A Fuzzy Multi-Criteria Model for Municipal Waste Treatment Systems Evaluation including Energy Recovery

Abstract

:1. Introduction

1.1. Literature Review

1.2. The Research Aim

- -

- We have defined the assessment parameters for waste sorting system efficiency, which are essential for waste sorting processes performance.

- -

- We have introduced a two-step assessment method to assess the waste sorting system efficiency based on fuzzy theory use.

- -

- We have implemented the proposed method to verify its diagnostic function and determine its labour intensity.

- -

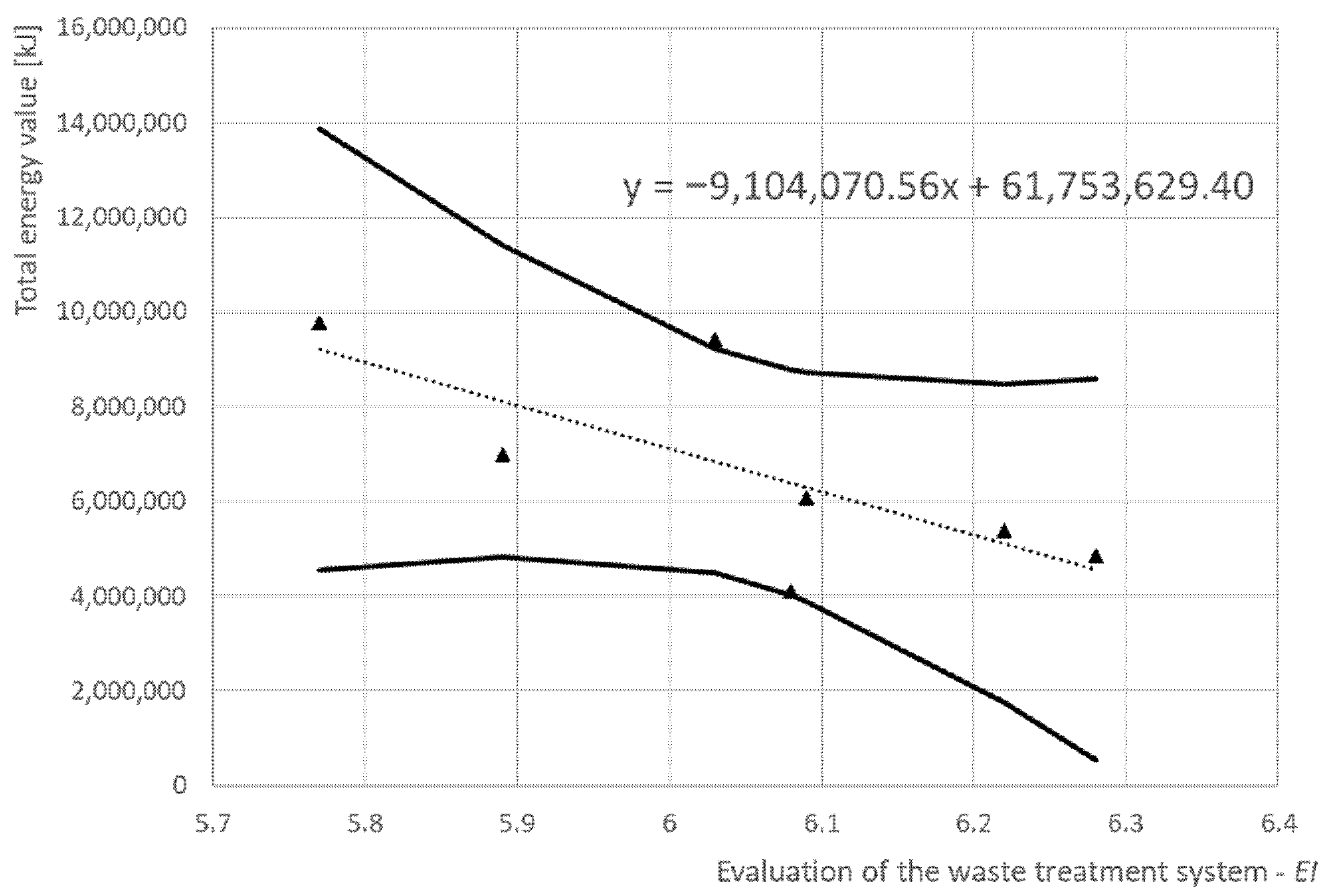

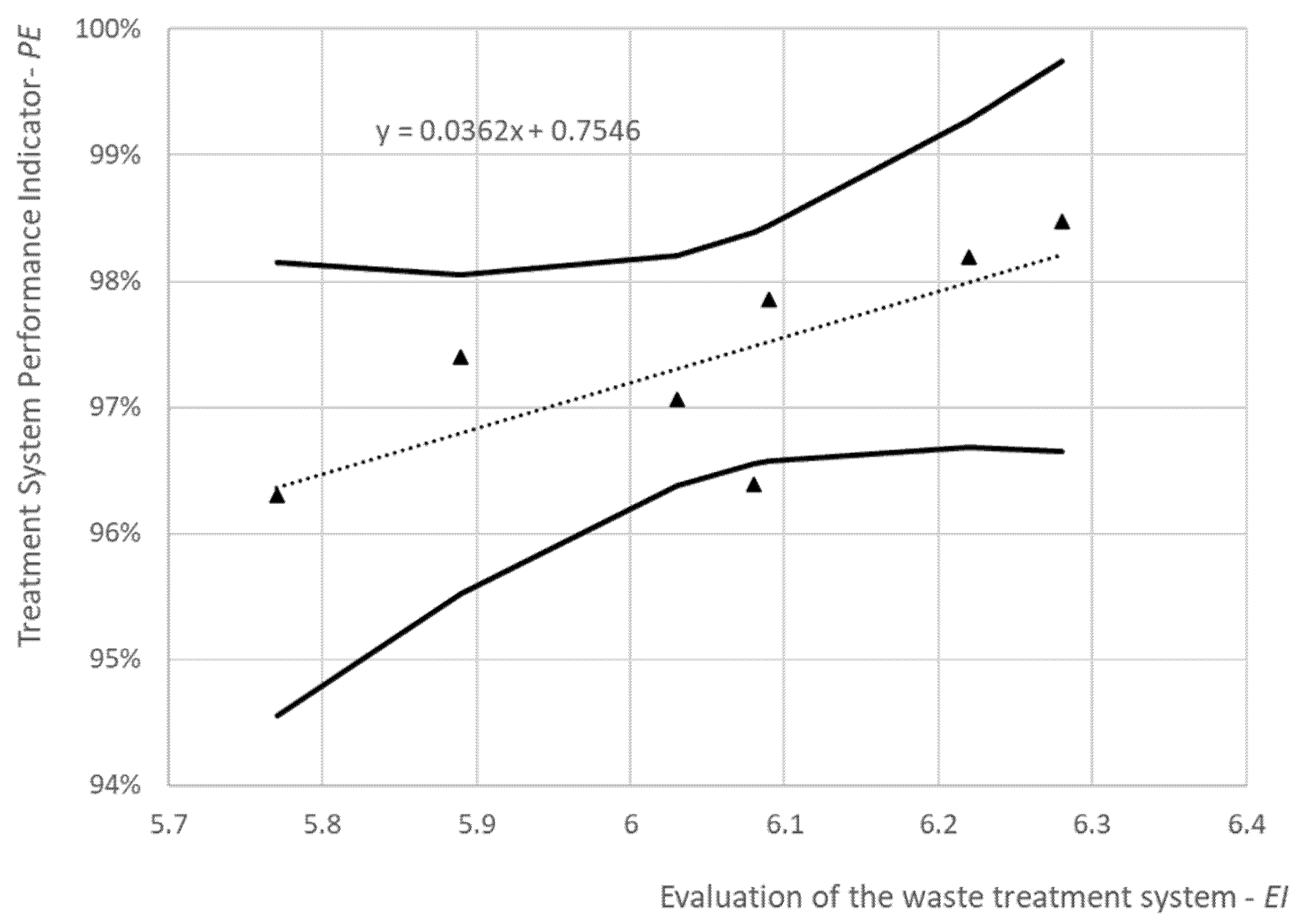

- We have analysed the impact of the system evaluation on RDF energy quality and sorting efficiency.

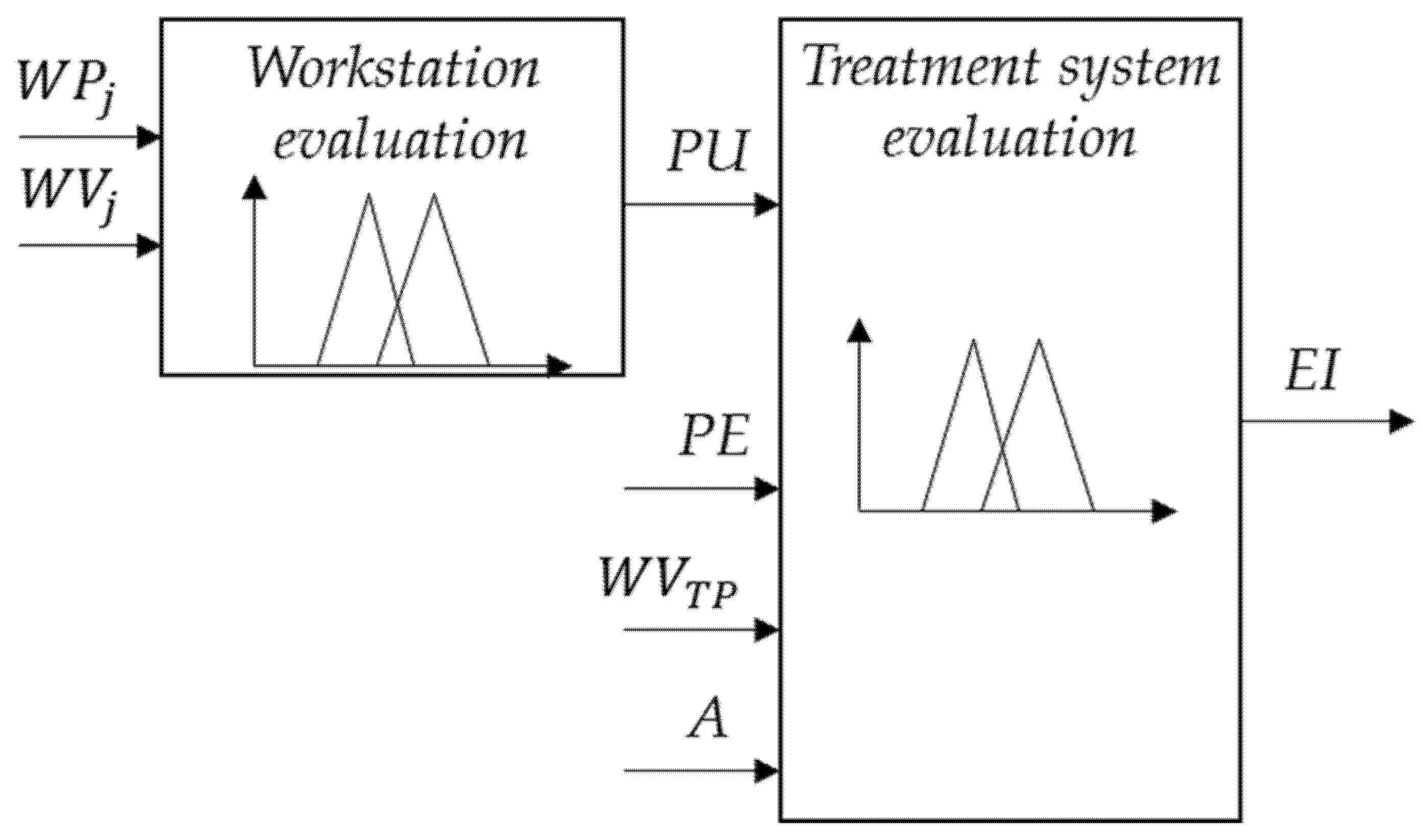

2. A Fuzzy Multi-Criteria Model for Evaluating Municipal Waste Treatment Systems

- -

- The utilisation rate of sorting points (PU).

- -

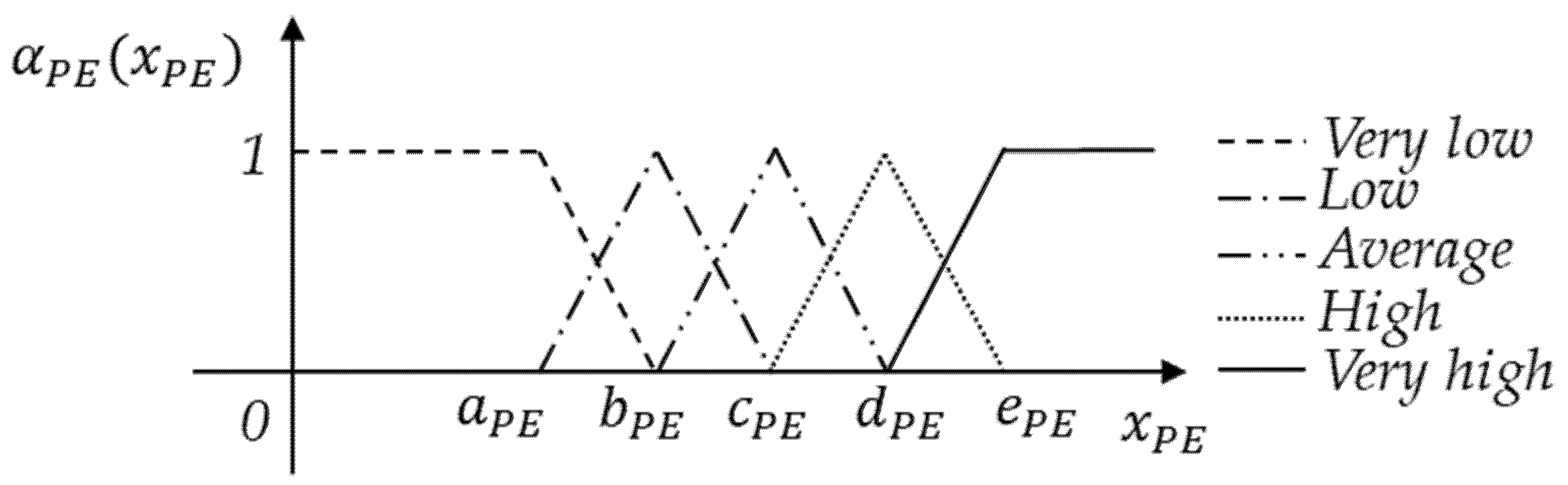

- Treatment System Performance Indicator (PE).

- -

- Indicator of irregularity of workstation stream in the waste treatment system ().

- -

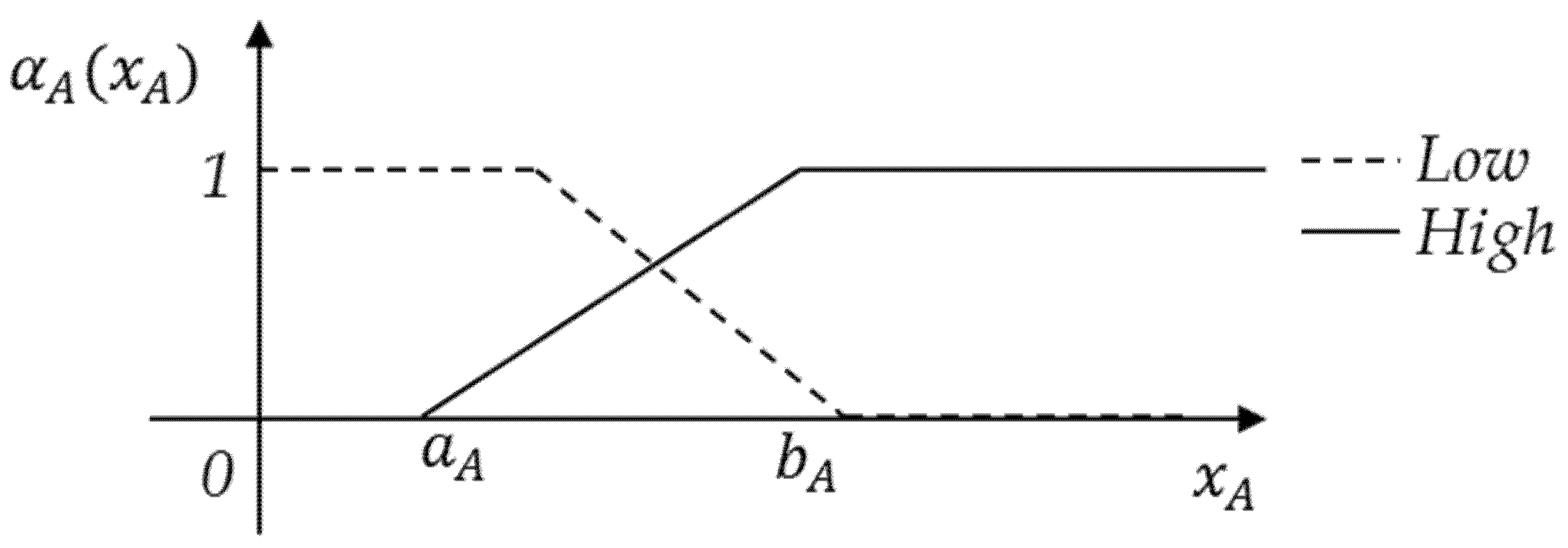

- Waste Treatment System availability Indicator (A).

3. Model Application—Case Study

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Unnisa, S.A.; Bhupatthi Rav, S. Sustainable Solid Waste Management; Apple Academic Press: Waretown, NJ, USA, 2012; ISBN 9781466559363. [Google Scholar] [CrossRef]

- Abis, M.; Bruno, M.; Kuchta, K.; Simon, F.G.; Grönholm, R.; Hoppe, M.; Fiore, S. Assessment of the synergy between recycling and thermal treatments in municipal solid waste management in europe. Energies 2020, 13, 6412. [Google Scholar] [CrossRef]

- Pomázi, I.; Szabó, E. Circular economy policy-related national initiatives in Visegrad countries. Eur. Spat. Res. Policy 2020, 27, 131–154. [Google Scholar] [CrossRef]

- Bonciu, F. The European economy: From a linear to a circular economy. Rom. J. Eur. Aff. 2014, 14, 78–91. [Google Scholar]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.H.; Ometto, A.R. From Linear to Circular Economy: PSS Conducting the Transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Spengler, T.; Geldermann, J.; Hähre, S.; Sieverdingbeck, A.; Rentz, O. Development of a multiple criteria based decision support system for environmental assessment of recycling measures in the iron and steel making industry. J. Clean. Prod. 1998, 6, 37–52. [Google Scholar] [CrossRef]

- Beyene, H.D.; Werkneh, A.A.; Ambaye, T.G. Current updates on waste to energy (WtE) technologies: A review. Renew. Energy Focus 2018, 24, 1–11. [Google Scholar] [CrossRef]

- Mukherjee, C.; Denney, J.; Mbonimpa, E.G.; Slagley, J.; Bhowmik, R. A review on municipal solid waste-to-energy trends in the USA. Renew. Sustain. Energy Rev. 2020, 119, 109512. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef] [PubMed]

- Cimpan, C.; Maul, A.; Jansen, M.; Pretz, T.; Wenzel, H. Central sorting and recovery of MSW recyclable materials: A review of technological state-of-the-art, cases, practice and implications for materials recycling. J. Environ. Manag. 2015, 156, 181–199. [Google Scholar] [CrossRef]

- Intharathirat, R.; Salam, P. Uncertainty of Forecasting of Municipal Solid Waste Generation and Composition: A Case Study of Thailand. EurAsia Waste Manag. Symp. 2014. Available online: https://www.researchgate.net/publication/263656234 (accessed on 21 December 2021).

- Ip, K.; Testa, M.; Raymond, A.; Graves, S.C.; Gutowski, T. Performance evaluation of material separation in a material recovery facility using a network flow model. Resour. Conserv. Recycl. 2018, 131, 192–205. [Google Scholar] [CrossRef] [Green Version]

- Bisinella, V.; Götze, R.; Conradsen, K.; Damgaard, A.; Christensen, T.H.; Astrup, T.F. Importance of waste composition for Life Cycle Assessment of waste management solutions. J. Clean. Prod. 2017, 164, 1180–1191. [Google Scholar] [CrossRef] [Green Version]

- Di Lonardo, M.C.; Lombardi, F.; Gavasci, R. Characterization of MBT plants input and outputs: A review. Rev. Environ. Sci. Biotechnol. 2012, 11, 353–363. [Google Scholar] [CrossRef]

- Bilitewski, B.; Oros, C.; Christensen, T.H. Mechanical Biological Treatment. In Solid Waste Technology & Management; Wiley: Hoboken, NJ, USA, 2010; Volume 2, pp. 628–638. ISBN 9781405175173. [Google Scholar]

- Montejo, C.; Tonini, D.; Márquez, M.d.C.; Fruergaard Astrup, T. Mechanical-biological treatment: Performance and potentials. An LCA of 8 MBT plants including waste characterization. J. Environ. Manag. 2013, 128, 661–673. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mastellone, M.L.; Cremiato, R.; Zaccariello, L.; Lotito, R. Evaluation of performance indicators applied to a material recovery facility fed by mixed packaging waste. Waste Manag. 2017, 64, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Galán, B.; Viguri, J.R.; Cifrian, E.; Dosal, E.; Andres, A. Influence of input streams on the construction and demolition waste (CDW) recycling performance of basic and advanced treatment plants. J. Clean. Prod. 2019, 236. [Google Scholar] [CrossRef]

- Wolf, M.I.; Colledani, M.; Gershwin, S.B.; Gutowski, T.G. A network flow model for the performance evaluation and design of material separation systems for recycling. IEEE Trans. Autom. Sci. Eng. 2013, 10, 65–75. [Google Scholar] [CrossRef]

- Gadaleta, G.; De Gisi, S.; Binetti, S.M.C.; Notarnicola, M. Outlining a comprehensive techno-economic approach to evaluate the performance of an advanced sorting plant for plastic waste recovery. Process Saf. Environ. Prot. 2020, 143, 248–261. [Google Scholar] [CrossRef]

- Huber, F. Modelling of material recovery from waste incineration bottom ash. Waste Manag. 2020, 105, 61–72. [Google Scholar] [CrossRef]

- Allegrini, E.; Vadenbo, C.; Boldrin, A.; Astrup, T.F. Life cycle assessment of resource recovery from municipal solid waste incineration bottom ash. J. Environ. Manag. 2015, 151, 132–143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wilts, H.; Garcia, B.R.; Garlito, R.G.; Gómez, L.S.; Prieto, E.G. Artificial intelligence in the sorting of municipalwaste as an enabler of the circular economy. Resources 2021, 10, 28. [Google Scholar] [CrossRef]

- Kang, H.Y.; Schoenung, J.M. Economic analysis of electronic waste recycling: Modeling the cost and revenue of a materials recovery facility in California. Environ. Sci. Technol. 2006, 40, 1672–1680. [Google Scholar] [CrossRef]

- Feil, A.; Thoden van Velzen, E.U.; Jansen, M.; Vitz, P.; Go, N.; Pretz, T. Technical assessment of processing plants as exemplified by the sorting of beverage cartons from lightweight packaging wastes. Waste Manag. 2016, 48, 95–105. [Google Scholar] [CrossRef]

- Feil, A.; Pretz, T.; Vitz, P.; Thoden Van Velzen, E.U. A methodical approach for the assessment of waste sorting plants. Waste Manag. Res. 2017, 35, 147–154. [Google Scholar] [CrossRef]

- Tanguay-Rioux, F.; Legros, R.; Spreutels, L. On the limits of empirical partition coefficients for modeling material recovery facility unit operations in municipal solid waste management. J. Clean. Prod. 2021, 293, 126016. [Google Scholar] [CrossRef]

- Połomka, J.; Jędrczak, A. RDF from compost-like-output’s produced in the MBT installation in the case of Marszów, Poland. Energies 2020, 13, 4353. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Albino, D.; Branham, M. Bayesian material separation model with applications to recycling. IEEE Int. Symp. Electron. Environ. 2007, 233–238. [Google Scholar] [CrossRef]

- Goulart Coelho, L.M.; Lange, L.C.; Coelho, H.M.G. Multi-criteria decision making to support waste management: A critical review of current practices and methods. Waste Manag. Res. 2017, 35, 3–28. [Google Scholar] [CrossRef] [PubMed]

- Rezaei, J. A systematic review of multi-criteria decision-making applications in reverse logistics. Transp. Res. Procedia 2015, 10, 766–776. [Google Scholar] [CrossRef] [Green Version]

- Ardolino, F.; Berto, C.; Arena, U. Environmental performances of different configurations of a material recovery facility in a life cycle perspective. Waste Manag. 2017, 68, 662–676. [Google Scholar] [CrossRef]

- Wang, Z.; Lv, J.; Gu, F.; Yang, J.; Guo, J. Environmental and economic performance of an integrated municipal solid waste treatment: A Chinese case study. Sci. Total Environ. 2020, 709. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R.C. A review of multi criteria decision making (MCDM) towards sustainable renewable energy development. Renew. Sustain. Energy Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Gramatikov, P.; Kovachev, V.; Gramatikova, M. Landfill gas from solid urban waste—An opportunity evaluation. Int. Symp. “Energetics 2004” Symp. Proc. B 2004, 2, 514. [Google Scholar]

- Islam, K.M.N.; Jashimuddin, M. Reliability and economic analysis of moving towards wastes to energy recovery based waste less sustainable society in Bangladesh: The case of commercial capital city Chittagong. Sustain. Cities Soc. 2017, 29, 118–129. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Khan, M.; Nasser, M.S.; Al-Saad, K.; Heng, O.E. Recent advances and applications of municipal solid wastes bottom and fly ashes: Insights into sustainable management and conservation of resources. Environ. Technol. Innov. 2021, 21, 101267. [Google Scholar] [CrossRef]

- Uusipaikka, E. Confidence Intervals in Generalized Regression Models; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

| Recycling Indicator | CO2 Emission | Recovery | Grade | Efficiency | Workability | Productivity Indicator | Yield indicator | Purity indicator | Compliance Indicator | Economic | Operation Experience | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [18] | + | + | + | |||||||||

| [17] | + | + | + | + | + | + | ||||||

| [19] | + | + | ||||||||||

| [12] | + | + | + | + | ||||||||

| [20] | + | + | + | |||||||||

| [21] | +1 | |||||||||||

| [22] | +1 | |||||||||||

| [23] | + | + | ||||||||||

| [24] | + | |||||||||||

| [6] | +1 | + | + | |||||||||

| [25] | + | + | + | |||||||||

| [26] | + | + | + | |||||||||

| [27] | + | + | ||||||||||

| Total | 1 | 1 | 12 | 2 | 1 | 1 | 1 | 3 | 6 | 1 | 4 | 1 |

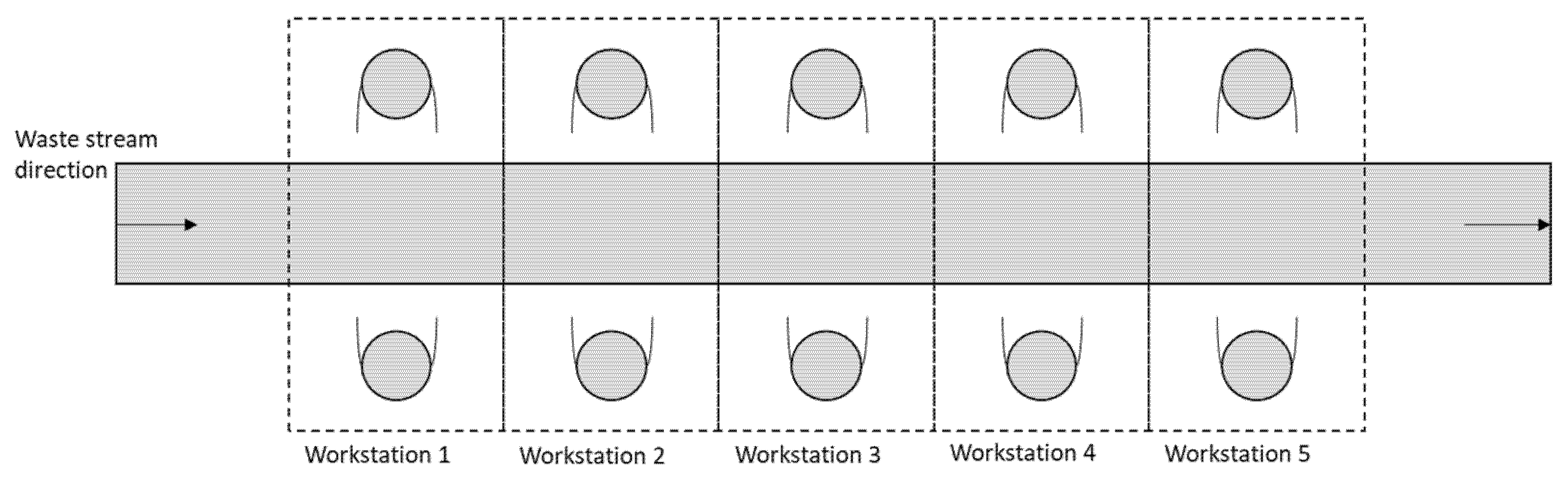

| Workstations | Picking Fractions |

|---|---|

| 1 | Blue PET |

| 2 | Blue PET, White PET, Aluminium, Tetra Pak |

| 3 | Blue PET, White PET, Aluminium, Tetra Pak |

| 4 | Blue PET, Green PET, White PET, Aluminium, Tetra Pak |

| 5 | Blue PET, Green PET, White PET, Aluminium, Tetra Pak, HDPE |

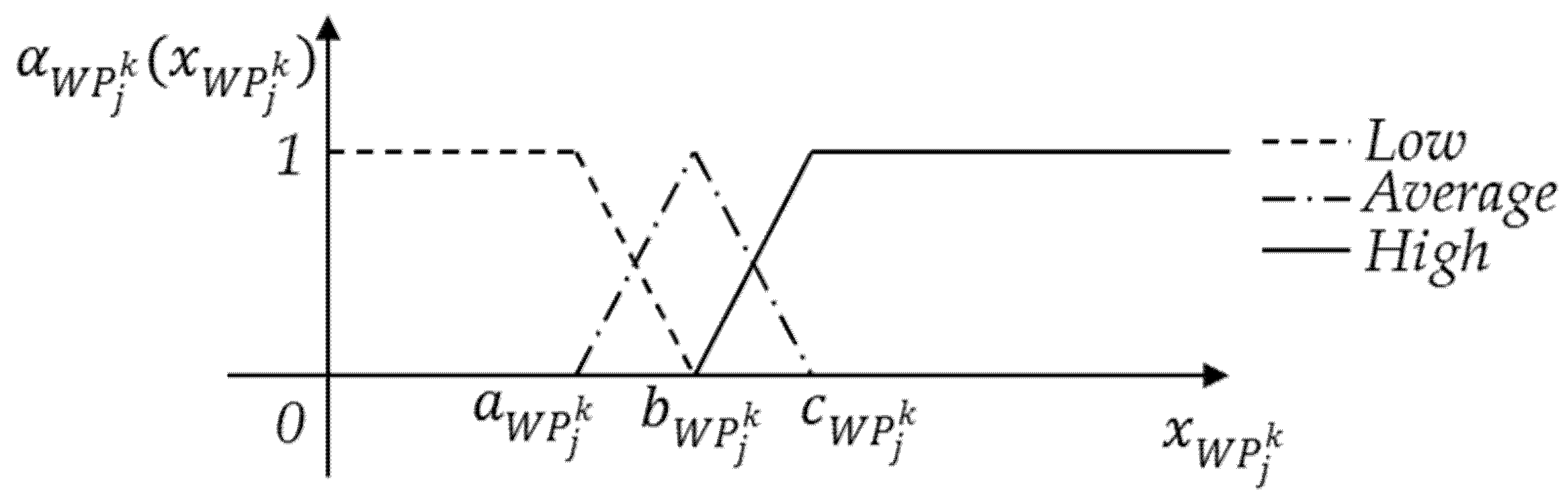

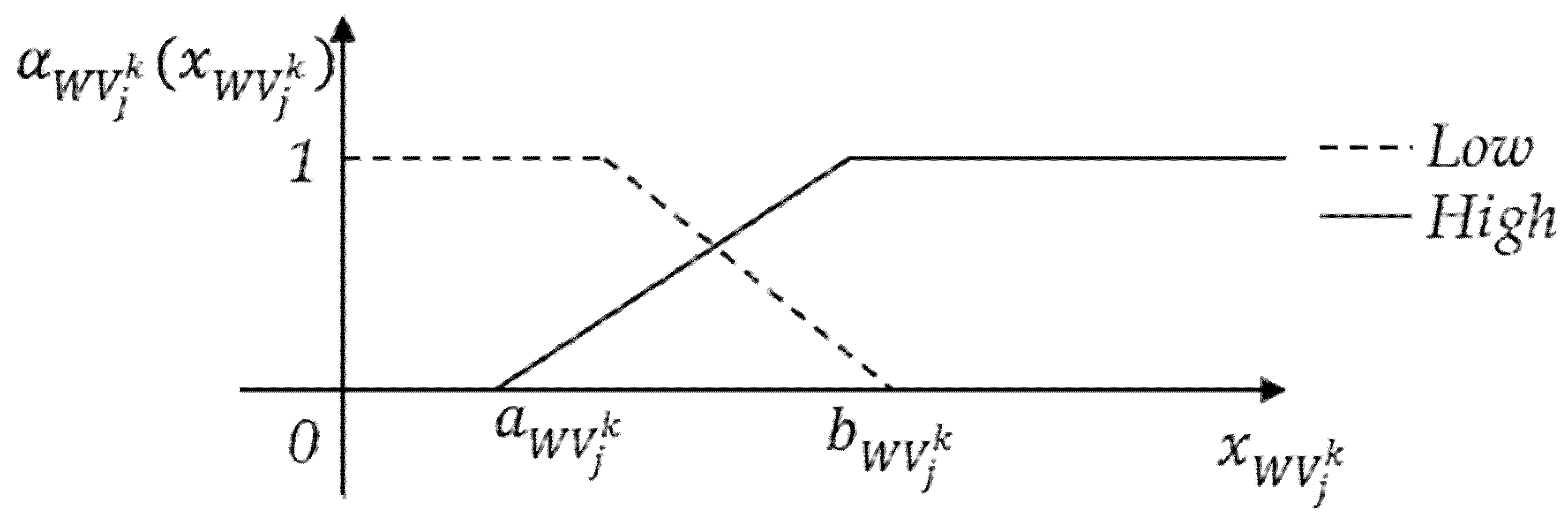

| Designation of Assessment Indicator | Symbol for a Linguistic Variable | Values of the Linguistic Variable |

|---|---|---|

| 0 | ||

| 0.5 | ||

| 1 | ||

| 0 | ||

| 0.56 | ||

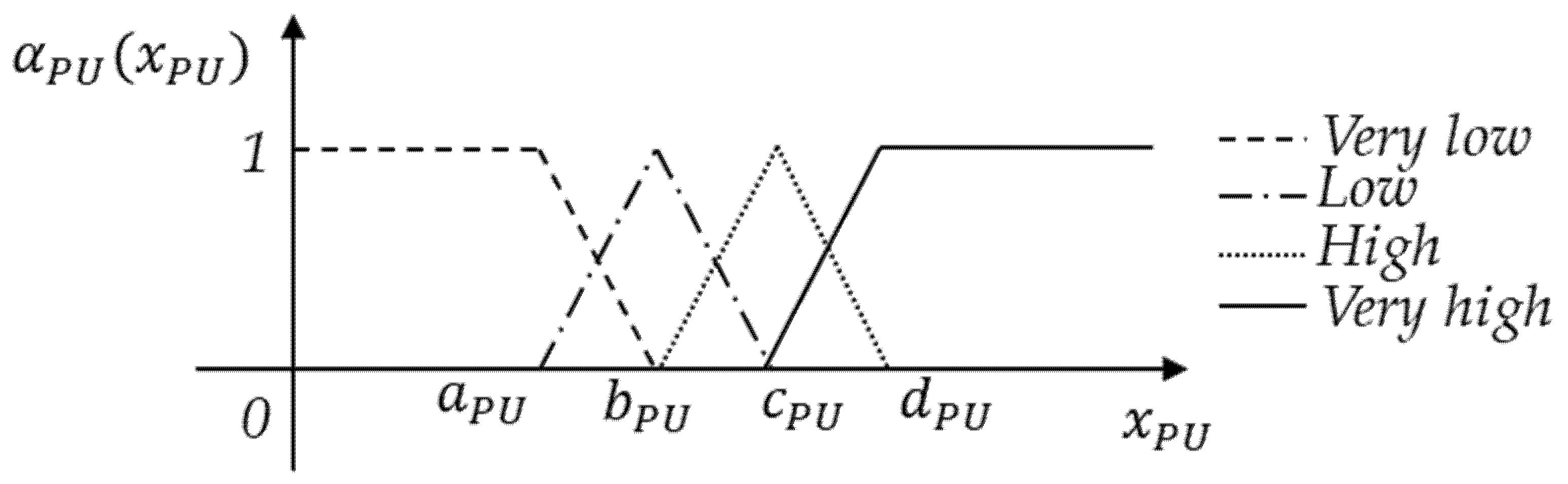

| PU | 0 | |

| 0.333 | ||

| 0.666 | ||

| 1 | ||

| PE | 0.16 | |

| 0.37 | ||

| 0.58 | ||

| 0.79 | ||

| 1 | ||

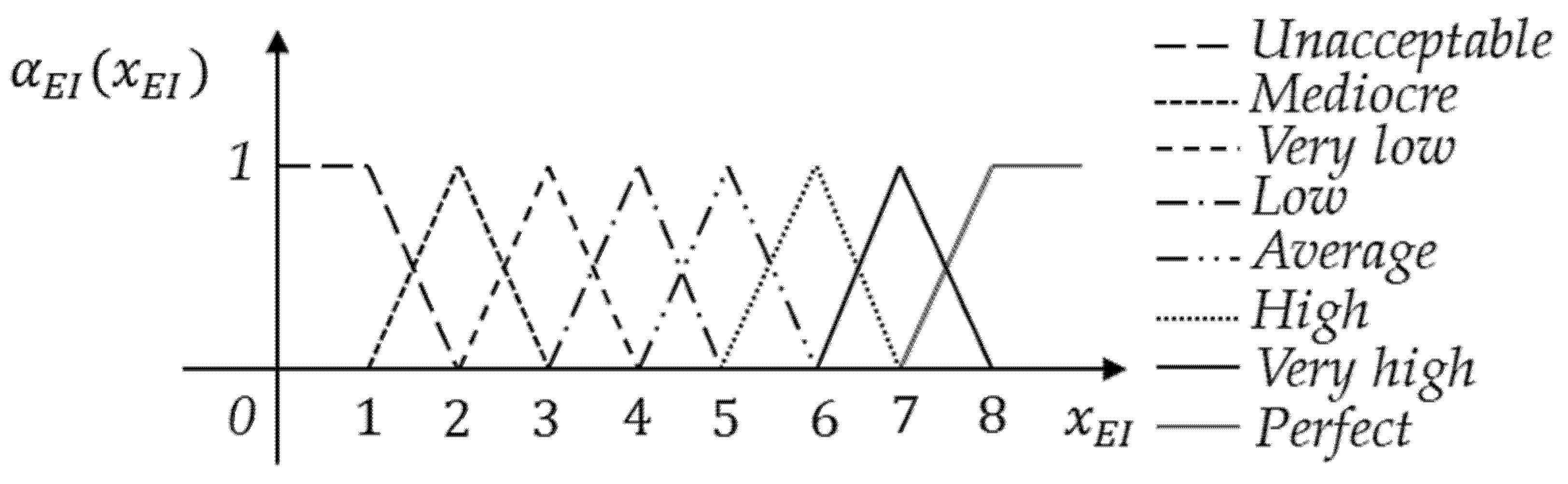

| - | - | |

| A | 0.89 | |

| 1 |

| WP1 | WP2 | WP3 | WP4 | WP5 | WV1 | WV2 | WV3 | WV4 | WV5 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Case 1 | 0.222 | 0.202 | 0.428 | 0.391 | 0.394 | 0.690 | 1.185 | 0.500 | 0.710 | 0.754 |

| Case 2 | 0.168 | 0.182 | 0.413 | 0.236 | 0.302 | 0.754 | 0.964 | 0.441 | 0.615 | 0.700 |

| Case 3 | 0.195 | 0.198 | 0.490 | 0.248 | 0.377 | 0.648 | 0.982 | 0.361 | 0.553 | 0.621 |

| Case 4 | 0.216 | 0.249 | 0.319 | 0.268 | 0.332 | 0.682 | 0.980 | 0.481 | 0.589 | 0.645 |

| Case 5 | 0.208 | 0.258 | 0.408 | 0.284 | 0.314 | 0.656 | 0.935 | 0.446 | 0.604 | 0.747 |

| Case 6 | 0.203 | 0.280 | 0.404 | 0.235 | 0.482 | 0.598 | 0.793 | 0.374 | 0.574 | 0.621 |

| Case 7 | 0.327 | 0.349 | 0.425 | 0.322 | 0.367 | 0.574 | 0.865 | 0.527 | 0.567 | 0.706 |

| PU | PE | A | EI | ||

|---|---|---|---|---|---|

| Case 1 | 0.650 | 0.985 | 0.483 | 1.000 | 6.28 |

| Case 2 | 0.637 | 0.982 | 0.533 | 1.000 | 6.22 |

| Case 3 | 0.595 | 0.979 | 0.561 | 1.000 | 6.09 |

| Case 4 | 0.632 | 0.964 | 0.499 | 1.000 | 6.08 |

| Case 5 | 0.621 | 0.971 | 0.460 | 1.000 | 6.03 |

| Case 6 | 0.537 | 0.974 | 0.483 | 1.000 | 5.89 |

| Case 7 | 0.553 | 0.963 | 0.408 | 1.000 | 5.77 |

| Fraction | Energy Value [kJ/kg] |

|---|---|

| Contaminants | 9000 |

| PET | 20,500 |

| HDPE | 40,092.12 |

| PVC | 17,408.42 |

| Paper | 16,747.28 |

| Metal | 697.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giel, R.; Kierzkowski, A. A Fuzzy Multi-Criteria Model for Municipal Waste Treatment Systems Evaluation including Energy Recovery. Energies 2022, 15, 31. https://doi.org/10.3390/en15010031

Giel R, Kierzkowski A. A Fuzzy Multi-Criteria Model for Municipal Waste Treatment Systems Evaluation including Energy Recovery. Energies. 2022; 15(1):31. https://doi.org/10.3390/en15010031

Chicago/Turabian StyleGiel, Robert, and Artur Kierzkowski. 2022. "A Fuzzy Multi-Criteria Model for Municipal Waste Treatment Systems Evaluation including Energy Recovery" Energies 15, no. 1: 31. https://doi.org/10.3390/en15010031