Analysis of Wind Turbine Aging through Operation Data Calibrated by LiDAR Measurement

Abstract

1. Introduction

2. Analysis Data

2.1. Shinan Wind Farm

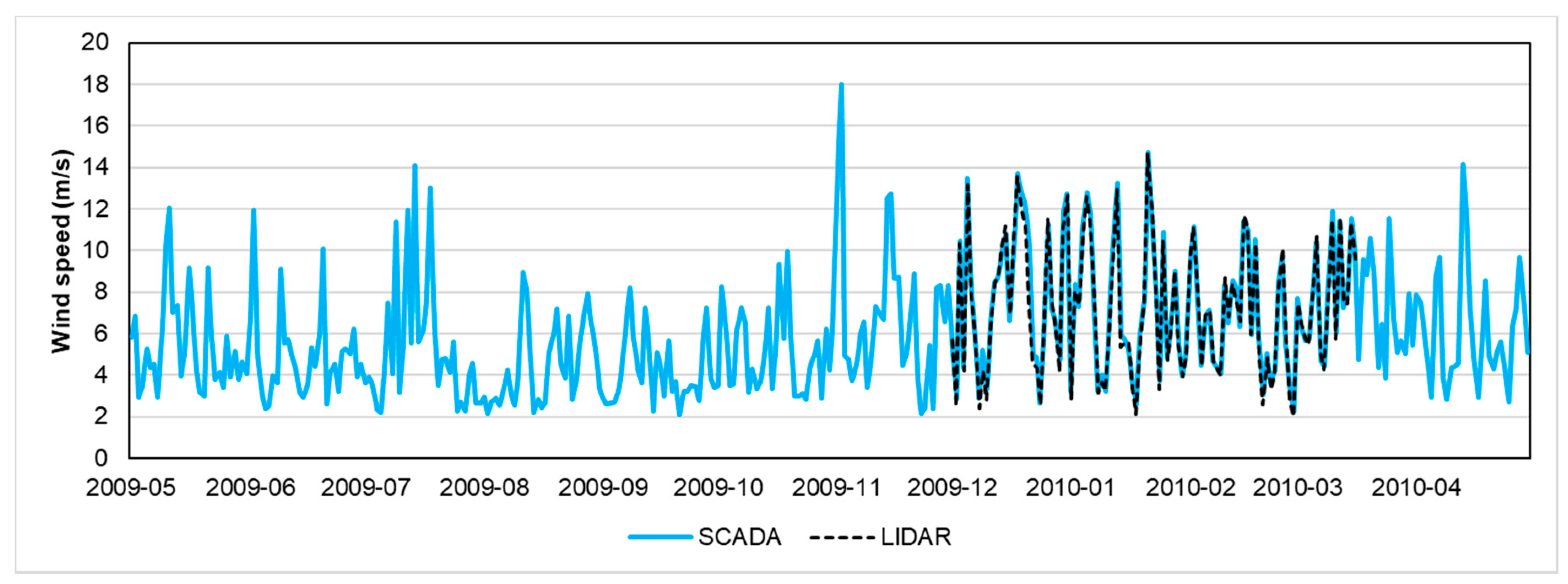

2.2. LiDAR Measurement Campaign

3. Analysis Methods

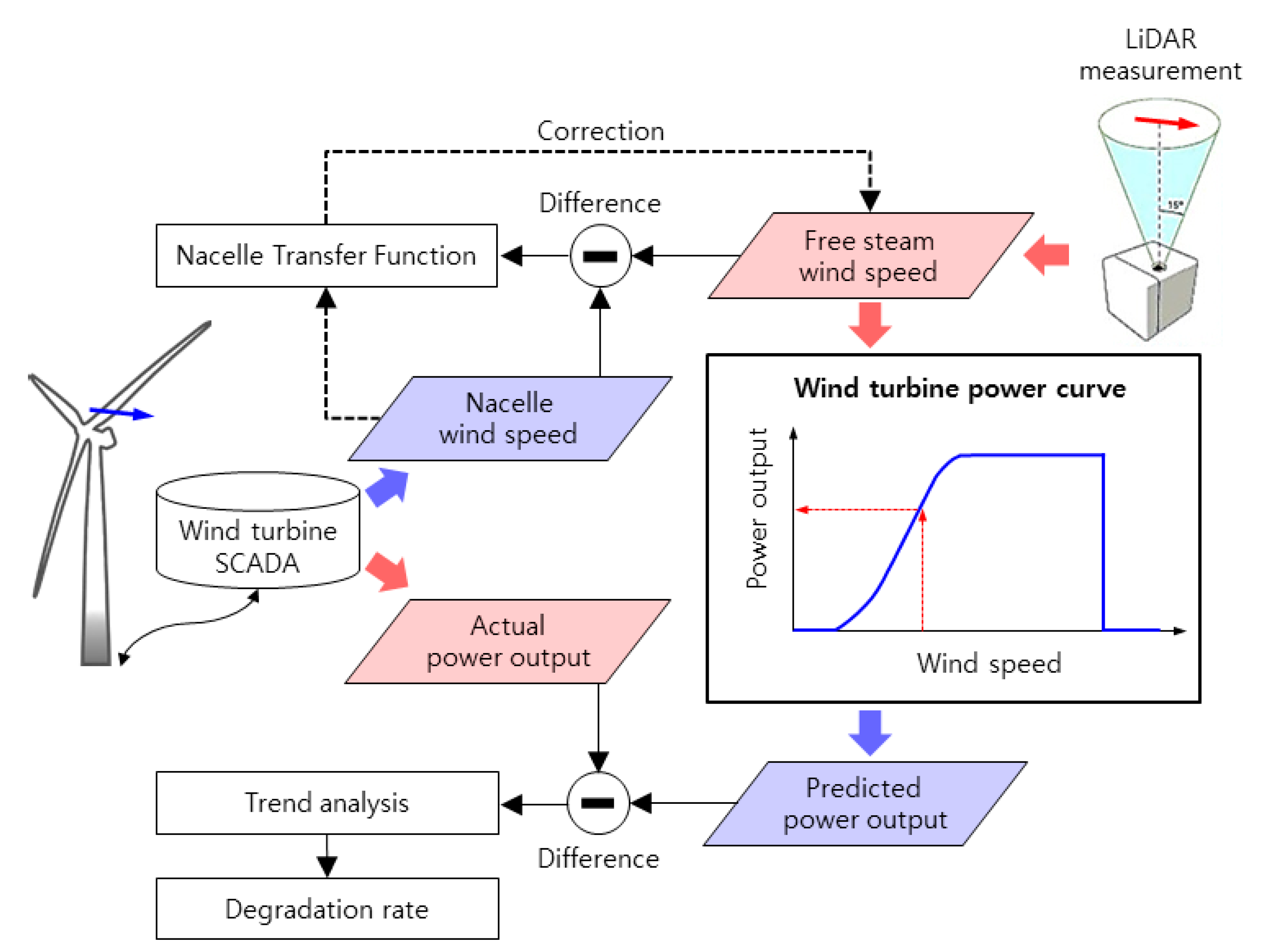

3.1. Derivation of the Nacelle Transfer Function

3.2. Trend Analysis of Wind Turbine Deterioration

- (1)

- The nacelle wind speed (Vnacelle) is calibrated to free stream wind speed (Vcorrected) using the NTF derived in Section 3.1.

- (2)

- The effective wind speed (Veff) is calculated to compensate the effect of air density when the performance curve is applied as follows. In the equation below, refers to the standard air density when the wind turbine performance curve is derived. The seasonal temperature change in Korea is about 26 °C, so accurate air density calculation is essential for wind resource assessment. In this study, air density was calculated using SCADA data and the nearby weather station data (located 2.5 km behind) such as air temperature, air pressure, and humidity.

- (3)

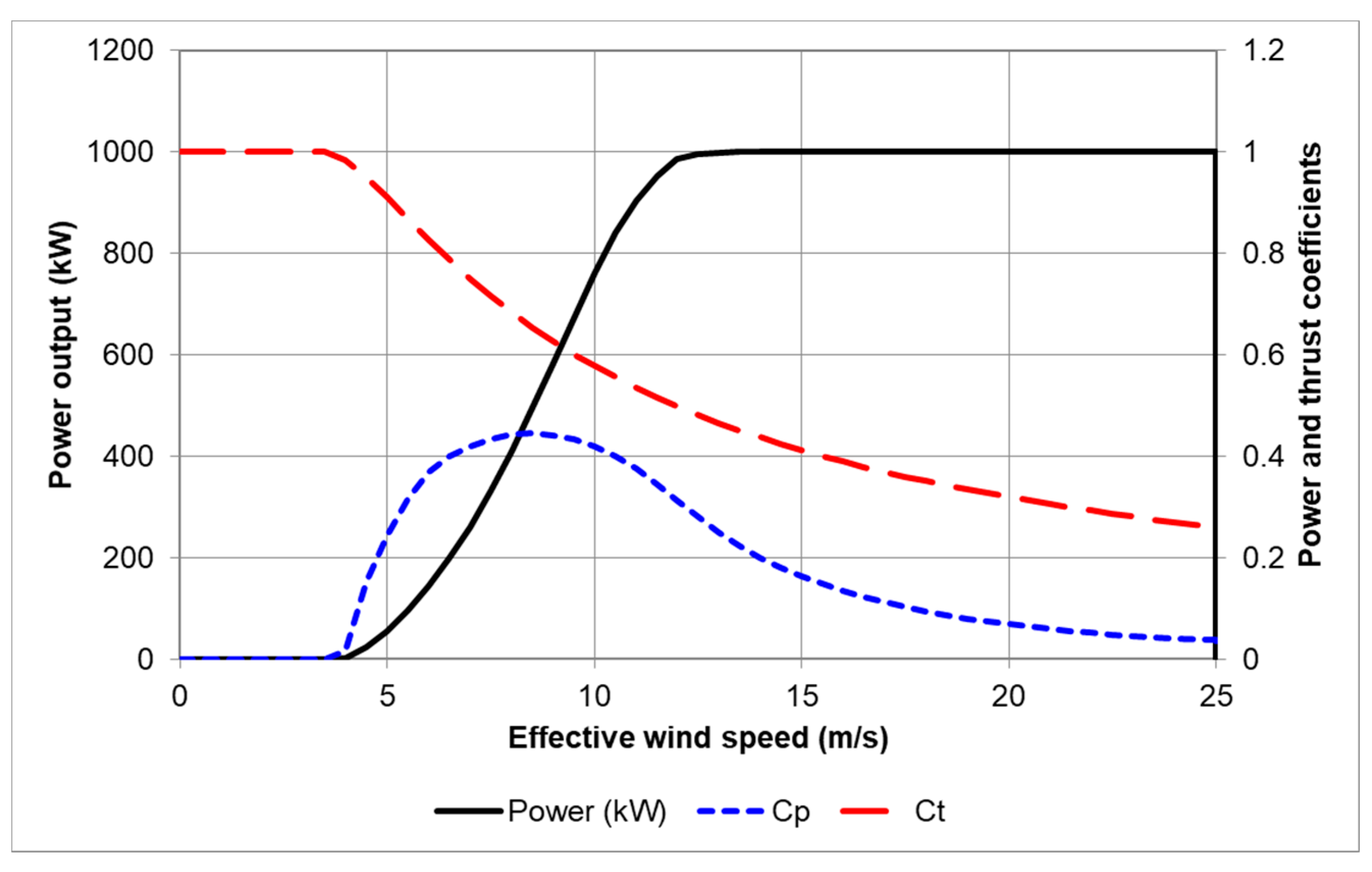

- The theoretically predicted power generation (Ppredicted) is calculated by substituting the effective wind speed (Veff) into the performance curve of the Mitsubishi MWT-1000A wind turbine (Figure 6). ‘Power output deficit’ (dP) refers to the difference between predicted and actual (PSCADA) power generation in a 10 min average.

- (4)

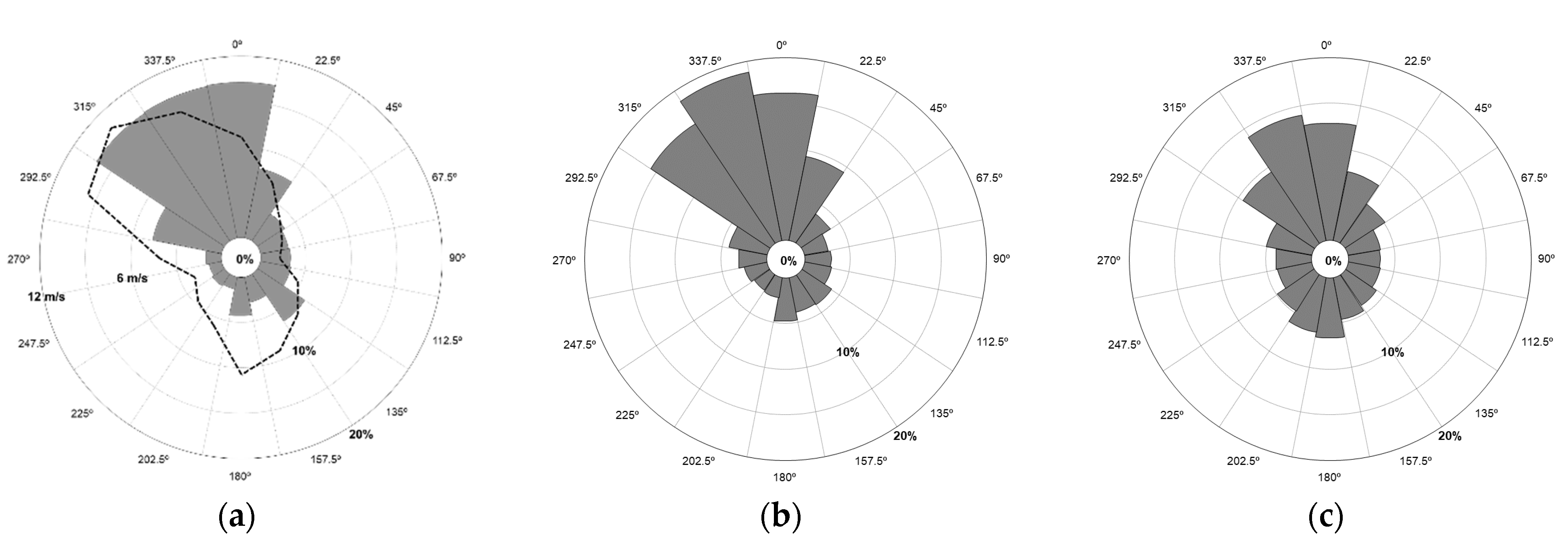

- Statistical outliers that are not included within 95% of the statistical distribution of the 10 min average power output deficit were eliminated. Note that the special care is needed when treating outliers if there were power curtailments. In this study, there was no power curtailment and non-operating period (PSCADA ≤ 0) were excluded.In addition, data other than the 285–0° and 0–35° sectors were also excluded. Figure 7 shows surface roughness length distribution around the LiDAR location where the disturbed wind directions due to wind turbine tower shading, wake zone, and topographic effect are identified [22]. The reason behind the selection of northerly winds (285–0° and 0–35°) only was to single out only sea breeze cases that can exclude influence factors due to wake and terrain features.The surface roughness length (zo) was calculated by a linear least square method to fit a logarithmic wind speed profile (Equation (6)) to measured wind speed data by LiDAR at 40 m, 70 m, and 100 m heights above ground. In the equation below, and κ are the friction velocity and von Kármán constant, respectively.

- (5)

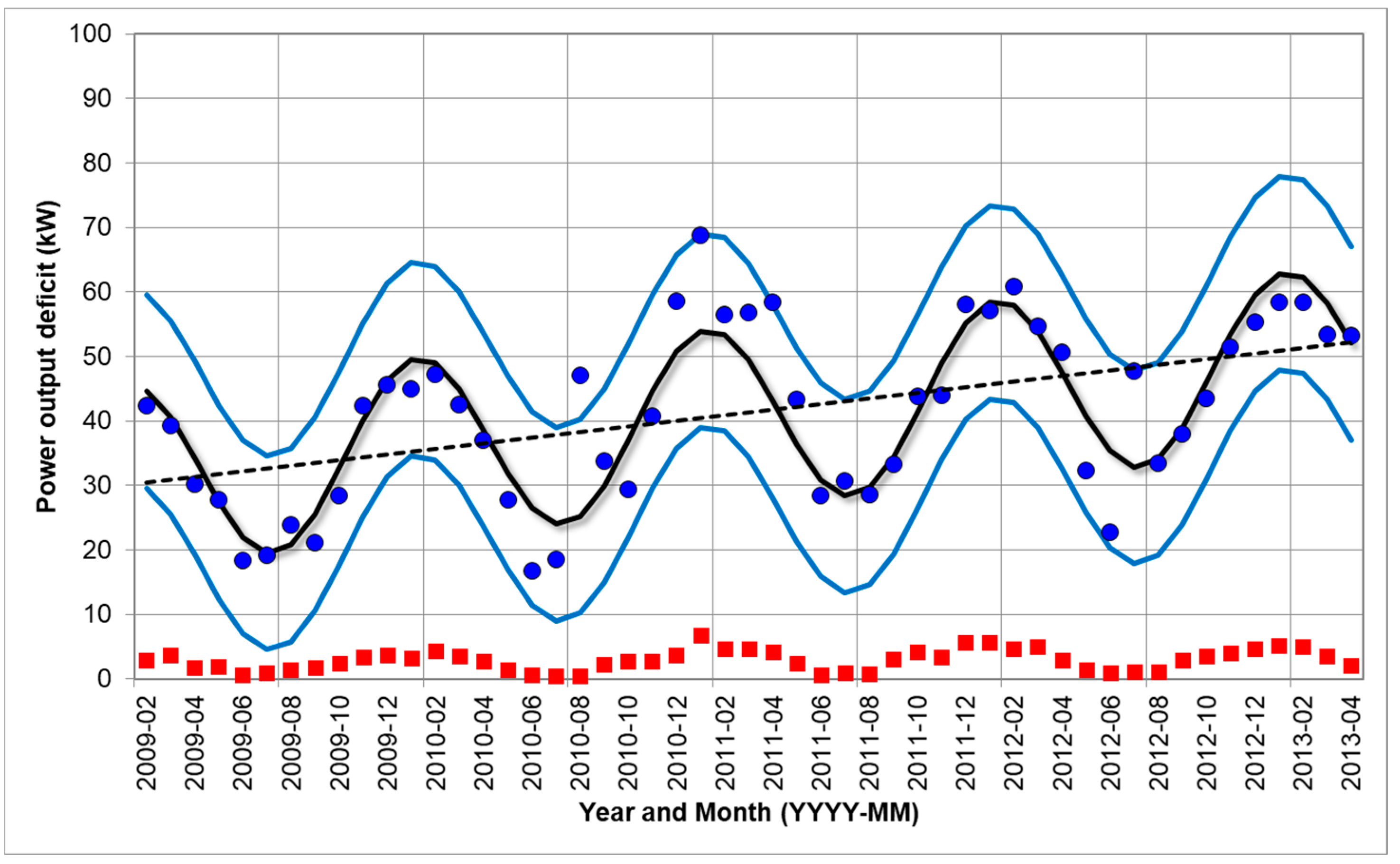

- Finally, the wind turbine deterioration rate was determined through the slope in the analysis of the monthly average of 10 min averaged power output deficit trend.

4. Results and Discussion

4.1. Derivation of the Nacelle Transfer Function

4.2. Analysis of the Wind Turbine Deterioration Trend

5. Conclusions

- (1)

- The trend analysis of power output deficit at the Shinan wind farm over 4 years showed that the rate of performance aging was –0.52%p per year, and that it progressed linearly. This value was similar to the figure of –0.48%p per year obtained for onshore wind farms in the UK, and −0.54%p per year in the US. This result implies that generally about 10% of performance aging occurs over the 20 years of wind farm operation, and this figure should be reflected when evaluating the cost of wind energy and setting national target.

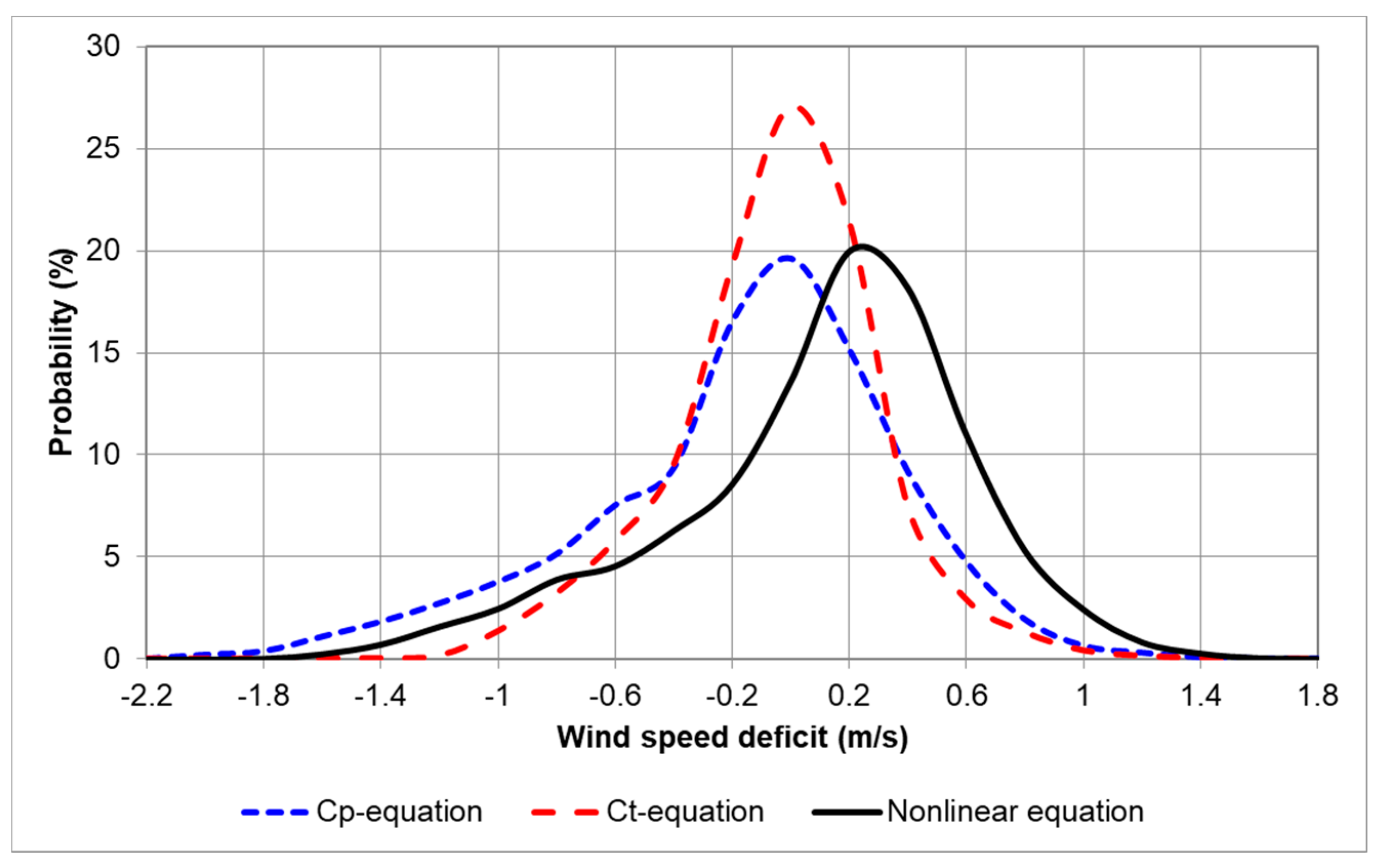

- (2)

- It was presumed that the nacelle wind speed is affected nonlinearly depending on the wind turbine’s control mode and related to the performance aging. Despite that the prediction accuracy of wind power output was significantly improved when the nacelle wind speed was corrected using the NTF based on CT curve, it was found that the performance aging is not directly affected by this correction. Since the wind turbine aging occurs in the mechanical drive, the nacelle wind speed is not affected by the aging of blade control mechanism. Therefore, it is conjectured that the correction using NTF is not mandatory when analyzing the performance aging of wind turbines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| IEC | International Electrotechnical Commission |

| LiDAR | Light Detection and Ranging |

| NTF | Nacelle Transfer Function |

| MERRA | Modern-Era Retrospective analysis for Research and Applications |

| SCADA | Supervisory Control And Data Acquisition |

| SODAR | SOnic Detection And Ranging |

References

- International Electrotechnical Commission. Wind Turbine, Part. 1: Design Requirement, IEC 61400-1, 3rd ed.; IEC: Geneva, Switzerland, 2005. [Google Scholar]

- Le, B.; Andrews, J. Modelling wind turbine degradation and maintenance. Wind Energy 2016, 19, 571–591. [Google Scholar] [CrossRef]

- Hughes, G. The Performance of Wind Farms in the United Kingdom and Denmark; Renewable Energy Foundation: London, UK, 2012; 48p. [Google Scholar]

- Bach, P.F. Capacity Factor Degradation for Danish Wind Turbines; Paul-Frederik Bach Consulting: Switzerland, 2012; 4p. [Google Scholar]

- Harrison, J. Economic Analysis of the Algonquin Power Company Amherst Island Wind Energy Generation System; Association to Protect Amherst Island: Amherst Island, ON, Canada, 2013. [Google Scholar]

- Staffell, I.; Green, R. How does wind farm performance decline with age? Renew. Energy 2014, 66, 775–786. [Google Scholar] [CrossRef]

- Byrne, R.; Astolfi, D.; Castellani, F.; Hewitt, N.J. A study of wind turbine performance decline with age through operation data analysis. Energies 2020, 13, 2086. [Google Scholar] [CrossRef]

- Astolfi, D.; Byrne, R.; Castellani, F. Analysis of wind turbine aging through operation curves. Energies 2020, 13, 5623. [Google Scholar] [CrossRef]

- Hamilton, S.D.; Millstein, D.; Bolinger, M.; Wiser, R.; Jeong, S.G. How Does Wind Project Performance Change with Age in the United States? Joule 2020, 4, 1–16. [Google Scholar] [CrossRef]

- Shin, D.H.; Ko, K.N.; Huh, J.C. A study on method for identifying capacity factor declination of wind turbines. Int. J. Environ. Ecol. Eng. 2015, 9, 55–59. [Google Scholar]

- Kim, H.G.; Jang, M.S.; Ko, S.H. Long-term wind resource mapping of Korean west-south offshore for the 2.5 GW offshore wind power project. J. Environ. Sci. Int. 2013, 22, 1305–1316. [Google Scholar] [CrossRef]

- Ministry of Trade, Industry and Energy. New & Renewable Energy Statistics 2019; Korea Energy Agency: Seoul, Korea, 2020.

- Kim, H.G.; Jeon, W.H.; Kim, D.H. Wind resource assessment for high-rise BIWT using RS-NWP-CFD. Remote Sens. 2016, 8, 1019. [Google Scholar] [CrossRef]

- Kim, H.G.; Meissner, C. Correction of LiDAR measurement error in complex terrain by CFD—Case study of the Yangyang pumped storage plant. Wind Eng. 2017, 41, 226–234. [Google Scholar] [CrossRef]

- Kim, H.G.; Kim, J.Y.; Kang, Y.H. Comparative evaluation of the third-generation reanalysis data for wind resource assessment of the southwestern offshore in South Korea. Atmosphere 2018, 9, 73. [Google Scholar]

- International Electrotechnical Commission. Wind Turbines—Part 12-2: Power Performance of Electricity Producing wind Turbines Based on Nacelle Anemometry; IEC 61400-12-2; IEC: Geneva, Switzerland, 2008. [Google Scholar]

- Kim, H.G.; Kang, Y.H.; Yun, C.Y. Derivation of nacelle transfer function using LiDAR measurement. Trans. Korean Soc. Mech. Eng. A 2015, 39, 929–936. [Google Scholar] [CrossRef]

- Kim, H.G. Method of calibration of nacelle anemometer using LiDAR measurements. In Korea Patent, 10-1383792; Korea Institute of Energy Research: Daejeon, Korea, 2014. [Google Scholar]

- Ormel, F.T.; Donth, A.; Siebers, T.; Faucherre, C.; Luetze, H. Correction method for wind speed measurement at wind turbine nacelle. In European Patent, 1793123B1; GE International Inc.: Munich, Germany, 2016. [Google Scholar]

- Martin, C.M.; Lundquist, J.K.; Clifton, A.; Poulos, G.S.; Schreck, S.J. Atmospheric turbulence affects wind turbine nacelle transfer functions. Wind Energy Sci. 2017, 2, 295–306. [Google Scholar] [CrossRef]

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 978-0-470-69975-1. [Google Scholar]

- Castellani, F.; Astolfi, D.; Mana, M.; Piccioni, E.; Becchetti, M.; Terzi, L. Investigation of terrain and wake effects on the performance of wind farms in complex terrain using numerical and experimental data. Wind Energy 2017, 20, 1277–1289. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-G.; Kim, J.-Y. Analysis of Wind Turbine Aging through Operation Data Calibrated by LiDAR Measurement. Energies 2021, 14, 2319. https://doi.org/10.3390/en14082319

Kim H-G, Kim J-Y. Analysis of Wind Turbine Aging through Operation Data Calibrated by LiDAR Measurement. Energies. 2021; 14(8):2319. https://doi.org/10.3390/en14082319

Chicago/Turabian StyleKim, Hyun-Goo, and Jin-Young Kim. 2021. "Analysis of Wind Turbine Aging through Operation Data Calibrated by LiDAR Measurement" Energies 14, no. 8: 2319. https://doi.org/10.3390/en14082319

APA StyleKim, H.-G., & Kim, J.-Y. (2021). Analysis of Wind Turbine Aging through Operation Data Calibrated by LiDAR Measurement. Energies, 14(8), 2319. https://doi.org/10.3390/en14082319