Identification of Inter-Turn Short-Circuits in Induction Motor Stator Winding Using Simulated Annealing

Abstract

1. Introduction

- −

- An innovative inter-turn short-circuit detection method applied in induction motors using the discrete wavelet transform approach performed on the Park vectors of current signals [3];

- −

- A presentation of the results of research concerning the application of axial flux in the diagnostics of an induction motor’s stator winding, supplied from a frequency converter during the motor’s operation in various conditions, registered in the LabVIEW environment [4];

- −

- Fault detection in an induction motor using a pattern recognition technique based on empirical wavelet transform and a convolutional neural network model used in the automatic extraction of relevant features from the image of a current signal presented in greyscale [5];

- −

- The application of a combination of a deep learning neural network with a complex cluster model and a classifier based on the support vector machine (SVM) in the detection of unknown electromechanical faults in industrial systems [6];

- −

- An analysis of stator current and vibration in the fault detection of induction motors using wavelet decomposition and the FCM data clustering method based on fuzzy logic [7];

- −

- The development of fault diagnosis methodology for a three-phase cage induction machine resulting from the process of training and classification using artificial neural networks applied in the processing of digital image data obtained from the calculation of power spectrum density (PSD) [8];

- −

- The presentation of a stator winding fault detection method in a three-phase induction motor using a discrete wavelet transform-based method and a quadrature discriminant-based method [9], and another method combining principal component analysis (PCA) with the training of selected artificial neural networks representing a multi-layer perceptron network and a network with radial base functions [10];

- −

- The detection of cracked bars in an induction motor using the method of stator current discrete wavelet transform coefficients, applied in the training of neural networks used in the ANFIS adaptive neural fuzzy inference system [11];

- −

- The design of a neutral network deep learning method and a special over-sampling technique used for the high-accuracy classification of induction motor faults [12];

- −

- The application of error-back-propagation-based training of a neutral network in the analysis of current and voltage components performed to detect the inter-turn short-circuit in induction motor stator winding [13];

- −

- A proof of the usefulness of the investigation of stator current variation in the converter drive of induction motors for the detection and classification of electrical faults using the Kohonen neural network [14];

- −

- The application of the genetic algorithm to the problem of the identification of parameters in the mathematical modelling of induction motors. The research was concentrated on the selection of the genetic algorithm’s stop criterion considering the convergence and accuracy of the analyzed process and the time required for numerical analysis [15];

- −

- The performance of tests of a control system applied to an induction machine using the genetic algorithm with many objective function used to conduct the evaluation of quality factors [16];

- −

- An analysis of the impact of inbreeding in the genetic algorithm on the results of parameter identification in the mathematical modelling of an induction motor [17];

- −

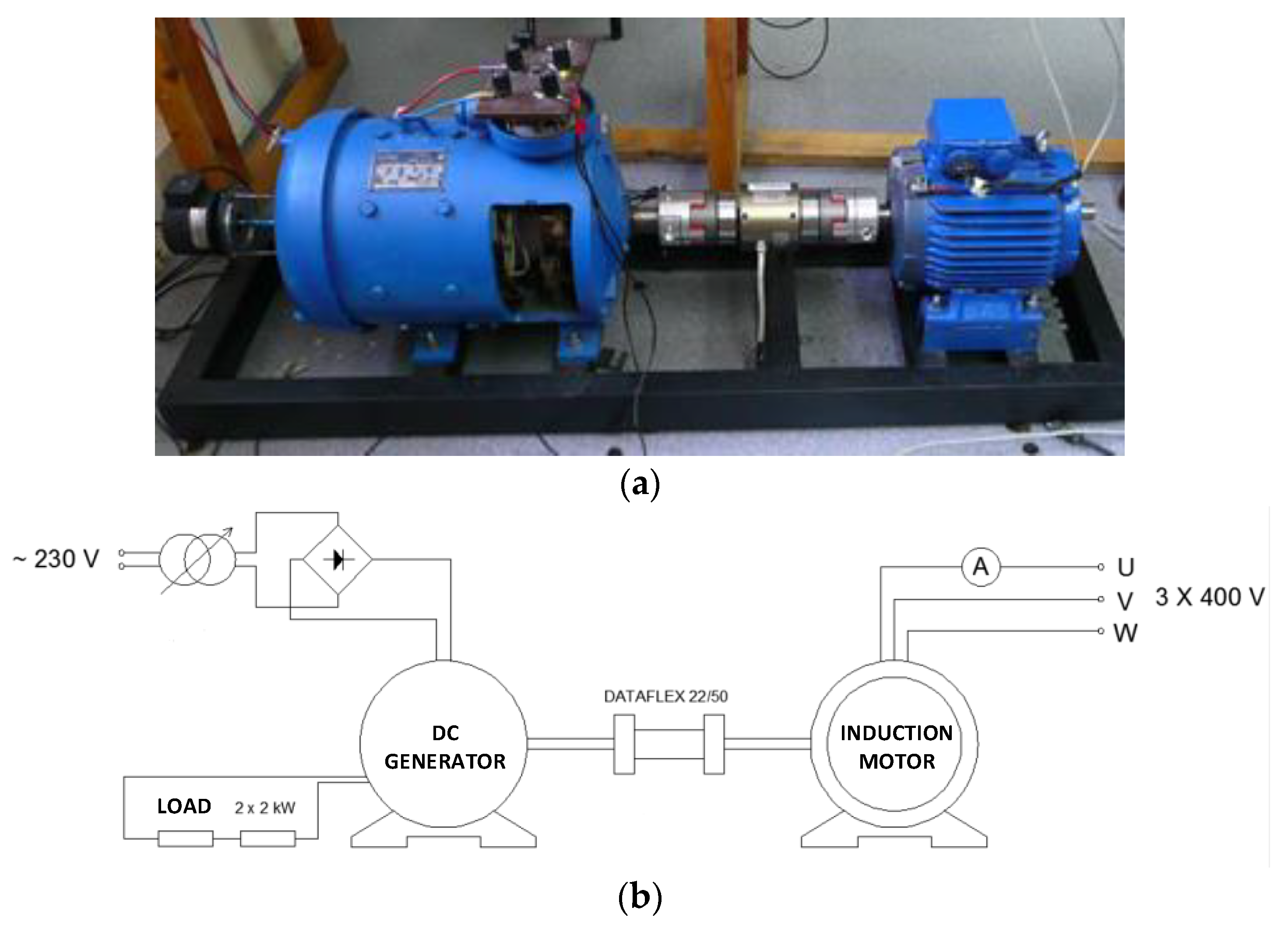

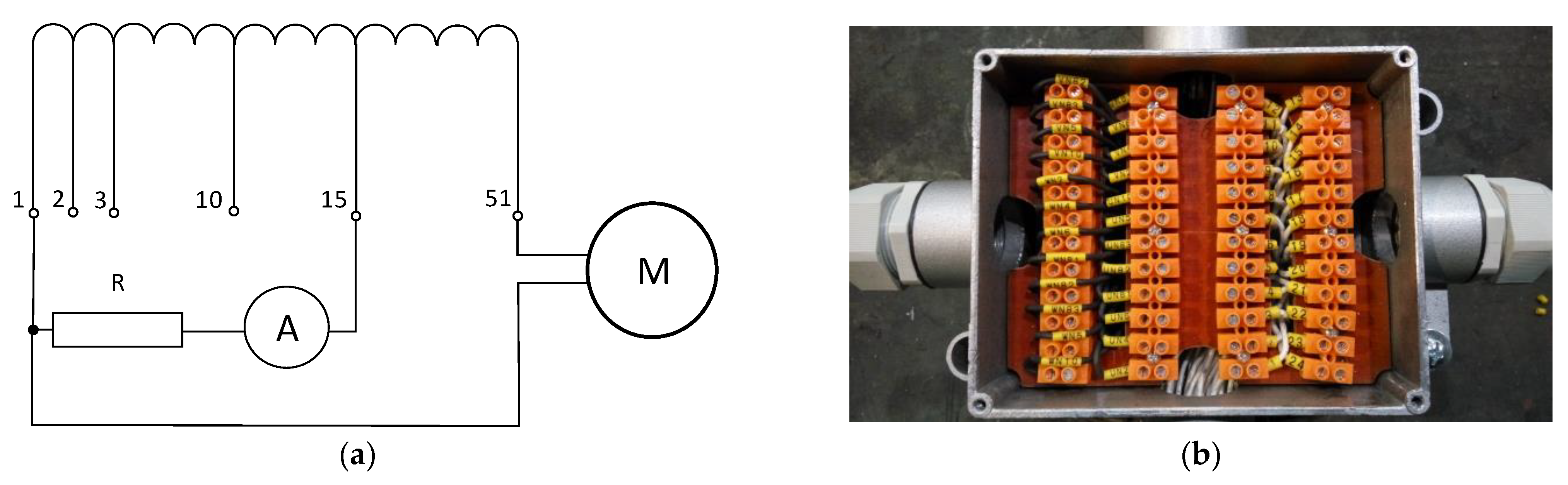

2. Materials and Theoretical Basis

Description of the Identification Process of the Inter-Turn Short-Circuit in the Induction Motor Model

- (a)

- Turn short-circuit current Iz;

- (b)

- Electromagnetic torque of the examined induction motor mel;

- (c)

- Voltage signal proportional to the rotational speed of the examined induction motor’s rotor n1;

- (d)

- Signal proportional to the axial flux ϕ1;

- (e)

- Vibration signal—acceleration in X axis—dx;

- (f)

- Vibration signal—acceleration in Y axis—dy;

- (g)

- Acoustic pressure—ps;

- (h)

- Phase voltage—u1, u2 and u3;

- (i)

- Phase current—i1, i2 and i3;

- (j)

- Neutral point voltage—u0.

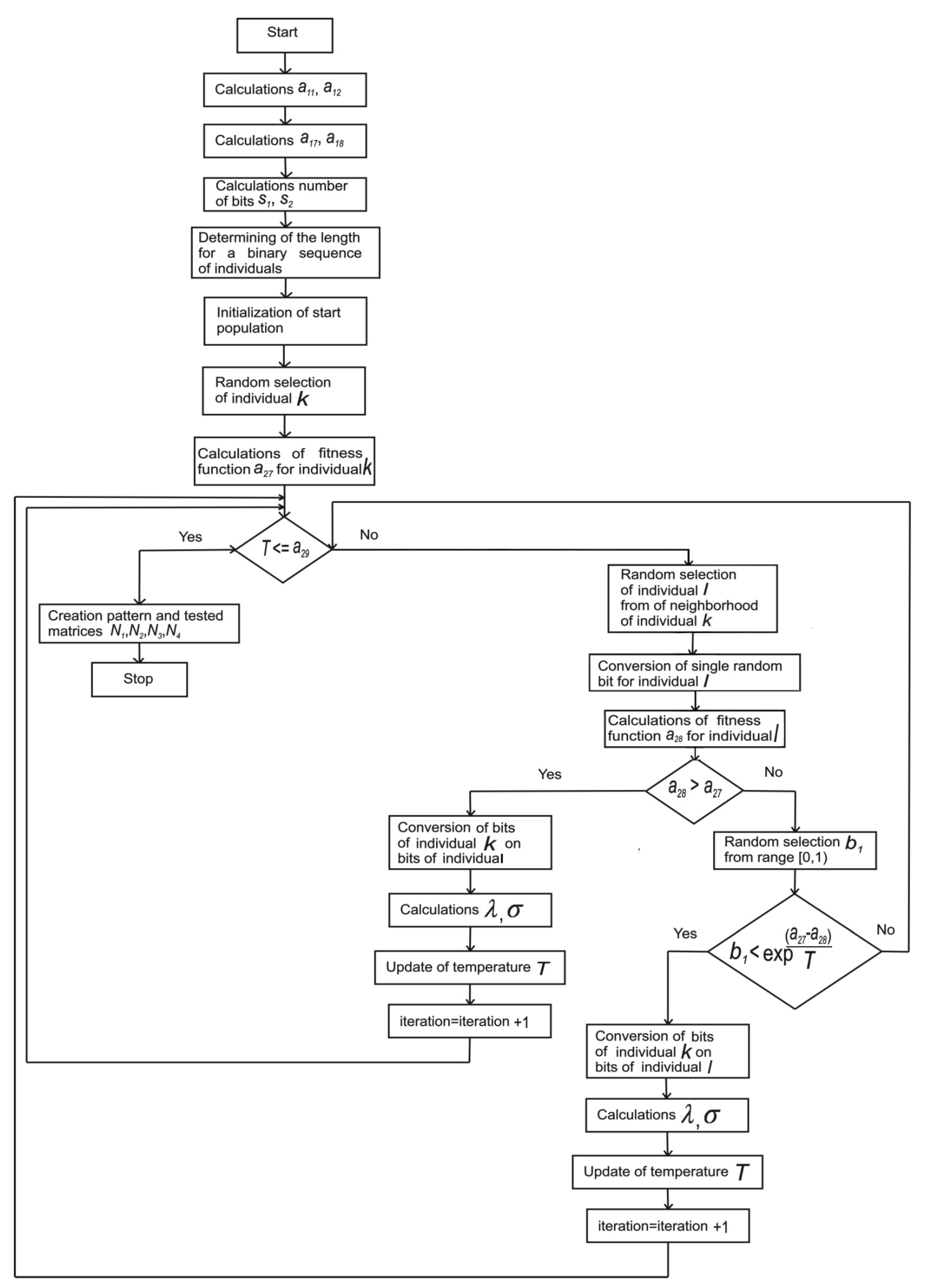

3. Proposed Method of Inter-Turn Short-Circuit Identification in Induction Motor

Description of Diagnostic Algorithm Used in Physical Magnitude Signal Processing Using the Genetic Algorithm of Simulated Annealing

- −

- Tests performed for the assumed first four cases of inter-turn short-circuiting using the parameters defined for acoustic pressure ps;

- −

- Tests performed for the assumed last four cases of inter-turn short-circuiting using the parameters defined for axial flux ϕ1.

- −

- Were stored in the reference matrix N1 and in the tested matrix N3 for the normalization of matrix X1, which was performed using the parameters calculated for axial flux.

- −

- Were stored in the reference matrix N2 and in the tested matrix N4 for the normalization of matrix X1, which was performed using the parameters calculated for acoustic pressure ps.

4. Results of Research on Diagnostic Algorithm Application in the Identification of Inter-Turn Short-Circuiting in Induction Motor Models

5. Conclusions

- −

- Obtain correct results when searching for a local optimal solution by calculating the length of the binary sequence of individuals with the parameters obtained by means of clustering in a fixed order and normalization of the data recorded via laboratory measurements and the adopted Schaffer F6 objective function;

- −

- Ensure the optimization of performance in terms of the quality of the results obtained via the identification process upon applying changes within the appropriate range of parameters of the genetic algorithm (population size, initial temperature value, accuracy parameter and convergence criterion);

- −

- Solve continuous and discrete optimization problems by ensuring a stochastic process during the GA operation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guedes, J.J.; Castoldi, M.F.; Goedtel, A.; Agulhari, C.M.; Sanches, D.S. Parameters estimation of three-phase induction motors using differential evolution. Electr. Power Syst. Res. 2018, 154, 204–212. [Google Scholar] [CrossRef]

- Chandralekha, R.; Yayanthi, D. Diagnosis of Faults in Three Phase Induction Motor Using Neuro Fuzzy Logic. Int. J. Appl. Eng. Res. 2016, 11, 5735–5740. [Google Scholar]

- Rajamany, G.; Srinivasan, S.; Rajamany, K.; Natarajan, R.K. Induction Motor Stator Interturn Short Circuit Fault Detection in Accordance with Line Current Sequence Components Using Artificial Neural Network. J. Electr. Comput. Eng. 2019, 2019, 4825787. [Google Scholar] [CrossRef]

- Smutnicki, C. Scheduling Algorithms; Akademicka Oficyna Wydawnicza EXIT: Warszawa, Poland, 2004. [Google Scholar]

- Duan, F.; Živanović, R. Induction Motor Stator Fault Detection by a Condition Monitoring Scheme Based on Parameter Estimation Algorithms. Electr. Power Compon. Syst. 2016, 44, 1138–1148. [Google Scholar] [CrossRef][Green Version]

- Arellano-Espitia, F.; Delgado-Prieto, M.; Gonzalez-Abreu, A.-D.; Saucedo-Dorantes, J.J.; Osornio-Rios, R.A. Deep-Compact-Clustering Based Anomaly Detection Applied to Electromechanical Industrial Systems. Sensors 2021, 21, 5830. [Google Scholar] [CrossRef] [PubMed]

- Asfani, D.A.; Negara, I.M.Y.; Perdana Surya, P. Short Circuit Detection in Stator Winding of Three Phase Induction Motor Using Wavelet Transform and Quadratic Discriminant Analysis. In Proceedings of the 3rd IIAE International Conference on Intelligent Systems and Image Processsing, Fukuoka, Japan, 2–5 September 2015; pp. 361–366. [Google Scholar]

- Kościelny, J.M.; Syfert, M.; Wnuk, P. Diagnostic Row Reasoning Method Based on Multiple-Valued Evaluation of Residuals and Elementary Symptoms Sequence. Energies 2021, 14, 2476. [Google Scholar] [CrossRef]

- Aswad, R.A.K.; Jassim, B.M.H. Impact of Induction Motor Faults on the Basic Parameters’ Values. J. Eng. 2020, 26, 66–80. [Google Scholar] [CrossRef]

- Ćalasan, M.; Micev, M.; Ali, Z.M.; Zobaa, A.F.; Aleem, S.H.E.A. Parameter Estimation of Induction Machine Single-Cage and Double-Cage Models Using a Hybrid Simulated Annealing–Evaporation Rate Water Cycle Algorithm. Mathematics 2020, 8, 1024. [Google Scholar] [CrossRef]

- Rutczyńska-Wdowiak, K. The scaling of fitness function in problem of parametric identification of induction motor mathematical model. Przegląd Elektrotechniczny 2017, 93, 149–153. [Google Scholar]

- Henrique, R.; Palacios, C.; Goedtel, A.; Godoy, W.F.; Fabri, J.A. Fault Identification in the Stator Winding of Induction Motors Using PCA with Artificial Neural Networks. J. Control Autom. Electr. Syst. 2016, 27, 406–418. [Google Scholar]

- Calado, J.M.F.; Korbicz, J.; Patan, K.; Patton, R.J.; Sá da Costa, J.M.G. Soft computing approaches to fault diagnosis for dynamic systems. Eur. J. Control 2001, 7, 248–286. [Google Scholar] [CrossRef]

- Michalewicz, Z. Genetic Algorithms + Data Structures = Evolution Programs; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Lakrout, A.; Bendjebbar, M.; Henini, N. Discrimination of Faults in induction machine based on pattern recognition and Neural Networks techniques. Przegląd Elektrotechniczny 2020, 96, 55–61. [Google Scholar] [CrossRef]

- Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Application of Self-Organizing Neural Networks to Electrical Fault Classification in Induction Motors. Appl. Sci. 2019, 9, 616. [Google Scholar] [CrossRef]

- Lee, Y.O.; Jo, J.; Hwang, J. Application of deep neural network and generative adversarial network to industrial maintenance: A case study of induction motor fault detection. In Proceedings of the IEEE International Conference on Big Data, Boston, MA, USA, 11–14 December 2017; pp. 3248–3253. [Google Scholar] [CrossRef]

- Rutczyńska-Wdowiak, K. The analysis of influence of crossover on example of the identification of induction motor mathematical model with the use of genetic algorithm. SSymulacja W Bad. I Rozw. 2017, 8, 55–61. [Google Scholar]

- Zając, M.; Sułowicz, M. The detection of coil shorting in induction motors by means of wavelet analysis. Tech. Trans. 2016, 2, 135–150. [Google Scholar]

- Aarts, E.H.L.; Van Laarhoven, P.J.M. Simulated annealing: A pedestration review of the theory and some applications. Pattern Recognit. Theory Appl. 1987, 30, 179–192. [Google Scholar] [CrossRef]

- Mohammadi, H.R.; Akhavan, A. Parameter Estimation of Three-Phase Induction Motor Using Hybrid of Genetic Algorithm and Particle Swarm Optimization. J. Eng. 2014, 2014, 1–6. [Google Scholar] [CrossRef]

- Hsueh, Y.-M.; Ittangihal, V.R.; Wu, W.-B.; Chang, H.-C.; Kuo, C.-C. Fault Diagnosis System for Induction Motors by CNN Using Empirical Wavelet Transform. Symmetry 2019, 11, 1212. [Google Scholar] [CrossRef]

- Sonje, D.M.; Kundu, P.; Chowdhury, A. A Novel Approach for Sensitive Inter-turn Fault Detection in Induction Motor Under Various Operating Conditions. Arab. J. Sci. Eng. 2019, 44, 6887–6900. [Google Scholar] [CrossRef]

- Sridhar, S.; Rao, K.U.; Harish, K.S.; Umesh, R. Simultaneous Detection of Broken Rotor Fault and PQ disturbances in the supply to Induction Motor using Neuro Fuzzy. Int. J. Innov. Res. Sci. Eng. Technol. 2016, 5, 599–607. [Google Scholar]

- Tomczyk, M.; Plichta, A.; Mikulski, M. Application of image analysis to the identification of mass inertia momentum in electromechanical system with changeable backlash zone. Appl. Comput. Sci. 2019, 15, 87–102. [Google Scholar]

- Wachowiak, D. Genetic Algorithm Approach for Gains Selection of Induction Machine Extended Speed Observer. Energies 2020, 13, 4632. [Google Scholar] [CrossRef]

- Wolkiewicz, M.; Skowron, M. Diagnostic System for Induction Motor Stator Winding Faults Based on Axial Flux. Power Electron. Drives 2017, 2, 137–150. [Google Scholar]

| Test Parameters | Results * 1011 | Test Parameters | Results * 1011 |

|---|---|---|---|

| inter-turn short-circuit 1_20, load current Iobc = 1 A, population size = 25, a29 = 9 * 10−5, δ = 1.5, iteration = 35 | 1.5165 1.5435 1.5238 1.5451 1.5096 1.4747 0.6304 2.4499 | inter-turn short-circuit 1_20, load current Iobc = 1 A, population size = 50, a29 = 9 * 10−5, δ = 5.0, iteration = 15 | 1.8195 1.8429 1.8197 1.8370 1.8056 1.6356 0.8436 2.1941 |

| inter-turn short-circuit 1_10, load current Iobc = 4 A, population size = 25, a29 = 9 * 10−5, δ = 1.5, iteration = 104 | 0.0085 0.0355 0.0157 0.0370 0.0016 0.0334 0.8777 3.9579 | inter-turn short-circuit 1_10, load current Iobc = 4 A, population size = 50, a29 = 9 * 10−5, δ = 5.0, iteration = 58 | 0.0141 0.0375 0.0144 0.0317 0.0003 0.1698 0.9617 3.9995 |

| Test Parameters | Results * 1011 | Test Parameters | Results * 1011 |

|---|---|---|---|

| inter-turn short-circuit 1_15, load current Iobc = 2 A, population size = 25, condition = 9 * 10−5, δ = 1.5, iteration = 38 | 0.4331 0.4192 0.4339 0.4217 0.3756 0.0739 0.8653 6.1794 | inter-turn short-circuit 1_15, load current Iobc = 2 A, population size = 50, condition = 9 * 10−5, δ = 5.0, iteration = 17 | 0.4494 0.4454 0.4507 0.4426 0.4054 0.0029 1.5368 7.0391 |

| inter-turn short-circuit 1_25, load current Iobc = 5 A, population size = 25, condition = 9 * 10−5, δ = 1.5, iteration = 34 | 7.3506 7.3494 7.3400 7.3432 7.2915 6.9687 5.7263 0.5185 | inter-turn short-circuit 1_25, load current Iobc = 5 A, population size = 50, condition = 9 * 10−5, δ = 5.0, iteration = 18 | 7.8657 7.8617 7.8670 7.8589 7.8217 7.4134 5.8795 0.4429 |

| Test Parameters | Results | Test Parameters | Results |

|---|---|---|---|

| inter-turn short-circuit 1_3, load current Iobc = 1 A, population size = 25, a29 = 9 * 10−6, δ = 1.5, iteration = 31 | 24,522 2309 12,972 20,211 | inter-turn short-circuit 1_3, load current Iobc = 1 A, population size = 50, a29 = 9 * 10−6, δ = 5.0, iteration = 14 | 24,263 206 12,830 23,643 |

| inter-turn short-circuit 1_5, load current Iobc = 4 A, population size = 25, a29 = 9 * 10−6, δ = 1.5, iteration = 27 | 36,991 20,738 16,198 5219 | inter-turn short-circuit 1_5, load current Iobc = 4 A, population size = 50, a29 = 9 * 10−6, δ = 5.0, iteration = 15 | 45,858 23,825 21,433 902 |

| Test Parameters | Results | Test Parameters | Results |

|---|---|---|---|

| inter-turn short-circuit 1_4, load current Iobc = 2 A, population size = 25, a29 =9 * 10−6, δ = 1.5, iteration = 22 | 23,325 11,396 699 22,413 | inter-turn short-circuit 1_4, load current Iobc = 2 A, population size = 50, a29 =9 * 10−6, δ = 5.0, iteration = 12 | 23,947 12,261 235 24,266 |

| inter-turn short-circuit 1_2, load current Iobc = 5 A, population size = 25, a29 = 9 * 10−6, δ = 1.5, iteration = 20 | 0 11,929 23,588 45,738 | inter-turn short-circuit 1_2, load current Iobc = 5 A, population size = 50, a29 = 9 * 10−6, δ = 5.0, iteration = 10 | 0 11,686 23,964 48,213 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomczyk, M.; Mielnik, R.; Plichta, A.; Goldasz, I.; Sułowicz, M. Identification of Inter-Turn Short-Circuits in Induction Motor Stator Winding Using Simulated Annealing. Energies 2022, 15, 117. https://doi.org/10.3390/en15010117

Tomczyk M, Mielnik R, Plichta A, Goldasz I, Sułowicz M. Identification of Inter-Turn Short-Circuits in Induction Motor Stator Winding Using Simulated Annealing. Energies. 2022; 15(1):117. https://doi.org/10.3390/en15010117

Chicago/Turabian StyleTomczyk, Marcin, Ryszard Mielnik, Anna Plichta, Iwona Goldasz, and Maciej Sułowicz. 2022. "Identification of Inter-Turn Short-Circuits in Induction Motor Stator Winding Using Simulated Annealing" Energies 15, no. 1: 117. https://doi.org/10.3390/en15010117

APA StyleTomczyk, M., Mielnik, R., Plichta, A., Goldasz, I., & Sułowicz, M. (2022). Identification of Inter-Turn Short-Circuits in Induction Motor Stator Winding Using Simulated Annealing. Energies, 15(1), 117. https://doi.org/10.3390/en15010117