Experimental Analysis of the Mechanical Properties and Resistivity of Tectonic Coal Samples with Different Particle Sizes

Abstract

:1. Introduction

2. Experimental Design and Methods of Tectonic Coal with Different Particle Sizes

2.1. Tectonic Coal Source

2.2. Experimental Design

2.2.1. Tectonic Coal Sample Preparation

2.2.2. Parameters and Experimental Design

Physical Property Parameters

Stress–Strain Curve and Mechanical Parameters

Resistivity

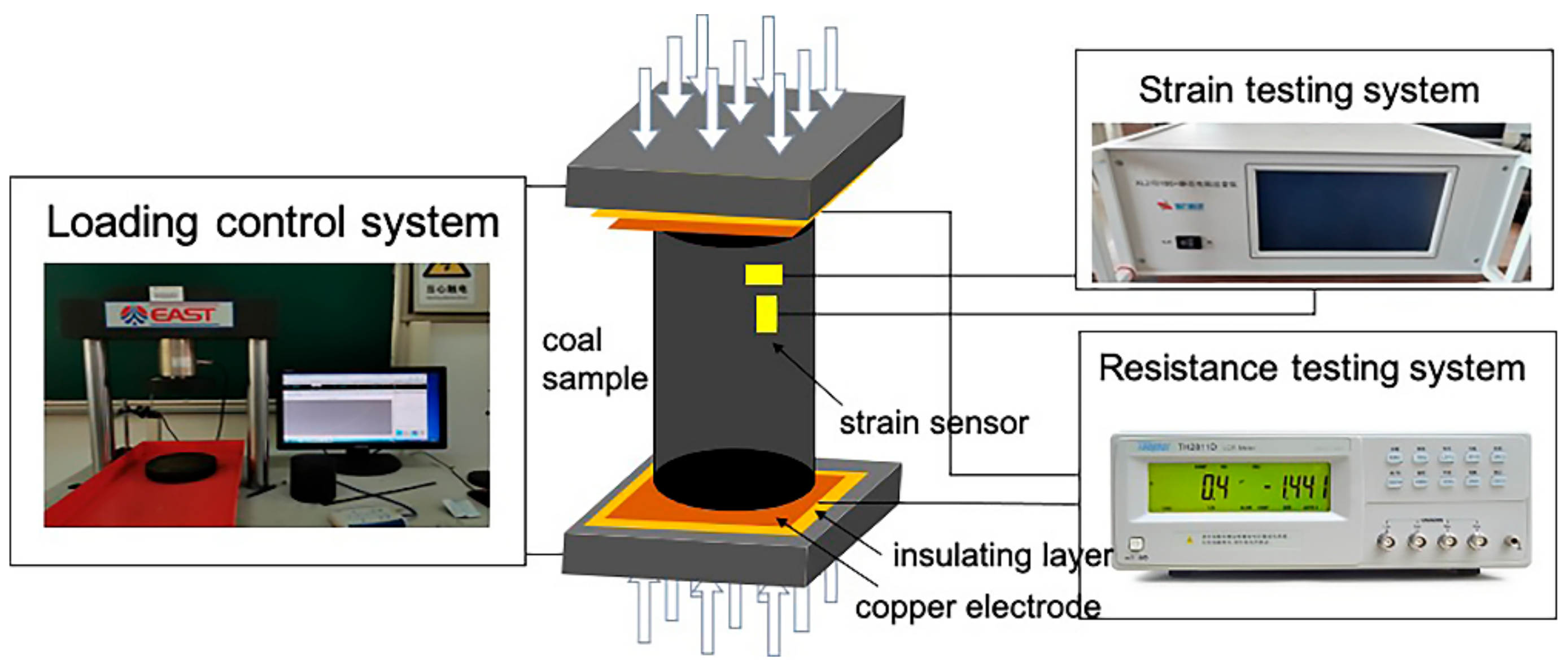

2.2.3. Experimental System

3. Results of Different Particle Size Tectonic Coal Sample Tests

3.1. Physical Parameters

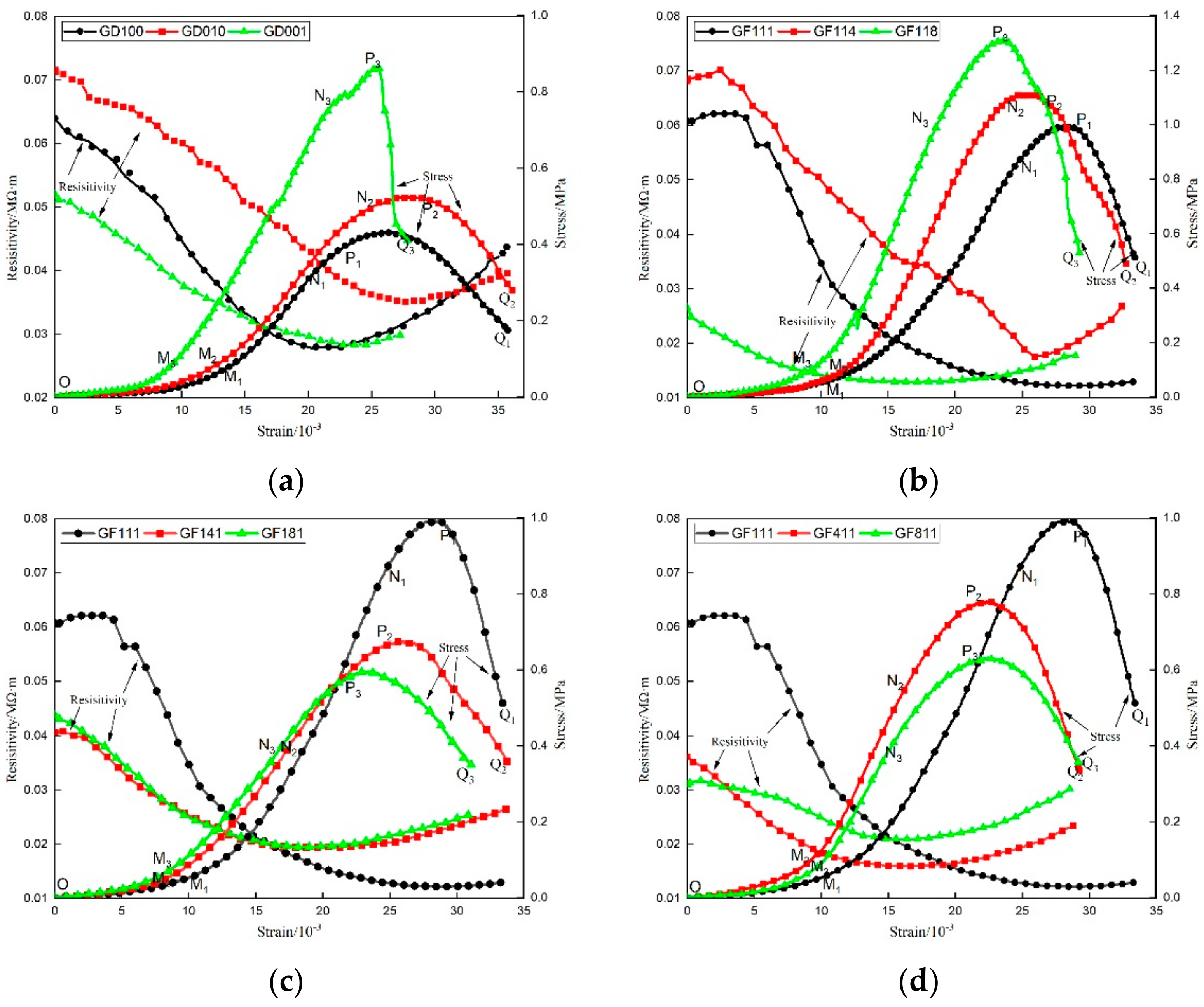

3.2. Stress–Strain Curves

- 1.

- Compaction stage (OM). The stress–strain curve rises with a small slope. The pores of the sample are closed immediately under force, and the coal particles rearrange their location. The deformation at this stage is plastic deformation, and the damage to the coal cannot recover.

- 2.

- Closure stage (MN). The stress–strain curve continues to rise, and the slope increases. The sample is further stressed, the pores are further closed, and the deformations begin to develop. According to the characteristics of deformation, the sample enters elastic deformation.

- 3.

- Fracturing stage (NP). The stress–strain curve rises and reaches a peak, and the slope begins to decrease. After the pore closure phase is over, the stress continues to rise, the sample becomes incompressible, plastic deformation begins to occur, tiny cracks develop, the skeleton begins to move, and cracks appear. The specimen begins to deform and fail.

- 4.

- Postpeak stage (PQ). The stress–strain curve drops. The sample fails, the pores increase, and crack formation quickly develops and penetrates.

3.3. Resistivity Curve

- In the compaction stage (OM), the resistivity curve declines fast with an extensive range.

- In the closure stage (MN), the resistivity curve declines steadily. The range is still relatively large. At the end of the stage, the rate of decline decreases.

- In the fracturing stage (NP), the resistivity curve turns from decline to increase, and the slope value changes from negative to positive.

- In the postpeak stage (PQ), the resistivity curve continues to rise, and the slope value increases.

4. Discussion of Mechanical Properties and Resistivity

4.1. Discussion of Mechanical Properties

4.1.1. Uniaxial Compressive Strength

4.1.2. Modulus

- In the compaction stage, the compression modulus of all tectonic coal samples is less than 10 MPa and far less than their elastic modulus. At this stage, the compaction deformation of the sample cannot recover after the pressure is relieved, and the main damage form is the fracture and fragmentation of the particles.

- In the elastic stage, the elastic modulus of the sample is affected by the particle size and gradation. Under single-particle gradation conditions, the larger the particle size is, the greater the elastic modulus. Under the composite-particle gradation condition, the proportion of fine particles increases as the elastic modulus increases. When it is close to 100%, the elastic modulus decreases. The proportion of medium or coarse particles increases, and the elastic modulus decreases.

- In the postpeak stage, there is a drop phenomenon in the stress–strain curve. Moreover, the postpeak modulus of the tectonic coal sample is related to particle size. The smallest particle size sample of single-particle gradation has the largest modulus and the most apparent drop effect.

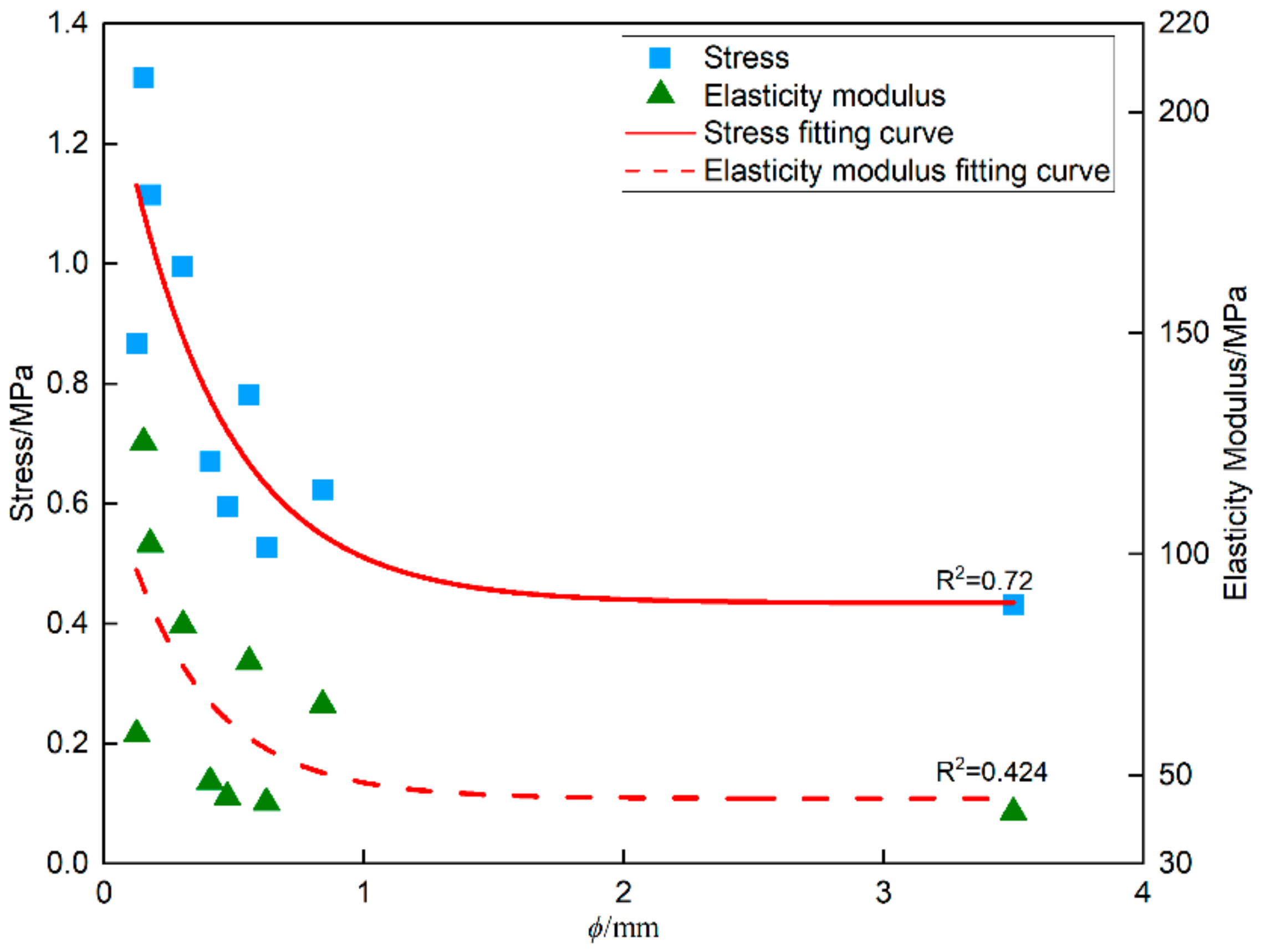

4.1.3. Relationship between Mechanical Property Parameters and Particle Size

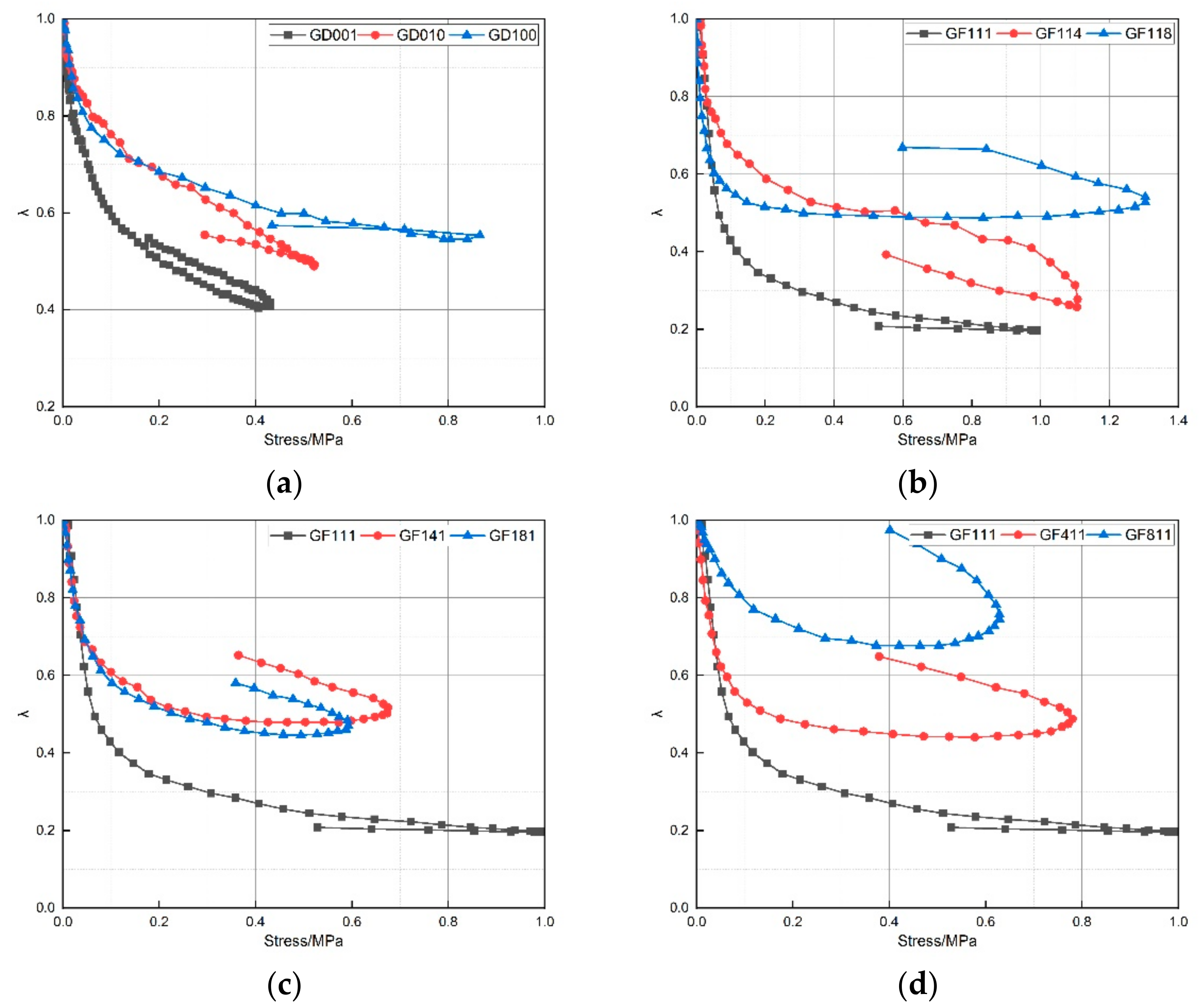

4.2. Discussion of Resistivity Change

5. Conclusions

- The stress–strain curve of tectonic coal samples with different particle sizes can be divided into four stages, and their shape is affected by particle size and proportion. In single-particle gradation, the stress–strain curve slope increases as the tectonic coal particle size decreases and the peak value becomes more evident. In composite-particle gradation, as the fine particle proportion of tectonic coal increases, the curve slope increases. As the proportion of medium particles or coarse particles increases, the curve slope decreases.

- The particle size and proportion of tectonic coal significantly impact the mechanical properties of tectonic coal. The samples composed of more fine particles have a higher value of mechanical parameters. As the converted particle size increases, the elastic modulus and strength first decrease and then tend to flatten. In single-particle gradation, the tectonic coal particle size changes from large to small, the sample strength and elastic modulus increase, and the yield performance approaches brittleness. As the proportion of fine particles increases in composite-particle gradation, the strength and elastic modulus first rise and then decrease slightly, yielding close ductility. As the proportion of medium or coarse particles increases, the strength and elastic modulus decrease, and their yield performances are close to ductility.

- The tectonic coal sample resistivity change is affected by the tectonic coal particle size and gradation. As the particle size decreases in single-particle gradation, the sample’s resistivity change decreases, and the proportion of resistivity change in the compaction stage increases. In composite-particle gradation, the proportion of fine, medium, or coarse particles increases, leading to the sample’s resistivity change decreasing, but the proportion of the resistivity change in the destruction stage increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fowler, P.; Gayer, R.A. The Association between Tectonic Deformation, Inorganic Composition and Coal Rank in the Bituminous Coals from the South Wales Coalfield, United Kingdom. Int. J. Coal Geol. 1999, 42, 1–31. [Google Scholar] [CrossRef]

- Frodsham, K.; Gayer, R.A. The Impact of Tectonic Deformation upon Coal Seams in the South Wales Coalfield, UK. Int. J. Coal Geol. 1999, 38, 297–332. [Google Scholar] [CrossRef]

- Ju, Y.; Li, X. New Research Progress on the Ultrastructure of Tectonically Deformed Coals. Prog. Nat. Sci. 2009, 19, 1455–1466. [Google Scholar] [CrossRef]

- Karayiğit, A.İ.; Mastalerz, M.; Oskay, R.G.; Gayer, R.A. Coal Petrography, Mineralogy, Elemental Compositions and Palaeoenvironmental Interpretation of Late Carboniferous Coal Seams in Three Wells from the Kozlu Coalfield (Zonguldak Basin, NW Turkey). Int. J. Coal Geol. 2018, 187, 54–70. [Google Scholar] [CrossRef]

- Karayiğit, A.İ.; Mastalerz, M.; Oskay, R.G.; Buzkan, İ. Bituminous Coal Seams from Underground Mines in the Zonguldak Basin (NW Turkey): Insights from Mineralogy, Coal Petrography, Rock-Eval Pyrolysis, and Meso-and Microporosity. Int. J. Coal Geol. 2018, 199, 91–112. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.; Song, X. Multifractal Analysis of Hg Pore Size Distributions of Tectonically Deformed Coals. Int. J. Coal Geol. 2015, 144, 138–152. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, B. Geochemical Alteration and Mineralogy of Coals under the Influence of Fault Motion: A Case Study of Qi’nan Colliery, China. Minerals 2019, 9, 389. [Google Scholar] [CrossRef] [Green Version]

- Deng, X.; Hu, Q.; Wei, S. Genesis and Property Classification of Tectonic Coal. J. Eng. Geol. 2014, 22, 1008–1014. [Google Scholar] [CrossRef]

- Ju, Y.; Jiang, B.; Hou, Q.; Wang, G. The new structure-genetic classification system in tectonically deformed coals and its geological significance. J. China Coal Soc. 2004, 29, 513–517. [Google Scholar]

- Yu, S.; Bo, J.; Ming, L.; Chenliang, H.; Shaochun, X. A Review on Pore-Fractures in Tectonically Deformed Coals. Fuel 2020, 278, 118248. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Chen, T.; Xu, S.; Zhu, G. Experimental Study on Ultrasonic Velocity and Anisotropy of Tectonically Deformed Coal. Int. J. Coal Geol. 2017, 179, 242–252. [Google Scholar] [CrossRef]

- Hou, S.; Wang, X.; Wang, X.; Yuan, Y.; Pan, S.; Wang, X. Pore Structure Characterization of Low Volatile Bituminous Coals with Different Particle Size and Tectonic Deformation Using Low Pressure Gas Adsorption. Int. J. Coal Geol. 2017, 183, 1–13. [Google Scholar] [CrossRef]

- Jiang, B.; Qu, Z.; Wang, G.G.X.; Li, M. Effects of Structural Deformation on Formation of Coalbed Methane Reservoirs in Huaibei Coalfield, China. Int. J. Coal Geol. 2010, 82, 175–183. [Google Scholar] [CrossRef]

- Cheng, Y.; Pan, Z. Reservoir Properties of Chinese Tectonic Coal: A Review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Sang, S.; Zhou, X.; Liu, S.; Wang, H.; Cao, L.; Liu, H.; Li, Z.; Zhu, S.; Liu, C.; Huang, H.; et al. Research advances in theory and technology of the stress release applied extraction of coalbed methane from tectonically deformed coals. J. China Coal Soc. 2020, 45, 2531–2543. [Google Scholar] [CrossRef]

- Xu, J.; Xian, X.; Du, Y.; Zhang, G. An Experimental Study on the Mechanical Property of the Gas-filled Coal. J. Chongqing Univ. 1993, 5, 42–47. [Google Scholar]

- Tu, Q. Study on Apparent Physical Structure of Tectonic Coal and Spallation Development Mechanism of Coal and Gas Outburst. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2019. [Google Scholar]

- Sobczyk, J. A Comparison of the Influence of Adsorbed Gases on Gas Stresses Leading to Coal and Gas Outburst. Fuel 2014, 115, 288–294. [Google Scholar] [CrossRef]

- Skoczylas, N.; Dutka, B.; Sobczyk, J. Mechanical and Gaseous Properties of Coal Briquettes in Terms of Outburst Risk. Fuel 2014, 134, 45–52. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Yang, D.; Li, X.; Jiang, C. Experimental Analysis of the Intensity and Evolution of Coal and Gas Outbursts. Fuel 2018, 226, 252–262. [Google Scholar] [CrossRef]

- Yuan, M.; Xu, J.; Li, B.; Wang, Z.; Du, Y.; Xu, S. Experimental Study on Influence of Particle Size on Mechanical Properties and Permeability of Briquette Coal Containing Gas. Saf. Coal Mines 2016, 47, 24–27. [Google Scholar] [CrossRef]

- Pang, L.; Yang, Y.; Wu, L.; Wang, F.; Meng, H. Effect of Particle Sizes on the Physical and Mechanical Properties of Briquettes. Energies 2019, 12, 3618. [Google Scholar] [CrossRef] [Green Version]

- Ji, D.; Wang, Z.; Zhang, L.; Ma, Y. The examination study of the size-composition of the fine-coal briquetting. J. China Coal Soc. 2005, 30, 100–103. [Google Scholar]

- Tian, B.; Xu, D.; Yang, F.; Pang, Y.; Xu, R.; Lin, X.; Wang, Y. Briquetting Pressure and Fine Coal Particle Distribution Affected to Performances of Cool Pressed Briquette. Coal Sci. Technol. 2013, 41, 125–128. [Google Scholar] [CrossRef]

- Chen, L.; Yang, H.; Zhao, Y.; Li, X.; Sun, T. The influence of raw coal gradation on the strength of briquette. Min. Saf. Environ. Prot. 2001, 1, 6–7. [Google Scholar]

- Zhang, J.; Guo, Z.; Yang, J.; Sun, C.; Sheng, J.; Xu, Z. Orthogonal Experiment Analysis of Briquette for Influencing Factors. Coal Technol. 2016, 35, 287–288. [Google Scholar] [CrossRef]

- Xu, J.; Liu, D.; Peng, S.; Wu, X.; Lu, Q. Experimental Research on Influence of Particle Diameter on Coal and Gas Outburst. Chin. J. Rock Mech. Eng. 2010, 29, 1231–1237. [Google Scholar]

- Xu, J.; Ye, G.; Li, B.; Cao, Y.; Zhang, M. Experimental study of mechanical and permeability characteristics of moulded coals with different binder ratios. Rock Soil Mech. 2015, 36, 104–110. [Google Scholar] [CrossRef]

- Meng, L.; Liu, M.; Wang, Y. Study on the rules of electrical resistivity variation of tectonic coal in uniaxial compression experiment. J. China Coal Soc. 2010, 35, 2028–2032. [Google Scholar] [CrossRef]

- Wang, E.; Chen, P.; Li, Z.; Shen, R.; Xu, J.; Zhu, Y. Resistivity response in complete stress-strain process of loaded coal. J. China Coal Soc. 2014, 39, 2220–2225. [Google Scholar] [CrossRef]

- Chen, P.; Wang, E.; Zhu, Y. Experimental study on resistivity variation regularities of loading coal. J. China Coal Soc. 2013, 38, 548–553. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, Z.; Liu, Y. Revised coal or rock under load damage mechanics model of coupled stress & electricity. J. Henan Polytech. Univ. Nat. Sci. 2011, 30, 11–14. [Google Scholar] [CrossRef]

- Chen, P.; Wang, E.; Chen, X.; Liu, Z.; Li, Z.; Shen, R. Regularity and Mechanism of Coal Resistivity Response with Different Conductive Characteristics in Complete Stress–Strain Process. Int. J. Min. Sci. Technol. 2015, 25, 779–786. [Google Scholar] [CrossRef]

- Qiu, H. Study on Variation of Coal Rock Loaded Resistivity during Fracturing Process. World Sci. Tech. R D 2016, 38, 245–248. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q.; An, Z.; Chen, X.; Zhang, F. Experimental Research on Electrical Resistivity Variation of Coal under Different Loading Modes. Arab. J. Geosci. 2020, 13, 1068. [Google Scholar] [CrossRef]

- Li, X.; An, Z.; Zhang, Q.; Chen, X.; Ye, X.; Jia, S. Analysis of Resistivity Anisotropy of Loaded Coal Samples. Adv. Mater. Sci. Eng. 2020, 2020, 1–13. [Google Scholar] [CrossRef]

- Liu, E.; Shen, Z. Study on Brittleness of Geomaterials. Chin. J. Rock Mech. Eng. 2005, 19, 51–55. [Google Scholar] [CrossRef]

- Brace, W.F.; Orange, A.S. Electrical Resistivity Changes in Saturated Rock under Stress. Science 1966, 153, 1525–1526. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Lin, Y. Stress–Strain–Electrical Resistance Effects and Associated State Equations for Uniaxial Rock Compression. Int. J. Rock Mech. Min. Sci. 2004, 41, 223–236. [Google Scholar] [CrossRef]

- China University of Mining and Tchnology. Evaluation of Coal-Bed Methane Resources in Coal Mine Area; China University of Mining and Tchnology: Xuzhou, Jiangsu, China, 2007. [Google Scholar]

- Jiang, W.; Liu, Y. Study on variation of electrical resistivity under uniaxial pressure environment for rocks. J. Geol. 2009, 33, 299–302. [Google Scholar]

- Li, S.; Xu, X.; Liu, Z.; Yang, W.; Liu, B.; Zhang, X.; Wang, Z.; Nie, L.; Li, J.; Xu, L. Electrical Resistivity and Acoustic Emission Response Characteristics and Damage Evolution of Sandstone during Whole Process of Uniaxial Compression. Chin. J. Rock Mech. Eng. 2014, 33, 14–23. [Google Scholar] [CrossRef]

- Tarasov, B.; Potvin, Y. Universal Criteria for Rock Brittleness Estimation under Triaxial Compression. Int. J. Rock Mech. Min. Sci. 2013, 59, 57–69. [Google Scholar] [CrossRef]

- Wu, G.; Wang, K.; Zhao, M.; Nie, Z.; Huang, Z. Analysis of Damage Evolution of Sandstone under Uniaxial Loading and Unloading Conditions Based on Resistivity Characteristics. Adv. Civ. Eng. 2019, 2019, 9286819. [Google Scholar] [CrossRef]

| Items | Mad | Ad | Vdaf | St.d | C | H | O | N |

|---|---|---|---|---|---|---|---|---|

| Content (%) | 2.30 | 19.70 | 36.92 | 0.52 | 84.41 | 5.39 | 8.85 | 1.34 |

| Number | Particle | Grade | Cu | Cc | ϕ/mm | Density/g·cm−3 | Resistivity/MΩ·m |

|---|---|---|---|---|---|---|---|

| GD100 | Φ1 | 1:0:0 | 2.43 | 1.42 | 3.500 | 1.40 | 0.0688 |

| GD010 | Φ2 | 0:1:0 | 2.15 | 0.32 | 0.625 | 1.31 | 0.0681 |

| GD001 | Φ3 | 0:0:1 | 6 | 0.04 | 0.125 | 1.29 | 0.0523 |

| GF111 | Φ1Φ2Φ3 | 1:1:1 | 11.33 | 0.06 | 0.304 | 1.37 | 0.0598 |

| GF114 | Φ1Φ2Φ3 | 1:1:4 | 6 | 0.06 | 0.177 | 1.34 | 0.0681 |

| GF118 | Φ1Φ2Φ3 | 1:1:8 | 6 | 0.05 | 0.152 | 1.33 | 0.0264 |

| GF141 | Φ1 Φ2Φ3 | 1:4:1 | 4.89 | 0.22 | 0.409 | 1.32 | 0.0408 |

| GF181 | Φ1Φ2Φ3 | 1:8:1 | 2.88 | 0.27 | 0.474 | 1.34 | 0.0447 |

| GF411 | Φ1Φ2Φ3 | 4:1:1 | 17.22 | 0.31 | 0.559 | 1.40 | 0.0369 |

| GF811 | Φ1Φ2Φ3 | 8:1:1 | 16 | 0.56 | 0.841 | 1.39 | 0.0308 |

| Number | Compaction Modulus e/MPa | Elastic Modulus E/MPa | Postpeak Modulus M/MPa | Brittleness Indexk |

|---|---|---|---|---|

| GD100 | 1.75 | 41.63 | −35.93 | 2.16 |

| GD010 | 1.58 | 43.82 | −41.31 | 2.06 |

| GD001 | 3.71 | 59.28 | −525.16 | 1.11 |

| GF111 | 3.90 | 83.96 | −143.41 | 1.59 |

| GF114 | 3.76 | 102.33 | −126.73 | 1.81 |

| GF118 | 6.37 | 125.40 | −147.82 | 1.85 |

| GF141 | 5.01 | 48.60 | −45.91 | 2.06 |

| GF181 | 5.59 | 45.08 | −41.65 | 2.08 |

| GF411 | 9.75 | 75.68 | −96.09 | 1.79 |

| GF811 | 5.10 | 65.95 | −62.97 | 2.05 |

| Mechanical Parameters | Particle Size Large→Small | Proportion of Different Particle Less→More | ||

|---|---|---|---|---|

| Coarse (1 mm~5 mm) | Medium (0.25 mm~1 mm) | Fine (0~0.25 mm) | ||

| Strength | Increase | Less decrease | Most decrease | Increase first then slightly decrease |

| Elastic modulus | Increase | Decrease | Decrease | Increase first then decrease |

| Yield performance | Approach brittleness | Second approach ductility | Most approach ductility | Least approach ductility |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, C.; Cao, L.; Geng, J.; Jiang, Z.; Zhang, S. Experimental Analysis of the Mechanical Properties and Resistivity of Tectonic Coal Samples with Different Particle Sizes. Energies 2021, 14, 2303. https://doi.org/10.3390/en14082303

Zhong C, Cao L, Geng J, Jiang Z, Zhang S. Experimental Analysis of the Mechanical Properties and Resistivity of Tectonic Coal Samples with Different Particle Sizes. Energies. 2021; 14(8):2303. https://doi.org/10.3390/en14082303

Chicago/Turabian StyleZhong, Congyu, Liwen Cao, Jishi Geng, Zhihao Jiang, and Shuai Zhang. 2021. "Experimental Analysis of the Mechanical Properties and Resistivity of Tectonic Coal Samples with Different Particle Sizes" Energies 14, no. 8: 2303. https://doi.org/10.3390/en14082303