Economic Feasibility of Green Hydrogen Production by Water Electrolysis Using Wind and Geothermal Energy Resources in Asal-Ghoubbet Rift (Republic of Djibouti): A Comparative Evaluation

Abstract

:1. Introduction

- The analysis of the wind energy potential of the Ghoubbet region

- The selection of the most appropriate wind turbine and electrolyzer for electricity and hydrogen production in the study area

- The performance of thermodynamic analysis to select the appropriate geothermal energy production processes for the Rift AG region

- Estimating the cost per Kg of hydrogen produced by combining a geothermal power plant in the Rift AG with an appropriate electrolyzer

- Evaluating the CO2 emission reduction of wind and geothermal energy in the study area.

2. Site Description and Data Collection

2.1. Site Description

2.2. Wind Data Source

3. Methodology

3.1. Wind Resource Assessment

3.1.1. Weibull Density Function

3.1.2. Wind Shear Coefficient

3.1.3. Wind Power Density

3.1.4. Annual Energy Production

3.2. Geothermal Resources Assessment

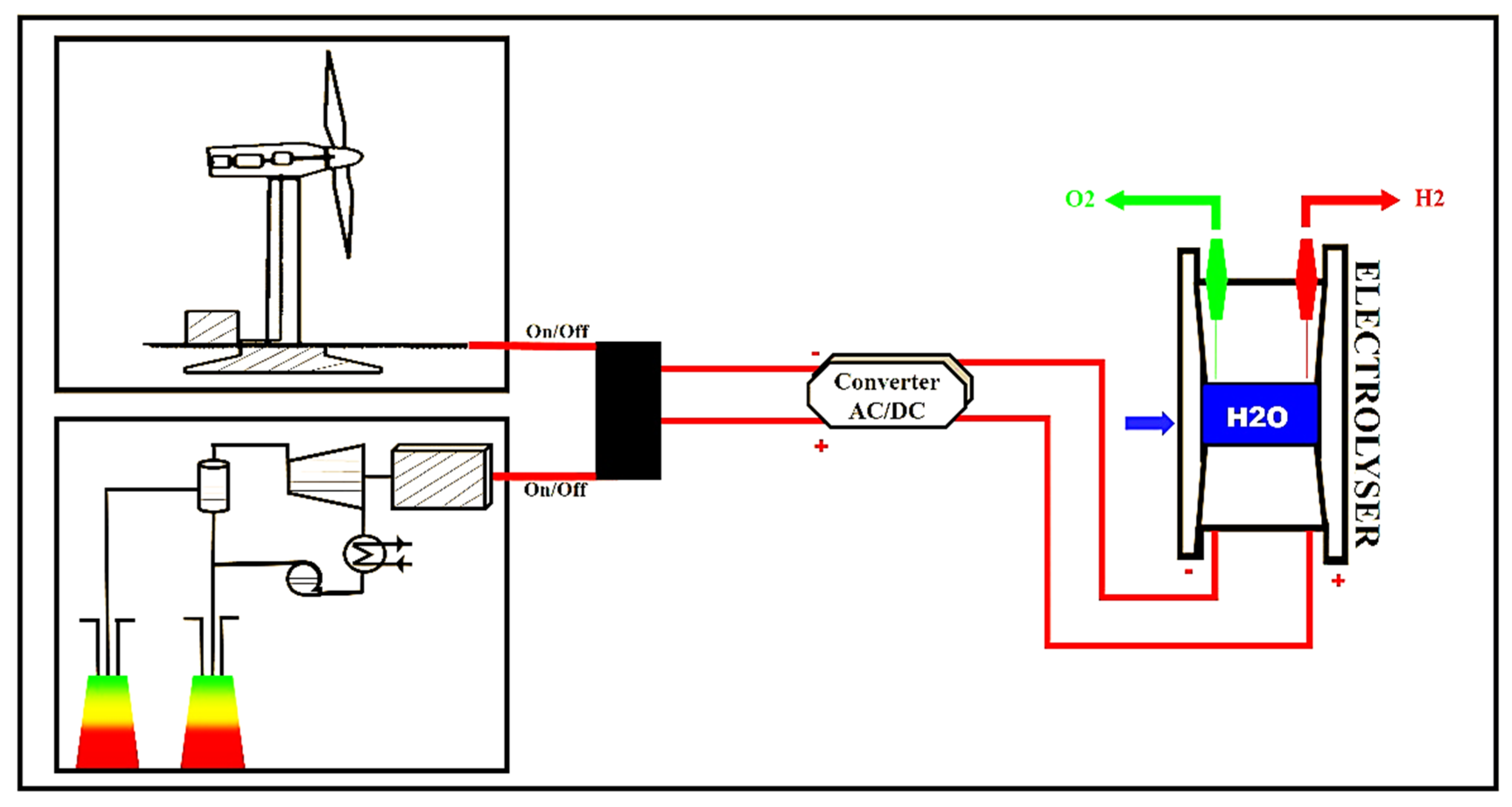

3.3. Hydrogen Production from Wind and Geothermal Energy

3.3.1. Hydrogen Production from Wind Energy

3.3.2. Hydrogen Production from Geothermal Energy

3.4. Economic Assessment of Wind Energy

3.5. Economic Evaluation of Geothermal Energy

3.6. Hydrogen Cost from Wind and Geothermal Energy

3.7. Energy and Exergy Analysis

4. Results

4.1. Wind Energy

4.1.1. Wind Resource Analysis

- ▪

- Fair (PD < 100 W/m2)

- ▪

- Fairly good (100 W/m2 ≤ PD < 300 W/m2)

- ▪

- Good (300 W/m2 ≤ PD < 700 W/m2)

- ▪

- Very good (PD ≥ 700 W/m2)

4.1.2. Performance of Wind Turbine

4.1.3. Cost Analysis for Wind Energy Generation

4.1.4. Hydrogen Production from Wind Energy

4.2. Geothermal Energy

4.2.1. Electrical Power Analysis

4.2.2. Thermoeconomic Analysis

4.2.3. Hydrogen Production from Geothermal Energy

5. Discussion

5.1. Wind Energy

5.2. Geothermal Energy

5.3. Overall Comparison

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Variables | |

| c | Specific heat of liquid water [kJ/kg K] |

| Capital cost of the electrolyzer wind system [$] | |

| Cost of wind electricity [$] | |

| Cf | Capacity Factor [%] |

| Cfuel | Cost of fuel [$] |

| CI | Total investment cost of Wind Energy [$] |

| CH2 | Cost of hydrogen from geothermal energy [$] |

| CAspec | Average specific cost of wind turbine [$/KW] |

| CO&M | Cost operating and maintenance of Wind Turbine [$] |

| Capital cost of geothermal power plant [$] | |

| Unit cost of electrolyzer [$/kW] | |

| Cost of construction [$] | |

| CWC | Completion well cost [$] |

| d | Well Depth [m] |

| Ec | Yearly cost of geothermal electricity [$] |

| Eelectrolyzer | Electricity required for 1 kg H2 [kWh/kgH2] |

| Eout | Wind electricity production [kWh] |

| GPP | Geothermal power plant [MWe] |

| H | Hydrogen rate production [kg/s] |

| i | Discount rate [%] |

| Ic | Capital cost of electrolyser-Geothermal system [$] |

| Id | Interest rate [%] |

| LCOE | Levelized cost of electricity [$/kWh] |

| LCOH | Levelized cost of hydrogen [$/kWh] |

| LF | Load Factor [%] |

| Molar mass of hydrogen [kg / kmol] | |

| Amount of hydrogen produced [kg] | |

| MOM | Operation and maintenance cost of electrolyser-Geothermal power plant system [$] |

| N | Period of study [year] |

| PD | Power Density [W/m2] |

| PVC | Present value cost [$] |

| Pr | Rated power of wind turbine [KW] |

| t | Life span of the commercial wind turbine [years] |

| T | Life time of the commercial electrolyser [years] |

| Ts | Reference temperature [°C] |

| T0 | Ambiant temperature [°C] |

| Minimum work required for an electrolyzer in non-ideal operation [kj/kg] | |

| WDC | Well drilling cost [$] |

| Steam Turbine net power output [kW] | |

| Maximum specific work [kj/kg] | |

| Minimum work required for an electrolyzer in ideal operation [kj/kg] | |

| Greek symbols | |

| Shear coefficient | |

| Electrolyzer efficiency [%] | |

| Efficiency of rectifier [%] | |

| Change in the Gibbs function [kJ/kmol] | |

| Subscripts | |

| 0 | Dead state |

| 1,2,3 | State numbers, wind speed level |

| a,b,c | Drilling Coefficients |

| geo | Geothermal fluid |

| H2O | Fresh Water |

| H2 | Hydrogen gas |

| CO2 | Carbone Dioxide |

| l | Large |

| m | Medium |

| n | Number of well |

| out | Output |

| rev | Reversible |

| s | Small |

| Abbreviations | |

| AG | Asal-Ghoubbet |

| AWE | Alkaline water electrolyzer |

| AWEl | Large-size Alkaline water electrolyzer |

| AWEm | Medium-size Alkaline water electrolyzer |

| AWEs | small-size Alkaline water electrolyzer |

| BSh | Semiarid tropical steppe climate |

| BWh | Hot desert climate |

| CDF | Cumulative probability distribution function |

| EARS | East African Rift System |

| Eq. | Equation |

| EMJ | Empirical Method of Jestus |

| HTE | High temperature electrolyzer |

| MAE | Mean Absolute Error |

| MLM | Maximum Likelihood Method |

| MM | Moment Method |

| O&M | Operation and Maintenance |

| Probability distribution function | |

| PEME | Polymer electrolyte membrane electrolyzer |

| PEMEl | Large-size Polymer electrolyte membrane electrolyzer |

| PEMEm | Medium-size Polymer electrolyte membrane electrolyzer |

| PEMEs | Small-size Polymer electrolyte membrane electrolyzer |

| RMSE | Root Mean Square Error |

| USGS | United States Geological Survey |

| WM | Wasp Method |

References

- Mlynarski, M.; Zlotnicki, J. Fluid circulation in the active emerged Asal-Ghoubbet Rif (east Africa, Djibouti) inferred from self-Potential and Telluric—Telluric Prospecting. Tectonophysics 2001, 339, 455–472. [Google Scholar] [CrossRef]

- Fouillac, A.M.; Fouillac, C.; Cesbron, F.; Pillard, F.; Legendre, O. Water-rock interaction between basalt and high-salinity fluids in the Asal-Ghoubbet Rif, Republic of Djibouti. Chem. Geol. 1989, 76, 271–289. [Google Scholar] [CrossRef]

- Aden, A.H.; Raymond, J.; Giroux, B.; Sanjuan, B. New Insights into Hydrothermal Fluid Circulation Affected by Regional Groundwater Flow in the Asal Rift, Republic of Djibouti. Energies 2021, 14, 1166. [Google Scholar] [CrossRef]

- D’Amore, F.; Giusti, D.; Abdallah, A. Geochemistry of the high-salinity geothermal field of Asal, Republic of Djibouti, Africa. Geothermics 1998, 27, 197–210. [Google Scholar] [CrossRef]

- Awaleh, M.O.; Hoch, F.B.; Boschetti, T.; Soubaneh, Y.D.; Egueh, N.M.; Elmi, S.A.; Jalludin, M.; Khaireh, M.A. The geothermal resources of the Republic of Djibouti—II: Geochemical study of the Lake Abhe geothermal field. J. Geochem. Explor. 2015, 159, 129–147. [Google Scholar] [CrossRef]

- Awaleh, M.O.; Boschetti, T.; Soubaneh, Y.D.; Baudron, P.; Kawalieh, A.D.; Dabar, O.A.; Ahmed, M.M.; Ahmed, S.I.; Daoud, M.A.; Egueh, N.M.; et al. Geochemical study of the Sakalol—Harralol geothermal field (Republic of Djibouti): Evidences of a low enthalpy aquifer between Manda-Inakir and Asal-Ghoubbet Rif settings. J. Volcanol. Geotherm. Res. 2017, 331, 26–52. [Google Scholar] [CrossRef]

- Awaleh, M.O.; Boschetti, T.; Soubaneh, Y.D.; Kim, Y.; Baudron, P.; Kawalieh, A.D.; Ahmed, M.M.; Daoud, M.A.; Dabar, O.A.; Kadieh, I.H.; et al. Geochemical, multi-isotopic studies and geothermal potential evaluation of the complex Djibouti volcanic aquifer (republic of Djibouti). Appl. Geochem. 2018, 97, 301–321. [Google Scholar] [CrossRef]

- Awaleh, M.O.; Boschetti, T.; Adaneh, A.E.; Daoud, M.A.; Ahmed, M.M.; Dabar, O.A.; Soubaneh, Y.D.; Kawalieh, A.D.; Kadieh, I.H. Hydrochemistry and multi isotope study of the waters from Hanlé-Gaggadé grabens (Republic of Djibouti, East African Rift System): A low-enthalpy geothermal resource from a transboundary aquifer. Geothermics 2020, 86, 101805. [Google Scholar] [CrossRef]

- Pillot, B.; Muselli, M.; Philippe Poggi, P.; Haurant, P.; Hared, I. Solar energy potential atlas for planning energy system off-grid electrification in the Republic of Djibouti. Energy Convers. Manag. 2013, 69, 131–147. [Google Scholar] [CrossRef] [Green Version]

- Daher, D.H.; Gaillard, L.; Amara, M.; Ménézo, C. Impact of tropical desert maritime climate on the performance of a PV grid-connected power plant. Renew. Energy 2018, 125, 729–737. [Google Scholar] [CrossRef]

- Assowe Dabar, O.; Awaleh, M.O.; Kirk-Davidoff, D.; Olauson, J.; Söder, L.; Awaleh, S.I. Wind resource assessment and economic analysis for electricity generation in three locations of the Republic of Djibouti. Energy 2019, 185, 884–894. [Google Scholar] [CrossRef]

- Assowe Dabar, O.; Camberlin, P.; Pohl, B.; Waberi, M.M.; Awaleh, M.O.; Silah-Eddine, S. Spatial and temporal variability of rainfall over the Republic of Djibouti from 1946 to 2017. Int. J. Climatol. 2021, 41, 2729–2748. [Google Scholar] [CrossRef]

- Elimax, H. Etude Strategique de Déploiement de L’énergie Eolienne en Afrique. Rapport Final; Canadian International Development Agency: Ottawa, ON, Canada, 2004. [Google Scholar]

- Aliyu, A.K.; Modu, B.; Tan, C.W. A review of renewable energy development in Africa: A focus in South Africa, Egypt and Nigeria. Renew. Sustain. Energy Rev. 2018, 8, 2502–2518. [Google Scholar] [CrossRef]

- Saidur, R.; Islam, M.R.; Rahim, N.A.; Solangi, K.H. A review on global wind energy policy. Renew. Sustain. Energy Rev. 2010, 14, 1744–1762. [Google Scholar] [CrossRef]

- Saeed, M.A.; Ahmed, Z.; Zhang, W. Wind energy potential and economic analysis with a comparison of different methods for determining the optimal distribution parameters. Renew. Energy 2020, 161, 1092–1109. [Google Scholar] [CrossRef]

- Soltani, M.; Mohammad Jabarifar, M.; Kashkooli, F.M.; Souri, M.; Rafiei, B.; Gharali, K.; Nathwani, J.S. Environmental, economic, and social impacts of geothermal energy systems. Renew. Sustain. Energy Rev. 2021, 140, 110750. [Google Scholar] [CrossRef]

- Mahmoud, M.; Ramadan, M.; Naher, S.; Pullen, K.; Abdelkareem, M.A.; Olabi, A.G. A review of geothermal energy-driven hydrogen production systems. Therm. Sci. Eng. Prog. 2021, 22, 100854. [Google Scholar] [CrossRef]

- Genç, M.S.; Çelik, M.; Karasu, I. A review on wind energy and wind–hydrogen production in Turkey: A case study of hydrogen production via electrolyzer system supplied by wind energy conversion system in Central Anatolian Turkey. Renew. Sustain. Energy Rev. 2012, 16, 6631–6646. [Google Scholar] [CrossRef]

- Short, W.; Blair, N.; Heimiller, D. Modeling the Market Potential of Hydrogen from Wind and Competing Sources; National Renewable Energy Lab: Golden, CO, USA, 2005.

- Kato, T.; Kubota, M.; Kobayashi, N.; Suzuoki, Y. Effective utilization of by-product oxygen from electrolyzer hydrogen production. Energy 2005, 30, 2580–2595. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Munda, J.L. Potential and economic viability of green hydrogen production by water electrolyzer using wind energy resources in South Africa. Int. J. Hydrogen Energy 2019, 44, 17669–17687. [Google Scholar] [CrossRef]

- Cornell, A. Hydrogen production by electrolyzer. In Proceedings of the 1st International Conference on Electrolyzer, Copenhagen, Denmark, 13–15 June 2017; pp. 12–15. [Google Scholar]

- Ishaq, H.; Dincer, I. Comparative assessment of renewable energy-based hydrogen production methods. Renew. Sustain. Energy Rev. 2021, 135, 110192. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Sahin, A.Z.; Ayar, T.; Yilbas, B.S. Techno-economic analysis and optimization of solar and wind energy systems for power generation and hydrogen production in Saudi Arabia. Renew. Sustain. Energy Rev. 2017, 69, 33–49. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Dehshiri, S.J.H.; Dehshiri, S.S.H.; Jahangiri, M. Prioritization of potential locations for harnessing wind energy to produce hydrogen in Afghanistan. Int. J. Hydrogen Energy 2020, 45, 33169–33184. [Google Scholar] [CrossRef]

- Rahmouni, S.; Negrou, B.; Settou, N.; Dominguez, J.; Gouareh, A. Prospects of hydrogen production potential from renewable resources in Algeria. Int. J. Hydrogen Energy 2017, 42, 1383–1395. [Google Scholar] [CrossRef]

- Ghazvini, M.; Sadeghzadeh, M.; Ahmadi, M.H.; Moosavi, S.; Pourfayaz, F. Geothermal energy use in hydrogen production: A review. Int. J. Energy Res. 2019, 43, 7823–7851. [Google Scholar] [CrossRef]

- Rahmouni, S.; Settou, N.; Chennouf, N.; Negrou, B.; Houari, M. A technical, economic and environmental analysis of combining geothermal energy with carbon sequestration for hydrogen production. Energy Procedia 2014, 50, 263–269. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, C.; Kanoglu, M.; Abusoglu, A. Exergetic cost evaluation of hydrogen production powered by combined flash-binary geothermal power plant. Int. J. Hydrogen Energy 2015, 40, 14021–14030. [Google Scholar] [CrossRef]

- Yilmaz, C.; Koyuncu, I.; Alcin, M.; Tuna, M. Artificial Neural Networks based thermodynamic and economic analysis of a hydrogen production system assisted by geothermal energy on Field Programmable Gate Array. Int. J. Hydrogen Energy 2019, 44, 17443–17459. [Google Scholar] [CrossRef]

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future Köppen-Geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef] [Green Version]

- Geiger, R. Klassifikation der klimate nachW. Köppen. Landolt-Börnstein– Zahlenwerte Und Funkt. Aust. Phys. Chem. Astron. Geophys. Technol. 1954, 3, 603–607. [Google Scholar]

- Manighetti, I.; Tapponnier, P.; Gillot, P.Y.; Jacques, E.; Courtillot, V.; Armijo, R.; Ruegg, J.C.; King, G. Propagation of rifting along the Arabia-Somalia plate boundary: Into Afar. J. Geophys. Res. 1998, 103, 4947–4974. [Google Scholar] [CrossRef]

- NRG Systems. 60m XHD NOW System. 2021. Available online: https://www.nrgsystems.com/products/complete-met-systems/wind-resource-assessment-systems/detail/34m-xhd-now-system/ (accessed on 27 January 2021).

- Mohammadi, K.; Mostafaeipour, A. Using different methods for comprehensive study of wind turbine utilization in Zarrineh, Iran. Energy Convers. Manag. 2013, 65, 463–470. [Google Scholar] [CrossRef]

- Akdag, S.A.; Dinler, A. A new method to estimate Weibull parameters for wind energy applications. Energy Convers. Manag. 2009, 50, 1761–1766. [Google Scholar] [CrossRef]

- Kwon, S.D. Uncertainty analysis of wind energy potential assessment. Appl. Energy 2010, 87, 856–865. [Google Scholar] [CrossRef]

- Ombeni, J.M. Performance evaluation of Weibull analytical methods using several empirical methods for predicting wind speed distribution. Energy Sources Part A Recovery Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

- Bahrami, A.; Teimourian, A.; Okoye, C.O.; Hiri, H. Technical and economic analysis of wind energy potential in Uzbekistan. J. Clean. Prod. 2019, 20, 801–814. [Google Scholar] [CrossRef]

- Mentis, D.; Hermann, S.; Howells, M.; Welsch, M.; Siyal, S.H. Assessing the technical wind energy potential in Africa a GIS-based approach. Renew. Energy 2015, 83, 110–125. [Google Scholar] [CrossRef]

- Abam, F.I.; Ohunakin, O.S. Economics of wind energy utilisation for water pumping and CO2 mitigation potential in Niger Delta, Nigeria. Int. J. Ambient Energy 2015, 38, 229–239. [Google Scholar] [CrossRef]

- Ahmed, A.S.; Hanitsch, R. Electricity generation and wind potential assessment at Hurghada, Egypt. Renew. Energy 2008, 33, 141–148. [Google Scholar] [CrossRef]

- Muffler, P.; Cataldi, R. Methods for regional assessment of geothermal resources. Geothermics 1978, 7, 53–89. [Google Scholar] [CrossRef] [Green Version]

- Ciriaco, A.E.; Zarrouk, S.J.; Zakeri, G. Geothermal resource and reserve assessment methodology: Overview, analysis and future directions. Renew. Sustain. Energy Rev. 2020, 119, 109515. [Google Scholar] [CrossRef]

- Rezaei, M.; Khozani, N.N.; Jafari, N. Wind energy utilization for hydrogen production in an underdeveloped country: An economic investigation. Renew. Energy 2019, 147, 1044–1057. [Google Scholar] [CrossRef]

- D’ Amore-Domenech, R.; Santiago, Ó.; Leo, T.J. Multicriteria analysis of seawater electrolyzer technologies for green hydrogen production at sea. Renew. Sustain. Energy Rev. 2020, 133, 110166. [Google Scholar] [CrossRef]

- Jónsson, V.K.; Gunnarsson, R.L.; Árnason, B.; Sigfússon, T.I. The feasibility of using geothermal energy in hydrogen production. Geothermics 1992, 21, 673–681. [Google Scholar] [CrossRef]

- Kanoglu, M.; Bolatturk, A.; Yilmaz, C. Thermodynamic analysis of models used in hydrogen production by geothermal energy. Int. J. Hydrogen Energy 2010, 35, 8783–8791. [Google Scholar] [CrossRef]

- Ueckerdt, F.; Hirth, L.; Luderer, G.; Edenhofer, O. System LCOE: What are the costs of variable renewables? Energy 2013, 63, 61–75. [Google Scholar] [CrossRef]

- Li, Y.; Wu, X.P.; Li, Q.S.; Tee, K.F. Assessment of onshore wind energy potential under different geographical climate conditions in China. Energy 2018, 152, 498–511. [Google Scholar] [CrossRef]

- Coskun, A.; Bolatturk, A.; Kanoglu, M. Thermodynamic and economic analysis and optimization of power cycles for a medium temperature geothermal resource. Energy Convers. Manag. 2014, 78, 39–49. [Google Scholar] [CrossRef]

- Sun, J.; Liu, Q.; Duan, Y. Effects of evaporator pinch point temperature difference on thermo-economic performance of geothermal organic Rankine cycle systems. Geothermics 2018, 75, 249–258. [Google Scholar] [CrossRef]

- Fallah, M.; Ghiasi, R.A.; Mokarram, N.H. A comprehensive comparison among different types of geothermal plants from exergy and thermoeconomic points of view. Therm. Sci. Eng. Prog. 2018, 5, 15–24. [Google Scholar] [CrossRef]

- Shamoushaki, M.; Fiaschi, D.; Manfrida, G.; Niknam, P.H.; Talluri, L. Feasibility study and economic analysis of geothermal well drilling. Int. J. Environ. Stud. 2021, 78, 1022–1036. [Google Scholar] [CrossRef]

- Lukawski, M.Z.; Anderson, B.J.; Augustine, C.; Capuano, L.E.; Beckers, K.F.; Livesay, B.; Tester, J.W. Cost analysis of oil, gas, and geothermal well drilling. J. Pet. Sci. Eng. 2014, 118, 1–14. [Google Scholar] [CrossRef]

- Yilmaz, C.; Kanoglu, M.; Bolatturk, A.; Gadalla, M. Economics of hydrogen production and liquefaction by geothermal energy. Int. J. Hydrogen Energy 2012, 37, 2058–2069. [Google Scholar] [CrossRef]

- Aquater. Djibouti Geothermal Exploration Project Republic of Djibouti: Final Report; Aquater: Djibouti, Republic of Djibouti, 1989; p. 159. [Google Scholar]

- Virkir-Orkint Consulting Group Ltd. Geothermal Scaling And corrosion Study, Final Report; Virkir-Orkint Consulting Group Ltd.: Reykjanik, Iceland, 1990. [Google Scholar]

- Lucas, B.; Silvio, M. The Big Portal for Wind Energy. Available online: https://en.wind-turbine-models.com/models (accessed on 25 July 2021).

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Amusan, T.O. Wind power utilization assessment and economic analysis of wind turbines across fifteen locations in the six geographical zones of Nigeria. J. Clean. Prod. 2016, 129, 341–349. [Google Scholar] [CrossRef]

- Banque Centrale de Djibouti (BCD). Rapport Annuel. 2019. Available online: https://banque-centrale.dj/wp-content/uploads/2020/09/BCD-Rapport-Annuel-2019.pdf (accessed on 22 December 2021).

- Greiner, C.; Korpas, M.; Holen, A. A Norwegian case study on the production of hydrogen from wind power. Int. J. Hydrogen Energy 2007, 32, 1500–1507. [Google Scholar] [CrossRef]

- Abdallah, A.; Gandino, A.; Sommaruga, C. Technical-economic studies of geothermal projects: The Djibouti case. Geothermics 1985, 14, 327–334. [Google Scholar] [CrossRef]

- Motazedi, K.; Salkuyeh, Y.K.; Laurenzi, I.J.; MacLean, H.L.; Bergerson, J.A. Economic and environmental competitiveness of high temperature electrolyzer for hydrogen production. Int. J. Hydrogen Energy 2021, 46, 21274–21288. [Google Scholar] [CrossRef]

- Adebayo, V.; Abid, M.; Adedeji, M.; Hussain Ratlamwala, T.A. Energy, exergy and exergo-environmental impact assessment of a solid oxide fuel cell coupled with absorption chiller & cascaded closed loop ORC for multi-generation. Int. J. Hydrogen Energy 2021, in press. [Google Scholar]

| Weibull Distribution Modeling | Parameters | Performance Weibull Model | Wind Speed (m/s) | |||

|---|---|---|---|---|---|---|

| k | c (m/s) | R2 | RMSE | MAE | Wavg (m/s) | |

| Moment Method (MM) | 2.68 | 11.25 | 0.90525 | 0.00984 | 0.00767 | 10.00 |

| WAsP Method (WM) | 2.96 | 11.25 | 0.88131 | 0.01102 | 0.00836 | 10.04 |

| Empirical Method of Jestus (EMJ) | 2.69 | 11.25 | 0.90500 | 0.00986 | 0.00769 | 10.00 |

| Maximum Likelihood Method (MLM) | 2.65 | 11.19 | 0.89932 | 0.01015 | 0.00780 | 9.947 |

| Parameters | Units | Values of Turbine T25 |

|---|---|---|

| Specific cost of wind turbine | US$/KW | 1600 a |

| Life time | Year | 20 b |

| Initial investment cost | US$ | 4,000,000 |

| Variable capital cost (30%) | % | 1,200,000 c |

| Total investment cost | US$ | 5,200,000 |

| Interest rate of Djibouti | % | 0.1087 d |

| Discount rate of Djibouti | % | 0.125 e |

| Operation & Maint. Cost (25%) | % | 1,300,000 f |

| Capacity factor of Turbine | % | 84.96 |

| Energy output of Turbine | KWh/yr | 18,606,641.39 |

| Present Value Cost | US$ | 15,640,958.47 |

| LCOE | US$/KWh | 0.04203 |

| Parameter | Unit | Value of AWEL | Value of PEMEm |

|---|---|---|---|

| Rated power | KW | 1000 1 | 185 2 |

| Specific cost of electrolyzer | US$/KW | 1547 1 | 900 2 |

| Unit cost of electrolyser | US$ | 1,547,000 | 166,500 |

| Capital investment cost | US$ | 4,629,860 | 3,463,096 |

| Installation cost of electrolyzer | US$ | 185,640 | 19,980 |

| Stack replacement cost | US$ | 618,800 | 66,600 |

| Operation & Maintenance cost | US$ | 61,880 | 6660 |

| Specific cost of converter | US$/KW | 155 1 | 155 1 |

| Investment of converter | US$ | 154,700 | 28,619.5 |

| Operation & Maintenance cost of converter | US$ | 6188 | 1145 |

| Total investment cost electrolyzer | US$ | 5,817,956.49 | 3,615,864.87 |

| Cost of electricity | US$ | 782,047.92 | 782,047.92 |

| Interest rate | % | 10.87 3 | 10.87 3 |

| Unit cost of hydrogen | US$/kg | 1.045 | 0.672 |

| Geothermal Power Plant | Dry Steam Power Plant | Single Flash Power Plant |

|---|---|---|

| Output power (MW) | 22.22 | 4.91 |

| Exergy destruction (MW) | 18.83 | 10.81 |

| First law efficiency (%) | 21.57 | 9.68 |

| Second law efficiency (%) | 54.13 | 31.24 |

| Isentropic efficiency (%) | 76.38 | 67.91 |

| Thermodynamic Operation | Electrolyser Coupled with Geothermal Power Plant | Maximum Work Requirement (kJ/kg) | Minimum Work Requirement (kJ/kg) | Minimum Work Input (kWh/kg) | H2 Produced (Tons/Year) | LCOH ($/kg) |

|---|---|---|---|---|---|---|

| Reversible case | Single flash-PEMEm | 362.05 | 117,651 | 32.68 | 731.44 | 5.51 |

| Dry steam-PEMEm | 362.05 | 117,651 | 32.68 | 3308.83 | 3.97 | |

| Single flash-HTE | 362.05 | 91,858 | 25.52 | 1426.66 | 4.56 | |

| Dry steam-HTE | 362.05 | 91,858 | 25.52 | 6453.78 | 3.31 | |

| Irreversible case | Single flash-PEMEm | 362.05 | 190,602 | 52.95 | 451.51 | 8.16 |

| Dry steam-PEMEm | 362.05 | 190,602 | 52.95 | 2042.49 | 5.80 | |

| Single flash-HTE | 362.05 | 97,721 | 27.14 | 1341.06 | 4.78 | |

| Dry steam-HTE | 362.05 | 97,721 | 27.14 | 6066.56 | 3.46 |

| Unit | Wind Turbine | Dry Steam * Power Plant | Single Flash * Power Plant | |

|---|---|---|---|---|

| Rated power | MW | 2.5 | 22.22 | 4.91 |

| Energy output | MWh/year | 18,606.6 | 175,186.6 | 38726.3 |

| Hydrogen produced | Tons/MW/year | 124.04 | 91.92 | 91.96 |

| CO2 avoided | Tons/MW/year | 2061.6 | 2183.9 | 2184.8 |

| Fuel oil saved | bbl/MW/year | 4540.02 | 4809.354 | 4811.216 |

| Energy cost | $/kWh | 0.042 | 0.086 | 0.125 |

| Hydrogen cost | $/kg | 0.672 | 5.80 | 8.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Osman Awaleh, M.; Adan, A.-B.; Assowe Dabar, O.; Jalludin, M.; Mahdi Ahmed, M.; Abdillahi Guirreh, I. Economic Feasibility of Green Hydrogen Production by Water Electrolysis Using Wind and Geothermal Energy Resources in Asal-Ghoubbet Rift (Republic of Djibouti): A Comparative Evaluation. Energies 2022, 15, 138. https://doi.org/10.3390/en15010138

Osman Awaleh M, Adan A-B, Assowe Dabar O, Jalludin M, Mahdi Ahmed M, Abdillahi Guirreh I. Economic Feasibility of Green Hydrogen Production by Water Electrolysis Using Wind and Geothermal Energy Resources in Asal-Ghoubbet Rift (Republic of Djibouti): A Comparative Evaluation. Energies. 2022; 15(1):138. https://doi.org/10.3390/en15010138

Chicago/Turabian StyleOsman Awaleh, Mohamed, Abdi-Basid Adan, Omar Assowe Dabar, Mohamed Jalludin, Moussa Mahdi Ahmed, and Ismael Abdillahi Guirreh. 2022. "Economic Feasibility of Green Hydrogen Production by Water Electrolysis Using Wind and Geothermal Energy Resources in Asal-Ghoubbet Rift (Republic of Djibouti): A Comparative Evaluation" Energies 15, no. 1: 138. https://doi.org/10.3390/en15010138

APA StyleOsman Awaleh, M., Adan, A.-B., Assowe Dabar, O., Jalludin, M., Mahdi Ahmed, M., & Abdillahi Guirreh, I. (2022). Economic Feasibility of Green Hydrogen Production by Water Electrolysis Using Wind and Geothermal Energy Resources in Asal-Ghoubbet Rift (Republic of Djibouti): A Comparative Evaluation. Energies, 15(1), 138. https://doi.org/10.3390/en15010138