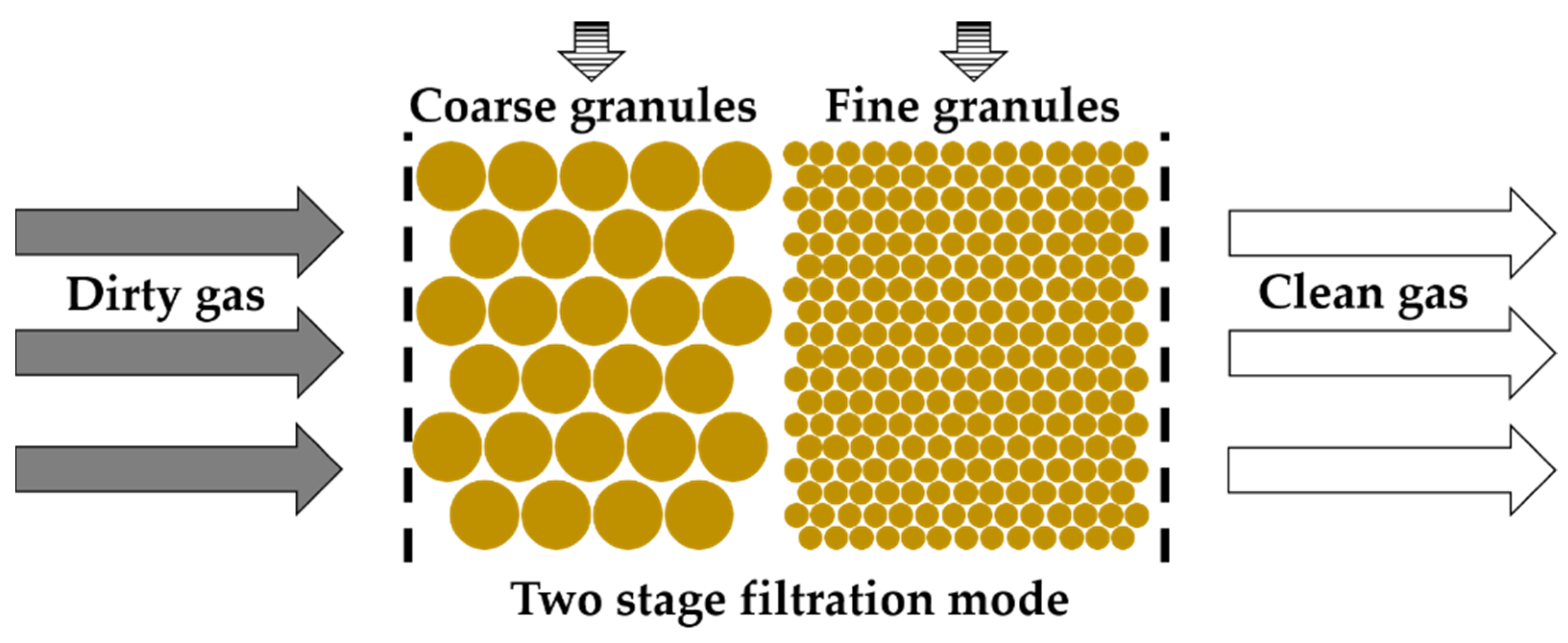

A New Approach of Dedusting for IGCC by a Two-Stage Moving Granular Bed Filter

Abstract

1. Introduction

2. Experimental Methodology

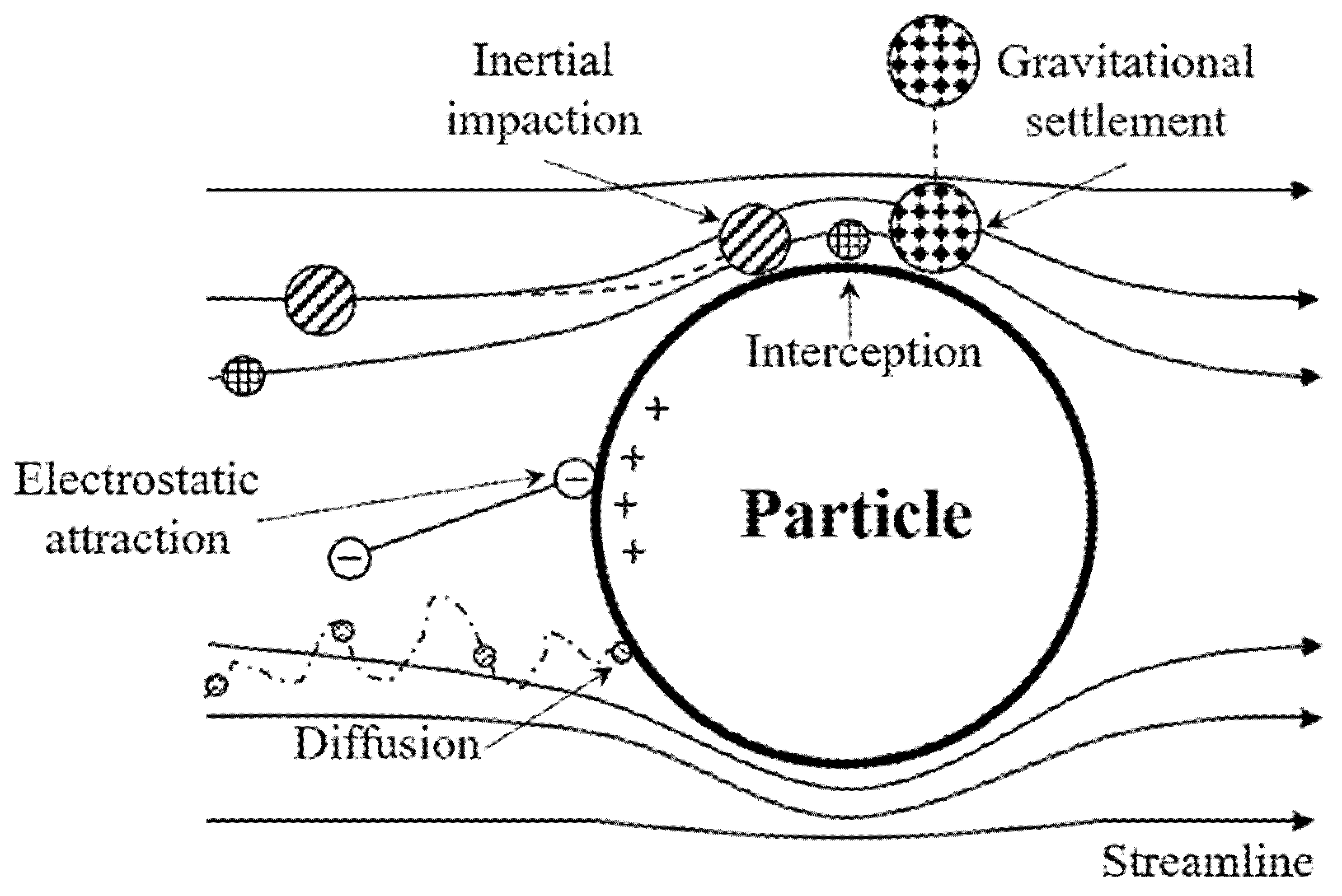

3. Mechanism of GBF

4. Results and Discussion

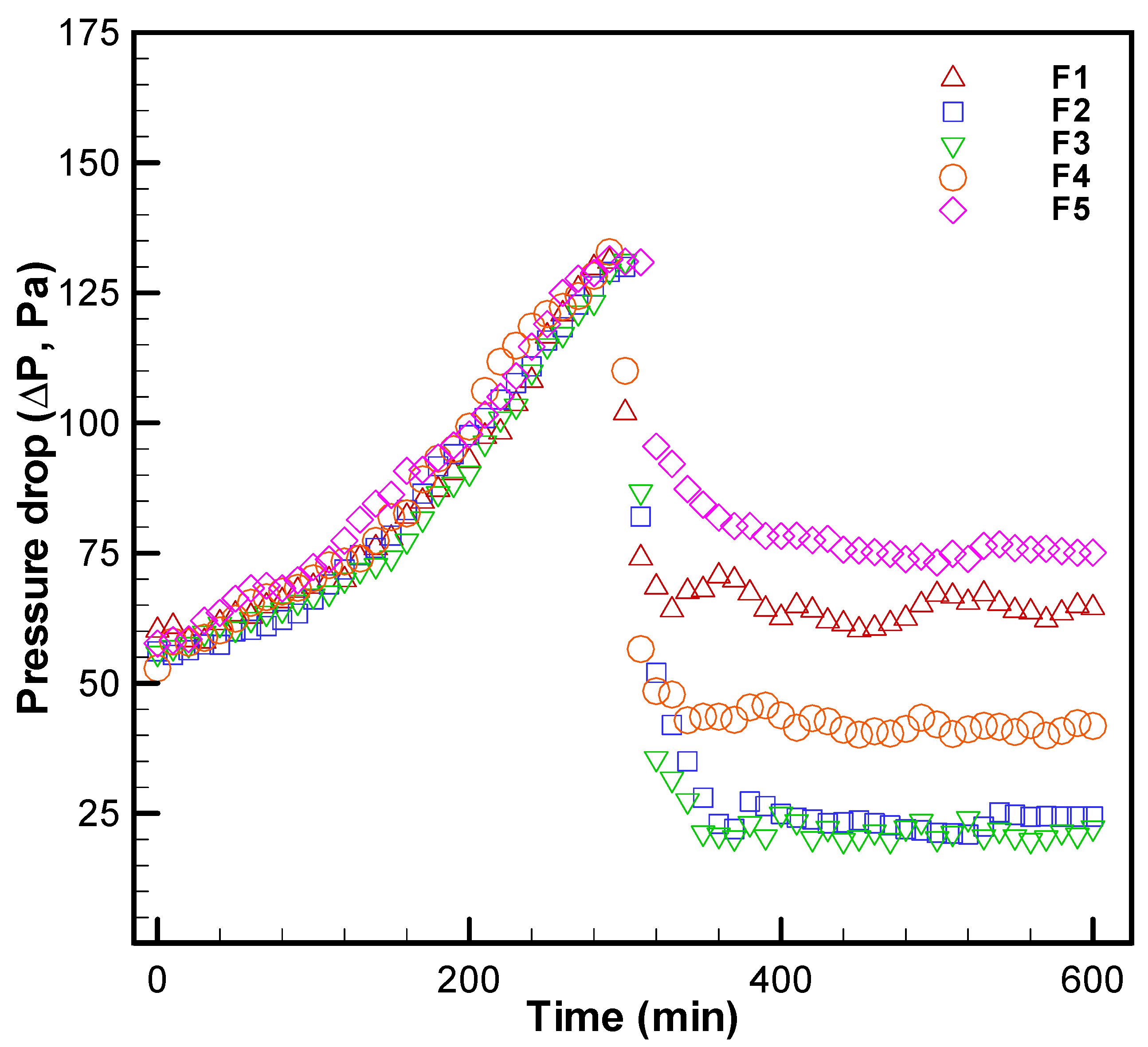

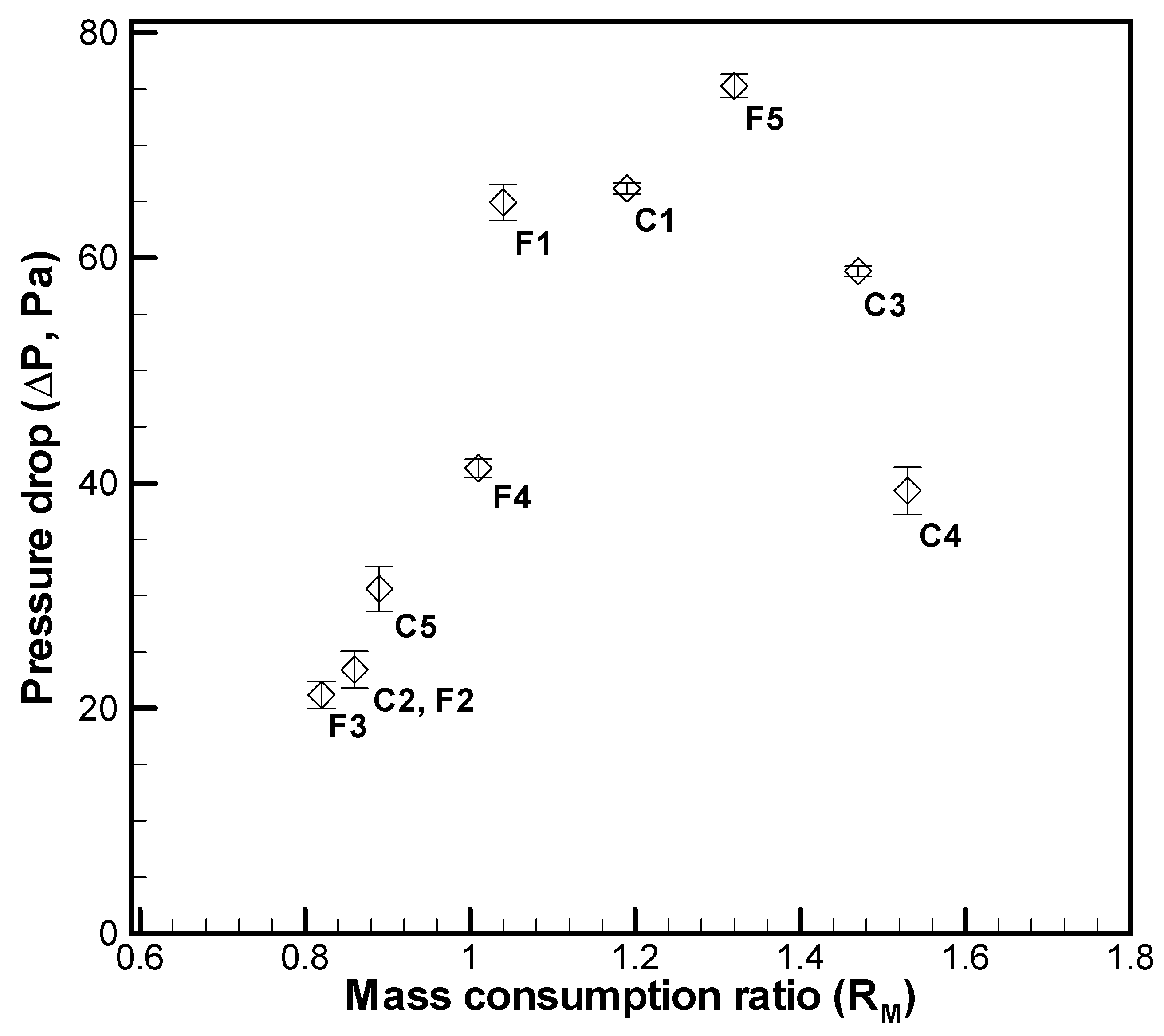

4.1. Pressure Drop under Different Mass Flow Rates of Coarse and Fine Granules

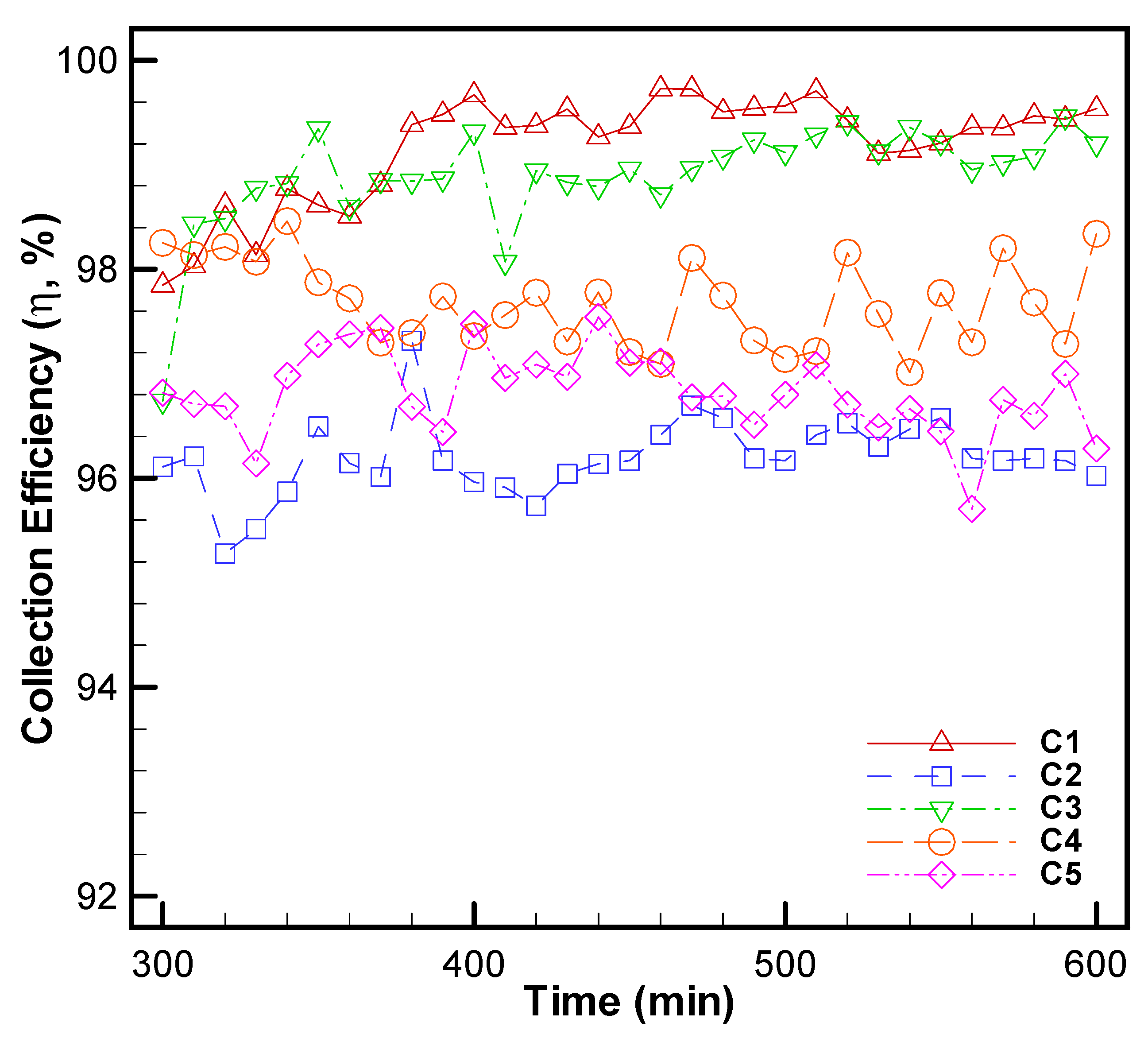

4.2. Collection Efficiency under Different Mass Flow Rates of Coarse and Fine Granules

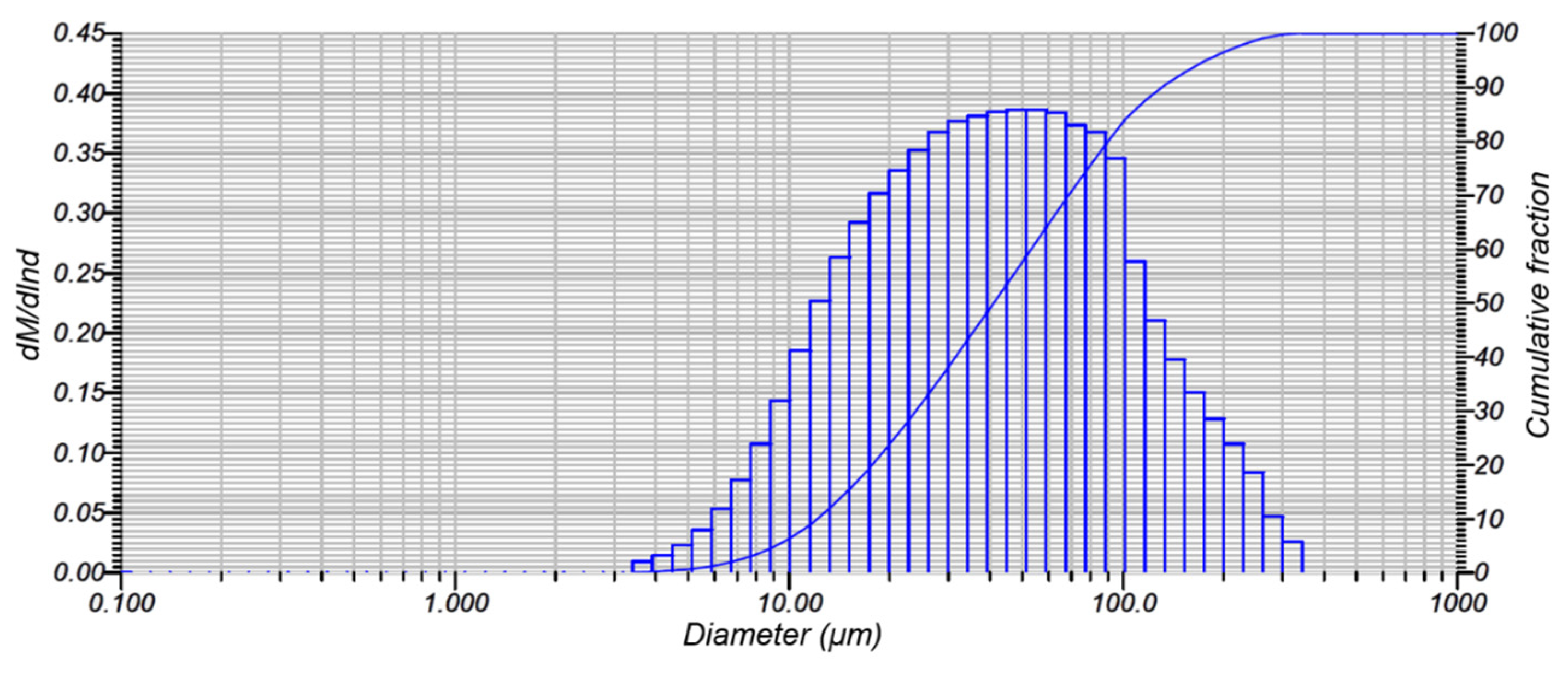

4.3. Size Distribution of Dust Particulates under Different Mass Flow Rates

5. Conclusions

- The pressure drop was affected by the interaction of coarse and fine granules in the mixed zone. The pressure drop increased with the increase in the mass consumption ratio until a mass consumption ratio of 1.32 but then decreased (i.e., Cases C3 and C4). Thus, a mass consumption ratio of 1.32 provided the maximum pressure drop.

- The highest collection efficiency reached 99.75% at a mass consumption ratio of 1.32, which was enhanced by the pressure drop. The higher energy loss due to the high pressure drop might be critical to address in gas turbine applications.

- In all setups of this study, the particulate size distribution of the dust at the filter’s outlet was <1.775 μm; this value is within a standard of 10 μm watershed required for the safe application of gas turbines.

- Better collection efficiency and particulate size distributions were achieved when ṁF = 1100 g/min and ṁC = 330 g/min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sax, S.N.; Zu, K.; Goodman, J.E. Air pollution and lung cancer in Europe. Lancet Oncol. 2013, 14, e439–e440. [Google Scholar] [CrossRef]

- Seville, J.P.K. Rigid ceramic filters for hot gas cleaning. KONA Powder Part J. 1993, 11, 41–56. [Google Scholar] [CrossRef][Green Version]

- Smith, D.H.; Ahmadi, G. Problems and progress in hot-gas filtration for pressurized fluidized bed combustion (PFBC) and integrated gasification combined cycle (IGCC). Aerosol. Sci. Technol. 1998, 29, 163–169. [Google Scholar] [CrossRef]

- Xiao, G.; Wang, X.; Yang, G.; Ni, M.; Gao, X.; Cen, K. An experimental investigation of electrostatic precipitation in a wire–cylinder configuration at high temperatures. Powder Technol. 2015, 269, 166–177. [Google Scholar] [CrossRef]

- Melchior, T.; Madlener, R. Economic evaluation of IGCC plants with hot gas cleaning. Appl. Energy 2012, 97, 170–184. [Google Scholar] [CrossRef]

- Li, G.; Wang, L.; Wang, C.; Wang, C.; Wu, P.; Che, D. Experimental study on coal gasification in a full-scale two-stage entrained-flow gasifier. Energies 2020, 13, 4937. [Google Scholar] [CrossRef]

- Hasegawa, T. Gas turbine combustion and ammonia removal technology of gasified fuels. Energies 2010, 3, 335–449. [Google Scholar] [CrossRef]

- Chen, Y.S.; Hsiau, S.S.; Lai, S.C.; Chyou, Y.P.; Li, H.Y.; Hsu, C.J. Filtration of dust particulates with a moving granular bed filter. J. Hazard. Mater. 2009, 171, 987–994. [Google Scholar] [CrossRef]

- Kamiya, H.; Sekiya, Y.; Horio, M. Thermal stress fracture of rigid ceramic filter due to char combustion in collected dust layer on filter surface. Powder Technol. 2001, 115, 139–145. [Google Scholar] [CrossRef]

- Xiao, G.; Wang, X.; Zhang, J.; Ni, M.; Gao, X.; Luo, Z.; Cen, K. Granular bed filter: A promising technology for hot gas clean-up. Powder Technol. 2013, 244, 93–99. [Google Scholar] [CrossRef]

- Wenzel, B.M.; Porciúncula, C.B.; Marcilio, N.R.; Menegolla, H.B.; Dornemann, G.M.; Godinho, M.; Martins, C.B. Filtration of dust in an intermittent moving granular bed filter: Performance and modeling. Sep. Purif. Technol. 2014, 133, 108–119. [Google Scholar] [CrossRef]

- El-Hedok, I.A.; Whitmer, L.; Brown, R.C. The influence of granular flow rate on the performance of a moving bed granular filter. Powder Technol. 2011, 214, 69–76. [Google Scholar] [CrossRef]

- Chen, Y.S.; Hsiau, S.S. Cake formation and growth in cake filtration. Powder Technol. 2009, 192, 217–224. [Google Scholar] [CrossRef]

- Böehm, L.; Jordan, S. On the filtration of sodium oxide aerosols by multilayer sand bed filters. J. Aerosol. Sci. 1976, 7, 311–318. [Google Scholar] [CrossRef]

- Stechkina, I.B.; Kirsh, V.A. Optimization of parameters of filters in a multistage system of fine gas filtration. Theor. Found. Chem. Eng. 2003, 37, 218–225. [Google Scholar] [CrossRef]

- Ochieng, G.M.M.; Otieno, F.A.O.; Ogada, T.P.M.; Shitote, S.M.; Menzwa, D.M. Performance of multistage filtration using different filter media against conventional water treatment systems. Water SA 2004, 30, 361–367. [Google Scholar] [CrossRef]

- Charvet, A.; Wingert, L.; Monnier, N.B.; Pacault, S.; Fournier, F.; Bemer, D.; Thomas, D. Multi-staged granular beds applied to the filtration of ultrafine particles: An optimization of collector diameters. Powder Technol. 2019, 342, 341–347. [Google Scholar] [CrossRef]

- Yu, Y.S.; Tao, Y.B.; Ma, Z.; He, Y.L. Experimental study and optimization on filtration and fluid flow performance of a granular bed filter. Powder Technol. 2018, 333, 449–457. [Google Scholar] [CrossRef]

- Shi, K.Y.; Yang, G.H.; Huang, S.; Tian, S.R.; Hu, Z.F.; Huang, B.L. Study on filtering characteristics of aerosol particulates in a powder-grain dual-layer granular bed. Powder Technol. 2015, 272, 54–63. [Google Scholar] [CrossRef]

- Chen, J.L.; Li, X.F.; Huai, X.L.; Zhou, J.Z. Collection efficiency in a three-dimensional randomly arranged dual-layer granular bed filter. Particuology 2020, 49, 88–94. [Google Scholar] [CrossRef]

- Chang, C.W.; Hsiau, S.S.; Chen, Y.S.; Chyou, Y.P.; Smid, J. Study of flow patterns in two-stage mode of moving granular bed filter. Aerosol. Air Qual. Res. 2017, 17, 2691–2704. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chyou, Y.P.; Li, S.C. Hot gas clean-up technology of dust particulates with a moving granular bed filter. Appl. Therm. Eng. 2015, 74, 146–155. [Google Scholar] [CrossRef]

- Zevenhoven, C.A.P. Particle Charging and Granular Bed Filtration for High Temperature Application. Ph.D. Thesis, Delft University, Delft, The Netherlands, 1992. [Google Scholar]

- Gal, E.; Tardos, G.; Pfeffer, R. A study of inertial effects in granular bed filtration. AIChE J. 1985, 31, 1093–1104. [Google Scholar] [CrossRef]

- Lee, K.W. Maximum penetration of aerosol particles in granular bed filters. J. Aerosol. Sci. 1981, 12, 79–87. [Google Scholar] [CrossRef]

- Cicero, D.C.; Dennis, R.A.; Geiling, D.W.; Schmidt, D.K. Hot-gas cleanup for coal based gas turbines. Mech. Eng. 1994, 116, 70–75. [Google Scholar]

| Test | Mass Flow Rate (g/min) | Mass Consumption (kg) | Ratio | ||

|---|---|---|---|---|---|

| Coarse Granules | Fine Granules | Coarse Granules | Fine Granules | ||

| C1 | 110 | 330 | 74.4 | 62.5 | 1.19 |

| C2 | 330 | 77.8 | 90.5 | 0.86 | |

| C3 | 440 | 138.5 | 94.2 | 1.47 | |

| C4 | 550 | 157.1 | 102.7 | 1.53 | |

| C5 | 1100 | 198.6 | 223.1 | 0.89 | |

| F1 | 330 | 110 | 69.7 | 67.0 | 1.04 |

| F2 1 | 330 | 77.8 | 90.5 | 0.86 | |

| F3 | 440 | 103.0 | 125.6 | 0.82 | |

| F4 | 550 | 123.5 | 122.3 | 1.01 | |

| F5 | 1100 | 235.0 | 178.0 | 1.32 | |

| Coarse Granules | Fine Granules | |

|---|---|---|

| Mean size, D50 (mm) | 2.483 | 0.412 |

| Wall friction angle, (°) | 15.78 | 20.90 |

| Bulk density, (kg/m3) | 1420 | 1530 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.; Chen, Y.; Sheng, L.; Hsiau, S. A New Approach of Dedusting for IGCC by a Two-Stage Moving Granular Bed Filter. Energies 2021, 14, 2534. https://doi.org/10.3390/en14092534

Chang C, Chen Y, Sheng L, Hsiau S. A New Approach of Dedusting for IGCC by a Two-Stage Moving Granular Bed Filter. Energies. 2021; 14(9):2534. https://doi.org/10.3390/en14092534

Chicago/Turabian StyleChang, Chiawei, Yishun Chen, Litsung Sheng, and Shusan Hsiau. 2021. "A New Approach of Dedusting for IGCC by a Two-Stage Moving Granular Bed Filter" Energies 14, no. 9: 2534. https://doi.org/10.3390/en14092534

APA StyleChang, C., Chen, Y., Sheng, L., & Hsiau, S. (2021). A New Approach of Dedusting for IGCC by a Two-Stage Moving Granular Bed Filter. Energies, 14(9), 2534. https://doi.org/10.3390/en14092534