1. Introduction

For many years, the world’s leading power coal consumers have not changed, and include China, India and the USA. In Europe, Poland is the largest coal consumer, and this example is the basis for the analyses in this paper. However, this does not mean that the problem only affects the above-mentioned countries.

The heating market in Poland is one of the largest in Europe. At the end of 2017, 412 companies were involved in the heating market. They operated in the areas of concessions, heat production, distribution and marketing. Since 2002, the number of heating companies has halved, mainly due to changes in the law, as well as organizational and ownership transformations in the heating sector. A significant reduction in the number of enterprises did not affect the size of the heat market. In 2017, the total thermal power amounted to 55,000 MW (compared to 71,000 MW in 2002), and the achievable power—54,000 MW (compared to 67,000 MW in 2002) [

1,

2]. Unfortunately, the diversification of fuels used to produce heat is progressing very slowly. Coal fuels still account for almost 74% of fuels used in heat sources. This is mainly due to the availability and price of the raw material, as well as the fact that the vast majority of heat plants in operation were designed and built in the 1970s and 1980s as coal-fired heat plants [

3,

4,

5].

The diversity of fuels used to produce heat is slightly greater among enterprises producing heat in cogeneration. Coal fuels also dominate in this group of companies, but 30.6% are other fuels, including 6.7% fuel oil, 8.5% natural gas and 9.1% biomass. Rational use of renewable energy resources is one of the most important elements of sustainable development in Poland [

1].

The amount of coal, type and quality directly influence boiler operation, heat generation efficiency, combustion process, and thus the amount of pollutant emissions. A high level of pollution is emitted during the normal operation of coal-fired boilers as well as in conditions different from normal, i.e., when the boiler operates below the nominal loads during low demand for heat from consumers. The amount of energy produced varies during the year due to, among other things, weather conditions. There is the summer season and the heating season. The summer season occurs outside the heating season, when, e.g., one boiler producing heat for the purpose of domestic hot water preparation operates in the heating plant, sometimes using only 10% of the nominal output. During the heating season, the plant covers the heat demand for heating and domestic hot water production, reaching its nominal output at low outdoor temperatures [

6,

7,

8,

9].

Due to the degradation of the natural environment, and in particular air pollution, one of the main elements of the energy policy of many countries, including Poland, is the increase in the efficiency of fuel and energy use. This also applies to the increase in the share of renewable fuels in the energy balance [

7,

10,

11]. One the technological solutions for the implementation of these fuels includes the co-combustion of coal and biomass in existing power boilers. Increasing the share of renewable energy in the fuel structure will have a positive impact on the overall improvement of the natural environment [

12,

13,

14].

The impact of gaseous pollutants generated in the combustion process on the environment and human health is the subject of many scientific studies and publications [

5,

13,

15,

16,

17,

18]. Heating boilers operating in conditions of variable loads (other than normal) generate a higher unit emission of harmful pollutants. The aim of the work was to investigate the impact of the amount of biomass in the co-combustion process on the boiler efficiency and the emission of selected gas pollutants. The topics of cofiring of biomass with coal have been described in many articles [

14,

18,

19,

20,

21]. This article examines a boiler that operated below the nominal heat load, which is extremely important from the cognitive point of view. There is no similar research conducted in this area in the literature. The current policy of many countries is to reduce the share of coal in the energy production process. The gradual increase in the share of renewable energy sources will reduce the power of the existing coal-fired boilers, and thus partially come down to the problem analyzed in this study.

2. Heating Market in Poland

Proven WR-type water grate boilers fired with hard coal fires are often used in district heating plants, which supply the inhabitants with heat. Boilers of this type achieve the highest design efficiency of 82% when operating with optimal boiler load, i.e., at the level of 85–95% of nominal output [

22,

23,

24]. Under these operating conditions, the generation of thermal energy is the most efficient, with the lowest fuel consumption rate resulting from combustion close to total. In addition, the effect of working under optimal load conditions is the lowest air pollutant emission rate per unit of heat produced, and the main combustion products are: dust, CO

2, SO

2 and NO

X. In reality, the operation of boilers often deviates from stable conditions [

2]. This is a complex subject and affects it, among other things [

25,

26,

27]:

weather conditions, which are strongly correlated with the current heat demand, and therefore the boilers operate with low load at higher outdoor temperatures;

decarbonization and increased interest in alternative and renewable energy sources in heating processes, which result from the introduction of European climate policy, whereby coal-fired boilers are put into operation periodically when other sources are not able to cover the current heat demand;

reduction of heat demand in both residential and industrial sectors through thermal upgrading of buildings, increased interest in energy-efficient buildings, improved energy efficiency index of industrial processes and technology;

oversizing of heat plants, which were designed for the current thermal needs as early as in the 1970s and 1980s.

In practice, this means that the boilers operated are operating more and more dynamically, often below the technical minimum, which is becoming their basic operating regime. The result is working with lower efficiency and the process of converting energy contained in fuel takes place in an inefficient way. Incomplete combustion takes place, which translates into a significant increase in emissions of harmful air pollutants. Taking into account the development prospects of the energy sector in Poland, the problem turns out to be extremely important and worth considering.

High potential for reducing fossil fuel consumption lies in district heating systems, from generation, transmission and distribution to consumers, rationalizing their heat consumption. The commitments made by Poland also concern an increase in the share of renewable fuels in the energy balance [

17,

28]. One of the technological solutions for the implementation of these fuels is the co-combustion of coal and biomass in power boilers [

29,

30].

Cofiring of solid fuels and biomass is understood as a set of processes consisting of burning coal with various types of properly selected solid biofuels or products derived from their processing. This process may take place in already existing boilers with high power output while ensuring high efficiency of chemical energy conversion contained in the fuel being burnt [

12,

13,

17,

31,

32,

33,

34,

35,

36]. Increasing the share of renewable energy in the fuel structure, inter alia through co-incineration, resulting primarily in the reduction of greenhouse gas and sulfur emissions, is also of great importance for increasing the security of energy supply and supporting technological development [

14,

37,

38,

39,

40,

41].

Due to relatively low investment outlays and the ability to adapt existing boilers, the most popular methods of co-combustion of biomass and coal is direct co-combustion. In such a system, the combustion chamber is supplied with a stream of coal and biomass or an appropriate mixture of these. The solution is optimal from the economic point of view, and maintaining constant boiler operation parameters is not a problem. Biomass plays the role of a cheap and clean energy carrier, while coal stabilizes the combustion process, compensating for periodic changes in the quality and quantity of biomass [

42]. The dimension of biomass is important for proper boiler operation. The WR boiler operates under negative pressure, which may cause the extraction of small biomass particles without their complete combustion [

43]. Excessive chips, as well as their high humidity, can lead to fuel suspension in the hopper and thus stop the feeding of biomass to the grate. Therefore, additional sight glasses are made in the hopper in order to be able to observe the fuel feed and unblock when necessary [

43]. In addition to sight glasses, electric vibrators are also installed, which induce vibrations supporting the process of feeding the fuel mixture onto the grate.

The advantage of cofiring fuels in such a system is practically zero or minimal costs of boiler preparation. The disadvantage, however, is the problem of preparing the right mix and then feeding it to the grate so that the fuel is mixed in the right proportions. Improper preparation of the mixture may lead to the formation of craters after biomass firing, and after a longer exploitation may lead to point burning of the grate elements [

17].

The further part of the work presents the results of tests of boiler efficiency and pollutant concentrations in the heat plant, where the process of direct co-incineration was carried out and the boiler operated significantly below the technical minimum.

3. Materials and Methods

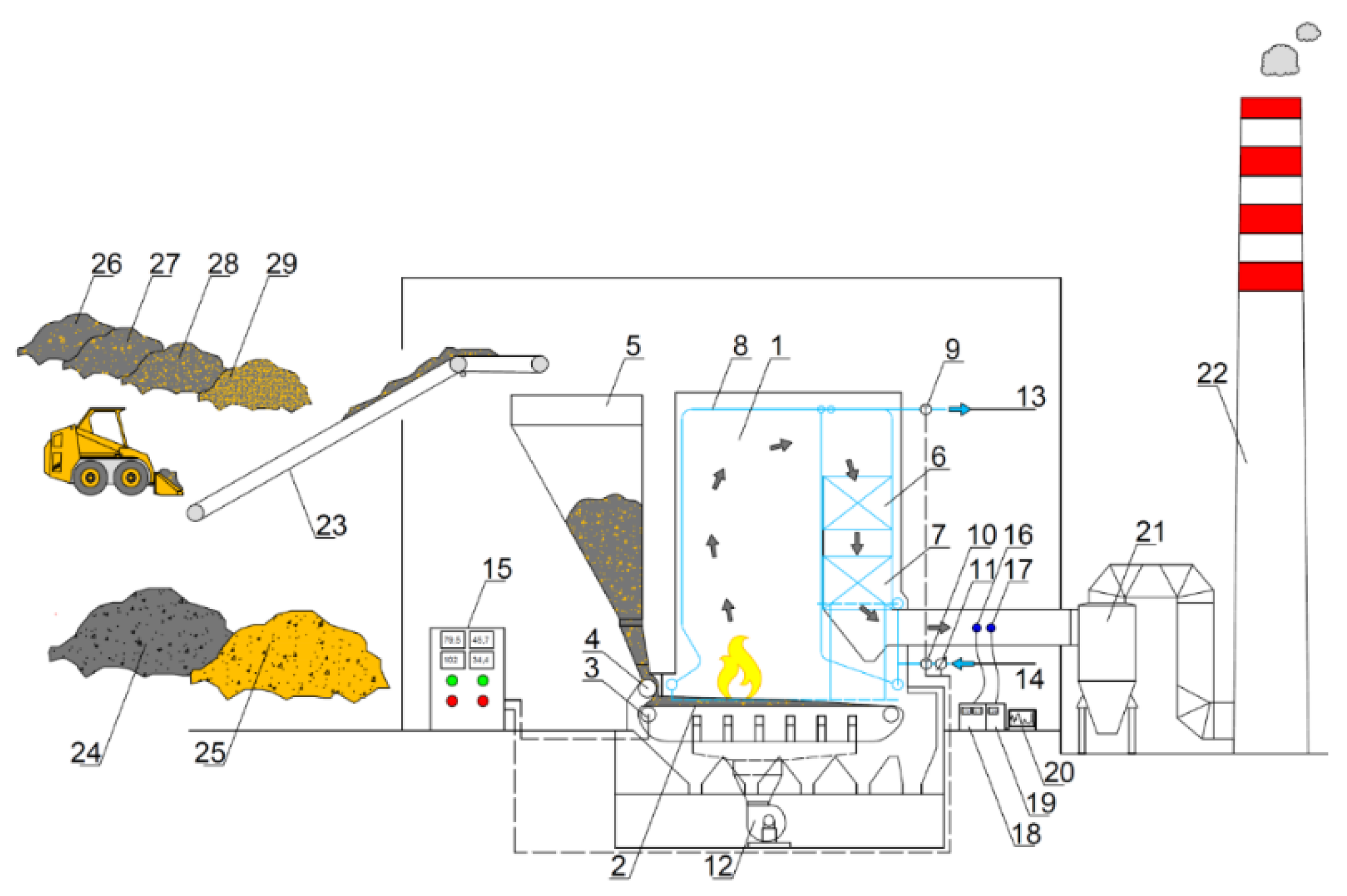

Measurements of boiler efficiency and gas pollution were carried out in a heat plant equipped with two WR-10 boilers. In the heat plant under study, the process of direct co-combustion of hard coal and wood chips coming from furniture factories was carried out. The mass share of biomass in the fuel was constant during each measurement and amounted to 35, 45, 60 or 70%. The heat plant was designed in the 1970s, and until the end of the 1990s, it supplied heat to municipal flats and the urban industrial zone. These operating conditions enabled the optimum load of two WR 10 boilers to be achieved. Currently, for economic reasons, only the city’s industrial zone is supplied with heat. For this reason, one WR-10 boiler operates in the heat plant, which is significantly below the optimum load depending on the current demand for heat from consumers. The diagram of the heat plant is shown in

Figure 1. Biomass was delivered to a separate part of the storage yard, where it was subjected to the following processes: storage, drying, grinding and mixed with hard coal in appropriate mass fractions.

The flue gas composition was measured behind the boiler in specially prepared measuring holes. Measurements were continuous and lasted from 2 to 8 h. The measurement of the basic parameters of hard coal and biomass was carried out in the Laboratory of Energy Conversion and Proecological Technologies at the Department of Heating and Air Conditioning at the Rzeszow University of Technology.

These measurements were used to determine the probable causal relationship between the co-combustion of biomass and hard coal during boiler operation below the nominal load and the ecological effect.

Sampling of hard coal and biomass samples and their preparation for further research were performed in accordance with the PN-90/G-04502 [

44] standard for hard coal. In accordance with the PN-81/G-04513 [

45] with the automatic calorimeter Parr 6300 the combustion heat and calorific value of coal, biomass and their mixtures were determined. Using the elementary analyzer Vario EL III C, H, N, S and O the percentage of carbon, hydrogen, nitrogen and sulfur in hard coal and biomass was determined. According to PN-80/G-0451 and PN-80/G-04512 [

46,

47] standards, the percentage content of moisture and ash in the fuels studied was determined. The boiler efficiency was measured in accordance with the PN-EN 12952-15 standard.

Determination of boiler operation parameters and pollutant concentrations in flue gases required appropriate measurement conditions. The ideal conditions would be to maintain the thermal equation balance, which means that all parameters remain constant during the measurement, with practically insignificant deviations from the average values. This is possible while maintaining a constant flow of heated medium and air and fuel supplied for combustion. Determination of the boiler operation conditions, mainly temperature distribution, is achieved after a period of several hours. Theoretically, the boiler operation time at the assumed load should be about 5 h [

48].

In fact, it was not possible to maintain thermal balance. The boiler plant operated with variable load over a period of time covering the current heat demand of consumers. Therefore, in order to ensure similar conditions during each measurement, characteristic 30 min intervals were determined, during which the boiler operated under constant load.

During the measurements for each heat load, the parameters for setting the height of the fuel layer were unchanged, the grate speed was known. The thickness of the fuel mixture layer was determined in this way, and knowing its bulk density, the fuel consumption was calculated for every 30 min of measurement. Boiler operation parameters, i.e., grate speed, temperature of water supplied to the boiler, heated water and its flow, were read from the boiler’s measurement meters. On the basis of energetic values of biomass and hard coal mixtures, sufficiently accurate measurements of the weight of fuel burned and conducting research on a typical low output WR boiler, the thermal efficiency of the boiler was determined using the direct method. It was assumed that the analysis of the measurement results would be within the 95% confidence interval. Exhaust gas composition measurement was performed in accordance with PN-ISO 10396:2001 [

49] standard by means of spectroscopy and flame ionization detection using GASMET DX-4000 analyzer and LZO J.U.M. OVF 3000 analyzer.

4. Results

Figure 2 and

Table 1 show the results of properties of hard coal, biomass and their mixtures.

The calorific value of fuels is most affected by the presence of bound carbon, followed by ballast such as moisture, ash and other impurities. The origin of the fuel has a significant impact on its composition, and thus the emission of pollutants in the combustion process. The fuels in the analyzed study came from the same source throughout the entire research period. The coal came from a Polish mine, while the biomass came from nearby wooden furniture plants. The analysis of the conducted tests indicated a large discrepancy in the fuel parameters. The calorific value of hard coal was 20,899 kJ/kg and was much higher than that of biomass, which was 11,580 kJ/kg. The content of the carbon element in the hard coal was much higher (65.43%) and the moisture content almost two times lower (13.91%) compared to the biomass.

Fuel quality is related to fuel consumption. To produce a heat unit a smaller amount of fuel with a high calorific value is needed than fuels with a low calorific value.

Biomass has more than three times lower sulfur content (0.21%) compared to hard coal, which translates into lower sulfur dioxide emissions in the process of fuel combustion. Moreover, the ash content in biomass is more than fifteen times lower (0.82%) compared to hard coal (13.21%). In connection with the above, it can be seen that with the increase in the amount of biomass in the fuel, the boiler efficiency is decreased due to the losses related to the need to evaporate the water contained in the biomass.

On the basis of the developed results of pollutant concentrations for different percentages of biomass in the fuel to be burned and at different thermal loads of the boiler, graphs and analysis of the Spearman rank correlations between the share of biomass or boiler output and the efficiency and concentrations of selected pollutants have been made. The results of the rank correlation analysis are presented in

Table 2. The analysis was performed with the use of STATISTICA software package. On that basis it was possible to determine the influence of independent variables, i.e., the amount of biomass and boiler output on dependent variables, i.e., changes in the concentration of individual pollutants and boiler efficiency [

50,

51,

52,

53].

Figure 3 shows that as the boiler output increased, its efficiency increased. The nature of the changes was similar for all biomass shares. At low boiler output there was a slight disturbance in the nature of changes in boiler efficiency, which may have resulted from the heat load of the boiler being significantly below the nominal one. The boiler reached the highest efficiency when cofiring coal with 35% share of biomass. As the amount of biomass in the fuel increased, the efficiency decreased. The decrease in efficiency resulted, among other things, from the energy properties of the fuel. The correlation of Spearman rankings showed high dependence of biomass share and boiler output on its efficiency. On the basis of R

2 determination coefficients it could be assumed that the power trend lines were well matched to the obtained efficiency results.

The diagram in

Figure 4 shows that with the increase in boiler output and the share of biomass, the amount of carbon dioxide in flue gases increased. The nature of the changes was maintained for all biomass shares. Minor disturbances may have resulted from the heat load of the boiler being significantly below the nominal one. At very light loads, it was necessary to increase the excess air ratio, which directly contributed to the reduction of CO

2 emissions. The Spearman rank correlation showed a high correlation between the share of biomass and boiler output on the concentration of carbon dioxide in flue gases. On the basis of R

2 determination coefficients it could be assumed that the power trend lines were well matched.

The diagram in

Figure 5 shows that with the increase in boiler output and the share of biomass, the amount of nitrogen oxides in the flue gases increased. The nature of the changes was maintained for all biomass shares. Minor disturbances may have resulted from the heat load of the boiler being significantly below the nominal parameters. The highest NO

X concentrations were observed during coal co-combustion with 60% and 70% share of biomass in the whole boiler output range. Significantly lower shares of NO

X in flue gases were observed with 35% and 45% share of biomass. As the boiler output increased, the temperature in the combustion chamber increased, which was conducive to the formation of nitrogen oxides by thermal and fast mechanisms. The amount of fuel burned was also increasing, i.e., organic fuel compounds containing nitrogen (fuel mechanism) were oxidized. The correlation of Spearman rank showed a high correlation between boiler output and nitric oxide concentrations. On the basis of R

2 determination coefficients it could be assumed that the polynomial trend lines were well matched to the concentrations of nitrogen oxides.

The graph in

Figure 6 shows that with the increase in boiler output and the share of coal, the amount of sulfur dioxide in flue gases increased. The nature of the changes was maintained for all biomass shares. The share of sulfur in hard coal was about 0.55%, while in biomass it was at the level of 0.21%, so the concentration of SO

2 was closely related to the content of sulfur in the fuel and the amount of fuel burned. The highest concentrations of SO

2 were observed during coal co-combustion with 35% share of biomass. The correlation of Spearman rank showed high dependence of biomass share and boiler output on SO

2 concentrations. On the basis of the determination coefficients R

2 it could be assumed that the exponential trend lines were well adjusted to the concentrations of sulfur dioxide.

The diagram in

Figure 7 shows that the share of hydrogen chloride in flue gases increased with the increase in boiler output and the share of coal. Chlorine is a natural element present in fossil fuels. It is likely that higher hydrogen chloride concentrations with smaller shares of biomass result from the presence of more chlorine compounds in hard coal than biomass. The nature of the changes was maintained for all cases considered. Minor disturbances may have resulted from unstable boiler operation well below the nominal output. The correlation of Spearman rank showed a high dependence of biomass share and boiler output on hydrogen chloride concentration. On the basis of R

2 determination coefficients it could be assumed that the trend lines were well adjusted to HCl concentrations.

The graph in

Figure 8 shows that the share of hydrogen fluoride in flue gases increased with the increase in boiler output and the share of biomass in the fuel mixture. Fluorine, like chlorine, is a natural element present in fossil fuels. It is likely that higher hydrogen fluoride concentrations with lower carbon shares result from the presence of more fluorine compounds in biomass than in hard coal. The nature of the changes was maintained for all cases considered. Minor disturbances may have resulted from unstable boiler operation well below the nominal output. The correlation of Spearman rank showed a high dependence of boiler output on hydrogen fluoride concentrations. On the basis of R

2 determination coefficients it could be assumed that the polynomial trend lines were well adjusted to hydrogen fluoride concentrations.

The diagram in

Figure 9 shows that with the increase in boiler output and the share of biomass, the VOC concentration decreases. The high proportion of VOC at low boiler loads may be due to the lack of stabilization of the combustion process. When the boiler output increased and the furnace operation stabilized, the level of volatile organic compounds dropped to 0.0 ppm. This may be due to the increased amount of volatile flammable substances, which increases the efficiency of the combustion process, thanks to which VOCs burn more [

54]. The nature of the changes was maintained for all cases considered. Slight disturbances may have resulted from unstable boiler operation well below the nominal output. The correlation of Spearman rank showed high dependence of boiler output on VOC concentration. On the basis of R

2 determination coefficients it could be assumed that the exponential trend lines were well adjusted to VOC concentrations.

5. Discussion

One of the technological solutions for reducing the consumption of fossil fuels and increasing the share of renewable fuels in the energy balance is co-combustion of hard coal and biomass in power boilers. This is particularly important in Poland, where heat is produced mainly from hard coal. Co-combustion of hard coal and biomass in the direct system in water-based grate boilers of the WR type can be carried out efficiently and practically without any investment, using the existing boilers, infrastructure and auxiliary equipment. In such a system, biomass acts as a cheap and clean energy carrier, while coal stabilizes the combustion process, compensating for periodic changes in the quality and quantity of biomass.

The co-combustion process affects the efficiency of heat generation and the concentration of gaseous pollutants in water power boilers, especially during boiler operation with a heat load significantly below the minimum. An increase in the share of biomass in the fuel burned results in a decrease in boiler efficiency, which results directly from the energy parameters of fuels, and thus their consumption. An increase in the share of biomass in the fuel burned results in an increase in the concentration of CO2, NOX and HF. A positive effect is the reduction of SO2, HCl and VOC emissions. The above changes result, among others, from the elemental composition of the fuel and its consumption.

As the heat load of the boiler increases, the combustion process stabilizes, thus increasing the efficiency of heat generation. The increase in the thermal load of the boiler is also associated with higher fuel consumption and temperature in the combustion chamber, which translates into higher concentrations of CO2, NOX, SO2, HCl, and HF. A positive effect is the reduction of VOC concentrations.

For each independent variable analyzed, a trend line with a high correlation coefficient R2 was matched. This may mean that even when the boiler operates below the nominal load, the behavior of the analyzed variable can be predicted, regardless of the dependent variable.

6. Conclusions

The article presents issues concerning the co-combustion of hard coal and biomass in the existing WR-type grate water boilers during operation with a heat load significantly below the nominal one. In the practical part, the influence of co-combustion of hard coal and biomass in various proportions on the efficiency of heat generation and concentration of gaseous pollutants was examined. A portable multiparameter exhaust gas analyzer GASMET DX-4000 and a volatile organic compounds analyzer J.U.M. OVF 3000 were used to measure concentrations of gaseous pollutants. The energy quantities of fuels were determined using the Parr 6300 calorimeter. The measurement results are presented in the form of diagrams. On this basis, it can be concluded that the co-combustion of hard coal and biomass, as well as the boiler power, affect the efficiency of heat generation and the concentration of gaseous pollutants in water power boilers during operation with a very low heat load. As a result of the research, it can be concluded that with the increase in the biomass content in the basic fuel, which is hard coal, the emissions of CO2, NOX, HF increase. There is also a decrease in boiler efficiency. A positive effect is the reduction of SO2, HCl and VOC emissions. As the heat load of the boiler increases, the combustion process stabilizes, and thus the efficiency of heat generation increases. Concentrations of CO2, NOX, SO2, HCl and HF also increase. A positive effect is the reduction of the concentration of volatile organic compounds. These observations are a prelude to further research on the influence of independent variables on dependent variables during the operation of a WR type water boiler in unstable conditions.