A Heater-Assisted Air Source Heat Pump Air Conditioner to Improve Thermal Comfort with Frost-Retarded Heating and Heat-Uninterrupted Defrosting

Abstract

:1. Introduction

2. Experimental Apparatus and Procedures

2.1. Experiment Apparatus

2.2. Test Procedures

3. Results and Discussion

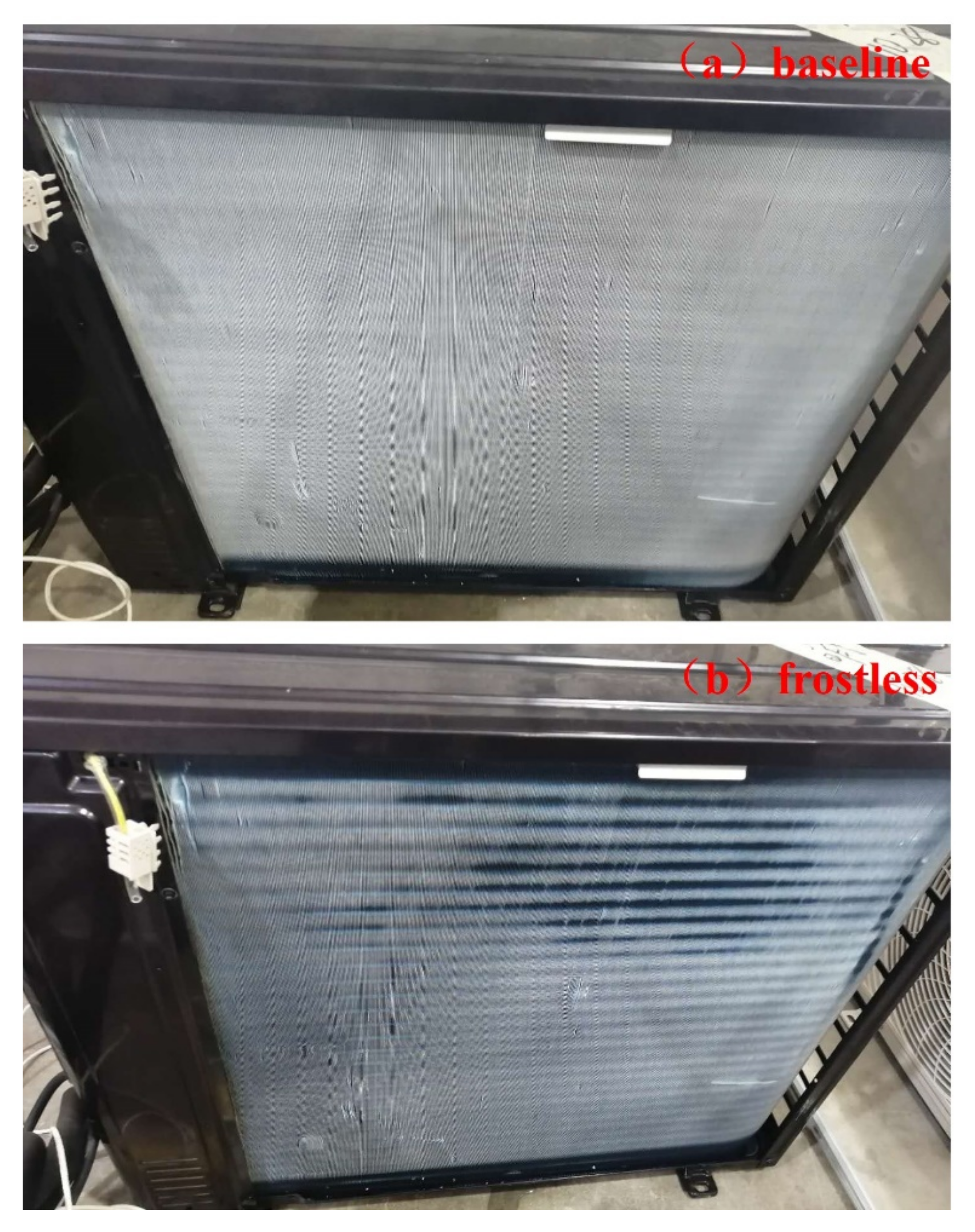

3.1. Heating Duration

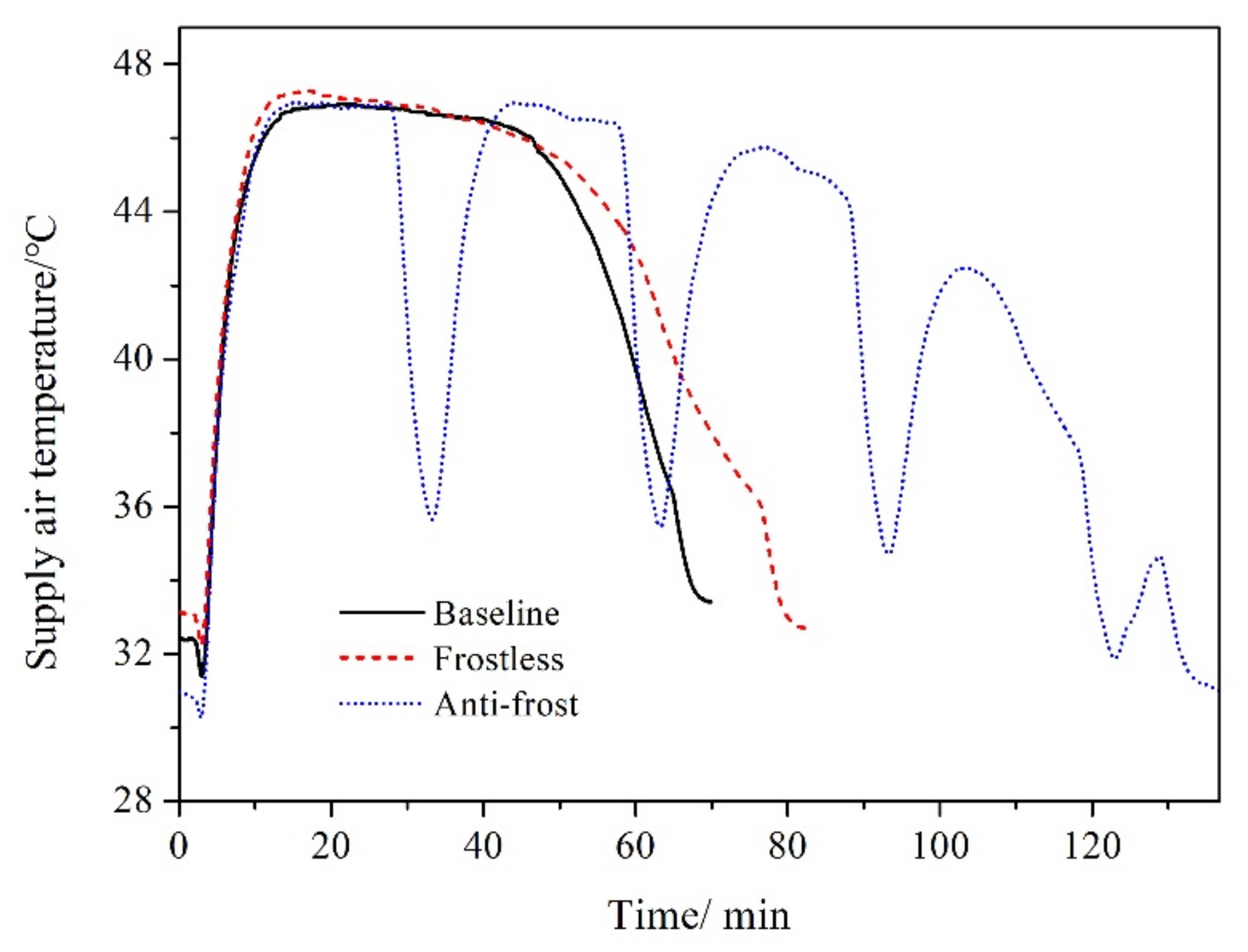

3.2. Supply-Air Temperature

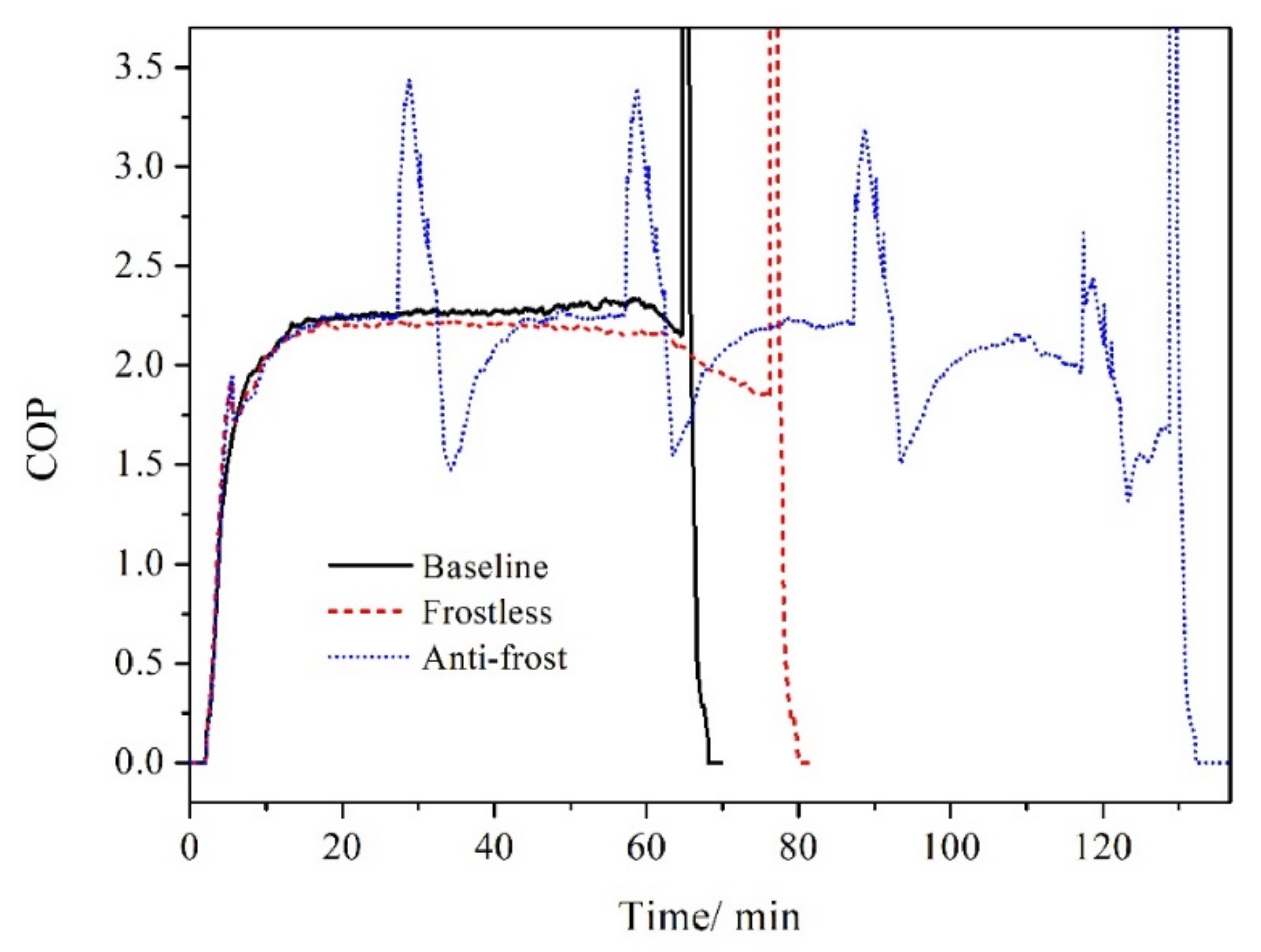

3.3. Energy Performance

4. Conclusions

- (1)

- The 800 W heating elevates evaporator surface temperature by 1.5 °C, which contributes to retarding frost and extending heating cycle duration by 17.9% in the frostless mode.

- (2)

- The intermittent action of the heater removes part of the frost on the outdoor heat exchanger without ceasing heat supply to indoor spacing. Consequently, the heating duration is extended by 97.9% in the anti-frost mode.

- (3)

- Both frostless and anti-frost modes exhibit comparative supply-air temperature by average to the baseline mode. Moreover, even the supply-air temperature during the EHD process in the anti-frost modes are higher than 36 °C.

- (4)

- The anti-frost mode yields similar COP with the baseline mode, which is 3% larger than that in the frostless modes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Silva, D.; Hermes, C.; Melo, C. Experimental study of frost accumulation on fan-supplied tube-fin heat evaporators. Appl. Therm. Eng. 2011, 31, 1013–1020. [Google Scholar] [CrossRef] [Green Version]

- Kondepudi, S.N.; O’Neal, D.L. The effects of different fin configurations on the performance of finned-tube heat exchangers under frosting conditions. ASHRAE Trans. 1990, 96, 439–444. [Google Scholar]

- Kristian, L.; Anica, T.; Frankovic, B. Prediction of an effective cooling output of the fin-and-tube heat exchanger under frosting conditions. Appl. Therm. Eng. 2009, 29, 2534–2543. [Google Scholar]

- Zhao, R.; Qiao, L.; Gao, Z.; Huang, D. Effect of Vacuum Insulation Panels on Energy Consumption and Thermal Load Transfer between Compartments in a Three-Temperature Frost-Free Refrigerator. Energies 2020, 13, 1559. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Wang, Z.; Zheng, Y.; Lin, Z. Performance investigation of a novel frost-free air-source heat pump water heater com-bined with energy storage and dehumidification. Appl. Energy 2015, 139, 212–219. [Google Scholar] [CrossRef]

- Giampieri, A.; Ma, Z.; Smallbone, A.; Roskilly, A.P. Thermodynamics and economics of liquid desiccants for heating, ventilation and air-conditioning—An overview. Appl. Energy 2018, 220, 455–479. [Google Scholar] [CrossRef] [Green Version]

- Kwak, K.; Bai, C. A study on the performance enhancement of heat pump using electric heater under the frosting condition: Heat pump under frosting condition. Appl. Therm. Eng. 2010, 30, 539–543. [Google Scholar] [CrossRef]

- Lee, M.; Kim, Y.; Lee, H. Air-side heat transfer characteristics of flat plate finned-tube heat exchangers with large fin pitches under frosting conditions. Int. J. Heat Mass Transf. 2010, 53, 2655–2661. [Google Scholar] [CrossRef]

- Park, J.-S.; Kim, D.R.; Lee, K.-S. Frosting behaviors and thermal performance of louvered fins with unequal louver pitch. Int. J. Heat Mass Transf. 2016, 95, 499–505. [Google Scholar] [CrossRef]

- Okoroafor, E.; Newborough, M. Minimizing frost growth on cold surfaces exposed to humid air by means of crosslinked hy-drophilic polymeric coatings. Appl. Therm. Eng. 2000, 20, 737–758. [Google Scholar] [CrossRef]

- Yang, W.; Zeng, B.; Zhang, Y.; He, S.; Zhao, X. Frosting Performance of a Nanoporous Hydrophilic Aluminum Surface. Energies 2018, 11, 3483. [Google Scholar] [CrossRef] [Green Version]

- Tang, J.; Gong, G.; Su, H.; Wu, F.; Herman, C. Performance evaluation of a novel method of frost prevention and retardation for air source heat pumps using the orthogonal experiment design method. Appl. Energy 2016, 169, 696–708. [Google Scholar] [CrossRef]

- Tang, J.; Hu, X.; Herman, C.; Gong, G. Computational modeling and prediction of the performance of air source heat pumps under frost prevention and retardation conditions. Energy Build. 2020, 224, 110264. [Google Scholar] [CrossRef]

- Byun, J.-S.; Lee, J.; Jeon, C.-D. Frost retardation of an air-source heat pump by the hot gas bypass method. Int. J. Refrig. 2008, 31, 328–334. [Google Scholar] [CrossRef]

- Mei, V.C.; Domitrovic, R.E.; Chen, F.C.; Kilpatrick, J. A frost-less heat pump. ASHRAE Trans. 2002, 108, 452–459. [Google Scholar]

- Song, M.; Deng, S.; Pan, D.; Mao, N. An experimental study on the effects of downwards flowing of melted frost over a ver-tical multi-circuit outdoor coil in an air source heat pump on defrosting performance during reverse cycle defrosting. Appl. Therm. Eng. 2014, 67, 258–265. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Dong, Z. Defrost improvement by heat pump refrigerant charge compensating. Appl. Energy 2008, 85, 1050–1059. [Google Scholar]

- Niu, F.; Ni, L.; Yao, Y.; Yu, Y.; Li, H. Performance and thermal charging/discharging features of a PCM assisted HP system in heating mode. Appl. Therm. Eng. 2013, 58, 536–541. [Google Scholar] [CrossRef]

- Song, M.; Pan, D.; Li, N.; Deng, S.S. An experimental study on the negative effects of downwards flow of the melted frost over a multi-circuit outdoor coil in an air source heat pump during reverse cycle defrosting. Appl. Energy 2015, 138, 598–604. [Google Scholar] [CrossRef]

- Zheng, C.; You, S.; Zhang, H.; Liu, Z.; Zheng, W.; Wu, Z.; Fan, M. Defrosting performance improvement of air-source heat pump combined refrigerant di-rect-condensation radiant floor heating system with phase change material. Energies 2020, 13, 1459. [Google Scholar] [CrossRef]

- Liang, C.-H.; Zhang, X.-S.; Li, X.-W.; Chen, Z.-Q. Control strategy and experimental study on a novel defrosting method for air-source heat pump. Appl. Therm. Eng. 2010, 30, 892–899. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, P.; Wang, Q.; Chi, Y.; Zhao, Z.; Chi, Y. Air source heat pump with water heater based on a bypass-cycle defrosting system using compressor casing thermal storage. Appl. Therm. Eng. 2018, 128, 1420–1429. [Google Scholar] [CrossRef]

- Yin, H.-J.; Yang, Z.; Chen, A.-Q.; Zhang, N. Experimental research on a novel cold storage defrost method based on air bypass circulation and electric heater. Energy 2012, 37, 623–631. [Google Scholar] [CrossRef]

- Tan, H.; Zhang, X.; Zhang, L.; Tao, T.; Xu, G. Ultrasonic Guided Wave Phased Array Focusing Technology and Its Application to Defrosting Performance Improvement of Air-Source Heat Pumps. Energies 2019, 12, 3117. [Google Scholar] [CrossRef] [Green Version]

- Byrne, P.; Miriel, J.; Lenat, Y. Experimental study of an air-source heat pump for simultaneous heating and cooling—Part 1: Basic concepts and performance verification. Appl. Energy 2011, 88, 1841–1847. [Google Scholar] [CrossRef] [Green Version]

- Byrne, P.; Miriel, J.; Lenat, Y. Experimental study of an air-source heat pump for simultaneous heating and cooling—Part 2: Dynamic behavior and two-phase thermosiphon defrosting technique. Appl. Energy 2011, 88, 3072–3078. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Huang, D.; Liu, X.; Chen, Q. Effect of non-uniform air velocity distribution on evaporator performance and its im-provement on a residential air conditioner. Appl. Therm. Eng. 2012, 40, 284–293. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, K.-S.; Yook, S.-J. Frost behavior on a fin considering the heat conduction of heat exchanger fins. Int. J. Heat Mass Transf. 2009, 52, 2581–2588. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef] [Green Version]

| Item | Average Supply-Air Temperature |

|---|---|

| Temperature | ±0.2 °C |

| Power | ±0.4% |

| Capacity | ±1.0% |

| COP | ±1.1% |

| Modes | Heater Action | Compressor Speed | EEV Opening |

|---|---|---|---|

| Baseline | OFF | 90 Hz | 85 °C discharge control |

| Frostless | Always ON | 90 Hz | 85 °C discharge control |

| Anti-frost | ON at 30-min intervals (for 5 min) | 65 Hz if heater on 90 Hz if heater off | 480 steps if heater on; 85 °C discharge control if heater off |

| Modes | Average Supply-Air Temperature |

|---|---|

| Baseline | 43.3 °C |

| Frostless | 43.0 °C |

| Anti-frost | 41.3 °C |

| Modes | Capacity/W | Power/W | COP |

|---|---|---|---|

| Baseline | 8780.8 | 4108.1 | 2.09 |

| Frostless | 8761.0 | 4229.4 | 2.02 |

| Anti-frost | 8077.8 | 3876.5 | 2.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Zhao, R.; Xu, W.; Huang, D.; Qu, Z. A Heater-Assisted Air Source Heat Pump Air Conditioner to Improve Thermal Comfort with Frost-Retarded Heating and Heat-Uninterrupted Defrosting. Energies 2021, 14, 2646. https://doi.org/10.3390/en14092646

Wang F, Zhao R, Xu W, Huang D, Qu Z. A Heater-Assisted Air Source Heat Pump Air Conditioner to Improve Thermal Comfort with Frost-Retarded Heating and Heat-Uninterrupted Defrosting. Energies. 2021; 14(9):2646. https://doi.org/10.3390/en14092646

Chicago/Turabian StyleWang, Fei, Rijing Zhao, Wenming Xu, Dong Huang, and Zhiguo Qu. 2021. "A Heater-Assisted Air Source Heat Pump Air Conditioner to Improve Thermal Comfort with Frost-Retarded Heating and Heat-Uninterrupted Defrosting" Energies 14, no. 9: 2646. https://doi.org/10.3390/en14092646