Energy Efficient Parallel Configuration Based Six Degree of Freedom Machining Bed

Abstract

:1. Introduction

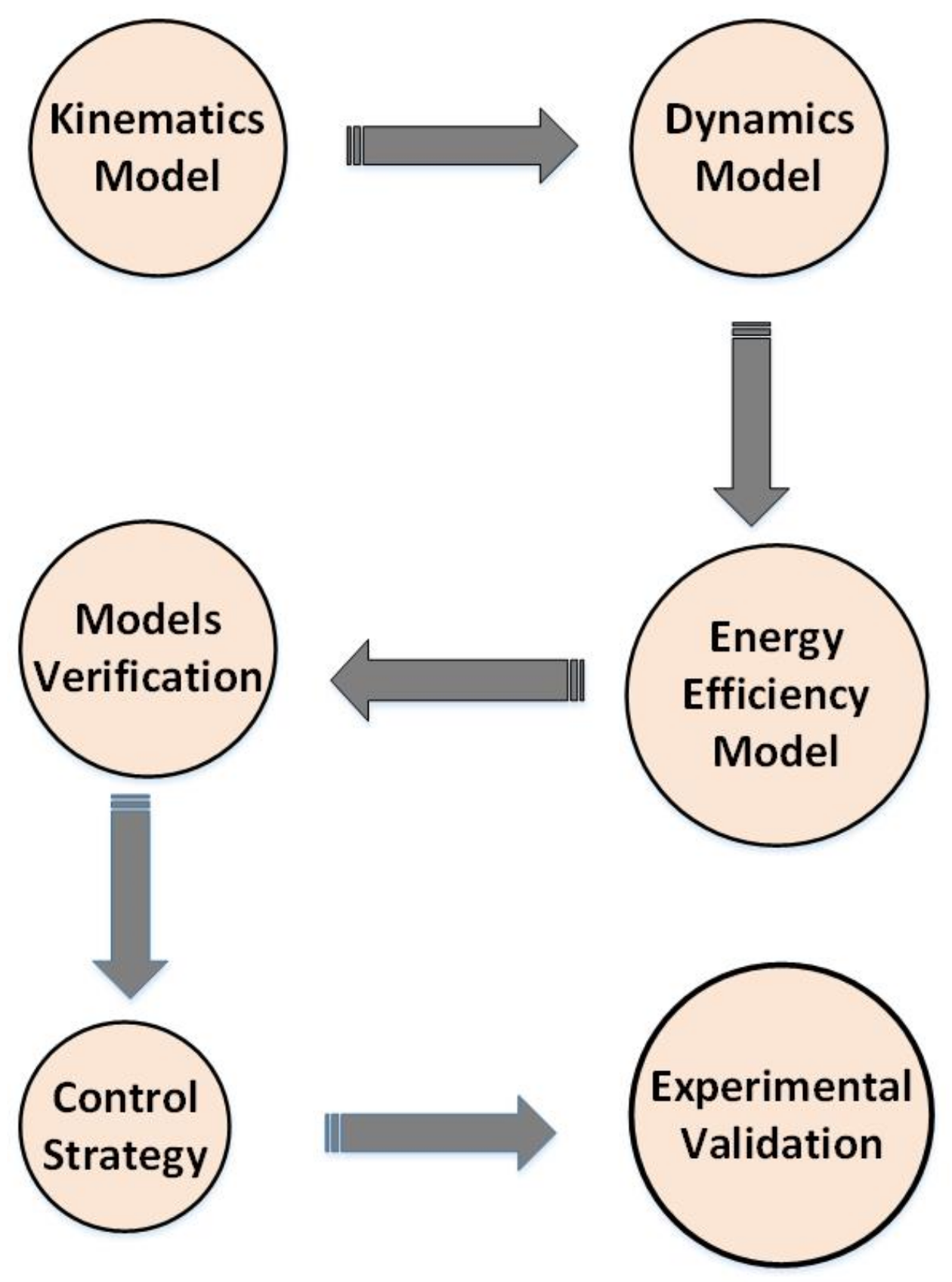

- The dynamics of the proposed machining bed is presented in detail to formulate the energy efficiency model.

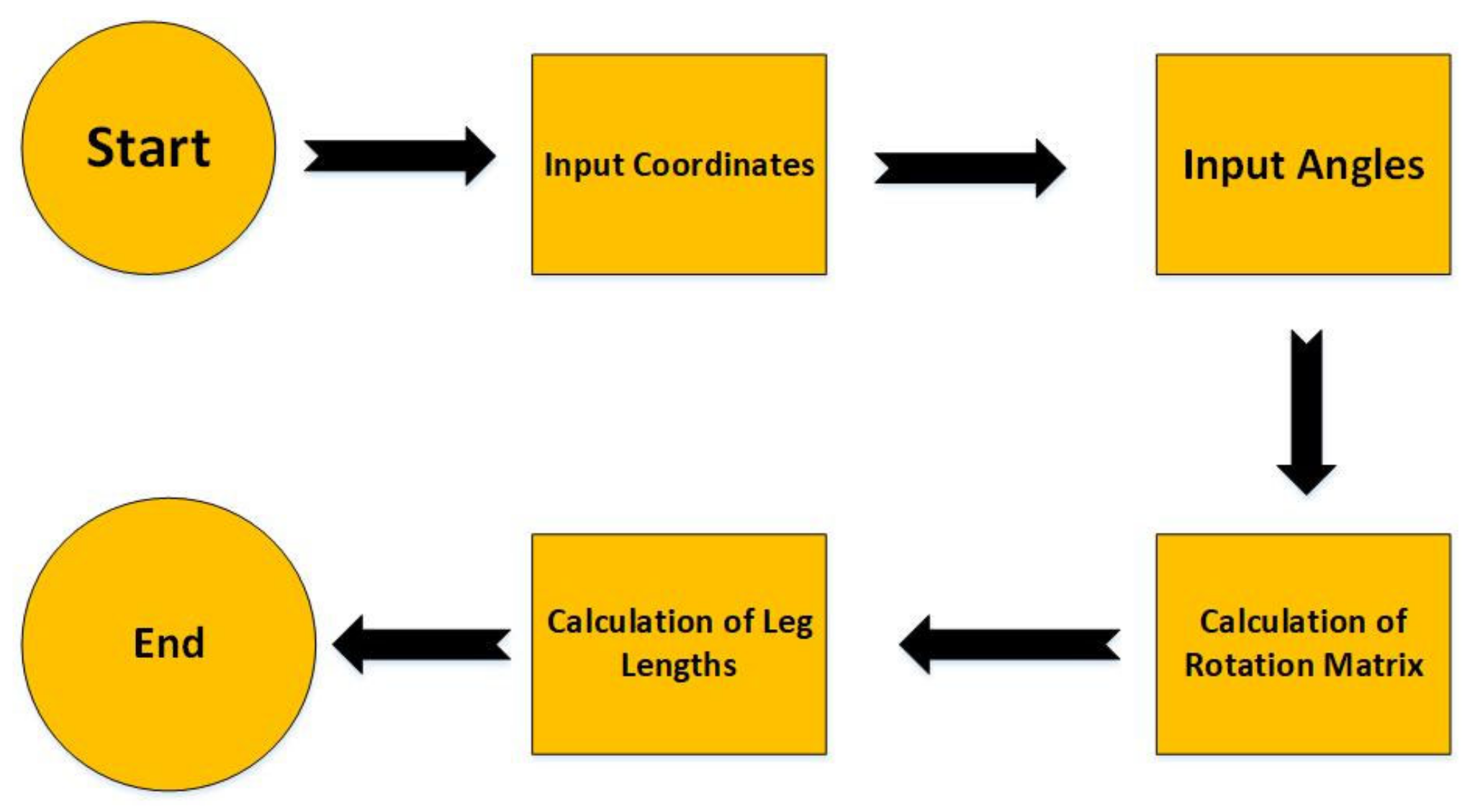

- An algorithm is proposed to reduce the computation time for the calculation of the leg lengths of the machining bed, which reduces the energy consumed.

- Section 2 describes the mechanism of the proposed machining bed. The configuration of the mechanism is presented

- Section 3 presents the mathematical model for the machining bed. This section presents the kinematics model and the dynamics model of the machining bed. Using the dynamics model the energy efficiency model developed is also discussed in this section.

- Section 4 presents the verification of models in simulation

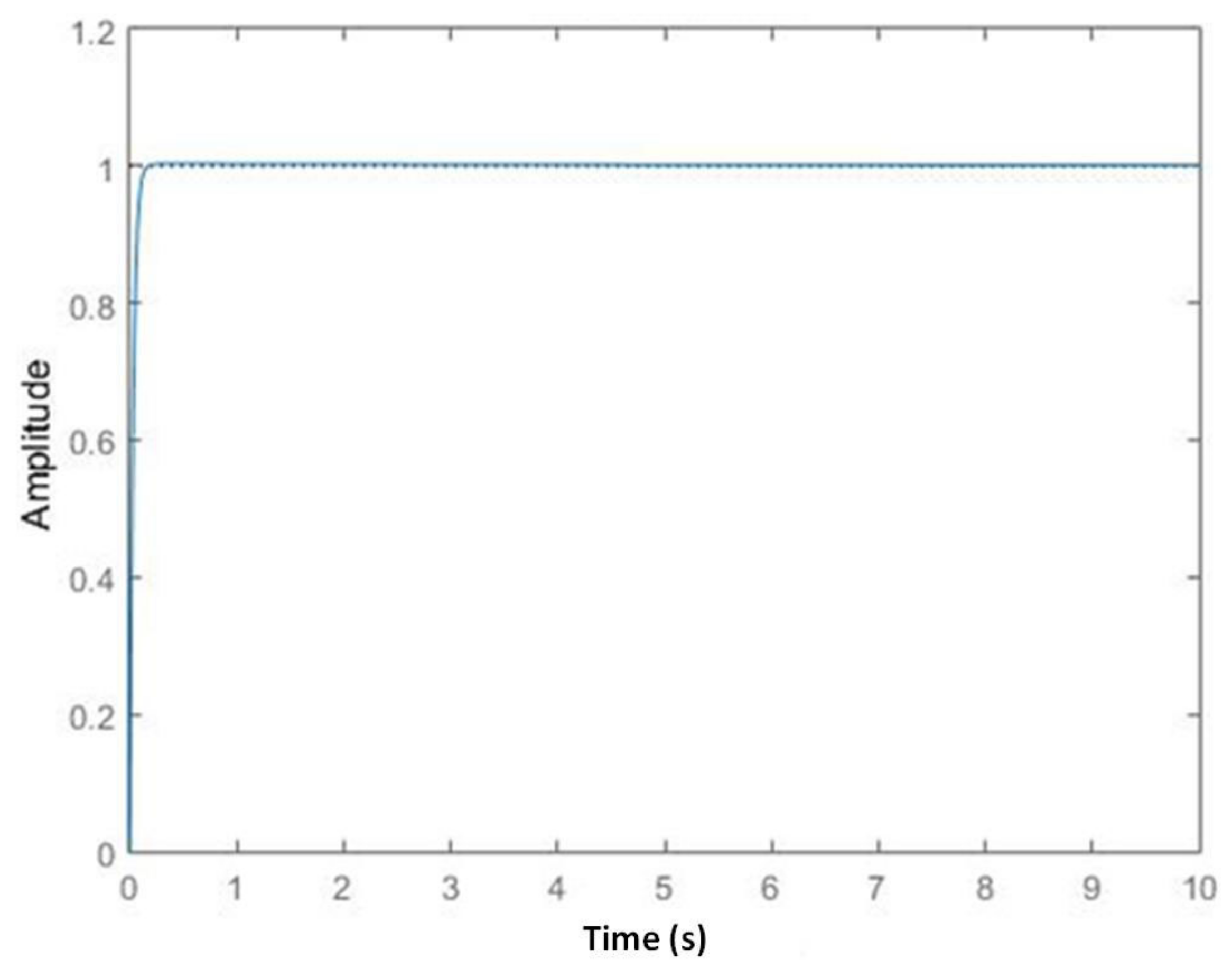

- Section 5 discusses the controller design for the machining bed to minimize the effects of overshoot and error obtained

2. Mechanism Description

3. Modeling

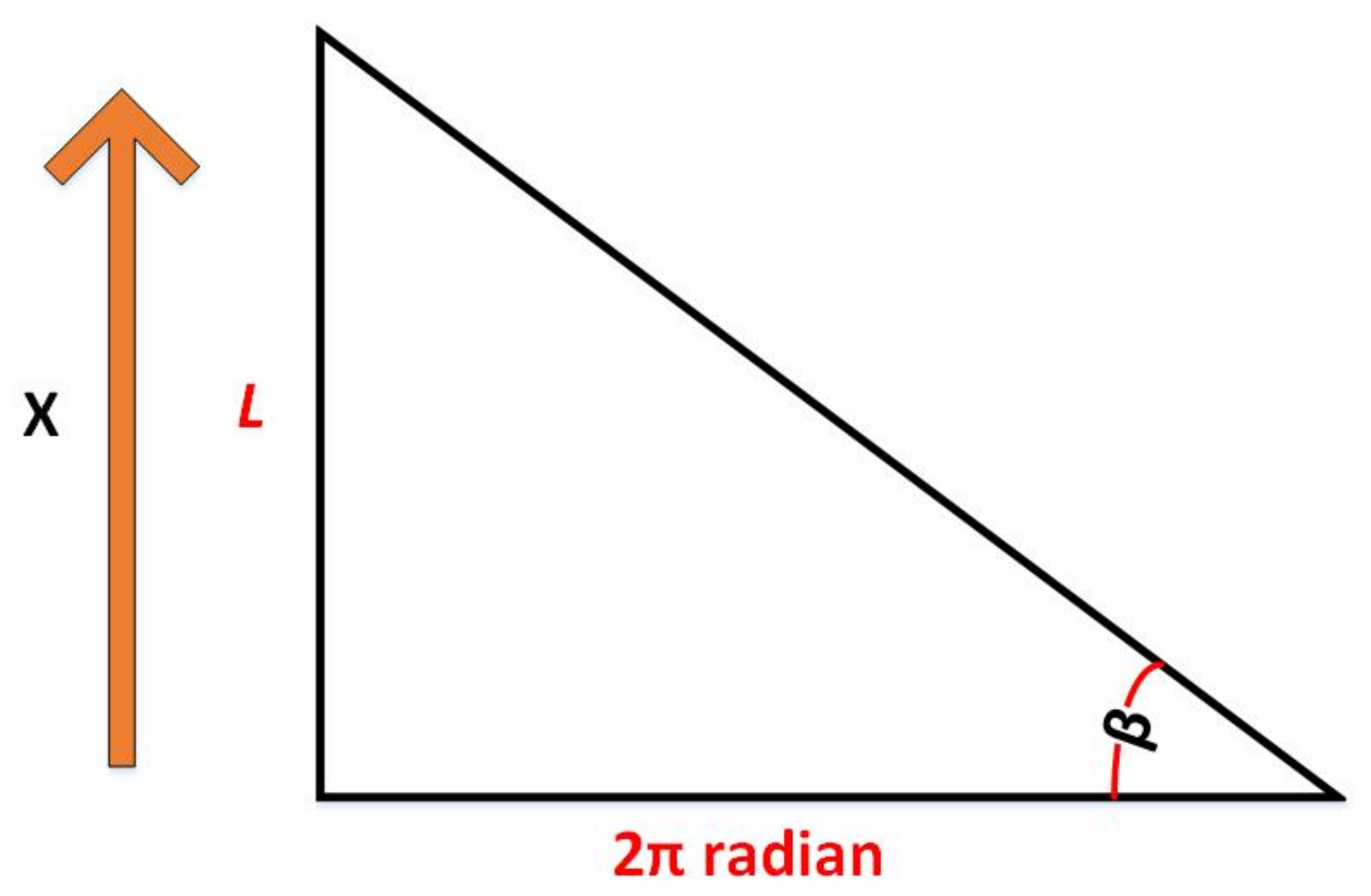

3.1. Kinematics Model of the Machining Bed

3.2. Dynamics Model

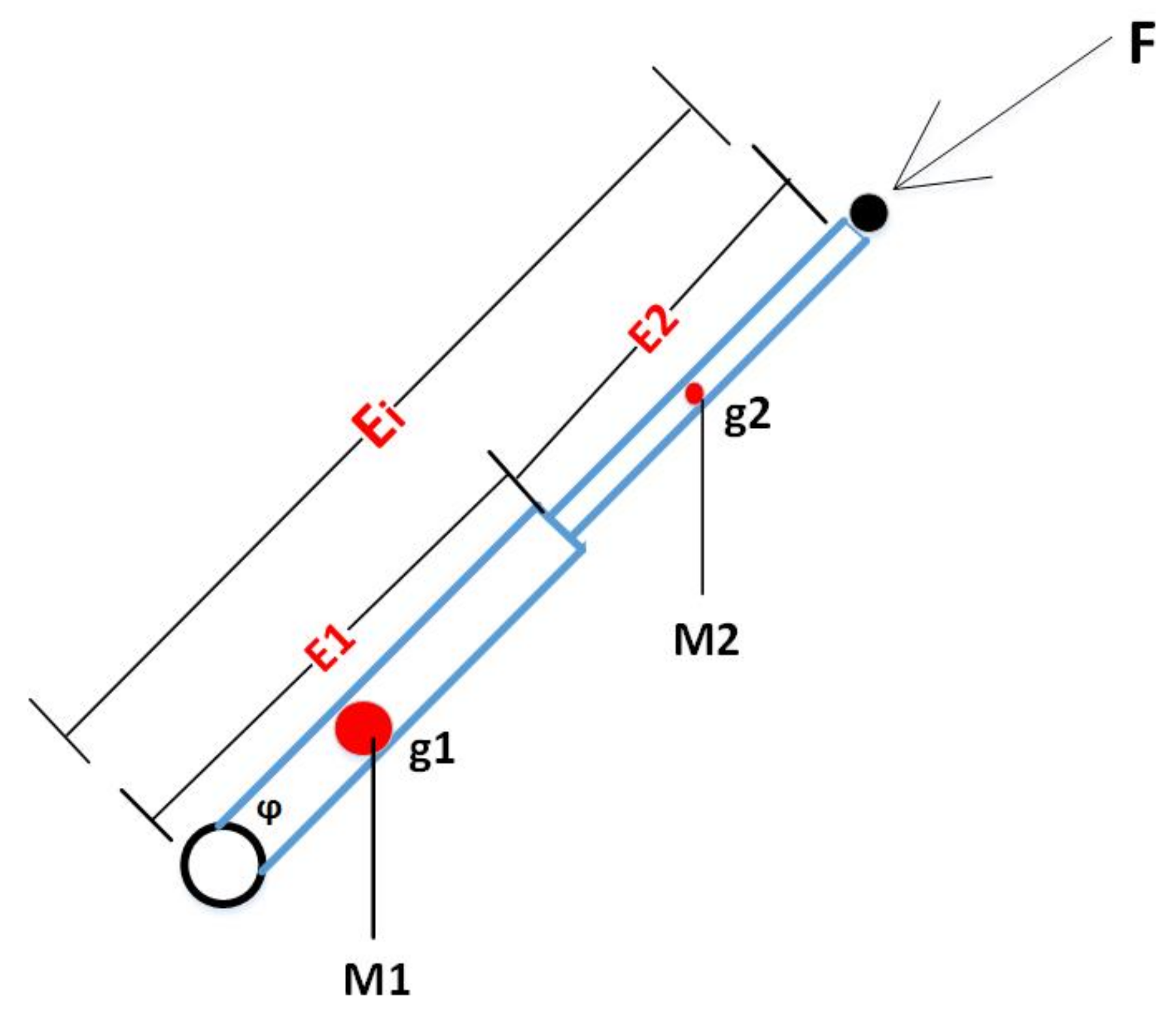

3.3. Dynamics Modelling of the Linear Actuator

3.4. Energy Efficiency Model

4. Model Verification

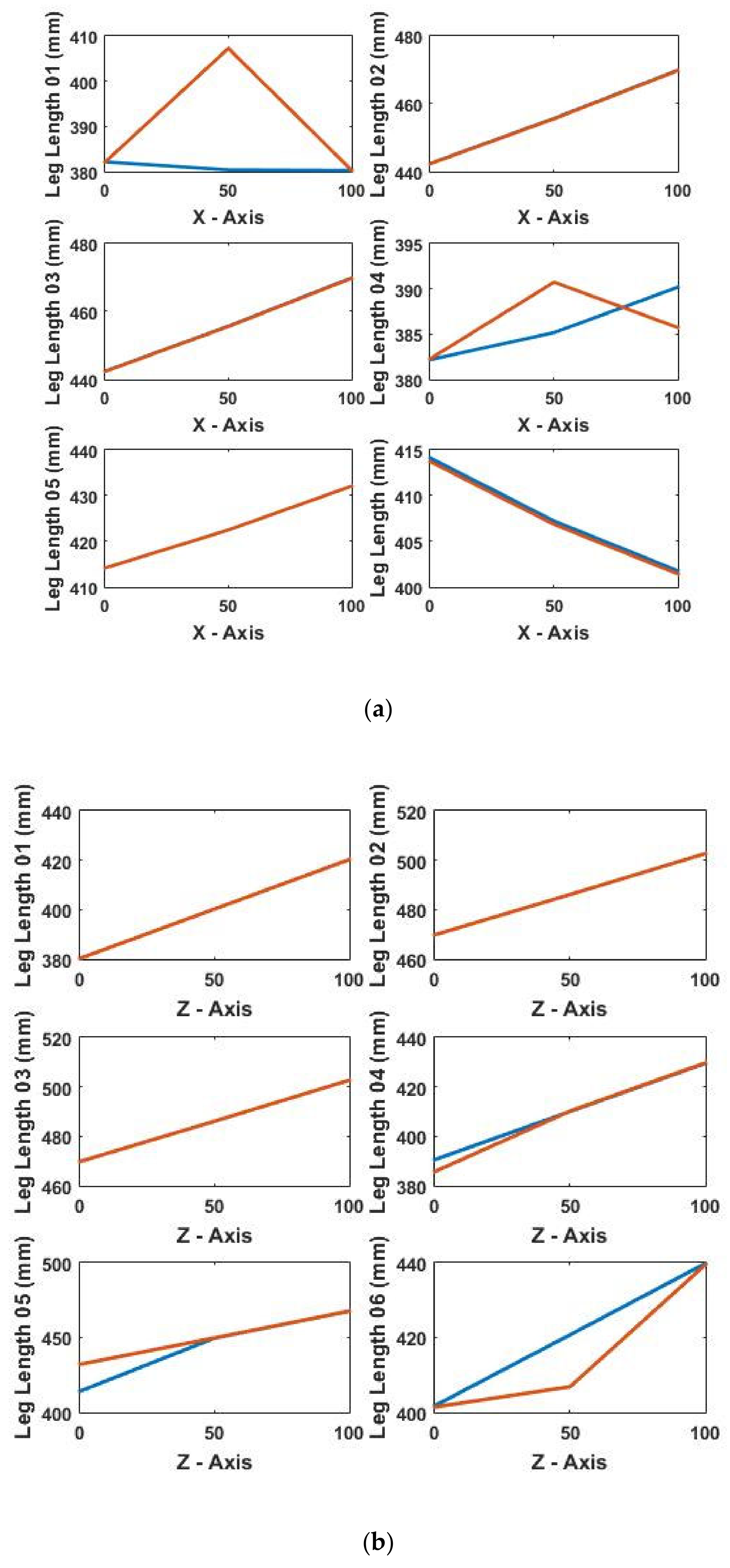

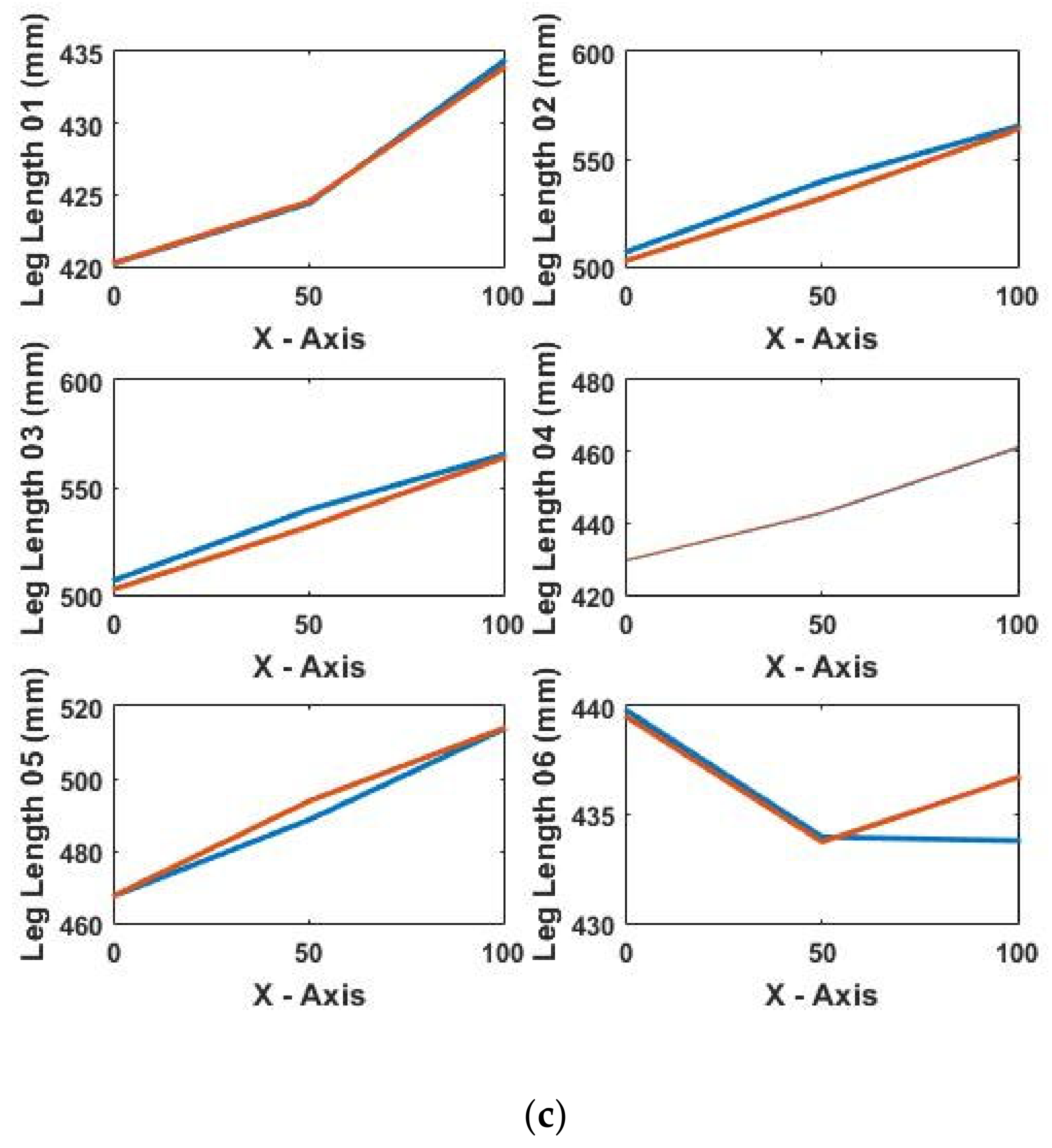

4.1. Kinematics Model Verification

4.2. Energy Efficiency Analysis

5. Controller Design

5.1. Position Control

5.2. Computational Time Control

6. Development of Machining Bed

6.1. Fabrication

6.2. Testing on Workpiece

6.3. Computational Time Algorithm Results

7. Conclusions

- The inverse kinematics model was presented and verified through different case studies and a workpiece.

- The dynamics model for the machining bed was presented. Using this dynamics model, an energy efficiency model was presented. The energy efficiency model gives the efficiency of more than 50% which is a satisfactory result in case of a machining bed.

- A PID controller was developed and implemented to reduce the errors in the workpiece trajectory through the leg lengths of the machining bed.

- Another objective of this paper was to reduce the computational time for the workpiece trajectory on the machining bed so the machining time can be reduced. To achieve this objective an algorithm was developed. The results obtained show that the machining time was reduced by 27% approximately. The computational time is reduced to a reasonable percentage which eventually reduced the energy utilization and hence this model can be applied for commercial machining purposes. Future studies will consider better controller designs for better machining and reduction in energy consumption.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Li | Leg Length of the ith leg of the proposed machining bed |

| Ti | Translation Vector |

| Xp | Distance between the center and the attachment of ith leg at the movable top plate |

| Xb | Distance between the center and the attachment of ith leg at the fixed base plate |

| Rotation Matrix | |

| M1 | Mass of the fixed part of the linear actuator |

| M2 | Mass of the movable part of the linear actuator |

| Vi | Angular velocity of the moveable top plate |

| Im | Rotational inertia matrix of the movable top plate |

| E1 | Length of the fixed part of the linear actuator |

| E2 | Length of the movable part of the linear actuator |

| g1 | Center of mass for the fixed part of the linear actuator |

| g2 | Center of mass for the movable part of the linear actuator |

| Ki | Total kinetic energy of the leg |

| Vb | Back emf |

| ωm | Angular velocity of the DC motor attached to the linear actuator |

| Tm | The torque of the DC motor attached to the linear actuator |

| J | Mass inertia of the DC motor attached to the linear actuator |

| D | Viscous damping of the DC motor attached to the linear actuator |

| Ɵm | Angular displacement of the DC motor attached to the linear actuator |

| Ei | Energy consumed by the linear actuator |

| Em | Energy of the movable platform |

| Eb | Total energy of the machining bed |

| Pi | Power consumed by the linear actuator |

| fi | Force exerted by the linear actuator |

| vi | Velocity of the linear actuator |

References

- Subagio, D.G.; Subekti, R.A.; Saputra, H.M.; Rajani, A.; Sanjaya, K.H. Three axis deviation analysis of CNC milling machine. J. Mechatron. Electr. Power Veh. Technol. 2019, 10, 93. [Google Scholar] [CrossRef]

- Lasemi, A.; Xue, D.; Gu, P. Recent development in CNC machining of freeform surfaces: A state-of-the-art review. CAD Comput. Aided Des. 2010, 42, 641–654. [Google Scholar] [CrossRef]

- Yamazaki, T. Development of A hybrid multi-tasking machine tool: Integration of additive manufacturing technology with CNC machining. Procedia CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- Stewart, D. A platform with six degrees of freedom. Proc. Inst. Mech. Eng. Part 1 1966, 180, 371. [Google Scholar] [CrossRef]

- Dasgupta, B.; Mruthyunjaya, T.S. Stewart platform manipulator: A review. Mech. Mach. Theory 2000, 35, 15–40. [Google Scholar] [CrossRef]

- Merlet, J.P. Force-Feedback control of parallel manipulators. In Proceedings of the IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988; pp. 1484–1489. [Google Scholar]

- Wapler, M.; Urban, V.; Weisener, T.; Stallkamp, J.; Dürr, M.; Hiller, A. A Stewart platform for precision surgery. Trans. Inst. Meas. Control 2003, 25, 329–334. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, L.; Yu, J. Kinematics and dynamics analysis of a novel serial-parallel dynamic simulator. J. Mech. Sci. Technol. 2016, 30, 5183–5195. [Google Scholar] [CrossRef]

- Uchiyama, M. Structures and characteristics of parallel manipulators. Adv. Robot. 1993, 8, 545–557. [Google Scholar] [CrossRef]

- Staicu, S. Dynamics of the 6-6 Stewart parallel manipulator. Robot. Comput. Integr. Manuf. 2011, 27, 212–220. [Google Scholar] [CrossRef]

- Shah, M.F.; Kausar, Z.; Farooq, S.S. Workspace design for 6 degree of freedom machining bed. J. Phys. Conf. Ser. 2018, 1016, 012018. [Google Scholar] [CrossRef]

- Huang, X.; Liao, Q.; Wei, S. Closed-Form forward kinematics for a symmetrical 6-6 Stewart platform using algebraic elimination. Mech. Mach. Theory 2010, 45, 327–334. [Google Scholar] [CrossRef]

- Liu, K.; Fitzgerald, J.M.; Lewis, F.L. Kinematic analysis of a Stewart platform manipulator. IEEE Trans. Ind. Electron. 1993, 40, 282–293. [Google Scholar] [CrossRef]

- Harib, K.; Srinivasan, K. Kinematic and dynamic analysis of Stewart platform-based machine tool structures. Robotica 2003, 21, 541–554. [Google Scholar] [CrossRef]

- Yang, G.; Chen, W.; Chen, I.M. A geometrical method for the singularity analysis of 3-RRR planar parallel robots with different actuation schemes. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; Volume 3, pp. 2055–2060. [Google Scholar]

- Shah, M.F.; Kausar, Z.; Farooq, M.U. Kinematic modeling and analysis of a 6 dof parallel machining bed. In Proceedings of the 22nd International Multitopic Conference INMIC 2019, Islamabad, Pakistan, 29–30 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–5. [Google Scholar]

- Shah, M.F.; Kausar, Z.; Durrani, F.K. Design, modeling and simulation of six degree of freedom machining bed. Proc. Pak. Acad. Sci. 2016, 53, 163–176. [Google Scholar]

- Hao, K.; Ding, Y. Screw theory and singularity analysis of parallel robots. In Proceedings of the IEEE International Conference on Mechatronics and Automation ICMA 2006, Luoyang, China, 25–28 June 2006; Volume 2006, pp. 147–152. [Google Scholar]

- Boudreau, R. A real time solution to the forward kinematic problem of a general spherical three-degree-of-freedom parallel manipulator. Trans. Can. Soc. Mech. Eng. 1997, 21, 19–32. [Google Scholar] [CrossRef]

- Wang, L.-C.T.; Oen, K.-T. Numerical direct kinematic analysis of fully parallel linearly actuated platform type manipulators. J. Robot. Syst. 2002, 19, 391–400. [Google Scholar] [CrossRef]

- Lee, S.; Song, J.; Choi, W.; Hong, D. Position control of a Stewart platform using inverse dynamics control with approximate dynamics. Mechatronics 2003, 13, 605–619. [Google Scholar] [CrossRef]

- Glazunov, V.; Kheylo, S. Dynamics and control of planar, translational, and spherical parallel manipulators. In Dynamic Balancing of Mechanisms and Synthesizing of Parallel Robots; Springer: Cham, Switzerland, 2016; pp. 365–402. ISBN 9783319176833. [Google Scholar]

- Cheng, H.; Yiu, Y.K.; Li, Z. Dynamics and control of redundantly actuated parallel manipulators. IEEE ASME Trans. Mechatron. 2003, 8, 483–491. [Google Scholar] [CrossRef]

- Zhang, C.-D.; Song, S.-M. An efficient method for inverse dynamics of manipulators based on the virtual work principle. J. Robot. Syst. 1993, 10, 605–627. [Google Scholar] [CrossRef]

- Dasgupta, B.; Mruthyunjaya, T.S. Closed-Form dynamic equations of the general Stewart platform through the Newton-Euler approach. Mech. Mach. Theory 1998, 33, 993–1012. [Google Scholar] [CrossRef]

- Lebret, G.; Liu, K.; Lewis, F.L. Dynamic analysis and control of a stewart platform manipulator. J. Robot. Syst. 1993, 10, 629–655. [Google Scholar] [CrossRef]

- Zhang, Y.; Liao, Q.; Wei, S.; Wei, F.; Li, D. A novel geometric modeling and solution method for forward displacement analysis of 6-3 Stewart platforms. Mathematics 2021, 9. [Google Scholar] [CrossRef]

- Fichter, E.F. A Stewart platform-based manipulator: General theory and practical construction. Int. J. Robot. Res. 1986, 5, 157–182. [Google Scholar] [CrossRef]

- Luces, M.; Mills, J.K.; Benhabib, B. A review of redundant parallel kinematic mechanisms. J. Intell. Robot. Syst. Theory Appl. 2017, 86, 175–198. [Google Scholar] [CrossRef]

- Li, Y.; Bone, G. Are parallel manipulators more energy efficient? In Proceedings of the IEEE International Symposium on Computational Intelligence in Robotics and Automation, Banff, AB, Canada, 29 July–1 August 2001; IEEE: Piscataway, NJ, USA, 2001; pp. 41–46. [Google Scholar]

- Pasand, A.M.; Naderi, D. Energy optimization of a planar parallel manipulator with kinematically redundant degrees of freedom. In Proceedings of the RSI/ISM International Conference on Robotics and Mechatronics, Tehran, Iran, 13–15 February 2013; pp. 362–367. [Google Scholar]

- Kucuk, S. Energy minimization for 3-RRR fully planar parallel manipulator using particle swarm optimization. Mech. Mach. Theory 2013, 62, 129–149. [Google Scholar] [CrossRef]

- Saclera, L.; Boscario, P.; Carabin, G.; Vidoni, R.; Gasparetto, A. Enhancing energy efficiency of a 4-DOF parallel robot through task-related analysis. Machines 2020, 8, 10. [Google Scholar] [CrossRef] [Green Version]

- Pierrot, F.; Dauchez, P.; Fournier, A. HEXA: A fast six-DOF fully-parallel robot. In Proceedings of the Fifth International Conference on Advanced Robotics ‘Robots in Unstructured Environments, Pisa, Italy, 19–22 June 1991; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2002; Volume 2, pp. 1158–1163. [Google Scholar]

- Li, Y.; Staicu, S. Inverse dynamics of a 3-PRC parallel kinematic machine. Nonlinear Dyn. 2012, 67, 1031–1041. [Google Scholar] [CrossRef]

- Zhufeng, S.; Xiaoqiang, T.; Xu, C.; Liping, W. Inertia match of a 3-RRR reconfigurable planar parallel manipulator. Chin. J. Mech. Eng. 2009, 22, 791–799. [Google Scholar] [CrossRef]

- Patel, Y.D.; George, P.M. Simulation of kinematic and workspace analysis of 3-PRS parallel manipulator. Int. J. Model. Simul. Sci. Comput. 2015, 6, 1550007. [Google Scholar] [CrossRef]

- Zhang, Y.; Liao, Q.; Su, H.J.; Wei, S. A new closed-form solution to the forward displacement analysis of a 5-5 in-parallel platform. Mech. Mach. Theory 2012, 52, 47–58. [Google Scholar] [CrossRef]

- Gan, D.; Liao, Q.; Dai, J.S.; Wei, S. Design and kinematics analysis of a new 3CCC parallel mechanism. Robotica 2010, 28, 1065–1072. [Google Scholar] [CrossRef]

- Shah, M.F.; Kausar, Z.; Farooq, M.U.; Khan, L.A.; Farooq, S.S. Accuracy analysis of machining trajectory contemplating workpiece dislocation on a six degree of freedom machining bed. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020. [Google Scholar] [CrossRef]

- Shah, M.F.; Kausar, Z.; Ahmad, M.M. PID control and stability analysis of a six degree of freedom machining bed. Procedia Manuf. 2018, 17, 927–934. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.H.; Zhang, X.N.; Dong, G.X. 1888. Fuzzy PID control of a two-link flexible manipulator. J. Vibroeng. 2016, 18, 250–266. [Google Scholar]

- Moradi, M.H. New techniques for PID controller design. In Proceedings of the IEEE Conference on Control Applications, Istanbul, Turkey, 25 June 2003; Volume 2, pp. 903–908. [Google Scholar] [CrossRef]

- Verma, B.; Padhy, P.K. Indirect IMC-PID controller design. IET Control Theory Appl. 2019, 13, 297–305. [Google Scholar] [CrossRef]

| Sr. No. | Proposed Configuration * | Reference |

|---|---|---|

| 1 | 3-PRC | [36] |

| 2 | 3-RRR | [37] |

| 3 | 3-PRS | [38] |

| 4 | 5-5-SPS | [39] |

| 5 | 3-CCC | [40] |

| Test | Coordinates (mm) | Leg Number | Predicted Length Computed from Kinematic Model (mm) |

|---|---|---|---|

| 1 | [0;100;380] | Leg 1 | 397.38 |

| Leg 2 | 458.10 | ||

| Leg 3 | 458.10 | ||

| Leg 4 | 397.10 | ||

| Leg 5 | 404.37 | ||

| Leg 6 | 404.37 | ||

| 2 | [200;50;380] | Leg 1 | 416.66 |

| Leg 2 | 574.84 | ||

| Leg 3 | 574.84 | ||

| Leg 4 | 453.17 | ||

| Leg 5 | 503.78 | ||

| Leg 6 | 391.18 | ||

| 3 | [200;100;380] | Leg 1 | 426.6 |

| Leg 2 | 583.12 | ||

| Leg 3 | 583.12 | ||

| Leg 4 | 462.38 | ||

| Leg 5 | 500.68 | ||

| Leg 6 | 387.19 |

| Test Number | Start Coordinates (mm) | End Coordinates (mm) | Movement of Workpiece in Axis |

|---|---|---|---|

| 1 | [50;0;380] | [125;0;380] | X-Axis |

| 2 | [125;0;380] | [125;0;430] | Z-Axis |

| 3 | [125;0;430] | [175;0;430] | X-Axis |

| Test Number | Leg Number | (%) | |||

|---|---|---|---|---|---|

| 1 | Leg 1 | 7.30 | 8.12 | 15.7 | 53% |

| Leg 2 | 7.66 | ||||

| Leg 3 | 7.67 | ||||

| Leg 4 | 7.35 | ||||

| Leg 5 | 8.32 | ||||

| Leg 6 | 7.32 | ||||

| 2 | Leg 1 | 5.33 | 7.8 | 13.1 | 60% |

| Leg 2 | 6.21 | ||||

| Leg 3 | 6.21 | ||||

| Leg 4 | 5.60 | ||||

| Leg 5 | 7.80 | ||||

| Leg 6 | 7.30 | ||||

| 3 | Leg 1 | 6.45 | 7.7 | 14.7 | 52% |

| Leg 2 | 7.33 | ||||

| Leg 3 | 7.33 | ||||

| Leg 4 | 6.34 | ||||

| Leg 5 | 7.20 | ||||

| Leg 6 | 6.66 |

| Parameter * | Rise Time | Settling Time | Steady State Error | Overshoot |

|---|---|---|---|---|

| Kp | ▼ | δ | ▼ | ▲ |

| Ki | ▼ | ▲ | X | ▲ |

| Kd | Δ | ▼ | ▲ | ▼ |

| Step No. | Action |

|---|---|

| Step 1 | Initialize |

| Step 2 | Input coordinates and angles |

| Step 3 | Calculation of rotation matrix |

| Step 4 | If (Coordinates are in Y and Z axis only) |

| Step 5 | Compute leg length for leg 1, leg 2 and leg 5 |

| Step 6 | If else (Coordinates are in X and Z axis) |

| Step 7 | Compute leg lengths for leg 1, leg 2, leg 4, leg 5, leg 6 |

| Step 8 | Else |

| Step 9 | Calculate all leg lengths |

| Step 10 | End |

| Position Coordinates (mm) | Leg Number | Leg Length (mm) * | Machining Time (without CTA) (s) | Machining Time (with CTA) (s) | Reduction in Computation Time (s) |

|---|---|---|---|---|---|

| [50;0;380] | L1 | 380.25 | 0.76 | 0.55 | 0.21 |

| L2 | 469.8 | ||||

| L3 | 469.8 | ||||

| L4 | 390.55 | ||||

| L5 | 431.99 | ||||

| L6 | 401.78 | ||||

| [125;0;430] | L1 | 438.47 | 0.43 | 0.28 | 0.15 |

| L2 | 555.11 | ||||

| L3 | 555.11 | ||||

| L4 | 460.55 | ||||

| L5 | 560.05 | ||||

| L6 | 442.89 | ||||

| [175;0;430] | L1 | 450.88 | 0.48 | 0.31 | 0.17 |

| L2 | 587.96 | ||||

| L3 | 587.96 | ||||

| L4 | 480.7 | ||||

| L5 | 537.47 | ||||

| L6 | 445.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, Z.; Shah, M.F.; Masood, Z.; Rehman, H.Z.U.; Khaydarov, S.; Saeed, M.T.; Razmkhah, O.; Yaqoob, H. Energy Efficient Parallel Configuration Based Six Degree of Freedom Machining Bed. Energies 2021, 14, 2642. https://doi.org/10.3390/en14092642

Kausar Z, Shah MF, Masood Z, Rehman HZU, Khaydarov S, Saeed MT, Razmkhah O, Yaqoob H. Energy Efficient Parallel Configuration Based Six Degree of Freedom Machining Bed. Energies. 2021; 14(9):2642. https://doi.org/10.3390/en14092642

Chicago/Turabian StyleKausar, Zareena, Muhammad Faizan Shah, Zeeshan Masood, Hafiz Zia Ur Rehman, Sardor Khaydarov, Muhammad Tallal Saeed, Omid Razmkhah, and Haseeb Yaqoob. 2021. "Energy Efficient Parallel Configuration Based Six Degree of Freedom Machining Bed" Energies 14, no. 9: 2642. https://doi.org/10.3390/en14092642