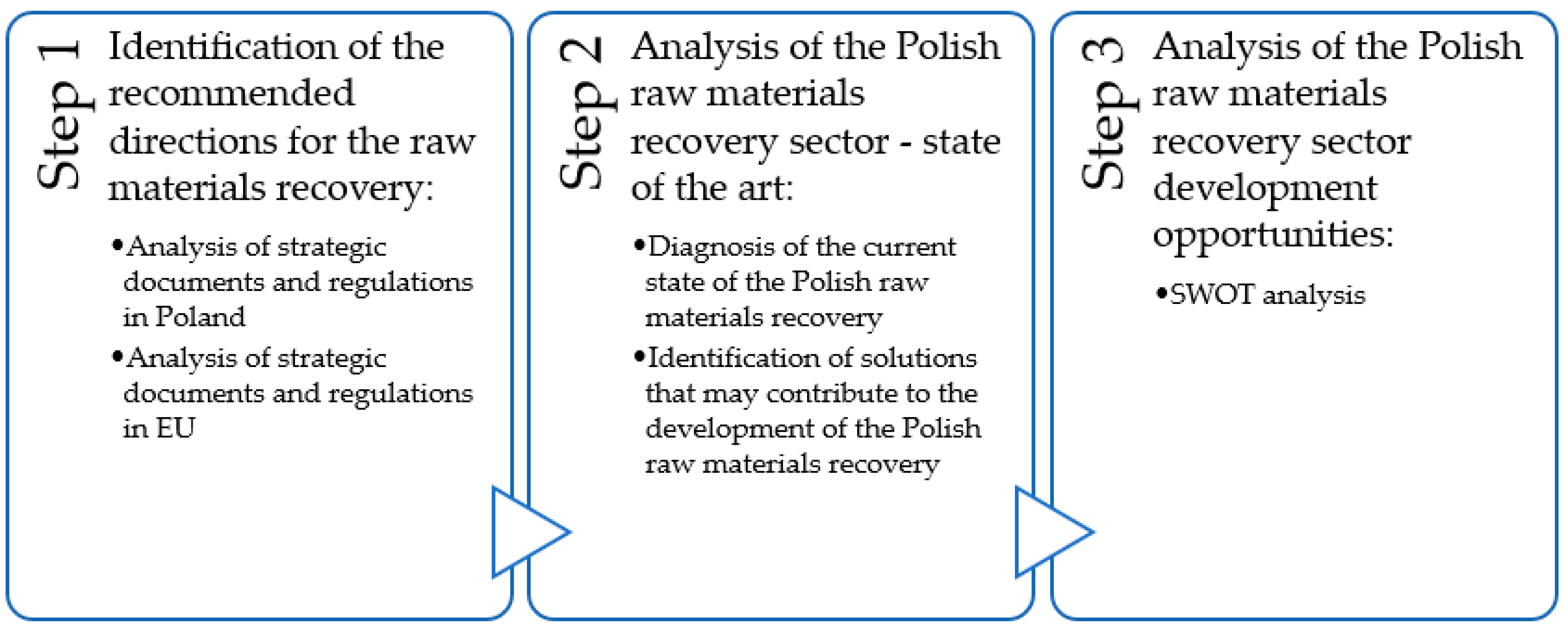

2. Materials and Methods

3. Results

3.1. Recommended Directions for the Raw Materials Management

3.2. Polish Raw Materials Recovery Sector

- (i)

- disassembly of used products (PKD 38.31), including disassembly of all types of end-of-life products and devices (cars, ships, computers, TV sets and other products) for the purpose of recovery of raw materials (PKD 38.31Z);

- (ii)

- recovery of raw materials from segregated materials (PKD 38.32), including the processing of metal and non-metal waste into secondary raw materials through a mechanical or chemical processing process; separation and sorting of recyclable raw materials derived from non-hazardous waste or the separation and sorting into various categories of various raw materials, such as paper, plastics, beverage cans, metal, suitable for processing or recovery (PKD 38.32Z). According to Polish law, the end product of waste management can either be destined for landfill or become an output for another production process.

3.3. Drivers and Barriers in the Development of the Raw Material Recovery Sector

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission Communication from the Commission: The European Green Deal; European Commission: Brussel, Belgium, 2019.

- Smol, M.; Marcinek, P.; Duda, J.; Szołdrowska, D. Importance of sustainable mineral resource management in implementing the circular economy (CE) model and the european green deal strategy. Resources 2020, 9, 55. [Google Scholar] [CrossRef]

- United Nations Resolution adopted by the General Assembly on 25 September 2015. Transforming our world: The 2030 Agenda for Sustainable Development. Int. J. Mar. Coast. Law 2015, A/RES/70/1. [CrossRef]

- European Commission Communication from the Commission—Towards a Circular Economy: A Zero Waste Programme for Europe; European Commission: Brussel, Belgium, 2014.

- European Commission Communication from the Commission. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussel, Belgium, 2015. [Google Scholar]

- European Commission Communication from the Commission. Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussel, Belgium, 2020. [Google Scholar]

- Blengini, G.A.; Nuss, P.; Dewulf, J.; Nita, V.; Talens Peiró, L.; Vidal-Legaz, B.; Latunussa, C.; Mancini, L.; Blagoeva, D.; Pennington, D.; et al. EU methodology for critical raw materials assessment: Policy needs and proposed solutions for incremental improvements. Resour. Policy 2017, 53, 12–19. [Google Scholar] [CrossRef]

- Mancini, L.; Benini, L.; Sala, S. Characterization of raw materials based on supply risk indicators for Europe. Int. J. Life Cycle Assess. 2018, 23, 726–738. [Google Scholar] [CrossRef]

- European Commission Communication from the Commission: On the Review of the List of Critical Raw Materials for the EU and the Implementation of the Raw Materials Initiative; European Commission: Brussel, Belgium, 2014.

- European Commission Communication from the Commission to the European Parliament, the Council, the Eurpean Economic and Social Committee and the Committee of the Regions on the 2017 List of Critical Raw Materials for the EU; European Commission: Brussel, Belgium, 2017.

- European Commission Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; European Commission: Brussel, Belgium, 2020.

- European Commission Tackling the Challenges in Commodity Markets and on Raw Materials; European Commission: Brussel, Belgium, 2011.

- European Commission Report on Critical Raw Materials and the Circular Economy; European Commission: Brussel, Belgium, 2018.

- Godlewska, J. Recovery and Recycling of Waste Tires in Poland. Procedia Eng. 2017, 182, 229–234. [Google Scholar] [CrossRef]

- Smol, M. The importance of sustainable phosphorus management in the circular economy (CE) model: The Polish case study. J. Mater. Cycles Waste Manag. 2019, 21, 227–238. [Google Scholar] [CrossRef]

- Zaleski, P.; Chawla, Y. Circular economy in Poland: Profitability analysis for two methods of waste processing in small municipalities. Energies 2020, 13, 5166. [Google Scholar] [CrossRef]

- Hobson, K.; Lynch, N. Diversifying and de-growing the circular economy: Radical social transformation in a resource-scarce world. Futures 2016, 82, 15–25. [Google Scholar] [CrossRef]

- Kostygova, L. Prospects for implementing a circular economy in industry based on territorial innovative clusters. Int. Multidiscip. Sci. GeoConf. Surv. Geol. Min. Ecol. Manag. SGEM 2018, 18, 631–638. [Google Scholar]

- Martins, F.F.; Castro, H. Raw material depletion and scenario assessment in European Union–A circular economy approach. Energy Rep. 2020, 6, 417–422. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.C.; Baldé, K.; Polder, M. Measuring resource efficiency and circular economy: A market value approach. Resour. Conserv. Recycl. 2017, 122, 163–171. [Google Scholar] [CrossRef]

- Mehr, J.; Jedelhauser, M.; Binder, C.R. Transition of the Swiss phosphorus system towards a circular economy-part 1: Current state and historical developments. Sustainability 2018, 10, 1479. [Google Scholar] [CrossRef]

- Wilts, H.; von Gries, N.; Bahn-Walkowiak, B. From waste management to resource efficiency-the need for policy mixes. Sustainabillity 2016, 8, 622. [Google Scholar] [CrossRef]

- Smol, M.; Adam, C.; Preisner, M. Circular economy model framework in the European water and wastewater sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef]

- ECESP Strategies. European Circulare Economy Stakeholder Platform. 2021. Available online: circulareconomy.europa.eu/platform (accessed on 9 March 2021).

- Roadmap Transformation towards a Circular Economy; Ministry of Economic Development: Warsaw, Poland, 2019.

- Graczyk, A. Social, economic and territorial cohesion and the development of energy sector in Strategy for Responsible Development. Optim. Econ. Stud. 2017, 90, 206–213. [Google Scholar] [CrossRef]

- Identification of Support Instruments for the Development of the Automotive Sector-Industry Report; Polish Agency for Enterprise Development, Institute for Labour Market Analyses: Warsaw, Poland, 2020.

- Hartley, K.; van Santen, R.; Kirchherr, J. Policies for transitioning towards a circular economy: Expectations from the European Union (EU). Resour. Conserv. Recycl. 2020, 155, 104634. [Google Scholar] [CrossRef]

- Smol, M.; Duda, J.; Czaplicka-Kotas, A.; Szołdrowska, D. Transformation towards circular economy (CE) in municipal waste management system: Model solutions for Poland. Sustainability 2020, 12, 456. [Google Scholar] [CrossRef]

- Iacovidou, E.; Velis, C.A.; Purnell, P.; Zwirner, O.; Brown, A.; Hahladakis, J.; Millward-Hopkins, J.; Williams, P.T. Metrics for optimising the multi-dimensional value of resources recovered from waste in a circular economy: A critical review. J. Clean. Prod. 2017, 166, 910–938. [Google Scholar] [CrossRef]

- Dróżdż, D.; Wystalska, K.; Malińska, K.; Grosser, A.; Grobelak, A.; Kacprzak, M. Management of poultry manure in Poland–Current state and future perspectives. J. Environ. Manag. 2020, 264. [Google Scholar] [CrossRef]

- Bień, J.D.; Bień, B. Utilisation of Municipal Sewage Sludge By Thermal Methods in the Face of Storage Disallowing. Inżynieria Ekol. 2015, 45, 36–43. [Google Scholar] [CrossRef]

- European Commission A Monitoring Framework for the Circular Economy; European Commission: Brussel, Belgium, 2018.

- European Commission Proposal for a Regulation on the Making Available on the Market of CE Marked Fertilising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 Annexes 1 to 5. 2016. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52016PC0157 (accessed on 15 March 2021).

- Act of 14 December 2012 on Waste; Ministry of the Environment: Warsaw, Poland, 2012.

- Regulation of the Minister of the Environment of January 20, 2015 Regarding the R10 Recovery Process; Ministry of the Environment: Warsaw, Poland, 2015.

- Ministry of Economic Development Strategy for Responsible Development for the Period Up to 2020 (Including the Perspective Up to 2030); Ministry of Environment: Warsaw, Poland, 2017.

- Draft of the Raw Material Policy (PSP); Ministry of Environment: Warsaw, Poland, 2018.

- Ministry of Economic Development Labour and Technology Polish Industrial Policy-Statement; Ministry of Environment: Warsaw, Poland, 2021.

- Statistical Yearbook of Industry–Poland; Statistics Poland: Warsaw, Poland, 2020.

- Regulation on Polish Classification of Activities (PKD); Council of Ministers: Warsaw, Poland, 2007.

- Environment 2020; Statistics Poland: Warsaw, Poland, 2020.

- Regulation of the Minister of the Environment, Republic of Poland, Catalogue of Waste; 2nd of January; Ministry of the Environment: Warsaw, Poland, 2020.

- European Union Directive 2018/851 amending Directive 2008/98/EC on waste Framework. Off. J. Eur. Union 2018, 30, 44.

- European Commission Eurostat. 2020. Available online: ec.europa.eu/eurostat (accessed on 9 March 2021).

- Materials management in 2019; Statistics Poland: Warsaw, Poland, 2020.

- Generowicz, A.; Gaska, K.; Hajduga, G. Multi-criteria Analysis of the Waste Management System in a Metropolitan Area. E3S Web Conf. 2018, 44, 1–8. [Google Scholar] [CrossRef]

- Vaverkova, M.; Adamcova, D.; Winkler, J.; Koda, E.; Petrzelova, L.; Maxianova, A. Alternative method of composting on a reclaimed municipal waste landfill in accordance with the circular economy: Benefits and risks. Sci. Total Environ. 2020, 723, 137971. [Google Scholar] [CrossRef] [PubMed]

- Jarosiński, A.; Zelazny, S.; Cholewa, M. Raw materials and possibilities of their obtaining in Poland. Inz. Miner. 2016, 17, 233–240. [Google Scholar]

- Rosiek, K. Directions and challenges in the management of municipal sewage sludge in Poland in the context of the circular economy. Sustainability 2020, 12, 3686. [Google Scholar] [CrossRef]

- Pietrzyk, S.; Tora, B. Processing of non-ferrous metals secondary raw materials in Poland-Trends, opportunities and threats. Inz. Miner. 2017, 2, 81–92. [Google Scholar]

- Tomaszewska, J. Polish transition towards circular economy: Materials management and implications for the construction sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef]

- Statista Registered unemployment rate during the coronavirus (COVID-19) epidemic in Poland from 2020 to 2021. 2021. Available online: www.statista.com/statistics/1112606/poland-unemployment-rate-during-covid-19-pandemic (accessed on 9 March 2021).

- Gajdzik, B.; Wolniak, R. Influence of the covid-19 crisis on steel production in poland compared to the financial crisis of 2009 and to boom periods in the market. Resources 2021, 10, 4. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V.; Guida, M. Compost from organic solid waste: Quality assessment and European regulations for its sustainable use. Resour. Conserv. Recycl. 2015, 94, 72–79. [Google Scholar] [CrossRef]

- Hicks, C.; Dietmar, R.; Eugster, M. The recycling and disposal of electrical and electronic waste in China-Legislative and market responses. Environ. Impact Assess. Rev. 2005, 25, 459–471. [Google Scholar] [CrossRef]

- Johansson, N.; Krook, J. How to handle the policy conflict between resource circulation and hazardous substances in the use of waste?: Three countries’ regulations on contaminants in waste and their implications for resource circulation. J. Ind. Ecol. 2021, 1–15. [Google Scholar] [CrossRef]

- Schoch, K.; Liedtke, C.; Bienge, K. Designing on the basis of recycling-metallurgy possibilities: Material-specific rules and standards for “anti-dissipative” products. Resources 2021, 10, 5. [Google Scholar] [CrossRef]

- Smol, M.; Adam, C.; Kugler, S.A. Thermochemical treatment of Sewage Sludge Ash (SSA)-potential and perspective in Poland. Energies 2020, 13, 5461. [Google Scholar] [CrossRef]

- Urbaniak, M. Building relationships with suppliers in new product development processes. Stud. Ekon. Zesz. Nauk. Uniw. Ekon. Katowicach 2017, 321, 9–19. [Google Scholar]

- Joanna, Z.; Żabińska, I.; Zarębski, A. Eco-Innovations in Poland-the Extent of Changes, Development and Barriers. Sci. Pap. Silesian Univ. Technol. Organ. Manag. Zesz. Nauk. Politech. Sl. Ser. Organ. Zarz. 2019, 245–256. [Google Scholar] [CrossRef]

- Panfiluk, E. Innovativeness of tourism enterprises: Example of Poland. Sustainability 2021, 13, 1024. [Google Scholar] [CrossRef]

- Kamizela, T.; Worwag, M. Processing of Water Treatment Sludge by Bioleaching. Energies 2020, 13, 6539. [Google Scholar] [CrossRef]

- Pyssa, J. Technical and technological aspects of sewage waste management after amendments in legislation in Poland. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012016. [Google Scholar] [CrossRef]

- Werle, S.; Sobek, S. Gasification of sewage sludge within a circular economy perspective: A Polish case study. Environ. Sci. Pollut. Res. 2019, 26, 35422–35432. [Google Scholar] [CrossRef]

- Lewandowska, A.; Szymańska, D. Municipal waste recycling in big cities in Poland in the context of ecologisation. Bull. Geogr. 2019, 43, 131–141. [Google Scholar] [CrossRef]

- Lewicka, E. Rational use of selected mining by-products in the ceramic industry in Poland. Gospod. Surowcami Miner. Miner. Resour. Manag. 2020, 36, 59–76. [Google Scholar]

- Borowski, P.F. Innovative processes in managing an enterprise from the energy and food sector in the era of industry 4.0. Processes 2021, 9, 381. [Google Scholar] [CrossRef]

- Żelazny, R. Determinants and measurement of smart growth: Evidence from Poland. J. Int. Stud. 2017, 10, 34–45. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of industry 4.0 on environmental sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Szostak, E.; Duda, P.; Duda, A.; Górska, N.; Fenicki, A.; Molski, P. Characteristics of Plastic Waste Processing in the Modern Recycling Plant Operating in Poland. Energies 2020, 14, 35. [Google Scholar] [CrossRef]

- Gródek-Szostak, Z.; Suder, M.; Kusa, R.; Szeląg-Sikora, A.; Duda, J.; Niemiec, M. Renewable Energy Promotion Instruments Used by Innovation Brokers in a Technology Transfer Network. Case Study of the Enterprise Europe Network. Energies 2020, 13, 5752. [Google Scholar] [CrossRef]

- Alwaeli, M. An overview of municipal solid waste management in Poland. The current situation, problems and challenges. Environ. Prot. Eng. 2015, 41, 181–193. [Google Scholar] [CrossRef]

- Kaur, G.; Uisan, K.; Ong, K.L.; Ki Lin, C.S. Recent Trends in Green and Sustainable Chemistry & Waste Valorisation: Rethinking Plastics in a circular economy. Curr. Opin. Green Sustain. Chem. 2018, 9, 30–39. [Google Scholar]

- Bombiak, E.; Marciniuk-Kluska, A. Green Human Resource Management as a Tool for the Sustainable Development of Enterprises: Polish Young Company Experience. Sustainability 2018, 10, 1739. [Google Scholar] [CrossRef]

- Hąbek, P. Corporate social responsibility reporting in mining sector. The European Union perspective. Sci. Pap. Silesian Univ. Technol. Organ. Manag. Ser. 2020, 2020, 159–172. [Google Scholar]

- Hąbek, P.; Lechowicz, P. Assessment of sustainable production practices. The case of company from metal industry. Multidiscip. Asp. Prod. Eng. 2019, 2, 447–456. [Google Scholar] [CrossRef][Green Version]

- Koda, E.; Osiński, P. Site Investigation of an Industrial Landfill for the Purpose of a Remedial Works Project. ASCE Geotech. Spec. Publ. 2016, 750–757. [Google Scholar] [CrossRef]

- Sady, M.; Żak, A.; Rzepka, K. The Role of Universities in Sustainability-Oriented Competencies Development: Insights from an Empirical Study on Polish Universities. Adm. Sci. 2019, 9, 62. [Google Scholar] [CrossRef]

- Pactwa, K.; Woźniak, J. Environmental reporting policy of the mining industry leaders in Poland. Resour. Policy 2017, 53, 201–207. [Google Scholar] [CrossRef]

- Sady, M.; Buła, P. Dual mission of startups: Defining and situating the concept. Contemp. Organ. Manag. Chall. Trends 2020, 3, 95–111. [Google Scholar]

- Havukainen, J.; Nguyen, M.T.; Hermann, L.; Horttanainen, M.; Mikkilä, M.; Deviatkin, I.; Linnanen, L. Potential of phosphorus recovery from sewage sludge and manure ash by thermochemical treatment. Waste Manag. 2016, 49, 221–229. [Google Scholar] [CrossRef]

- Wanat, L.; Potkański, T.; Chudobiecki, J.; Mikołajczak, E.; Mydlarz, K. Intersectoral and intermunicipal cooperation as a tool for supporting local economic development: Prospects for the forest and wood-based sector in Poland. Forests 2018, 9, 531. [Google Scholar] [CrossRef]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_ typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Wasiluk, A.; Ginevičius, R. Pro-innovative motives for establishing cooperation by enterprises: An empirical study in Poland. Econ. Sociol. 2020, 13, 258–278. [Google Scholar] [CrossRef]

- Radomska, J.; Wołczek, P.; Sołoducho-Pelc, L.; Silva, S. The impact of trust on the approach to management—A case study of creative industries. Sustainability 2019, 11, 816. [Google Scholar] [CrossRef]

- Kwiek, M. Poland: An Abundance of Doctoral Students but a Scarcity of Doctorates. In Trends and Issues in Doctoral Education: A Global Perspective; Sage: Thosand Oaks, CA, USA, 2019; pp. 103–126. [Google Scholar]

| Specification | Total | Entities by Value of Sold Production in Million EUR * | |||||

|---|---|---|---|---|---|---|---|

| ≤2.00 | 2.01–5.00 | 5.01–10.00 | 10.01–20.00 | 20.01–40.00 | ≥40.01 | ||

| Number of entities conducting activity during the year | 1062 | 153 | 289 | 221 | 179 | 125 | 95 |

| Sold production in million EUR * | 3890.2 | 37.8 | 205.3 | 355.3 | 543.7 | 754.9 | 1993.2 |

| Average paid employment in thousands | 59.1 | 2.3 | 5.5 | 7.3 | 10.1 | 12.8 | 21.1 |

| SWOT Element | Description |

|---|---|

| STRENGTHS | High importance of the sector in the national economy:

|

Dynamic development of the recovery industry and the formation of new companies:

| |

Impact on innovation and competitiveness of national economy:

| |

Impact on the environment and society:

| |

| WEAKNESSES | Imperfections of science-business cooperation:

|

Impact on the financial resources of enterprises:

| |

Market barriers:

| |

Technological barriers:

| |

| OPPORTUNITIES | Further development of policy and recommendations for the recovery of raw materials:

|

Further implementation of recommended actions in strategic national and international documents:

| |

Development of tools supporting the development of the market for secondary raw materials:

| |

Social and environmental drivers:

| |

Technological perspectives:

| |

| THREATS | Lack of sufficient law instruments:

|

Market barriers:

| |

Social concerns:

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smol, M.; Marcinek, P.; Koda, E. Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector. Energies 2021, 14, 2219. https://doi.org/10.3390/en14082219

Smol M, Marcinek P, Koda E. Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector. Energies. 2021; 14(8):2219. https://doi.org/10.3390/en14082219

Chicago/Turabian StyleSmol, Marzena, Paulina Marcinek, and Eugeniusz Koda. 2021. "Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector" Energies 14, no. 8: 2219. https://doi.org/10.3390/en14082219

APA StyleSmol, M., Marcinek, P., & Koda, E. (2021). Drivers and Barriers for a Circular Economy (CE) Implementation in Poland—A Case Study of Raw Materials Recovery Sector. Energies, 14(8), 2219. https://doi.org/10.3390/en14082219