Future Technology Mix—Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)—An Overview of Selected Projects as an Example for Future Investments in Poland

Abstract

:1. Introduction

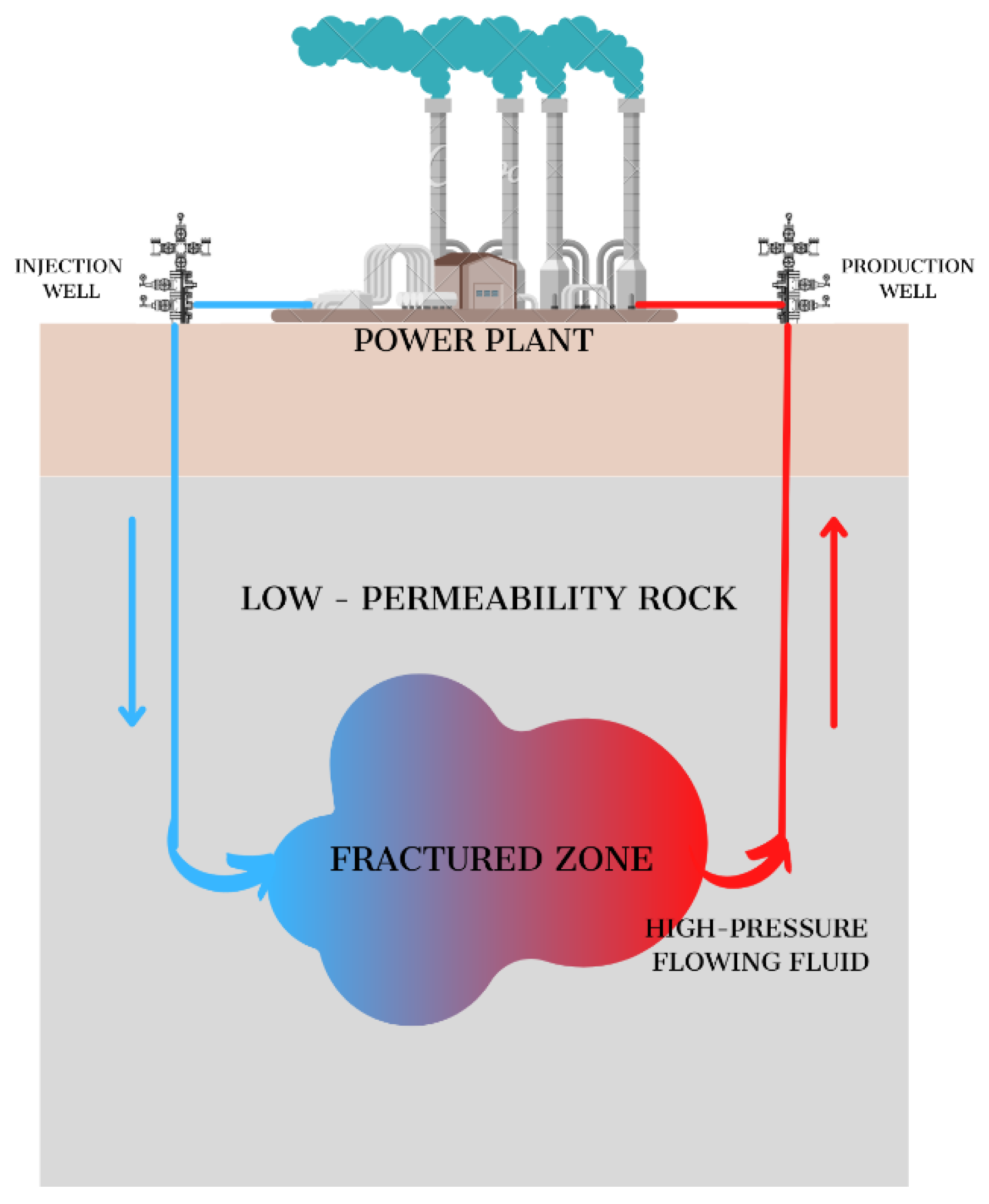

2. An Enhanced Geothermal System

2.1. EGS Technology

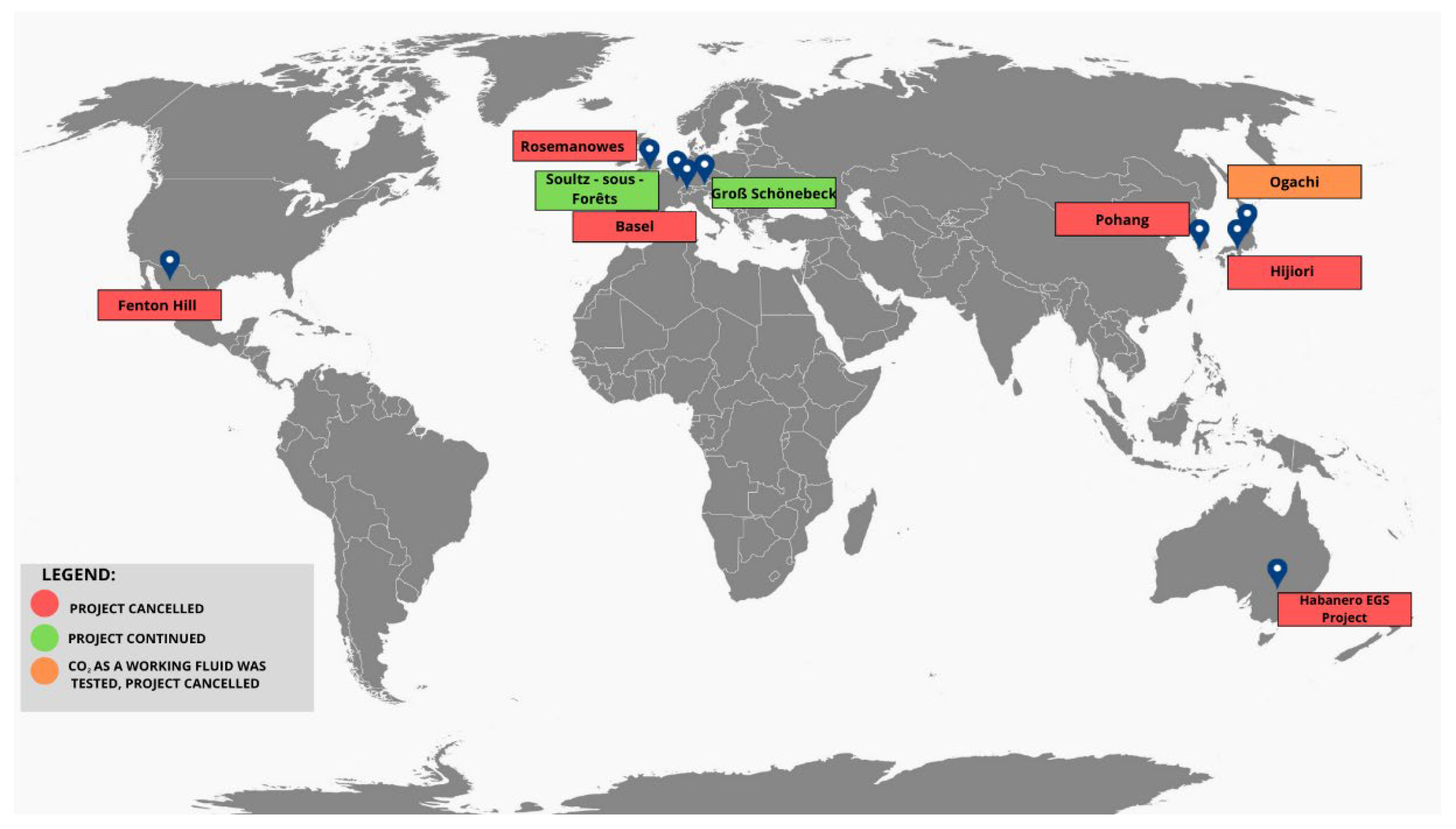

2.2. An Overview of EGS Installation over the World

2.2.1. EGS Installation in Europe

Great Britain—Rosemanowes

Switzerland—Basel

France—Soultz-Sous-Forêts

2.2.2. EGS Installation in Asia

Japan—Hijiori

Japan—Ogachi

South Korea—Pohang

2.2.3. EGS Installation in Australia

Habanero EGS Project

2.2.4. EGS Installation in United States of America

Fenton Hill

3. Carbon Capture, Utilization, and Storage (CCUS)

3.1. CCUS Technology

- Government support of research/feasibility studies, which is necessary to start business.

- Storage of CO2 captured at many industrial sites interconnected with a network pipeline system.

- Proximity to the geological structure enabling long-term storage (decades).

- Large scale of project, assuring unit-cost reduction.

- Synergies between various CO2 producers and the storage operator to reduce risks of commercial viability.

3.2. Examples of CCUS Hubs

3.2.1. Alberta Carbon Trunk Line, ACTL

3.2.2. North Dakota CarbonSAFE

3.2.3. CarbonSAFE Illinois Macon Country

3.2.4. Integrated Mid-Continent Stacked Carbon Storage Project

3.2.5. The Wabash CarbonSAFE project

3.2.6. Gulf of Mexico CCUS Hub

3.2.7. Petrobras Santos Basin CCS network

3.2.8. Northern Lights HUB

3.2.9. The Net Zero Teesside

3.2.10. Zero Carbon Humber (ZCH)

3.2.11. The Port of Rotterdam CCUS Backbone Initiative (PORTHOS)

3.2.12. AmsterdamIJmuiden–CO2 Transport Hub and Offshore Storage (ATHOS)

3.2.13. The United Arab Emirates Mussafah

3.2.14. Xinjiang CCUS Hub

3.2.15. CarbonNet

4. Polish Experiences in Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)

4.1. EGS Research Projects

4.2. CCS Programs

5. Economic Aspect of CO2–EGS Installation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ledesert, B.A.; Hebert, R.L. The Soultz–sous–Forêts Enhanced Geothermal System: A Granit Basement Used as a Heat Exchanger to Produce Electricity. In Heat Exchangers—Basic Design Applications; IntechOpen: London, UK, 2012; ISBN 978-953-51-0278-6. [Google Scholar]

- Sowiżdżał, A. Geothermal energy resources in Poland—Overview of the current state of knowledge. Renew. Sustain. Energy Rev. 2018, 82, 4020–4027. [Google Scholar] [CrossRef]

- Sowiżdżał, A.; Kaczmarczyk, M. Analysis of thermal parameters of Triassic, Permian and Carboniferous sedimentary rocks in central Poland. Geol. J. 2016, 51, 65–67. [Google Scholar] [CrossRef]

- Sowiżdżał, A.; Papiernik, B.; Machowski, G.; Hajto, M. Characterization of petrophysical parameters of the Lower Triassic deposits in a prospective location for enhanced geothermal system (central Poland). Geol. Q. 2013, 57, 729–743. [Google Scholar] [CrossRef] [Green Version]

- Sowiżdżał, A. Possibilities of petrothermal energy resources utilization in central part of Poland. Appl. Ecol. Environ. Res. 2016, 14, 555–574. [Google Scholar] [CrossRef]

- Sowiżdżał, A.; Gładysz, P.; Pająk, L. Sustainable Use of Petrothermal Resources—A Review of the Geological Conditions in Poland. Resources 2021, 10, 8. [Google Scholar] [CrossRef]

- Gładysz, P.; Sowiżdżał, A.; Miecznik, M.; Pająk, L. Carbon dioxide-enhanced geothermal systems for heat and electricity production: Energy and economic analyses for central Poland. Energy Convers. Manag. 2020, 220, 113142. [Google Scholar] [CrossRef]

- Gładysz, P.; Sowiżdżał, A.; Miecznik, M.; Hacaga, M.; Pająk, L. Techno-economic assessment of a combined heat and power plant integrated with carbon dioxide removal technology: A case study for Central Poland. Energies 2020, 13, 2841. [Google Scholar] [CrossRef]

- Huenges, E.; Holl, H.G.; Bruhn, D.; Brandt, W.; Saadat, A.; Moeck, I.; Zimmermann, G. Current state of the EGS project Groß Schönebeck-drilling into the deep sedimentary geothermal reservoir. In Proceedings of the European Geothermal Congress 2007, Unterhaching, Germany, 30 May–1 June 2007. [Google Scholar]

- Pająk, L.; Sowiżdżał, A.; Gładysz, P.; Tomaszewska, B.; Miecznik, M.; Andresen, T.; Frengstad, B.S.; Chmielowska, A. 2021: Multi-Criteria Studies and Assessment Supporting the Selection of Locations and Technologies Used in CO2–EGS Systems. Energies 2021, 14, 7683. [Google Scholar] [CrossRef]

- Sowiżdżał, A.; Gładysz, P.; Andresen, T.; Miecznik, M.; Frengstad, B.S.; Liszka, M.; Chmielowska, A.; Gawron, M.; Løvseth, S.W.; Pająk, L.; et al. CO2-enhanced geothermal systems for climate neutral energy supply. In Proceedings of the TCCS-11-Trondheim Conference on CO2 Capture, Transport and Storage, Trondheim, Norway, 11–23 June 2021. [Google Scholar]

- White, J.C.; Williams, G.; Chadwick, A.; Furre, A.; Kiaer, A. The ongoing challenge to determine the thickness of a thin CO2 layer. Int. J. Greenh. Gas Control 2018, 69, 81–95. [Google Scholar] [CrossRef]

- Turan, G.; Zapantis, A.; Kearns, D.; Tamme, E.; Staib, C.; Zhang, T.; Burrows, J.; Gillespie, A.; Havercroft, I.; Rassool, D.; et al. Global Status of CCS Report; Global CCS Institute: Docklands, Australia, 2021. [Google Scholar]

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies and Environmental Impact; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Avanthi Isaka, B.L.; Ranjith, P.G.; Rathnaweera, T.D. The use of super-critical carbon dioxide as the workingfluid in enhanced geothermal systems (EGSs): A review study. Sustain. Energy Technol. Assess. 2019, 36, 100547. [Google Scholar]

- Brown, D.W.; Duchane, D.; Heiken, G.; Hriscu, V.T. Mining the Earth’s Heat: Hot Dry Rock Geothermal Energy; Springer: Berlin/Heidelberg, Germany, 2012; p. 657. [Google Scholar]

- Tester, J.W.; Anderson, B.J.; Batchelor, A.S.; Blackwell, D.D.; DiPippo, R.; Drake, E.M.; Garnish, J.; Livesay, B.; Moore, M.C.; Nichols, K.; et al. The Future of Geothermal Energy: Impact of Enhanced Geothermal System (EGS) on the United States in the 21st Century; Massachusetts Institute of Technology: Cambridge, MA, USA, 2006. Available online: https://www1.eere.energy.gov/geothermal/pdfs/future_geo_energy.pdf (accessed on 12 February 2022).

- Aminu, M.D.; Nabavi, S.A.; Rochelle, C.A.; Manovic, V. A review of developments in carbon dioxide storage. Appl. Energy 2017, 208, 1389–1419. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.Z.; Xu, R.N.; Jiang, P.X. Thermodynamic analysis of enhanced geothermal systems using impure CO2 as the geofluid. Appl. Therm. Eng. 2016, 99, 1277–1285. [Google Scholar] [CrossRef]

- Cui, G.; Ren, S.; Rui, Z.; Ezekiel, J.; Zhang, L.; Wang, H. The influence of complicated fluid-rock interactions on the geothermal exploitation in the CO2 plume geothermal system. Appl. Energy 2018, 227, 49–63. [Google Scholar] [CrossRef]

- Olasolo, P.; Juárez, M.C.; Morales, M.P.; Olasolo, A.; Agius, M.R. Analysis of working fluids applicable in Enhanced Geothermal Systems: Nitrous oxide as an alternative working fluid. Energy 2018, 157, 150–161. [Google Scholar] [CrossRef]

- Pruess, K. On production behavior of enhanced geothermal systems with CO2 as working fluid. Energy Convers. Manag. 2008, 49, 1446–1454. [Google Scholar] [CrossRef] [Green Version]

- Calcagno, P.; Genter, A.; Huenges, E.; Kaltschmitt, M.; Karytsas, C.; Kohl, T.; Ledru, P.; Manzella, A.; Thorhallsson, S.; van Wees, J.D. The ENGINE Coordination Action (ENhanced Geothermal Innovative Network for Europe). In Proceedings of the World Geothermal Congress 2010, Bali, Indonesia, 25–29 April 2010. [Google Scholar]

- Blöcher, G.; Peters, E.; Kluge, C.; Ilangovan, N.; Bruhn, D.; Nick, H. The Horizon 2020 SURE Project: Deliverable 3.1 Report on Stimulation Technologies for Geothermal Reservoirs; GFZ German Research Centre for Geosciences: Potsdam, Germany, 2016. [Google Scholar] [CrossRef]

- Lu, S.M. A global review of enhanced geothermal system (EGS). Renew. Sustain. Energy Rev. 2018, 81, 2902–2921. [Google Scholar] [CrossRef]

- Haring, M.O.; Schanz, U.; Ladner, F.; Dyer, B.C. Characterisation of the Basel 1 enhanced geothermal system. Geothermics 2008, 37, 469–495. [Google Scholar] [CrossRef]

- Ladner, F.; Haring, M. Hydraulic Characteristic of the Basel 1 Enhanced Geothermal System. GRC Trans. 2009, 33, 199–203. [Google Scholar]

- Cuenot, N.; Faucher, J.P.; Fritsch, D.; Genter, A.; Szabliński, D. The European EGS project at Soultz-sous-Forêts: From extensive exploration to power production. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting—Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008. [Google Scholar]

- Baria, R.; Baugmartner, J.; Gerard, A.; Jung, R.; Garnish, J. European HDR research programme at Soultz-sous-Forêts (France) 1987–1996. Geothermics 1999, 28, 655–669. [Google Scholar] [CrossRef]

- Mouchot, J.; Genter, A.; Cuenot, N.; Scheiber, J.; Seibel, O.; Bosia, C.; Ravier, G. First Year of Operation from EGS Geothermal Plants in Alsace, France: Scaling Issues. In Proceedings of the 43rd Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 12–14 February 2018. [Google Scholar]

- Sanjuan, B.; Millot, R.; Dezayes, C.; Brach, M. Main characteristics of the deep geothermal brine (5 km) at Soultz-sous-Forêts (France) determined using geochemical and tracer test data. Comptes Rendus Geosci. 2010, 342, 546–559. [Google Scholar] [CrossRef]

- Yanagisawa, N.; Matsunaga, I.; Sugita, H.; Sato, M.; Okabe, T. Temperature-dependent scale precipitation in the Hijiori Hot Dry Rock system, Japan. Geothermics 2008, 37, 1–18. [Google Scholar] [CrossRef]

- Keieda, H.; Ito, H.; Kiho, K.; Suzuki, K.; Suenaga, H.; Shin, K. Review of the Ogachi HDR Project in Japan. In Proceedings of the World Geothermal Congress, Antalya, Turkey, 24–29 April 2005. [Google Scholar]

- Park, S.; Kim, K.; Xie, L.; Yoo, H.; Min, K.; Kim, M.; Yoon, B.; Kim, K.; Zimmermann, G.; Guinot Meier, P. Observations and analyses of the first two hydraulic stimulations in the Pohang geothermal development site, South Korea. Geothermics 2020, 88, 101905. [Google Scholar] [CrossRef]

- Kim, K.; Min, K.; Choi, J.; Yoon, K.; Yoon, W.; Yoon, B.; Lee, T.; Song, Y. Protocol for induced microseismicity in the first enhanced geothermal systems project in Pohang, Korea. Renew. Sustain. Energy Rev. 2018, 91, 1182–1191. [Google Scholar] [CrossRef]

- Grigoli, F.; Cesca, S.; Rinaldi, A.P.; Manconi, A.; López-Comino, A.; Clinton, J.F.; Westaway, R.; Cauzzi, C.; Dahm, T.; Wiemer, S. The November 2017 Mw 5.5 Pohang earthquake: A possible case of induced seismicity in South Korea. Science 2018, 360, 1003–1006. [Google Scholar] [CrossRef] [Green Version]

- Hogarth, R.; Holl, H.-G. Lessons learned from the Habanero EGS project. Geotherm. Resour. Counc. Trans. 2017, 41, 865–877. [Google Scholar]

- Humphreys, B.; Hodson-Clarke, A.; Hogarth, R. Habanero Geothermal Project Field Development Plan; Geodynamics Ltd.: Brisbane, Australia, 2014. [Google Scholar]

- Hogarth, R.; Bour, D. Flow Performance of the Habanero EGS Closed Loop. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- Kelkar, S.; WoldeGabriel, G.; Rehfeldt, K. Lessons learned from the pioneering hot dry rock project at Fenton Hill, USA. Geothermics 2016, 63, 5–14. [Google Scholar] [CrossRef] [Green Version]

- Tcvetkov, P.; Cherepovitsyn, A.; Fedoseev, S. The Changing Role of CO2 in the Transition to a Circular Economy: Review of Carbon Sequestration Projects. Sustainability 2019, 11, 5834. [Google Scholar] [CrossRef] [Green Version]

- Hasan, M.F.; First, E.L.; Boukouvala, F.; Floudas, C.A. A multi-scale framework for CO2 capture, utilization, and sequestration: CCUS and CCU. Comput. Chem. Eng. 2015, 81, 2–21. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Zhuang, Y.; Liu, L.; Zhang, L.; Du, J. Optimization-based approach for CO2 utilization in carbon capture, utilization and storage supply chain. Comput. Chem. Eng. 2020, 139, 106885. [Google Scholar] [CrossRef]

- Ghiat, I.; Al-Ansari, T. A review of carbon capture and utilisation as a CO2 abatement opportunity within the EWF nexus. J. CO2 Util. 2021, 45, 101432. [Google Scholar] [CrossRef]

- Safe Geologic Storage of Captured Carbon Dioxide—DOE’s Carbon Storage R & D Program: Two Decades in Review, National Energy Technology Laboratory, Pittsburgh, 13 April 2020. Available online: https://www.netl.doe.gov/sites/default/files/Safe%20Geologic%20Storage%20of%20Captured%20Carbon%20Dioxide_April%2015%202020_FINAL.pdf (accessed on 12 July 2021).

- ACTL. Available online: https://www.globalccsinstitute.com/news-media/latest-news/alberta-carbon-trunk-line-now-fully-operational/ (accessed on 12 July 2021).

- ACTL. Available online: https://www.gasworld.com/alberta-ccs-project-fully-operational/2019258.article (accessed on 12 July 2021).

- North Dakota Carbonsafe. Available online: https://www.netl.doe.gov/node/1288 (accessed on 12 July 2021).

- North Dakota Carbonsafe. Available online: https://www.osti.gov/biblio/1606011-north-dakota-integrated-carbon-storage-complex-feasibility-study (accessed on 12 July 2021).

- Carbonsafe Illinois Macon County. Available online: https://www.netl.doe.gov/node/1300 (accessed on 12 July 2021).

- IMSCSH. Available online: https://www.netl.doe.gov/node/1343 (accessed on 12 July 2021).

- IMSCSH November 2019. Available online: https://www.kgs.ku.edu/PRS/IMSCSH/about.html (accessed on 12 July 2021).

- Dalkhaa, C.; Jiang, T.; Burton-Kelly, M.E.; Scharenberg, M.; Smith, V.; Walker, J.L.; Duguid, A.; Heinrichs, M.R.; Bosshart, N.W.; Sorensen, J.A. A simulation study of carbon storage with active reservoir management. Greenh. Gases Sci. Technol. 2022, 12, 4–23. [Google Scholar] [CrossRef]

- Wabash. Available online: https://www.prnewswire.com/news-releases/the-largest-us-carbon-capture-and-sequestration-project-to-be-developed-by-wabash-valley-resources-with-funding-support-from-ogci-climate-investments-300852906.html (accessed on 12 July 2021).

- Wabash. Available online: https://www.netl.doe.gov/projects/project-information.aspx?p=FE0031626 (accessed on 12 July 2021).

- Gulf of Mexico CCUS Hub. Available online: https://www.nrg.com/case-studies/petra-nova.html (accessed on 12 July 2021).

- Gulf of Mexico CCUS Hub. Available online: http://www.netl.doe.gov/publications/factsheets/project/FE0002381.pdf (accessed on 12 July 2021).

- Gulf of Mexico CCUS. Available online: https://www.data.boem.gov/Main/GandG.aspx (accessed on 12 July 2021).

- Petrobras Brazil Hub. Available online: http://www.jogmec.go.jp/content/300370543.pdf (accessed on 12 July 2021).

- Petrobras Brazil Hub. Available online: http://www.ipsnews.net/2020/10/capture-co2-hydrogen-part-latin-americas-energy-future/ (accessed on 12 July 2021).

- Global-Projects-Map 2021. Available online: https://32zn56499nov99m251h4e9t8-wpengine.netdna-ssl.com/bookstore/wp-content/uploads/sites/2/2021/03/Global-CCS-Projects-Map.pdf (accessed on 12 July 2021).

- Northern Lights’ HUB. Available online: https://northernlightsccs.com/reports/ (accessed on 12 July 2021).

- Net Zero Teesside. Available online: https://www.netzeroteesside.co.uk/project/ (accessed on 12 July 2021).

- Net Zero Teesside. Available online: https://www.offshore-mag.com/production/article/14169025/majors-support-north-sea-carbon-capture-project (accessed on 12 July 2021).

- Zero Carbon Humber (ZCH). Available online: https://www.zerocarbonhumber.co.uk/ (accessed on 12 July 2021).

- The Port of Rotterdam CCUS Backbone Initiative (PORTHOS)}. Available online: https://www.porthosco2.nl/en/project/ (accessed on 12 July 2021).

- ATHOS. Available online: https://athosccus.nl/project-en/ (accessed on 12 July 2021).

- ATHOS. Available online: https://www.ccusnetwork.eu/network-members/athos-consortium (accessed on 12 July 2021).

- United Arab Emirates, Mussafah Project. Available online: https://www.cslforum.org/cslf/Projects/AlReyadah (accessed on 12 July 2021).

- Xinjiang CCUS Hub. Available online: https://www.globaltimes.cn/content/1165522.shtml (accessed on 12 July 2021).

- CarbonNet CCS for Victoria, Australia. Available online: https://www.dnv.com/cases/advancing-ccs-for-victoria-australia-the-carbonnet-project-181994 (accessed on 15 June 2021).

- Wójcicki, A.; Sowiżdżał, A.; Bujakowski, W. (Eds.) Evaluation of Potential, Thermal Balance and Prospective Geological Structures for Needs of Unconventional Geothermal Systems (Hot Dry Rocks) in Poland; Ministry of the Environment: Warsaw, Poland, 2013; p. 246. (In Polish) [Google Scholar]

- Sowiżdżał, A.; Semyrka, R. Analyses of permeability and porosity of sedimentary rocks in terms of unconventional geothermal resource explorations in Poland. Geologos 2016, 22, 149–163. [Google Scholar] [CrossRef] [Green Version]

- Bujakowski, W.; Barbacki, A.; Miecznik, M.; Pająk, L.; Skrzypczak, R.; Sowiżdżał, A. Modelling geothermal and operating parameters of EGS installations in the Lower Triassic sedimentary formations of the central Poland area. Renew. Energy 2015, 80, 441–453. [Google Scholar] [CrossRef]

- Lubaś, J.; Szott, W. 15-year experience of acid gas storage in natural gas structure of Borzecin—Poland. Nafta-Gaz 2010, 66, 333–338. [Google Scholar]

- Pagnier, H.; van Bergen, F.; van der Meer, L. Field experiment of ECBM in the Silesian Coal Basin of Poland RECOPOL. In Proceedings of the International Coalbed Methane Symposium 2003, Tuscaloosa, AL, USA, 5–9 May 2003. [Google Scholar]

- Jura, B.; Krzystolik, P.; Skiba, J. 2007—RECOPOL and MOVECBM projects, opportunities and challenges. In Proceedings of the CO2 NET Seminar, Lisbon, Portugal, 6–7 November 2008. [Google Scholar]

- Assessment of Formations and Structures Suitable for Safe Co2 Geological Storage (In Poland) Including the Monitoring Plans. Available online: https://skladowanie.pgi.gov.pl/ (accessed on 12 July 2021).

- Tarkowski, R. (Ed.) Podziemne składowanie CO2 w Polsce w Głębokich Strukturach Geologicznych (Ropo-Gazo- i Wodonośnych), Wyd. IGSMiE PAN. 2005. Available online: https://www.researchgate.net/profile/Radoslaw-Tarkowski/publication/281178492_Podziemne_skladowanie_CO2_w_Polsce_w_glebokich_strukturach_geologicznych_ropo-_gazo-_i_wodonosnych/links/55da309208aec156b9ae7430/Podziemne-skladowanie-CO2-w-Polsce-w-glebokich-strukturach-geologicznych-ropo-gazo-i-wodonosnych.pdf (accessed on 15 March 2022).

- Uliasz-Bocheńczyk, A. Mineralna sekwestracja CO2 w Wybranych Odpadach. Studia, Rozprawy, Monografie 153, Wydawnictwo Instytutu Gospodarki Surowcami Mineralnymi i Energi PAN, Cracow. 2009. Available online: https://se.min-pan.krakow.pl/ksiazki/sir_2009_ulzg_rynki_z.pdf (accessed on 15 March 2022).

- Tarkowski, R.; Uliasz-Misiak, B. Prospects for the use of carbon dioxide in enhanced geothermal systems in Poland. J. Clean. Prod. 2019, 229, 1189–1197. [Google Scholar] [CrossRef]

- Tarkowski, R. (Ed.) Potencjalne Struktury Geologiczne do Składowania CO2 w Utworach Mezozoiku Niżu Polskiego (Charakterystyka oraz ranking), “Studia Rozprawy i Monografie”. 2010. Available online: https://www.researchgate.net/publication/280774308_Potencjalne_struktury_geologiczne_do_skladowania_CO2_w_utworach_mezozoiku_Nizu_Polskiego_charakterystyka_oraz_ranking (accessed on 15 February 2022).

- Interaktywny Atlas Prezentujący Możliwości Geologicznej Sekwestracji CO2 w Polsce. Available online: http://skladowanie.pgi.gov.pl/co2atlas/atlas.phtml (accessed on 15 June 2021).

- Tarkowski, R.; Uliasz-Misiak, B. Podziemne magazynowanie dwutlenku węgla. Przegląd Geol. 2003, 51, 402–409. [Google Scholar]

- SITECHAR Characterisation of European CO2 Storage. Available online: https://cordis.europa.eu/project/id/256705/reporting (accessed on 15 June 2021).

- CGS Baltic Seed Project (S81) Project Substance Report. Available online: https://bcforum.net/content/CGSBalticSeedProject_SubstanceReport_2017.pdf (accessed on 15 June 2021).

- Olasolo, P.; Juárez, M.C.; Olasolo, J.; Morales, M.P.; Valdani, D. Economic analysis of Enhanced Geothermal Systems (EGS). A review of software packages for estimating and simulating costs. Appl. Therm. Eng. 2016, 104, 647–658. [Google Scholar] [CrossRef]

- Hollett, D. Fiscal Year 2013 Budget Request Briefing; U.S. Department of Energy Geothermal Technologies Office: Washington, DC, USA, 2012; p. 23. [Google Scholar]

- Zhong, C.; Xu, T.; Yuan, Y.; Feng, B.; Yu, H. The feasibility of clean power generation from a novel dual-vertical-well enhanced geothermal system (EGS): A case study in the Gonghe Basin, China. J. Clean. Prod. 2022, 344, 131109. [Google Scholar] [CrossRef]

- Atrens, A.D.; Gurgenci, H.; Rudolph, V. Economic optimization of a CO2-based EGS power plant. Energy Fuels 2011, 25, 3765–3775. [Google Scholar] [CrossRef]

- Kölbel, T.; Eggeling, L.; Münch, W.; Schlagermann, P. Geothermal achieving competitivity: Cost of power generation. Geopower Eur. 2021, 6–7. [Google Scholar]

- Raos, S.; Hranić, J.; Ivan Rajsl, I.; Bar, K. An extended methodology for multi-criteria decision-making process focused on enhanced geothermal systems. Energy Convers. Manag. 2022, 258, 115253. [Google Scholar] [CrossRef]

- Di Pippo, R.; Renner, J. Future Energy, 2nd ed; Elsevier: London, UK, 2014. [Google Scholar]

| Name (Country) | Duration | Capacity | Working Fluid | Reservoir Rock | Temperature °C | Extra Information |

|---|---|---|---|---|---|---|

| Habanero EGS Project (Australia) | 2003–2013 | 1 MW | brine | granite | 263 | Project completed in 2013, operation test of the power plant capacity about 1 MW |

| Soultz-sous-Forêts (France) | 1984–present | 1.7 MW | brine | granite | 200 | The first EGS installation of 1.7 MW on a commercial scale; The operation is on the basis of ORC cycle |

| Ogachi (Japan) | 1989–2002 | - | water | granodiorite | 160 | In 2006, the test of the EGS installation at shallow depths was launched; The test was carried out on the possibility of geological CO2 storage in rock structures for closed-system EGS project |

| Hijiori (Japan) | 1985–2002 | 130 kW | water | granodiorite | 190 | The project was closed due to large losses of working fluid |

| Pohang (South Korea) | 2010–2017 | 1 MW | water | granodiorite | - | A few days after the end of the hydraulic stimulation, a strong earthquake with magnitude 5.5 occurred, which led to the closing of the project |

| Groß Schönebeck (Germany) | 2000–present | 1 MW | water | sandstone, andesite (Rotliegend formation) | 145 | The construction of 1 MW power plants is planned |

| Basel (Switzerland) | 2005–2009 | 3 MW | water | granite | 200 | The project was closed after an earthquake (magnitude 2.7) that occurred a few days after the end of stimulation; it was planned to build a heat and power plant with an electricity capacity of 3 MW and a heat plant capacity of 20 MW |

| Rosemanowes (Great Britain) | 1977–1991 | - | water | granite | 80–100 | Experimental project |

| Fenton Hill (USA) | 1974–1995 | 60 kW | water | granite | 192 | The world’s first pilot EGS installation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sowiżdżał, A.; Starczewska, M.; Papiernik, B. Future Technology Mix—Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)—An Overview of Selected Projects as an Example for Future Investments in Poland. Energies 2022, 15, 3505. https://doi.org/10.3390/en15103505

Sowiżdżał A, Starczewska M, Papiernik B. Future Technology Mix—Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)—An Overview of Selected Projects as an Example for Future Investments in Poland. Energies. 2022; 15(10):3505. https://doi.org/10.3390/en15103505

Chicago/Turabian StyleSowiżdżał, Anna, Magdalena Starczewska, and Bartosz Papiernik. 2022. "Future Technology Mix—Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)—An Overview of Selected Projects as an Example for Future Investments in Poland" Energies 15, no. 10: 3505. https://doi.org/10.3390/en15103505

APA StyleSowiżdżał, A., Starczewska, M., & Papiernik, B. (2022). Future Technology Mix—Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)—An Overview of Selected Projects as an Example for Future Investments in Poland. Energies, 15(10), 3505. https://doi.org/10.3390/en15103505