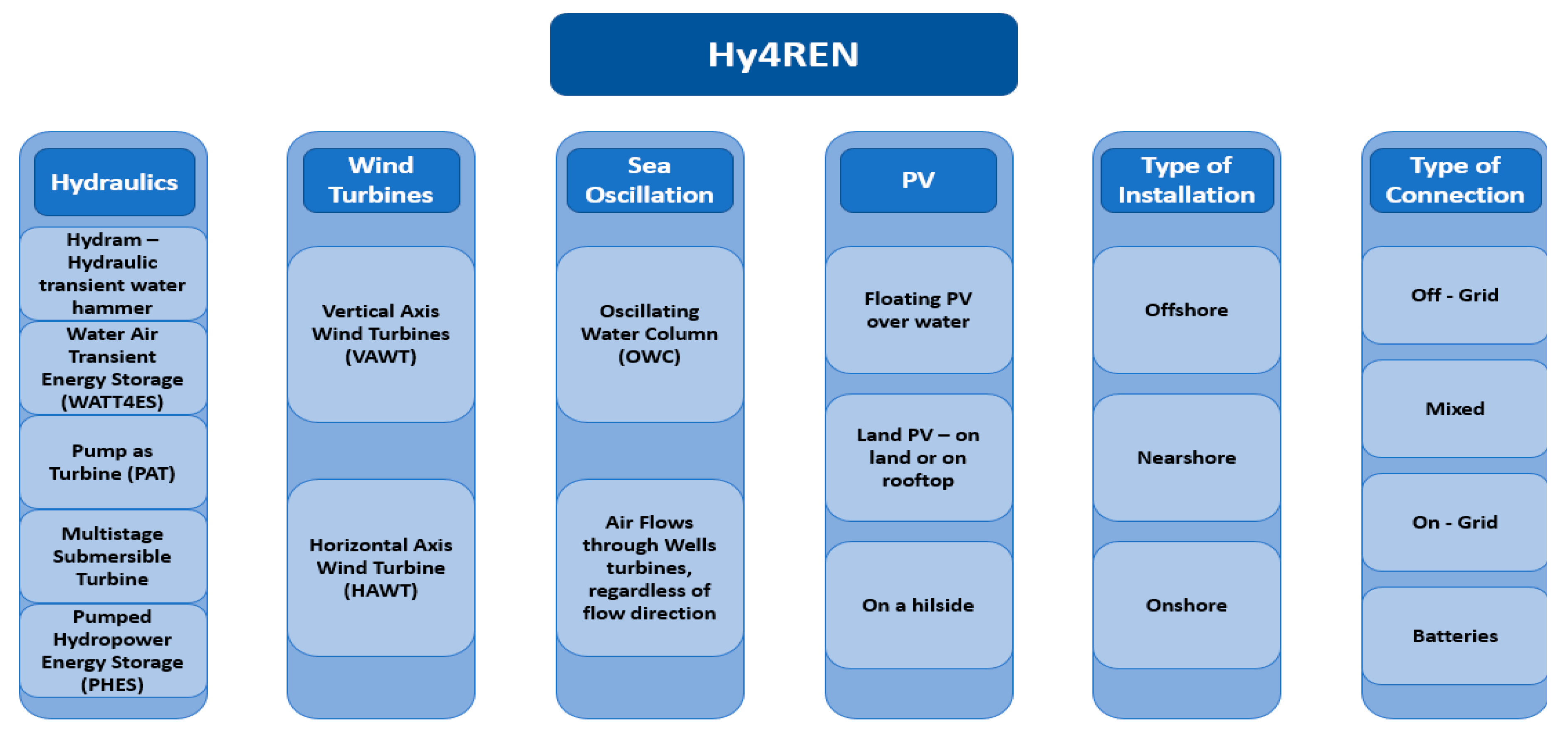

New Integrated Energy Solution Idealization: Hybrid for Renewable Energy Network (Hy4REN)

Abstract

:1. Brief Introduction

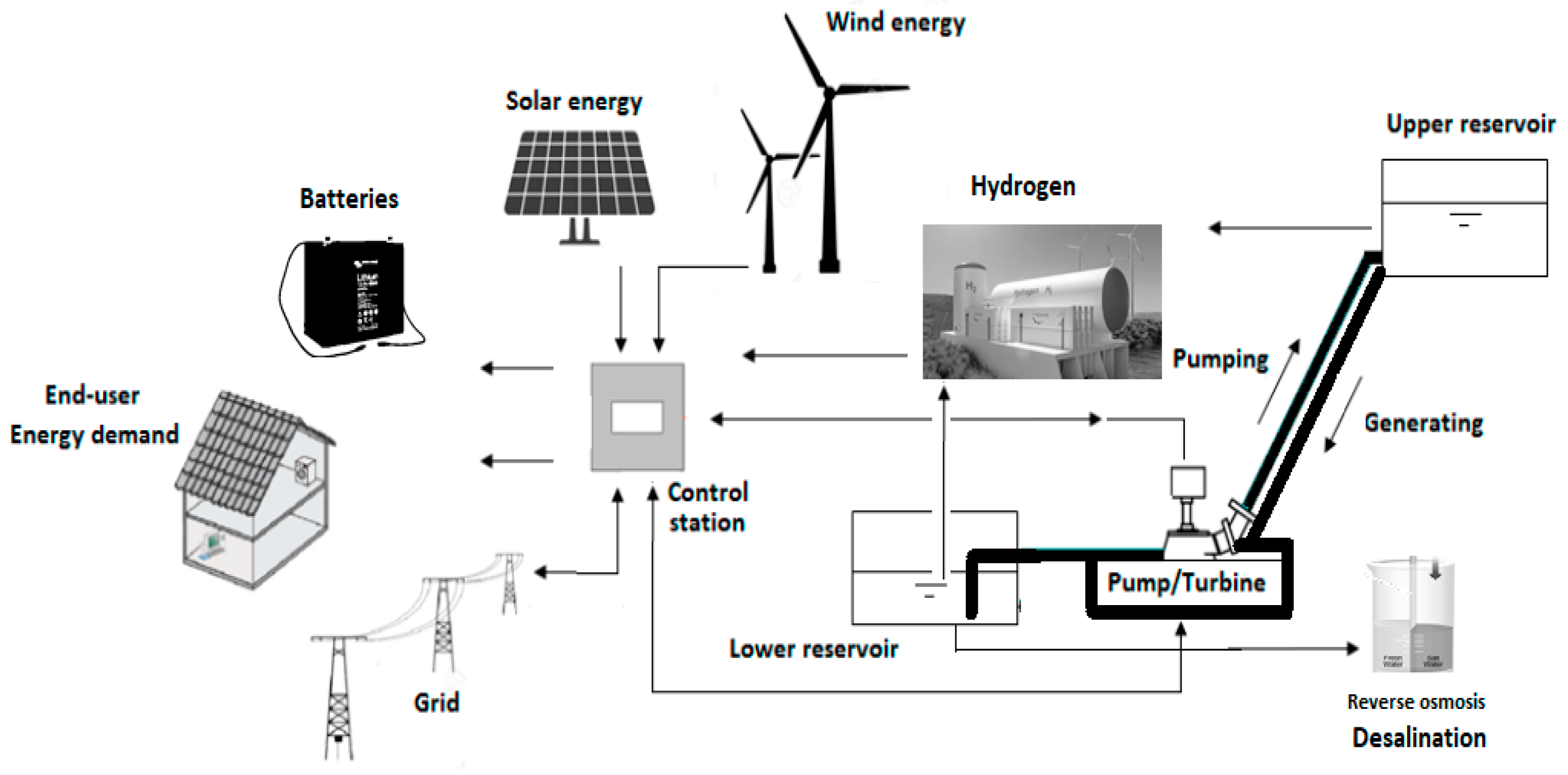

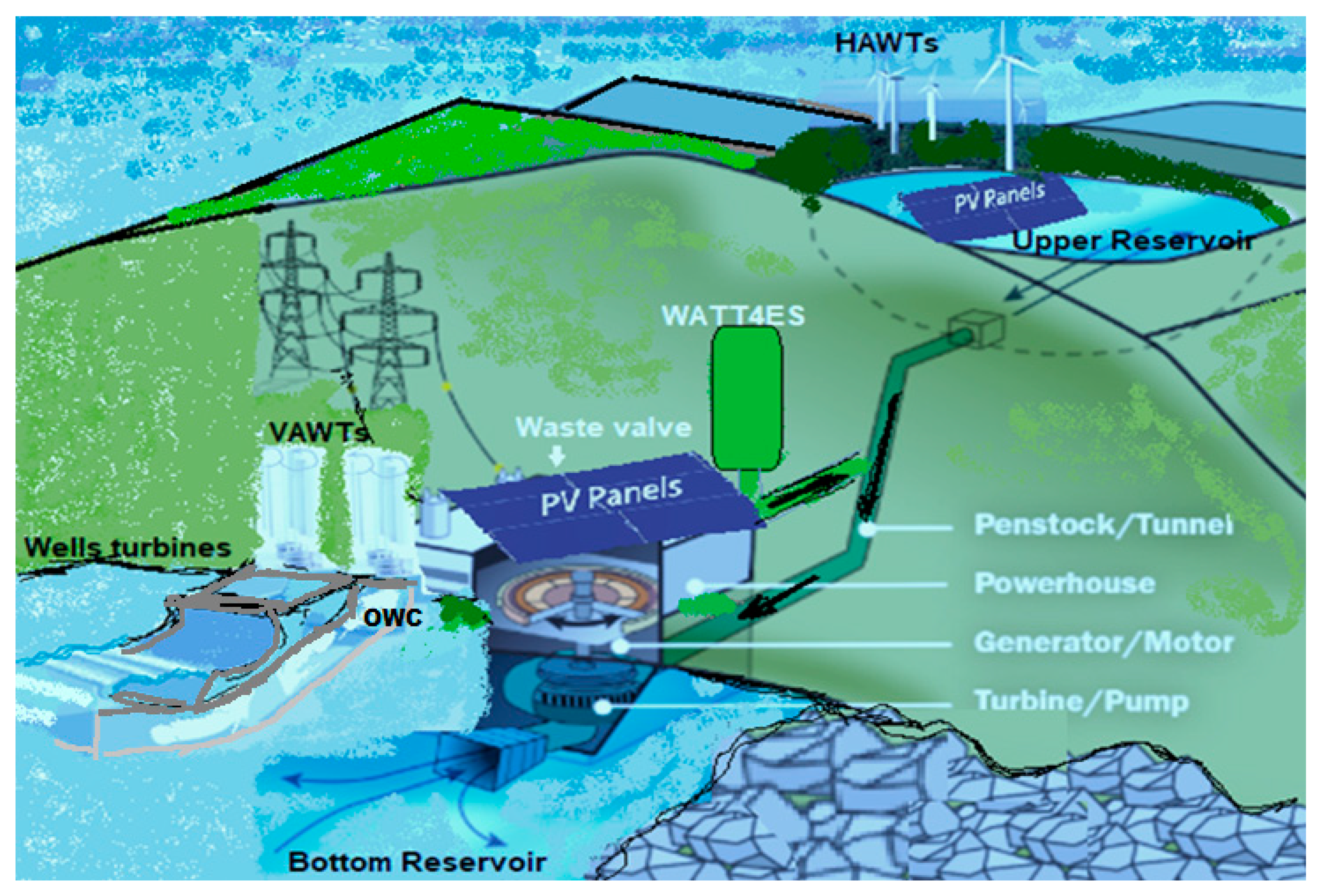

2. Baseline Studies and Fundamentals to Support the New Concept

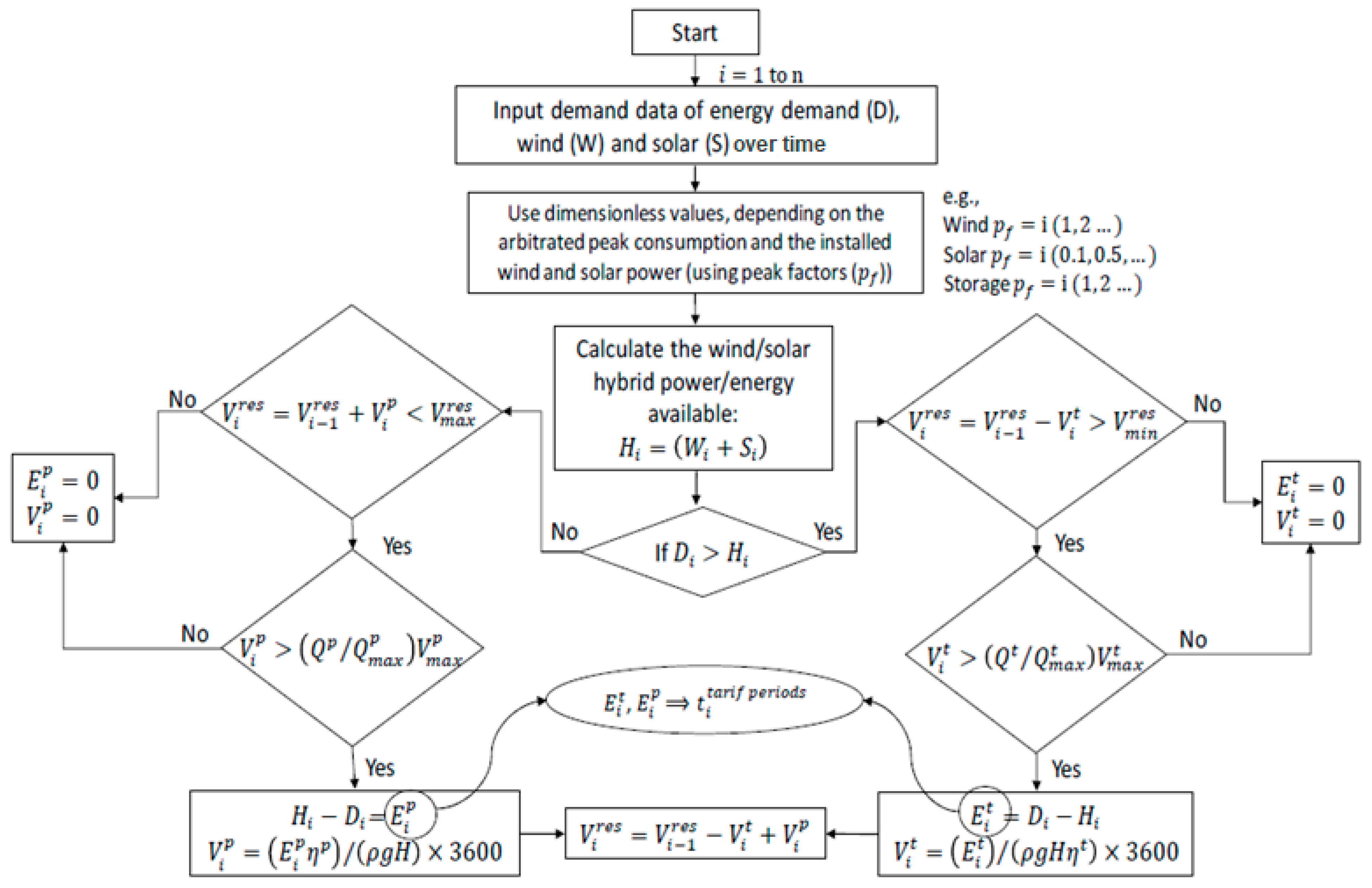

2.1. Pumped Hydropower Energy Storage (PHES)

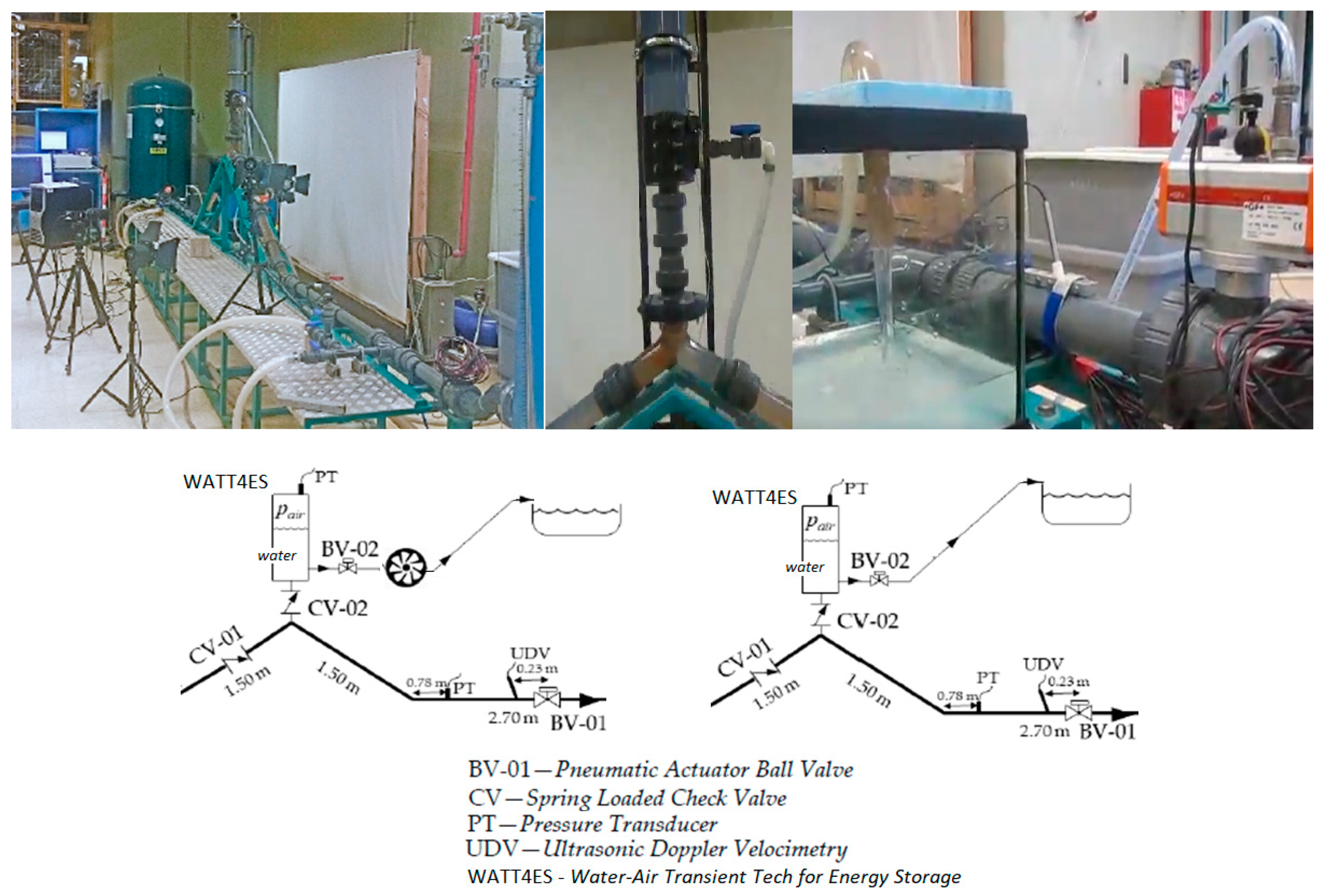

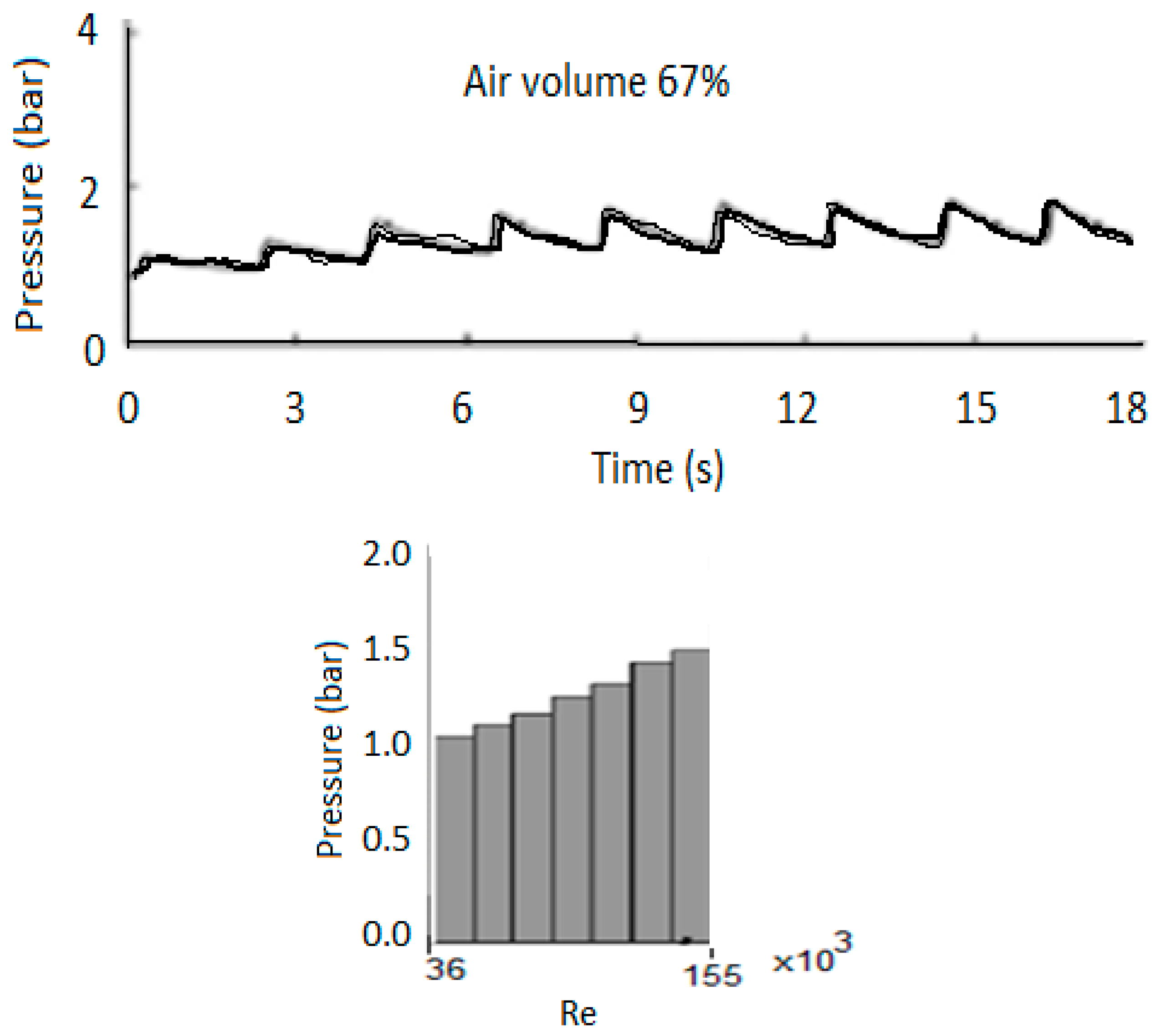

2.2. Water-Air Transient Technology for Energy Storage (WATT4ES)

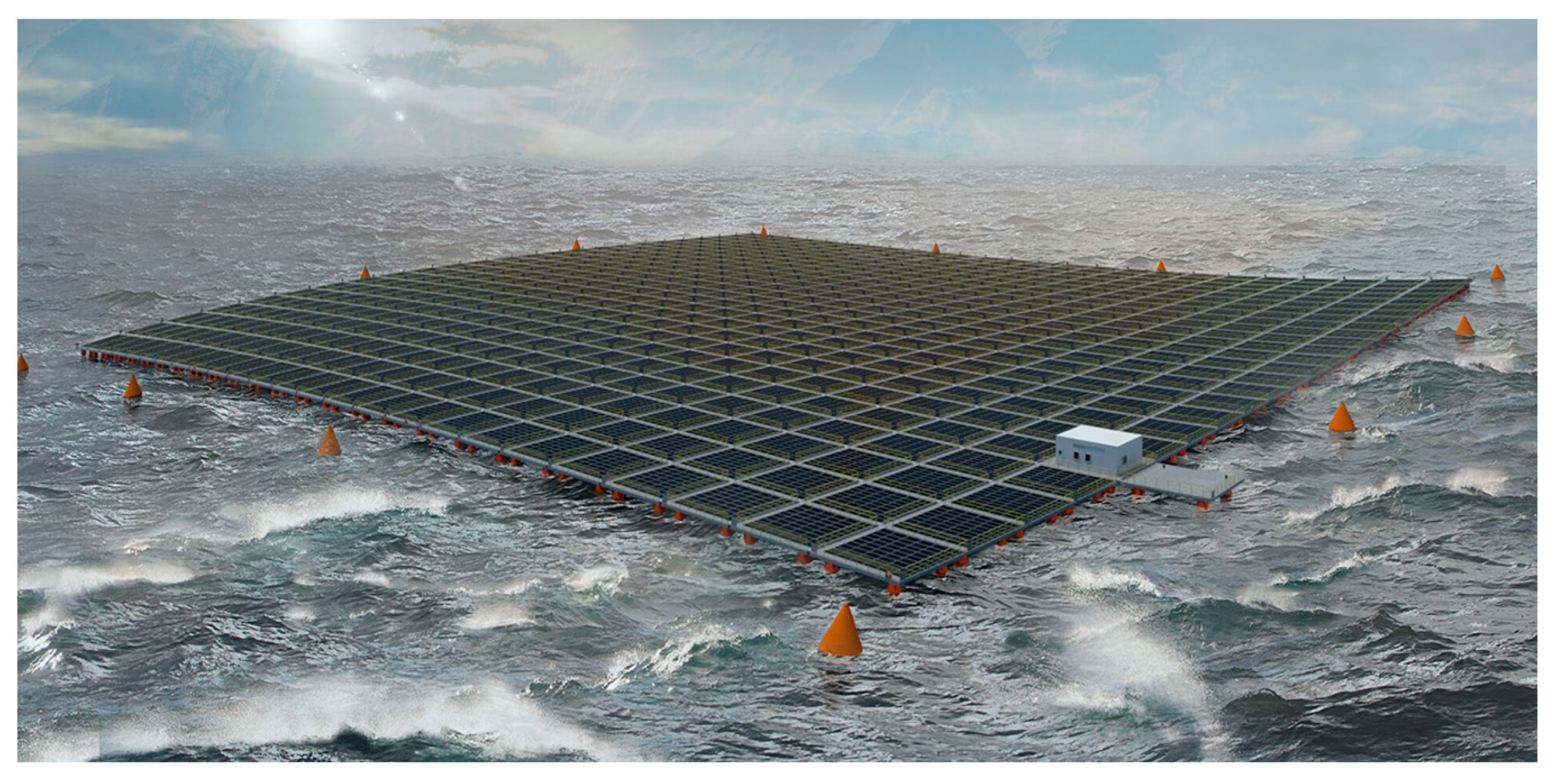

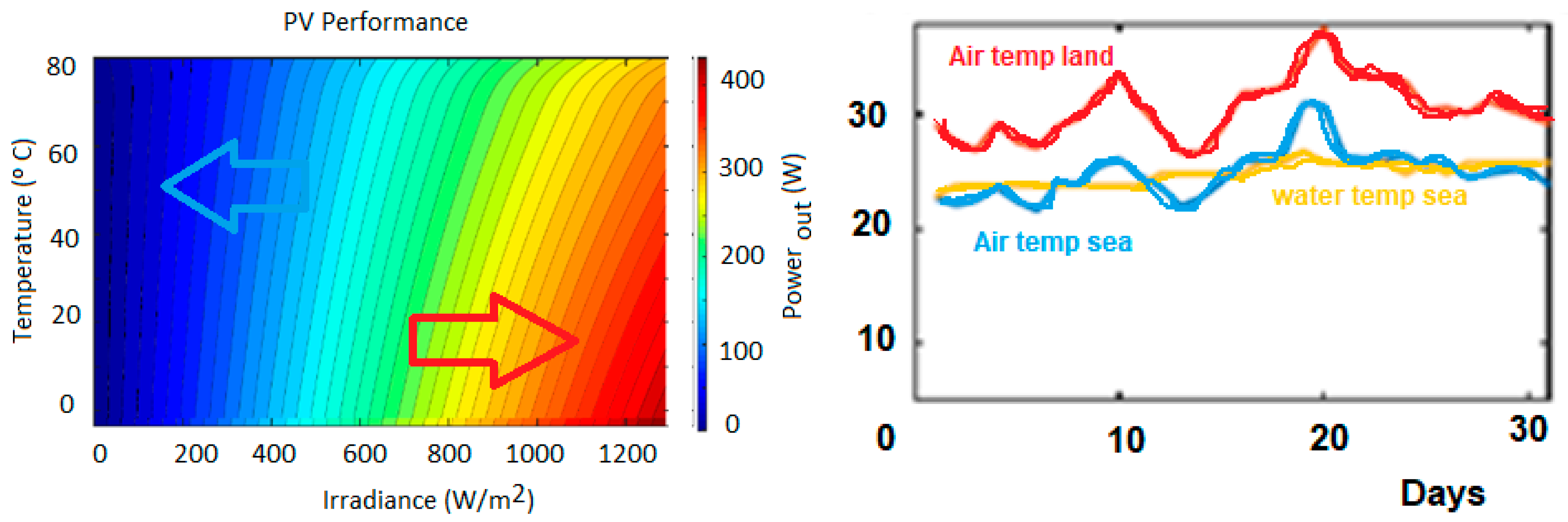

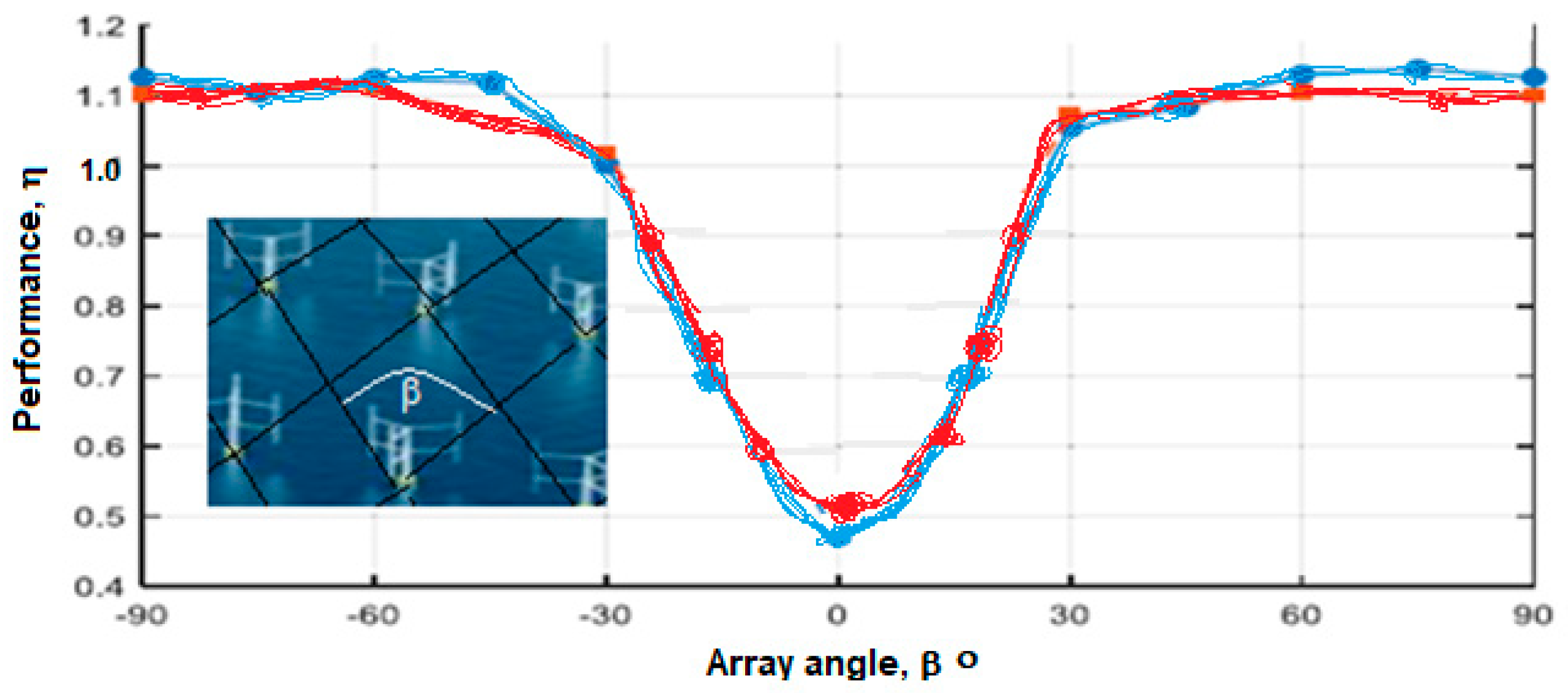

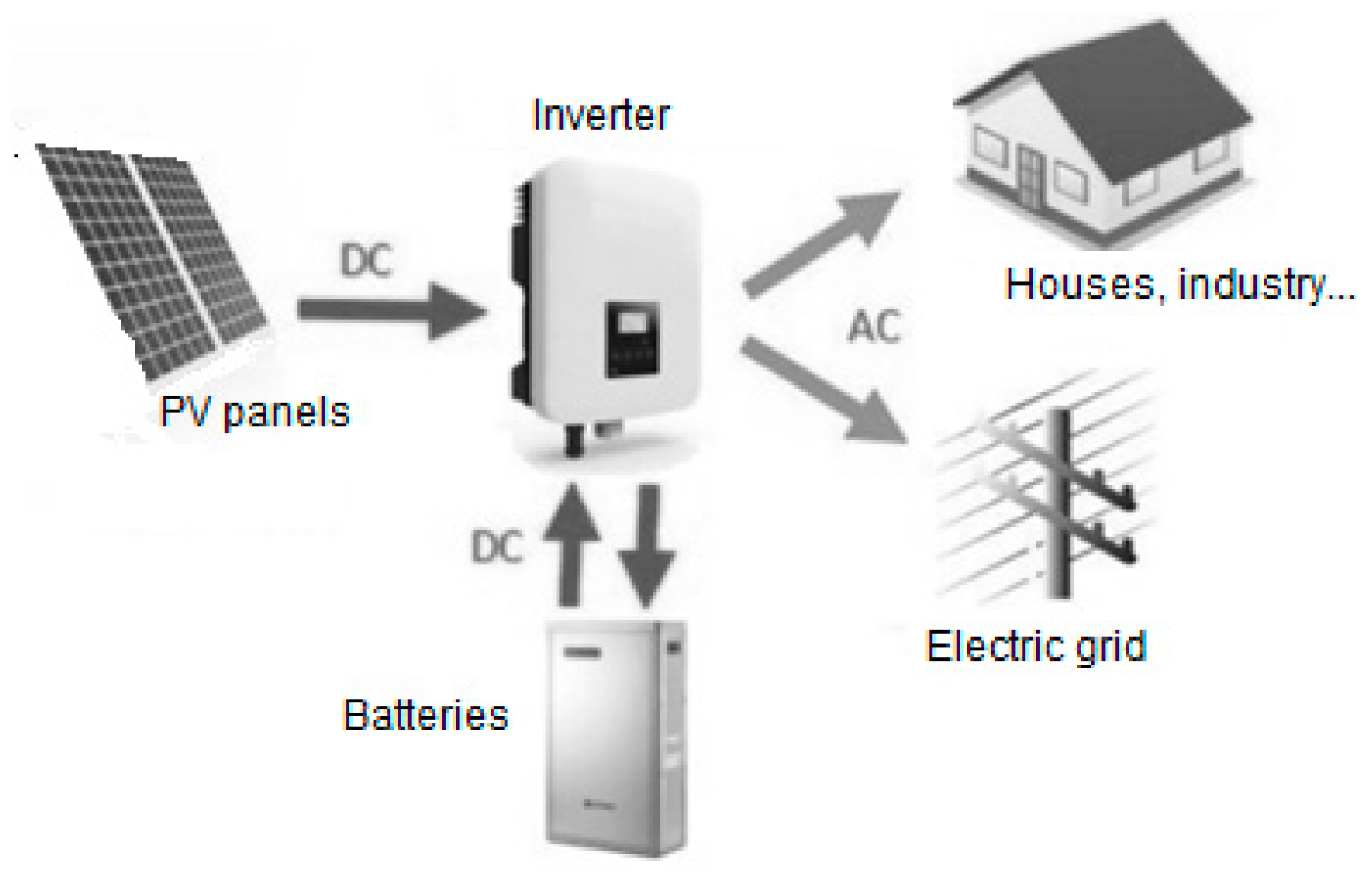

2.3. Solar PV

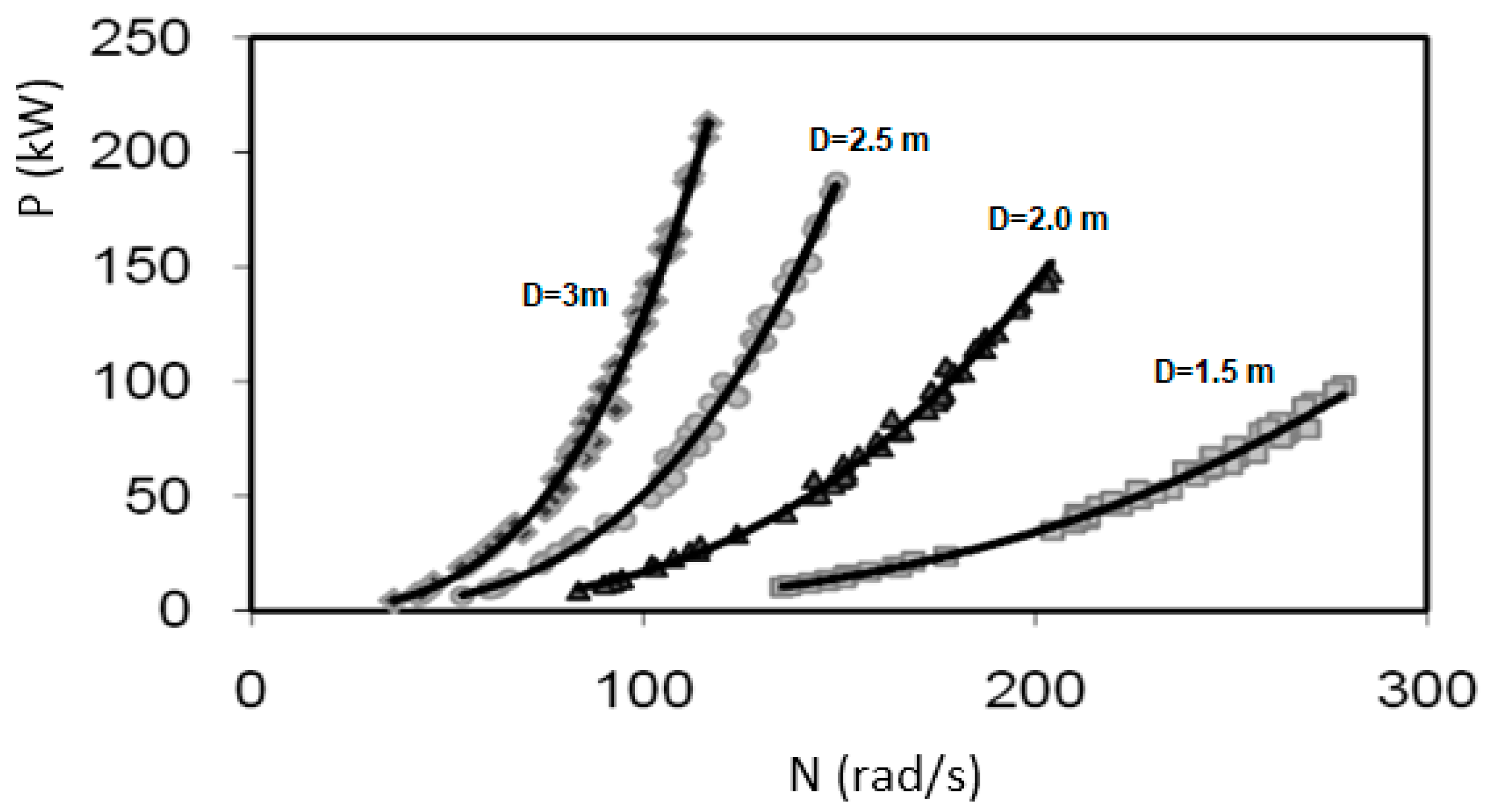

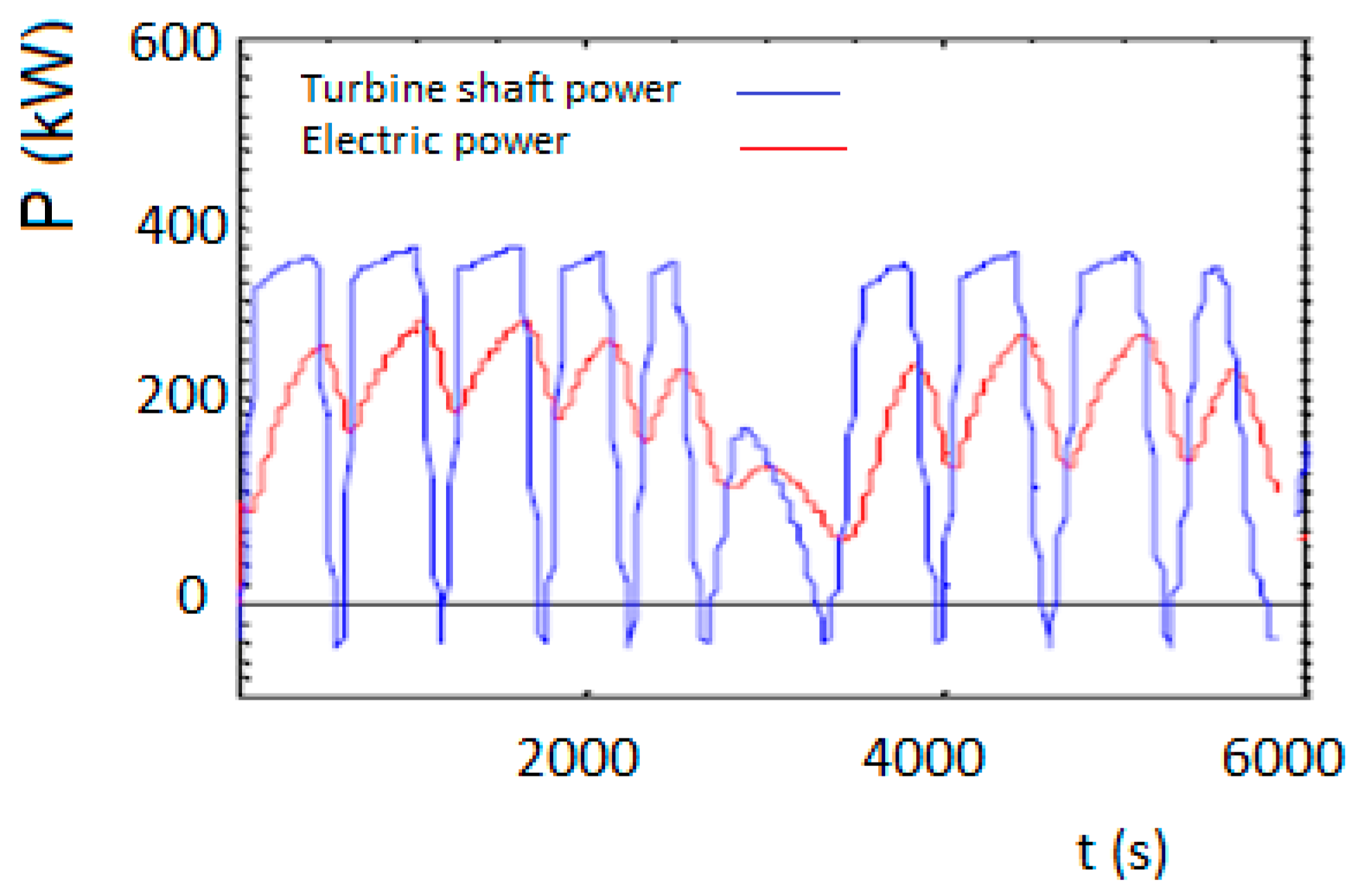

2.4. Oscillating Water Column (OWC) and Wells Turbines

2.5. Wind Turbine

2.6. Green Hydrogen Production and Storage

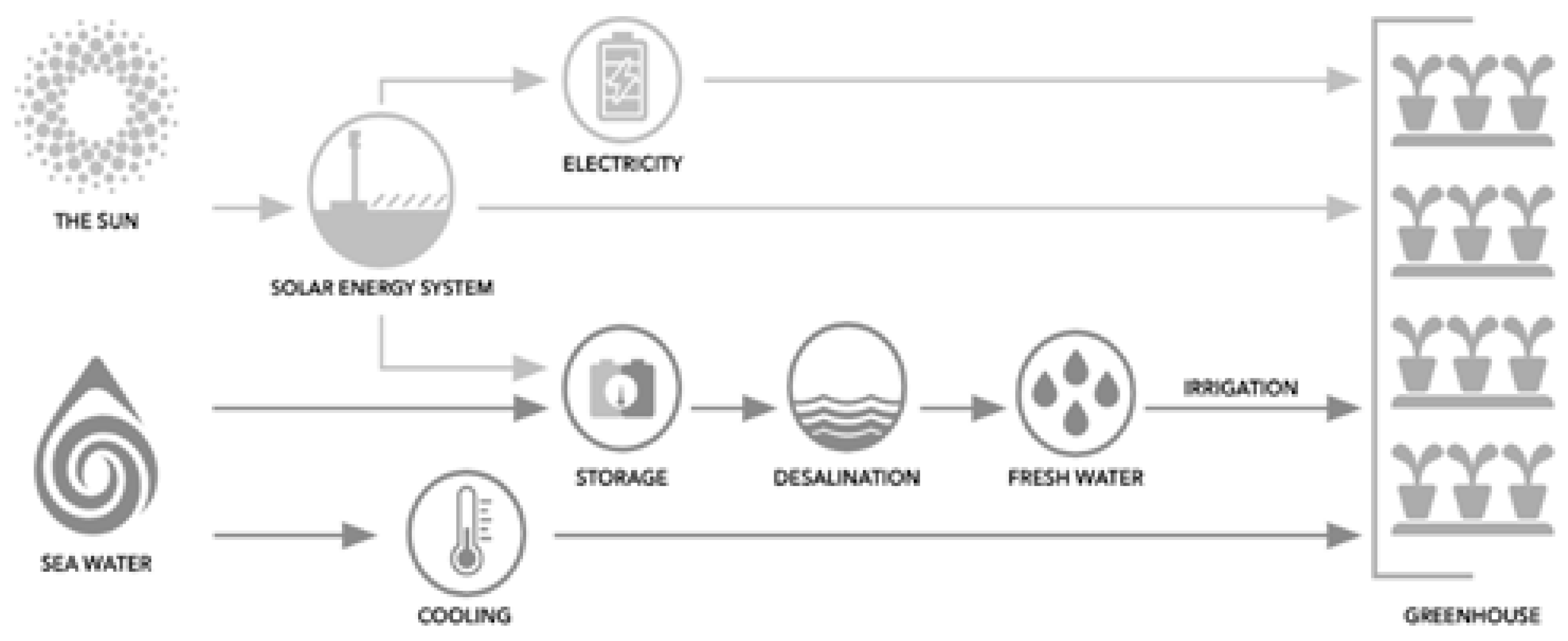

2.7. Desalination

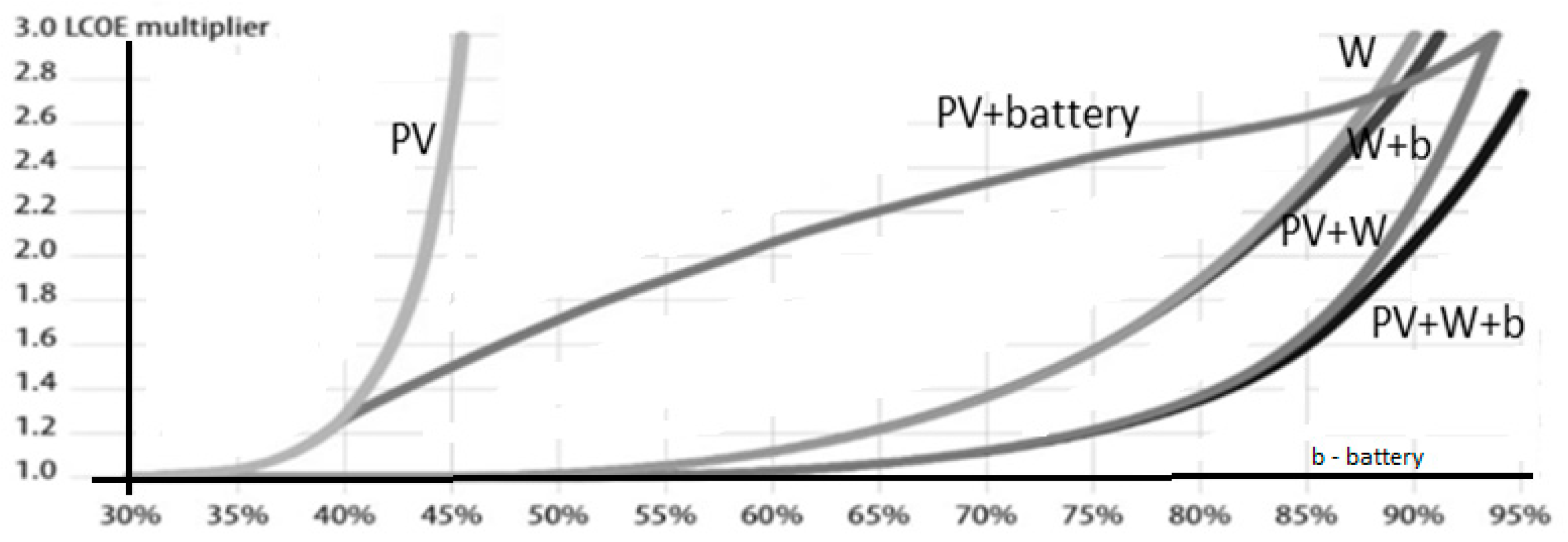

2.8. Batteries

2.9. Power Converters

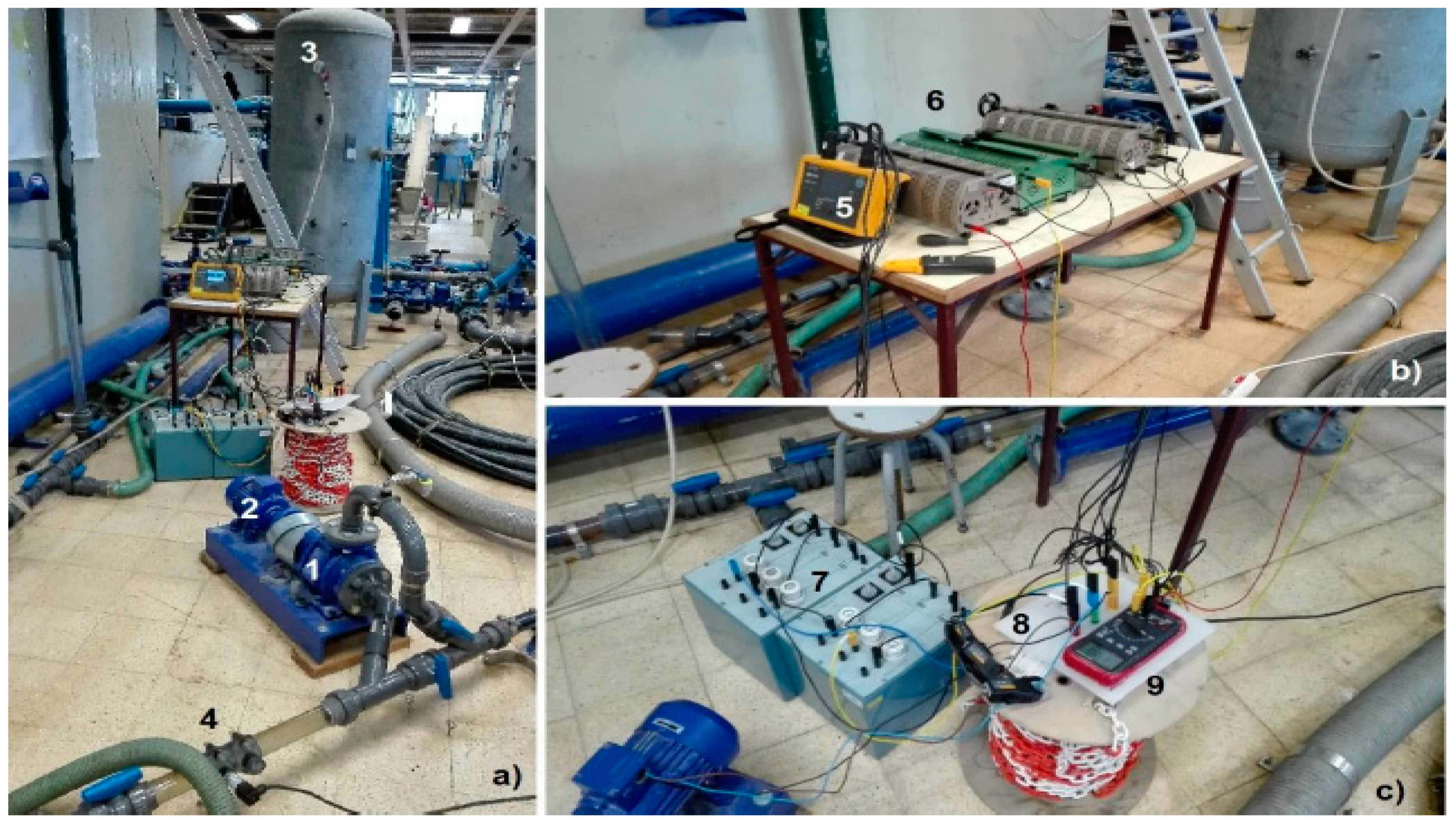

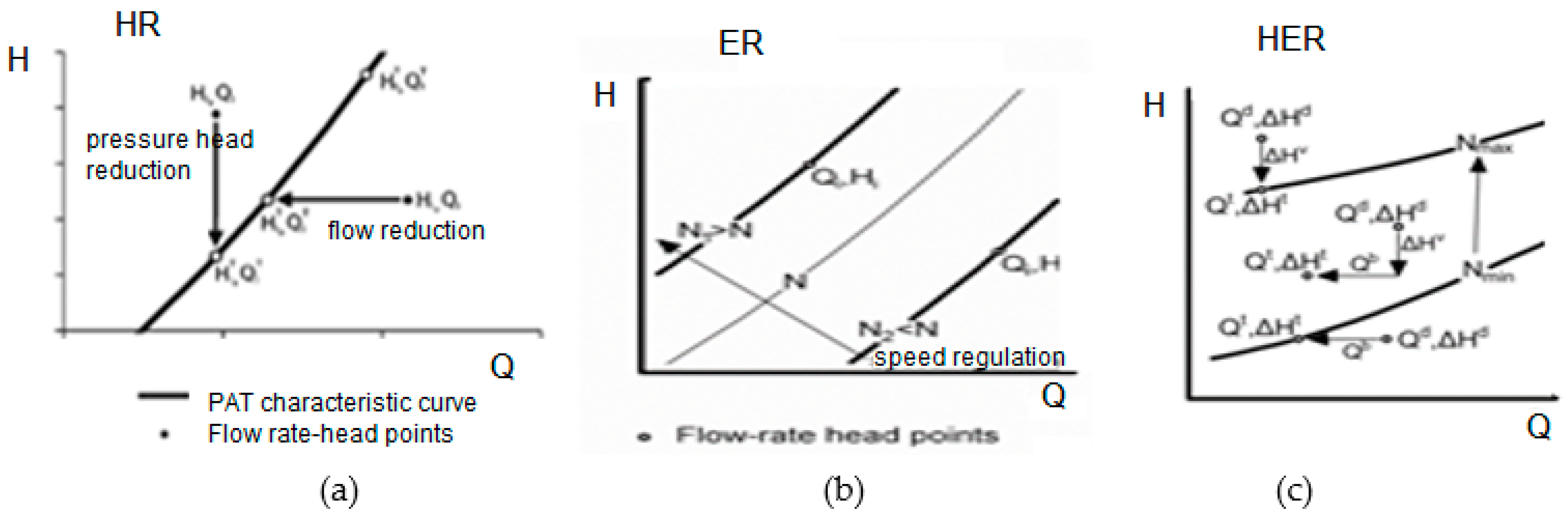

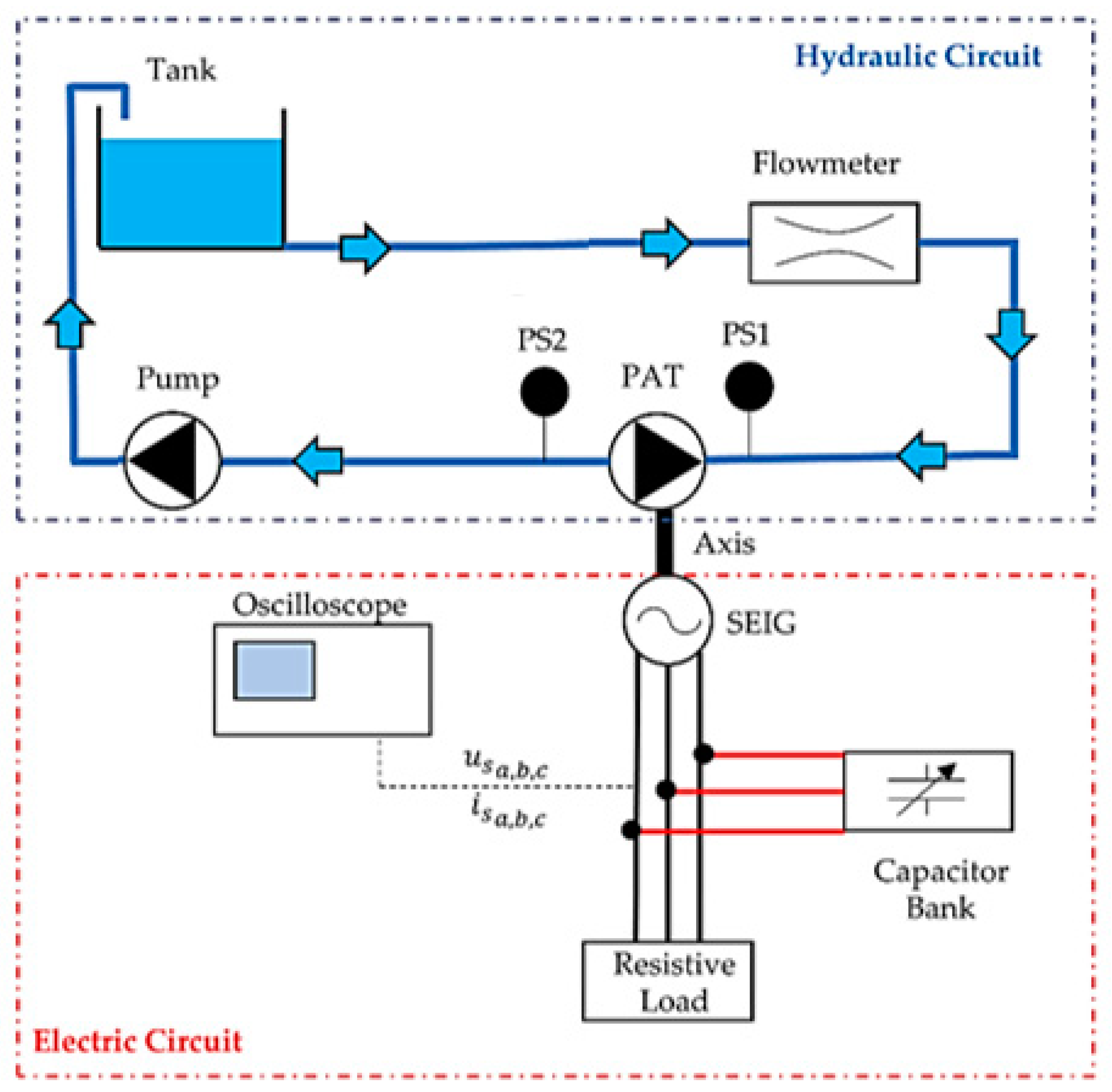

2.10. PAT Self-Excited Induction Generator (PAT-SEIG) Model

3. Materials and Methods of the Idealized Energy Concept

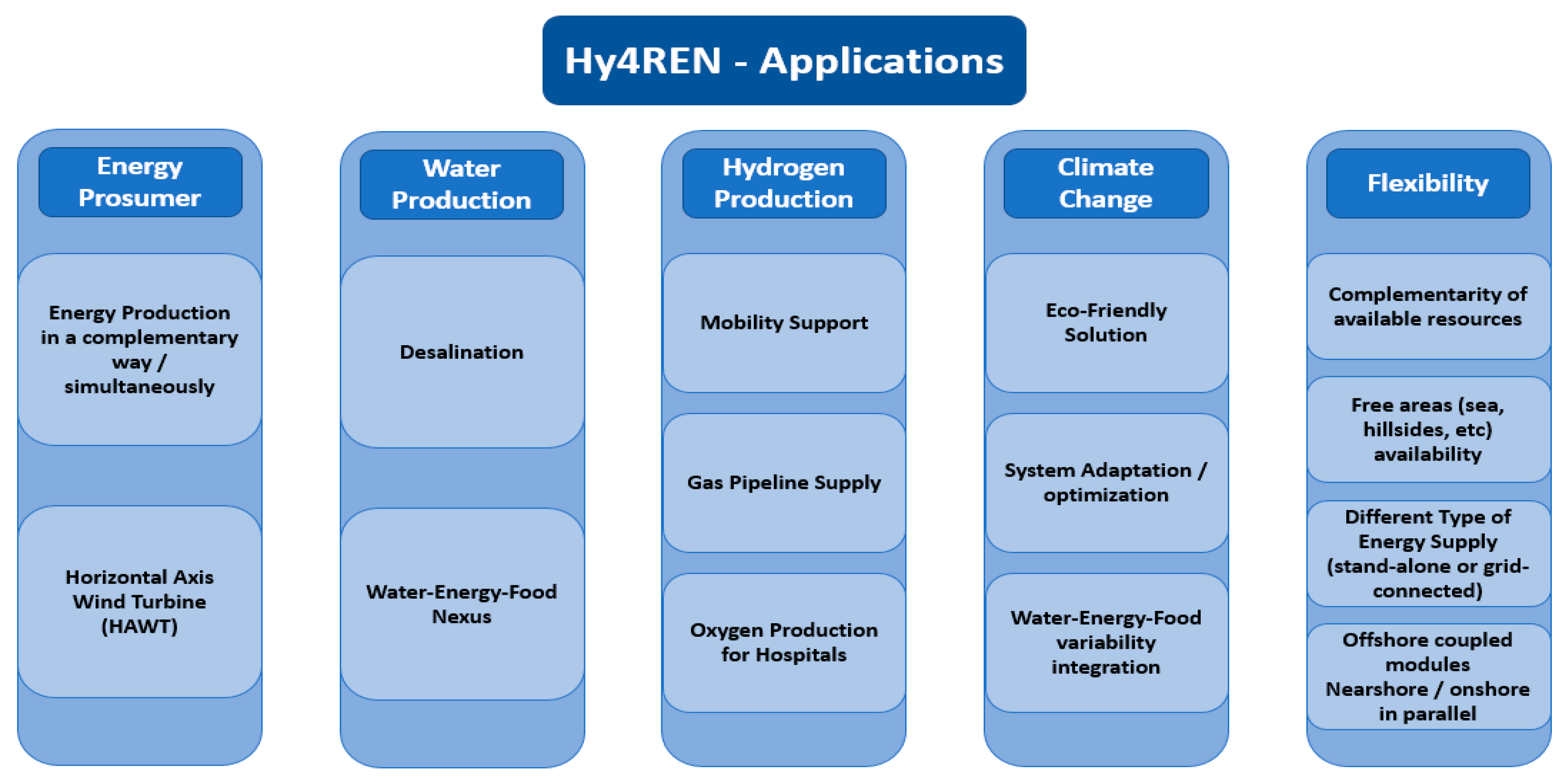

3.1. Reasons for this Research

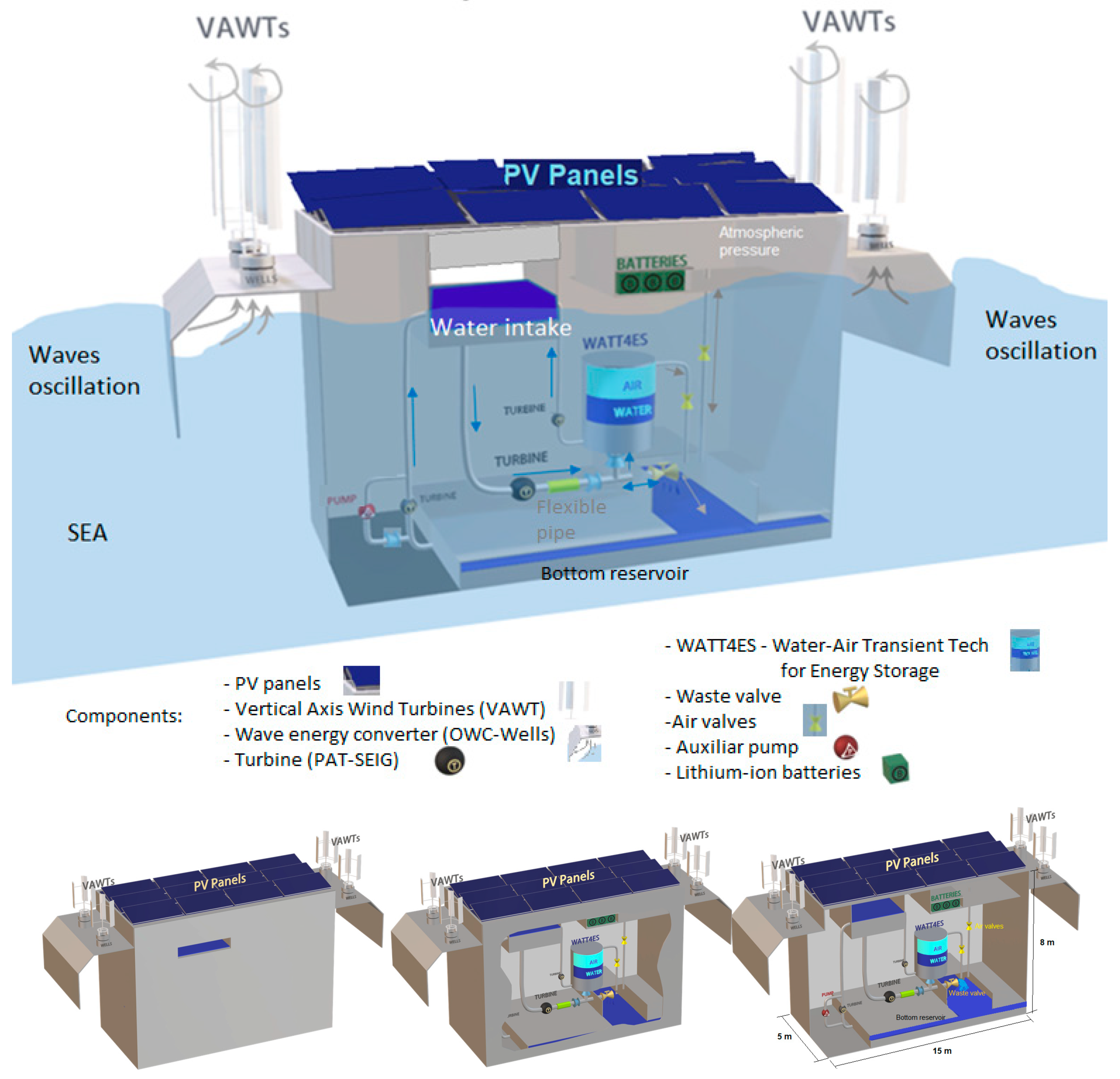

3.2. Conceptualization

3.3. Main Components and Type of Operation

3.3.1. Hydro

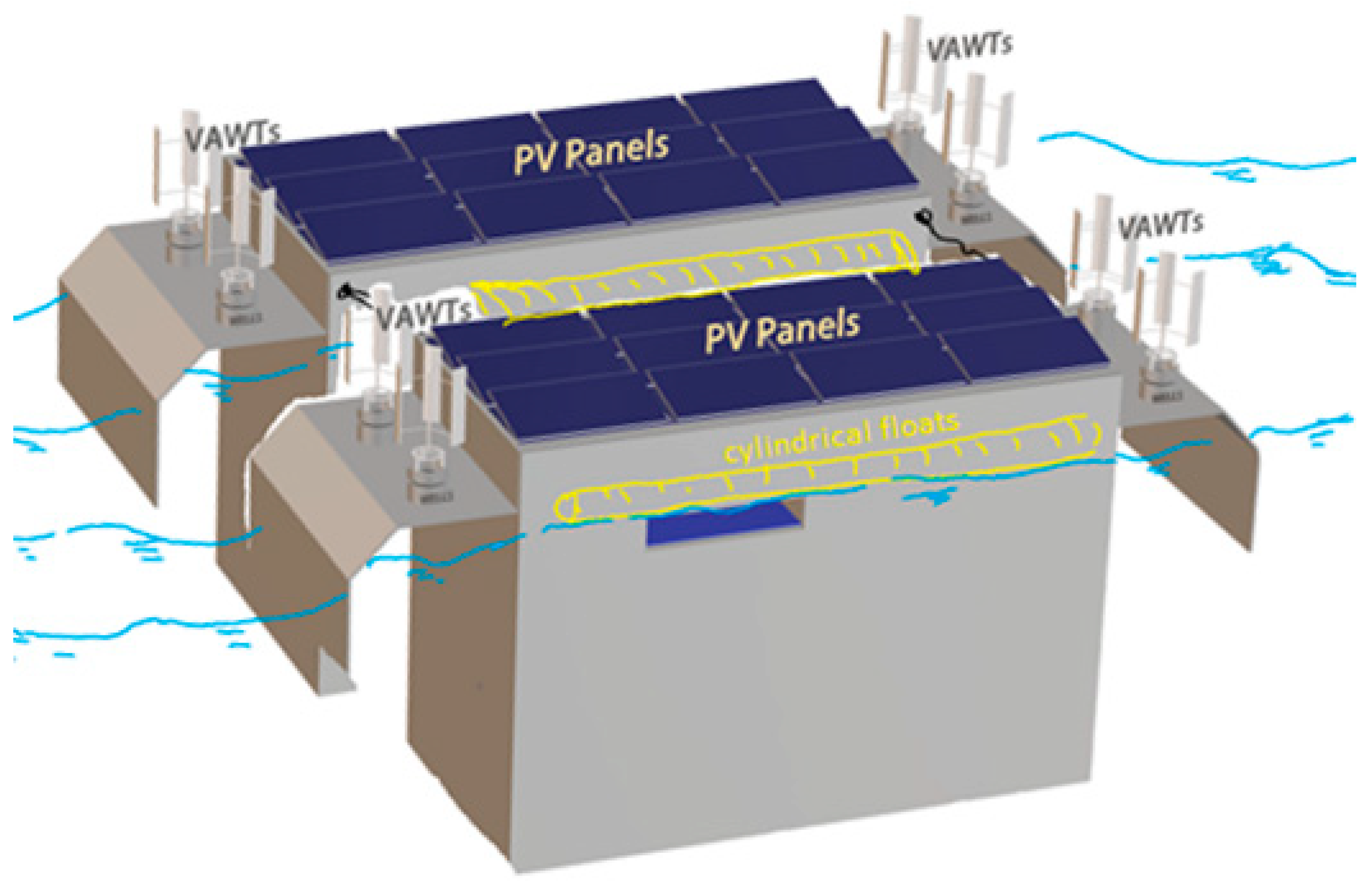

3.3.2. Solar

3.3.3. Wind

3.3.4. Wave or Sea Water Surface Oscillation

3.3.5. Energy Storage System

3.4. Expected Impacts

4. Design Evaluation and Business Model

4.1. Innovative Design Configuration of the Coupled System

4.2. Pumped Hydropower Storage

4.3. Solar PV

4.4. Wind Turbines

4.5. Wave Energy Conversion

4.6. Business Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IHA. The World’s Water Battery: Pumped Hydropower Storage and the Clean Energy Transition; International Hydropower Association, IHA Working Paper: London, UK, 2018. [Google Scholar]

- IHA. Pumped Storage Hydropower Has ‘Crucial Role’ in Europe’s Energy Strategy; International Hydropower Association, IHA Working Paper: London, UK, 2020. [Google Scholar]

- Bhandari, B.; Poudel, S.R.; Lee, K.-T.; Ahn, S.-H. Mathematical modeling of hybrid renewable energy system: A review on small hydro-solar-wind power generation. Int. J. Precis. Eng. Manuf. Technol. 2014, 1, 157–173. [Google Scholar] [CrossRef]

- Available online: https://pplware.sapo.pt/informacao/marrocos-vai-instalar-um-dos-cabos-submarinos-mais-longos-do-mundo-para-enviar-eletricidade/ (accessed on 25 April 2022).

- Hong, C.-M.; Ou, T.-C.; Lu, K.-H. Development of intelligent MPPT (maximum power point tracking) control for a grid-connected hybrid power generation system. Energy 2013, 50, 270–279. [Google Scholar] [CrossRef]

- Kapsali, M.; Kaldellis, J. Combining hydro and variable wind power generation by means of pumped-storage under economically viable terms. Appl. Energy 2010, 87, 3475–3485. [Google Scholar] [CrossRef]

- Xu, B.; Chen, D.; Venkateshkumar, M.; Xiao, Y.; Yue, Y.; Xing, Y.; Li, P. Modeling a Pumped Storage Hydropower Integrated to a Hybrid pEnergy Storage News. Available online: https://www.energy-storage.news/blogs/storage-will-be-vital-for-hydrogen-to-help-solve-renewable-energys-big-chal (accessed on 9 February 2022).

- Energy Storage News. Available online: https://event.webinarjam.com/register/264/4qqkks6y (accessed on 3 November 2021).

- Simão, M.; Ramos, H.M. Hybrid pumped hydro storage energy solutions towards wind and PV integration: Improvement on flexibility, reliability and energy costs. Water 2020, 12, 2457. [Google Scholar] [CrossRef]

- Besharat, M.; Dadfar, A.; Viseu, M.; Brunone, B.; Ramos, H.M. Transient-flow induced compressed air energy storage (TI-CAES) system towards new energy concept. Water 2020, 12, 601. [Google Scholar] [CrossRef] [Green Version]

- Fatahi-Alkouhi, R.; Lashkar-Ara, B.; Keramat, A. On the measurement of ram-pump power by changing in water hammer pressure wave energy. Ain Shams Eng. J. 2019, 10, 681–693. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L.; Peng, J. Technical feasibility study on a standalone hybrid solar-wind system with pumped hydro storage for a remote island in Hong Kong. Renew. Energy 2014, 69, 7–15. [Google Scholar] [CrossRef]

- Bajpai, P.; Dash, V. Hybrid renewable energy systems for power generation in stand-alone applications: A review. Renew. Sustain. Energy Rev. 2012, 16, 2926–2939. [Google Scholar] [CrossRef]

- Golroodbari, S.Z.; Van Sark, W. Simulation of performance differences between offshore and land-based photovoltaic systems. Prog. Photovolt. Res. Appl. 2020, 28, 873–886. [Google Scholar] [CrossRef]

- Breyer, C.; Bogdanov, D.; Aghahosseini, A.; Gulagi, A.; Child, M.; Oyewo, A.S.; Farfan, J.; Sadovskaia, K.; Vainikka, P. Solar photovoltaics demand for the global energy transition in the power sector. Prog. Photovolt. Res. Appl. 2017, 26, 505–523. [Google Scholar] [CrossRef]

- Jager-Waldau, A. Snapshot of Photovoltaics—February 2019. Available online: https://www.mdpi.com/1996-1073/12/5/769 (accessed on 17 November 2021).

- Haysom, J.E.; Jafarieh, O.; Anis, H.; Hinzer, K.; Wright, D. Learning curveanalysis of concentrated photovoltaic systems. Prog. Photovolt. Res. Appl. 2014, 23, 1678–1686. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Cicu, M.; Rosa-Clot, M.; Tina, G.M.; Ventura, C. Floating photovoltaic plants: Performance analysis and design solutions. Renew. Sustain. Energy Rev. 2018, 81, 1730–1741. [Google Scholar] [CrossRef]

- Pringle, A.M.; Handler, R.; Pearce, J. Aquavoltaics: Synergies for dual use of water area for solar photovoltaic electricity generation and aquaculture. Renew. Sustain. Energy Rev. 2017, 80, 572–584. [Google Scholar] [CrossRef] [Green Version]

- OWC Pico Power Plant Website. Available online: http://www.pico-owc.net/ (accessed on 8 October 2014).

- Corvelo, E. Analysis and Performance Comparison of an OWC Wave Power Plant Equipped with Wells and Impulse Turbines. Master’s Thesis, Instituto Superior Técnico, Lisboa, Portugal, 2009. Available online: https://fenix.tecnico.ulisboa.pt/downloadFile/395142732839/dissertacao%20eugenio%20corvelo.pdf (accessed on 17 November 2021).

- Sarmento, A.; Melo, A.B.; Pontes, M.T. The Influence of the wave climate on the design and annual production of electricity by OWC wave power plants. In Proceedings of the 20th International Conference on Offshore Mechanics and Arctic Engineering, Rio de Janeiro, Brazil, 3–8 June 2001. [Google Scholar]

- Mendes, A.C. Preliminary Design of a Power Take-Off System for the Breakwater-Integrated Oscillating Water Column at Leixões Harbour. Master’s Thesis, Instituto Superior Técnico, Lisboa, Portugal, 2019. [Google Scholar]

- Hansen, J.T.; Mahak, M.; Tzanakis, I. Numerical modelling and optimization of vertical axis wind turbine pairs: A scale up approach. Renew. Energy 2021, 171, 1371–1381. [Google Scholar] [CrossRef]

- Henriques, J.; Lopes, M.; Gomes, R.; Gato, L.; Falcão, A. On the annual wave energy absorption by two-body heaving WECs with latching control. Renew. Energy 2012, 45, 31–40. [Google Scholar] [CrossRef]

- SciTechDaily. Available online: https://scitechdaily.com/more-compact-and-efficient-vertical-turbines-could-be-the-future-for-wind-farms/ (accessed on 8 October 2021).

- Bianchini, A.; Balduzzi, F.; Bachant, P.; Ferrara, G.; Ferrari, L. Effectiveness of two-dimensional CFD simulations for Darrieus VAWTs: A combined numerical and experimental assessment. Energy Convers. Manag. 2017, 136, 318–328. [Google Scholar] [CrossRef]

- PV Magazine. Available online: https://www.pv-magazine.com/2021/05/29/the-weekend-read-age-of-green-hydrogen-causes-co-location-rethink/ (accessed on 10 October 2021).

- Robbins, J. As Water Scarcity Increases, Desalination Plants Are on the Rise, Yale Environment 360. Available online: https://e360.yale.edu/features/as-water-scarcity-increases-desalination-plants-are-on-the-rise (accessed on 25 June 2021).

- Bundschuh, J.; Kaczmarczyk, M.; Ghaffour, N.; Tomaszewska, B. State-of-the-art of renewable energy sources used in water desalination: Present and future prospects. Desalination 2021, 508, 115035. [Google Scholar] [CrossRef]

- EcoSaviour Engineers. Available online: https://www.indiamart.com/proddetail/hybrid-solar-pv-power-plant-with-battery-backup-19669763973.html (accessed on 10 April 2022).

- Fernandes, J.F.; Pérez-Sánchez, M.; da Silva, F.F.; López-Jiménez, P.A.; Ramos, H.M.; Branco, P.C. Optimal energy efficiency of isolated PAT systems by SEIG excitation tuning. Energy Convers. Manag. 2019, 183, 391–405. [Google Scholar] [CrossRef]

- Ramos, H.M.; Dadfar, A.; Besharat, M.; Adeyeye, K. Inline pumped storage hydropower towards smart and flexible energy recovery in water networks. Water 2020, 12, 2224. [Google Scholar] [CrossRef]

- Carravetta, A.; Del Giudice, G.; Fecarotta, O.; Ramos, H.M. Pump as turbine (PAT) design in water distribution network by system effectiveness. Water 2013, 5, 1211–1225. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Sánchez, M.; López-Jiménez, P.A.; Ramos, H.M. Modified affinity laws in hydraulic machines towards the best efficiency line. Water Resour. Manag. 2017, 32, 829–844. [Google Scholar] [CrossRef] [Green Version]

- Fecarotta, O.; Ramos, H.M.; Derakhshan, S.; Del Giudice, G.; Carravetta, A. Fine tuning a PAT hydropower plant in a water supply network to improve system effectiveness. J. Water Resour. Plan. Manag. 2018, 144, 04018038. [Google Scholar] [CrossRef]

- Carravetta, A.; Houreh, S.D.; Ramos, H.M. Pumps as Turbines; Springer Tracts in Mechanical Engineering; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Pugliese, F.; De Paola, F.; Fontana, N.; Giugni, M.; Marini, G. Experimental characterization of two Pumps As Turbines for hydropower generation. Renew. Energy 2016, 99, 180–187. [Google Scholar] [CrossRef]

- McNabola, A.; Coughlan, P.; Corcoran, L.; Power, C.; Williams, A.P.; Harris, I.; Gallagher, J.; Styles, D. Energy recovery in the water industry using micro-hydropower: An opportunity to improve sustainability. Water Policy 2014, 16, 168–183. [Google Scholar] [CrossRef]

- Pérez-Sánchez, M.; Fernandes, J.; Branco, P.; López-Jiménez, P.; Ramos, H. PATs behavior in pressurized irrigation hydrants towards sustainability. Water 2021, 13, 1359. [Google Scholar] [CrossRef]

| ∀ WATT4ES|m (m3) | Air Volume (%) | ∀ Air (m3) | D (m) | p (kPa) | Q (m3/s) | Phyd (kW) | E (kWh) |

|---|---|---|---|---|---|---|---|

| 4.70 | 33 | 1.55 | 0.2 | 1467 | 0.08 | 124 | 1.96 |

| 50 | 2.33 | 1452 | 0.09 | 131 | 2.08 | ||

| 67 | 3.10 | 1379 | 0.09 | 125 | 1.98 |

| Turbine/Characteristics | D (m) | Shaft Power (kW) | Efficiency (%) |

|---|---|---|---|

| Wells with rotational speed limits and relief valve | 1.5 | 71 | 0.6 |

| 2.0 | 91 | 0.6 | |

| 2.5 | 102 | 0.59 | |

| 3.0 | 103 | 0.55 |

| Hydropower Component | ||

|---|---|---|

| Equivalent diameter | m | 0.24 |

| Velocity | m/s | 3 |

| Equivalent flow | m3/s | 0.136 |

| Efficiency η | - | 0.65 |

| Equivalent head | m | 12 |

| Equivalent friction losses | m | 0.54 |

| Turbine Power | kW | 9.91 |

| Turbine Flow Volume | hm3 | 4.28 |

| Energy Produced/year | MWh | 86.8 |

| WATT4ES | ||

|---|---|---|

| Drive head | m | 2 |

| Drive pipe diameter | m | 0.23 |

| Drive pipe length | m | 3 |

| Diameter Hydram body | m | 0.1725 |

| Delivery pipe diameter | m | 0.08 |

| Delivery pipe length | m | 10.2 |

| Static delivery head | m | 12 |

| Waste valve stroke | m | 0.008 |

| Waste valve mass | kg | 1.08 |

| Delivery flow | m3/s | 0.0504 |

| Hydram Efficiency η | - | 0.42 |

| WATT4ES volume | m3 | 5.8 |

| Air fraction | - | 0.33 |

| Air Volume | m3 | 1.914 |

| Internal pressure | kPa | 1467 |

| Turbined flow | m3/s | 0.08 |

| WATT4ES Efficiency η | - | 0.66 |

| Auxiliary Electrical Pump | ||

|---|---|---|

| Residual flow | m3/s | 0.085 |

| Pump rated flow | m3/s | 0.054 |

| Rated Power 3 | kW | 3.7 |

| Efficiency η | - | 0.72 |

| Volume pumped | hm3 | 2.421 |

| Energy consumed/year | MWh | 23.3 |

| Average Solar PV Irradiance | ||

|---|---|---|

| Month | W/m2 | |

| Jan | 135.2 | |

| Feb | 165.71 | |

| Mar | 192.18 | |

| Apr | 233.13 | |

| May | 262.55 | |

| Jun | 273.28 | |

| Jul | 296.37 | |

| Aug | 294.31 | |

| Sep | 240.65 | |

| Oct | 192.16 | |

| Nov | 155.46 | |

| Dec | 136.37 | |

| Total | 214.78 | |

| Solar FPV Component | ||

| Module | Jinko 400W Cheetah | |

| N° Panels | 16 | |

| Panel Power | W | 400 |

| PV panels area | m2 | 30.5 |

| Power installed | kW | 6.4 |

| Tilt | °C | 15 |

| Average T° | °C | 16.5 |

| Average Irradiation | Wh/m2 | 1750 |

| Average Irradiance | Wh/m2 | 214.8 |

| Energy Produced/year | MWh | 11 |

| Wind Component (One Turbine) | ||

|---|---|---|

| Roughness length | m | 0.0002 |

| Air density | kg/m3 | 1.23 |

| Wind Velocity | m2/s | 6.85 |

| Swept Area | m2 | 3.8 |

| Power available | kW | 0.75 |

| Efficiency η (Betz Limit) | - | 0.54 |

| Power produced | kW | 0.41 |

| Number of wind turbines | Power | |

| 1 | kW | 0.41 |

| 2 | 0.81 | |

| 3 | 1.22 | |

| 4 | 1.62 | |

| Capacity factor | - | 0.33 |

| Energy Produced/year | MWh | 4.7 |

| OWC Component | ||

|---|---|---|

| Wave amplitude | m | 1.6 |

| Wave period | s | 7.8 |

| Water density | kg/m3 | 1025 |

| Volume of Air Chamber | m3 | 13.44 |

| Power Wave | kW/m | 9.78 |

| Maximum Power | kW | 993.57 |

| Radiation conductance | m4s/kg | 0.000136 |

| Radiation susceptance | m4s/kg | 0.00131 |

| Equivalent inner structure radius | m | 2 |

| Excitation flow rate amplitude | m3/s | 36.45 |

| Turbine diameter | m | 0.5 |

| Air density | kg/m3 | 1.23 |

| Pressure oscillation | Pa | 69 |

| Power absorbed | kW | 9.68 |

| Turbine power | kW | 6.53 |

| Efficiency η | - | 0.67 |

| Energy Produced/year | MWh | 38.1 |

| Batteries | ||

|---|---|---|

| Model | Discover AES | |

| Total Capacity | kWh | 7.4 |

| Output Power | KW | 6.65 |

| Surge/Peak Power | KW | 15.3 |

| Warranty | years | 10 |

| Hy4REN Project Investment Costs | |

|---|---|

| Hydraulic System | €1100 |

| Electrical System | €12,300 |

| Automation and Control | €9000 |

| Module Structure | €12,600 |

| Moorings | €2500 |

| Buoyancy System | €9800 |

| Installation Cost | €61,000 |

| Hydropower Component Costs | |

| Upper tank | €200 |

| Bottom reservoir tank | €300 |

| Inlet funnel + Filter | €90 |

| Pressure Stainless Steel Pipe | €410 |

| Flexible pipe | €120 |

| WATT4ES vessel | €600 |

| Turbine PAT-SEIG | €2550 |

| Water Pump 10 HP | €1672 |

| Secondary Turbine | €1020 |

| Solar PV Floating Costs | |

| Solar Panels 400 W | €2448 |

| Inverter | €1290 |

| Batteries 7.4 kW | €920 |

| Wind Power Component Costs | |

| Vertical Wind Turbines 340 W | €350 |

| Wave Energy Converter Costs | |

| Wells Turbine 9 kW | €475 |

| Total | €120,745 |

| Economic Assessment | |

|---|---|

| Initial Investment | €120,745 |

| O&M | €3864 |

| Licenses | €2700 |

| Pump replacement | €1672 |

| Batteries replacement | €920 |

| Insurance | €6300 |

| Sales of electricity | €25,061 |

| Discount rate | 5% |

| Project Lifecycle | 25 |

| CO2 emissions savings | €7626 |

| Price of Electricity (€) | 0.21 |

| LCOE (€/MW) | 105.95 |

| Payback Period (years) | 7.5 |

| NPV (€) | 156,426 |

| IRR (%) | 16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, H.M.; Vargas, B.; Saldanha, J.R. New Integrated Energy Solution Idealization: Hybrid for Renewable Energy Network (Hy4REN). Energies 2022, 15, 3921. https://doi.org/10.3390/en15113921

Ramos HM, Vargas B, Saldanha JR. New Integrated Energy Solution Idealization: Hybrid for Renewable Energy Network (Hy4REN). Energies. 2022; 15(11):3921. https://doi.org/10.3390/en15113921

Chicago/Turabian StyleRamos, Helena M., Brandon Vargas, and João Roquette Saldanha. 2022. "New Integrated Energy Solution Idealization: Hybrid for Renewable Energy Network (Hy4REN)" Energies 15, no. 11: 3921. https://doi.org/10.3390/en15113921

APA StyleRamos, H. M., Vargas, B., & Saldanha, J. R. (2022). New Integrated Energy Solution Idealization: Hybrid for Renewable Energy Network (Hy4REN). Energies, 15(11), 3921. https://doi.org/10.3390/en15113921