Analysis of Synthetic Voltage vs. Capacity Datasets for Big Data Li-ion Diagnosis and Prognosis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Half-Cell Data

2.2. Simulations

2.3. FOI Definition and Selection

3. Results

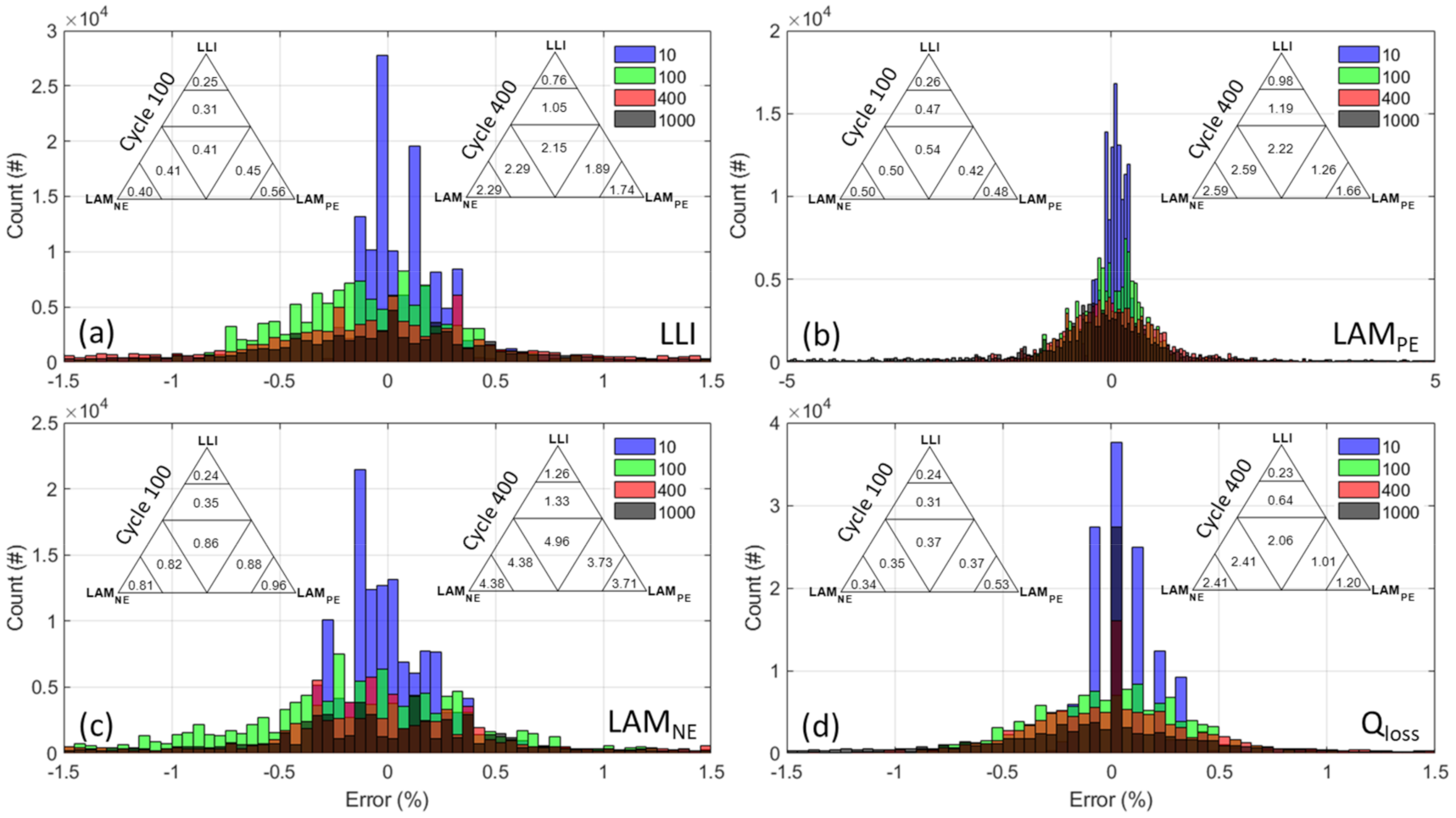

3.1. FOI vs. Diagnosis

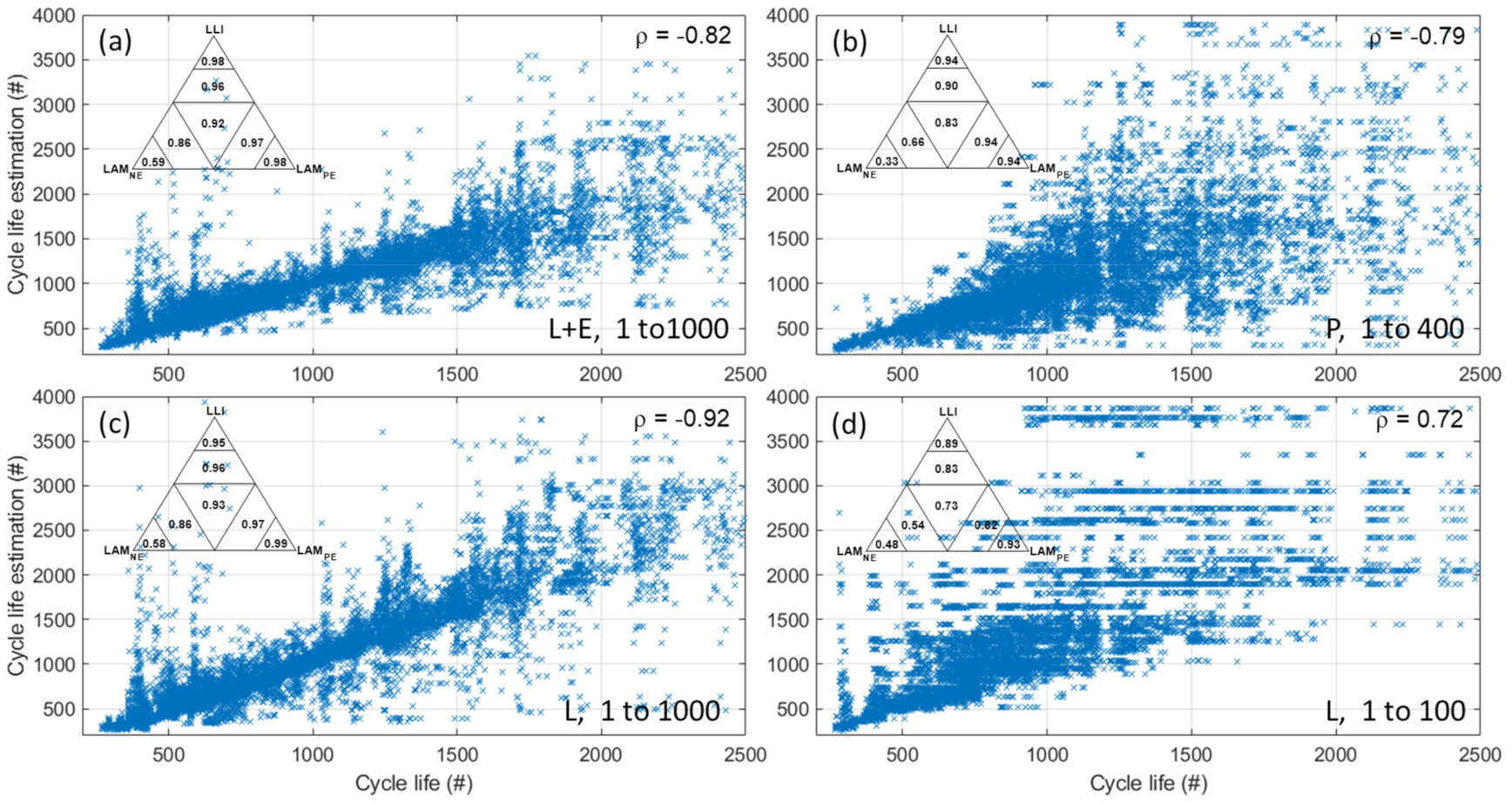

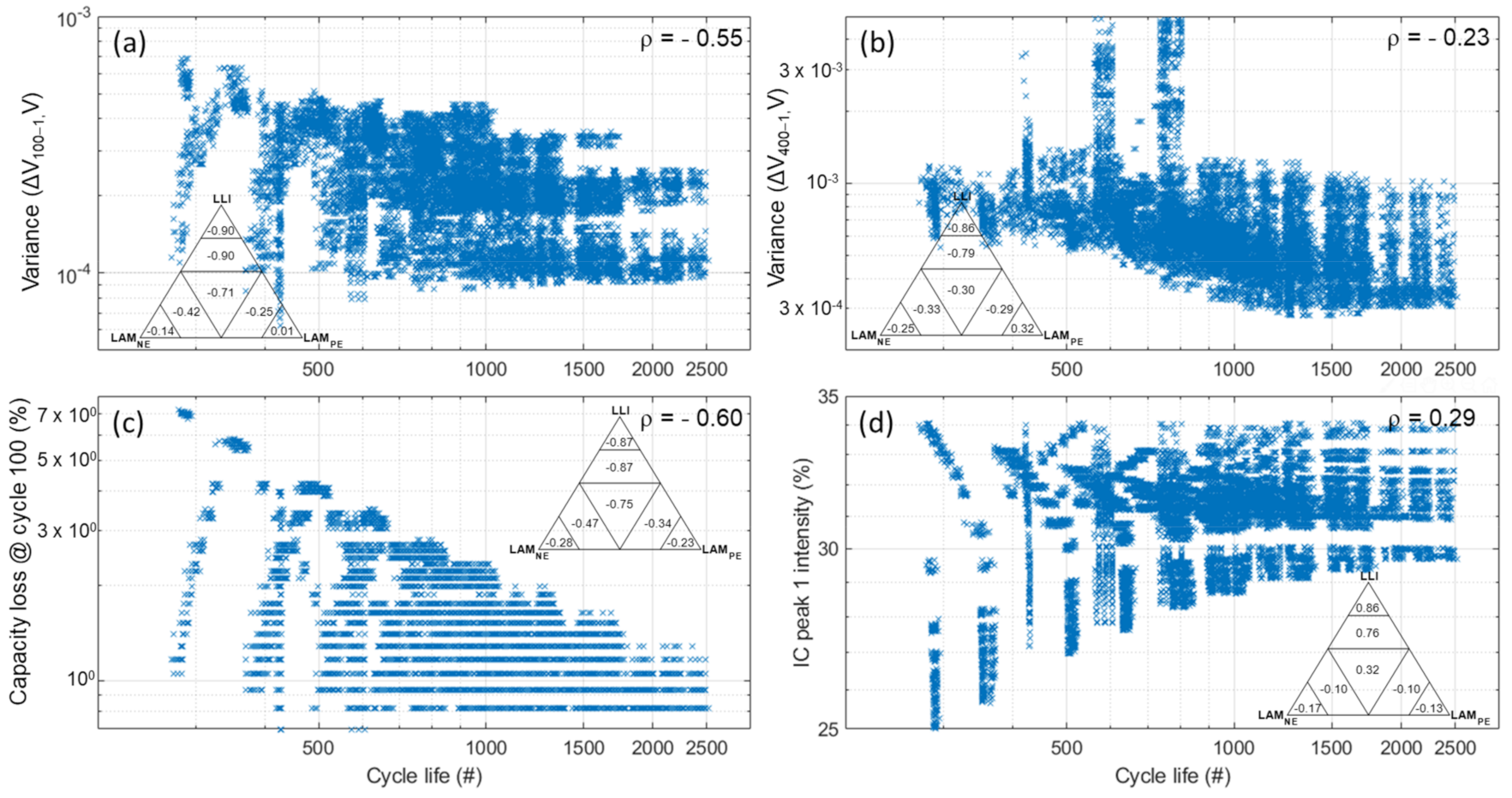

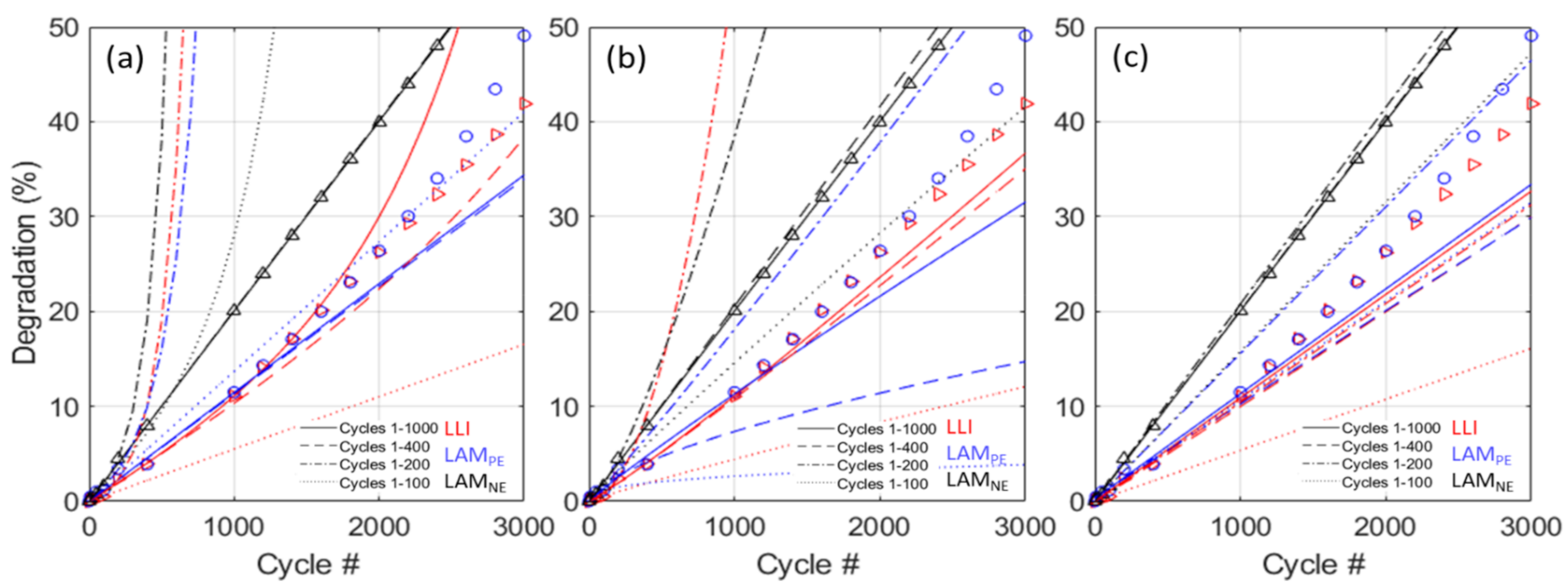

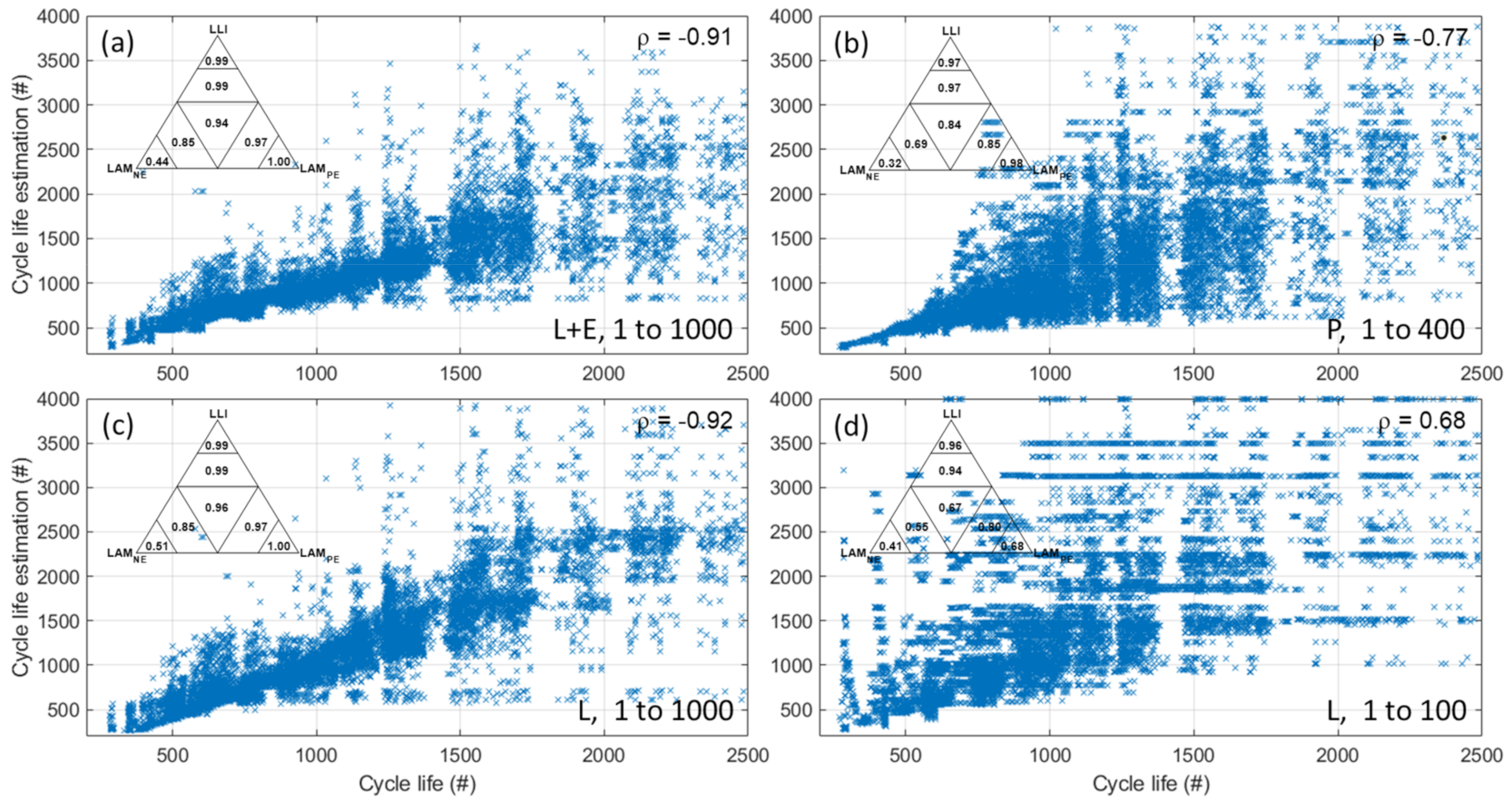

3.2. Learnable Parameters vs. Early Prognosis

4. Discussion

4.1. Diagnosis

4.2. Early Prognosis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Simulation Parameters

Appendix A.1. Cell Emulation

| Parameter | LFP | NCA | NMC811 |

|---|---|---|---|

| PE | ANR26650M [23,45] | NCR 18650B [35,40,41,42,43] | INR18650-35E [44] |

| NE | ANR26650M [23,45] | NCR 18650B [35,40,41,42,43] | Stock electrode |

| Loading ratio | 0.95 | 1.05 | 0.90 |

| Offset | 12.5 | 1.5 | 10 |

| Resistance adjustment | −0.07 | −0.18 | 0 |

| PE kinetic adjustment | None | None | None |

| NE kinetic adjustment | None | 0.75 | None |

Appendix A.2. Duty Cycle Calculations

| Parameter | Description | Values (% per Cycle) |

|---|---|---|

| p1 | Linear Coeff. LLI | 0.007, 0.010, 0.013, 0.017, 0.021, 0.027, 0.034, 0.048, 0.06 |

| p2 | Exp. Coeff. LLI | 0.000001, 0.002, 0.0033 |

| p3 | Delay Exp. LLI | 600, 1200, 1800 |

| p4 | Linear Coeff. LAMPE | 0.001, 0.005, 0.01, 0.015, 0.02, 0.025, 0.03, 0.0375, 0.05, 0.07 |

| p5 | Exp. Coeff. LAMPE | 0.000001, 0.001, 0.0013 |

| p6 | Linear Coeff. LAMNE | 0.001, 0.005, 0.0,1 0.015, 0.02, 0.025, 0.03, 0.0375, 0.05, 0.07 |

| p7 | Exp. Coeff. LAMNE | 0.000001, 0.001, 0.0013 |

| p8 | Plating Reversibility | 0, 50, 100 |

Appendix A.3. FOI Selection and Resolution

| FOI | Description | Resolution in 3D Map |

|---|---|---|

| LFP-FOI1 | Area between 3.35 and 3.40 V | 0.4% Q |

| LFP-FOI2 | Area between 3.20 and 3.35 V | 0.6% Q |

| LFP-FOI3 | Position maximum between 3.00 and 3.25 V | 0.002 V |

| LFP-FOI4 | Intensity maximum between 3.00 and 3.25 V | 3.5% Q/V |

| LFP-FOI5 | Area between 3.42 and 3.50 V | 1.0% Q |

| NCA-FOI1 | Area between 4.02 and 4.05 V | 0.04%Q |

| NCA-FOI2 | Position minimum between 3.60 and 3.98 V | 0.004 V |

| NCA-FOI3 | Intensity minimum between 3.60 and 3.98 V | 1.2% Q/V |

| NCA-FOI4 | Capacity difference between 2 peaks between 20 and 60% Q | 0.4% Q |

| NCA-FOI5 | Area between 4.15 and 4.255 V | 0.1% Q |

| NCA-FOI6 | Intensity maximum between 3.00 and 3.6 V | 6% Q/V |

| NCA-FOI7 | Position maximum between 3.00 and 3.6 V | 0.006 V |

| NMC-FOI1 | Area between 4.02 and 4.05 V | 0.04% Q |

| NMC-FOI2 | Position minimum between 3.60 and 3.98 V | 0.004 V |

| NMC-FOI3 | Intensity minimum between 3.60 and 3.98 V | 1% Q/V |

| NMC-FOI4 | Capacity difference between 2 peaks between 20 and 60% Q | 0.4% Q |

| NMC-FOI5 | Area between 4.15 and 4.295 V | 0.18 % Q |

| NMC-FOI6 | Intensity maximum between 3.00 and 3.59 V | 3% Q/V |

| NMC-FOI7 | Position maximum between 3.00 and 3.59 V | 0.006 V |

Appendix B. Supplementary Tables and Figures

Appendix B.1. Gr//NCA, C/33 Charge

| LLI | LAMPE | LAMNE | Capacity Loss | |

|---|---|---|---|---|

| FOI1 | 0.08 | −0.98 | −0.08 | −0.44 |

| FOI2 | 0.73 | −0.46 | −0.41 | 0.24 |

| FOI3 | −0.89 | 0.18 | 0.11 | −0.48 |

| FOI4 | 0.08 | −0.51 | −0.64 | −0.50 |

| FOI5 | −0.35 | −0.65 | 0.64 | −0.49 |

| FOI6 | −0.63 | 0.53 | −0.24 | −0.40 |

| FOI7 | 0.68 | −0.66 | 0.18 | 0.27 |

| FOIs (1,2,4) | 0.95 | 0.96 | 0.89 | 0.97 |

| FOIs (1,3,4) | 0.85 | 0.96 | 0.92 | 0.82 |

| FOIs (1,5,4) | 0.74 | 0.98 | 0.89 | 0.88 |

| FOIs (1,6,4) | 0.89 | 0.95 | 0.89 | 0.93 |

| FOIs (1,7,4) | 0.83 | 0.96 | 0.90 | 0.88 |

| LLI | LAMPE | LAMNE | Capacity Loss | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle 10 | 0.07 | ± | 0.16 | 0.07 | ± | 0.17 | −0.01 | ± | 0.20 | 0.06 | ± | 0.15 |

| Cycle 50 | −0.11 | ± | 0.27 | −0.12 | ± | 0.43 | −0.15 | ± | 0.41 | −0.11 | ± | 0.30 |

| Cycle 100 | −0.10 | ± | 0.42 | −0.02 | ± | 0.50 | −0.18 | ± | 0.83 | −0.01 | ± | 0.35 |

| Cycle 200 | −0.14 | ± | 0.95 | 0.13 | ± | 0.97 | −0.16 | ± | 2.30 | 0.14 | ± | 0.76 |

| Cycle 400 | −0.09 | ± | 2.28 | 0.29 | ± | 2.57 | −0.17 | ± | 4.37 | 0.42 | ± | 2.39 |

| Cycle 1000 | −0.67 | ± | 7.22 | −0.02 | ± | 5.21 | −2.64 | ± | 9.02 | 0.08 | ± | 4.96 |

| Linear Fit, Cycles 1–200 | Linear Fit, Cycles 1–100 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| ρ | RMSE | MAPE | R2 | ρ | RMSE | MAPE | R2 | ||

| >50% LLI | 0.96 | 191 | 6 | 0.75 | 0.83 | 403 | 15 | −0.12 | |

| >80% LLI | 0.97 | 87 | 3 | 0.94 | 0.89 | 273 | 8 | 0.38 | |

| >50% LAMPE | 0.96 | 102 | 7 | 0.78 | 0.82 | 321 | 11 | −1.24 | |

| >80% LAMPE | 0.98 | 32 | 5 | 0.92 | 0.93 | 71 | 7 | 0.63 | |

| >50% LAMNE | 0.65 | 616 | 43 | −1.41 | 0.54 | 968 | 69 | −4.95 | |

| >80% LAMNE | 0.60 | 487 | 22 | −0.34 | 0.48 | 1059 | 38 | −5.34 | |

| <50% all | 0.86 | 335 | 17 | −0.12 | 0.73 | 591 | 38 | −2.48 | |

Appendix B.2. GIC//NMC811 C/25 Charges

| LLI | LAMPE | LAMNE | Capacity Loss | |

|---|---|---|---|---|

| FOI1 | 0.10 | −0.95 | −0.08 | 0.05 |

| FOI2 | 0.51 | −0.24 | −0.04 | 0.45 |

| FOI3 | 0.63 | −0.65 | 0.08 | 0.57 |

| FOI4 | −0.46 | 0.03 | −0.96 | −0.57 |

| FOI5 | −0.09 | −0.89 | 0.36 | −0.06 |

| FOI6 | 0.41 | −0.18 | −0.13 | 0.35 |

| FOI7 | 0.42 | −0.41 | 0.44 | 0.45 |

| FOIs (1,2,4) | 0.98 | 0.94 | 0.94 | 0.98 |

| FOIs (1,3,4) | 0.89 | 0.92 | 0.94 | 0.90 |

| FOIs (1,5,4) | 0.65 | 0.96 | 0.94 | 0.69 |

| FOIs (1,6,4) | 0.70 | 0.92 | 0.94 | 0.72 |

| FOIs (1,7,4) | 0.94 | 0.93 | 0.94 | 0.95 |

| LLI | LAMPE | LAMNE | Capacity Loss | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle 10 | 0.11 | ± | 0.20 | 0.15 | ± | 0.19 | 0.08 | ± | 0.22 | 0.12 | ± | 0.22 |

| Cycle 50 | −0.11 | ± | 0.31 | −0.14 | ± | 0.53 | −0.11 | ± | 0.52 | −0.12 | ± | 0.36 |

| Cycle 100 | −0.08 | ± | 0.32 | −0.08 | ± | 0.57 | −0.09 | ± | 0.59 | −0.08 | ± | 0.38 |

| Cycle 200 | 0.16 | ± | 1.37 | 0.14 | ± | 1.52 | 0.17 | ± | 1.82 | 0.27 | ± | 1.85 |

| Cycle 400 | 0.45 | ± | 3.14 | 0.67 | ± | 3.73 | 0.91 | ± | 4.56 | 0.99 | ± | 4.07 |

| Cycle 1000 | −0.62 | ± | 5.58 | 0.23 | ± | 5.34 | −0.59 | ± | 8.48 | 0.28 | ± | 5.06 |

| Linear Fit, Cycles 1–200 | Linear Fit, Cycles 1–100 | |||||||

|---|---|---|---|---|---|---|---|---|

| ρ | RMSE | MAPE | R2 | ρ | RMSE | MAPE | R2 | |

| >50% LLI | 0.97 | 117 | 7 | 0.87 | 0.96 | 131 | 8 | 0.84 |

| >80% LLI | 0.98 | 101 | 4 | 0.90 | 0.95 | 150 | 7 | 0.78 |

| >50% LAMPE | 0.83 | 277 | 33 | 0.01 | 0.70 | 517 | 34 | −2.45 |

| >80% LAMPE | 0.96 | 217 | 36 | −0.64 | 0.84 | 193 | 30 | −0.30 |

| >50% LAMNE | 0.86 | 308 | 14 | 0.55 | 0.62 | 786 | 22 | −1.92 |

| >80% LAMNE | 0.55 | 508 | 20 | −0.38 | 0.50 | 530 | 23 | −0.50 |

| <50% all | 0.86 | 238 | 13 | 0.47 | 0.79 | 484 | 21 | −1.18 |

References

- Raj, T.; Wang, A.A.; Monroe, C.W.; Howey, D.A. Investigation of Path-Dependent Degradation in Lithium-Ion Batteries. Batter. Supercaps 2020, 3, 1377–1385. [Google Scholar] [CrossRef]

- Gering, K.L.; Sazhin, S.V.; Jamison, D.K.; Michelbacher, C.J.; Liaw, B.Y.; Dubarry, M.; Cugnet, M. Investigation of path dependence in commercial lithium-ion cells chosen for plug-in hybrid vehicle duty cycle protocols. J. Power Sources 2011, 196, 3395–3403. [Google Scholar] [CrossRef]

- Ng, M.-F.; Zhao, J.; Yan, Q.; Conduit, G.J.; Seh, Z.W. Predicting the state of charge and health of batteries using data-driven machine learning. Nat. Mach. Intell. 2020, 2, 161–170. [Google Scholar] [CrossRef] [Green Version]

- Vidal, C.; Malysz, P.; Kollmeyer, P.; Emadi, A. Machine Learning Applied to Electrified Vehicle Battery State of Charge and State of Health Estimation: State-of-the-Art. IEEE Access 2020, 8, 52796–52814. [Google Scholar] [CrossRef]

- How, D.N.T.; Hannan, M.A.; Lipu, M.S.H.; Ker, P.J. State of Charge Estimation for Lithium-Ion Batteries Using Model-Based and Data-Driven Methods: A Review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Klass, V.; Behm, M.; Lindbergh, G. A support vector machine-based state-of-health estimation method for lithium-ion batteries under electric vehicle operation. J. Power Sources 2014, 270, 262–272. [Google Scholar] [CrossRef]

- Klass, V.; Behm, M.; Lindbergh, G. Evaluating Real-Life Performance of Lithium-Ion Battery Packs in Electric Vehicles. J. Electrochem. Soc. 2012, 159, A1856–A1860. [Google Scholar] [CrossRef]

- Hu, C.; Jain, G.; Schmidt, C.L.; Strief, C.; Sullivan, M. Online estimation of lithium-ion battery capacity using sparse Bayesian learning. J. Power Sources 2015, 289, 105–113. [Google Scholar] [CrossRef]

- Richardson, R.R.; Birkl, C.R.; Osborne, M.A.; Howey, D.A. Gaussian Process Regression for In Situ Capacity Estimation of Lithium-Ion Batteries. IEEE Trans. Ind. Inform. 2019, 15, 127–138. [Google Scholar] [CrossRef] [Green Version]

- Pan, H.; Lü, Z.; Wang, H.; Wei, H.; Chen, L. Novel battery state-of-health online estimation method using multiple health indicators and an extreme learning machine. Energy 2018, 160, 466–477. [Google Scholar] [CrossRef]

- Attia, P.M.; Grover, A.; Jin, N.; Severson, K.A.; Markov, T.M.; Liao, Y.-H.; Chen, M.H.; Cheong, B.; Perkins, N.; Yang, Z.; et al. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nat. Cell Biol. 2020, 578, 397–402. [Google Scholar] [CrossRef] [Green Version]

- Cripps, E.; Pecht, M. A Bayesian nonlinear random effects model for identification of defective batteries from lot samples. J. Power Sources 2017, 342, 342–350. [Google Scholar] [CrossRef]

- Roman, D.; Saxena, S.; Robu, V.; Pecht, M.; Flynn, D. Machine learning pipeline for battery state-of-health estimation. Nat. Mach. Intell. 2021, 1–10. [Google Scholar] [CrossRef]

- Attia, P.M.; Severson, K.A.; Witmer, J.D. Statistical learning for accurate and interpretable battery lifetime prediction. arXiv 2021, arXiv:2101.01885. [Google Scholar]

- Kollmeyer, P.; Vidal, C.; Naguib, M.; Skells, M. LG 18650HG2 Li-ion Battery Data and Example Deep Neural Network xEV SOC Estimator Script. Available online: https://data.mendeley.com/datasets/cp3473x7xv/3 (accessed on 12 April 2021).

- Kollmeyer, P. Panasonic 18650PF Li-ion Battery Data, Mendeley Data, v1. Available online: https://data.mendeley.com/datasets/wykht8y7tg/1#folder96f196a8-a04d-4e6a-827d-0dc4d61ca97b (accessed on 12 April 2021).

- Saha, B.; Goebel, K. Battery Data Set. In NASA Ames Prognostics Data Repository; NASA Ames Research Center: Moffett Field, CA, USA. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/ (accessed on 12 April 2021).

- Barkholtz, H.M.; Fresquez, A.; Chalamala, B.R.; Ferreira, S.R. A Database for Comparative Electrochemical Performance of Commercial 18650-Format Lithium-Ion Cells. J. Electrochem. Soc. 2017, 164, A2697–A2706. [Google Scholar] [CrossRef]

- Pecht, M. Battery Research Data. Available online: https://calce.umd.edu/data (accessed on 12 April 2021).

- Birkl, C.R.; Offer, G.J. Oxford Battery Degradation Dataset from the Howey Research Group. Available online: https://ora.ox.ac.uk/objects/uuid%3a03ba4b01-cfed-46d3-9b1a-7d4a7bdf6fac (accessed on 14 April 2021).

- Aykol, M.; Babinec, S.; Beck, D.A.C.; Blaiszik, B.; Chen, B.R.; Crabtree, G.; Angelis, V.D.; Dechent, P.; Dubarry, M.; Dufek, E.; et al. Principles of a Battery Data Genome. Nature 2021. under review. [Google Scholar]

- Anseán, D.; Dubarry, M.; Devie, A.; Liaw, B.; García, V.; Viera, J.; González, M. Operando lithium plating quantification and early detection of a commercial LiFePO4 cell cycled under dynamic driving schedule. J. Power Sources 2017, 356, 36–46. [Google Scholar] [CrossRef] [Green Version]

- Dubarry, M.; Berecibar, M.; Devie, A.; Anseán, D.; Omar, N.; Villarreal, I. State of health battery estimator enabling degradation diagnosis: Model and algorithm description. J. Power Sources 2017, 360, 59–69. [Google Scholar] [CrossRef]

- Dubarry, M.; Baure, G.; Anseán, D. Perspective on State-of-Health Determination in Lithium-Ion Batteries. J. Electrochem. Energy Convers. Storage 2020, 17, 1–25. [Google Scholar] [CrossRef]

- Dubarry, M.; Beck, D. Big data training data for artificial intelligence-based Li-ion diagnosis and prognosis. J. Power Sources 2020, 479, 228806. [Google Scholar] [CrossRef]

- Bloom, I.; Jansen, A.N.; Abraham, D.P.; Knuth, J.; Jones, S.A.; Battaglia, V.S.; Henriksen, G.L. Differential voltage analyses of high-power, lithium-ion cells. J. Power Sources 2005, 139, 295–303. [Google Scholar] [CrossRef]

- Honkura, K.; Honbo, H.; Koishikawa, Y.; Horiba, T. State Analysis of Lithium-Ion Batteries Using Discharge Curves. ECS Meet. Abstr. 2008, 13, 61–73. [Google Scholar] [CrossRef]

- Dahn, H.M.; Smith, A.J.; Burns, J.C.; Stevens, D.A.; Dahn, J.R. User-Friendly Differential Voltage Analysis Freeware for the Analysis of Degradation Mechanisms in Li-Ion Batteries. J. Electrochem. Soc. 2012, 159, A1405–A1409. [Google Scholar] [CrossRef]

- Dubarry, M.; Truchot, C.; Liaw, B.Y. Synthesize battery degradation modes via a diagnostic and prognostic model. J. Power Sources 2012, 219, 204–216. [Google Scholar] [CrossRef]

- Dubarry, M. Graphite//LFP synthetic training duty cycle dataset. Mendeley Data. 2020, Volume 2021. Available online: https://data.mendeley.com/datasets/6s6ph9n8zg/1 (accessed on 14 April 2021).

- Dubarry, M. Graphite//LFP synthetic training V vs. Q dataset. Mendeley Data. 2020, Volume 2021. Available online: https://data.mendeley.com/datasets/6s6ph9n8zg/2 (accessed on 14 April 2021).

- Dubarry, M. Graphite//NCA synthetic V vs. Q & duty cycle datasets. Mendeley Data. 2021. Available online: https://data.mendeley.com/datasets/2h8cpszy26/1 (accessed on 14 April 2021).

- Dubarry, M. Graphite//NMC synthetic V vs. Q & duty cycle datasets. Mendeley Data. 2021. Available online: https://data.mendeley.com/datasets/pb5xpv8z5r/1 (accessed on 14 April 2021).

- Baure, G.; Dubarry, M. Synthetic vs. Real Driving Cycles: A Comparison of Electric Vehicle Battery Degradation. Batteries 2019, 5, 42. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Yang, S.; Jiang, J.; Zhang, C.; Zhang, W.; Zhou, X. The Mechanism and Characterization of Accelerated Capacity Deterioration for Lithium-Ion Battery with Li(NiMnCo) O2 Cathode. J. Electrochem. Soc. 2019, 166, A1623–A1635. [Google Scholar] [CrossRef]

- Yang, X.-G.; Leng, Y.; Zhang, G.; Ge, S.; Wang, C.-Y. Modeling of lithium plating induced aging of lithium-ion batteries: Transition from linear to nonlinear aging. J. Power Sources 2017, 360, 28–40. [Google Scholar] [CrossRef]

- Schuster, S.F.; Bach, T.; Fleder, E.; Müller, J.; Brand, M.; Sextl, G.; Jossen, A. Nonlinear aging characteristics of lithium-ion cells under different operational conditions. J. Energy Storage 2015, 1, 44–53. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Charging protocols for lithium-ion batteries and their impact on cycle life—An experimental study with different 18650 high-power cells. J. Energy Storage 2016, 6, 125–141. [Google Scholar] [CrossRef]

- Devie, A.; Dubarry, M. Durability and Reliability of Electric Vehicle Batteries under Electric Utility Grid Operations. Part 1: Cell-to-Cell Variations and Preliminary Testing. Batteries 2016, 2, 28. [Google Scholar] [CrossRef]

- Dubarry, M.; Baure, G.; Devie, A. Durability and Reliability of EV Batteries under Electric Utility Grid Operations: Path Dependence of Battery Degradation. J. Electrochem. Soc. 2018, 165, A773–A783. [Google Scholar] [CrossRef]

- Dubarry, M.; Devie, A.; McKenzie, K. Durability and reliability of electric vehicle batteries under electric utility grid operations: Bidirectional charging impact analysis. J. Power Sources 2017, 358, 39–49. [Google Scholar] [CrossRef]

- Schindler, S.; Baure, G.; Danzer, M.A.; Dubarry, M. Kinetics accommodation in Li-ion mechanistic modeling. J. Power Sources 2019, 440, 227117. [Google Scholar] [CrossRef]

- Anseán, D.; Baure, G.; González, M.; Cameán, I.; García, A.; Dubarry, M. Mechanistic investigation of silicon-graphite/LiNi0.8Mn0.1Co0.1O2 commercial cells for non-intrusive diagnosis and prognosis. J. Power Sources 2020, 459, 227882. [Google Scholar] [CrossRef]

- Anseán, D.; Dubarry, M.; Devie, A.; Liaw, B.; García, V.; Viera, J.; González, M. Fast charging technique for high power LiFePO4 batteries: A mechanistic analysis of aging. J. Power Sources 2016, 321, 201–209. [Google Scholar] [CrossRef]

- Dubarry, M.; Baure, G. Perspective on Commercial Li-ion Battery Testing, Best Practices for Simple and Effective Protocols. Electron. 2020, 9, 152. [Google Scholar] [CrossRef] [Green Version]

- Fath, J.P.; Dragicevic, D.; Bittel, L.; Nuhic, A.; Sieg, J.; Hahn, S.; Alsheimer, L.; Spier, B.; Wetzel, T. Quantification of aging mechanisms and inhomogeneity in cycled lithium-ion cells by differential voltage analysis. J. Energy Storage 2019, 25. [Google Scholar] [CrossRef]

- Nuhic, A.; Terzimehic, T.; Soczka-Guth, T.; Buchholz, M.; Dietmayer, K. Health diagnosis and remaining useful life prognostics of lithium-ion batteries using data-driven methods. J. Power Sources 2013, 239, 680–688. [Google Scholar] [CrossRef]

- Liu, D.; Luo, Y.; Liu, J.; Peng, Y.; Guo, L.; Pecht, M. Lithium-ion battery remaining useful life estimation based on fusion nonlinear degradation AR model and RPF algorithm. Neural Comput. Appl. 2013, 25, 557–572. [Google Scholar] [CrossRef]

- Liu, D.; Pang, J.; Zhou, J.; Peng, Y.; Pecht, M. Prognostics for state of health estimation of lithium-ion batteries based on combination Gaussian process functional regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- Lee, C.; Jo, S.; Kwon, D.; Pecht, M.G. Capacity-Fading Behavior Analysis for Early Detection of Unhealthy Li-Ion Batteries. IEEE Trans. Ind. Electron. 2021, 68, 2659–2666. [Google Scholar] [CrossRef]

- Strange, C.; Li, S.; Gilchrist, R.; dos Reis, G. Elbows of Internal Resistance Rise Curves in Li-Ion Cells. Energies 2021, 14, 1206. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, D.; Pecht, M.G. Reduction of Li-ion Battery Qualification Time Based on Prognostics and Health Management. IEEE Trans. Ind. Electron. 2018, 66, 7310–7315. [Google Scholar] [CrossRef]

- Fermín-Cueto, P.; McTurk, E.; Allerhand, M.; Medina-Lopez, E.; Anjos, M.F.; Sylvester, J.; dos Reis, G. Identification and machine learning prediction of knee-point and knee-onset in capacity degradation curves of lithium-ion cells. Energy AI 2020, 1, 100006. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, X.; Pan, R.; Wang, Y.; Chen, Z. A novel Gaussian process regression model for state-of-health estimation of lithium-ion battery using charging curve. J. Power Sources 2018, 384, 387–395. [Google Scholar] [CrossRef]

- Goh, T.; Park, M.; Seo, M.; Kim, J.G.; Kim, S.W. Successive-approximation algorithm for estimating capacity of Li-ion batteries. Energy 2018, 159, 61–73. [Google Scholar] [CrossRef]

- Goh, T.; Park, M.; Seo, M.; Kim, J.G.; Kim, S.W. Capacity estimation algorithm with a second-order differential voltage curve for Li-ion batteries with NMC cathodes. Energy 2017, 135, 257–268. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Bertrand, N.; Delétage, J.-Y.; Vinassa, J.-M. Behavior and state-of-health monitoring of Li-ion batteries using impedance spectroscopy and recurrent neural networks. Int. J. Electr. Power Energy Syst. 2012, 42, 487–494. [Google Scholar] [CrossRef]

- Saha, B.; Poll, S.; Goebel, K.; Christophersen, J. An Integrated Approach to Battery Health Monitoring Using Bayesian Regression and State Estimation; International Automatic Testing Conference: Baltimore, MD, USA, 2007; pp. 646–653. [Google Scholar]

- Zhang, Y.; Tang, Q.; Zhang, Y.; Wang, J.; Stimming, U.; Lee, A.A. Identifying degradation patterns of lithium ion batteries from impedance spectroscopy using machine learning. Nat. Commun. 2020, 11, 216. [Google Scholar] [CrossRef]

- Marongiu, A.; Nlandi, N.; Rong, Y.; Sauer, D.U. On-board capacity estimation of lithium iron phosphate batteries by means of half-cell curves. J. Power Sources 2016, 324, 158–169. [Google Scholar] [CrossRef]

- Weng, C.; Cui, Y.; Sun, J.; Peng, H. On-board state of health monitoring of lithium-ion batteries using incremental capacity analysis with support vector regression. J. Power Sources 2013, 235, 36–44. [Google Scholar] [CrossRef]

- Tang, X.; Zou, C.; Yao, K.; Chen, G.; Liu, B.; He, Z.; Gao, F. A fast estimation algorithm for lithium-ion battery state of health. J. Power Sources 2018, 396, 453–458. [Google Scholar] [CrossRef]

- Li, Y.; Abdel-Monem, M.; Gopalakrishnan, R.; Berecibar, M.; Nanini-Maury, E.; Omar, N.; Bossche, P.V.D.; Van Mierlo, J. A quick on-line state of health estimation method for Li-ion battery with incremental capacity curves processed by Gaussian filter. J. Power Sources 2018, 373, 40–53. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, X.; Liu, L.; Pan, C. State of health estimation of battery modules via differential voltage analysis with local data symmetry method. Electrochim. Acta 2017, 256, 81–89. [Google Scholar] [CrossRef]

- Berecibar, M.; Garmendia, M.; Gandiaga, I.; Crego, J.; Villarreal, I. State of health estimation algorithm of LiFePO4 battery packs based on differential voltage curves for battery management system application. Energy 2016, 103, 784–796. [Google Scholar] [CrossRef]

- Wang, L.; Pan, C.; Liu, L.; Cheng, Y.; Zhao, X. On-board state of health estimation of LiFePO4 battery pack through differential voltage analysis. Appl. Energy 2016, 168, 465–472. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Yan, J. Prognostic health condition for lithium battery using the partial incremental capacity and Gaussian process regression. J. Power Sources 2019, 421, 56–67. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.M.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H.E. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113. [Google Scholar] [CrossRef]

- She, C.; Wang, Z.; Sun, F.; Liu, P.; Zhang, L. Battery Aging Assessment for Real-World Electric Buses Based on Incremental Capacity Analysis and Radial Basis Function Neural Network. IEEE Trans. Ind. Inform. 2020, 16, 3345–3354. [Google Scholar] [CrossRef]

- Sarasketa-Zabala, E.; Martinez-Laserna, E.; Berecibar, M.; Gandiaga, I.; Rodriguez-Martinez, L.; Villarreal, I. Realistic lifetime prediction approach for Li-ion batteries. Appl. Energy 2016, 162, 839–852. [Google Scholar] [CrossRef]

- Berecibar, M.; Devriendt, F.; Dubarry, M.; Villarreal, I.; Omar, N.; Verbeke, W.; Van Mierlo, J. Online state of health estimation on NMC cells based on predictive analytics. J. Power Sources 2016, 320, 239–250. [Google Scholar] [CrossRef]

- Harris, S.J.; Harris, D.J.; Li, C. Failure statistics for commercial lithium ion batteries: A study of 24 pouch cells. J. Power Sources 2017, 342, 589–597. [Google Scholar] [CrossRef] [Green Version]

- Sulzer, V.; Mohtat, P.; Lee, S.; Siegel, J.B.; Stefanopoulou, A.G. Promise and Challenges of a Data-Driven Approach for Battery Lifetime Prognostics. arXiv 2021, arXiv:2010.07460v1. [Google Scholar]

- Baure, G.; Dubarry, M. Battery durability and reliability under electric utility grid operations: 20-year forecast under different grid applications. J. Energy Storage 2020, 29, 101391. [Google Scholar] [CrossRef]

- Baure, G.; Devie, A.; Dubarry, M. Battery Durability and Reliability under Electric Utility Grid Operations: Path Dependence of Battery Degradation. J. Electrochem. Soc. 2019, 166, A1991–A2001. [Google Scholar] [CrossRef]

- Fei, Z.; Yang, F.; Tsui, K.-L.; Li, L.; Zhang, Z. Early prediction of battery lifetime via a machine learning based framework. Energy 2021, 225, 120205. [Google Scholar] [CrossRef]

| LLI | LAMPE | LAMNE | Capacity Loss | |

|---|---|---|---|---|

| FOI1 | −0.74 | −0.03 | 0.62 | −0.72 |

| FOI2 | −0.03 | 0.09 | −0.99 | −0.06 |

| FOI3 | 0.04 | −0.36 | 0.73 | 0.07 |

| FOI4 | 0.38 | −0.17 | −0.79 | 0.36 |

| FOI5 | −0.51 | −0.26 | 0.78 | −0.47 |

| FOIs (1,2,3) | 0.99 | 0.44 | 0.98 | 0.99 |

| FOIs (1,2,4) | 0.99 | 0.80 | 0.99 | 0.99 |

| FOIs (1,2,5) | 0.99 | −0.07 | 0.98 | 0.99 |

| LLI | LAMPE | LAMNE | Capacity Loss | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cycle 10 | 0.03 | ± | 0.12 | 0.20 | ± | 0.21 | 0.05 | ± | 0.14 | 0.04 | ± | 0.14 |

| Cycle 50 | −0.06 | ± | 0.19 | −0.15 | ± | 0.78 | −0.05 | ± | 0.22 | −0.06 | ± | 0.22 |

| Cycle 100 | −0.06 | ± | 0.20 | −0.22 | ± | 1.06 | −0.06 | ± | 0.27 | −0.06 | ± | 0.24 |

| Cycle 200 | −0.01 | ± | 0.22 | −0.29 | ± | 1.43 | 0.00 | ± | 0.28 | −0.01 | ± | 0.24 |

| Cycle 400 | −0.03 | ± | 0.35 | −0.28 | ± | 2.31 | −0.03 | ± | 0.33 | −0.04 | ± | 0.36 |

| Cycle 1000 | −0.80 | ± | 3.80 | −0.55 | ± | 5.17 | −0.27 | ± | 2.97 | −0.70 | ± | 3.79 |

| LFP | NCA | NMC811 | |

|---|---|---|---|

| ΔVariance (10-1) | −0.05 | −0.22 | −0.47 |

| ΔVariance (50-1) | −0.52 | −0.41 | −0.73 |

| ΔVariance (100-1) | −0.55 | −0.50 | −0.80 |

| ΔVariance (200-1) | −0.37 | −0.64 | −0.74 |

| ΔVariance (400-1) | −0.23 | −0.74 | −0.49 |

| ΔVariance (1000-1) | −0.33 | −0.74 | −0.40 |

| Capacity loss (%) | −0.60 | −0.69 | −0.72 |

| FOI | 0.29 | 0.49 | 0.33 |

| LFP | NCA | NMC811 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fit | Range | ρ | RMSE | MAPE | R2 | ρ | RMSE | MAPE | R2 | ρ | RMSE | MAPE | R2 |

| L + E | 1000 | 0.91 | 156 | 11 | 0.82 | 0.92 | 137 | 10 | 0.84 | 0.90 | 186 | 19 | 0.73 |

| L + E | 400 | 0.63 | 351 | 20 | 0.11 | 0.67 | 280 | 15 | 0.35 | 0.69 | 302 | 23 | 0.29 |

| L + E | 200 | 0.38 | 503 | 40 | −0.83 | 0.45 | 461 | 34 | −0.76 | 0.43 | 480 | 39 | −0.78 |

| L + E | 100 | 0.35 | 597 | 56 | −1.58 | 0.42 | 521 | 49 | −1.24 | 0.41 | 715 | 46 | −2.95 |

| P | 1000 | 0.60 | 542 | 12 | −1.13 | 0.85 | 216 | 9 | 0.61 | 0.52 | 547 | 21 | −1.31 |

| P | 400 | 0.77 | 324 | 15 | 0.24 | 0.79 | 278 | 11 | 0.36 | 0.26 | 1461 | 22 | >|5| |

| P | 200 | 0.33 | 1249 | 41 | >|5| | 0.32 | 2472 | 38 | >|5| | 0.20 | 8413 | 49 | >|5| |

| P | 100 | 0.17 | 17,182 | 297 | >|5| | 0.28 | 14,805 | 212 | >|5| | 0.33 | 20,573 | 273 | >|5| |

| L | 1000 | 0.92 | 183 | 13 | 0.76 | 0.92 | 165 | 10 | 0.77 | 0.89 | 199 | 20 | 0.69 |

| L | 400 | 0.82 | 325 | 14 | 0.24 | 0.92 | 204 | 11 | 0.66 | 0.89 | 200 | 17 | 0.69 |

| L | 200 | 0.77 | 401 | 26 | −0.17 | 0.83 | 377 | 20 | −0.17 | 0.86 | 244 | 16 | 0.54 |

| L | 100 | 0.68 | 666 | 43 | −2.20 | 0.72 | 642 | 37 | −2.40 | 0.74 | 510 | 22 | −1.01 |

| Linear Fit, Cycles 1–200 | Linear Fit, Cycles 1–100 | |||||||

|---|---|---|---|---|---|---|---|---|

| ρ | RMSE | MAPE | R2 | ρ | RMSE | MAPE | R2 | |

| >50% LLI | 0.98 | 86 | 3 | 0.93 | 0.94 | 131 | 7 | 0.85 |

| >80% LLI | 0.98 | 57 | 3 | 0.96 | 0.96 | 85 | 5 | 0.92 |

| >50% LAMPE | 0.90 | 219 | 15 | 0.39 | 0.80 | 506 | 27 | −2.28 |

| >80% LAMPE | 0.89 | 132 | 17 | 0.39 | 0.68 | 357 | 19 | −3.45 |

| >50% LAMNE | 0.60 | 709 | 58 | −1.76 | 0.55 | 965 | 76 | −4.12 |

| >80% LAMNE | 0.57 | 730 | 38 | −1.50 | 0.41 | 733 | 36 | −1.52 |

| <50% all | 0.83 | 280 | 21 | 0.38 | 0.67 | 618 | 43 | −2.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubarry, M.; Beck, D. Analysis of Synthetic Voltage vs. Capacity Datasets for Big Data Li-ion Diagnosis and Prognosis. Energies 2021, 14, 2371. https://doi.org/10.3390/en14092371

Dubarry M, Beck D. Analysis of Synthetic Voltage vs. Capacity Datasets for Big Data Li-ion Diagnosis and Prognosis. Energies. 2021; 14(9):2371. https://doi.org/10.3390/en14092371

Chicago/Turabian StyleDubarry, Matthieu, and David Beck. 2021. "Analysis of Synthetic Voltage vs. Capacity Datasets for Big Data Li-ion Diagnosis and Prognosis" Energies 14, no. 9: 2371. https://doi.org/10.3390/en14092371

APA StyleDubarry, M., & Beck, D. (2021). Analysis of Synthetic Voltage vs. Capacity Datasets for Big Data Li-ion Diagnosis and Prognosis. Energies, 14(9), 2371. https://doi.org/10.3390/en14092371