Study on Influence of Joint Locations and Hydraulic Coupling Actions on Rock Masses’ Failure Process

Abstract

:1. Introduction

2. Simulation Programs and Comparison Optimization on Rock Failure

2.1. Implementation of Crack Propagation in DDARF

- (1)

- Generation of triangular block system

- (2)

- Weibull distribution of material heterogeneity

- (3)

- Cracking algorithm of virtual joints

2.2. Implementation of Crack Propagation in RFPA

- (1)

- Rock is dispersed into a numerical model composed of meso-quadrilateral elements, it is isotropic and elastic-brittle in meso-scale, and the macroscopic failure behavior of rock masses is the collective effect of mechanical behavior of these meso-quadrilateral elements.

- (2)

- Mechanical parameters of these meso-quadrilateral elements obey Weibull distribution, which is the same as the DDARF method. Thus, the relationship between mesoscopic and macroscopic mechanical properties of rock masses is established.

- (3)

- Phase change and damage criterion are introduced to analyze the contact between elements fails or not, and the phase transition point is judged by the modified Mohr–Coulomb criterion. On the other hand, elements’ stress and strain is calculated by the finite element method (FEM, which is used as the stress analysis solver). It should be noted that the stress analysis solver is independent with the analysis of phase change. At the same time, in RFPA, it is assumed crack propagation in rock masses is a quasi-static process, and thus the effect of inertia force is ignored.

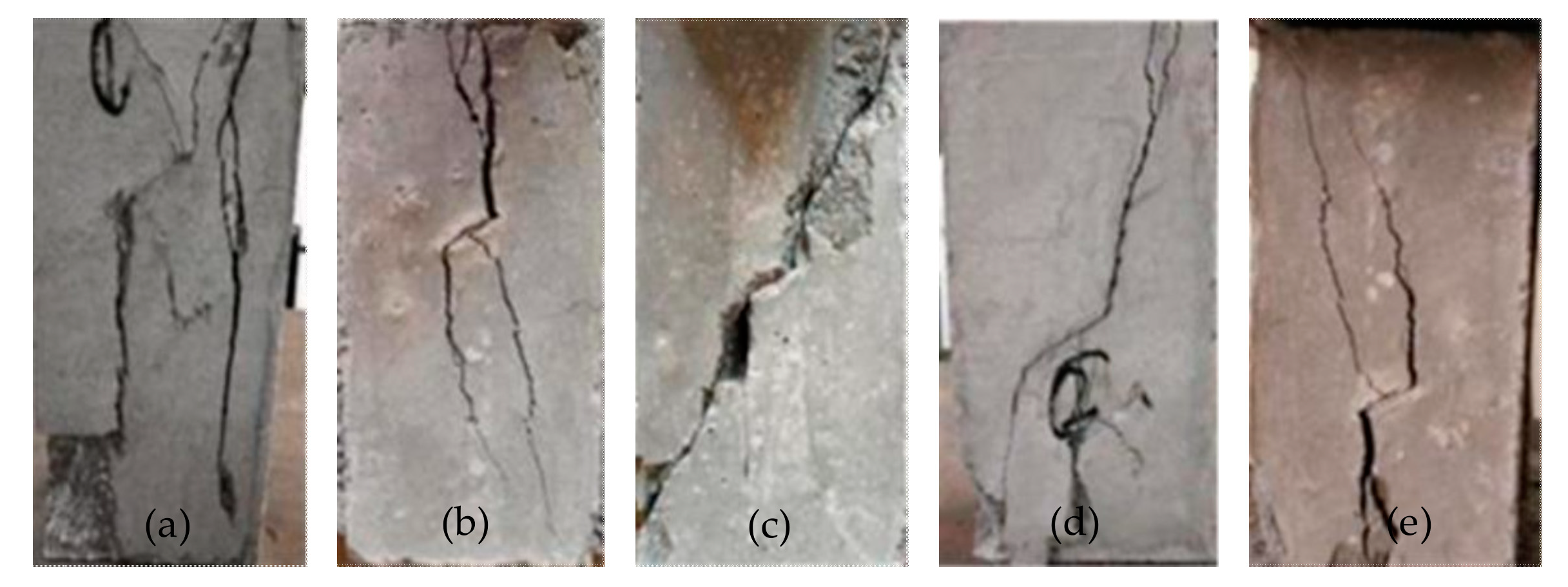

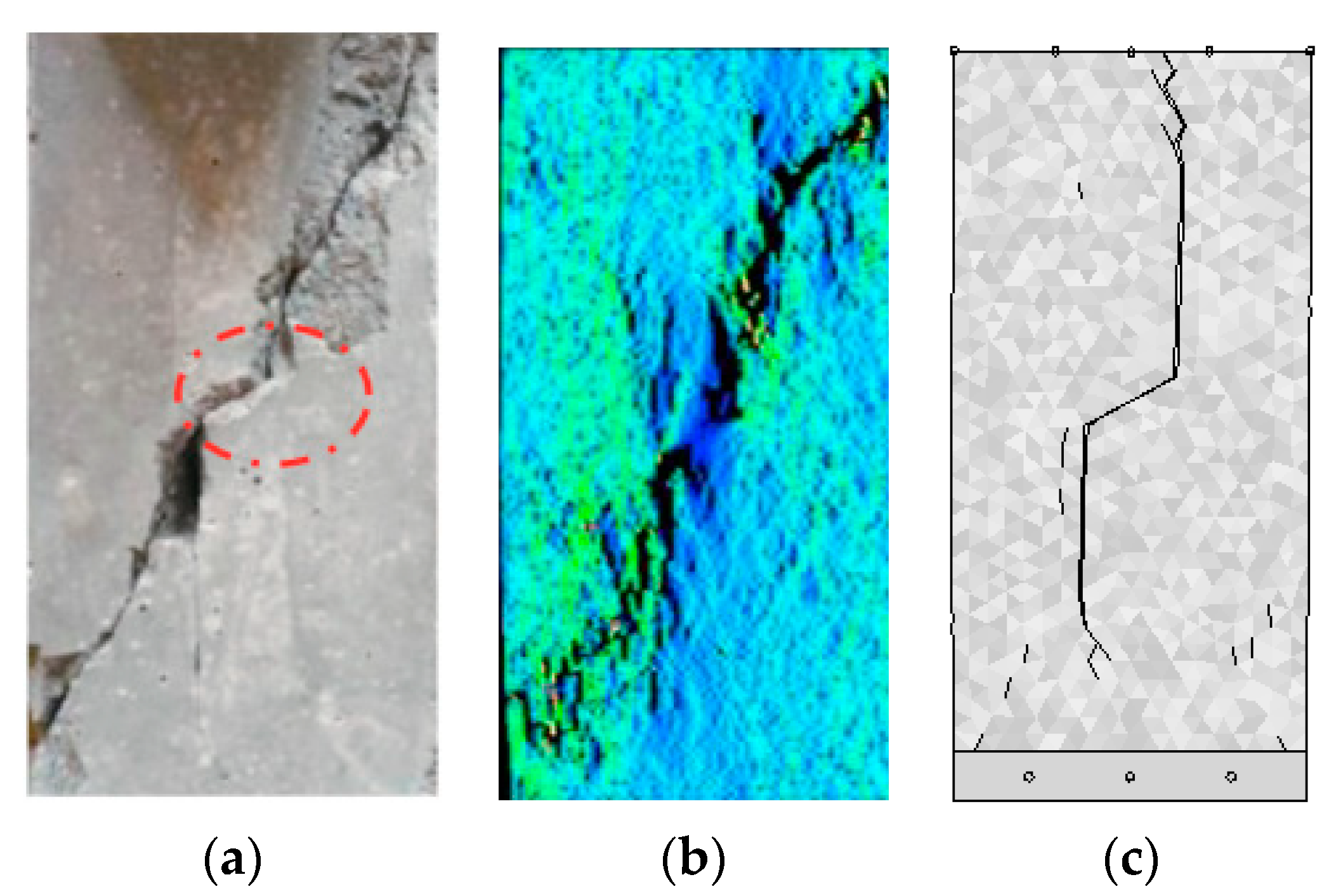

2.3. Laboratory Test and Numerical Simulation on Crack Propagation of Rock-Like Specimens

2.3.1. Laboratory Test on Crack Propagation

2.3.2. Numerical Simulation and Optimization Analysis on Crack Propagation

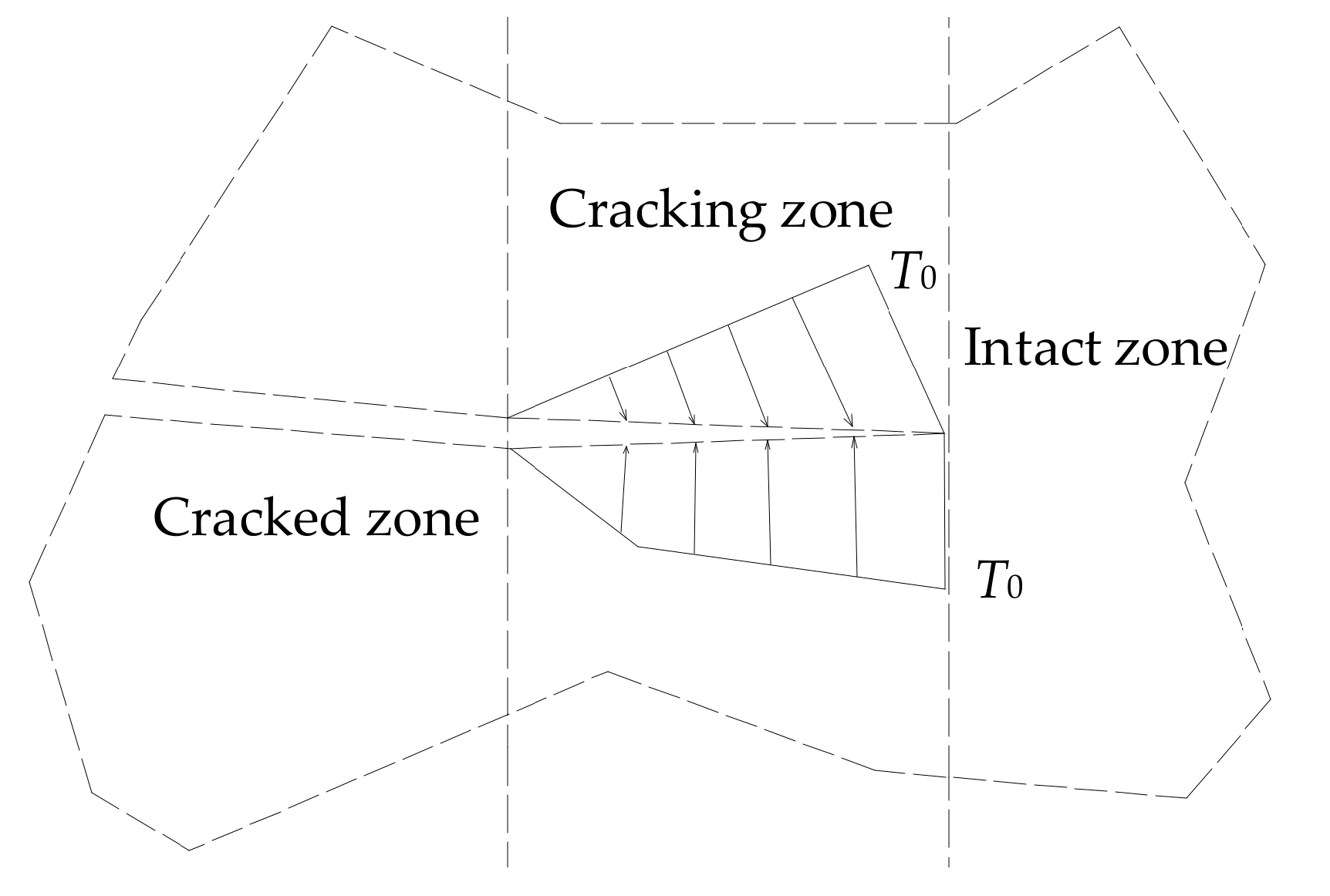

3. Study on Rock Failure Process under Hydraulic Coupling Condition

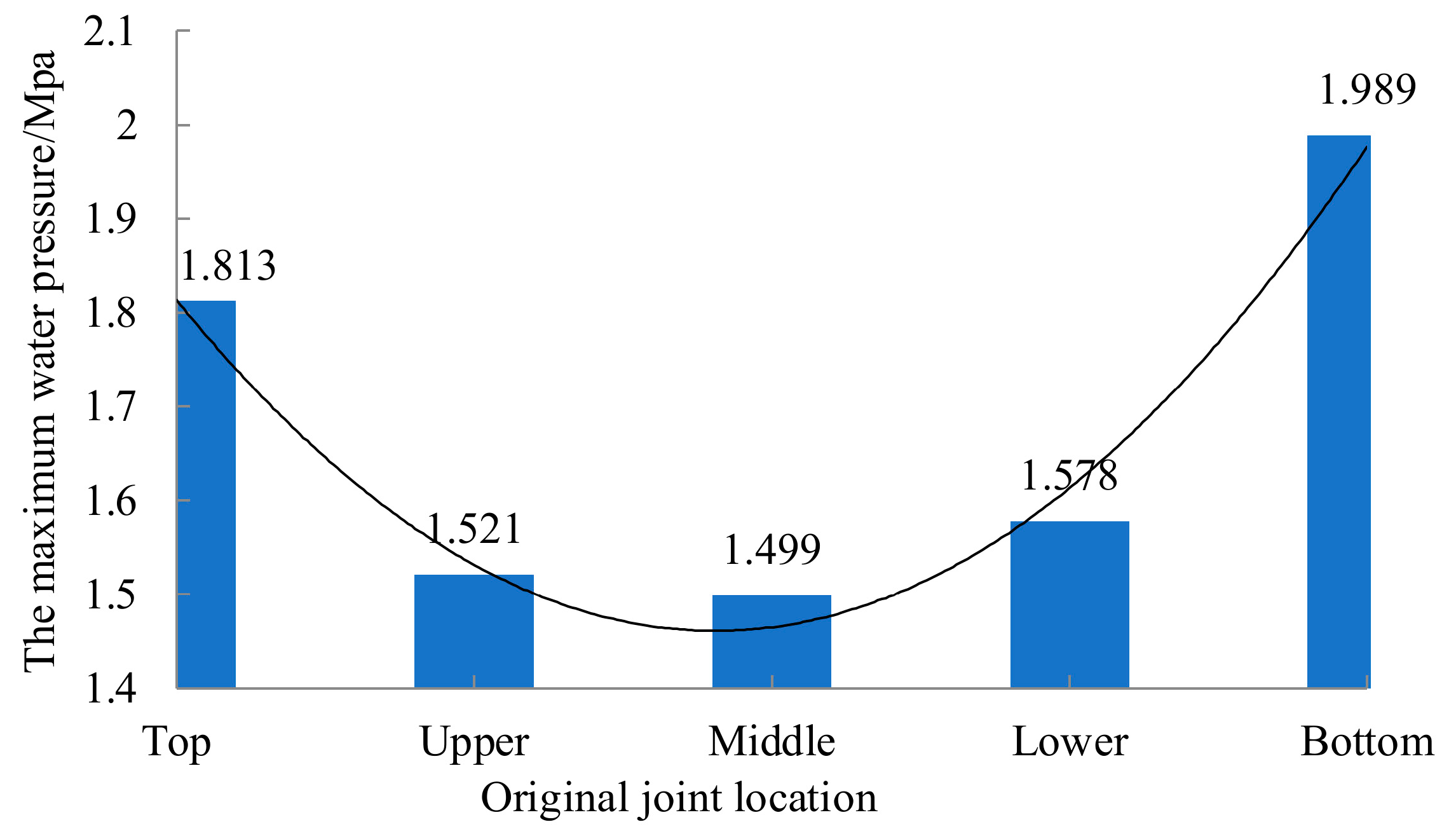

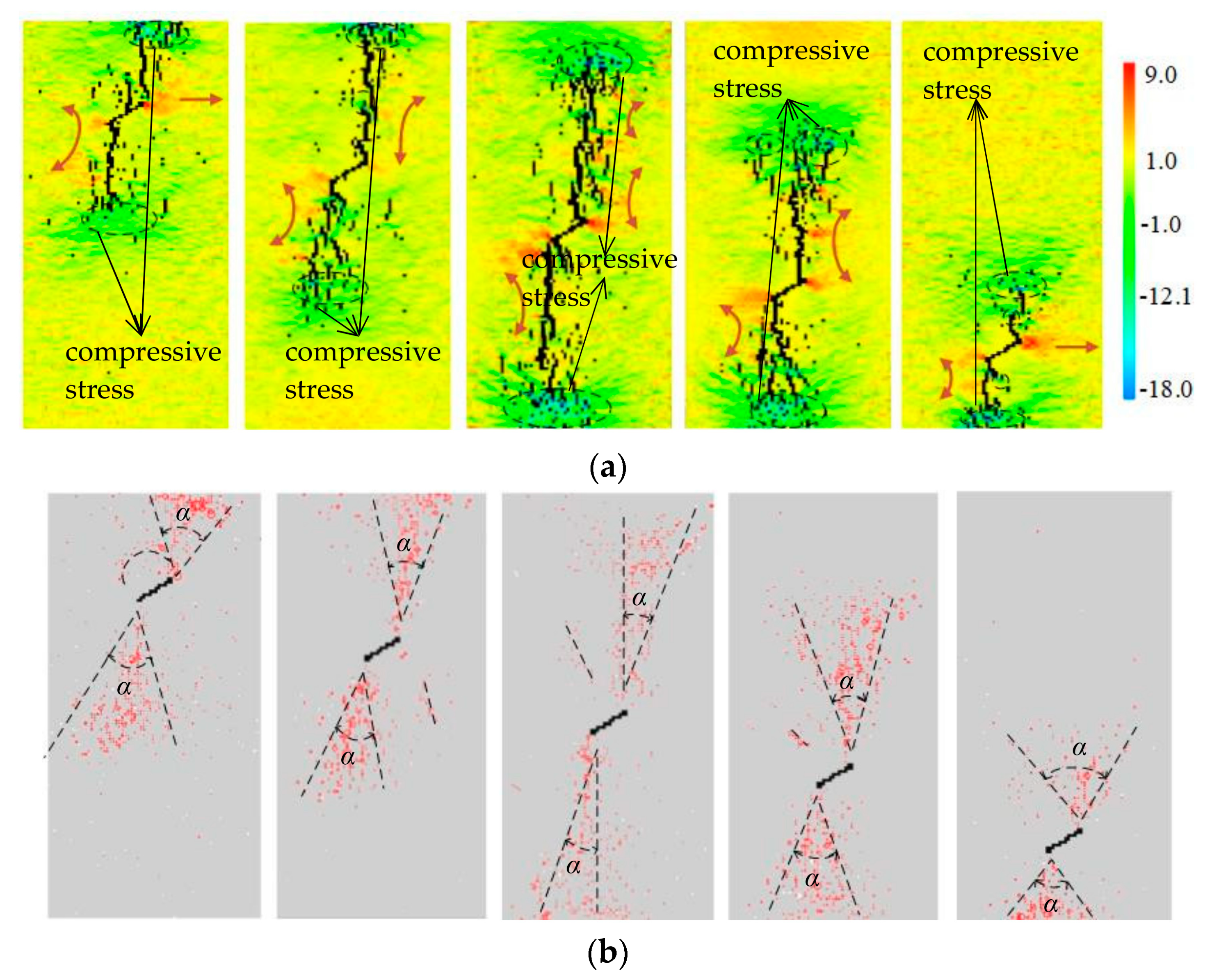

3.1. Rock Failure Process with Different Joint Locations of the Same Water Pressure

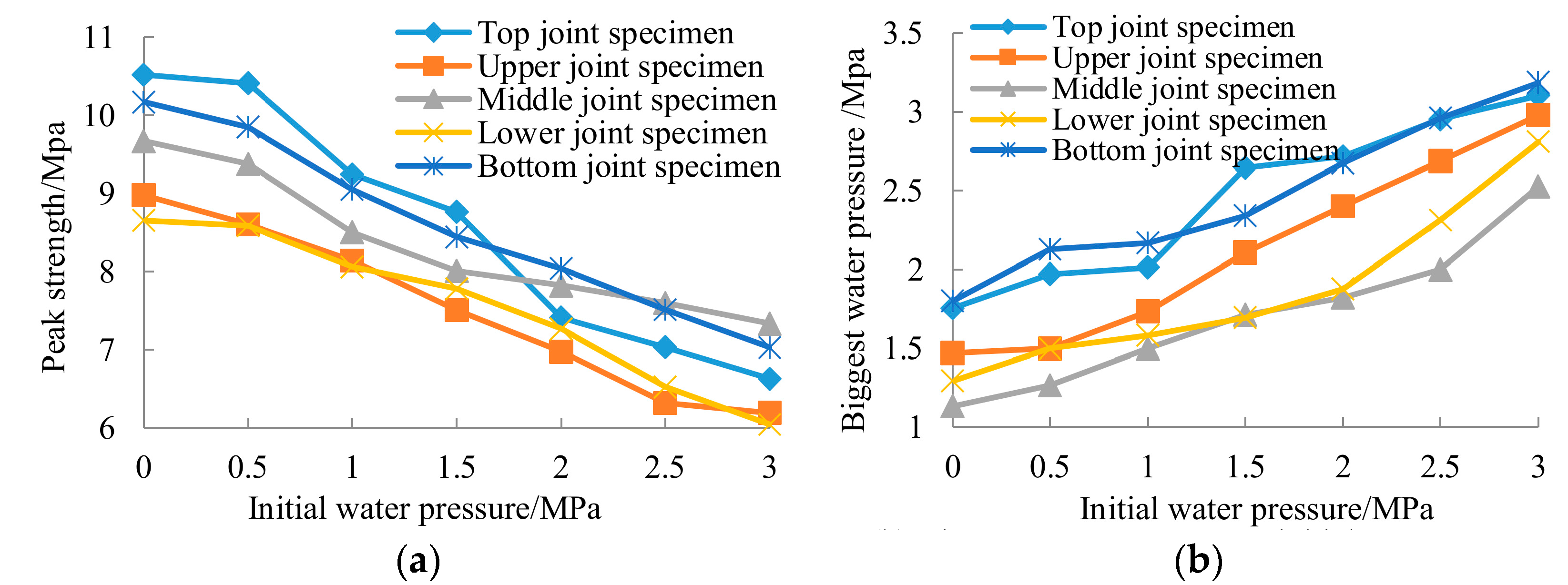

3.2. Rock Failure Process with Different Joint Locations and Different Water Pressure

4. Analysis on Energy Dissipation Laws in Rock Failure Process

4.1. Acoustic Emission Energy Analysis

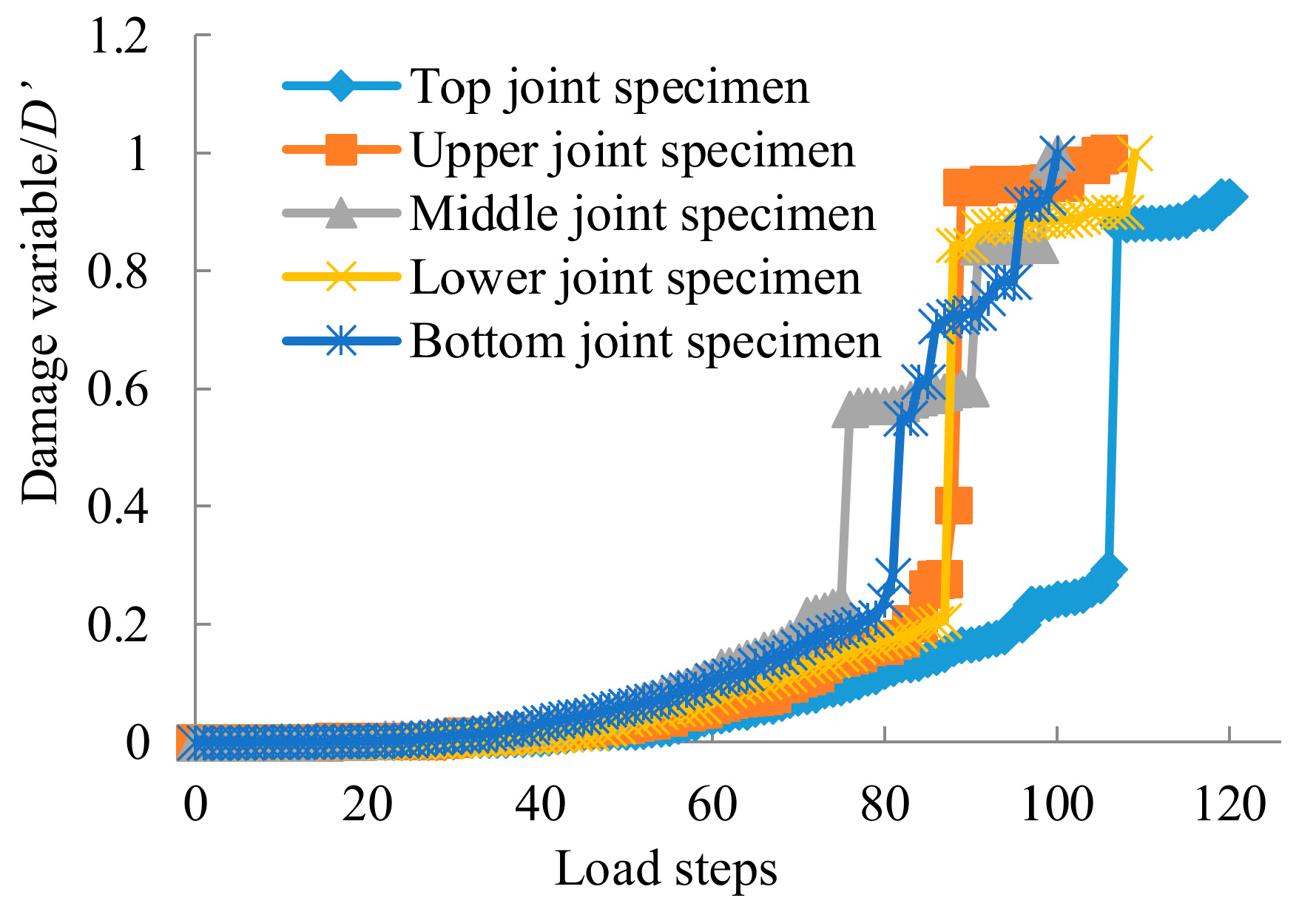

4.2. Damage Evolution Process Analysis

5. Conclusions

- (1)

- Under the hydraulic coupling action, a large tensile stress region is generated on both ends of the original joint with the micro-cracks’ propagation. Water pressure in the cracks promotes the generation of tensile stress to a certain extent, and the rock specimen is mainly subjected to tensile failure. The further away the original joint from the middle part of the rock specimen, the greater the damage effect angle is; crack paths are all approximately parallel to the maximum principal stress direction at all the different joint locations.

- (2)

- Under the same initial water pressure, the water pressure has a certain auxiliary effect on the main crack failure when the original joint is close to the middle part of the specimen, and the water pressure has a dominant effect on the local crack failure when the original joint is far away from the middle part. At low initial water pressure, stresses of the specimens with symmetrical joint locations have similar evolution trends, while at high initial water pressure, the jointed specimens’ destruction effect by water pressure is reduced, and the water pressure in cracks has significant dissipation, and thus the maximum water pressure in the system does not exceed the initial value.

- (3)

- The length of the main crack path is positively proportional to the amount of acoustic emission and the energy accumulation capacity. In addition, for the rock specimens with all joint locations, the amount of acoustic emission and the cumulative energy shows a nonlinear sharp increase in the failure stage. The damage variable D’ can reflect the failure degree of jointed rock masses, and the evolution of damage variable D’ basically shows a development trend of steady growth-rapid growth-steady growth.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Havrevoll, O.H.; Vereide, K.; Lia, L. Efficiency of pressurized rock traps for unlined hydropower tunnels. Energies 2021, 14, 4344. [Google Scholar] [CrossRef]

- Seto, M.; Nag, D.K.; Vutukuril, V.S. Acoustic emission in coal and sandstone under triaxial compressive stress condition. In Proceedings of the Rockbursts and Seismicity in Mines, Rotterdam, The Netherlands, 31 December 1997; pp. 427–431. [Google Scholar]

- Han, J.Y.; Liu, D.; Guan, Y.P.; Chen, Y.; Li, T.; Jia, D.; Yan, F.; Jia, P.; Zhao, Y. Study on shear behavior and damage constitutive model of tendon-grout interface. Constr. Build. Mater. 2022, 320, 126–223. [Google Scholar] [CrossRef]

- Hashemnejad, A.; Aghda, S.M.F.; Talkhablou, M. Introducing a new classification of soft rocks based on the main geological and engineering aspects. B Eng. Geol. Environ. 2021, 80, 4235–4254. [Google Scholar] [CrossRef]

- Riabokon, E.; Turbakov, M.; Popov, N.; Kozhevnikov, E.; Poplygin, V.; Guzev, M. Study of the influence of nonlinear dynamic loads on elastic modulus of carbonate reservoir rocks. Energies 2021, 14, 8559. [Google Scholar] [CrossRef]

- Abbass, T.; Andre, V. Failure of layered sandstone under Brazilian test conditions: Effect of micro-scale parameters on macro-scale behaviour. Rock Mech. Rock Eng. 2010, 43, 641–653. [Google Scholar]

- Chitrala, Y.; Moreno, C.; Sondergeld, C.; Rai, C. An experimental investigation into hydraulic fracture propagation under different applied stresses in tight sands using acoustic emissions. J. Petrol. Sci. Eng. 2013, 108, 151–161. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Li, T.B.; Chen, G.Q.; Zhang, H. Experimental study of acoustic emission characteristics of sandstone under hydro-mechanical coupling action. Rock Soil Mech. 2014, 35, 2815–2822. [Google Scholar]

- Lian, Z.L.; Zhang, J.; Wu, H.A.; Wang, X.X.; Xue, B. A simulation study of hydraulic fracturing propagation with a solid-fluid coupling model. Rock Soil Mech. 2008, 29, 3021–3026. [Google Scholar]

- Zhang, S.C.; Biao, F.J.; Liu, H.; Zhang, J. A numerical study of parameter influences on horizontal hydraulic fracture. Eng. Mech. 2011, 28, 228–236. [Google Scholar]

- Li, G.; Shen, J.L.; Li, G.H.; Dai, L.P. Numerical simulation for deformation behavior of soft rock roadway under the condition of water-rock interaction. J. Saf. Environ. 2016, 16, 146–150. [Google Scholar]

- Kharghani, M.; Goshtasbi, K.; Nikkah, M.; Ahangari, K. Investigation of the Kaiser effect in anisotropic rocks with different angles by acoustic emission method. Appl. Acoust. 2021, 175, 107831. [Google Scholar] [CrossRef]

- Charlie, C.L.; Zhao, T.B.; Zhang, Y.B.; Wan, W. A study on the energy sources and the role of the surrounding rock mass in strain burst. Int. J. Rock Mech. Min. Sci. 2022, 154, 105114. [Google Scholar]

- Rodrígueza, P.; Celestino, T.B. Application of acoustic emission monitoring and signal analysis to the qualitative and quantitative characterization of the fracturing process in rocks. Eng. Fract. Mech. 2019, 210, 54–69. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Song, L.L.; Jia, Z.C.; Gao, C.Z. Study on failure time prediction of rock based on acoustic emission energy judging index. Coal Saf. Environ. 2016, 48, 117–119. [Google Scholar]

- Jin, Y.; Fan, M.; Fu, W.N.; Chen, M.; Han, H.F.; Zhou, X. Experimental study on fracture propagation behavior based on acoustic emission characteristics. Chin. J. Rock Mech. Eng. 2018, 37, 3834–3841. [Google Scholar]

- Liu, G.; Li, Y.M.; Xiao, F.K. Study on failure mechanics behavior and damage evolution law of yellow sandstone under uniaxial triaxial and pore water action. Chin. J. Rock Mech. Eng. 2019, 38, 3532–3544. [Google Scholar]

- Golshani, A.; Thanh, T.C. Energy analysis of hydraulic fracturing. Ksce J. Civ. Eng. 2009, 13, 219–224. [Google Scholar] [CrossRef] [Green Version]

- Hajibagherpour, A.R.; Mansouri, H.; Bahaaddini, M. Numerical modeling of the fractured zones around a blasthole. Comput. Geotech. 2020, 123, 103535. [Google Scholar] [CrossRef]

- Hiroyuki, S.; Sumihiko, M.; Tsuyoshi, I. The distinct element analysis for hydraulic fracturing in hard rock considering fluid viscosity and particle size distribution. Int. J. Rock Mech. Min. 2011, 48, 712–727. [Google Scholar]

- Mu, K.; Yu, J.; Li, H.; Cai, Y.; Chen, X. Acoustic emission of sandstone with hydro-mechanical coupling and PFC-based modelling of energy dissipation. Rock Soil Mech. 2015, 36, 1496–1504. [Google Scholar]

- Yu, J.; Li, T.B.; Zheng, C.T.; Cai, Y.Y.; Tu, B.X.; Mu, K. Numerical simulation research on Duncan-Chang model of coastal soft soil. Chin. J. Rock Mech. Eng. 2014, 33, 4271–4281. [Google Scholar]

- Lin, C.; Yu, J.; Chen, X.; Cai, Y.Y.; Wen, Z.J. Mesoscopic numerical simulation on crack expansion and energy evolution of sandstone with prefabricated joint under hydro-mechanical coupling condition. J. Huaqiao Univ. (Nat. Sci.) 2018, 39, 538–544. [Google Scholar]

- Chen, Y.J.; Li, S.C.; Zhu, W.S.; Yu, S.; Wang, W.; Zhao, C.L. Rock failure and its jointed surrounding rocks: A multi-scale grid meshing method for DDARF. Tunn. Undergr. Space Technol. 2014, 43, 370–376. [Google Scholar]

- Li, S.C.; Chen, Y.J.; Zhu, W.S.; Zhao, C.L.; Li, L.P.; Yin, F.Q. New reinforcement algorithms in discontinuous deformation analysis for rock failure. Geomech. Eng. 2016, 11, 787–803. [Google Scholar]

- Chen, Y.J.; Zhang, X.; Zhu, W.S.; Wang, W. Modified discontinuous deformation analysis for rock failure: Crack propagation. Geomech. Eng. 2018, 14, 325–336. [Google Scholar]

- Ma, K.; Sun, X.Y.; Tang, C.A.; Wang, S.J.; Yuan, F.Z.; Peng, Y.L.; Liu, K. An early warning method for water inrush in Dongjiahe coal mine based on microseismic moment tensor. J. Cent. South Univ. 2020, 27, 3133–3148. [Google Scholar] [CrossRef]

- Ma, K.; Tang, C.A.; Xu, N.W.; Liu, F.; Xu, J.W. Failure precursor of surrounding rock mass around cross tunnel in high-steep rock slope. J. Cent. South Univ 2013, 20, 207–217. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yang, S.Q.; Liu, X.R. Experimental and numerical study on the mechanical characteristics of rock-like materials. J. Exp. Mech. 2014, 29, 239–249. [Google Scholar]

- Chen, Y.J.; Zhu, W.S.; Li, S.C.; Zhao, T.B.; Li, L.P.; Zhang, Q.Q. Similar rock specimen’s creep constitutive test and realization by FLAC3D. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 3015–3021. [Google Scholar] [CrossRef]

- Li, Y.; Cai, W.B.; Zhu, W.S.; Dong, Z.; Zhang, Q. Particle flow analysis of parallel double crack evolution under uniaxial compression. J. Cent. South Univ. 2019, 50, 3035–3045. [Google Scholar]

- Li, G.; Tang, C.A. A statistical meso-damage mechanical method for modeling trans-scale progressive failure process of rock. Int. J. Rock Mech. Min. 2015, 74, 133–150. [Google Scholar] [CrossRef]

| Materials | Compressive Strength /MPa | Tensile Strength /MPa | Elastic Modulus /GPa | Poisson Ratio | Density/(g/cm3) |

|---|---|---|---|---|---|

| Rock-like specimen | 55 | 5 | 6 | 0.20 | 2.25 |

| Sandstone [31] | 20~170 | 4~25 | 3~35 | 0.02~0.25 | 2.10~2.40 |

| Mechanical Parameters | Value |

|---|---|

| Homogeneous degree/m | 2 |

| Elastic modulus/GPa | 3 |

| Poisson ratio | 0.2 |

| Density/(g/cm3) | 2.25 |

| Frictional angle/° | 45 |

| Compressive strength vs tensile strength | 10 |

| Permeability coefficient /m·d−1 | 0.1 |

| Water pressure coefficient | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Gao, T.; Yin, F.; Liu, X.; Wang, J. Study on Influence of Joint Locations and Hydraulic Coupling Actions on Rock Masses’ Failure Process. Energies 2022, 15, 4024. https://doi.org/10.3390/en15114024

Chen Y, Gao T, Yin F, Liu X, Wang J. Study on Influence of Joint Locations and Hydraulic Coupling Actions on Rock Masses’ Failure Process. Energies. 2022; 15(11):4024. https://doi.org/10.3390/en15114024

Chicago/Turabian StyleChen, Yunjuan, Tao Gao, Fuqiang Yin, Xiaozhi Liu, and Jun Wang. 2022. "Study on Influence of Joint Locations and Hydraulic Coupling Actions on Rock Masses’ Failure Process" Energies 15, no. 11: 4024. https://doi.org/10.3390/en15114024

APA StyleChen, Y., Gao, T., Yin, F., Liu, X., & Wang, J. (2022). Study on Influence of Joint Locations and Hydraulic Coupling Actions on Rock Masses’ Failure Process. Energies, 15(11), 4024. https://doi.org/10.3390/en15114024