Combustion Performance of Methane/Air in a Micro Combustor Embedded Hollow Hemispherical Slotted Bluff Body

Abstract

:1. Introduction

2. Numerical Model

2.1. Physical Model

2.2. Mathematical Model

2.3. Reaction Kinetic Model

2.4. Computational Model

2.5. Grid Independence and Model Validation

3. Results and Discussion

3.1. Comparative Analysis of Combustion Performance

3.1.1. Flow Characteristics

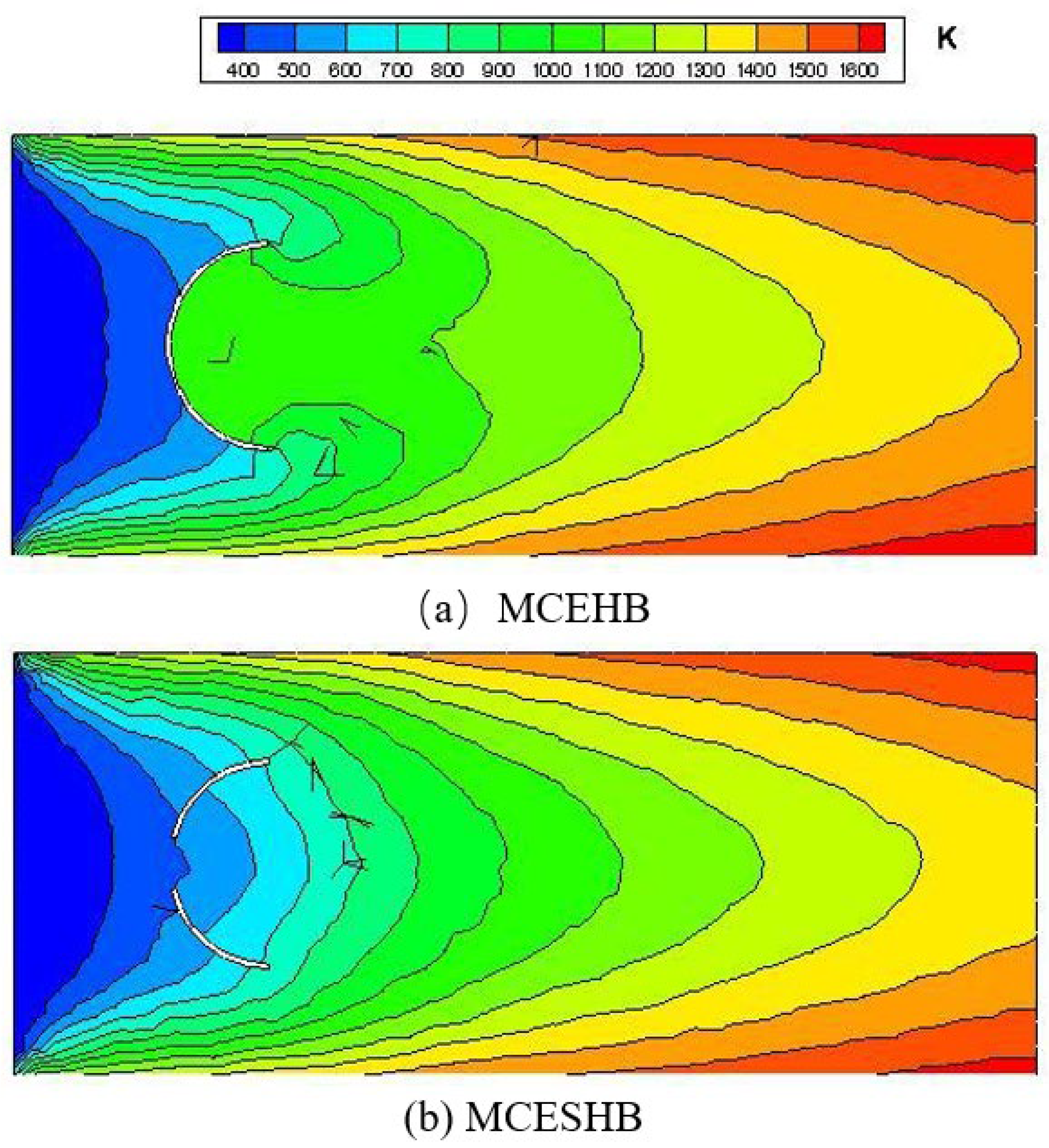

3.1.2. Thermal Characterization Analysis

3.1.3. Analysis of Combustion Characteristics

3.2. The Effect of Slot Width Ratio

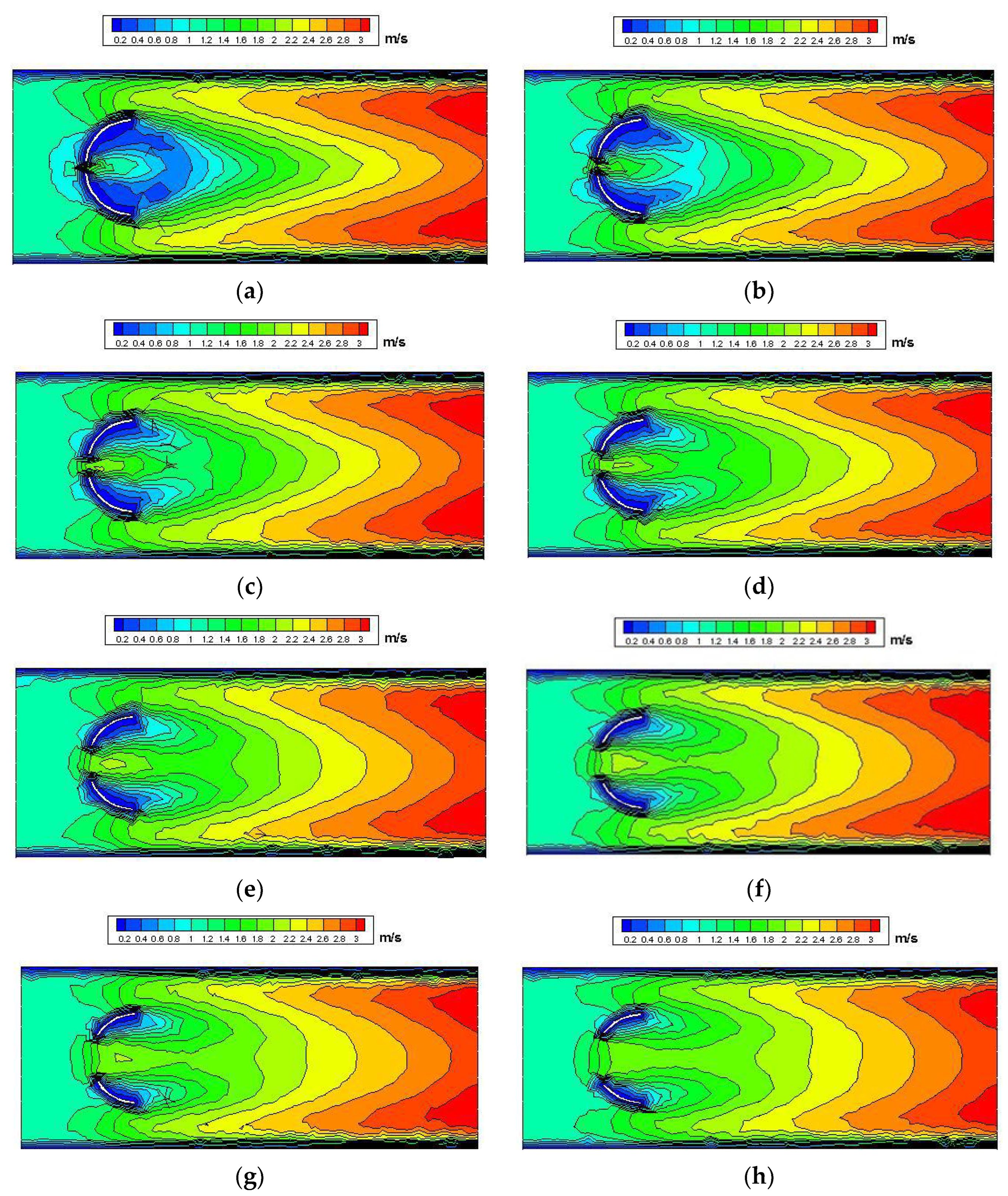

3.2.1. The Effect of B on the Flow Field

3.2.2. The Effect of B on Methane Conversion

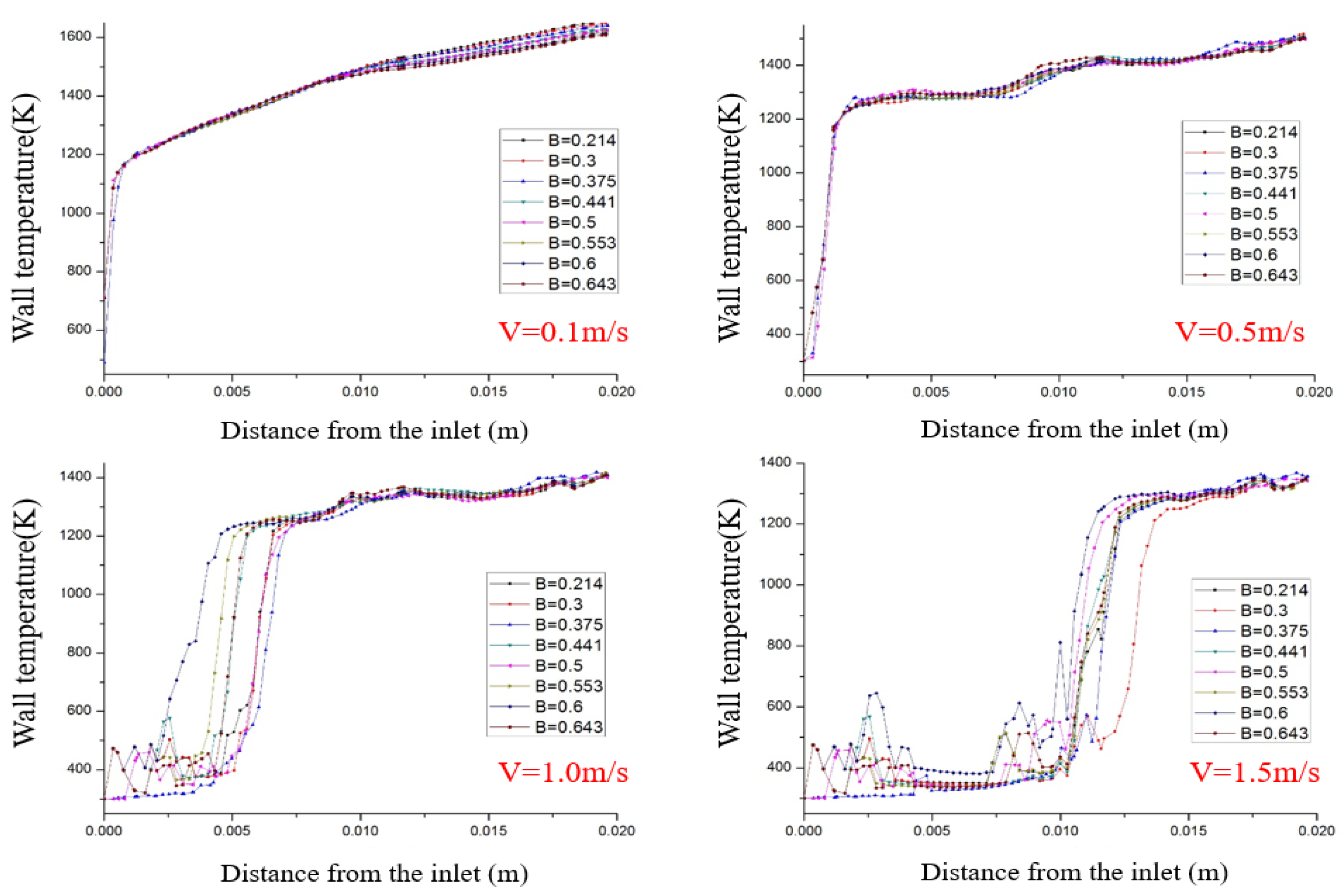

3.2.3. The Effect of B on Wall Temperature

4. Conclusions

- The jet flow in a slotted bluff body not only disturbs the velocity field and temperature field behind the blunt body but also promotes the preheating and combustion of low-temperature gas. With the inlet velocity increasing, the methane conversion efficiency of the slotted bluff body combustor increases first and then decreases, but it is also higher than that of the MCEHB at the same velocity.

- Too large or too small slot size of bluff body is not conducive to methane combustion near the wall. A slot that is too small to bring significant disturbance to the fluid behind blunt body, but too large of a slot can increase the mixing gas volume at low temperature and decrease the mixing velocity, which also provides a slight effect. Setting the slot width ratio B to 0.553 can bring the maximum jet velocity, resulting in the strongest flow field disturbance behind the bluff body.

- Methane conversion is affected by inlet velocity and slot width. With the increase of slot width ratio B, methane conversion firstly increases and then decreases. The slot width ratio corresponding to the peak is less than 0.5. Since the inlet velocity is lower than 0.5 m/s, the optimal slot width ratio B is in the range of 0.3–0.375. However, as the inlet velocity exceeds 0.5 m/s, the optimal slot width ratio B moves to the range of 0.375–0.553.

- With too large or too small slot width, the wall temperature near the bluff body fluctuates obviously along the axis direction, and this uneven wall temperature distribution is detrimental to the performance; thus, it is a reasonable choice to set the slot width ratio B at 0.375.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qian, P.; Liu, M. Influencing factors of wall temperature and flame stability of micro-combustors in micro-thermophotovoltaic and micro-thermoelectric systems. Fuel 2022, 310, 122436. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, Y.; Yang, W.; Liu, J.; Wang, Z.; Cen, K. Combustion of hydrogen–air in catalytic micro-combustors made of different material. Int. J. Hydrogen Energy 2009, 34, 3535–3545. [Google Scholar] [CrossRef]

- Wan, J.; Fan, A. Recent progress in flame stabilization technologies for combustion-based micro energy and power systems. Fuel 2021, 286, 119391. [Google Scholar] [CrossRef]

- E, J.; Ding, J.; Chen, J.; Liao, G.; Zhang, F.; Luo, B. Process in micro-combustion and energy conversion of micro power system: A review. Energy Convers. Manag. 2021, 246, 114664. [Google Scholar] [CrossRef]

- Chang, J.; Zhang, J.; Bao, W.; Yu, D. Research progress on strut-equipped supersonic combustors for scramjet application. Prog. Aerosp. Sci. 2018, 103, 1–30. [Google Scholar] [CrossRef]

- Huang, W.; Du, Z.-b.; Yan, L.; Moradi, R. Flame propagation and stabilization in dual-mode scramjet combustors: A survey. Prog. Aerosp. Sci. 2018, 101, 13–30. [Google Scholar] [CrossRef]

- Chanphavong, L.; Zainal, Z.A. Characterization and challenge of development of producer gas fuel combustor: A review. J. Energy Inst. 2019, 92, 1577–1590. [Google Scholar] [CrossRef]

- Shirsat, V.; Gupta, A.K. A review of progress in heat recirculating meso-scale combustors. Appl. Energy 2011, 88, 4294–4309. [Google Scholar] [CrossRef]

- Anand, V.; Gutmark, E. Rotating detonation combustors and their similarities to rocket instabilities. Prog. Energy Combust. Sci. 2019, 73, 182–234. [Google Scholar] [CrossRef] [Green Version]

- Chia, L.C.; Feng, B. The development of a micropower (micro-thermophotovoltaic) device. J. Power Sources 2007, 165, 455–480. [Google Scholar] [CrossRef]

- Ruan, C.; Chen, F.; Cai, W.; Qian, Y.; Yu, L.; Lu, X. Principles of non-intrusive diagnostic techniques and their applications for fundamental studies of combustion instabilities in gas turbine combustors: A brief review. Aerosp. Sci. Technol. 2019, 84, 585–603. [Google Scholar] [CrossRef]

- Xue, Z.; Yan, Y.; He, Z.; Shen, K.; Zhang, C. Comprehensive numerical insight the thermal performance improvement of the micro combustors with internal bionic Y-shaped fins for micro-thermal voltaic system applications. Fuel 2022, 318, 123610. [Google Scholar] [CrossRef]

- Ni, S.; Zhao, D.; Zhu, X. Heat transfer and entropy production evaluation on premixed hydrogen/air-fuelled micro-combustors with internal threads. Fuel 2021, 303, 131325. [Google Scholar] [CrossRef]

- Gao, W.; Yan, Y.; Shen, K.; Huang, L.; Zhao, T.; Gao, B. Combustion characteristic of premixed H2/air in the micro cavity combustor with guide vanes. Energy 2022, 239, 121975. [Google Scholar] [CrossRef]

- Mohseni, S.; Nadimi, E.; Jafarmadar, S.; Rezaei, R.A. Enhance the energy and exergy performance of hydrogen combustion by improving the micro-combustor outlet in thermofluidic systems. Int. J. Hydrogen Energy 2021, 46, 6915–6927. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Cai, L.; Li, J.; Ding, J.; Chen, J.; Luo, B. Effects analysis on the catalytic combustion and heat transfer performance enhancement of a non-premixed hydrogen/air micro combustor. Fuel 2022, 309, 122125. [Google Scholar] [CrossRef]

- Li, L.; Yang, G.; Fan, A. Non-premixed combustion characteristics and thermal performance of a catalytic combustor for micro-thermophotovoltaic systems. Energy 2021, 214, 118893. [Google Scholar] [CrossRef]

- Yan, Y.; Wu, G.; Huang, W.; Zhang, L.; Li, L.; Yang, Z. Numerical comparison study of methane catalytic combustion characteristic between newly proposed opposed counter-flow micro-combustor and the conventional ones. Energy 2019, 170, 403–410. [Google Scholar] [CrossRef]

- Lu, Q.; Gou, J.; Pan, J.; Zhang, Y.; Zhu, J.; Quaye, E.K. Comparison of the effect of heat release and products from heterogeneous reaction on homogeneous combustion of H2/O2 mixture in the catalytic micro combustor. Int. J. Hydrogen Energy 2019, 44, 31557–31566. [Google Scholar] [CrossRef]

- Chen, J.; Song, W.; Gao, X.; Xu, D. Hetero-/homogeneous combustion and flame stability of fuel-lean propane–air mixtures over platinum in catalytic micro-combustors. Appl. Therm. Eng. 2016, 100, 932–943. [Google Scholar] [CrossRef]

- Wu, Y.; Peng, Q.; Yang, M.; Shan, J.; Yang, W. Entropy generation analysis of premixed hydrogen–air combustion in a micro combustor with porous medium. Chem. Eng. Processing-Process Intensif. 2021, 168, 108566. [Google Scholar] [CrossRef]

- Ni, S.; Zhao, D.; Cai, T.; Cao, F. Energy conversion efficiency improvement studies on unconventional premixed micro-combustors partially inserted with porous medium. Fuel Process. Technol. 2021, 215, 106774. [Google Scholar] [CrossRef]

- Li, Q.; Li, J.; Shi, J.; Guo, Z. Effects of heat transfer on flame stability limits in a planar micro-combustor partially filled with porous medium. Proc. Combust. Inst. 2019, 37, 5645. [Google Scholar] [CrossRef]

- Wei, J.; Fu, G.; Yang, W.; Li, S.; E, J.; Peng, Q.; Zhang, A. Investigation on hydrogen-fueled combustion characteristics and thermal performance in a micro heat-recirculation combustor inserted with block. Int. J. Hydrogen Energy 2021, 46, 36515–36527. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Feng, S.; Li, X.; Yang, Z.; Ran, J.; Gan, Y. Investigation on premixed methane/air combustion characteristics in heat recirculation micro combustor with separating cylinder. Chem. Eng. Process.-Process Intensif. 2020, 153, 107987. [Google Scholar] [CrossRef]

- Tang, A.; Cai, T.; Deng, J.; Xu, Y.; Pan, J. Experimental investigation on combustion characteristics of premixed propane/air in a micro-planar heat recirculation combustor. Energy Convers. Manag. 2017, 152, 65–71. [Google Scholar] [CrossRef]

- Pan, J.; Zhang, C.; Pan, Z.; Wu, D.; Zhu, Y.; Lu, Q.; Zhang, Y. Investigation on the effect of bluff body ball on the combustion characteristics for methane/oxygen in micro combustor. Energy 2020, 190, 116465. [Google Scholar] [CrossRef]

- Yan, Y.; Yan, H.; Zhang, L.; Li, L.; Zhu, J.; Zhang, Z. Numerical investigation on combustion characteristics of methane/air in a micro-combustor with a regular triangular pyramid bluff body. Int. J. Hydrogen Energy 2018, 43, 7581–7590. [Google Scholar] [CrossRef]

- Wang, M.; Li, P.; Wang, F. Dependence of the blowout limit on flow structure, heat transfer, and pressure loss in a bluff-body micro-combustor. Int. J. Hydrogen Energy 2020, 45, 19912–19925. [Google Scholar] [CrossRef]

- Fan, A.; Wan, J.; Liu, Y.; Pi, B.; Yao, H.; Liu, W. Effect of bluff body shape on the blow-off limit of hydrogen/air flame in a planar micro-combustor. Appl. Therm. Eng. 2014, 62, 13–19. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, J.; Yan, Y.; Guo, H.; Yang, Z. Numerical investigation on the combustion characteristics of methane/air in a micro-combustor with a hollow hemispherical bluff body. Energy Convers. Manag. 2015, 94, 293–299. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, Y.; Li, L.; Cui, Y.; Zhang, L.; Yang, Z.; Zhang, Z. Numerical comparison of H2/air catalytic combustion characteristic of micro–combustors with a conventional, slotted or controllable slotted bluff body. Energy 2019, 189, 6901–6914. [Google Scholar] [CrossRef]

- Yan, Y.; Xu, F.; Xu, Q.; Zhang, L.; Yang, Z.; Ran, J. Influence of controllable slot width and angle of controllable flow on hydrogen/air premixed combustion characteristics in micro combustor with both sides–slotted bluff body. Int. J. Hydrogen Energy 2019, 44, 20482–20492. [Google Scholar] [CrossRef]

- Gao, W.; Yan, Y.; Huang, L.; Shen, K.; He, Z.; Gao, B. Numerical comparison of premixed H2/air combustion characteristic of three types of micro cavity-combustors with guide vanes, bluff body, guide vanes and bluff body respectively. Int. J. Hydrogen Energy 2021, 46, 24382–24394. [Google Scholar] [CrossRef]

- Xu, F.; Yan, Y.; He, Z.; Yang, Z.; Zhang, L. Numerical study on the influence of controllable flow ratio on combustion characteristics of a controllable central slotted bluff body and cavity combined micro combustor. Int. J. Hydrogen Energy 2021, 46, 6901–6914. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Fang, R.; Ou, Z.; Zhang, Z.; Yang, Z.; Zhang, Z. Numerical investigation of a novel micro combustor with a central and bilateral slotted blunt body. Int. J. Hydrogen Energy 2021, 46, 23564–23579. [Google Scholar] [CrossRef]

- Li, L.; Fan, A. A numerical study on non-premixed H2/air flame stability in a micro-combustor with a slotted bluff-body. Int. J. Hydrogen Energy 2021, 46, 2658–2666. [Google Scholar] [CrossRef]

- Deutschmann, O.; Maier, L.I.; Riedel, U.; Stroemman, A.H.; Dibble, R.W. Hydrogen assisted catalytic combustion of methane on platinum. Catal. Today 2000, 59, 141–150. [Google Scholar] [CrossRef]

- Leach, T.T.; Cadou, C.P. The role of structural heat exchange and heat loss in the design of efficient silicon micro-combustors. Proc. Combust. Inst. 2005, 30, 2437–2444. [Google Scholar] [CrossRef]

- Jiang, D.; Yang, W.; Chua, K.J.; Ouyang, J. Thermal performance of micro-combustors with baffles for thermophotovoltaic system. Appl. Therm. Eng. 2013, 61, 670–677. [Google Scholar] [CrossRef]

- Yan, Y.; Pan, W.; Zhang, L.; Tang, W.; Chen, Y.; Li, L. Numerical study of the geometrical parameters on CH4/air premixed combustion in heat recirculation micro-combustor. Fuel 2015, 159, 45–51. [Google Scholar] [CrossRef]

| Order | Elementary | A/[(cm3/mol)n−1/s] | B | E/(kJ/mol) |

|---|---|---|---|---|

| 1 | H2 + Pt(s) + Pt(s) ⇒ H(s) + H(s) | 4.60 × 10−2 | 0.0 | 0.0 |

| 2 | H(s) + H(s) ⇒ Pt(s) + Pt(s) + H2 | 3.70 × 1021 | 0.0 | 67.4 |

| 3 | H + Pt(s) ⇒ H(s) | 1.0 | 1.0 | 0.0 |

| 4 | O2 + Pt(s) + Pt(s) ⇒ O(s) + O(s) | 1.80 × 1021 | −0.5 | 0.0 |

| 5 | O2 + Pt(s) + Pt(s) ⇒ O(s) + O(s) | 2.30 × 10−2 | 0.0 | 0.0 |

| 6 | O(s) + O(s) ⇒ Pt(s) + Pt(s) + O2 | 3.70 × 1021 | 0.0 | 213.2 |

| 7 | O + Pt(s) ⇒ O(s) | 1.0 | 1.0 | 0.0 |

| 8 | H2O + Pt(s) ⇒ H2O(s) | 0.75 | 0.0 | 0.0 |

| 9 | H2O(s) ⇒ H2O + Pt(s) | 1.00 × 1013 | 0.0 | 40.3 |

| 10 | OH+ Pt(s) ⇒ OH(s) | 1.0 | 0.0 | 0.0 |

| 11 | OH(s) + Pt(s) ⇒ OH | 1.00 × 1013 | 0.0 | 192.8 |

| 12 | O(s) + H(s) ⇒ Pt(s) + OH(s) | 3.70 × 1021 | 0.0 | 11.5 |

| 13 | H(s) + OH(s) ⇒ H2O(s) + Pt(s) | 3.70 × 1021 | 0.0 | 17.4 |

| 14 | OH(s) + OH(s) ⇒ H2O(s) + O(s) | 3.70 × 1021 | 0.0 | 48.2 |

| 15 | CO + Pt(s) ⇒ CO(s) | 8.40 × 10−1 | 0.5 | 0.0 |

| 16 | CO(s) ⇒ CO + Pt(s) | 1.00 × 1013 | 0.0 | 125.5 |

| 17 | CO2(s) ⇒ CO2 + Pt(s) | 1.00 × 1013 | 0.0 | 20.5 |

| 18 | CO(s) + O(s) ⇒ CO2(s) + Pt(s) | 3.70 × 1021 | 0.0 | 105.0 |

| 19 | CH4(s) + Pt(s) + Pt(s) ⇒ CH3(s) + H(s) | 1.00 × 10−2 | 0.5 | 0.0 |

| 20 | CH3(s) + Pt(s) ⇒ CH2(s) + H(s) | 3.70 × 1021 | 0.0 | 20.0 |

| 21 | CH2(s) + Pt(s) ⇒ CH(s) + H(s) | 3.70 × 1021 | 0.0 | 20.0 |

| 22 | CH(s) + Pt(s) ⇒ C(s) + H(s) | 3.70 × 1021 | 0.0 | 20.0 |

| 23 | C(s) + O(s) ⇒ CO(s) + Pt(s) | 3.70 × 1021 | 0.0 | 62.8 |

| 21 | CO(s) + Pt(s) ⇒ C(s) + O(s) | 1.00 × 1018 | 0.0 | 184.0 |

| Boundary | Parameter | Value |

|---|---|---|

| Inlet (Velocity inlet) | Temperature | 300 K |

| Gauge pressure | 0 | |

| Outlet (pressure outlet) | Slip | No-slip |

| Fluid-Solid Surface |

| Serial Numbers | Slot Height (mm) | Slot Width Ratio |

|---|---|---|

| 1 | 0.5 | 0.214 |

| 2 | 0.75 | 0.300 |

| 3 | 1.0 | 0.375 |

| 4 | 1.25 | 0.441 |

| 5 | 1.5 | 0.500 |

| 6 | 1.75 | 0.553 |

| 7 | 2.0 | 0.600 |

| 8 | 2.25 | 0.643 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, Y.; Zhang, C.; Chen, Y.; Yan, Y. Combustion Performance of Methane/Air in a Micro Combustor Embedded Hollow Hemispherical Slotted Bluff Body. Energies 2022, 15, 4033. https://doi.org/10.3390/en15114033

Liao Y, Zhang C, Chen Y, Yan Y. Combustion Performance of Methane/Air in a Micro Combustor Embedded Hollow Hemispherical Slotted Bluff Body. Energies. 2022; 15(11):4033. https://doi.org/10.3390/en15114033

Chicago/Turabian StyleLiao, Yunzhe, Chenghua Zhang, Yanrong Chen, and Yunfei Yan. 2022. "Combustion Performance of Methane/Air in a Micro Combustor Embedded Hollow Hemispherical Slotted Bluff Body" Energies 15, no. 11: 4033. https://doi.org/10.3390/en15114033

APA StyleLiao, Y., Zhang, C., Chen, Y., & Yan, Y. (2022). Combustion Performance of Methane/Air in a Micro Combustor Embedded Hollow Hemispherical Slotted Bluff Body. Energies, 15(11), 4033. https://doi.org/10.3390/en15114033