LCA-Based Regional Distribution and Transference of Carbon Emissions from Wind Farms in China

Abstract

:1. Introduction

2. Methodology

2.1. Methodological Framework

2.2. IO-LCA

2.3. IO-LCA of Wind Farms in China

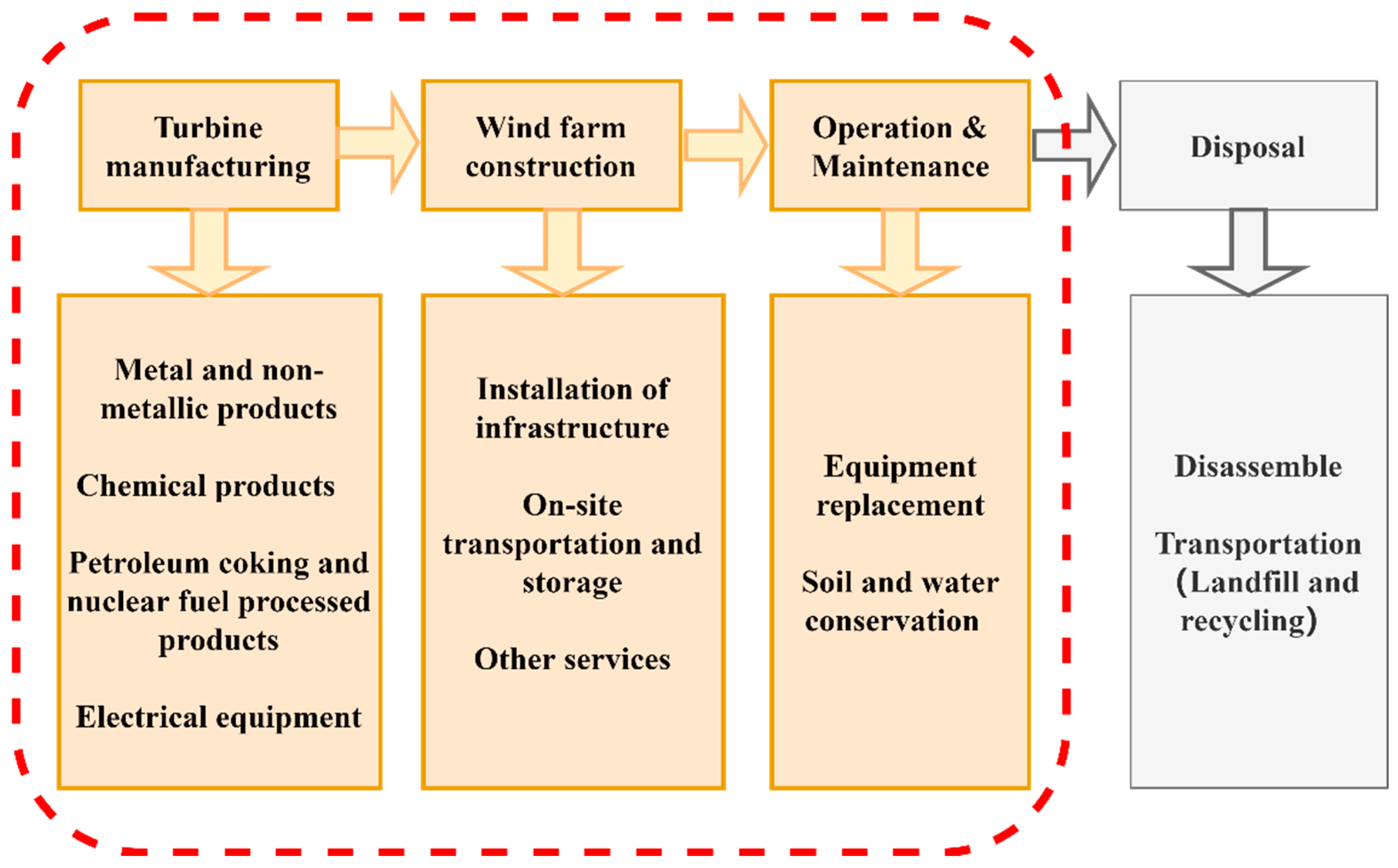

2.3.1. System Boundary

2.3.2. Preparation of the Material List

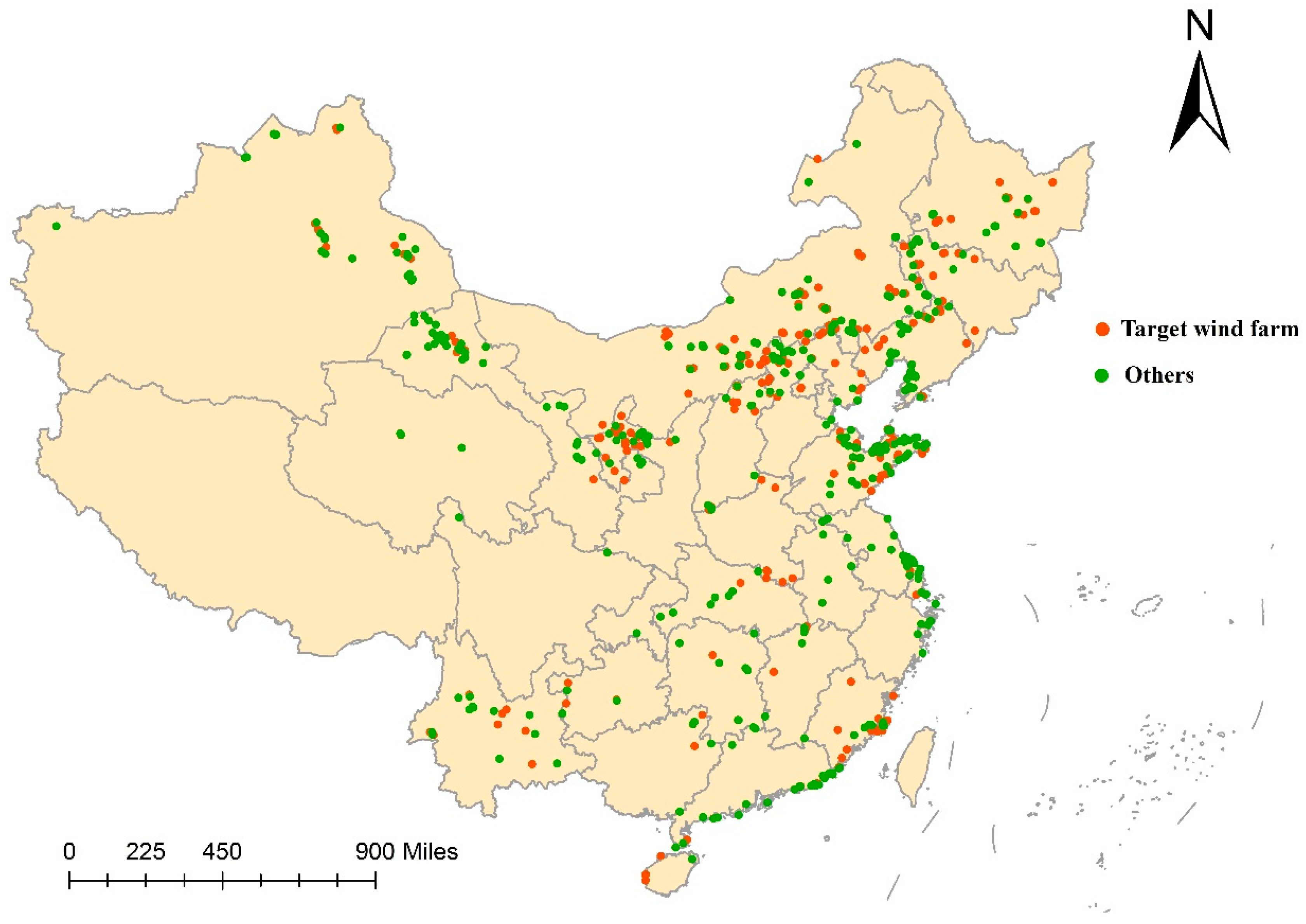

2.3.3. Data Sources

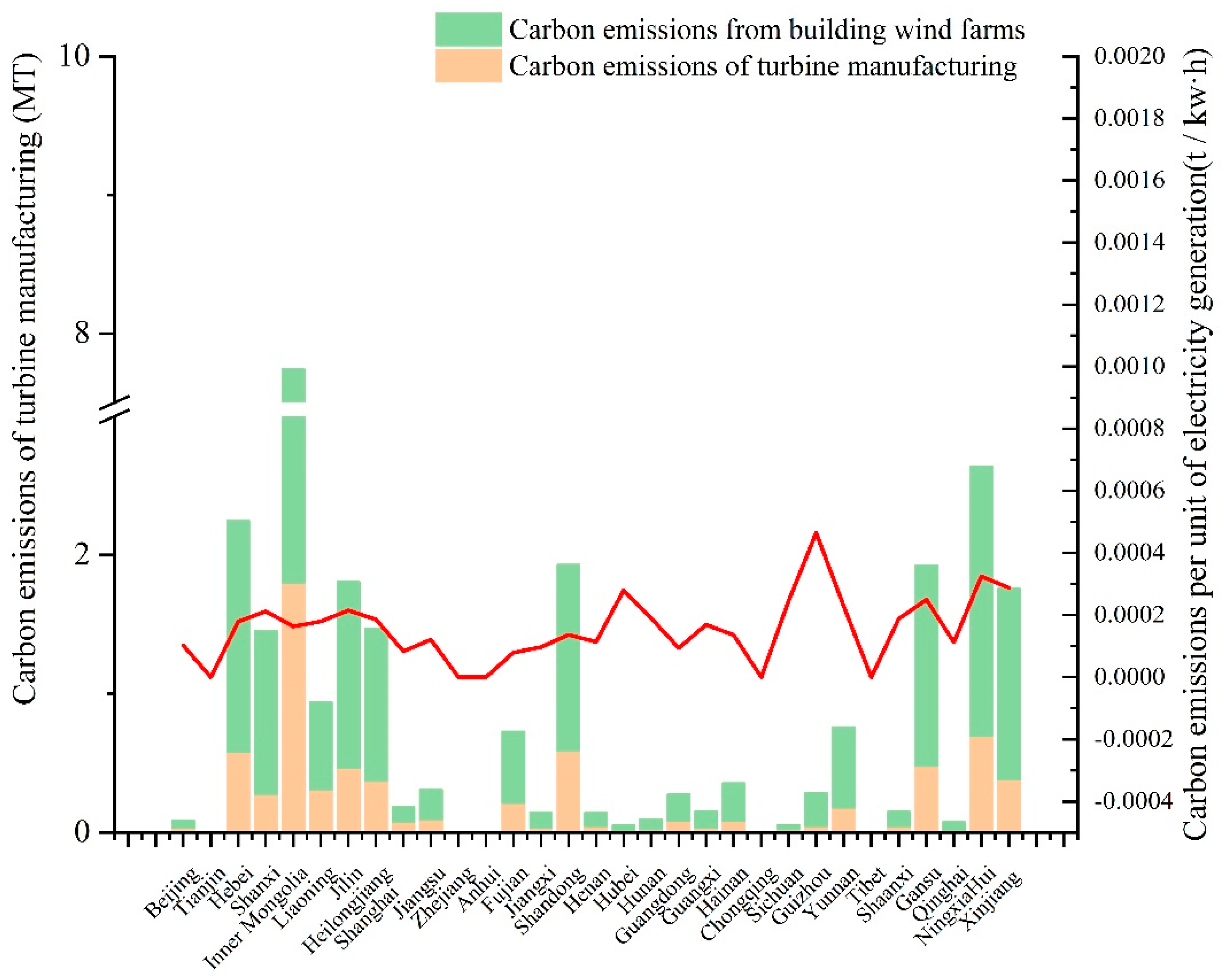

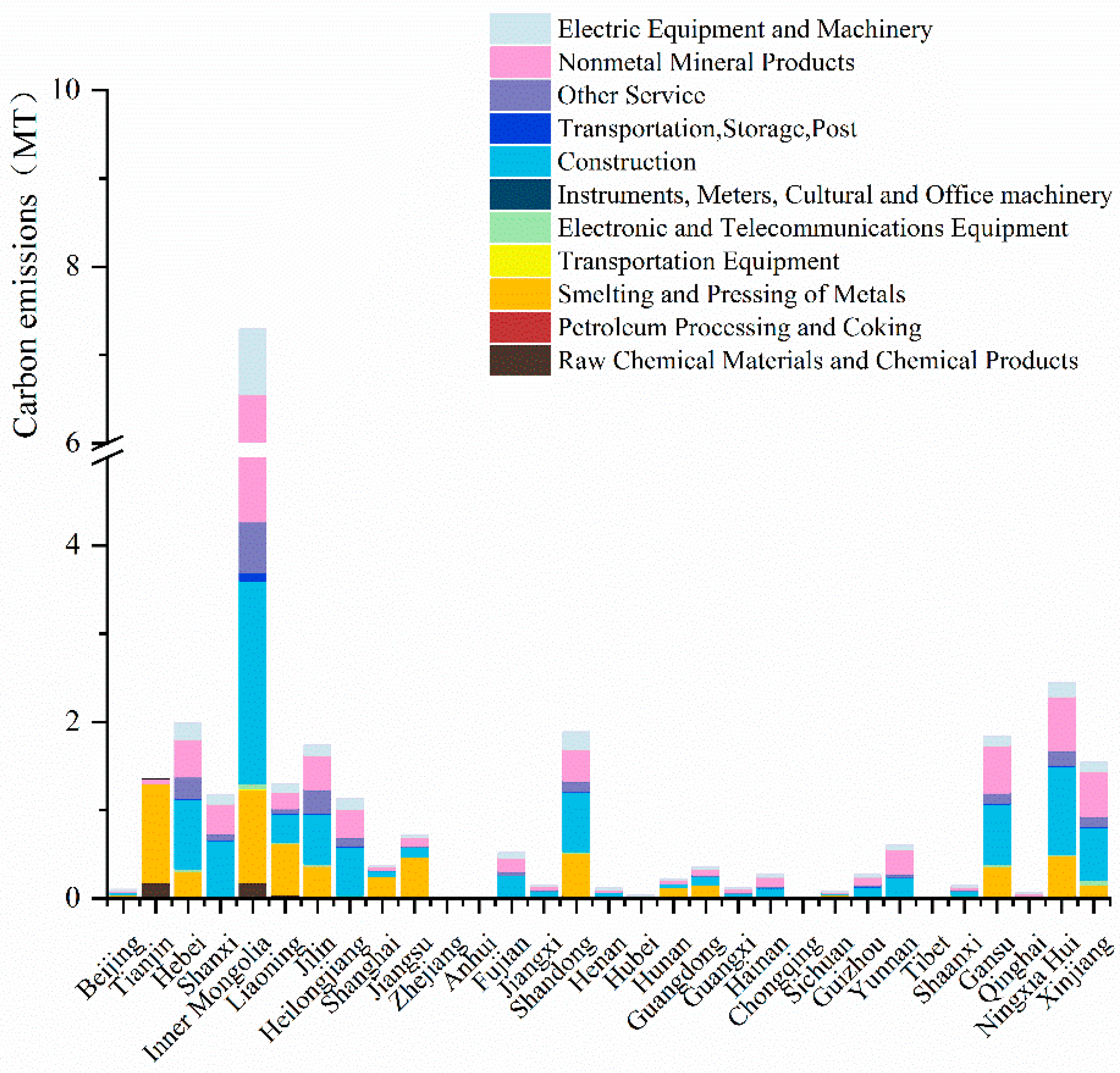

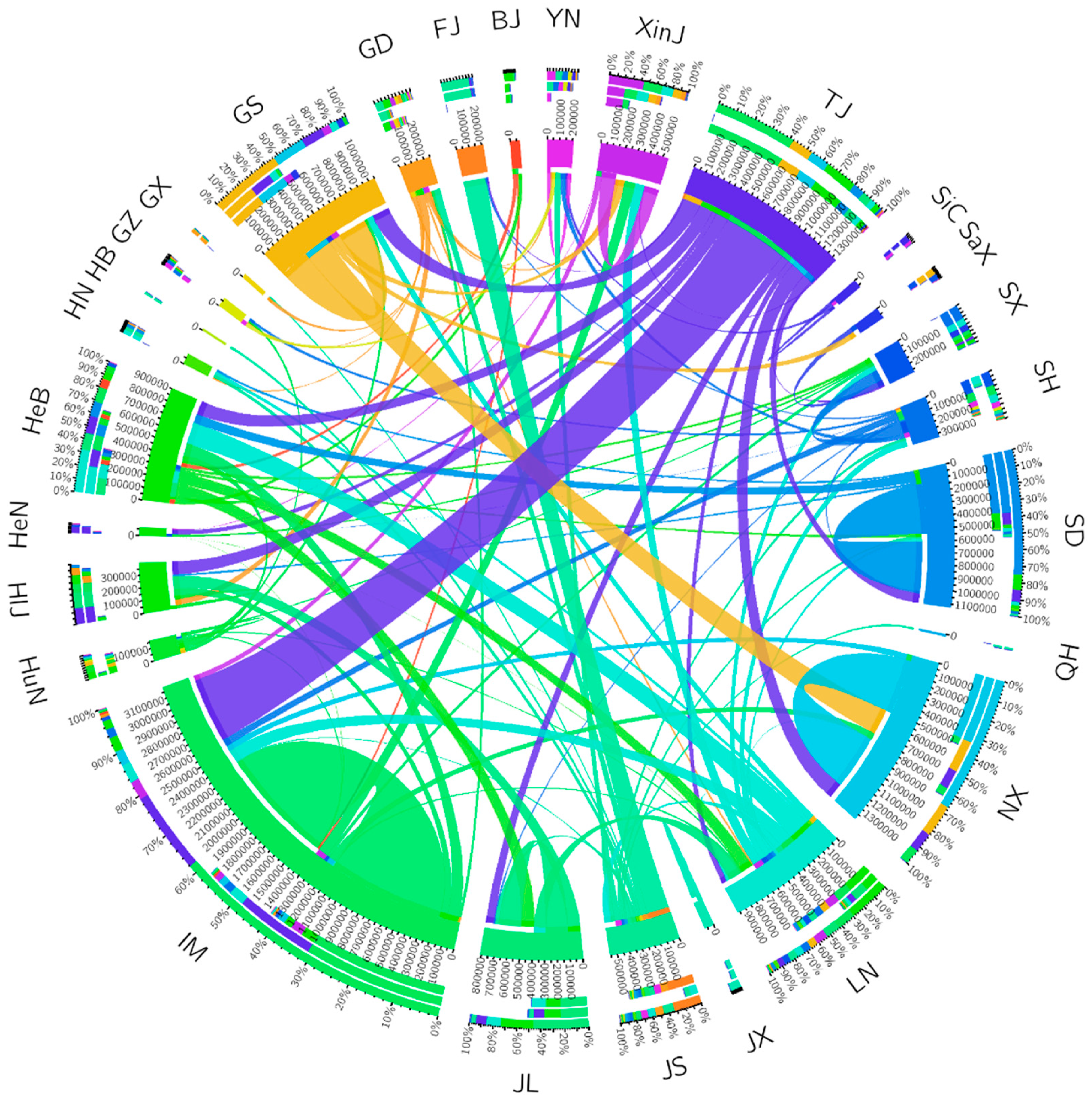

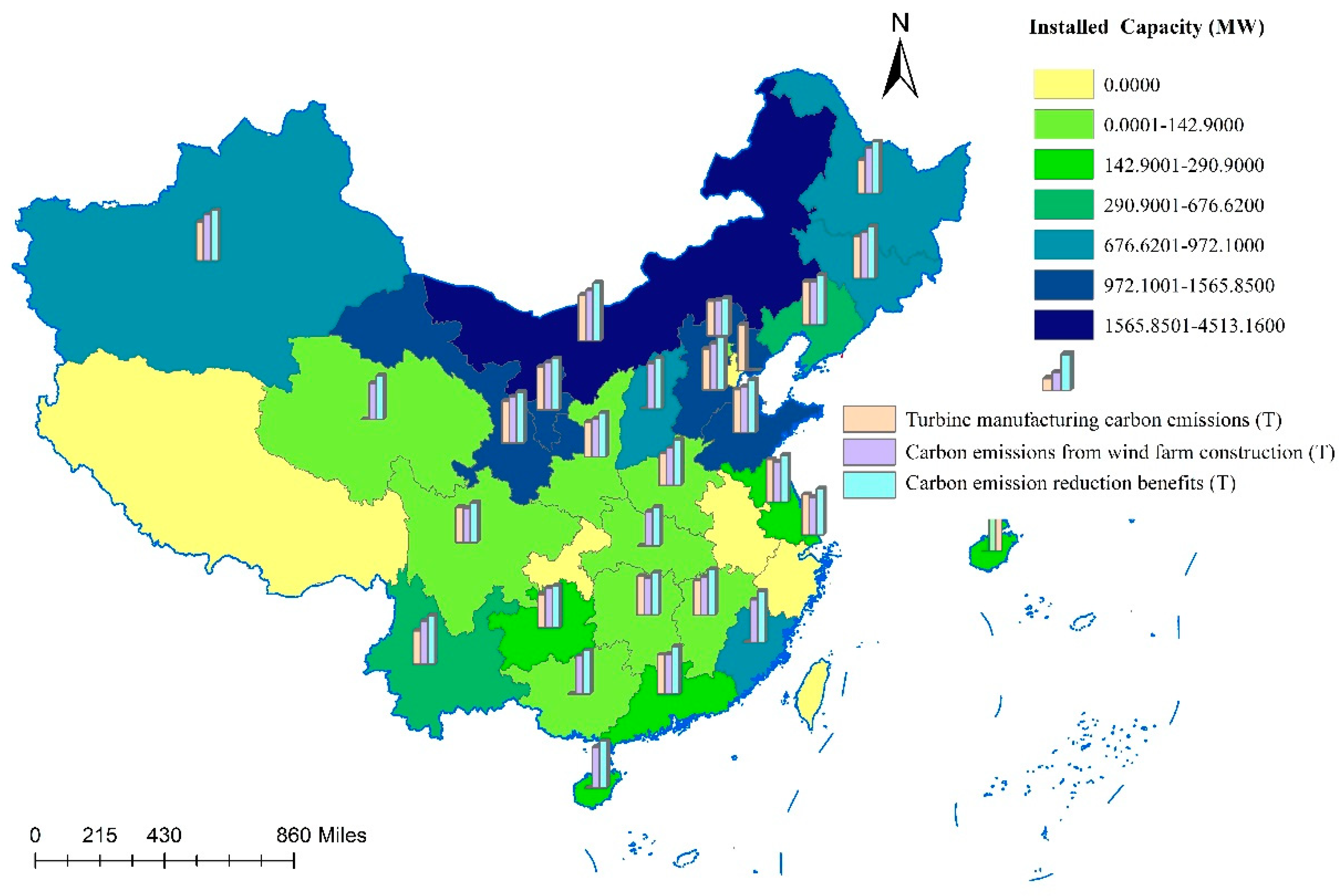

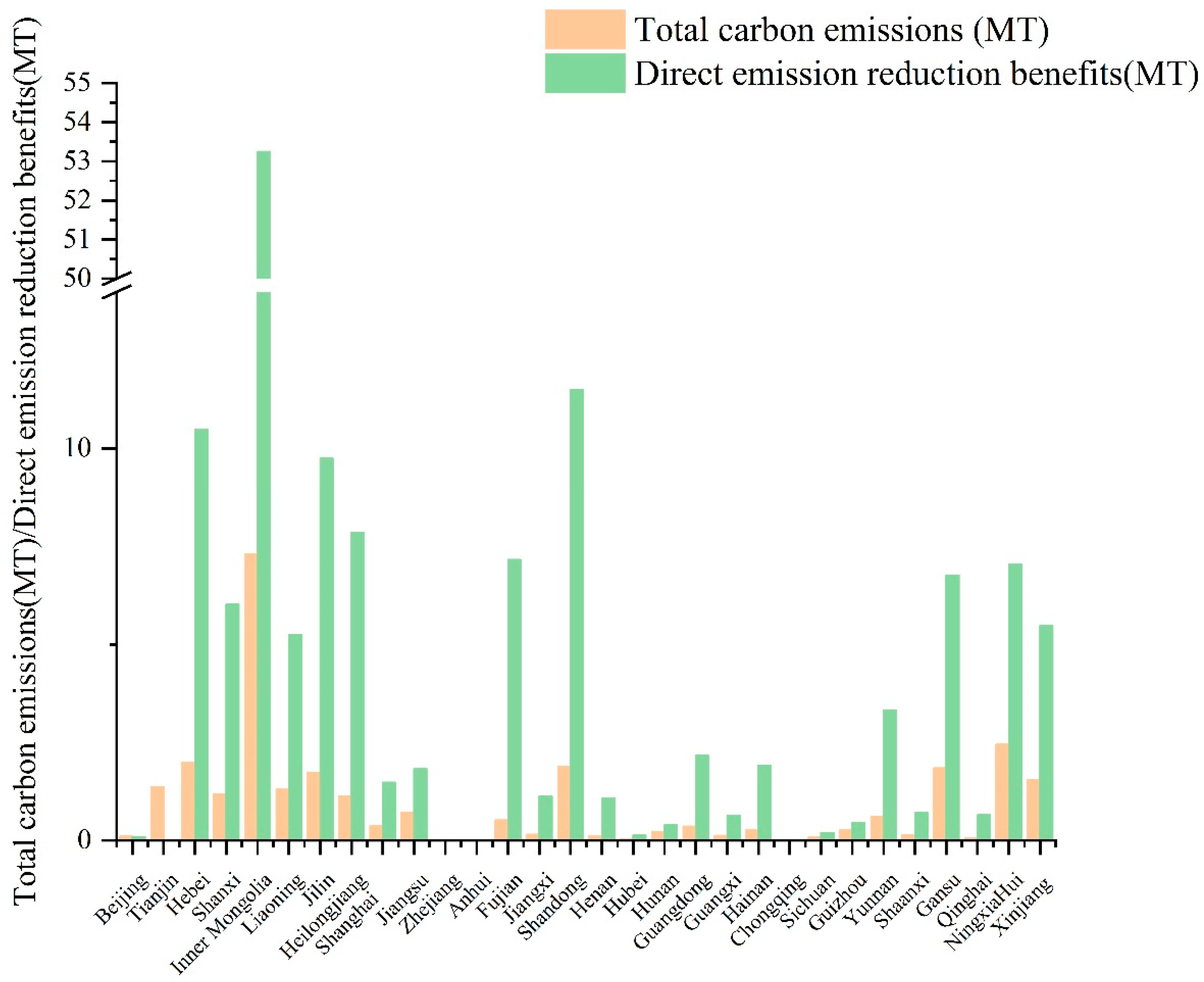

3. Results and Discussion

4. Uncertainty Analysis

5. Conclusions and Policy Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Future of Wind-Irena. Available online: https://irena.org/-/media/Files/IRENA/Agency/Publication/2019/Oct/IRENA_Future_of_wind_2019_summ_EN.PDF?la=en&hash=D07089441980EBABC7F4BED63B62C83820C18724 (accessed on 11 December 2021).

- Yang, J.; Chen, B. Integrated evaluation of embodied energy, greenhouse gas emission and economic performance of a typical wind farm in China. Renew. Sustain. Energy Rev. 2013, 27, 559–568. [Google Scholar] [CrossRef]

- Yang, D.; Liu, J.; Yang, J.; Ding, N. Carbon footprint of wind turbine by life cycle assessment. Acta Sci. Circumstantiae 2015, 35, 927–934. (In Chinese) [Google Scholar]

- Gomaa, M.R.; Rezk, H.; Mustafa, R.J.; Al-Dhaifallah, M. Evaluating the Environmental Impacts and Energy Performance of a Wind Farm System Utilizing the Life-Cycle Assessment Method: A Practical Case Study. Energies 2019, 12, 3263. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Jiang, H.; Dong, K.; Wei, Y.; Liao, H. A comparative analysis of the life cycle environmental emissions from wind and coal power: Evidence from China. J. Clean. Prod. 2020, 248, 119192. [Google Scholar] [CrossRef]

- Xu, L.; Pang, M.; Zhang, L.; Poganietz, W.R.; Marathe, S.D. Life cycle assessment of onshore wind power systems in China. Resour. Conserv.Recycl. 2018, 132, 361–368. [Google Scholar] [CrossRef]

- Al-Behadili, S.H.; El-Osta, W.B. Life Cycle Assessment of Dernah (Libya) wind farm. Renew. Energy 2015, 83, 1227–1233. [Google Scholar] [CrossRef]

- Alsaleh, A.; Sattler, M. Comprehensive life cycle assessment of large wind turbines in the US. Clean Technol. Environ. Policy 2019, 21, 887–903. [Google Scholar] [CrossRef]

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef] [Green Version]

- Pairotti, M.B.; Cerutti, A.K.; Martini, F.; Vesce, E.; Padovan, D.; Beltramo, R. Energy consumption and GHG emission of the Mediterranean diet: A systemic assessment using a hybrid LCA-IO method. J. Clean. Prod. 2015, 103, 507–516. [Google Scholar] [CrossRef]

- Henriques, C.O.; Coelho, D.H.; Cassidy, N.L. Employment impact assessment of renewable energy targets for electricity generation by 2020—An IO LCA approach. Sustain. Cities Soc. 2016, 26, 519–530. [Google Scholar] [CrossRef]

- Beylot, A.; Corrado, S.; Sala, S. Environmental impacts of European trade: Interpreting results of process-based LCA and environmentally extended input–output analysis towards hotspot identification. Int. J. Life Cycle Assess. 2020, 25, 2432–2450. [Google Scholar] [CrossRef] [Green Version]

- Feng, K.; Davis, S.J.; Sun, L.; Li, X.; Guan, D.; Liu, W.; Liu, Z.; Hubacek, K. Outsourcing CO2 within China. Proc. Natl. Acad. Sci. USA 2013, 110, 11654–11659. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, Z.; Long, R. Embodied Carbon in China’s Exports Based on the Rationality Index. Resour. Sci. 2013, 35, 1220–1228. (In Chinese) [Google Scholar]

- Wang, Z.; Yang, L. An Analysis of Household Indirect Energy Consumption in China based on Ecological Footprint. Sci. Res. Manag. 2014, 35, 128–135. (In Chinese) [Google Scholar]

- Wang, Z.; Liu, W.; Yin, J. Driving forces of indirect carbon emissions from household consumption in China: An input–output decomposition analysis. Nat. Hazards 2015, 75, 257–272. [Google Scholar] [CrossRef]

- Liu, Z.; Davis, S.J.; Feng, K.; Hubacek, K.; Liang, S.; Anadon, L.D.; Chen, B.; Liu, J.; Yan, J.; Guan, D. Targeted opportunities to address the climate–trade dilemma in China. Nat. Clim. Chang. 2016, 6, 201–206. [Google Scholar] [CrossRef]

- Tian, C.; Zhang, S. Source Decomposition Analysis of Carbon Footprint in China’s Industry Supply Chain: Based on IO-LCA Model. J. Environ. Econ. 2019, 4, 58–75. (In Chinese) [Google Scholar]

- Wang, W.; Cui, W.; Wang, Q. Environmental Impact Analysis Based on Product Life Cycle Assessment. J. Technol. 2020, 20, 176–180, 188. (In Chinese) [Google Scholar] [CrossRef]

- Li, Q.; Duan, H.; Xie, M.; Kang, P.; Ma, Y.; Zhong, R.; Gao, T.; Zhong, W.; Wen, B.; Bai, F.; et al. Life cycle assessment and life cycle cost analysis of a 40 MW wind farm with consideration of the infrastructure. Renew. Sustain. Energy Rev. 2021, 138, 110499. [Google Scholar] [CrossRef]

- Wang, C.; Malik, A.; Wang, Y.; Chang, Y.; Lenzen, M.; Zhou, D.; Pang, M.; Huang, Q. The social, economic, and environmental implications of biomass ethanol production in China: A multi-regional input-output-based hybrid LCA model. J. Clean. Prod. 2020, 249, 119326. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. USA 2015, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Feng, K.; Siu, Y.; Hubacek, K. Energy-water nexus of wind power in China: The balancing act between CO2 emissions and water consumption. Energy Policy 2012, 45, 440–448. [Google Scholar] [CrossRef]

- Nagashima, S.; Uchiyama, Y.; Okajima, K. Hybrid input–output table method for socioeconomic and environmental assessment of a wind power generation system. Appl. Energy 2017, 185, 1067–1075. [Google Scholar] [CrossRef] [Green Version]

- Xin, L.; Feng, K.; Siu, Y.; Hubacek, K. Challenges faced when energy meets water: CO2 and water implications of power generation in inner Mongolia of China. Renew. Sustain. Energy Rev. 2015, 45, 419–430. [Google Scholar] [CrossRef]

- Acquaye, A.A.; Wiedmann, T.; Feng, K.; Crawford, R.H.; Barrett, J.; Kuylenstierna, J.; Duffy, A.P.; Koh, S.C.L.; McQueen-Mason, S. Identification of ‘Carbon Hot-Spots’ and Quantification of GHG Intensities in the Biodiesel Supply Chain Using Hybrid LCA and Structural Path Analysis. Environ. Sci. Technol. 2011, 45, 2471–2478. [Google Scholar] [CrossRef] [Green Version]

- Suh, S.; Huppes, G. Methods for Life Cycle Inventory of a product. J. Clean. Prod. 2005, 13, 687–697. [Google Scholar] [CrossRef]

- Wiedmann, T.O.; Suh, S.; Feng, K.; Lenzen, M.; Acquaye, A.; Scott, K.; Barrett, J.R. Application of Hybrid Life Cycle Approaches to Emerging Energy Technologies—The Case of Wind Power in the UK. Environ. Sci. Technol. 2011, 45, 5900–5907. [Google Scholar] [CrossRef]

- Ewertowska, A.; Galán-Martín, A.; Guillén-Gosálbez, G.; Gavaldá, J.; Jiménez, L. Assessment of the environmental efficiency of the electricity mix of the top European economies via data envelopment analysis. J. Clean. Prod. 2016, 116, 13–22. [Google Scholar] [CrossRef]

- Ji, S.; Chen, B. Carbon footprint accounting of a typical wind farm in China. Appl. Energy 2016, 180, 416–423. [Google Scholar] [CrossRef]

- Joshi, S. Product Environmental Life-Cycle Assessment Using Input-Output Techniques. J. Ind. Ecol. 1999, 3, 95–120. [Google Scholar] [CrossRef]

- Chen, G.; Yang, Q.; Zhao, Y. Renewability of wind power in China: A case study of nonrenewable energy cost and greenhouse gas emission by a plant in Guangxi. Renew. Sustain. Energy Rev. 2011, 15, 2322–2329. [Google Scholar] [CrossRef]

- Crawford, R.H. Life cycle energy and greenhouse emissions analysis of wind turbines and the effect of size on energy yield. Renew. Sustain. Energy Rev. 2009, 13, 2653–2660. [Google Scholar] [CrossRef]

- Rashedi, A.; Sridhar, I.; Tseng, K.J. Life cycle assessment of 50 MW wind firms and strategies for impact reduction. Renew. Sustain. Energy Rev. 2013, 21, 89–101. [Google Scholar] [CrossRef]

- Ozoemena, M.; Hasan, R.; Cheung, W. Analysis of technology improvement opportunities for a 1.5 MW wind turbine using a hybrid stochastic approach in life cycle assessment. Renew. Energy 2016, 93, 369–382. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Bina, S.M.; Rahmani, K. Life Cycle Energy and Greenhouse Gas Emission Assessment of a Wind Turbine Installed in Northeast of Iran. Int. J. Energy Policy Manag. 2018, 3, 8–15. [Google Scholar]

- Jensen, J.P. Evaluating the environmental impacts of recycling wind turbines. Wind. Energy 2019, 22, 316–326. [Google Scholar] [CrossRef]

- Pan, C.; Peters, G.P.; Andrew, R.M.; Korsbakken, J.I.; Li, S.; Zhou, P.; Zhou, D. Structural Changes in Provincial Emission Transfers within China. Environ. Sci. Technol. 2018, 52, 12958–12967. [Google Scholar] [CrossRef]

- Gao, C.; Dong, J.; Zhu, W.; Wang, W. Environmental load analysis of wind turbines based on life cycle assessment. J. Northeast. Univ. 2012, 33, 1034–1037. [Google Scholar]

- Yang, Q.; Chen, G.; Zhao, Y.; Chen, B.; Li, Z.; Zhang, B.; Chen, Z.; Chen, H. Energy cost and greenhouse gas emissions of a Chinese wind farm. Procedia Environ. Sci. 2011, 5, 25–28. [Google Scholar] [CrossRef] [Green Version]

| Stages | Inputs | 0.66 MW | 0.85 MW | 1.25 MW | 1.5 MW | 2 MW | 3 MW | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Turbine Manufacturing | Materials (t) | Turbine | Material | Mass (t) | Material | Mass (t) | Material | Mass (t) | Material | Mass (t) | Material | Mass (t) | Material | Mass (t) |

| Steel | 66.43 | Steel | 90.86 | Steel | 101 | Steel | 193.31 | Steel | 237.21 | Steel | 222.34 | |||

| Polyethene | 11.38 | R-F | 20.07 | Iron | 17.1 | Cast iron | 21.03 | Cast iron | 23.64 | R-F | 5.02 | |||

| Al | 8.37 | Iron | 19.20 | Cast iron | 11.4 | Copper | 15.4 | Fiberglass | 11.24 | Iron | 4.80 | |||

| Cast iron | 6.00 | Copper | 1.05 | R-F | 6.60 | Concrete | 12.00 | Casting | 9.49 | Copper | 3.99 | |||

| Polybutadiene | 5.14 | Paint | 0.93 | Fiberglass | 4.40 | Fiberglass | 7.48 | Concrete | 7.20 | Al | 2.31 | |||

| GRP | 4.95 | Al | 0.60 | Copper | 3.80 | Paint | 5.29 | Al | 4.07 | Paint | 1.24 | |||

| Copper | 3.76 | PVC | 0.18 | Silica | 0.40 | Epoxy resin | 4.55 | Polymer | 3.83 | PVC | 0.70 | |||

| Painting | 0.39 | Polyester resin | 2.16 | Carbon fiber | 2.76 | |||||||||

| Polypropylene | 0.12 | Iron | 1.55 | GRP | 1.89 | |||||||||

| Lubricant | 0.11 | Electronics | 2.47 | Copper | 1.55 | |||||||||

| PVC | 0.07 | PVC | 1.99 | Adhesive | 1.36 | |||||||||

| Bronze | 0.01 | Gear oil | 0.94 | Lubricant | 1.28 | |||||||||

| Polyethene | 0.69 | Wires | 1.28 | |||||||||||

| Al | 0.23 | Panting | 0.65 | |||||||||||

| Polyamide | 0.23 | Paint | 0.63 | |||||||||||

| Others | 3.85 | China | 0.01 | |||||||||||

| Brass | 0.04 | |||||||||||||

| Construction | Foundation | Concrete | 4097.28 | Concrete | 480 | Concrete | 365 | Concrete | 575 | Concrete | 1116 | Concrete | 1140 | |

| Steel | 122.53 | Steel | 15 | Steel | 43.5 | Steel | 39.54 | Steel | 58.53 | Steel | 36 | |||

| Amount (Ten thousand yuan) | Electric equipment | 39.01 | 50.24 | 73.89 | 88.67 | 118.22 | 177.33 | |||||||

| Transport and storage | 4.09 | 5.26 | 7.74 | 9.29 | 12.38 | 18.57 | ||||||||

| Metering equipment | 0.17 | 0.21 | 0.32 | 0.38 | 0.51 | 0.76 | ||||||||

| Traffic equipment | 0.93 | 1.20 | 1.77 | 2.12 | 2.83 | 4.24 | ||||||||

| Other manufacturing | 123.01 | 158.40 | 232.98 | 279.58 | 372.77 | 559.16 | ||||||||

| Technical Services | 48.91 | 62.99 | 92.64 | 111.16 | 148.22 | 222.33 | ||||||||

| Operation | Equipment replacement | 1.13 | 1.46 | 2.14 | 2.57 | 3.43 | 5.14 | |||||||

| Soil and water conservation | 5.11 | 6.58 | 9.68 | 11.62 | 15.49 | 23.24 | ||||||||

| Sector Code | MRIO Sectors | Sector Code | Sector of National Economy Industry Classification |

|---|---|---|---|

| 14 | Smelting and Pressing of Metals | 31, 32 | Nonferrous metals, ferrous metals, rare metal smelting and calendering processing, alloy manufacturing |

| 12 | Raw Chemical Materials and Chemical Products | 26 | Chemical raw materials and chemical products manufacturing |

| 11 | Petroleum Processing and Coking | 25 | Crude oil and oil products manufacturing, synthetic crude oil production, processing of nuclear fuel |

| 17 | Transportation Equipment | 36 | Automobile manufacturing and spare parts manufacturing |

| 19 | Electronic and Telecommunications Equipment | 39 | Communication transmission equipment, electronic computers, electronic components manufacturing |

| 20 | Instruments, Meters, Cultural and Office machinery | 40 | Manufacturing of industrial automatic control system, electrical instruments and meters, environmental testing equipment, etc. |

| 24 | Construction | 49, 59 | Building engineering, construction services, building installation and decoration |

| 25 | Transportation, Storage, Post | 54, 59 | Road cargo transport, cargo storage, loading, unloading, handling, and other transport services |

| 30 | Other Service | 74, 76, 77, 78 | Scientific research and technology services, water conservancy, environment, and public facilities management |

| 13 | Nonmetal Mineral Products | 30 | Cement, stone, brick and tile, and glass and glass fiber products |

| 18 | Electric Equipment and Machinery | 38 | Manufacturing of electrical machinery, wire, cable and other power stations, electrical machinery, and equipment production equipment |

| Province | Iron and Steel | Copper | Aluminum | Glass Fiber | Resin |

|---|---|---|---|---|---|

| Anhui | 33 | 9 | 63 | 29 | 37 |

| Beijing | 3 | 0 | 0 | 3 | 1 |

| Fujian | 40 | 2 | 42 | 19 | 10 |

| Gansu | 10 | 2 | 66 | 3 | 0 |

| Guangdong | 77 | 8 | 241 | 40 | 69 |

| Guangxi | 10 | 5 | 77 | 4 | 1 |

| Guizhou | 6 | 1 | 91 | 0 | 1 |

| Hainan | 4 | 0 | 7 | 0 | 0 |

| Hebei | 114 | 3 | 125 | 26 | 9 |

| Henan | 51 | 8 | 135 | 18 | 5 |

| Heilongjiang | 10 | 0 | 21 | 3 | 0 |

| Hubei | 46 | 1 | 57 | 11 | 12 |

| Hunan | 30 | 14 | 140 | 8 | 18 |

| Jilin | 15 | 0 | 27 | 7 | 1 |

| Jiangsu | 118 | 6 | 328 | 95 | 50 |

| Jiangxi | 19 | 26 | 60 | 14 | 8 |

| Liaoning | 58 | 6 | 122 | 19 | 8 |

| Inner Mongolia | 12 | 7 | 44 | 6 | 1 |

| Ningxia | 6 | 2 | 5 | 0 | 1 |

| Shandong | 89 | 6 | 83 | 72 | 46 |

| Shanxi | 21 | 1 | 80 | 4 | 0 |

| Shaanxi | 24 | 2 | 69 | 4 | 7 |

| Shanghai | 10 | 1 | 52 | 7 | 10 |

| Sichuan | 17 | 10 | 83 | 16 | 11 |

| Tianjin | 77 | 1 | 62 | 5 | 14 |

| Xinjiang | 19 | 3 | 31 | 9 | 0 |

| Yunnan | 7 | 11 | 66 | 0 | 2 |

| Zhejiang | 25 | 6 | 80 | 42 | 28 |

| Chongqing | 10 | 2 | 45 | 7 | 5 |

| Manufacturing (%) | Construction & Operation (%) | Wind Turbine | Reference |

|---|---|---|---|

| * | 76.74% | 2 MW | [30] |

| 25.10% | 72.3% | * | [32] |

| 30.01% | 66.90% | 850 KW | [39] |

| 30% | 70% | 1.5 MW | [40] |

| 46.87% | 36.64% | 1.5 MW | [2] |

| 25.15% | 74.85% | Six types of turbines | In this study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, X.; Yang, J.; Yang, S. LCA-Based Regional Distribution and Transference of Carbon Emissions from Wind Farms in China. Energies 2022, 15, 198. https://doi.org/10.3390/en15010198

Bi X, Yang J, Yang S. LCA-Based Regional Distribution and Transference of Carbon Emissions from Wind Farms in China. Energies. 2022; 15(1):198. https://doi.org/10.3390/en15010198

Chicago/Turabian StyleBi, Xintian, Jin Yang, and Siyuan Yang. 2022. "LCA-Based Regional Distribution and Transference of Carbon Emissions from Wind Farms in China" Energies 15, no. 1: 198. https://doi.org/10.3390/en15010198

APA StyleBi, X., Yang, J., & Yang, S. (2022). LCA-Based Regional Distribution and Transference of Carbon Emissions from Wind Farms in China. Energies, 15(1), 198. https://doi.org/10.3390/en15010198