Numerical Analysis of a Residential Energy System That Integrates Hybrid Solar Modules (PVT) with a Heat Pump

Abstract

:1. Introduction

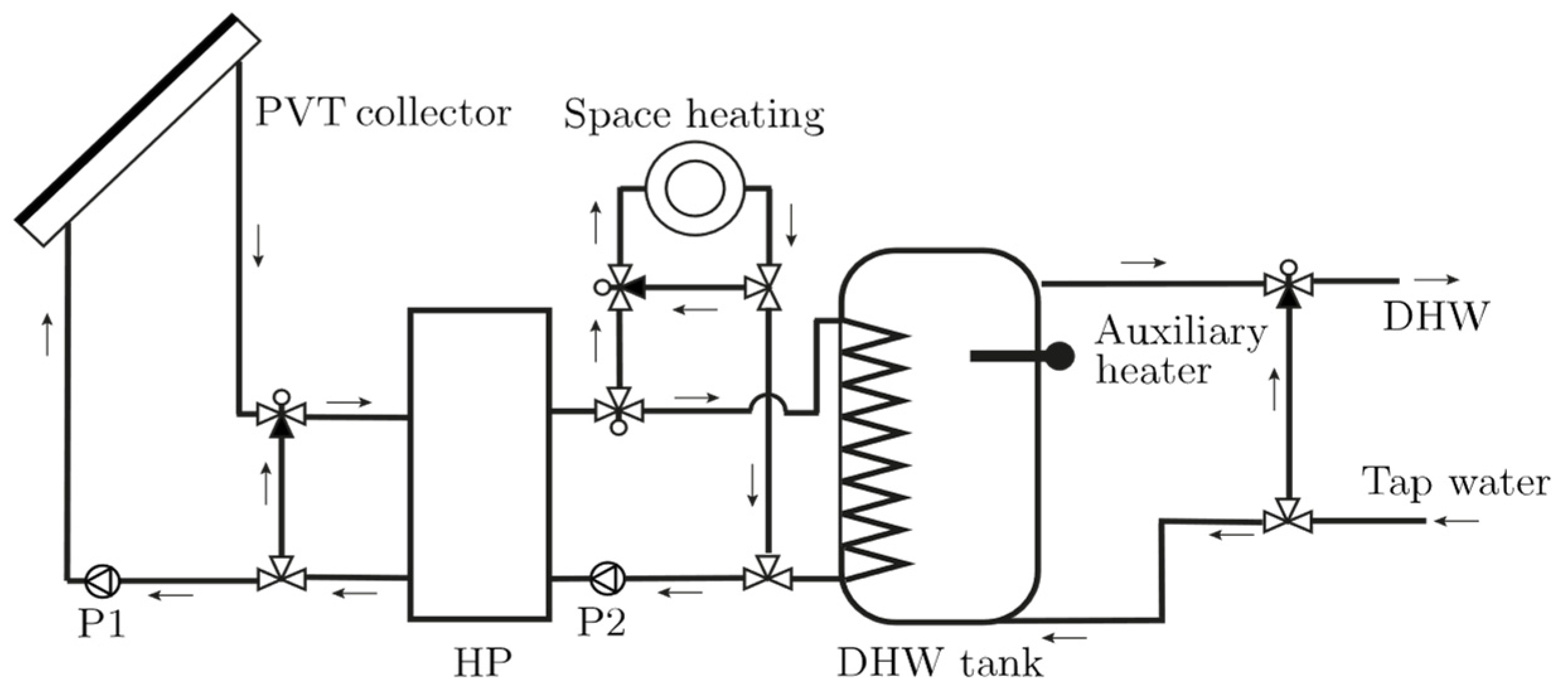

2. System Description

3. Simulation Models, Boundary Conditions and System Design

3.1. Simulation Models and Parameters

3.2. Boundary Conditions

3.2.1. Weather Data

3.2.2. Building

3.2.3. Occupancy

3.2.4. Domestic Hot Water Profile

3.3. System Design

3.3.1. PVT Collector

3.3.2. Heat Pump

3.3.3. Domestic Hot Water Storage Tank

3.3.4. Secondary System Components

3.3.5. System Dimensioning

- Ambient air temperature: °C

- Boundary temperature of the partition walls between adjacent building: °C

- Infiltration rate: 0.5 ACH

- Setpoint temperature: 21 °C

3.3.6. System Control

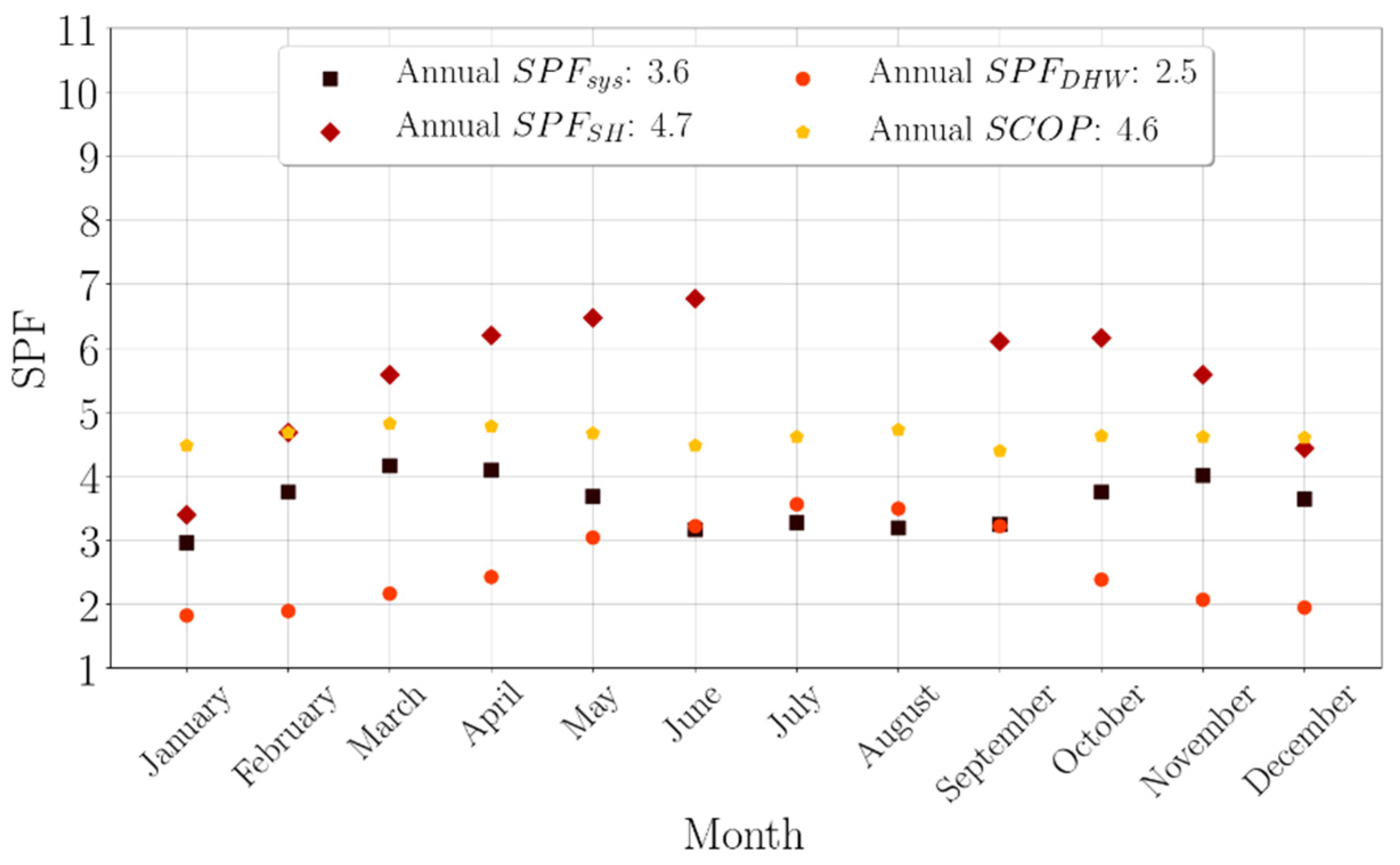

4. Key Performance Indicators and Method of Analysis

4.1. Seasonal Performance Factor

4.2. On-Site Energy Fraction and On-Site Energy Matching

4.3. Performance Indicators of the Key System Components

4.3.1. PVT Collectors

4.3.2. Heat Pump

4.3.3. Comfort in the Building

5. Simulation Cases

5.1. Reference Case

5.2. Scenario Analysis

6. Simulation Results

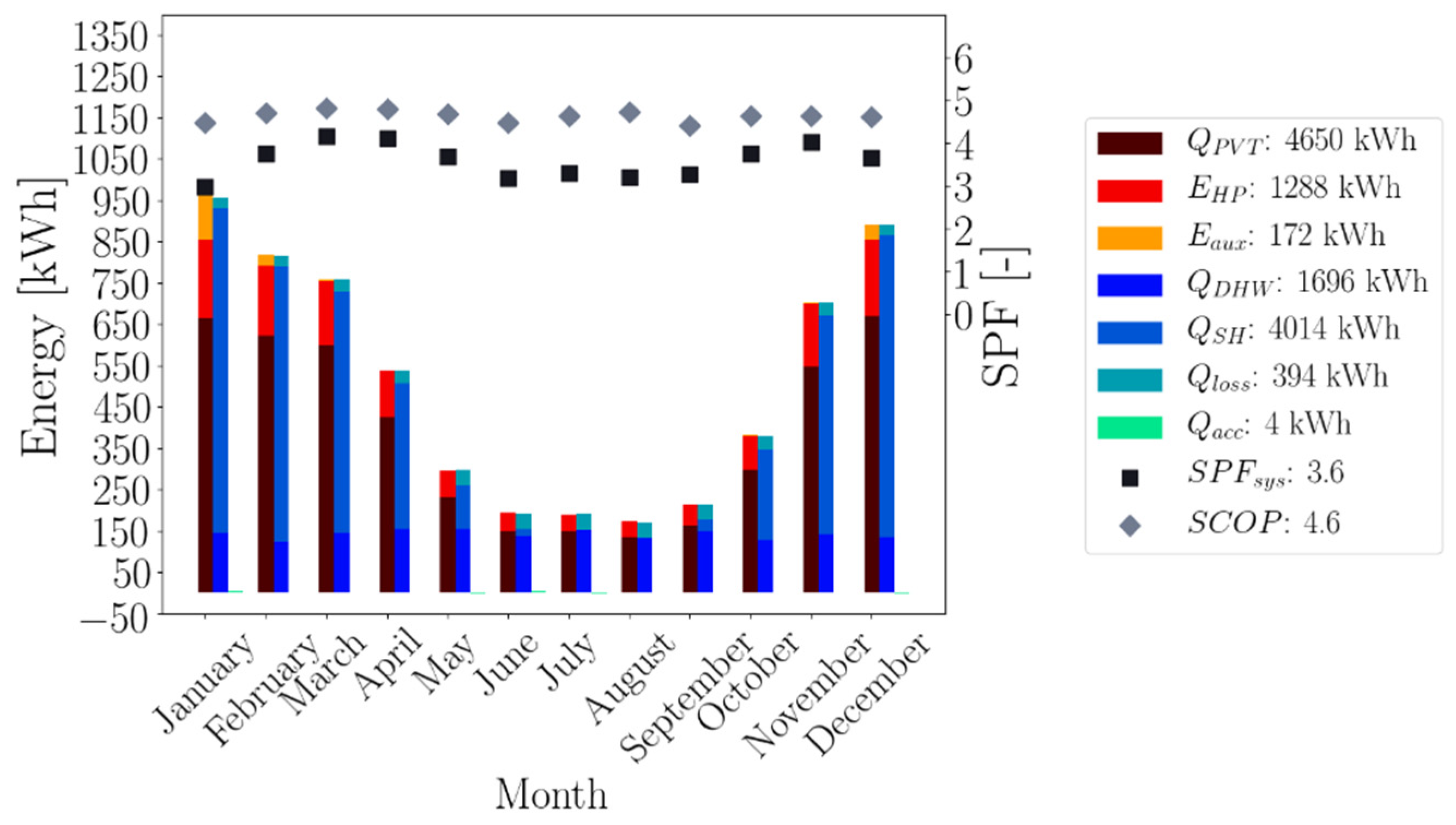

6.1. Reference Case

6.1.1. System Performance

6.1.2. System Operation and Control

6.1.3. DHW Storage Tank

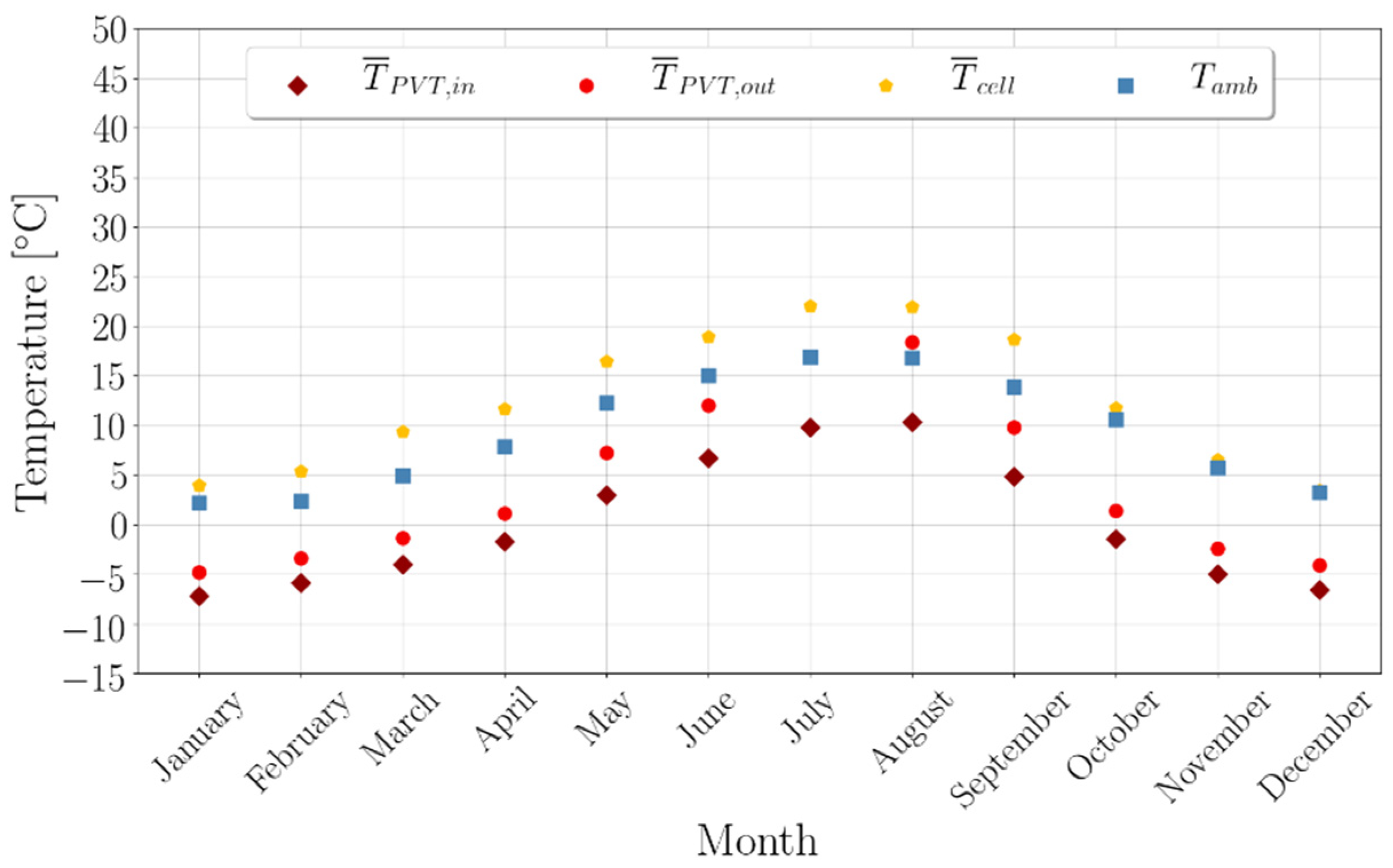

6.1.4. PVT Collector Performance

6.1.5. On-site Energy Fraction and On-site Energy Matching

6.1.6. Indoor Conditions in the Building

6.2. Scenario Analysis

6.2.1. Climate Conditions

6.2.2. Occupancy Profiles

6.2.3. Building Orientation

6.2.4. PVT Collector Area

6.2.5. PVT Collector Type

7. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A. Occupancy Profiles

References

- United Nations Environment; Global Alliance for Buildings and Construction and the International Energy Agency (IEA). Global Status Report 2017. Available online: https://globalabc.org/resources/publications/2017-global-status-report-buildings-and-construction (accessed on 10 March 2019).

- Central Bureau of Statistics (CBS). Greenhouse Gas Emissions 3 Percent Down in 2019. 2020. Available online: https://www.rvo.nl/onderwerpen/duurzaam-ondernemen/gebouwen/wetten-en-regels/nieuwbouw/energieprestatie-beng/ontwikkelingen#:~:text=De%20Wet%20Voortgang%20Energietransitie%20(wet,Lees%20meer%20over%20aardgasvrij (accessed on 19 January 2020).

- Rijksdienst voor Ondernemend Nederland (RVO). Ontwikkelingen BENG. Available online: https://www.rvo.nl/onderwerpen/duurzaam-ondernemen/gebouwen/wetten-en-regels/nieuwbouw/energieprestatie-beng/ontwikkelingen (accessed on 2 April 2020).

- Jonas, D.; Frey, G.; Theis, D. Simulation and performance analysis of combined parallel solar thermaland ground or air source heat pump systems. Sol. Energy 2017, 150, 500–511. [Google Scholar] [CrossRef]

- Emmi, G.; Zarrella, A.; De Carli, M. A heat pump coupled with photovoltaic thermal hybrid solar collectors: A case study of a multi-source energy system. Energy Convers. Manag. 2017, 151, 386–399. [Google Scholar] [CrossRef]

- Bertram, E.; Glembin, J.; Rockendorf, G. Unglazed PVT collectors as addtional heat source in heat pump systems with borehold heat exchanger. Energy Procedia 2012, 30, 414–423. [Google Scholar] [CrossRef] [Green Version]

- Sakellariou, E.; Wright, A.; Axaopoulos, P.; Oyinlola, M. PVT based solar assisted ground source heat pump system: Modelling approach and sensitivity analyses. Sol. Energy 2019, 193, 37–50. [Google Scholar] [CrossRef]

- Solar Energy Application Centre (SEAC). Openbaar Eindrapport Project “WenSDak”—Esthetisch Gebouwgeïntegreerd zonneWarmte en Stroomdak; SEAC: Eindhoven, The Netherlands, 2017. [Google Scholar]

- Vallati, A.; Oclon, P.; Colucci, C.; Mauri, L.; de Lieto Vollaro, R.; Taler, J. Energy analysis of a thermal system composed by a heat pump. Energy 2019, 174, 91–96. [Google Scholar] [CrossRef]

- Thermal Energy System Specialists, LLC. TRNSYS17; Thermal Energy System Specialists, LLC: Madison, WI, USA, 2017; Available online: http://www.trnsys.com/ (accessed on 20 April 2020).

- Jonas, D.; Lämmle, M.; Theis, D.; Schneider, S.; Frey, G. Performance modeling of PVT collectors: Implementation, validation and parameter identification approach using TRNSYS. Sol. Energy 2019, 193, 51–64. [Google Scholar] [CrossRef]

- Haller, M.; Perers, B.; Bale, C.; Paavilainen, J.; Dalibard, A.; Fischer, S.; Bertram, E. TRNSYS Type 832 v5.00 “Dynamic Collector Model by Bengt Perers" Updated Input-Output Reference. 2012. Available online: https://backend.orbit.dtu.dk/ws/files/51568914/121113_Collector%20Model%20Type%20832v500%20-%20Input-Output%20Reference.pdf (accessed on 1 June 2020).

- Drück, H. Multiport Store—Model for TRNSYS Type 340 Version 1.99F. 2006. Available online: https://www.trnsys.de/download/en/ts_type_340_en.pdf (accessed on 1 June 2020).

- V Meteotest AG. Meteonorm; Meteotest AG: Bern, Switzerland, 2020; Available online: https://meteonorm.com/en/ (accessed on 23 January 2020).

- Interngovernmental Panel on Climate Change (IPCC). Special Report on Emissions Scenarios. 2000. Available online: https://www.ipcc.ch/site/assets/uploads/2018/03/emissions_scenarios-1.pdf (accessed on 23 January 2020).

- Ministerie van Binnenlandse Zaken en Koninkrijksrelaties. Bouwbesluit 2012 (Vanaf 01-07-2019). Available online: https://www.onlinebouwbesluit.nl/ (accessed on 5 January 2020).

- Bedir, M. Occupant Behavior and Energy Consumption in Dwellings: An Analysis of Behavioral Models and Actual Energy Consumption in the Dutch Housing Stock. 2017. Available online: https://journals.open.tudelft.nl/abe/article/view/1876 (accessed on 5 January 2020).

- Jordan, U.; Vajen, K. DHWcalc: Program to generate domestic hot water profiles with statistical means for used defined conditions. In Proceedings of the ISES 2005 Solar World Congress, Orlando, FL, USA, 8–12 August 2005. [Google Scholar]

- Psimmenoy, M. Performance Analysis of a PVT with a Heat Pump System under Outdoor Testing and Numerical Modelling. 2019. Available online: https://research.tue.nl/en/studentTheses/performance-analysis-of-a-pvt-combined-with-heat-pump-system-usin (accessed on 20 June 2019).

- Viessmann Nederland B.V. Ground-Water Heat Pump Vitocal 300-G. Available online: https://www.viessmann.nl/nl/eengezinswoning/warmtepompen/brine-waterwarmtepompen/vitocal-300g.html (accessed on 10 September 2020).

- ISSO. ISSO-Publicatie 72 Ontwerpen van Individuele en Kleine Elektrische Warmtepompsystemen voor Woningen; ISSO: Haarlem, The Netherlands, 2017; Available online: https://www.wasco.nl/content/isso-72 (accessed on 17 December 2021).

- Heimrath, R.; Haller, M. The Reference Heating System—The Template Solar System of Task 32. 2007. Available online: https://www.iea-shc.org/data/sites/1/publications/task32-Reference_Heating_System.pdf (accessed on 5 July 2020).

- Vakblad Warmtepompen. Basiseigenschappen en Voordelen van Vloerverwarming. Available online: http://locatherm.nl/informatie-vloerwarming/ (accessed on 21 October 2021).

- Rijksdienst voor Ondernemend Nederland (RVO). PVT Integrated Solar Heat Pump Systems. Available online: https://www.rvo.nl/subsidies-regelingen/projecten/pvt-integrated-solar-heat-pump-systems (accessed on 17 January 2020).

| System Component | Simulation Model | System Component | Simulation Model |

|---|---|---|---|

| PVT collector | Type 835 [11] Type 832 [12] | Flow diverters | Type 647 |

| Heat pump | Type 927 | Flow mixers | Type 649 |

| DHW tank | Type 340 [13] | Differential controllers | Type 2 |

| Building | Type 56 | Internal backup heater HP | Type 659 |

| Pumps | Type 114 | Ground temperature | Type 77 |

| Pipes | Type 31 | Controller for bypass valves | Type 953 |

| Thermostat controllers | Type 698 | ||

| Symbol | Value | Characteristic |

|---|---|---|

| 52.10 | Latitude [°] | |

| 5.18 | Longitude [°] | |

| 40 | Altitude [m] | |

| 9.5 | Annual average temperature [°C] | |

| −11.7 | Annual minimum temperature [°C] | |

| 30.9 | Annual maximum temperature [°C] | |

| 968 | Global horizontal irradiation [kWh/m²] | |

| 382 | Beam irradiation [kWh/m²] | |

| 586 | Diffuse irradiation [kWh/m²] | |

| 79.8 | Annual average relative humidity [%] | |

| 3.3 | Annual average windspeed [m/s] |

| Area | |

| Front façade (% windows) | 29.6 (16%) |

| Back façade (% windows) | 29.6 (34%) |

| Side façade | 63.9 |

| Front side roof (% windows) | 24.3 (5%) |

| Back side roof | 38.3 |

| Volume | |

| Ground floor | 118.4 |

| First floor | 118.4 |

| Attic | 93.5 |

| Angle of Inclination | |

| Front side roof | 65° |

| Back side roof | 35° |

| Building Element | R-Value [m² K W−1] (U-Value [W m−2 K−1]) |

|---|---|

| External wall | 4.5 |

| Ground floor | 3.5 |

| Interior floor | 3.0 |

| Roof | 6.0 |

| Partition walls | 3.0 |

| Window: glazing | (1.2) |

| Window: frame | (3.0) |

| Building Zone | ||

|---|---|---|

| Occupancy Profile | Ground Floor | First Floor |

| Reference | 20 (18) °C | 18 °C |

| Mostly away | 19 (17) °C | 17 °C |

| Mostly at home | 21 (19) °C | 19 °C |

| Number of Occupants | |||

|---|---|---|---|

| Occupancy Profile | Building Zone | 2 | 4 |

| Reference | Ground floor First floor | 7.1 2.3 | 10.7 5.0 |

| Mostly at home | Ground floor First floor | 6.3 4.0 | 9.0 5.9 |

| Mostly away | Ground floor First floor | 5.2 2.3 | 10.0 3.9 |

| Category → Characteristics ↓ | 1 | 2 | 3 |

|---|---|---|---|

| Mean flow rate in l h−1 | 300 | 220 | 180 |

| Standard deviation of the flow rate in l h−1 | 60 | 45 | 45 |

| Average duration of draw-off in min | 8 | 2 | 1 |

| Relative part in % | 50 | 30 | 20 |

| Manufacturer | ||||

|---|---|---|---|---|

| Parameter | Dimark Solar (DS) | SolarTech (ST) | ExaSun (XS) | Parameter Description |

| 0.183 | 0.153 | 0.202 | The electrical efficiency under Standard Test Conditions (STC) | |

| 25 | 25 | 25 | The cell temperature under Standard Test Conditions (STC) °C | |

| 0.07 | 0.125 | 0.139 | Constant for the Incidence Angle Modifier (IAM) | |

| −0.00019 | −0.00019 | −0.00019 | Parameter in the correction factor for irradiance losses [m² W−1] | |

| −0.047 | −0.047 | −0.047 | Parameter in the correction factor for irradiance losses | |

| −1.4 | −1.4 | −1.4 | Parameter in the correction factor for irradiance losses | |

| −0.38 | −0.38 | −0.38 | Temperature coefficient [%/K] | |

| Manufacturer | ||||

|---|---|---|---|---|

| Parameter | Dimark Solar (DS) | SolarTech (ST) | ExaSun (XS) | Parameter Description |

| 0.47 | 0.20 | 0.09 | Zero-loss efficiency of the PVT collector | |

| 1 | 1 | 1 | The Incidence Angle Modifier for beam irradiance | |

| 12.1 | 3.5 | 1.9 | Heat loss coefficient [W m−2 K−1] | |

| 0 | 0 | 0 | Temperature dependence of the heat losses [W m−2 K−2] | |

| 1.25 | 0 | 0.14 | Wind speed dependence of the heat losses [J m−3 K−1] | |

| 0 | 0 | 0 | Long wavelength dependence of the heat losses | |

| 17,173 | 6455 | 4640 | Effective thermal capacitance of the PVT collector [J m−2 K−1] | |

| 0.029 | 0.016 | 0.007 | Wind dependence of the zero-loss efficiency s m−1] | |

| 40 | 6 | 15 | Heat transfer coefficient between the PV panel and the collector fluid | |

| Performance Characteristic/Operating Condition | Value |

|---|---|

| Rated source side (evaporator) temperature | 0 °C |

| Rated load side (condenser) temperature | 35 °C |

| Rated capacity | 5.7 kW |

| Rated power | 1.2 kW |

| Rated coefficient of performance (COP) | 4.6 |

| Parameter | Value | Parameter Description |

|---|---|---|

| 1.3 m | Internal height of the DHW tank | |

| 0.41 m | Internal diameter of the DHW tank | |

| 175 L/250 L | Internal volume of the DHW tank (two-/four-person household) | |

| 5 L | Internal volume of the heat exchanger | |

| 0 | Rel. height of the tap water inlet | |

| 1 | Rel. height of the DHW outlet | |

| 0.60 | Rel. height of the heat exchanger inlet | |

| 0.05 | Rel. height of the heat exchanger outlet | |

| 0.70 | Rel. position pf the backup heater | |

| 0.90 | Rel. position of the controller for the backup heater |

| Mode | Heat Source | Heat Load |

|---|---|---|

| 1 | Standby | Standby |

| 2 | PVT-HP | DHW tank |

| 3 | PVT-HP | FHS: ground floor |

| 4 | PVT-HP | FHS: first floor |

| 5 | PVT-HP | FHS: both floors |

| 6 | Internal backup heater HP | FHS: ground floor |

| 7 | Internal backup heater HP | FHS: first floor |

| 8 | Internal backup heater HP | FHS: both floors |

| PVT-HP System Design | Boundary Conditions | ||

|---|---|---|---|

| System type | Serial PVT-HP system | Building type | Newly built terraced house |

| PVT collectors | 15 m2—Dimark Solar | Space heating demand | 15 GJ |

| Heat pump | Capacity: 4.0; COP: 4.6 (B0/W35) | DHW demand | 6 GJ |

| DHW tank | 175 L | Location | De Bilt, the Netherlands |

| Manufacturer | |||

|---|---|---|---|

| Dimark Solar | SolarTech | ExaSun | |

| SPF | 4.0 | 2.8 | 2.2 |

| [kWh] | 115 | 537 | 1072 |

| [kWh] | 4853 | 4094 | 3493 |

| [kWh] | 4453 | 3718 | 5058 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rijvers, L.; Rindt, C.; de Keizer, C. Numerical Analysis of a Residential Energy System That Integrates Hybrid Solar Modules (PVT) with a Heat Pump. Energies 2022, 15, 96. https://doi.org/10.3390/en15010096

Rijvers L, Rindt C, de Keizer C. Numerical Analysis of a Residential Energy System That Integrates Hybrid Solar Modules (PVT) with a Heat Pump. Energies. 2022; 15(1):96. https://doi.org/10.3390/en15010096

Chicago/Turabian StyleRijvers, Len, Camilo Rindt, and Corry de Keizer. 2022. "Numerical Analysis of a Residential Energy System That Integrates Hybrid Solar Modules (PVT) with a Heat Pump" Energies 15, no. 1: 96. https://doi.org/10.3390/en15010096

APA StyleRijvers, L., Rindt, C., & de Keizer, C. (2022). Numerical Analysis of a Residential Energy System That Integrates Hybrid Solar Modules (PVT) with a Heat Pump. Energies, 15(1), 96. https://doi.org/10.3390/en15010096