Optimal Generation Scheduling in Hydro-Power Plants with the Coral Reefs Optimization Algorithm

Abstract

:1. Introduction

2. Materials and Methods

2.1. Problem Definition and Generation Scheduling Modelling

2.1.1. Hydraulic Losses Model

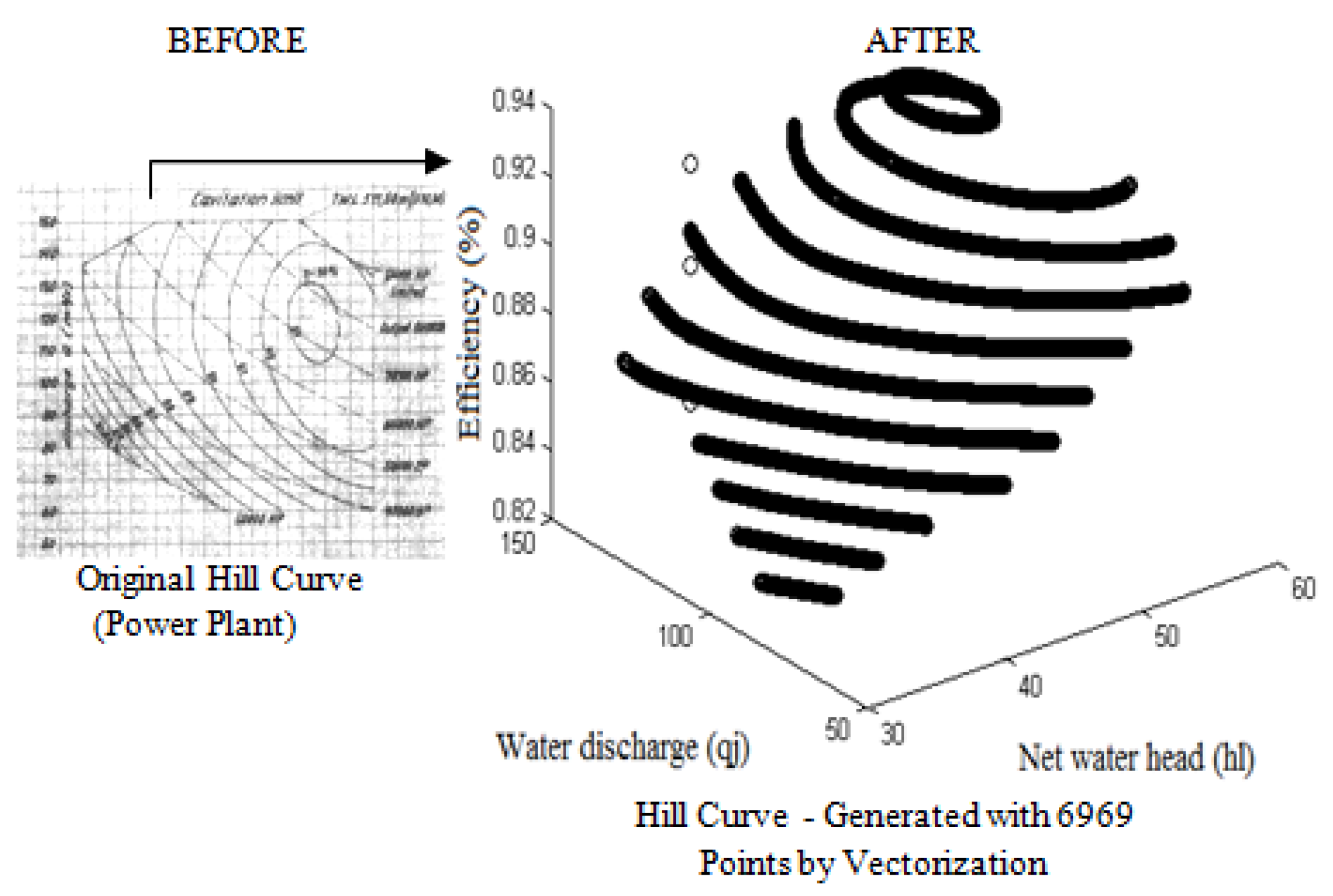

2.1.2. Adjustment of the Model from Data

2.1.3. Optimization Modelling

- The power demand produced (()) can be considered approximately equal to the power demand requested (D), with an acceptable error ().

- The water discharge boundaries for each turbine-generator ( and ).

- The electric power boundaries ( and ) for each turbine-generator in operating zones ().

- Each turbine-generator has only one operating zone: on or off (, on (1) or off (0)).

2.2. Evolutionary Meta-Heuristic Proposed: The Coral Reefs Optimization Algorithm

- (1)

- Initialization. The algorithm is initialized by assigning random candidate solutions to a random number of squares of the grid, leaving the rest empty. Each solution is labeled with the problem’s objective function (i.e. the healthy function).

- (2)

- Reef formation. It is an iterative process that takes place over iterations. At each iteration several operators or search procedures are applied to emulate the corals’ reproduction in the reef. Therefore, new candidate solutions are obtained and try to settle on the reef. If the square of the reef found (i,j) is free, the coral settles in the hole. If the square is occupied, the candidate solution fights with the settled solution and the one with higher health function stays in the hole. If the new candidate cannot settle, it tries to find a new square, but after attempts without finding a place to grow, the candidate solution is discarded.

- (3)

- Predation. Once settlement of new corals has taken place, a predation phase may occur with probability . Should predation happen, a percentage of the reef has preyed and solutions previously settled are lost. Thus leaving holes for new candidate solutions (with bad health functions) from other areas of the search space, to enter the reef (and escape from local minima).

- (4)

- Stop. if halting criteria are satisfied; otherwise go to step (2) for the next cycle.The best individual in the reef is considered to be the final solution to the problem.

- Harmony Search mutation (HS): Mutation is recreating the Harmony Search algorithm [43]. New candidate is obtained: using the same values of the component from other reefs’ coral, with a probability HMCR (Harmony Memory Considering Rate); or performing slight modifications to the candidate, with a probability PAR (Pitch Adjusting Rate) ;

- Differential Evolution mutation (DE): Mutation implementing a Differential Evolution algorithm [44]. New candidates are obtained by combining a reef’s coral with a perturbation vector . Two different strategies have been used to find the perturbation:DEB: (using the best), andDER: (on a random basis)(where F stands for the evolution factor that weights the perturbation amplitude, in our case );

- Differential Evolution mutation with crossover (DEX): Mutation recreating the Differential Evolution algorithm [44]. New candidates are obtained after a crossover is applied between a coral from the reef and a perturbation vector generated by DER.

- Gaussian mutation (GM): The new candidate is obtained by applying gaussian mutation to a coral from the reef (, where ) is a random number following the Gaussian distribution. The Gaussian probability density function is:where value linearly decreases during the run, from to , being the search domain. Therefore, at the beginning the mutation is strong while at the end it is a fine tuning.

3. Experiments and Results

3.1. Case Study and Parameter Settings

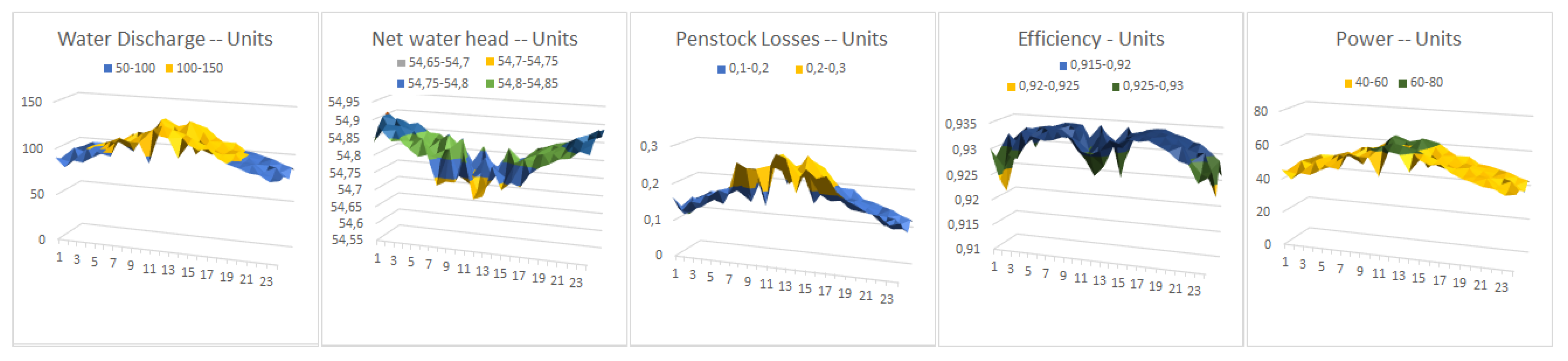

3.2. Daily Dispatch Programming Experiment

3.3. Hourly Dispatch Programming Experiment

4. Discussion

- visually we can see differences among the true means of and the rest of the algorithms, favouring version, but cannot perceive the overlap with others;

- it is not possible to conclude if a statistical significant difference of the means computed of RGA, , , , and algorithms exists (or not).

5. Conclusions

- Proposal of an effective mathematical modeling to power electric dispatch in HPP. The proposed model extends the electric power equation (Equation (9)), bringing modularity to the obtaining of (using regression fit) and (fluid mechanics’ model) terms. This modeling has been described and discussed in detail, being easily replicable.

- Inclusion of a hydraulic losses model in the mathematical modeling, to bring greater reality to the dynamics of the electric dispatch problem. In this sense, net water head () was obtained (Equation. (7)).

- Proposal and testing of the CRO algorithm using a combination of search operators or search operators independently. In this work, the latter has concluded on best results when the CRO with Gaussian mutation was used, outperforming real encoded genetic algorithms and differential evolution.

- Proposal of a statistical inference methodology to compare results from the meta-heuristics has been applied. To test the samples’ normality, the Kolmogorov-Smirnov test was implemented, showing that the behaviour using CRO(4) and DE(best/1/bin) algorithms is non-normal. Also, Kruskal-Wallis test was used to determine the differences among the mean ranks, resulting in statistically significant difference between the algorithms results. Finally, Tukey test was performed, confirming that CRO(4) configurations generate solutions with higher fitness function values.

Author Contributions

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie grant agreement No 754382. This research has been partially funded by Ministerio de Economía y Competitividad of Spain (Grant Ref. TIN2017-85887-C2-2-P), by Comunidad de Madrid, PROMINT-CM project (grant No. P2018/EMT-4366), and Brazilian research agencies: CAPES (Finance Code 001) and CNPq for support. “The content of this publication does not reflect the official opinion of the European Union. Responsibility for the information and views expressed herein lies entirely with the author(s)”.

This project has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie grant agreement No 754382. This research has been partially funded by Ministerio de Economía y Competitividad of Spain (Grant Ref. TIN2017-85887-C2-2-P), by Comunidad de Madrid, PROMINT-CM project (grant No. P2018/EMT-4366), and Brazilian research agencies: CAPES (Finance Code 001) and CNPq for support. “The content of this publication does not reflect the official opinion of the European Union. Responsibility for the information and views expressed herein lies entirely with the author(s)”.Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Padhy, N. Unit Commitment—A Bibliographical Survey. IEEE Trans. Power Syst. 2004, 19, 1196–1205. [Google Scholar] [CrossRef]

- Yang, L.; Li, W.; Xu, Y.; Zhang, C.; Chen, S. Two novel locally ideal three-period unit commitment formulations in power systems. Appl. Energy 2020, 284, 1–19. [Google Scholar]

- Arce, A.; Soares, S.; Ohishi, T.; Cicogna, A. Unit Commitment of Hydro Dominated Systems. Electr. Power Syst. Res. 2008, 9, 1–17. [Google Scholar]

- Brito, B.; Finardi, E.; Takigawa, F. Unit-commitment via logarithmic aggregated convex combination in multi- unit hydro plants. Electr. Power Syst. Res. 2020, 81, 1–7. [Google Scholar]

- Ceran, B.; Jurasz, J.; Wroblewski, R.; Guderski, A.; Ztotecka, D.; Kazmierczak, L. Impact of the Minimum Head on Low-Head Hydropower Plants Energy Production and Profitability. Energies 2020, 13, 6728. [Google Scholar] [CrossRef]

- Abdi, H. Profit-based unit commitment problem: A review of models, methods, challenges, and future directions. Renew. Sustain. Energy Rev. 2020, 1, 1–28. [Google Scholar] [CrossRef]

- Kong, J.; Skjelbred, H.; Fosso, O. An overview on formulations and optimization methods for the unit-based short-term hydro scheduling problem. Electr. Power Syst. Res. 2020, 118, 1–14. [Google Scholar] [CrossRef]

- Daadaa, M.; Seguin, S.; Demeester, K.; Anjos, M. An optimization model to maximize energy generation in short-term hydropower unit commitment using efficiency points. Int. J. Electr. Power Energy Syst. 2021, 125, 1–8. [Google Scholar] [CrossRef]

- Yoo, J.H. Maximization of hydropower generation throught the application of a linear programming model. J. Hydrol. 2013, 376, 182–187. [Google Scholar] [CrossRef]

- Bento, P.; Mariano, S.; Calado, M.; Ferreira, L. A Novel Lagrangian Multiplier Update Algorithm for Short-Term Hydro-Thermal Coordination. Energies 2020, 13, 1–19. [Google Scholar]

- Finardi, E.; da Silva, E.L. Unit commitment of single hydroelectric plant. Electr. Power Syst. Res. 2005, 75, 116–123. [Google Scholar] [CrossRef]

- Zhang, R.; Zhow, J.; Ouyang, S.; Wang, X.; Zhang, H. Optimal operation of multi-reservoir system by multi-elite guide particle swarm optimization. Int. J. Electr. Power Energy Syst. 2013, 48, 58–68. [Google Scholar] [CrossRef]

- Na, F.; Zhou, J.; Zhang, R.; Liu, Y.; Zhang, Y. A hybrid of real coded genetic algorithm and artificial fish swarm algorithm for short-term optimal hydrothermal scheduling. Int. J. Electr. Power Energy Syst. 2014, 62, 617–629. [Google Scholar]

- Glotic, A.; Glotic, A.; Kitak, P.; Pihler, J.; Ticar, I. Parallel Self-Adaptive Differential Evolution Algorithm for Solving Short-Term Hydro Scheduling Problem. IEEE Trans. Power Syst. 2014, 29, 2347–2358. [Google Scholar] [CrossRef]

- He, Z.; Zhou, J.; Jia, H.; Lu, C. Long-term joint scheduling of hydropower station group in the upper reaches of the Yangtze River using partition parameter adaptation differential evolution. Eng. Appl. Artif. Intell. 2020, 81, 1–13. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, D.; Yao, W.; Ba, D.; Ma, X. Non-linear fuzzy predictive control of hydroelectric system. IET Gener. Transm. Distrib. 2017, 11, 1966–1975. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, L. Machine learning approaches to the unit commitment problem: Current trends, emerging challenges, and new strategies. Electr. J. 2021, 34, 369–389. [Google Scholar]

- Nan, Y.; Di, Y.; Zheng, Z.; Jiazhan, C.; Daojun, C.; Xiaoming, W. MResearch on modelling and solution of stochastic SCUC under AC power flow constraints. IET Gener. Transm. Distrib. 2018, 12, 3618–3625. [Google Scholar] [CrossRef]

- Cioffi, F.; Gallerano, F. Multi-objective analysis of dam release flows in rivers downstream from hydropower reservoirs. Appl. Math. Model. 2013, 36, 2868–2889. [Google Scholar] [CrossRef] [Green Version]

- Doganis, P.; Sarimveis, H. Optimization of power production through coordinated use of hydroelectric and conventional power units. Appl. Math. Model. 2014, 38, 2051–2062. [Google Scholar] [CrossRef]

- Reddy, K.; Panwar, L.; Panigrahi, B.; Kumar, R. Binary whale optimization algorithm: A new metaheuristic approach for profit-based unit commitment problems in competitive electricity markets. Eng. Optim. 2019, 51, 369–389. [Google Scholar] [CrossRef]

- Perumal, R.; Krishnan, m.; Subramanian, K. A hybrid LR-FA technique to optimize the profit function of gencos in a restructured power system. Electr. Power Syst. Res. 2012, 32, 113–120. [Google Scholar] [CrossRef]

- Singh, A.; Khamparia, A. A hybrid whale optimization-differential evolution and genetic algorithm based approach to solve unit commitment scheduling problem: WODEGA. Sustain. Comput. Inform. Syst. 2020, 28, 1–10. [Google Scholar] [CrossRef]

- Marcelino, C.; Baumann, M.; Carvalho, L.; Chibeles-Martins, N.; Weil, M.; Almeida, P.; Wanner, E. A combined optimisation and decision-making approach for battery-supported HMGS. J. Oper. Res. Soc. 2020, 71, 762–774. [Google Scholar] [CrossRef]

- Marcelino, C.; Almeida, P.; Wanner, E.; Baumann, M.; Weil, M.; Cavalho, L.; Miranda, V. Solving security constrained optimal power flow problems: A hybrid evolutionary approach. Appl. Intell. 2018, 48, 3672–3690. [Google Scholar] [CrossRef] [Green Version]

- Sharma, D.; Trivedi, D.; Srinivasan, D.; Thillainathan, L. Multi-agent modeling for solving profit based unit commitment problem. Appl. Soft Comput. 2013, 13, 3751–3761. [Google Scholar] [CrossRef]

- Dhaliwal, J.; Dhillon, J. Profit based unit commitment using memetic binary differential evolution algorithm. Appl. Soft Comput. 2019, 81, 1–20. [Google Scholar] [CrossRef]

- Salcedo-Sanz, S. A review on the coral reefs optimization algorithm: New development lines and current applications. Prog. Artif. Intell. 2017, 6, 1–15. [Google Scholar] [CrossRef]

- Garcia-Hernandez, L.; Garcia-Hernandez, J.; Salas-Morena, L.; Carmona-Munoz, C.; Alghamdi, N.; Valente de Oliveira, J.; Salcedo-Sanz, S. Addressing Unequal Area Facility Layout Problems with the Coral Optimization algorithm with Substrate Layers. Eng. Appl. Artif. Intell. 2020, 93, 1–11. [Google Scholar] [CrossRef]

- Massey, B. Mech. Fluids; Spon Press: Abingdon, VA, USA, 2012. [Google Scholar]

- Levenberg, K. A Method for the Solution of Certain Non-Linear Problems in Least Squares. Q. Appl. Math. 1944, 2, 164–168. [Google Scholar] [CrossRef] [Green Version]

- Marquardt, D. An Algorithm for Least-Squares Estimation of Nonlinear Parameters. SIAM J. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Braun-Cruz, C.; Tritico, H.; Beregula, R.; Girard, P.; Zeihofer, P.; Ribeiro, L.; Fantin-Cruz, I. Evaluation of Hydrological Alterations at the Sub-Daily Sacale Caused by a Small Hydroelectric Facility. Water 2021, 13, 206. [Google Scholar] [CrossRef]

- Salcedo-Sanz, S.; Del Ser, J.; Landa-Torres, I.; Gil-Lopez, S.; Portilla-Figueras, J.A. The coral reefs optimization algorithm: A novel metaheuristic for efficiently solving optimization problems. Sci. World J. 2014, 2014, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Salcedo-Sanz, S.; Del Ser, J.; Landa-Torres, I.; Gil-Lopez, S.; Portilla-Figueras, J.A. The coral reefs optimization algorithm: An efficient meta-heuristic for solving hard optimization problems. In Proceedings of the 15th International Conference on Applied Stochastic Models and Data Analysis (ASMDA2013), Mataró (Barcelona), Spain, 25–28 June 2013; Volume 1, pp. 751–758. [Google Scholar]

- Garcia-Hernandez, L.; Salas-Morera, L.; Carmona-Muñoz, C.; Abraham, A.; Salcedo-Sanz, S. A Hybrid Coral Reefs Optimization - Variable Neighborhood Search Approach for the Unequal Area Facility Layout Problem. IEEE Access 2020, 8, 134042–134050. [Google Scholar] [CrossRef]

- García-Hernandez, L.; Salas-Morera, L.; Carmona-Muñoz, C.; Abraham, A.; Salcedo-Sanz, S. A novel multi-objective Interactive Coral Reefs Optimization algorithm for the Unequal Area Facility Layout Problem. Swarm Evol. Comput. 2020, 55, 100688. [Google Scholar] [CrossRef]

- Camacho-Gómez, C.; Marsá-Maestre, I.; Giménez-Guzmán, J.; Salcedo-Sanz, S. A Coral Reefs Optimization algorithm with substrate layer for robust Wi-Fi channel assignment. Soft Comput. 2019, 23, 12621–12640. [Google Scholar] [CrossRef]

- Durán-Rosal, A.; Gutiérrez, P.; Salcedo-Sanz, S.; Hervás-Martínez, C. A statistically-driven Coral Reef Optimization algorithm for optimal size reduction of time series. Appl. Soft Comput. 2018, 63, 139–153. [Google Scholar] [CrossRef]

- Sánchez-Montero, R.; Camacho-Gómez, C.; López-Espí, P.; Salcedo-Sanz, S. Optimal Design of a Planar Textile Antenna for Industrial Scientific Medical (ISM) 2.4 GHz Wireless Body Area Networks (WBAN) with the CRO-SL Algorithm. Sensors 2018, 18, 1982. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salcedo-Sanz, S.; García-Díaz, P.; Del-Ser, J.; Bilbao, M.; Portilla-Figueras, J. A novel Grouping Coral Reefs Optimization algorithm for optimal mobile network deployment problems under electromagnetic pollution and capacity control criteria. Expert Syst. Appl. 2016, 55, 388–402. [Google Scholar] [CrossRef]

- Salcedo-Sanz, S.; Camacho-Gómez, C.; Mallol-Poyato, R.; Jiménez-Fernández, S.; Del Ser, J. A novel Coral Reefs Optimization algorithm with substrate layers for optimal battery scheduling optimization in micro-grids. Soft Comput. 2016, 20, 4287–4300. [Google Scholar] [CrossRef]

- Geem, Z.; Kim, J.; Loganathan, G. A new heuristic optimization algorithm: Harmony search. Simulation 2001, 76, 60–68. [Google Scholar] [CrossRef]

- Storn, R.; Proce, K. Differential Evolution - A Simple and Efficient Heuristic for global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Salcedo-Sanz, S.; Camacho-Gómez, C.; Molina, D.; Herrera, F. A coral reefs optimization algorithm with substrate layers and local search for large scale global optimization. In Proceedings of the IEEE Congress on Evolutionary Computation, CEC 2016, Vancouver, BC, Canada, 24–29 July 2016; pp. 3574–3581. [Google Scholar]

- Deb, K.; Deb, D. Analysing mutation schemes for real-parameter genetic algorithms. Int. J. Artif. Intell. Soft Comput. 2014, 4, 1–28. [Google Scholar] [CrossRef]

- Justel, A.; Pena, D.; Zamar, R. A multivariate Kolmogorov-Smirnov test of goodness of fit. Stat. Probab. Lett. 1997, 35, 251–258. [Google Scholar] [CrossRef] [Green Version]

- Kruskal, W.; Wallis, W. Use of Ranks in One-Criterion Variance Analysis. J. Am. Stat. Assoc. 1952, 47, 583–621. [Google Scholar] [CrossRef]

- Tukey, J. Comparing Individual Means in the Analysis of Variance. Biometrics 1949, 5, 99–114. [Google Scholar] [CrossRef] [PubMed]

- Marcelino, C.; Carvalho, L.; Almeida, P.; Wanner, E.; Miranda, V. Application of Evolutionary Multiobjective Algorithms for solving the problem of Energy Dispatch in Hydroelectric Power Plants. Lect. Notes Comput. Sci. 2014, 4, 403–417. [Google Scholar]

- Marcelino, C.; Wanner, E.; Almeida, P. A novel mathematical modeling approach to the electric dispatch problem: Case study using Differential Evolution algorithms. In Proceedings of the IEEE Congress on Evolutionary Computation (CEC), Cancun, Mexico, 20–23 June 2013; Volume 1, pp. 400–407. [Google Scholar]

| Coefficient | Estimation | RMSE | p-Value |

|---|---|---|---|

| 0.1463 | <0.0001 | ||

| 0.018076 | <0.0001 | ||

| 0.0050502 | <0.0001 | ||

| −3.5254e-05 | <0.0001 | ||

| −0.00112337 | <0.0001 | ||

| −1.4507e-05 | <0.0001 |

| D | RGA | DEB | DER | |||

|---|---|---|---|---|---|---|

| 255 | 0.40 | 0.71 | 0.70 | −0.36 | 1.19 | 0.79 |

| 265 | 1.20 | 1.68 | 1.75 | −0.25 | 0.93 | 1.87 |

| 275 | 2.49 | 2.66 | 2.49 | 4.91 | 3.61 | 2.76 |

| 285 | 2.98 | 3.46 | 3.43 | 2.01 | 3.11 | 3.59 |

| 295 | 2.14 | 4.12 | 3.88 | 4.78 | 4.32 | 4.30 |

| 305 | 3.43 | 4.62 | 4.25 | 3.52 | 5.53 | 4.68 |

| 315 | 2.95 | 4.93 | 4.78 | 3.06 | 4.85 | 5.07 |

| 325 | 3.03 | 4.57 | 4.76 | 3.66 | 6.23 | 5.22 |

| 335 | 3.50 | 4.54 | 4.03 | 2.01 | 4.49 | 5.02 |

| 345 | 3.09 | 4.35 | 4.51 | 3.50 | 3.27 | 4.63 |

| 355 | 3.27 | 3.72 | 3.73 | 8.36 | 2.78 | 3.88 |

| 365 | 1.17 | 2.64 | 2.49 | 3.20 | 2.33 | 2.87 |

| 365 | 1.35 | 2.58 | 2.69 | 3.20 | 3.06 | 2.87 |

| 355 | 3.37 | 3.19 | 3.78 | 8.36 | 3.74 | 3.91 |

| 345 | 4.10 | 4.47 | 4.52 | 3.50 | 4.32 | 4.63 |

| 335 | 4.46 | 4.81 | 5.11 | 2.01 | 4.81 | 5.06 |

| 325 | 3.59 | 5.04 | 5.02 | 3.66 | 6.21 | 5.19 |

| 315 | 3.17 | 4.45 | 4.97 | 3.06 | 5.71 | 5.09 |

| 305 | 3.66 | 4.62 | 4.56 | 3.52 | 5.29 | 4.75 |

| 295 | 2.67 | 4.06 | 4.18 | 4.78 | 4.27 | 4.22 |

| 285 | 2.99 | 3.46 | 3.46 | 2.29 | 3.59 | 3.58 |

| 275 | 2.33 | 2.66 | 2.58 | 4.91 | 3.60 | 2.82 |

| 265 | 1.37 | 1.74 | 1.82 | 2.10 | 1.22 | 1.85 |

| 255 | 0.61 | 0.71 | 0.70 | −0.36 | 1.48 | 0.84 |

| ASW (m/s) | 63.3 | 83.8 | 84.2 | 79.4 | 89.9 | 89.5 |

| ASW (L/day) | 227.9 mi | 301.7 mi | 303.1 mi | 285.9 mi | 323.8 mi | 322.2 mi |

| D | ||||||

| 255 | 0.85 | 1.59 | 0.69 | 1.42 | 1.68 | 0.71 |

| 265 | 1.73 | 2.83 | 1.88 | 2.80 | 2.69 | 1.72 |

| 275 | 2.71 | 3.76 | 2.70 | 3.52 | 3.69 | 2.83 |

| 285 | 3.06 | 4.65 | 3.37 | 4.55 | 4.55 | 3.47 |

| 295 | 4.23 | 5.33 | 4.16 | 5.10 | 5.30 | 4.26 |

| 305 | 4.05 | 5.94 | 4.55 | 5.06 | 5.75 | 4.79 |

| 315 | 5.04 | 6.37 | 4.80 | 6.08 | 5.96 | 4.90 |

| 325 | 4.90 | 6.39 | 5.15 | 5.06 | 5.93 | 4.89 |

| 335 | 5.02 | 6.24 | 4.85 | 6.12 | 5.95 | 4.78 |

| 345 | 4.57 | 5.78 | 4.62 | 5.63 | 4.89 | 4.62 |

| 355 | 3.73 | 5.33 | 3.70 | 4.92 | 2.50 | 4.04 |

| 365 | 2.71 | 4.10 | 2.88 | 3.94 | 3.74 | 2.84 |

| 365 | 2.95 | 4.12 | 2.88 | 4.18 | 3.99 | 2.83 |

| 355 | 3.86 | 5.13 | 3.70 | 5.14 | 3.63 | 5.88 |

| 345 | 4.59 | 6.10 | 4.60 | 5.82 | 5.30 | 4.59 |

| 335 | 5.02 | 6.32 | 5.03 | 6.22 | 6.27 | 5.12 |

| 325 | 5.25 | 6.52 | 5.37 | 5.86 | 6.28 | 5.13 |

| 315 | 5.14 | 6.21 | 5.10 | 6.09 | 6.19 | 5.31 |

| 305 | 4.49 | 5.94 | 4.55 | 5.44 | 5.83 | 4.85 |

| 295 | 4.25 | 5.33 | 4.35 | 5.29 | 5.34 | 4.37 |

| 285 | 3.54 | 4.70 | 3.57 | 4.64 | 4.62 | 3.68 |

| 275 | 2.82 | 3.69 | 2.70 | 3.62 | 3.75 | 2.64 |

| 265 | 1.66 | 2.83 | 1.88 | 2.80 | 2.74 | 1.86 |

| 255 | 0.79 | 1.74 | 0.69 | 1.80 | 1.71 | 0.71 |

| ASW (m/s) | 87.0 | 116.9 | 87.8 | 111.1 | 108.3 | 90.8 |

| ASW (L/day) | 313.2 mi | 420.9 mi | 315.9 mi | 399.9 mi | 389.8 mi | 326.9 mi |

| | | |||||

|---|---|---|---|---|---|

| UN | () | (m/s) | (%) | () | () |

| 1 | 54.6 | 109.00 | 0.93 | 54.76 | 0.24 |

| 2 | 55.7 | 111.00 | 0.93 | 54.81 | 0.19 |

| 3 | 54.5 | 108.73 | 0.93 | 54.81 | 0.19 |

| 4 | 53.2 | 106.01 | 0.93 | 54.82 | 0.18 |

| 5 | 53.7 | 107.02 | 0.93 | 54.81 | 0.19 |

| 6 | 53.3 | 106.3 | 0.93 | 54.80 | 0.20 |

| SUM | 324.99 | 648.05 | Flow in SCM: 653.1 (m/s) | ||

| SUB | −0.01 | 5.05 | Productivity index: 0.50148 | ||

| | | |||||

| UN | () | (m/s) | (%) | () | () |

| 1 | 54.6 | 109.00 | 0.93 | 54.76 | 0.24 |

| 2 | 54.2 | 108.00 | 0.93 | 54.8 | 0.20 |

| 3 | 53.9 | 107.42 | 0.93 | 54.81 | 0.19 |

| 4 | 53 | 105.63 | 0.93 | 54.82 | 0.18 |

| 5 | 54.2 | 108.06 | 0.93 | 54.84 | 0.18 |

| 6 | 53.1 | 109.92 | 0.93 | 54.84 | 0.18 |

| SUM | 325.01 | 648.04 | Flow in SCM: 653.1 (m/s) | ||

| SUB | +0.01 | 5.15 | Productivity index: 0.50152 | ||

| | | |||||

| UN | () | (m/s) | (%) | () | () |

| 1 | 53.6 | 107 | 0.93 | 54.77 | 0.23 |

| 2 | 54.7 | 109 | 0.93 | 54.8 | 0.20 |

| 3 | 54.3 | 108.2 | 0.93 | 54.81 | 0.19 |

| 4 | 53.9 | 107.4 | 0.93 | 54.81 | 0.19 |

| 5 | 53.7 | 107.4 | 0.93 | 54.82 | 0.18 |

| 6 | 54.7 | 109.02 | 0.93 | 54.81 | 0.19 |

| SUM | 324.92 | 647.78 | Flow in SCM: 653.1 (m/s) | ||

| SUB | −0.08 | 5.32 | Productivity index: 0.50155 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcelino, C.G.; Camacho-Gómez, C.; Jiménez-Fernández, S.; Salcedo-Sanz, S. Optimal Generation Scheduling in Hydro-Power Plants with the Coral Reefs Optimization Algorithm. Energies 2021, 14, 2443. https://doi.org/10.3390/en14092443

Marcelino CG, Camacho-Gómez C, Jiménez-Fernández S, Salcedo-Sanz S. Optimal Generation Scheduling in Hydro-Power Plants with the Coral Reefs Optimization Algorithm. Energies. 2021; 14(9):2443. https://doi.org/10.3390/en14092443

Chicago/Turabian StyleMarcelino, Carolina Gil, Carlos Camacho-Gómez, Silvia Jiménez-Fernández, and Sancho Salcedo-Sanz. 2021. "Optimal Generation Scheduling in Hydro-Power Plants with the Coral Reefs Optimization Algorithm" Energies 14, no. 9: 2443. https://doi.org/10.3390/en14092443