Selected Environmental Impact Indicators Assessment of Wind Energy in India Using a Life Cycle Assessment

Abstract

:1. Introduction

2. Literature Review

3. Life Cycle Assessment Methodology

3.1. Goal and Scope of the Present Study

3.1.1. Functional Unit

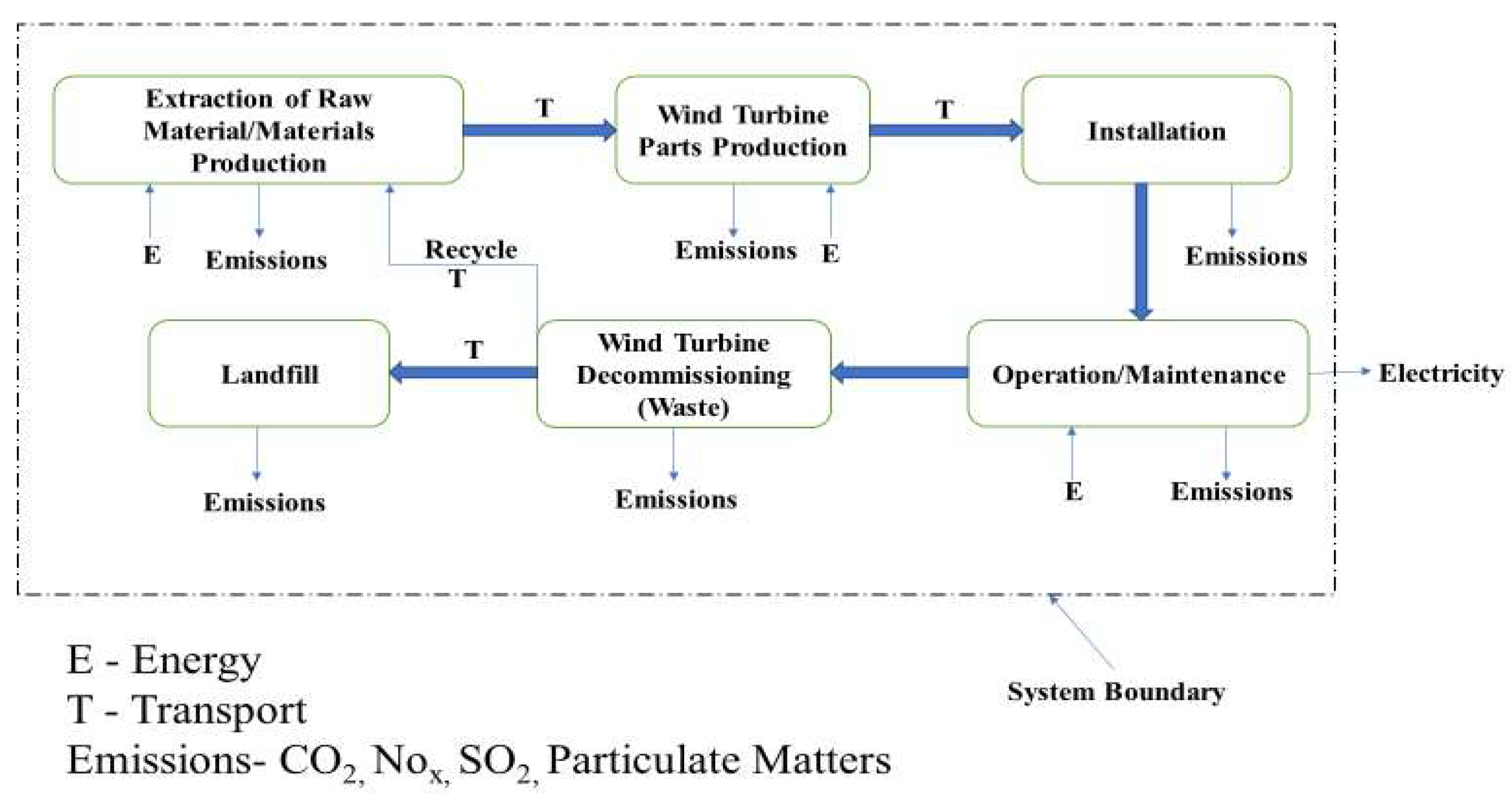

3.1.2. System Boundary

3.2. Material Inventory Assessment

3.2.1. Material Data Used in the Production of a Wind Turbine

3.2.2. Breakdown of Material in a Complete Wind Farm

3.2.3. Calculation of Electricity Production

- CF: Capacity Factor (dimensionless),

- AEP: Annual Energy Production in MWh, Capacity in MW.

4. Results and Discussion

4.1. Environmental Impact of a Complete Wind Farm

4.2. Comparison of the Wind Results with Previous Literature

4.3. Comparison of Wind Power with Coal Scenario and Other Greener Technologies

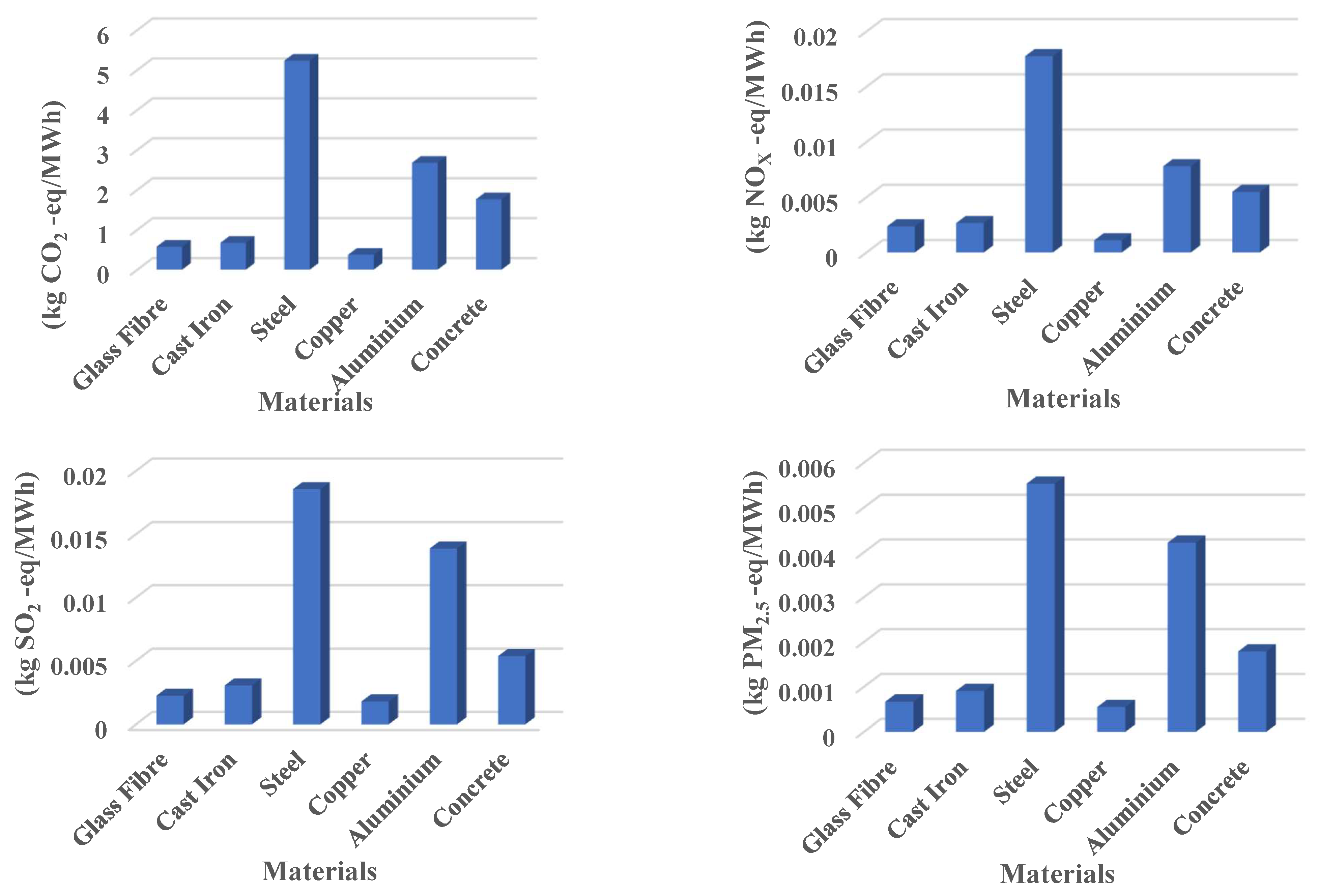

4.4. Pollutant Emissions from Different Materials

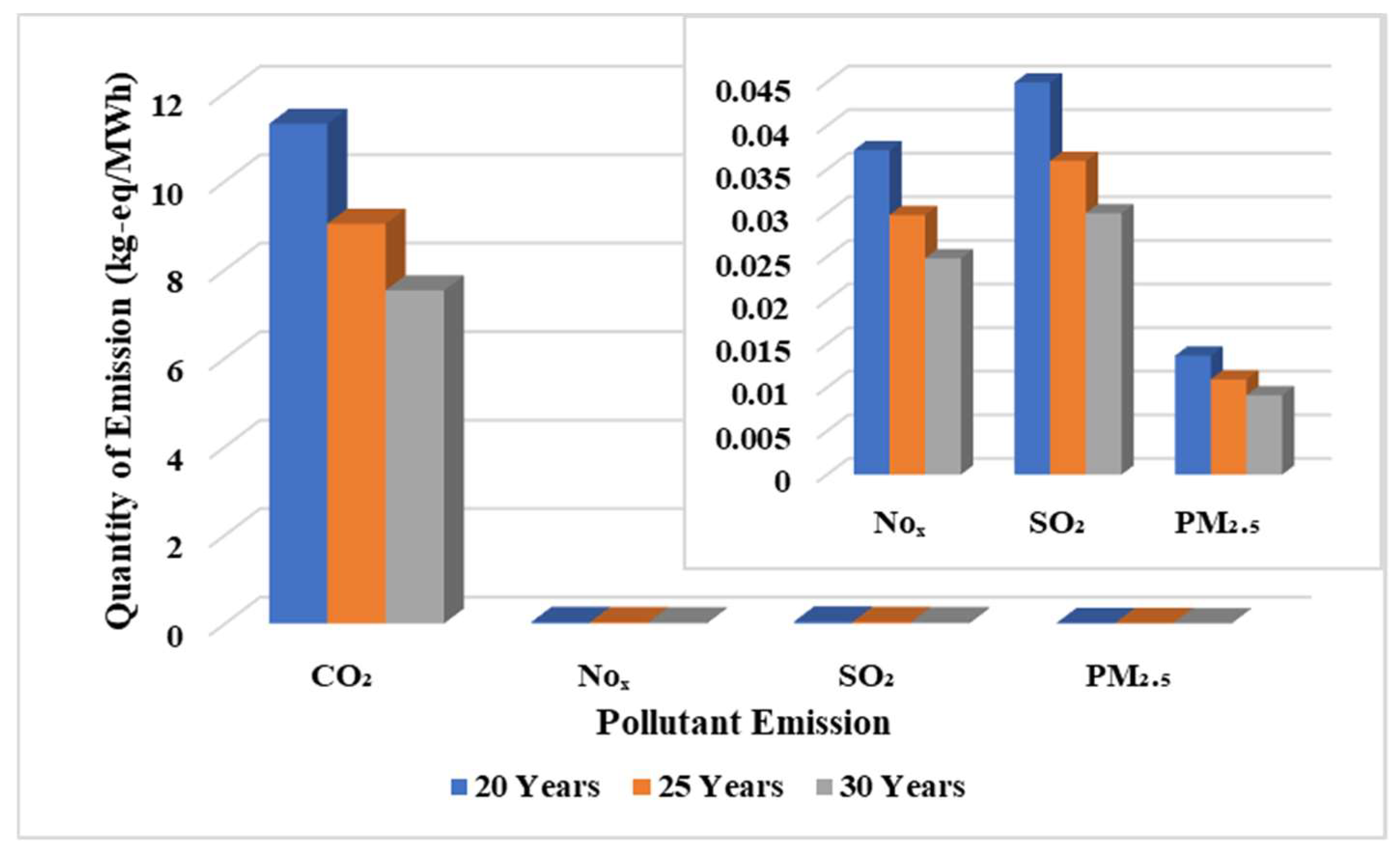

4.5. Effect of the Operational Life of Wind Turbine on Environmental Impact

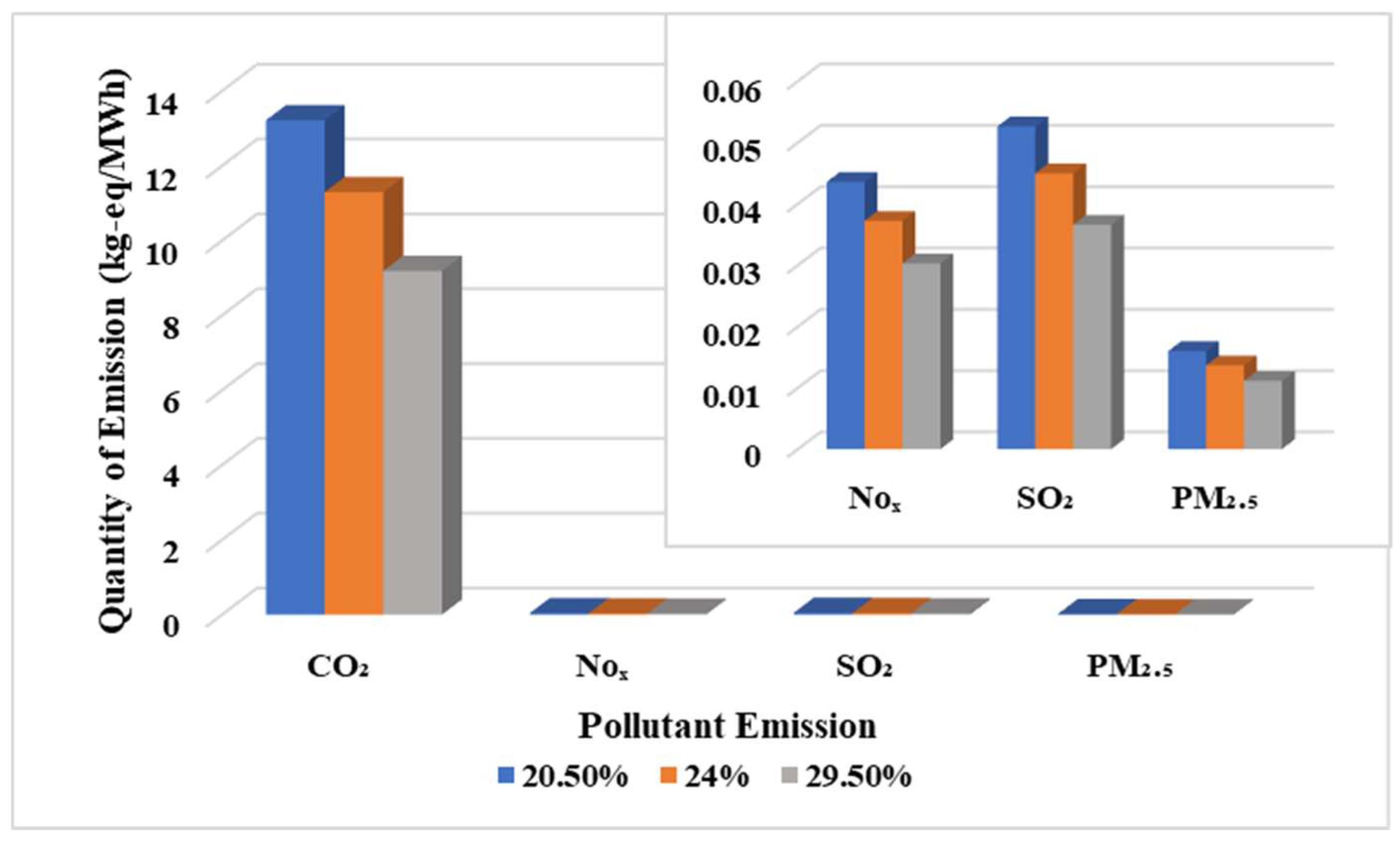

4.6. Effect of the Capacity Factor Variation on Environmental Impact

5. Conclusions and Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The World Bank. Population Growth (Annual %)—India. Available online: data.worldbank.org (accessed on 3 October 2020).

- Gargiulo, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Italian Electricity Scenarios to 2030. Energies 2020, 13, 3852. [Google Scholar] [CrossRef]

- CEA. Growth of Electricity Sector in India from 1947–2019; CEA: New Delhi, India, 2020. [Google Scholar]

- BP. Statistical Review of World Energy, 2019, 68th ed.; BP: London, UK, 2019. [Google Scholar]

- Munawer, M.E. Human health and environmental impacts of coal combustion and post-combustion wastes. J. Sustain. Min. 2018, 17, 87–96. [Google Scholar] [CrossRef]

- Yin, L.; Liao, Y.; Zhou, L.; Wang, Z.; Ma, X. Life cycle assessment of coal-fired power plants and sensitivity analysis of CO2 emissions from power generation side. IOP Conf. Ser. Mater. Sci. Eng. 2017, 199, 012055. [Google Scholar] [CrossRef] [Green Version]

- Odeh, N.A.; Cockerill, T.T. Life cycle analysis of UK coal fired power plants. Energy Convers. Manag. 2008, 49, 212–220. [Google Scholar] [CrossRef]

- Tang, L.; Yokoyama, T.; Kubota, H.; Shimota, A. Life cycle assessment of a pulverized coal-fired power plant with CCS technology in Japan. Energy Procedia 2014, 63, 7437–7443. [Google Scholar] [CrossRef] [Green Version]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life-cycle assessment of a 2-MW rated power wind turbine: CML method. Int. J. Life Cycle Assess. 2009, 14, 52. [Google Scholar] [CrossRef]

- Yang, J.; Chang, Y.; Zhang, L.; Hao, Y.; Yan, Q.; Wang, C. The life-cycle energy and environmental emissions of a typical offshore wind farm in China. J. Clean. Prod. 2018, 180, 316–324. [Google Scholar] [CrossRef]

- Xu, L.; Pang, M.; Zhang, L.; Poganietz, W.R.; Marathe, S.D. Life cycle assessment of onshore wind power systems in China. Resour. Conserv. Recycl. 2018, 132, 361–368. [Google Scholar] [CrossRef]

- EIA. Annual Energy Outlook 2019; U.S. Energy Information Administration: Washington, DC, USA, 2019.

- IEA. India 2020; IEA: Paris, France, 2020; Available online: https://www.iea.org/reports/india-2020 (accessed on 8 October 2020).

- IEA. Electricity Mix in India, January–August 2020; IEA: Paris, France, 2020; Available online: https://www.iea.org/data-andstatis-tics/charts/electricity-mix-in-india-january-august-2020 (accessed on 20 October 2020).

- IRENA. Renewable Capacity Statistics 2019; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019; ISBN 978-92-9260-123-2. [Google Scholar]

- MNRE. Physical Progress; Ministry of New and Renewable Energy: New Delhi, India, 2019. Available online: https://mnre.gov.in/physical-progress-achievements (accessed on 20 October 2020).

- National Institute of Wind Energy. India’s Wind Potential Atlas at 120m agl; Ministry of New and Renewable Energy, Government of India: New Delhi, India, 2019.

- Verma, S.; Paul, A.R.; Haque, N. Assessment of Materials and Rare Earth Metals Demand for Sustainable Wind Energy Growth in India. Minerals 2022, 12, 647. [Google Scholar] [CrossRef]

- CEA. Summary of All India Provisional Renewable Energy Generation; CEA: New Delhi, India, 2019. [Google Scholar]

- Caduff, M.; Huijbregts, M.A.; Althaus, H.J.; Koehler, A.; Hellweg, S. Wind power electricity: The bigger the turbine, the greener the electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef]

- Guezuraga, B.; Zauner, R.; Pölz, W. Life cycle assessment of two different 2 MW class wind turbines. Renew. Energy 2012, 37, 37–44. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, M.; Cellura, M.; Brano, V.L. Energy performances and life cycle assessment of an Italian wind farm. Renew. Sustain. Energy Rev. 2008, 12, 200–217. [Google Scholar] [CrossRef]

- Oebels, K.B.; Pacca, S. Life cycle assessment of an onshore wind farm located at the north eastern coast of Brazil. Renew. Energy 2013, 53, 60–70. [Google Scholar] [CrossRef]

- Xie, J.B.; Fu, J.X.; Liu, S.Y.; Hwang, W.S. Assessments of carbon footprint and energy analysis of three wind farms. J. Clean. Prod. 2020, 254, 120159. [Google Scholar] [CrossRef]

- Simons, P.J.; Cheung, W.M. Development of a quantitative analysis system for greener and economically sustainable wind farms. J. Clean. Prod. 2016, 133, 886–898. [Google Scholar] [CrossRef]

- Verma, S.; Paul, A.R.; Jain, A. Performance investigation and energy production of a novel horizontal axis wind turbine with winglet. Int. J. Energy Res. 2022, 46, 4947–4964. [Google Scholar] [CrossRef]

- Verma, S.; Paul, A.R. Power augmentation in H-Type Darrieus wind turbine using wind lens. J. Phys. Conf. Ser. 2022, 2217, 012040. [Google Scholar] [CrossRef]

- Loganathan, B.; Chowdhury, H.; Allehibi, H.; Alam, F.; Paul, A.R. A Micro Multi-blade Vertical Axis Wind Turbine for Built-Up Areas. In Proceedings of the 16th Asian Congress of Fluid Mechanics, Bangalore, India, 13–17 December 2019; Springer: Singapore, 2021; pp. 149–157. [Google Scholar] [CrossRef]

- Verma, S.; Paul, A.R.; Jain, A.; Alam, F. Numerical investigation of stall characteristics for winglet blade of a horizontal axis wind turbine. E3S Web Conf. 2021, 321, 03004. [Google Scholar] [CrossRef]

- Kadiyala, A.; Kommalapati, R.; Huque, Z. Characterization of the life cycle greenhouse gas emissions from wind electricity generation systems. Int. J. Energy Environ. Eng. 2017, 8, 55–64. [Google Scholar] [CrossRef] [Green Version]

- Arceo, A.; Biswas, W.; Rosano, M. Review of Tools for Sustainability Assessment of Renewable Energy Technologies for Remote Area Power Supply. J. Fundam. Renew. Energy Appl. 2018, 8, 2. [Google Scholar] [CrossRef]

- Schleisner, L. Life cycle assessment of a wind farm and related externalities. Renew. Energy 2000, 20, 279–288. [Google Scholar] [CrossRef]

- Kabir, M.R.; Rooke, B.; Dassanayake, G.M.; Fleck, B.A. Comparative life cycle energy, emission, and economic analysis of 100 kW nameplate wind power generation. Renew. Energy 2012, 37, 133–141. [Google Scholar] [CrossRef]

- Vargas, A.V.; Zenón, E.; Oswald, U.; Islas, J.M.; Güereca, L.P.; Manzini, F.L. Life cycle assessment: A case study of two wind turbines used in Mexico. Appl. Therm. Eng. 2015, 75, 1210–1216. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, T. Life cycle assessment of CO2 emissions from wind power plants: Methodology and case studies. Renew. Energy 2012, 43, 30–36. [Google Scholar] [CrossRef]

- Li, H.; Jiang, H.D.; Dong, K.Y.; Wei, Y.M.; Liao, H. A comparative analysis of the life cycle environmental emissions from wind and coal power: Evidence from China. J. Clean. Prod. 2019, 248, 119192. [Google Scholar] [CrossRef]

- Al-Behadili, S.H.; El-Osta, W.B. Life cycle assessment of Dernah (Libya) wind farm. Renew. Energy 2015, 83, 1227–1233. [Google Scholar] [CrossRef]

- Chipindula, J.; Botlaguduru, V.S.V.; Du, H.; Kommalapati, R.R.; Huque, Z. Life cycle environmental impact of onshore and offshore wind farms in Texas. Sustainability 2018, 10, 2022. [Google Scholar] [CrossRef] [Green Version]

- Alsaleh, A.; Sattler, M. Comprehensive life cycle assessment of large wind turbines in the US. Clean Technol. Environ. Policy 2019, 21, 887–903. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P. Comparative life cycle assessment of electricity generation by different wind turbine types. J. Clean. Prod. 2019, 233, 561–572. [Google Scholar] [CrossRef]

- Wang, W.C.; Teah, H.Y. Life cycle assessment of small-scale horizontal axis wind turbines in Taiwan. J. Clean. Prod. 2017, 141, 492–501. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Rezk, H.; Mustafa, R.J.; Al-Dhaifallah, M. Evaluating the Environmental Impacts and Energy Performance of a Wind Farm System Utilizing the Life-Cycle Assessment Method: A Practical Case Study. Energies 2019, 12, 3263. [Google Scholar] [CrossRef] [Green Version]

- Demir, N.; Taşkın, A. Life cycle assessment of wind turbines in Pınarbaşı-Kayseri. J. Clean. Prod. 2013, 54, 253–263. [Google Scholar] [CrossRef]

- Ozoemena, M.; Cheung, W.M.; Hasan, R. Comparative LCA of technology improvement opportunities for a 1.5-MW wind turbine in the context of an onshore wind farm. Clean Technol. Environ. Policy 2018, 20, 173–190. [Google Scholar] [CrossRef] [Green Version]

- Stavridou, N.; Koltsakis, E.; Baniotopoulos, C.C. A comparative life-cycle analysis of tall onshore steel wind-turbine towers. Clean Energy 2020, 4, 48–57. [Google Scholar] [CrossRef]

- Gkantou, M.; Rebelo, C.; Baniotopoulos, C. Life cycle assessment of tall onshore hybrid steel wind turbine towers. Energies 2020, 13, 3950. [Google Scholar] [CrossRef]

- Teffera, B.; Assefa, B.; Björklund, A.; Assefa, G. Life cycle assessment of wind farms in Ethiopia. Int. J. Life Cycle Assess. 2021, 26, 76–96. [Google Scholar] [CrossRef]

- Kouloumpis, V.; Sobolewski, R.A.; Yan, X. Performance and life cycle assessment of a small-scale vertical axis wind turbine. J. Clean. Prod. 2020, 247, 119520. [Google Scholar] [CrossRef]

- Nagle, A.J.; Delaney, E.L.; Bank, L.C.; Leahy, P.G. A Comparative Life Cycle Assessment between landfilling and Co-Processing of waste from decommissioned Irish wind turbine blades. J. Clean. Prod. 2020, 277, 123321. [Google Scholar] [CrossRef]

- Bi, X.; Yang, J.; Yang, S. LCA-Based Regional Distribution and Transference of Carbon Emissions from Wind Farms in China. Energies 2022, 15, 198. [Google Scholar] [CrossRef]

- Xu, K.; Chang, J.; Zhou, W.; Li, S.; Shi, Z.; Zhu, H.; Chen, Y.; Guo, K. A comprehensive estimate of life cycle greenhouse gas emissions from onshore wind energy in China. J. Clean. Prod. 2022, 338, 130683. [Google Scholar] [CrossRef]

- Doerffer, K.; Bałdowska-Witos, P.; Pysz, M.; Doerffer, P.; Tomporowski, A. Manufacturing and Recycling Impact on Environmental Life Cycle Assessment of Innovative Wind Power Plant. Part 1/2. Materials 2021, 14, 220. [Google Scholar] [CrossRef] [PubMed]

- Morini, A.A.; Ribeiro, M.J.; Hotza, D. Carbon footprint and embodied energy of a wind turbine blade—A case study. Int. J. Life Cycle Assess. 2021, 26, 1177–1187. [Google Scholar] [CrossRef]

- ISO 14044; Environmental Management–Life Cycle Assessment–Requirements and Guidelines. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2006.

- Wang, S.; Wang, S.; Liu, J. Life-cycle green-house gas emissions of onshore and offshore wind turbines. J. Clean. Prod. 2019, 210, 804–810. [Google Scholar] [CrossRef]

- The Wind Power. Wind Energy Market Intelligence. Available online: https://www.thewindpower.net/windfarm_en_26892_anabaru.php (accessed on 18 August 2020).

- Schmidt, A. Life cycle assessment of electricity produced from onshore sited wind power plants based on Vestas V82-1.65 MW turbines. In Vestas Reports 2007; Vestas: Aarhus, Denmark, 2007. [Google Scholar]

- ICF International. Capacity Value of Wind Generation in India—An Assessment; ICF: Fairfax, VA, USA., 2014. [Google Scholar]

- SimaPro, Version 9.0.0.33; SimaPro: Utrecht, The Netherlands, 2019.

- GaBi Software and Database for Life Cycle Assessment. Available online: http://www.gabi-software.com (accessed on 20 August 2020).

- Union of Concerned Scientists. Environmental Impacts of Solar Power. 2013. Available online: https://www.ucsusa.org/resources/environmental-impacts-solar-power (accessed on 18 May 2022).

| References | Turbine Capacity | Location | Wind Farm Site | Life (Years) | Capacity Factor (%) | CO2 Emission (gCO2-eq/kWh) |

|---|---|---|---|---|---|---|

| Kabir et al. [33] | 5 KW 20 kW 100 kW | Canada | Onshore | 25 | 23 22 24 | 42.7 25.1 17.8 |

| Oebels and Pacca [23] | 1.5 MW | Brazil | Onshore | 20 | 34.25 | 7.1 |

| Al-Behadili and El-Osta [37] | 1.65 MW | Libya | Onshore | 20 | - | 10.42 |

| Yang et al. [20] | 3.6 MW 5 MW | China | Offshore | 25 | - | 25.5 |

| Chipindula et al. [38] | 20 | |||||

| 1–2.3 MW | Onshore | 30 | 5.63–7.13 | |||

| 2–2.3 MW | Offshore | 45 | 6.23–9.11 | |||

| Texas | (Shallow water) | |||||

| Gulf Coast | Offshore | |||||

| 2.3–5 MW | (Deepwater) | 47 | 6.98–7.58 | |||

| Alsaleh and Sattler [39] | 2 MW | USA | Onshore | 20 25 30 | - | 52.7 42.2 35.3 |

| Components | Sub-Components | Materials | Quantity (Tonnes) |

|---|---|---|---|

| Turbine | Rotor | Epoxy, fibre glass, birchwood, | 252 |

| Balsawood etc | |||

| Cast Iron | 113 | ||

| Steel | 42 | ||

| Steel Engineering (Tool Steel) | 15 | ||

| Nacelle | Cast Iron | 180 | |

| Steel | 63 | ||

| Steel Engineering (Tool Steel) | 130 | ||

| Stainless Steel | 78 | ||

| Copper | 16 | ||

| Fibre Glass | 18 | ||

| Plastic | 10 | ||

| Aluminium | 5 | ||

| Electronics | 3 | ||

| Oil | 3 | ||

| Tower | Steel | 1260 | |

| Aluminium | 26 | ||

| Electronics | 22 | ||

| Plastic | 20 | ||

| Copper | 13 | ||

| Oil | 10 | ||

| Foundation | Concrete | 8050 | |

| Steel | 270 | ||

| Internal cables | Aluminium | 3.5 | |

| Plastic | 3 | ||

| Copper | 1.7 | ||

| Transformer station | Steel | 5 | |

| Copper | 1.3 | ||

| Transformer Oil | 2.1 | ||

| Others | 1.1. | ||

| Plastic | 83.5 | ||

| External cables | Aluminium | 52.4 | |

| Copper | 13.1 |

| Power System/ Emission Factor | Capacity Value | CO2 (kg-eq./MWh) | NOX (kg-eq./MWh) | SO2 (kg-eq./MWh) | PM2.5 (kg-eq./MWh) |

|---|---|---|---|---|---|

| Wind power system | 24% | 11.3 | 0.037 | 0.045 | 0.014 |

| Coal power plant | 70% | 965 | 4.77 | 3.26 | 0.092 |

| PV power plant | - | 32–82 | - | -- | -- |

| CSP Power plant | - | 36–91 | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verma, S.; Paul, A.R.; Haque, N. Selected Environmental Impact Indicators Assessment of Wind Energy in India Using a Life Cycle Assessment. Energies 2022, 15, 3944. https://doi.org/10.3390/en15113944

Verma S, Paul AR, Haque N. Selected Environmental Impact Indicators Assessment of Wind Energy in India Using a Life Cycle Assessment. Energies. 2022; 15(11):3944. https://doi.org/10.3390/en15113944

Chicago/Turabian StyleVerma, Shalini, Akshoy Ranjan Paul, and Nawshad Haque. 2022. "Selected Environmental Impact Indicators Assessment of Wind Energy in India Using a Life Cycle Assessment" Energies 15, no. 11: 3944. https://doi.org/10.3390/en15113944